#Industrial Water Treatment Chemicals Market

Text

Booming Blue: A Deep Dive into the Water Treatment Chemicals Market

Water is the elixir of life, yet ensuring its safety and purity for human consumption and industrial use requires a range of sophisticated processes. At the heart of these processes lies a crucial player: the water treatment chemicals market.

This dynamic market, valued at USD 36.7 billion in 2023, is projected to reach a staggering USD 43.9 billion by 2028, growing at a CAGR of 3.6%. But what exactly drives this impressive growth, and what are the key trends shaping the future of this vital industry?

Driving the Demand for Crystal Clear Water

Several factors are fueling the water treatment chemicals market's expansion:

Rising concern about water quality: Growing awareness of waterborne diseases and pollution is pushing municipalities and industries to invest heavily in water treatment infrastructure.

Stringent regulations: Governments across the globe are implementing stricter water quality standards, necessitating the use of advanced water treatment chemicals.

Urbanization and industrialization: The increasing concentration of people and industries puts immense pressure on water resources, making efficient treatment essential.

Focus on sustainability: Growing emphasis on environmental responsibility is driving the development of eco-friendly water treatment chemicals and processes.

A Chemical Orchestra: Key Players in the Market

The water treatment chemicals market is a diverse ensemble, with each type of chemical playing a specific role in the purification process. Here are some of the main players:

Coagulants and flocculants: These chemicals bind impurities together, forming larger particles that can be easily removed from the water.

Disinfectants: Chlorine, ozone, and ultraviolet radiation are commonly used to kill harmful bacteria and viruses.

Corrosion inhibitors: These chemicals prevent pipes and equipment from corroding, ensuring the integrity of the water treatment system.

pH adjusters: Maintaining the optimal pH level is crucial for effective water treatment and prevents pipe damage.

Scale inhibitors: These chemicals prevent the buildup of mineral deposits, which can clog pipes and reduce efficiency.

Regional Variations: Where the Growth is Flowing

The water treatment chemicals market is witnessing dynamic growth across various regions:

Asia Pacific: This region is expected to be the fastest-growing market, driven by rapid urbanization and industrialization in countries like China and India.

North America: The US and Canada remain significant players, with a focus on advanced treatment technologies and stricter regulations.

Europe: The European Union's stringent environmental regulations are driving demand for sustainable water treatment chemicals.

Latin America and Africa: These regions are experiencing rising investments in water infrastructure, creating opportunities for market growth.

Innovations Stirring the Waters: What's New in Water Treatment Chemicals?

The water treatment chemicals market is constantly evolving, with new technologies and products emerging to address specific challenges:

Nanotechnology: Nanoparticles are being used to develop more efficient and targeted water treatment chemicals.

Membrane technology: Advanced membranes are filtering out even the most minute contaminants from water.

Biological treatment: Using bacteria and other microorganisms to break down pollutants is becoming a more sustainable approach.

Smart sensors and automation: Real-time monitoring and control systems are optimizing water treatment processes and reducing chemical usage.

The Future of Water Treatment Chemicals: A Clearer Picture

As the world grapples with water scarcity and pollution, the water treatment chemicals market is poised for continued growth. By embracing innovation, focusing on sustainability, and addressing regional needs, this vital industry will play a crucial role in ensuring access to safe and clean water for all.

Download PDF Brochure :

Investing in a Sustainable Future

The water treatment chemicals market is not just about profits; it's about protecting our most precious resource. By investing in sustainable practices and developing eco-friendly chemicals, companies can contribute to a healthier planet and a brighter future for generations to come.

0 notes

Text

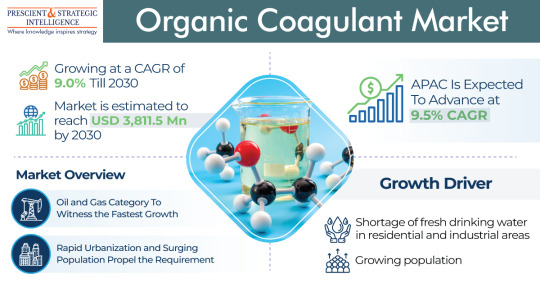

Harnessing Nature: Insights into the Organic Coagulant Market

The organic coagulant market is projected to reach at USD 3,811.5 million in 2030 with a CAGR of 9% in the years to come.

