#Injection Mold Tooling Services and Part Production

Explore tagged Tumblr posts

Text

The Benefits of Working with a Manufacturer Who Offers Injection Mold Tooling Services and Part Production

Not all injection molding manufacturers offer injection mold tooling services and part production. The availability of tooling services depends on the size, capabilities, and business model of the injection molding manufacturer that you are partnering with.

0 notes

Text

Best Injection Moulding Companies in Ahmedabad

Ahmedabad is considered the industrial hub of Gujarat because of its strong industrial ecosystem, proficient workforce, and advanced manufacturing technologies utilized by different manufacturing industries. Injection molding companies are one of these industries that have been thriving in Ahmedabad for many years. These injection molding companies in Ahmedabad (Gujarat) are known for their advanced technology, precision engineering, and premium quality work. The injection molding manufacturers in Ahmedabad deliver high-quality products to several sectors like automotive, consumer goods, healthcare, packaging, and etc.

We have curated a list of top injection molding companies in Ahmedabad based on their expertise, experience, and client feedback:

1. Precision Technoplast Pvt. Ltd.:

Precision Technoplast is a leading injection molding company with more than 40 years of experience in producing high-precision injection molds & plastic components. With the utilization of its incredible services, you can get end-to-end solutions for all your injection molding needs, from CAD designing to mold development with precision machining and automation integration. This company is perfect for those customers who are looking for precision tooling, integrated robotics, and export-ready molding solutions.

2. OPM Plastics:

OPM is one of the top injection molding companies in Ahmedabad, which has been delivering premium plastic molded products for more than 60 years. This plastic injection molding manufacturer in Ahmedabad is recognized for its high-precision products and timely delivery. With the utilization of its large factory, this company can deliver bulk orders and small orders on time without compromising the quality of the product. It has a team of professionals who use advanced machinery and modern technologies to deliver their best products in every sector like automotive, healthcare, consumer goods, and many more.

3. Shivam Engitech:

Shivam Engitech is another leading firm in injection molding in Ahmedabad which is well-known for its high-quality mold dyes. This company manufactures a wide range of molds including sanitary ware, household products, industrial components, and toys. With its focus on innovation, product quality, and customer satisfaction, this company has made a strong place in the market of injection molding.

4. Sadhi Machinery:

Being in business for many years, Sadhi Machinery is renowned for its plastic blow molding machines. This company is committed to customer satisfaction and provides customized solutions for injection molding in the packaging and consumer goods sectors. The products manufactured by this company are built using premium materials for long-term performance.

5. Alvin Group:

Recognized as Nissei Machines, Alvin Group is famous for its all-electric injection molding machines that are highly energy efficient. These highly efficient machines are known for their precision and speed, which is perfect for manufacturing products in different sectors like automotive, medical, electronics, and packaging. The energy-efficient machines of this company can perform clean-room operations and manufacture products with high repeatability.

Tips for Selecting the Right Injection Molding Company in Ahmedabad

Choosing the right injection molding company in Ahmedabad can be challenging, but if you follow these tips, you can find the perfect plastic mold manufacturers in Ahmedabad for your business:

It is important for you to know your needs before contacting a company offering injection molding services in Ahmedabad, like whether you want molded parts or machines.

Based on your precision and energy needs, you can choose the machine type from hydraulic, servo, or electric.

You should also know your production volume before selecting one of the best injection molding companies in Ahmedabad.

The top injection molding companies in Ahmedabad (Gujarat) offer added services like CAD design and printing/assembly.

To get sustainable services, you can lean towards electric systems for efficiency.

Also, you can check for the expertise, client feedback, and years of experience of the company before associating with them.

The type of material used by the company is another thing to consider before selection.

How OPM Helps:

Being in plastic injection molding companies in India for many years, OPM brings advanced technology and deep technical expertise to the injection molding market of Ahmedabad. With the utility of high-speed servo injection molders and precision tooling systems, OPM ensures premium quality, consistency, and bulk production. The key specialties of this plastic injection molding manufacturer in Ahmedabad are the production of multi-cavity and complex molds, the use of specialized plastic materials like ABS, PP, Nylon, PC, PET, etc., rapid prototyping, and 3D modeling integration.

Recognized for its customized, end-to-end solutions in injection molding, this company is committed to delivering solutions from concept to final product. Its plastic injection molding services in Ahmedabad include product designing, custom mold fabrication, injection molding & assembly, surface finishing, and quality inspection before packaging.

As one of the best injection molding companies in Ahmedabad (Gujarat), this company ensures that every component meets the industry-specific standards at every stage. It uses energy-efficient servo machines and biodegradable materials to contribute to a greener environment.

With technical expertise, modern infrastructure, a customer-centric approach, and dedication towards quality, OPM is contributing to elevating not only its growth but the Ahmedabad’s growth.

Contact OPM today to explore more about its technical expertise and tailored solutions for injection molding and reach the next level of success!

#plastic injection molding manufacturer in Ahmedabad#injection molding companies in Ahmedabad#injection molding companies#plastic injection molding companies in India

0 notes

Text

Zinc Parts Manufacturing in India – Processes, Applications & Top Manufacturer

India’s industrial and manufacturing landscape is undergoing rapid transformation. One of the key materials driving this growth is zinc — a versatile metal that is widely used for creating strong, durable, and corrosion-resistant components across various industries.

From automotive parts to sanitary hardware, zinc parts manufacturing has become a vital backbone of engineering and precision production in India.

In this article, we’ll explore:

What zinc parts manufacturing is

Why zinc is preferred over other metals

Applications of zinc components

The manufacturing process

And the leading zinc parts manufacturer in India: DST Industries

What is Zinc Parts Manufacturing?

