#Industrial inkjet coding

Explore tagged Tumblr posts

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Text

Hidden Costs of Choosing the Wrong Industrial Coding Machine

Understand the many applications of industrial coding with Technopack's inkjet coders. These machines deliver high-speed, accurate printing for batch numbers, expiration dates, and barcodes, supporting diverse production lines across food, pharma, and logistics sectors.

1 note

·

View note

Text

Label Printer Machine: The Ultimate Guide for Efficient and Professional Product Labeling

What is a Label Printer Machine?

A label printer machine is a device that prints custom or standardized labels for products, containers, cartons, and shipping packages. It can print on paper, plastic, thermal material, or synthetic labels using technologies like thermal transfer, direct thermal, or inkjet. Label printer machines are essential in packaging, inventory management, retail, pharmaceuticals, logistics, and food processing.

Types of Label Printer Machines

1. Thermal Transfer Label Printers

These use heat to transfer ink from a ribbon onto the label. Ideal for long-lasting, waterproof, smudge-resistant labels, commonly used in pharmaceuticals, electronics, and industrial labeling.

2. Direct Thermal Label Printers

No ribbon is used; heat-sensitive label paper darkens when heated. Best for short-term applications like shipping labels, receipts, and food packaging.

3. Inkjet Label Printers

Produce high-resolution, colorful labels. Suitable for custom branding, marketing labels, and retail packaging.

4. Laser Label Printers

Offer speed and sharpness. Used when mass label printing is needed, especially for office or warehouse environments.

5. Portable Label Printers

Handheld or mobile devices used in field service, retail, logistics, and inventory control.

6. RFID Label Printers

Print and encode RFID tags and barcodes for real-time tracking and supply chain automation.

Common Applications Across Industries

1. Food and Beverage

Nutritional labels, expiry dates, batch codes

Tamper-evident and waterproof labels

2. Pharmaceuticals

Regulatory-compliant labels with dosage info, QR codes, batch numbers

High print precision and barcode clarity

3. Cosmetics

High-resolution brand and ingredient labels

Sleek, colorful, water-resistant finishes

4. Manufacturing

Asset labels, compliance tags, quality control stickers

5. Logistics and Warehousing

Shipping and barcode labels

SKU and inventory management tags

6. Retail

Price tags, promotional stickers, and shelf labels

Key Features of High-Quality Label Printer Machines

1. Print Resolution

Measured in DPI (dots per inch). For clear text and barcodes, 203 DPI is standard, while 300–600 DPI is used for high-definition images and small text.

2. Print Speed

Ranges from 2 to 14 inches per second (IPS). Higher speeds are ideal for bulk printing operations.

3. Connectivity Options

USB, Ethernet, Bluetooth, Wi-Fi—essential for integration with POS systems, warehouse management software, or industrial PLCs.

4. Media Compatibility

Should support a variety of label rolls: paper, PET, PP, BOPP, synthetic, glossy, and matte.

5. Software Integration

Compatibility with label design software like BarTender, NiceLabel, or ZebraDesigner.

6. Auto-Cutter and Peeler

Helps in high-speed workflows by automatically cutting or peeling off printed labels.

Advantages of Using a Label Printer Machine

Professional Packaging: Clean, precise labels reflect product quality

Customization: Easily print logos, barcodes, and QR codes on demand

Efficiency: Reduce dependency on pre-printed labels and minimize stockouts

Compliance: Meet legal labeling requirements effortlessly

Traceability: Boost product tracking across supply chains

Cost-Saving: In-house label printing reduces outsourcing costs

0 notes

Text

VIDEOJET PRINTING INK Compatibility with Modern Coding Technologies

In today’s fast-paced industrial environment, reliable coding and marking solutions are essential for maintaining efficiency, compliance, and product traceability. One of the leading names in this space is VIDEOJET PRINTING INK, known for its outstanding performance across a wide range of production needs. As modern coding technologies continue to evolve, the compatibility of VIDEOJET PRINTING INK with these advanced systems plays a crucial role in enhancing operational workflows and ensuring high-quality output.

Let’s explore how VIDEOJET PRINTING INK seamlessly integrates with modern coding technologies and why it remains a preferred choice across industries.

Meeting the Demands of Evolving Coding Systems

Modern coding technologies have rapidly advanced to support higher production speeds, diverse substrates, and more stringent compliance requirements. Whether it's continuous inkjet (CIJ), thermal inkjet (TIJ), laser marking, or large character printing (LCP), every technology demands ink formulations that are optimized for specific applications.

VIDEOJET PRINTING INK is designed with compatibility in mind. It works effectively across multiple coding systems, especially with CIJ and TIJ printers, which are widely used in industries like food & beverage, pharmaceuticals, cosmetics, and electronics. Its superior adhesion properties and quick-drying characteristics make it suitable for a variety of materials such as glass, plastic, cardboard, and metals — all without compromising print clarity.

Precision and Consistency Across Substrates

The success of any modern coding solution relies heavily on consistent, legible prints — even on complex or irregular surfaces. VIDEOJET PRINTING INK is specially formulated to deliver high-contrast codes on challenging substrates, including slick plastic bottles, coated cartons, and flexible packaging.

For instance, when used with thermal inkjet printers, VIDEOJET PRINTING INK can produce high-resolution prints suitable for detailed information like QR codes, barcodes, and batch numbers. This level of precision ensures products meet regulatory and supply chain requirements without costly rework or delays.