The major reasons for this development of the industry are the scarcity of drinking and fresh water in residential and industrial areas along with the rising population, and urbanization.

And the rising demand for facilities like sewage treatment, industrial water treatment, fertilizer production, food & beverage industry, and paper manufacturing helps the demand for the chemical to grow.

And another major reason for the increasing demand is the growing population, which is creating an enormous demand for clean water and for which a need for advanced purification methods and also with the expansion of infrastructure for water treatment by government to meet the demand are all contributing the growth of eco-friendly water purification.

The oil & gas category will grow at a highest CAGR of 10% over the years, which is driven by the increasing use of organic chemicals with water at a required concentration for drilling and petroleum extraction purposes.

While, onshore and offshore operations both require different filtration processes as in onshore normal water is available, whereas offshore require advanced system to filter seawater.

In addition, research and development activities are also contributing to the demand for organic coagulants, with eco-friendly solutions being explored for wastewater treatment.

Moreover, the increasing government focus to implement policies for water quality monitoring because of the increasing population all over the world. Strict regulations to prevent the direct release of harmful chemicals from industries and untreated sewage into water bodies.

APAC will grow the fastest in the organic coagulant market at a CAGR of 9.5% in the years to come due to the rapid urbanization and industrialization with rising population along with the rising investments in water treatment plant development and strict regulations on sewage disposal. Countries like India, China, South Korea, and Japan are expanding their contribution for the water treatment.

#organic coagulant#water treatment#wastewater treatment#coagulation solutions#eco-friendly chemicals#sustainable water treatment#natural coagulants#organic flocculants#water purification#organic coagulant applications#environmental sustainability#industrial water treatment#market growth#coagulation technology#organic chemicals

0 notes

Text

#Australia Water Treatment Chemicals Market#Australia Water Treatment Chemicals Market Size#Australia Water Treatment Chemicals Market Share#Australia Water Treatment Chemicals Market Analysis#Australia Water Treatment Chemicals Market Trends#Australia Water Treatment Chemicals Market Growth#Australia Water Treatment Chemicals Market Report#Australia Water Treatment Chemicals Market Research#Australia Water Treatment Chemicals Industry#Australia Water Treatment Chemicals Industry Report

0 notes

Text

Water and wastewater treatment chemicals market is segmented into coagulants & flocculants. Market to grow at a CAGR of 5.35% during the forecast period, 2019-2029. Water and wastewater treatment chemicals report by BIS Research provides deep market insight that will help your business to grow.

#Water and Wastewater Treatment Chemicals Market#Water and Wastewater Treatment Chemicals Report#Water and Wastewater Treatment Chemicals Industry#Chemicals#Bisresearh

0 notes

Text

The MEA Water & Waste Water Treatment Chemicals Market is projected to grow at around 5% CAGR during the forecast period, i.e., 2022-27. The growth of the market is likely to be driven by the rapidly increasing concerns over water contamination, improper treatment & disposal of waste from industries in water bodies, and the burgeoning demand for potable water by the rapidly growing population across the region.

#MEA Water & Waste Water Treatment Chemicals Market#MEA Water & Waste Water Treatment Chemicals Market growth#MEA Water & Waste Water Treatment Chemicals Market size#MEA Water & Waste Water Treatment Chemicals Market industry

0 notes

Link

According to a new market research report “Water Treatment Chemicals Market by Type (Coagulants & Flocculants, Corrosion Inhibitors, Scale Inhibitors, Biocides & Disinfectants, Chelating Agents), End-Use (Residential, Commercial, Industrial) and Region - Global Forecast to 2027" published by MarketsandMarkets The global water treatment chemicals market size is estimated to be USD 35.9 billion in 2022 and is forecasted to grow to USD 42.2 billion by 2027, at a CAGR of 3.2%, during the forecast period.