Zinc parts manufacturing involves producing complex, high-precision components using zinc alloys, often through a process known as pressure die casting. Zinc is preferred because of its excellent strength, fluidity, corrosion resistance, and low melting point, which allows manufacturers to create detailed shapes and designs with minimal machining.

Why Zinc? Benefits at a Glance

High Dimensional Accuracy

Excellent Surface Finish

Corrosion Resistance

Great Electrical Conductivity

Ideal for High-Volume Production

Cost-Effective vs. Other Alloys

Zinc parts are especially useful when small, intricate, and durable components are required.

Zinc Die Casting: The Core Manufacturing Method

The most common technique for zinc parts manufacturing is high-pressure die casting. Here's a simplified breakdown of the process:

Step 1: Tooling & Mold Creation

A steel mold (also called a die) is designed based on the final part’s geometry.

Step 2: Melting Zinc Alloy

Zinc alloy is melted at ~400°C in a furnace.

Step 3: Injection into Die

Molten zinc is injected into the die cavity under high pressure (15,000–20,000 psi) for precise molding.

Step 4: Cooling & Ejection

The cast cools rapidly, and the part is ejected from the die.

Step 5: Trimming & Finishing

Excess material is removed, and the part may undergo CNC machining, polishing, plating, or powder coating.

Common Zinc-Based Parts Manufactured

Zinc’s versatility means it’s used in a wide variety of products:

Automotive Components

Door locks, handles, and hinges

Carburetor parts

Transmission components

Decorative trims

Sanitary & Plumbing Hardware

Taps, faucet handles, and diverters

Bathroom fittings and spouts

Shower arms and holders

Architectural Hardware

Door knobs, window locks, hinges

Furniture handles and fittings

Electrical & Industrial Equipment

Switchgear parts

Electronic enclosures

Precision instrument housings

India’s Zinc Parts Manufacturing Hub

India has become one of the top global suppliers of zinc die cast parts due to its cost-effective labor, advanced tooling capabilities, and robust industrial infrastructure.

One name that stands out in this space is:

DST Industries – Leading Zinc Parts Manufacturer in India

Website: www.dst-industries.com

DST Tech is a premium zinc die casting company based in Haryana, India. With over a decade of experience, DST specializes in manufacturing high-precision zinc parts for various industries including:

Automotive

Sanitary ware

Architectural hardware

Industrial machinery

Why Choose DST Industries?

In-house tool design and development

High-pressure zinc die casting machines with modern tech

Full-service capabilities: CNC machining, polishing, plating & powder coating

ISO-certified processes

Custom part development from prototyping to production

Quick turnaround and reliable delivery

Whether you need bulk production or custom engineered zinc parts, DST Industries delivers quality and precision with each batch.

Zinc is no longer just a protective coating — it’s a strategic material for modern engineering. As demand for lightweight, strong, and corrosion-resistant parts rises, manufacturers like DST Industries are pushing the boundaries of what's possible with zinc die casting.

If you’re looking for a trusted zinc parts manufacturing partner in India, DST Industries offers the infrastructure, experience, and expertise to bring your designs to life.

0 notes

Text

Accelerate Your Ideas with Plastic Product Realization Services – Powered by Clixroute

In today's fast-paced market, bringing a plastic product from concept to reality requires more than just an idea — it demands precision, experience, and integrated manufacturing support. That’s where Clixroute comes in. Our end-to-end plastic product realization services are designed to turn your vision into a tangible, market-ready product with efficiency and accuracy.

What Are Plastic Product Realization Services?

Plastic product realization services refer to the comprehensive process of transforming a design concept into a fully functional plastic product. This includes every stage of development — from initial design and prototyping to tooling, molding, and final production.

Clixroute offers a seamless solution for companies, entrepreneurs, and industries looking to develop custom plastic parts or products with superior quality and reduced time to market.

Why Choose Clixroute for Plastic Product Realization?

At Clixroute, we don’t just manufacture plastic parts — we partner with you to ensure your product is optimized for performance, manufacturability, and cost. Our approach is customer-focused, detail-oriented, and innovation-driven.

Our Key Capabilities:

Concept Design & 3D Modeling: Collaborate with our experts to develop design-ready concepts.

Rapid Prototyping: Create functional prototypes to test form, fit, and function quickly.

Mold Design & Tooling: Precision tooling solutions for high-volume, repeatable quality.

Injection Molding: Advanced molding techniques for high-performance plastic components.

Post-Processing & Assembly: Value-added services like finishing, assembly, and packaging.

Whether it’s a single part or a complex assembly, Clixroute ensures excellence at every step.

Industries We Serve

Our plastic product realization services are trusted by clients across various industries:

Consumer Electronics

Automotive Components

Medical Devices

Home Appliances

Industrial Equipment

Packaging Solutions

No matter the complexity or scale, Clixroute is equipped to deliver.

The Clixroute Advantage

State-of-the-Art Facility: Equipped with the latest machinery and software.

Expert Engineering Team: Highly skilled professionals who understand both design and manufacturing.

Quality Assurance: Strict quality checks at every stage to ensure defect-free production.

Cost Efficiency: Optimized processes for competitive pricing without compromising quality.

End-to-End Support: From idea to product launch, we guide you throughout the journey.

Conclusion

Your plastic product deserves more than just manufacturing — it deserves intelligent realization. With Clixroute’s plastic product realization services, you gain a trusted partner committed to transforming your ideas into durable, high-quality plastic products that succeed in the market.

Ready to bring your plastic product idea to life? Partner with Clixroute for innovative, reliable, and expert-led plastic product realization services that drive real results.