Compatibility with Automation and Smart Production Lines

As Industry 4.0 and smart manufacturing trends continue to reshape factories, VIDEOJET PRINTING INK proves its adaptability by integrating seamlessly with automated systems. Today’s coding technologies often feature built-in software for remote monitoring, predictive maintenance, and real-time data tracking.

Whether integrated into robotic arms or smart conveyors, VIDEOJET-compatible printers and ink cartridges can work in sync with automated lines to minimize downtime and improve traceability. The chemical stability of VIDEOJET PRINTING INK ensures that the ink does not dry out or clog the printer even during extended idle times — a key advantage in automated environments.

Supporting Eco-Friendly and Regulatory Needs

Sustainability and compliance have become top priorities in modern manufacturing. VIDEOJET PRINTING INK is available in a range of formulations, including low-VOC (Volatile Organic Compounds) and MEK-free options, making it environmentally safer while still delivering strong performance.

Moreover, these inks comply with international safety and packaging regulations, including FDA, RoHS, and REACH standards, making them ideal for food, beverage, and pharmaceutical packaging. Modern coding technologies often come equipped with ink usage monitoring features, and VIDEOJET’s efficient ink formulations help reduce waste and operating costs over time.

Easy Integration with a Wide Range of Printers

One of the greatest strengths of VIDEOJET PRINTING INK is its wide printer compatibility. It is engineered to work perfectly with Videojet’s own series of printers, including the popular 1000 Line CIJ printers, 8510 TIJ printers, and more. This ensures plug-and-play functionality and optimal performance from the first print to the last.

For companies using a mix of legacy and new printing equipment, the versatility of VIDEOJET PRINTING INK provides a unified solution without the need for multiple ink inventories. This not only simplifies operations but also reduces maintenance and training time for machine operators.

Why Manufacturers Trust VIDEOJET PRINTING INK

Manufacturers around the globe rely on VIDEOJET PRINTING INK for its unmatched reliability, durability, and adaptability. Whether it's high-speed bottling lines or precise electronics labeling, this ink continues to deliver consistent results that keep operations running smoothly.

At SH HITECH SOLUTIONS, we understand how critical it is to choose the right ink for the right technology. That’s why we recommend VIDEOJET PRINTING INK for businesses looking to future-proof their production lines with high-performance, compatible ink solutions.

Final Thoughts

As coding technologies become smarter, faster, and more complex, the demand for high-performance inks that can keep up has never been greater. VIDEOJET PRINTING INK rises to the challenge, offering exceptional compatibility with modern coding technologies, from CIJ to TIJ and beyond.

For manufacturers seeking to streamline operations, maintain compliance, and ensure reliable product identification, VIDEOJET PRINTING INK remains a leading solution that supports both today’s needs and tomorrow’s innovations.

0 notes

Text

Comprehensive Study of the Global Coding and Marking Equipment Industry

The global coding and marking equipment market was valued at USD 17.53 billion in 2024, and it is anticipated to grow at a compound annual growth rate (CAGR) of 6.1% from 2025 to 2030. This projected growth is largely attributed to the increasing emphasis on product traceability across several key industrial sectors, including food and beverage, pharmaceuticals, cosmetics, and electronics. The demand for advanced coding and marking systems is further fueled by the implementation of stringent regulatory frameworks related to product labeling, safety, and quality standards. These regulations compel manufacturers to adopt more sophisticated, accurate, and efficient identification technologies.

One of the main catalysts driving this market expansion is the continuous innovation in coding technologies, particularly the development and adoption of laser marking systems and Thermal Inkjet (TIJ) solutions. These advancements are closely aligned with the broader trend of automation in manufacturing and packaging processes, enabling companies to improve throughput, reduce human error, and streamline operations.

The evolution of coding and marking technologies has significantly enhanced the ability of companies to achieve greater operational efficiency and cost-effectiveness. Advanced systems with high-precision capabilities—such as laser coding, Thermal Inkjet (TIJ), Continuous Inkjet (CIJ), and thermal transfer technologies—are playing a pivotal role in ensuring accurate, durable, and compliant labeling across a wide variety of substrates and materials. These technologies are indispensable in sectors such as food and beverage, pharmaceuticals, cosmetics, electronics, automotive, logistics, and packaging. Their applications include product identification, traceability, regulatory compliance labeling, date coding, and batch numbering, all of which are essential for maintaining high standards in quality control, safety assurance, and anti-counterfeiting measures.

Businesses, especially leading players in manufacturing and supply chains, are increasingly integrating these technologies to enhance operational productivity, reduce labeling errors, and optimize supply chain logistics. By adopting modern coding and marking systems, companies are better equipped to respond to evolving regulatory requirements and customer expectations for transparency and traceability.

For instance, in September 2024, Domino Printing Sciences, a well-recognized name in the coding and marking sector, introduced a new high-speed laser coding system designed specifically for the packaging industry. This advanced technology delivers precise, consistent coding across a range of materials while simultaneously reducing operational costs. It enables companies—particularly those operating in heavily regulated markets—to maintain high levels of compliance, productivity, and cost efficiency.

Moreover, increasing public and private sector investments in research and development (R&D) across key regions such as North America, Europe, and Asia Pacific are contributing to the rapid advancement of coding and marking technologies. Initiatives such as the U.S. National Innovation Strategy and Germany’s Industry 4.0 program are designed to support digital transformation and technological innovation, creating a favorable environment for market growth. As these technologies continue to evolve, organizations benefit from enhanced traceability, improved regulatory compliance, and strengthened product authentication, all of which contribute to the overall expansion and resilience of the coding and marking equipment market.