#Water Treatment Chemicals Manufacturers#Water Treatment Chemicals Market#Water Treatment Chemicals#Water Treatment Chemicals Industry

0 notes

Text

Water Treatment Chemicals Market Growth, Overview with Detailed Analysis 2022-2028

Water Treatment Chemicals Market Growth, Overview with Detailed Analysis 2022-2028

The Water Treatment Chemicals Market research report 2022-2030 provides an in-depth analysis of the changing trends, opportunities, and challenges influencing the growth over the next decade. The study includes a detailed summary of each market along with data related to demand, supply and distribution. The report examines Water Treatment Chemicals market growth strategies adopted by leading…

View On WordPress

#Covid-19 Impact Analysis#Water Treatment Chemicals#Water Treatment Chemicals forecast#Water Treatment Chemicals Industry#Water Treatment Chemicals Market#Water Treatment Chemicals price#Water Treatment Chemicals report#Water Treatment Chemicals research#Water Treatment Chemicals share#Water Treatment Chemicals trends

0 notes

Text

Engineering a coating for disease-free produce

Dr. Mustafa Akbulut, professor of chemical engineering, has teamed up with horticultural science professor Luis Cisneros-Zevallos to engineer longer-lasting, bacteria-free produce.

According to Akbulut's recent publication in Current Research in Food Science, the global fruit and vegetable market loses over 50% of agricultural fruit production during various stages of produce handling and post-harvest treatments.

Many fruits and vegetables already have a layer of food-grade wax that is applied for cosmetic reasons and to prevent water loss. Akbulut's research combines such wax with nano-encapsulated cinnamon-bark essential oil in protein carriers to enhance them with antibacterial properties.

"We are living in an age where technology has advanced so much," Akbulut said. "However, the food industry has not competed with these advances, and there are continuous problems with food safety. News about foodborne diseases and outbreaks reporting hundreds of people becoming sick from unhygienic food frequently appears at the national level."

Read more.

15 notes

·

View notes

Text

Common Problems Solved by Emulsion Breakers in Crude Oil Processing

Crude oil processing is a complex and challenging task, fraught with numerous obstacles that can hinder efficiency and productivity. One of the most persistent issues faced by the oil industry is the formation of emulsions. Emulsions, which are mixtures of water and crude oil, can cause significant operational problems. This is where emulsion breakers come into play. These specialized chemicals are designed to separate emulsions into their constituent parts, allowing for smoother and more efficient processing.

Imperial Oilfield Chemicals Pvt. Ltd., a leading emulsion breaker manufacturer in Vadodara, has been at the forefront of providing solutions to these common problems. As a prominent emulsion breaker manufacturer in India and an oil chemical exporter in Vadodara, the company has extensive expertise in addressing the challenges posed by emulsions in crude oil processing.

Understanding Emulsions in Crude Oil

Emulsions in crude oil are formed when water droplets are finely dispersed within the oil. These emulsions can be stable or unstable, with stable emulsions being particularly problematic due to their persistence and resistance to separation. Factors such as the presence of natural surfactants, mechanical agitation during extraction, and the composition of the crude oil itself contribute to the formation and stability of these emulsions.

Common Problems Caused by Emulsions

1. Reduced Oil Quality

Emulsions can significantly degrade the quality of crude oil. The presence of water in the oil reduces its purity, which in turn affects the value and marketability of the final product. High water content in crude oil can also lead to increased corrosion in pipelines and storage tanks, further compromising the quality and integrity of the oil.

2. Increased Processing Costs

The presence of emulsions complicates the refining process, leading to higher operational costs. Additional treatments and processing steps are required to separate the water from the oil, consuming more energy and resources. This not only increases the cost of production but also reduces overall efficiency.

3. Equipment Corrosion and Damage

Water and other contaminants in emulsions can cause significant corrosion and damage to processing equipment. This leads to increased maintenance costs and downtime, negatively impacting productivity. Over time, the wear and tear on equipment can result in the need for costly replacements and repairs.

4. Environmental and Regulatory Concerns

Improper handling of emulsions can lead to environmental contamination and regulatory non-compliance. Discharging emulsified water into the environment can cause pollution and harm to aquatic ecosystems. Regulatory bodies impose strict guidelines on the disposal of emulsified water, and failure to comply can result in hefty fines and legal repercussions.

How Emulsion Breakers Address These Problems

Emulsion breakers, also known as demulsifiers, are chemical agents specifically designed to separate emulsions into oil and water. As a leading emulsion breaker exporter in India, Imperial Oilfield Chemicals Pvt. Ltd. provides high-quality solutions that effectively address the common problems caused by emulsions in crude oil processing.