Visit us https://www.clixroute.com/services/product-realization/

0 notes

Text

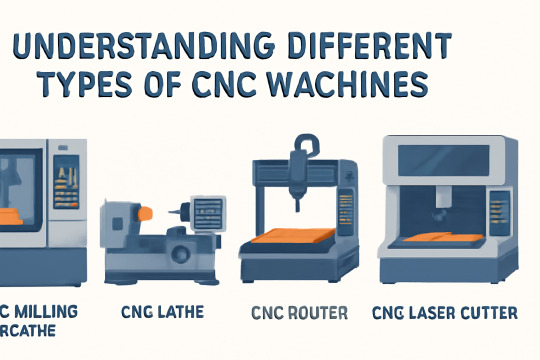

Understanding Different Types of CNC Machines

Introduction to CNC Machines

CNC machines have revolutionized manufacturing and production industries across the globe. These advanced tools have transformed how products are designed, engineered, and built, enabling unprecedented precision and efficiency. But what exactly is a CNC machine, and why is it so vital in modern production?

CNC stands for Computer Numerical Control, a system that uses computer software to control the movement of machinery and tools. Unlike traditional manual machining, CNC machines execute pre-programmed sequences with incredible accuracy, allowing for the production of complex parts and components with minimal human intervention. This precision reduces errors, waste, and production times significantly.

CNC machines can work with a wide variety of materials, including metals, plastics, wood, and composites. This versatility makes them indispensable in industries such as aerospace, automotive, electronics, and medical device manufacturing. Their ability to produce intricate designs and maintain consistency over high production runs is unmatched by conventional methods.

Basic Categories of CNC Machines

There are several primary types of CNC machines, each designed to perform specific functions in the manufacturing process. Understanding these categories helps in selecting the right machine for your project’s needs.

CNC Milling Machines

CNC milling machines are among the most versatile and commonly used CNC equipment. These machines use rotating cutting tools to remove material from a workpiece to create various shapes, holes, and profiles. Milling machines can operate along multiple axes — from simple 2-axis milling to complex 5-axis or more — allowing for intricate and precise machining.

Some of the popular subtypes of CNC milling machines include vertical mills, horizontal mills, and gantry mills. Vertical milling machines have the spindle oriented vertically and are widely used for precision tasks. Horizontal mills, where the spindle lies horizontally, are suitable for heavy-duty material removal and larger parts. Gantry mills offer an extended working area, often used for large, complex parts.

CNC milling machines find applications across many sectors, including aerospace parts manufacturing, automotive components, and even intricate molds for plastic injection molding. Their adaptability makes them a staple in many machine shops.

CNC Turning Machines (Lathes)

Turning machines, commonly known as CNC lathes, operate by rotating the workpiece against a cutting tool, which removes material to form cylindrical shapes. Unlike milling, which moves the cutting tool, turning rotates the material itself. This method is especially effective for producing symmetrical parts like shafts, bolts, and pulleys.

Modern CNC lathes can be equipped with multiple axes and tools, allowing for highly complex shapes and features. The ability to perform drilling, threading, and grooving operations on a single machine improves efficiency and reduces handling time.

If your project involves creating round or tubular parts, CNC turning machines are often the best choice. They provide excellent surface finishes and high repeatability, making them ideal for high-volume manufacturing.

Exploring CNC Machining Services

When looking to manufacture precision parts efficiently, many businesses turn to cnc machining services. These services offer access to a wide range of CNC machines and expert operators who can handle everything from design assistance to final production. Utilizing professional machining services means you benefit from optimized setups, high-quality materials, and fast turnaround times without investing heavily in your own equipment.

By outsourcing your CNC machining needs, you gain flexibility and scalability, allowing your production to adapt quickly to changes in demand or product design. Whether you require small prototype runs or mass production, CNC machining services can tailor their approach to fit your project’s requirements.

Specialized CNC Machines

Beyond the basic milling and turning machines, the CNC world includes specialized equipment designed for cutting, shaping, and finishing with unique technologies.

Laser Cutting CNC Machines

Laser cutting machines use a focused beam of light to cut through materials with extreme precision. The laser heats the material until it melts or vaporizes, creating clean cuts with minimal kerf (cut width) and no mechanical contact.

This technology is excellent for processing thin metals, plastics, and even wood with intricate patterns or designs. Laser cutting is popular in industries requiring fine detail, such as electronics enclosures, signage, and jewelry manufacturing.

Advantages of laser cutting include reduced material distortion, fast processing speeds, and the ability to cut complex shapes without the need for expensive tooling. However, laser cutting is generally limited to thinner materials and may not be suitable for thick, dense metals.

Plasma Cutting Machines

Plasma cutting machines operate by sending a high-velocity jet of ionized gas (plasma) through an electrically conductive workpiece, melting the metal and blowing away the molten material. This method allows for fast cutting of thick metals that would be challenging with laser technology.

Plasma cutting is widely used in fabrication shops, automotive repair, and construction where precision is essential but not as fine as laser cutting. It’s cost-effective for medium to heavy-duty cutting applications and works well with materials like steel, aluminum, and stainless steel.

Compared to traditional cutting methods, plasma cutting reduces manual labor and speeds up production, making it a popular choice for large-scale metalworking.

Electrical Discharge Machines (EDM)

Electrical Discharge Machining is a unique CNC process where material is removed from a workpiece by electrical sparks. There are two primary types: Wire EDM and Sinker EDM.

Wire EDM uses a thin wire electrode to cut intricate shapes through electrically conductive materials.

Sinker EDM involves a shaped electrode that erodes the workpiece to form cavities or complex internal shapes.

EDM is highly effective for producing parts that are difficult to machine using conventional methods, such as hardened tool steel molds, dies, and complex internal geometries. Its precision can reach tolerances in the micrometer range, and it leaves excellent surface finishes.

This technique is invaluable in industries like aerospace, medical implants, and mold making, where exacting standards are mandatory.