Get a preview of the latest developments in the Coding And Marking Equipment Market? Download your FREE sample PDF copy today and explore key data and trends

Detailed Segmentation:

Product Insights

The Continuous Inkjet (CIJ) printer segment led the coding and marking equipment industry in 2024, accounting for 32.3% of the revenue. Known for their non-contact, high-speed coding capabilities, CIJ printers support versatile, reliable marking across high-volume production lines.

End Use Insights

In 2024, the food and beverage sector dominated the coding and marking equipment market, driven by stringent safety standards required for online and retail channels. Reliable coding systems facilitate clear labeling of expiration dates, batch numbers, and traceability, which is essential for brand protection and differentiation.

Regional Insights

North America led the global coding and marking equipment market in 2024 with a revenue share of 30.9%, driven by continuous R&D, a growing manufacturing base, and the presence of established coding technology providers. Stringent regulatory standards in pharmaceuticals, food & beverage, and automotive industries fuel the demand for precise, reliable coding solutions in the region.

Key Coding And Marking Equipment Company Insights

Some key companies in the coding and marking equipment industry are Danaher Corporation, Hitachi Ltd., and ProMach Inc. Major market participants are adopting strategies such as innovation, enhanced focus on R&D activities, expansions, portfolio enhancements, partnerships, and collaborations to address growing competition and rising technology adoption.

Danaher Corporation offers a comprehensive range of precision coding and marking solutions through subsidiaries like Videojet and Linx, targeting various industries, such as pharmaceuticals, food & beverage, and manufacturing. Known for high-performance inkjet, laser, and thermal transfer technologies, Danaher’s solutions support compliance, traceability, and product authentication with advanced data integration features.

Hitachi Ltd. delivers reliable coding and marking systems, including continuous inkjet and laser solutions tailored for high-speed production in the automotive, electronics, and consumer goods sectors. With a strong focus on innovation, Hitachi integrates IoT-enabled and automation features to enhance traceability and operational efficiency in large-scale manufacturing.

Key Coding And Marking Equipment Companies:

The following are the leading companies in the coding and marking equipment market. These companies collectively hold the largest market share and dictate industry trends.

Danaher Corporation

Domino Printing Sciences plc

Comp3

Hitachi Ltd.

Markem-Imaje Group

Matthews International Corporation

Leibinger Group

REA Elektronik GmbH

ProMach Inc.

Koenig & Bauer Coding GmbH

HSA Systems A/S

Recent Developments

In September 2024, Domino Printing Sciences launched the K300, a compact monochrome inkjet printer, at Labelexpo Americas. Designed for high-speed variable data printing, it integrates easily into existing lines, enabling label customization with QR codes and batch information. The K300 will be featured alongside a code verification solution from Lake Image Systems, meeting the rising demand for 2D codes in packaging.

In April 2024, Markem-Imaje launched the MW2160P, a versatile opaque white ink for extruded products like PVC and rubber, compatible with its 9750+ CIJ printers. This durable ink offers strong visibility and adhesion, resisting bending and water exposure, making it ideal for demanding industrial applications. Nicknamed the “Swiss Army Knife” of CIJ inks, it ensures reliable print quality across various substrates.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

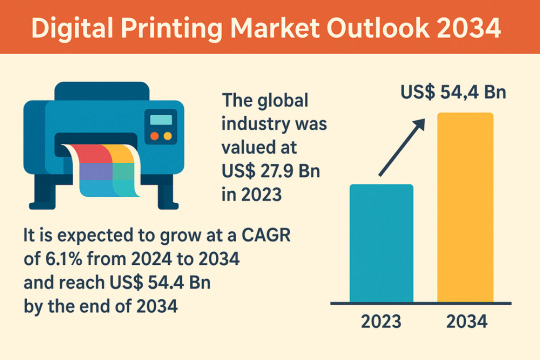

Digital Printing Market to Reach $54.4 Billion by 2034 Amid Rising Demand for On-Demand Solutions

The global digital printing market reached a valuation of US$ 27.9 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.1% between 2024 and 2034, culminating in a market worth US$ 54.4 billion by December 31, 2034. Digital printing bypasses the need for traditional printing plates by transferring digital files directly onto substrates such as paper, canvas, textiles, and synthetics. This seamless workflow supports on-demand production, reduces waste, and delivers high-throughput performance of up to 4,800 sheets per hour once printing begins.

Industry analysts anticipate that continued investments in print manufacturing efficiencies, supply chain integration, and time-to-market acceleration will drive digital printing adoption. Key growth verticals include textile and packaging, where high-definition, on-demand print capabilities facilitate product personalization and rapid iteration. The rise of direct-to-consumer printing models—particularly in can printing further cements digital printing’s role as a versatile, customer-centric technology.

Market Drivers & Trends

Technological Upgrades in Printing: Major players are embedding automation, AI-driven color management, and new printheads into their presses. For instance, in 2022, Hewlett Packard unveiled its Indigo 15K and 100K Digital Press platforms to enhance automation, reduce labor and plate costs, and slash turnaround times for medium to high-volume short runs.