1. Improving Oil Quality

Emulsion breakers work by breaking the bonds between water and oil molecules, allowing for the separation of water from the crude oil. This results in higher purity oil with reduced water content, improving its quality and marketability. The use of emulsion breakers ensures that the final product meets industry standards and fetches a higher market price.

2. Reducing Processing Costs

By facilitating the efficient separation of water from oil, emulsion breakers streamline the refining process. This reduces the need for additional treatment steps, conserving energy and resources. Consequently, the overall cost of production decreases, enhancing the profitability of crude oil processing operations.

3. Preventing Equipment Corrosion and Damage

The removal of water and contaminants from crude oil minimizes the risk of corrosion and damage to processing equipment. This extends the lifespan of the equipment, reduces maintenance costs, and minimizes downtime. Emulsion breakers thus play a crucial role in maintaining the operational integrity of oil processing facilities.

4. Ensuring Environmental Compliance

Effective emulsion breaking and water separation allow for the proper handling and disposal of water, ensuring compliance with environmental regulations. By preventing the discharge of emulsified water into the environment, companies can avoid fines and legal issues, while also contributing to environmental sustainability.

Why Choose Imperial Oilfield Chemicals Pvt. Ltd.?

As a top-tier emulsion breaker manufacturer in Vadodara and a leading oil chemical exporter in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. stands out for several reasons:

Expertise and Innovation

Imperial Oilfield Chemicals Pvt. Ltd. has a team of experts dedicated to researching and developing innovative solutions for the oil industry. Their in-depth knowledge and experience ensure that they produce highly effective emulsion breakers tailored to the specific needs of their clients.

Quality and Reliability

The company is committed to delivering high-quality products that meet stringent industry standards. Their emulsion breakers are known for their reliability and effectiveness, ensuring consistent performance in crude oil processing operations.

Global Reach

As a prominent emulsion breaker exporter in India, Imperial Oilfield Chemicals Pvt. Ltd. serves clients worldwide. Their extensive distribution network ensures timely delivery and support, regardless of the client’s location.

Customer-Centric Approach

The company prides itself on its customer-centric approach, offering personalized solutions and support to meet the unique needs of each client. Their commitment to customer satisfaction has earned them a reputation as a trusted partner in the oil industry.

Conclusion

The challenges posed by emulsions in crude oil processing are significant, but they can be effectively addressed with the right solutions. Emulsion breakers play a crucial role in separating water from crude oil, improving oil quality, reducing processing costs, preventing equipment damage, and ensuring environmental compliance.

Imperial Oilfield Chemicals Pvt. Ltd., a leading emulsion breaker manufacturer in Vadodara and a top oil chemical exporter in Vadodara, offers high-quality emulsion breakers that solve these common problems. Their expertise, innovation, and commitment to quality make them a trusted partner for oil companies worldwide.

By leveraging the solutions provided by Imperial Oilfield Chemicals Pvt. Ltd., businesses in the oil industry can enhance their operational efficiency, reduce costs, and ensure the production of high-quality crude oil. In an industry where efficiency and quality are paramount, the right emulsion breakers can make all the difference, helping companies build a stronger and more profitable future.

#Best chemical company in Vadodara#Drag reducing agent manufacturer in India#DRA systems manufactured by ICPL#Oil chemical exporter in Vadodara#Emulsion breaker manufacturer in India#Emulsion breaker manufacturer in Vadodara#Emulsion breaker exporter in India#Oilfield chemicals manufacturer and exporter in India#Turbine cleaner manufacturer in India#Turbine cleaners manufactured by ICPL#Best oilfield chemicals company in Gujarat#Scale inhibitor manufacturer in India#Scale inhibitor manufacturer in Vadodara#scale inhibitors manufactured by ICPL

4 notes

·

View notes

Text

Navigating the Waves: Unveiling the Dynamics of the Water Treatment Chemicals Market

In the vast landscape of water treatment, chemicals play a pivotal role in ensuring the purity and safety of our water supply. The water treatment chemicals market, a critical component of this industry, stands as a cornerstone in addressing diverse challenges. Let's embark on a journey to unravel the intricacies of this dynamic market.

How Big is the Water Chemical Market

The water treatment chemicals market has witnessed remarkable growth in recent years. As of 2023, the global market size is estimated to be USD 36.7 billion, projected to reach USD 43.9 billion in 2028, at an impressive CAGR of 3.6%. This upward trajectory underscores the increasing awareness regarding water quality and the surge in demand for treated water across various end-use industries. Stringent water and wastewater regulations further propel the rapid growth of this vital market.