Benefits of Using CNC Machines

Using CNC machines provides a wide array of advantages, which is why they have become the backbone of modern manufacturing.

Precision and Accuracy

CNC machines follow digital instructions with extreme precision, often achieving tolerances within microns. This accuracy ensures parts fit together perfectly, reducing rework and improving overall product quality.

Increased Production Speed

Because CNC machines operate continuously and quickly, they drastically cut down production times compared to manual machining. Their ability to automate complex tasks means higher throughput and faster time-to-market.

Consistency and Repeatability

Once a program is set, CNC machines produce identical parts consistently, even across thousands of runs. This repeatability is crucial in industries where uniformity directly impacts safety and functionality.

Reduced Human Error

Automation reduces the potential for mistakes caused by fatigue, misreading blueprints, or manual setup errors. CNC machines execute the program exactly as written, leading to fewer defects and less scrap.

Factors to Consider When Choosing CNC Machines

Choosing the right CNC machine depends on several critical factors to match your project’s unique needs.

Material Type and Thickness: Some machines are better suited for metals, others for plastics or composites. Material thickness also influences the choice, especially for cutting processes.

Complexity of Design: More complex parts may require multi-axis machines or specialized cutting methods.

Production Volume: High-volume production benefits from machines with faster cycle times and automation options, while prototyping might prioritize flexibility.

Budget and Cost Efficiency: Initial investment, operating costs, and maintenance should be balanced against the expected production output and quality requirements.

Selecting the right machine upfront prevents costly adjustments and downtime later.

The Future of CNC Technology

The future of CNC machining looks exciting as advances continue to push boundaries.

Automation and Smart CNC Machines

Integration with robotic systems and automated material handling will further increase efficiency. Smart CNC machines equipped with sensors can monitor tool wear, adjust parameters in real-time, and predict maintenance needs.

Integration with AI and IoT

Artificial intelligence and the Internet of Things will enable machines to learn from previous runs, optimize cutting paths, and communicate seamlessly with other factory systems, creating truly smart manufacturing environments.

Sustainability and Eco-Friendly Manufacturing

As environmental concerns grow, CNC technology is evolving to reduce energy consumption and waste. Efficient machining processes, recyclable materials, and eco-friendly coolants are becoming standard.

Understanding the types of CNC machines and their applications helps manufacturers and businesses make informed decisions that drive quality, efficiency, and innovation. Whether you need simple milling or complex EDM, there’s a CNC solution to fit every need and push your production capabilities forward.

0 notes

Text

Custom Plastic Injection Molding

Custom plastic injection molding is the preferred solution for companies that need specialized plastic parts tailored to exact design specifications. At XCMachining, our custom plastic injection molding capabilities enable clients across diverse industries—such as aerospace, medical, and consumer goods—to achieve parts with specific material properties, complex geometries, and tight tolerances.

Our custom approach begins with in-depth consultations. During this stage, our design engineers work hand-in-hand with clients to review CAD models, suggest design for manufacturability (DFM) improvements, and select suitable thermoplastics—whether you need medical-grade polycarbonate or engineering-grade PEEK. By optimizing gate location, wall thickness, and draft angles, we reduce cycle times and ensure part consistency.

Once the design is finalized, we create precision molds using high-quality tool steel and 5-axis CNC machining. Our mold-making expertise guarantees excellent surface finishes and consistent cavity replication. With multi-cavity and family mold options available, we can seamlessly transition from prototype runs to high-volume production, saving you both time and money.

XCMachining’s custom plastic injection molding offers more than just part fabrication. We deliver end-to-end project management, including mold flow analysis, material selection guidance, and secondary operations such as ultrasonic welding or pad printing. Our in-house quality lab employs color spectrophotometers, tensile testers, and coordinate measuring machines (CMM) to validate that each batch of parts adheres to stringent customer requirements.

Flexibility is a hallmark of our service. Whether you require low-volume runs for market testing or large volumes for full product launches, our scalable production line adapts to your timelines. Lead times are minimized through our efficient scheduling and rapid tool-building capabilities, enabling you to hit market windows faster.

Choosing XCMachining for custom plastic injection molding means entrusting your part development to a team committed to innovation, precision, and customer satisfaction. From initial concept all the way through quality inspection, we ensure your custom plastic parts meet performance expectations and contribute to your product’s success.

0 notes

Text

Trusted Melt Flow Index Tester Manufacturer in India

Source of Info: https://www.perfectgroupindia.co.in/blog/trusted-melt-flow-index-tester-manufacturer-in-india

Introduction

The Melt Flow Index Tester is important to measure how easily plastic flows when melted and allows industries to maintain product quality. Many businesses in India are looking for reliable tools for testing the flow rate of plastic materials. Accurate outcomes and durability are guaranteed when you choose the correct manufacturer. Perfect Group India is a reputable company that provides high-quality equipment with designs that are easy to use. They support industries like packaging, automotive and plastic manufacturing with the focus on customer needs and modern technology. Businesses can more easily test and analyze material properties with confidence and accuracy thanks to their testers.

What is a Melt Flow Index Tester?

A laboratory tool called a Melt Flow Index Tester is used to measure how quickly a thermoplastic polymer flows at a given temperature and pressure. Test results are often measured in grams per 10 minutes (g/10 min). An important item of quality assurance and product development, this value shows how easily the material can be processed.

By using this device manufacturers can:

• Monitor the quality of raw plastic materials

• Guarantees the final product meets industry standards

• Compare different batches for reliability

• Improve impact in the molding or extrusion process

Importance of Choosing a Reliable Manufacture

The future benefits and support you get from buying a testing instrument are just as important as the actual equipment. A reliable manufacturer guarantees:

• Accurate in measurements

• Durability of the device

• User-friendly design

• Quick and reliable customer service

• Availability of spare parts and maintenance support

These features allow industries to function easily and without unnecessary downtime or errors.