Textile & Packaging Industry Growth: The global textile sector, valued at US$ 4.4 trillion, is rapidly embracing digital print to enable limitless design options and shorter production cycles. Likewise, packaging manufacturers are deploying UV LED and single-pass inkjet presses to deliver variable data printing—such as QR codes and barcodes—at scale.

On-Demand & Personalized Printing: Digital technology empowers brands to engage customers directly by crowdsourcing can designs, securing approvals, and fulfilling orders without intermediaries. This strategy has spurred increased consumer engagement and brand loyalty.

Latest Market Trends

High-Speed Single-Pass Inkjet: Next-generation presses with robust sheet feeders are driving throughputs that rival and often exceed traditional lithography, enabling signage and packaging that formerly required multiple litho sheets to be completed in a single digital pass.

Water-Based Polymer Inks: Sustainability concerns have prompted Canon’s 2022 launch of an automated production facility in Venlo for water-based CMYK inks, designed to curtail waste while ensuring consistent, premium output.

Strategic Partnerships & Acquisitions: Industry consolidation remains robust. In October 2023, ARC Document Solutions partnered with Canon Solutions America to integrate Arizona printing and Colex cutting systems, bolstering its digital color printing services.

Explore pivotal insights and conclusions from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86049

Key Players and Industry Leaders

Prominent companies shaping the digital printing landscape include:

Amcor plc

Avery Dennison Corporation

Canon Inc.

ColorJet Group

DIC Corporation

Durst Group

Electronics for Imaging, Inc.

Hewlett Packard Enterprise

Inca Digital Printers Ltd.

Konica Minolta, Inc.

Mimaki Engineering Co., Ltd.

The Ricoh Company, Limited

Roland DG Corporation

Seiko Epson Corporation

Toshiba Corporation

Xeikon B.V.

Xerox Holdings Corporation

Other

Recent Developments

April 2023: Kyocera Corporation acquired NIKKA S.A.S., enhancing its inkjet print engine capabilities and strengthening its presence in Japan’s digital printing market.

January 2022: Smurfit Kappa invested over US$ 33 million to install high-end printers in Brazil, supporting the booming e-commerce packaging segment.

September 2023: Fiery LLC inked an R&D partnership with Esko to advance digital print technologies with a focus on color and workflow automation.

Market Opportunities and Challenges

Opportunities:

Sustainability Focus: Development of eco-friendly inks and substrates presents new revenue streams as brands seek greener packaging solutions.

Emerging Economies: Rapid industrialization in Asia Pacific and Latin America offers fertile ground for new installations and service offerings.

4.0 Factory Integration: Combining IoT, AI, and advanced robotics with digital print presses can revolutionize mass customization.

Challenges:

High Capital Expenditure: Upfront costs of advanced digital presses may deter smaller enterprises despite long-term ROI advantages.

Skill Shortages: Operating and maintaining sophisticated digital printing systems requires specialized training.

Ink and Substrate Compatibility: Ensuring consistent print quality across diverse materials remains a technical hurdle.

Future Outlook

By 2034, digital printing is expected to account for more than half of global print volumes in packaging and textiles, driven by:

Automation & AI: Presses will self-optimize color, media handling, and maintenance schedules.

Personalization at Scale: Brands will offer hyper-customized products with batch sizes as low as one, unlocking new business models in retail and direct-to-consumer markets.

Hybrid Production Lines: Integration of digital and traditional printing methods will enable seamless transitions between high-definition short runs and high-volume lithography.

Market Segmentation

By Printing Type:

Inkjet (leading segment due to superior tonal range)

Laser

By Ink Type:

Aqueous

UV-Cured

Solvent

Latex

Dye Sublimation

Others

By Substrate Type:

Paper

Textile

Plastic Films or Foils

Ceramic

Glass

Others

Regional Insights

Asia Pacific dominated the digital printing market in 2023 and is forecast to maintain its leadership through 2034. China’s pivot toward end-to-end digitized value chains and strategic investments—such as Tomato Cloud Technology’s order for 10 Fujifilm Jet Press 750S machines in October 2021—have underpinned regional growth. In April 2023, Kyocera’s acquisition of NIKKA S.A.S. further underscores Japan’s commitment to inkjet innovation. North America and Europe remain important hubs for R&D, particularly in sustainable ink and substrate development.

Why Buy This Report?

Comprehensive Market Analysis: In-depth quantitative and qualitative insights covering 2020–2022 historical data, 2024–2034 forecasts, Porter’s Five Forces, value chain assessment, and SWOT analysis.

Competitive Landscape: Detailed profiles of leading players, product portfolios, strategic initiatives, market share breakdowns, and financial comparisons.

Actionable Segmentation: Granular analysis by printing type, ink, substrate, and region to inform targeted investment and expansion strategies.

Excel & PDF Formats: Ready-to-use data tables in Excel for custom modeling, alongside an executive-ready PDF report.

Explore Latest Research Reports by Transparency Market Research:

Ring Laser Gyroscope Market: https://www.transparencymarketresearch.com/ring-laser-gyroscope-market.html

Lithography Equipment Market: https://www.transparencymarketresearch.com/lithography-equipment-market.html

Compact Camera Module Market: https://www.transparencymarketresearch.com/compact-camera-module-market.html

Grow Light Market: https://www.transparencymarketresearch.com/grow-light-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Commercial Printing Market Insights: Detailed Overview of Market Size, Share, Projected Growth

The global commercial printing market size is estimated to reach USD 598.06 billion by 2030, registering a CAGR of 3.2% from 2025 to 2030, according to a new report by Grand View Research, Inc. The rising demand for commercial printing for producing promotional material such as brochures, flyers, newspaper inserts, and pamphlets, among others, is expected to be one of the driving factors for the target market growth. The demand for commercial printing spans several industries, including manufacturing, advertising, food and beverage, retail, and healthcare.