Major Chemicals in Water Treatment

Various chemicals contribute to the effectiveness of water treatment processes. Among these, chlorine, ozone, alum, ferric chloride, and activated carbon stand out as key players. Each chemical serves a specific purpose, from disinfection and coagulation to pH adjustment and corrosion control. The synergy of these chemicals ensures the removal of contaminants and pathogens, safeguarding the quality of our water resources.

Key Market Players

Prominent players like Kemira OYJ (Finland), BASF SE (Germany), Ecolab Inc. (U.S.), Dow Inc. (U.S.), and Solenis LLC (U.S.) have established a robust foothold in the water treatment chemicals market. Their strategic initiatives, including expansions, joint ventures, and mergers & acquisitions, contribute significantly to their market dominance.

Best Chemical Treatment for Water

Determining the "best" chemical treatment depends on the specific water source and the contaminants it harbors. For disinfection, chlorine and ozone are often preferred, while alum and ferric chloride excel in coagulation. Activated carbon proves effective in removing organic impurities. The selection process involves a careful analysis of water composition, highlighting the need for tailored solutions to achieve optimal results.

Market Trends in Water Treatment

Keeping a pulse on market trends is crucial for stakeholders in the water treatment chemicals domain. The industry is witnessing a notable shift towards sustainable and eco-friendly solutions. Innovations in advanced oxidation processes and the integration of smart technologies for water monitoring are gaining traction. Additionally, the surge in water recycling and reuse initiatives is reshaping the market landscape, reflecting a growing emphasis on water sustainability.

Download PDF Brochure

As we navigate the waves of the water treatment chemicals market, it becomes evident that its significance extends beyond commercial interests. It's a vital force in preserving our most precious resource – water. The market's growth, fueled by technological advancements and a global commitment to environmental stewardship, promises a future where access to clean water is a reality for all.

0 notes

Text

What are the extraction methods for CBD oils?

Supercritical method, cold pressing, vegetable oil, solvent… So many terms that qualify the manufacture of CBD products. But what reality is hidden behind each of these practices? Is there a fundamental difference between CBD products extracted in this way or that way? What is the best mode of extraction? In this blog, you will explore the manufacture of CBD and its impact on the different CBD oils.

The origin of CBD

CBD (cannabidiol) is a molecule naturally present in hemp and known for its relaxing effects. A notable property of CBD is its lipophilic character. Chemically, CBD can only bind to fat or oil. Thus, it is not soluble in water. In order to transform CBD into oil, there are several Cannabis extraction methods, more or less natural, each with its own taste and specificities.

Extraction methods to create CBD oil

Let's review the four main methods of extracting CBD: supercritical extraction (1), cold pressing extraction (2), vegetable oil extraction (3), and extraction. by solvent (4).

1. Supercritical CO2 extraction

CO2 extraction aims to create phase changes (state of matter) in the CO2 and make it reach a so-called supercritical state. This process makes it possible to extract CBD while maintaining the number of terpenes in the plant material (CBN, CBG, etc.). Manufacturers favor this method for its efficiency and relative simplicity: no use of solvents or chemicals could alter the product's purity. However, CBD oil extracted with supercritical CO2 must be reprocessed to remove all traces of THC, which requires laboratory intervention.

CO2, a non-volatile element, is also already used in several industries wishing to control the concentration of a molecule, such as coffee and essential oils. At the end of the process, the CO2 is condensed and stored for reuse. Nothing is lost; everything is reused!

Thus, supercritical extraction is often used for the creation of rich and flavorful Full Spectrum CBD oils.

2. Cold Press Extraction

CBD extraction is often done cold for the same reason: to maintain a natural result while retaining the taste of the terpenes.

With the cold-press cannabis cbd oil extraction equipment, you can run the frozen hemp flowers through a press yourself and extract the CBD and terpenes as low-CBD hemp oil. It is a simple and ecological method to produce your own CBD. Disadvantage? It is not a very effective method when it comes to cannabidiol… Indeed, it takes a lot of hemp flowers to produce little CBD. This is why, apart from edible hemp oil, you will not find or find very few cold-pressed CBD oils on the market.