Why India is Emerging as a Leader in Testing Equipment

The manufacturing industry in India is expanding quickly and there is a growing need for trustworthy plastic testing equipment. With world-class engineering talent and increasing investment in research, Indian manufacturers are now producing advanced testing equipment at low prices.

Indian companies offer instruments that are:

• Built with high-quality products

• Suitable for various types of plastics

• Adjusted to meet international testing requirements such as ISO 1133 and ASTM D1238

• Designed for easy integration in quality control labs

This makes India a perfect choice for sourcing a Melt Flow Index Tester, especially for businesses looking for quality without overspending.

Features to Look For in a Melt Flow Index Tester

Not all testers are the same. Here are the key features that set a high-quality instrument:

• Digital Display: Clear and easy-to-read interface

• Temperature Control: Accurate heating system to maintain consistent test conditions

• Weight Loading Mechanism: Smooth and accurate uses of test loads

• Corrosion-Resistant Build: Durable material for durability use

• Sample Cutter: Clean and simple removal of test samples

• Safety Features: Proper insulation and safety interlocks

• Test Report Output: Option to print or save test data

• Ease of Maintenance: Quick access to parts for routine checks

• Compact Design: Space-saving models for all lab sizes

• Compliance with Standards: Certified to match global testing protocols

If you’re in the market for a new Melt Flow Index Tester, make sure your chosen equipment includes these features to get the best results.

Applications Across Industries

This tester is widely used across various sectors such as:

• Plastic Manufacturing Units

• Injection Molding Plants

• Polymer Research Laboratories

• Automotive Component Makers

• Pipe and Fitting Industries

• Packaging Film Producers

Each of these industries depends heavily on the quality and behavior of plastic materials. The right Melt Flow Index Tester helps maintain quality, improves product strength and reduces the risk of error.

What Makes a Manufacturer Trustworthy?

Melt Flow Index Tester is a reliable products and trusted manufacturer stands out by providing:

• Customized Solutions: Adjusts the equipment to your specific needs

• Training and Demonstration: Offers product examples and hands-on training

• On-Time Delivery: Delivers instruments within the promised time

• Long-Term Support: Includes warranty, spare parts and servicing

• Customer Satisfaction: Positive feedback from previous buyers

Choosing a manufacturer that prioritizes customer needs and provides complete support before and after sales provides peace of mind.

Perfect Group India – A Trusted Name

As a well-known testing instrument manufacturer, we take fulfillment in providing precision-built, high-performance Melt Flow Index Testers for both Indian and international markets. Our company guarantees that each product is carefully manufactured and passes demanding quality checks.

We always have engineers and support workers on hand to help with installation, use and regular maintenance. To make sure your team is comfortable using our instruments, we also offer simple instruction and troubleshooting.

With years of experience and many satisfied customers we are dedicated to making it simple for companies to follow quality standards.

Conclusion

The Melt Flow Index Tester is an important device for analyzing the flow properties of plastic materials during manufacturing. Choosing the right device guarantees higher-quality products and accurate results. Perfect Group India provides solutions you can trust on if you're searching for a reliable choice. It helps industries improve their testing processes with its modern design and user-friendly functionality. Whether you work in plastics, automotive or packaging, having proper testing equipment helps in maintaining quality standards. Invest in equipment that will provide quality and durable productivity. When it comes to manufacturing success and quality control a reliable option is important.

0 notes

Text

Why is CNC machining preferred for manufacturing medical devices?

The medical industry demands the highest standards of precision, quality, and safety in the production of its components and devices. To meet these requirements, many manufacturers turn to CNC machining service providers—specifically those specializing in Medical CNC applications—for the fabrication of medical equipment, instruments, and implants. CNC (Computer Numerical Control) machining has become a preferred manufacturing method in the medical sector for a variety of critical reasons.

Exceptional Precision and Accuracy

Medical devices often require tight tolerances and complex geometries that must be produced consistently and accurately. CNC machines can achieve micron-level precision, making them ideal for manufacturing parts like surgical instruments, orthopedic implants, and diagnostic equipment. This high level of accuracy helps ensure that each component performs reliably and safely in medical applications.

Compatibility with Medical-Grade Materials

CNC machining supports a wide range of biocompatible materials commonly used in the medical field, such as titanium, stainless steel, PEEK, and medical-grade plastics. These materials are essential for applications involving direct contact with the human body or exposure to sterilization processes. CNC machining enables these tough and specialized materials to be shaped with precision and care.

Clean, Contaminant-Free Processes

A major concern in medical manufacturing is cleanliness. CNC machining is a subtractive process that produces minimal heat and dust compared to other methods, reducing the risk of contamination. Parts can also be machined in controlled environments to meet strict hygiene standards. Many CNC machining facilities that serve the medical sector adhere to ISO 13485 certification and FDA regulations.

Repeatability and Consistency

When manufacturing medical devices, consistency is key. CNC machining delivers highly repeatable results, which is crucial for both mass production and the manufacturing of custom components. Whether making 1 or 10,000 parts, CNC machines ensure that each item meets the same specifications without deviation.

Rapid Prototyping and Short Lead Times

Innovation in the medical field is constant, requiring fast development cycles. CNC machining is well-suited for rapid prototyping, allowing engineers to quickly produce and test new designs. Turnaround times are often shorter than with other manufacturing methods, making it easier to get life-saving devices to market quickly.

Complex Geometries and Customization

Medical devices frequently involve intricate shapes that are difficult to produce using conventional manufacturing methods. With multi-axis CNC machines, manufacturers can create highly detailed and customized parts in a single setup. This capability is especially valuable for patient-specific implants and surgical guides tailored to individual anatomy.