The growing advertising needs of businesses contribute significantly to the demand for commercial printing of advertising materials. Commercial printing primarily involves printing on different types of paper and canvas for packaging, publishing, or advertising needs. Typesetting, bookbinding, fulfillment services, designing services, and finishing, which include folding, cutting, and binding, are some of the ancillary services provided by the market players, along with printing services. The fulfillment services include packaging, storage, and delivery of the printed material services.

The growth of online shopping and the demand for personalized experiences have boosted the demand for commercial printing from the packaging sector. Packaging is considered one of the most important marketing tools, and hence businesses are utilizing packaging to display products’ best features. Also, the packaging is being used as a tool to create an unboxing experience for the users.

As a result, many packaging companies are investing in high-technology commercial printing solutions. For instance, in October 2022, Comexi, a flexible packaging service provider, announced the launch of Digiflex, a machine designed for flexible packaging and label converters to print variable data such as QR codes, data matrix variable codes, barcodes, alphanumeric text, and other numbering & marking applications.

The COVID-19 pandemic severely impacted the commercial printing market. The pandemic led to reduced demand for commercial printing as businesses, and their operations were halted. Furthermore, the outbreak disrupted the supply chain and led to an increase in costs of raw materials and labor, and also severely impacted the distribution, which in turn impacted the growth of the target market negatively.

The advent of digital media is restricting the growth of the target market as it continues to replace print media with digital media. Users are adopting the digital form of books and magazines instead of the printed medium. Also, businesses are utilizing digital media for advertising purposes. Despite the impact of digitization, the print industry is, however, pivoting its business models by taking into account the changing needs, trends, and new realities of the market.

For More Details or Sample Copy please visit link @: Commercial Printing Market Report

Commercial Painting Market Report Highlights

The digital printing segment is expected to grow at the fastest CAGR of 4.4% over the forecast period. The growth is attributed to the rapid adoption of inkjet and laser printing solutions across the paper and packaging printing sector due to the cost-efficient and flexible nature of the technology.

The packaging segment accounted for the largest revenue share of over 54.2% in 2024. The packaging segment includes printing on labels, tags, and flexible packaging.

North America held the second-largest share in the commercial printing market in 2024 and accounted for a revenue share of over 33.2% of the global revenue.

Asia Pacific is expected to grow at the highest CAGR of 3.7% over the forecast period, and it was also the dominant region in the global market in 2024. The regional growth is attributed primarily to advancements in the print industry, such as digital technologies, particularly in China and India.

#CommercialPrinting#PrintingIndustry#PrintSolutions#OffsetPrinting#DigitalPrinting#FlexographicPrinting#GravurePrinting#ScreenPrinting

0 notes

Text

How fast does a badge print?

In the event industry, trade fairs and business conferences, time is equal to money. Another very common inquiry from customers is: How long does it take to print a badge? That varies based on various parameters such as the shape of the badge, the mode of printing, and the number to be processed. If you want to have world-class and hassle-free badge printing service in Abu Dhabi, then go ahead with the knowledge of the process and time.

Understanding Badge Printing Speed

Badge printing time varies from a few seconds to a few minutes per badge. The following is an explanation of the most important factors that affect badge printing time:

1. Printing Method

There are different printing technologies applied to badge printing:

Direct Thermal Printing: Economical and quick, suitable for temporary use badges. It takes 2–5 seconds to print a badge.

Thermal Transfer Printing: A bit slower but provides higher print quality and durability. Printing occurs at about 5–10 seconds per badge.

Inkjet or Laser Printing: Utilized for detailed badge designs. These are 10–30 seconds, depending on design complexity.

2. Design Complexity

Simple text-based badges print much faster than those with:

Full-color logos

QR codes or barcodes

Photographs or custom graphics

The greater the amount of data and design elements, the longer it takes to process and print out individual badges.

3. Quantity Required

When printing out a large number of badges for an event or conference, the issue of speed becomes paramount. Industrial badge printers operated by professional printing services in Abu Dhabi handle bulk printing at rates of up to 150 badges per hour or more.

4. Customization Requirements

Individualized badges that bear personal names, images, or job titles take longer to produce than their equivalent badge print counterparts. Most sophisticated badge printers employed in the services of Abu Dhabi badge printing support such personalization effectively using batch processing software.

If you require quick and trustworthy badge printing in Abu Dhabi, some providers provide same-day or next-day delivery for urgent needs. For business events, trade exhibitions, school identification cards, or security badges, experienced printing companies in Abu Dhabi provide:

High-quality material

Quick turnaround times

Customized precision

Reasonable prices for bulk orders

Others even provide on-site badge printing services at events to accelerate the registration process and reduce delays.

How to Get Badges Printed Faster?

To have your badges printed sooner, follow these tips:

Have your badge design pre-done

Supply correct data in an editable format (Excel/CSV)

Select the appropriate type of badge material

Get associated with a well-established badge printing Abu Dhabi service provider with a good track record of event and ID badge printing

Conclusion

In general, badge printing can be as fast as a few seconds per badge, particularly with the assistance of high-end machinery and streamlined workflows. If you don't have time and require professional output, consider outsourcing to a local professional in Abu Dhabi for badge printing, who provides rapid, quality service that is attentive to your requirements.