3. Vegetable oil extraction

Another DIY method, vegetable oil extraction, involves using hot oil to extract CBD from hemp. Instead, use olive, sesame, or coconut oil. This natural method makes it possible to produce tasty CBD oil. But the problems associated with artisanal extraction remain: you need a lot of hemp for little product; moreover, the hot oil may damage the molecules you are trying to extract.

4. Solvent extraction

The hemp is bathed in a solvent in order to extract the CBD. The solvent can be either ethanol, butane, or propane. By heating the liquid, the solvent evaporates, and only the CBD oil remains. The aforementioned solvents are flammable, even explosive; this process is reserved for knowledgeable chemists and CBD Growers.

What is the best CBD oil extraction method?

Supercritical extraction is the most effective way to produce natural, flavor-rich CBD oil. When cold, it keeps the CBD and terpenes pure, does not alter molecules, and uses no solvents, although a second treatment may be required to achieve less than 0.2% THC in the final bottle.

Very effective, it uses a minimum of hemp for a maximum of oil. Finally, ecologically, it reuses CO2 and requires very little energy for high yields. Artisanal extraction may have its charm, but supercritical extraction remains the most efficient and guarantees cost control for both the producer and the consumer.

3 notes

·

View notes

Text

GOTS Certification : Training - Consulting Provider - Global Organic Textile Standard

Global Organic Textile Standard Overview

The Global Organic Textile Standard (GOTS) is the worldwide leading textile processing standard for organic fibers, including ecological and social criteria, backed up by independent certification of the entire textile supply chain. The aim of the standard is to define world-wide recognized requirements that ensure organic status of textiles, from harvesting of the raw materials, through environmentally and socially responsible manufacturing up to labelling in order to provide a credible assurance to the end consumer

In USA the clothing’s certified by GOTS are only termed Organic

Scope And Applicability Of GOTS

Textile products that contain a minimum of 70% organic fibers can opt for GOTS certification. GOTS is applicable to entire textile supply chain.

It is applicable to industries processing, manufacturing, packaging, labelling, trading and distribution of all textiles made from at least 70% certified organic natural fibers.

Textile processing, manufacturing and trading entities.

Retailers selling GOTS Goods to end consumers may also voluntarily apply to become GOTS certified.

textile processing facilities that have processes such as ginning, spinning, weaving/knitting, dyeing & printing and stitching

GOTS Training

Our team of GOTS Consultants offers a customized GOTS training program on GOTS for

GOTS Requirements

SPECIFIC REQUIREMENTS

GOTS certification requires use of organic fibers certified by standards from IFOAM family (95% for “organic” label and 70% for “made with organic” label) in addition to requirements specified related to:-

Socially responsibilities

Quality Assurance System

Ecological Environment Conditions

Safe Working Conditions

International Labor Organization criteria

Toxicological criteria

DOCUMENTATION REQUIREMENTS

Depending on the processing stages performed, the policy should include procedures such as to monitor and minimize waste and discharges.

A program for continual improvement.

Wet processing units must keep full records of the use of chemicals, energy, water consumption and waste water treatment, including the disposal of sludge.

Benefits Of GOTS Implementation

Processors and manufacturers that receive a GOTS certificate of compliance are authorized to accept orders for GOTS compliant processing / manufacturing in their certified scope.

Certified exporters as well as traders are authorized to trade GOTS textile products that belong to the scope of their granted certification.

Entities that receive a GOTS scope certificate are free to advertise their certified status on the market.

Become listed in the GOTS public database on the website. Gaining End users trust in the products Organic Authenticity.

#GOTS Certification#GOTS Certification Training#GOTS Training#GOTS Consultants#GOTS Consulting#Benefits Of GOTS Implementation#Benefits Of GOTS#GOTS Requirements#Application Of GOTS#Global Organic Textile Standard

2 notes

·

View notes

Text

Buy MS Blind Flange Online – Quality and Affordability at Udhhyog

Buy MS Blind Flanges Online from Udhhyog – The Perfect Solution for Industrial Closures

Are you looking to buy MS blind flanges online? Look no further than Udhhyog, your trusted partner for all mild steel blind flange needs. Our MS blind flanges are designed to provide a tight seal for piping systems, making them indispensable in industries like oil & gas, water treatment, and manufacturing.