Cost-Effectiveness for Low to Mid-Volume Production

For small to medium production runs, CNC machining is often more cost-effective than processes like injection molding, which require expensive tooling. This makes it an ideal solution for specialty medical devices and limited production volumes, such as custom implants or specialized surgical tools.

Conclusion

CNC machining has earned its place as a preferred manufacturing method in the medical industry due to its unmatched precision, material versatility, cleanliness, and ability to produce both prototypes and final products efficiently. By partnering with a qualified CNC machining service, medical device manufacturers can ensure the delivery of safe, high-quality components that meet strict regulatory standards and improve patient outcomes.

0 notes

Text

Die Casting Services in India: A One-Stop Solution for Global Manufacturing Needs

India is fast becoming a global powerhouse in precision manufacturing, with die casting services in India playing a pivotal role across various industries. From automotive to electronics, the demand for high-quality, cost-effective, and scalable metal component production is pushing global businesses to explore India’s thriving manufacturing ecosystem.

At the same time, India’s capabilities in plastic manufacturing are growing in parallel, making the country a versatile hub for both metal and polymer-based production. In this article, we explore why India is a go-to destination for die casting, how digital platforms like FindingMFG are transforming sourcing, and how die casting and plastic manufacturing go hand in hand.

What Is Die Casting?

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. It is widely used for producing strong, complex, and dimensionally accurate components in large volumes.

Common Die Casting Materials:

Aluminum

Zinc

Magnesium

Copper

Industries Served:

Automotive

Aerospace

Consumer Electronics

Industrial Equipment

Medical Devices

Die casting offers excellent surface finish, repeatability, and minimal post-processing—making it ideal for precision engineering needs.

Why Choose Die Casting Services in India?

India has emerged as a global leader in die casting services for a variety of reasons:

1. Cost Advantage

India offers significantly lower production costs compared to Western countries, without sacrificing quality or turnaround time.

2. Skilled Labor Force

With a growing pool of engineers and technicians trained in advanced manufacturing techniques, India provides access to top talent for complex projects.

3. Modern Facilities

Indian die casting companies operate ISO-certified plants equipped with cutting-edge machinery and automation tools.

4. Global Connectivity

India's export-friendly policies and developed logistics infrastructure make it easier to serve international markets reliably.

FindingMFG: Streamlining Die Casting and Plastic Manufacturing Sourcing

FindingMFG is a digital B2B platform that connects global buyers with verified manufacturing partners in India, offering end-to-end visibility, competitive pricing, and dependable delivery timelines.

What Makes FindingMFG Unique?

Curated network of die casting and plastic manufacturing service providers

Instant online quotation system

Real-time order tracking

Built-in communication and project management tools

Quality and compliance assurance

Whether you need aluminum die casting or custom plastic components, FindingMFG helps you simplify sourcing and reduce time to market.

Types of Die Casting Services Available in India

India’s manufacturing sector offers a wide range of die casting solutions to meet diverse project needs:

● High-Pressure Die Casting (HPDC)

Used for high-volume production of complex aluminum and zinc components.

● Low-Pressure Die Casting (LPDC)

Ideal for producing robust parts like automotive wheels.

● Gravity Die Casting

Cost-effective method for medium batch sizes with high strength.

● Vacuum Die Casting

Preferred for industries requiring minimal porosity and tight tolerances.

These specialized services allow businesses to source components that meet international standards for quality, durability, and precision.

The Role of Plastic Manufacturing in India

While die casting dominates metal component production, plastic manufacturing is equally important for industries that require lightweight, corrosion-resistant, and cost-efficient parts.

Key Plastic Manufacturing Methods:

Injection Molding

Blow Molding

Thermoforming

Plastic Extrusion

India’s plastic manufacturing industry serves diverse sectors including packaging, electronics, automotive, healthcare, and home appliances. These services are also available through platforms like FindingMFG, making it easy to combine metal and plastic component sourcing in one place.

Die Casting and Plastic Manufacturing: A Strategic Combination

In many product designs, both metal and plastic components are essential. For example, an automotive control module might use an aluminum die cast housing with an injection-molded plastic cover.

By sourcing die casting and plastic manufacturing from the same country—or even the same supplier—you can reduce logistical complexity, streamline communication, and improve product integration.

How to Choose the Right Manufacturing Partner in India

Selecting the right supplier is critical for long-term success. Here's what to look for:

Certifications: ISO 9001, IATF 16949, and others ensure process quality.

Industry Experience: A supplier with domain-specific knowledge can better meet your needs.

Production Capacity: Ensure the manufacturer can handle your volume requirements.

Transparency: Look for real-time communication and clear timelines.

Platform Support: Using a trusted platform like FindingMFG can significantly reduce risk.

Real-World Applications and Case Studies

Indian die casting manufacturers have delivered precision parts for:

European automotive brands

North American medical equipment companies

Global consumer electronics firms

Similarly, Indian plastic manufacturers have exported millions of molded parts used in mobile devices, appliances, and industrial packaging.

Final Thoughts: India as a Dual Hub for Metal and Plastic Manufacturing

The synergy between die casting services in India and the country’s robust plastic manufacturing industry creates unmatched value for global businesses. With high-quality output, scalable capacity, and tech-driven sourcing platforms like FindingMFG, India stands out as a premier manufacturing partner for companies worldwide.

Ready to Start Sourcing?

If you're looking for dependable die casting or plastic manufacturing services, don't waste time vetting suppliers one by one. Let FindingMFG connect you to India's most trusted manufacturers—quickly and efficiently.