No matter if it's a tiny batch or a huge event, the correct badge printing partner will save you time, cut down on mistakes, and ensure your event is a success.

0 notes

Text

Variable information printing

Surface Material

Thermal PP

Thermal paper

Thermal transfer paper

Surface Color

White

Typical Applications

Business standard, Logistics labels, Aviation labels, Medical labels, Stationery cultural labels, etc.

Product Features

Environmental protection surface material, surface coating waterproof, oil proof, scratch resistance, printing and printing color, color effect is good.

Our premium thermal Variable information printing is designed for a wide range of professional applications, offering high durability and excellent print quality. Made from environmentally friendly materials, it ensures waterproof, oil-resistant, and scratch-resistant properties, making it ideal for industries that demand long-lasting and high-performance labels.

Surface Material: Thermal PP, Thermal Paper, Thermal Transfer Paper

Surface Color: White

Printing Quality: Supports high-resolution printing with vibrant colors and sharp details

Durability: Resistant to water, oil, and scratches for long-lasting performance

Applications: Perfect for business, logistics, aviation, medical, and stationery labels

Technical Support

Our Variable Information Printing Paper is specifically designed to accommodate high-quality, on-demand printing of dynamic data for labels, tags, invoices, and more. Perfect for industries needing flexibility in customizing print jobs with unique, variable information.

Advantages of Variable information printing:

High-Quality Print Surface: Smooth, bright finish ideal for crisp text, barcodes, and graphics.

Perfect for Variable Data: Optimized for printing variable data such as names, addresses, serial numbers, and QR codes.

Compatible with Multiple Printers: Works seamlessly with inkjet, laser, and thermal transfer printers.

Strong Adhesion & Durability: Long-lasting print quality that resists fading, smudging, and water damage.

Eco-Friendly Options: Available in FSC-certified and recycled paper for environmentally conscious printing.

Wide Range of Sizes: Available in sheets, rolls, and custom formats to meet diverse printing needs.

Contact Technical Support

For questions about selecting the right Variable Information Printing Paper or assistance with printing techniques, our team is here to help.

Phone: 0086-0573-8789 5888 / 87896955 / 87896899

Email: [email protected] / [email protected]

Website: https://en.wbllabel.com/

Reach out for expert advice and solutions to enhance your printing process!

0 notes

Text

Future Trends in the Point of Sales (PoS) Printers Market: What You Need to Know

The Point of Sales (PoS) printers market plays a critical role in the retail, hospitality, and service industries by ensuring smooth and efficient transactions. These devices generate receipts, invoices, order tickets, and other essential transaction documentation. As businesses increasingly move towards automation and digital solutions, the PoS printer market has witnessed significant growth and innovation in recent years. However, like any evolving industry, it faces its share of challenges and opportunities, which are shaping its future.

Understanding the PoS Printer Market

A PoS printer, fundamentally, is a printer designed for use in retail environments, often coupled with a PoS terminal or system. These printers come in various types, including thermal printers, impact printers, and inkjet printers, each catering to different business needs. Thermal printers, which use heat to print on special paper, have become the dominant choice due to their speed, reliability, and cost-efficiency. They are widely used for generating receipts, labels, and barcodes. On the other hand, impact printers are still favored for certain applications, such as in environments requiring multi-part receipts (for example, in automotive repair shops), while inkjet printers may still be seen in more specialized, high-end applications.

The global PoS printer market is a dynamic and competitive landscape, fueled by the widespread adoption of retail technologies and the increasing demand for streamlined and customer-friendly transactions.

Market Drivers

1. Retail and E-commerce Growth

As retail environments become more advanced, the demand for efficient PoS systems has surged. Both traditional brick-and-mortar retailers and online sellers who also have physical presence require PoS printers that can quickly process sales and print receipts. The increasing use of self-checkout kiosks, mobile PoS solutions, and omnichannel sales models also contributes to this trend. These innovations demand reliable PoS hardware, including printers that can keep up with the pace and provide seamless transaction experiences.

E-commerce giants, like Amazon and Alibaba, have also set new standards for operational efficiency, pressuring smaller retailers to follow suit by investing in advanced PoS systems that incorporate top-tier printers for smooth customer interactions.

2. Technological Advancements

Technological innovation is another major driver for the growth of the PoS printer market. The development of faster, more reliable, and versatile PoS printers has opened up new possibilities for businesses. Features like wireless connectivity, cloud-based printing, and integrated barcode and QR code printing have made PoS printers more versatile and useful for businesses.

Furthermore, the shift toward mobile PoS systems, where smartphones or tablets function as the main terminal, has created a need for compact, lightweight PoS printers that can seamlessly connect to mobile devices. This trend is especially noticeable in the foodservice industry, where mobile PoS systems are becoming the norm for taking orders and processing payments.

3. Increased Demand for Contactless Payments

The global pandemic accelerated the adoption of contactless payment methods, which are now expected to continue as consumers and businesses embrace safety and convenience. PoS printers are evolving to accommodate the rising demand for contactless payments by integrating seamlessly with mobile wallets, NFC-enabled payment methods, and QR codes. The ability to provide digital receipts, or offer customers a choice between paper and digital versions, is becoming a key feature for modern PoS printers.