At Udhhyog, we offer a wide selection of MS blind flanges, combining high performance with cost-efficiency. With our easy-to-use online platform, you can quickly browse, compare, and purchase the right blind flanges for your project.

Why Buy MS Blind Flanges from Udhhyog?

Seamless Online Shopping Experience: Udhhyog’s website offers a straightforward, hassle-free shopping experience, allowing you to easily buy the MS blind flange that fits your exact requirements. With detailed product descriptions and specifications, finding the right flange has never been easier.

Premium Quality Mild Steel: Our MS blind flanges are made from high-quality mild steel, ensuring they offer both durability and strength for a range of applications. This means that when you buy from Udhhyog, you're investing in a product that can handle the most demanding environments.

Best Prices in the Market: When you choose Udhhyog, you benefit from the lowest prices on MS blind flanges without sacrificing quality. Our pricing is competitive, making us the ideal choice for industries looking to optimize their procurement budget.

Wide Range of Sizes: We understand that different projects require different specifications, which is why we offer MS blind flanges in a variety of sizes. Whether you need small-diameter flanges for tight spaces or larger ones for heavy-duty applications, we have you covered.

Reliable Shipping and Fast Delivery: No matter where you are in India, Udhhyog provides reliable shipping and fast delivery. When you buy from us, you can trust that your order will arrive on time and in perfect condition.

Applications of MS Blind Flanges

MS blind flanges are crucial for closing off sections of piping systems and ensuring they remain secure under pressure. Some common uses include:

Maintenance shutdowns: Temporarily sealing off sections of piping systems to perform routine maintenance or repairs.

Testing and isolation: Safely testing sections of pipe for pressure levels or leaks.

Flow control: Regulating or completely stopping the flow of fluids in a pipeline during various stages of production or processing.

These features make Udhhyog’s MS blind flanges a versatile choice for a range of industries, including oil & gas, chemical processing, and water management.

Exclusive Deals on Bulk Orders

If you need to buy MS blind flanges in large quantities, Udhhyog offers special pricing and bulk order discounts to provide even more value for your investment. Reach out to our sales team for customized quotes and find out how much you can save on bulk purchases.

#BuyMSBlindFlange#MildSteelBlindFlange#MSFlangeOnline#Udhhyog#IndustrialFlanges#AffordableFlanges#MSBlindFlanges#SealingFlanges#PipelineSolutions#OnlineIndustrialProcurement

1 note

·

View note

Text

Brine Concentration Technology Market Size, Share, Trends & Forecast

According to a new report by UnivDatos Market Insights, the Brine Concentration Technology Market is expected to reach USD ~23.3 billion by 2032 by growing at a CAGR of ~5.8%. The Brine Concentration Technology (BCT) market has recently become significant, especially when industries and governments face water scarcity and environmental conservation problems. Pre- and post-treatment are among the comprehensive processes referenced by BCT, and they help in handling and treating brine, which is generated through several industrial activities such as desalination. This article further explains the BCT market in terms of the market demands, usage, production mechanism, and future.

Demand:

Growing Need for Water Treatment

The most influential factor that has contributed to the growth of the BCT market is the growing demand of people worldwide for water treatment. Due to the increasing difficulties in obtaining freshwater, people have now paid much attention to effective and efficient technologies for desalination. That way, technologies in concentrating the brine are useful to counteract the problem of saline byproducts of the desalination process, including addressing certain ecological factors or consequences.

Industrial Waste Management

Some specific industries involved in this sector include oil and gas, chemical manufacturing, and power generation industries, which generate large volumes of wastewater with high TDS concentrations. This industrial wastewater has to be properly dealt with to ensure that it does not pollute the environment in its treatment stages. BCT also offers a sound approach to dealing with the brine which, when treated, can be more easily disposed of or concentrated.

Stringent Environmental Regulations

Governments worldwide are implementing stringent regulations to protect water bodies from industrial pollution. These regulations mandate industries to treat their effluents before discharge, further propelling the demand for advanced brine concentration technologies. Compliance with these regulations not only helps in preserving natural resources but also enhances the reputation of industries as responsible corporate entities.