🔗 Explore More at www.findingmfg.com

0 notes

Text

Choosing the Right Plastic Mold Manufacturer: A Guide to Precision and Performance

In today’s fast-paced manufacturing environment, selecting the right plastic mold manufacturer can make or break the success of your product. From automotive and medical components to consumer goods and electronics, plastic parts are everywhere — and they all start with a high-quality mold.

The role of a plastic mold manufacturer goes beyond simply building molds. They are essential partners in the product development process, offering engineering support, tooling precision, and production reliability. In this blog, we’ll explore what a plastic mold manufacturer does, why it matters, how to choose one, and the key trends reshaping the industry.

What Is a Plastic Mold Manufacturer?

A plastic mold manufacturer is a company or workshop that specializes in designing and producing precision molds used in plastic injection molding. These molds are the foundation of creating plastic components, ensuring that each part meets strict specifications, tolerances, and surface quality requirements.

Typically, a plastic mold manufacturer offers services including:

CAD/CAM mold design

CNC machining and EDM (Electrical Discharge Machining)

Mold assembly and testing

Mold maintenance and repair

Prototype tooling and mass production tooling

High-quality molds contribute directly to the success of plastic injection molding projects by reducing cycle times, improving part quality, and increasing production efficiency.

Why Choosing the Right Plastic Mold Manufacturer Matters

When you work with a reliable plastic mold manufacturer, you’re investing in more than just tooling. You're building a partnership that affects your production line, product quality, and bottom line. Here’s why it matters:

Precision and Tolerances

A skilled plastic mold manufacturer ensures that your mold is machined to tight tolerances, resulting in accurate and consistent parts every time.

Durability and Longevity

Using high-quality materials like hardened steel or aircraft-grade aluminum, an experienced manufacturer builds molds that can withstand thousands — even millions — of cycles with minimal maintenance.

Optimized Production

Proper mold design reduces cycle time, minimizes material waste, and improves cooling efficiency, all of which contribute to higher throughput and lower costs.

Design for Manufacturability

Top manufacturers offer design consultations and simulations to help optimize your part design, reduce tooling costs, and avoid costly redesigns later.

Key Capabilities of a Trusted Plastic Mold Manufacturer

When evaluating a plastic mold manufacturer, consider the following essential capabilities:

1. In-House Design and Engineering

A competent plastic mold manufacturer will have a team of in-house designers and engineers who can translate your product ideas into precise mold designs using advanced CAD software.

2. Advanced Tooling Technology

Look for facilities equipped with modern CNC machines, wire EDM, and high-speed milling. These tools ensure precision in mold making and reduce turnaround time.

3. Material Expertise

From thermoplastics like ABS and polycarbonate to high-performance materials like PEEK and nylon, your manufacturer should be familiar with a wide range of materials and their tooling requirements.

4. Testing and Validation

Top manufacturers test molds under real-world conditions before full-scale production begins. This includes mold flow analysis, part sampling, and dimensional inspections.

Industries That Rely on a Plastic Mold Manufacturer

A wide variety of industries rely on expert plastic mold manufacturers for custom tooling and high-volume production:

Automotive: Interior and exterior trim, engine parts, clips, and connectors

Medical: Syringes, enclosures, surgical tools, and device housings

Electronics: Device casings, switches, and plug-and-play components

Consumer Goods: Toys, kitchen products, containers, and packaging

Industrial Equipment: Custom parts, covers, and protective enclosures

Each industry has its own standards and compliance requirements, which a skilled plastic mold manufacturer understands and accommodates.

How to Select the Right Plastic Mold Manufacturer

Here are critical factors to consider when choosing a plastic mold manufacturer:

Experience and Portfolio

Check how long they’ve been in the business and review their project portfolio. Experience with similar parts or industries is a significant advantage.

Quality Assurance

Choose a manufacturer with a documented quality management system (e.g., ISO 9001). They should offer quality reports, first article inspections, and CMM (Coordinate Measuring Machine) verification.

Lead Time and Capacity

Ask about their lead times and ability to scale production. A reliable plastic mold manufacturer should provide realistic timelines and meet urgent deadlines when necessary.

Communication and Support

Clear and open communication is essential for a successful tooling project. Look for a partner who offers regular updates, technical support, and post-delivery services.

Future Trends in the Plastic Mold Manufacturer Industry

The landscape of plastic molding and tooling is constantly evolving. Here are some trends reshaping how molds are designed and produced:

Smart Tooling with Sensors

Modern molds are being fitted with sensors to monitor temperature, pressure, and flow, enabling real-time feedback for optimized production.

Sustainable Tooling

Manufacturers are focusing on sustainable practices by using recyclable tool steel and offering energy-efficient mold designs.

Hybrid Manufacturing with 3D Printing

Combining traditional machining with additive manufacturing allows for rapid prototyping and complex mold geometries that were previously impossible.

Digital Twin Technology

A digital replica of the mold is created and tested virtually before physical production, reducing errors and lead times.

Conclusion

Partnering with the right plastic mold manufacturer is a critical step in your product development journey. From tool design to high-volume production, their role is central to ensuring your plastic parts are produced with precision, efficiency, and durability.

By understanding the capabilities, services, and industry applications of a plastic mold manufacturer, you can make an informed decision that supports both your product goals and business success.

Whether you're launching a new product or scaling existing production, investing in the right mold partner lays the foundation for quality, consistency, and long-term value.

#custom plastic injection molding#dalal plastics#plastic injection moulding#plastic injection molding company

0 notes

Text

Exploring the Growing Demand for Aluminium Die Casting in India

Aluminium die casting has emerged as one of the most efficient and cost-effective methods for producing high-performance metal components used across various industries. With the rise of the manufacturing sector and the Make in India initiative, aluminium die casting in India has gained significant momentum. From automotive and electrical to aerospace and industrial applications, aluminium die cast components are now integral to India’s industrial growth story.