Challenges in the PoS Printer Market

While the PoS printer market is thriving, there are several challenges that businesses and manufacturers need to navigate in order to stay competitive.

1. Environmental Impact and Sustainability

As concerns about sustainability grow, businesses are becoming more conscious of their environmental footprint. PoS printers, especially thermal printers, are often seen as a contributor to paper waste and excessive plastic use. With increasing scrutiny from regulators and customers alike, manufacturers are under pressure to develop eco-friendly solutions. The adoption of recyclable paper rolls and energy-efficient printing technologies is on the rise, but sustainability remains a challenge, particularly in high-volume environments.

2. Price Sensitivity and Competition

Price sensitivity is a common issue faced by businesses, especially small and medium-sized enterprises (SMEs), which are often hesitant to make substantial investments in PoS printers due to their relatively high initial cost. This challenge has spurred intense competition among manufacturers to offer lower-priced yet high-quality alternatives, leading to the rise of both local and international players in the market. The competition also extends to software integration and the added services that PoS printers can offer, such as advanced analytics and reporting tools.

3. Technological Fragmentation

Although technological advancements are a driving force in the PoS printer market, the sheer pace of innovation can also lead to fragmentation. Businesses may struggle to keep up with rapid changes in hardware and software compatibility, particularly when newer models may not integrate easily with older PoS systems. This poses a challenge for companies seeking to upgrade their existing infrastructure without significant disruption to their operations.

Future Outlook for the PoS Printer Market

Looking ahead, the PoS printer market is expected to continue its expansion, driven by further technological innovations and the growing demand for more efficient, customer-centric retail experiences. Cloud printing, integration with artificial intelligence (AI) for inventory management, and the use of advanced analytics for customer data are all areas where PoS printers can evolve.

Additionally, sustainability initiatives will likely take center stage, with manufacturers increasingly focusing on reducing their environmental impact. From producing printers that require less energy to designing systems that minimize paper usage, the future of PoS printing will likely be shaped by an emphasis on sustainability and eco-friendly materials.

In conclusion, the PoS printer market is at an exciting crossroads. While the industry faces challenges related to sustainability and technological fragmentation, it also presents significant growth opportunities fueled by technological advancements, the rise of contactless payments, and the continued evolution of the retail sector. For businesses, staying up-to-date with the latest trends and innovations in PoS technology will be crucial for maintaining competitive advantage in a fast-moving market.

0 notes

Text

Boost Traceability and Compliance with an Inkjet Batch Coding Machine

Stay ahead of industry standards and meet regulatory demands effortlessly with an Inkjet batch coding machine. Designed for precision and adaptability, these machines provide fast, non-contact coding for a wide range of materials and packaging formats. Ideal for fast-moving consumer goods, pharmaceuticals, and industrial products, an Inkjet batch coding machine allows you to print detailed data—like manufacturing dates, expiry information, and serial numbers—directly onto your products. With features like quick-dry ink, variable font sizes, and customizable settings, it enhances traceability, prevents counterfeiting, and boosts brand credibility. Make your packaging smarter and your production line more efficient with this powerful tool.

1 note

·

View note

Video

youtube

Auto L sealer machine with Shrink tunnel machine

Royal Inks & Equipments Pvt. Ltd.

Pioneering Excellence in Printing Inks & Industrial Machinery Since 1994.

At Royal Inks & Equipments Pvt. Ltd., we are a trusted manufacturer and supplier of high-quality printing inks and industrial coding & marking solutions. With over 25 years of industry expertise, we have been at the forefront of innovation, precision, and reliability in the printing and packaging industry, catering to both domestic and international markets.

Our Product Range 🔹 Printing Inks: ✔️ Marking Inks – Ensuring long-lasting impressions and superior adhesion. ✔️ Water-Based Flexographic Inks – Ideal for eco-friendly, high-speed printing applications. ✔️ Solvent-Based Poly Inks – Designed for flexible packaging and high-quality prints. ✔️ Lino Inks & Offset Inks – Delivering sharp, vibrant, and consistent color output. 🔹 Industrial Coding & Packaging Machinery: ✔️ Handy Coder Machines – Reliable for batch coding and marking. ✔️ Batch Coding & Inkjet Coding Machines – Enabling seamless product labeling and traceability. ✔️ Auto Coder Machines – Designed for automated, high-speed printing requirements. ✔️ Filler & Packing Machines – Enhancing efficiency in packaging operations.

0 notes

Text

Model IJP – T-360-O (18mm)

"Unlock efficiency with the IJP-T360-O Industrial Inkjet Printer! ✨ Designed for high-quality, low-cost printing on bottles, cartons, and pouches, it offers zero maintenance and 200 dpi resolution. Perfect for batch coding and expiry date printing. Save time, reduce costs, and boost productivity with this reliable solution!

Ready to upgrade your printing? 🔥

👉 Learn More & Shop Now

1 note

·

View note

Text

0 notes

Text

Revolutionizing Lithium Battery Production with Semco’s Advanced Laser Marking Solutions

In the rapidly evolving landscape of lithium battery production, speed and accuracy are paramount. Semco is at the forefront of this revolution, offering advanced laser marking solutions designed to meet the demands to enhance efficiency and accuracy in fast-paced manufacturing.

The global demand for lithium batteries is surging, driven by their critical role in electric vehicles (EVs), renewable energy storage, and consumer electronics. As manufacturers race to keep up with this demand, precision, efficiency, and traceability have become essential factors in ensuring quality and regulatory compliance.