Applications:

Industrial Wastewater Treatment

The biggest market for BCT application is the treatment of industrial effluent or industrial wastewater. Different industries generate so much wastewater that good treatment methods have to be availed to help manage such waste. To enable BCT technologies such as Reverse Osmosis (RO), Electrodialysis, and thermal desalination to concentrate and treat discharged brine it goes through lawful discharge procedures.

Desalination

This method is mostly used in BCT in desalination plants due to the scarcity of freshwater resources, especially in arid geographical zones. These technologies allow the plants to be more sustainable for the environment through the reduction of brine disposal impacts. Since the use of desalination has continued to grow for the provision of potable water and with the grammatical to consummate BCT’s role, the demand for BCT should be imminent.

Food & Beverage Industry

Water is one of the most important and frequently utilized commodities in the food and beverage industry to facilitate production and for many other purposes, such as sanitation. There are some wastewater issues, and BCT is still a leader in the industry in terms of providing solutions to practical questions such as process water reuse and product concentration. Processes like electrodialysis are also becoming more prominent in this trade due to their efficacy.

Chemical & Petrochemical Industry

The chemical and petrochemical industry particularly emits large concentrations of wastewater that include high concentrations of salts and other pollutant materials. BCT is utilized in order to treat and recover such effluents so that their handling and disposal are made more efficient. This not only allows for following the environmental requirements but also recovers the opportunities from the waste stream.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=62941

Manufacturing

Technology Segmentation

The BCT market is characterized by a diverse range of technologies, each with its unique advantages and applications. Reverse Osmosis (RO) is the most widely used technology due to its high efficiency in separating salts from water. RO systems are extensively deployed in desalination plants and industrial wastewater treatment facilities.

Electrodialysis is another rapidly growing segment in the BCT market. This technology uses an electric field to drive ions through selective membranes, separating salts from water. Electrodialysis is favoured for its energy efficiency and versatility, making it suitable for various industrial applications.

Thermal desalination technologies, including Multi-Stage Flash (MSF) and Multi-Effect Distillation (MED), significantly contribute to the BCT market. These technologies use heat to evaporate water, leaving behind concentrated brine. They are particularly effective in treating high-salinity brine and are commonly used in large-scale desalination projects.

Manufacturing Processes

The manufacturing of BCT systems involves a combination of advanced engineering and materials science. Key components such as membranes, pressure vessels, and pumps are designed to withstand harsh operating conditions and ensure long-term reliability. Manufacturers invest heavily in research and development to improve the efficiency and durability of these components.

Quality control is paramount in the production of BCT systems. Rigorous testing and certification processes ensure that the systems meet international standards and perform effectively in real-world applications. Manufacturers also provide comprehensive maintenance and support services to ensure optimal performance over the system’s lifespan.

Conclusion:

The Brine Concentration Technology (BCT) market is envisioned to expand at a good growth rate in the future since it is expected that there will be more demand for water treatment. there are so many environmental legislations and the ever-expanding use of the process of desalination. As industries intensify their efforts to become more efficient and environmentally friendly, and as governments set their sustainability goals, there is a solid expectation that the need for enhanced brine concentration will be increased.

This makes BCT provide a durable technique in the treatment of saline byproducts so that they can be effectively disposed of properly to some extent so that they will not affect the environment. Technology continues to be developed and adapted, and the consciousness about the environment and climate change is growing constantly; therefore, the BCT market will have great potential to contribute to the development of a sustainable future.

In conclusion, it can be stated that the BCT market is one of the most significant segments that unites advanced technology, business, and environmentally friendly strategies. Hence through the incorporation and implementation of modern brine concentration technologies, industries can support increased legislative compliance to water and environmental conservation initiatives. Therefore, in relation to market stability, further research and cooperation will remain the key to the solution of numerous problems and the enhancement of the efficiency of brine concentration facilities.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The GCC Water & Waste Water Treatment Chemicals Market is projected to grow at a CAGR of around 18.2% during the forecast period, i.e., 2023-2028, says MarkNtel Advisors. The market growth primarily attributes to the increasing issues of water contamination, burgeoning waste from industries, which gets discharged in water bodies, and mounting need for potable water due to rapid industrialization & expansion across the Gulf countries.

#GCC Water & Waste Water Treatment Chemicals Market#GCC Water & Waste Water Treatment Chemicals Market growth#GCC Water & Waste Water Treatment Chemicals Market size#GCC Water & Waste Water Treatment Chemicals Market industry

0 notes