Key Features and Benefits

Speed and Efficiency:

Semco's laser marking systems are engineered for high-throughput production, enabling rapid and precise marking of battery components. Compared to traditional marking methods like inkjet printing or mechanical engraving, laser marking significantly reduces cycle times, enhancing overall production efficiency.

Accuracy and Precision:

Ensure consistent and reliable marking with Semco's high-precision laser technology, crucial for traceability and quality control in battery manufacturing. Accurate markings play a vital role in:

Identification of individual cells and modules – Enabling better tracking and maintenance.

Tracking production data – Ensuring manufacturing consistency and process optimization.

Compliance with industry standards – Meeting regulatory requirements for safety and authenticity.

Versatility and Flexibility:

Semco's laser marking solutions can handle a wide range of battery materials and component sizes, offering flexibility for diverse production needs. The ability to mark various types of codes enhances traceability and security, including:

QR codes

Data Matrix codes

Serial numbers

Integration and Automation:

Seamlessly integrate Semco's laser marking systems into existing production lines with advanced automation capabilities. The benefits of automation include:

Reduced manual labor, leading to cost savings.

Minimized errors, improving production accuracy.

Increased overall efficiency, optimizing manufacturing workflows.

Laser Welding and Its Role in Production

Laser welding is another critical aspect of lithium battery production, ensuring strong and reliable connections between battery cells and components. Laser marking and laser welding work in conjunction with production lines by enabling precise identification and quality assurance throughout the manufacturing process. With Semco’s cutting-edge solutions, manufacturers can streamline both marking and welding, ensuring a seamless and efficient production environment.

Semco's Laser Marking Solutions

Semco is dedicated to providing reliable and high-performance laser marking solutions, backed by expert support and service. Our technology ensures that lithium battery manufacturers achieve superior product traceability, compliance, and operational efficiency. From multi-station large-size machines to portable fiber laser marking machines, Semco provides tailored solutions based on application, material, and surface characteristics.

Conclusion

Semco's laser marking technology is revolutionizing the battery manufacturing industry by providing precision, speed, and versatility. As the demand for sustainable energy solutions grows, Semco's innovative solutions are poised to play a crucial role in enhancing production efficiency and product quality.

#Electric Vehicles#Energy Storage#Energy Storage Solutions#EV#laser marking#laser marking solutions#laser welding#laser welding machine#laser welding machine in India#lithium-ion batteries#lithium-ion battery packs

0 notes

Text

Chuke intelligent marking machine is popular all over the world and has won high recognition and praise from customers

In recent years, the various series of marking machines produced by Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") have been exported to many countries and regions around the world. With its excellent performance and high-quality services, it has won high praise from domestic and foreign customers.

As an intelligent equipment export enterprise integrating R&D, manufacturing, sales and service, Chuke Intelligent has always adhered to the development concept of "quality-oriented, innovation-driven" since its establishment, and is committed to providing customers with efficient and accurate marking solutions. The company has inherited Chongqing Zixu Machinery Factory's 13 years of production and R&D experience and 10 years of export experience. Combining advanced technologies in the field of intelligent equipment at home and abroad, it has successfully launched a number of marking machine products with independent intellectual property rights.

Chuke Intelligent's marking machine series covers a variety of types such as laser marking machines and inkjet printers, which are suitable for marking needs of various materials such as metals, plastics, paper, and wood. These devices not only support high-precision printing of patterns, texts, QR codes and barcodes, but also use advanced Internet of Things technology to realize remote monitoring, fault warning and data analysis functions, greatly improving operation and maintenance efficiency and reducing enterprise operating costs.

With its outstanding performance and high-quality service, Chuke Intelligent's marking machine products have successfully entered the international market and are exported to many countries and regions such as Europe, North America, and Southeast Asia. The company's customers are spread across many industries such as automotive parts manufacturing, electronic product production, and food and beverage processing, providing efficient and accurate marking solutions for their production lines.

Foreign customers have given high praise to Chuke Intelligent's marking machine products. They have said that Chuke Intelligent's marking machine is not only easy to operate and has stable performance, but also has a clear and lasting marking effect, which greatly improves their production efficiency and product quality. Especially in the field of automobile manufacturing, Chuke Intelligent's marking machine has become an indispensable marking tool for automobile manufacturers with its excellent durability and anti-counterfeiting ability.

It is worth mentioning that Chuke Intelligent has not only made remarkable achievements in product research and development and manufacturing, but also made great efforts in market expansion and service. The company has a professional foreign trade service team, who rely on their rich experience and superb technical strength to provide overseas customers with efficient and convenient foreign trade solutions. Especially in the Russian Federation market, Chuke Intelligent has reached a strategic cooperation with Chongqing Chengyouqing Network Technology Co., Ltd. to jointly explore the unlimited possibilities of the Russian Federation market. This cooperation not only brings more market opportunities to Chuke Intelligence, but also further enhances its popularity and influence in the international market.

In the future, Chuke Intelligence will continue to uphold the corporate philosophy of "innovation, professionalism, and service" and continue to explore new boundaries of intelligent marking technology. The company will continue to increase R&D investment, promote technological innovation and industrial upgrading, and provide customers with better quality and more efficient marking solutions. At the same time, Chuke Intelligence will also actively expand the international market, strengthen cooperation and exchanges with overseas customers, and jointly promote the global development of intelligent marking technology.

0 notes