What is Aluminium Die Casting?

Aluminium die casting is a manufacturing process where molten aluminium is injected into a steel mold (die) under high pressure. The result is a durable and dimensionally accurate metal component that requires minimal machining. This method is widely preferred for its ability to produce complex parts with excellent surface finish, high strength-to-weight ratio, and corrosion resistance.

In India, this technology is being rapidly adopted due to its scalability, reduced production cycle time, and ability to meet high-volume demands without compromising on quality.

Why is Aluminium Die Casting Booming in India?

Several factors contribute to the rising popularity of aluminium die casting in India:

1. Cost-Effective Manufacturing

India offers a cost advantage in terms of labor, raw materials, and energy. This has made the country a preferred destination for global clients seeking affordable yet high-quality aluminium die casting services.

2. Thriving Automotive Industry

India is the fourth-largest automotive market in the world. Aluminium die cast parts such as engine components, gearbox housings, brackets, and wheels are in high demand due to the industry’s shift towards lightweight, fuel-efficient designs.

3. Government Support

Policies like Make in India, PLI schemes, and foreign investment encouragement have fueled the growth of die casting foundries. These policies offer both infrastructural support and financial incentives for aluminium casting units.

4. Sustainable and Recyclable

Aluminium is 100% recyclable without losing its properties. As environmental consciousness grows, industries are switching to eco-friendly manufacturing materials like aluminium, boosting demand for aluminium die casting.

Applications of Aluminium Die Casting

India’s die casting industry caters to a wide range of sectors:

Automotive: Cylinder heads, transmission parts, engine blocks

Electronics: Enclosures, connectors, heat sinks

Aerospace: Lightweight structural parts

Consumer Appliances: Mixer parts, fan blades, housings

Industrial Equipment: Pumps, valves, brackets

Why Choose Indian Manufacturers?

Indian die casting manufacturers, particularly those based in industrial hubs like Coimbatore, Pune, and Rajkot, are known for their technical expertise, affordable pricing, and ability to deliver export-grade quality. Whether it's high-pressure die casting, gravity die casting, or sand casting, Indian foundries are well-equipped with the latest technology, in-house tool rooms, and automated machines to meet international standards.

Partner with a Trusted Aluminium Die Casting Manufacturer

If you are looking for reliable, precise, and high-quality aluminium cast components, Adithya Technologies is a name you can trust. With decades of experience in engineering and casting services, Adithya Tec delivers customized aluminium die cast solutions for domestic and global clients.

To learn more or request a quote, visit aluminium die casting in India.

Final Thoughts

As global industries increasingly focus on lightweight materials, cost efficiency, and sustainability, aluminium die casting continues to rise in importance. India’s aluminium die casting industry is well-positioned to meet this demand with quality, scale, and value.

Whether you’re in the automotive sector, electronics, or industrial machinery, partnering with a trusted Indian aluminium die casting company ensures consistent performance and competitive advantage.

0 notes

Text

Achieve Precision in Mold Design with Plastic Flow Simulation

In today’s competitive manufacturing landscape, optimizing plastic part design and mold tooling is critical to ensuring product quality, reducing time-to-market, and minimizing costly rework. Plastic Flow Simulation empowers mold designers and manufacturers to visualize the behavior of molten plastic during the injection molding process — before a single mold is cut. DDSPLM brings cutting-edge plastic flow simulation capabilities powered by Siemens NX and Moldex3D, enabling manufacturers to validate, optimize, and refine mold designs digitally.

What is Plastic Flow Simulation?

Plastic flow simulation is a virtual injection molding analysis process that predicts how molten plastic will fill a mold cavity. It provides insights into potential problems such as air traps, weld lines, sink marks, short shots, warpage, and cycle time inefficiencies. This simulation allows for early detection and correction of design flaws, reducing the number of mold trials and rework costs.

Features of Plastic Flow Simulation

Supports simulation of filling, packing, cooling, and warpage phases

Built-in material database for accurate behavior prediction

Gate optimization tools for ideal injection locations

Cooling channel analysis with 3D visualization

Shrinkage and warpage prediction using real-world parameters

Integration with NX CAD and Moldex3D for seamless workflow

Capability to simulate multi-cavity molds and hot runner systems

Benefits of Plastic Flow Simulation

Minimize mold trial costs and reduce development cycle

Improve part quality and reduce defects like warpage or sink marks

Optimize gate locations and runner design

Prevent costly mold modifications

Increase confidence in mold performance before manufacturing

Improve customer satisfaction by delivering consistent results

Ensure better part strength and dimensional accuracy

Why Choose DDSPLM?

DDSPLM is your trusted partner in delivering end-to-end digital manufacturing solutions. Here’s why leading mold makers and manufacturers choose DDSPLM for plastic flow simulation:

Expertise in Siemens NX & Moldex3D

Tailored Simulation Services

Proven Track Record

Training and Support

Seamless Integration

Conclusion

Plastic Flow Simulation is no longer optional — it’s essential for competitive mold and tooling design. By visualizing how molten plastic flows, cools, and warps, manufacturers can design better parts, reduce trial runs, and save on time and costs. DDSPLM enables this transformation with powerful tools and deep domain expertise. Whether you’re designing complex automotive parts or high-precision consumer goods, DDSPLM’s plastic flow simulation solutions help you bring reliable, defect-free products to market — faster.

0 notes

Text

Precision Plastic Injection Molding Solutions in India – Clixroute

In today’s manufacturing world, precision and quality matter more than ever. Whether it’s automotive parts, medical components, or consumer products, plastic plays a key role in nearly every industry. That’s why Precision Plastic Injection Molding is in high demand. If you’re looking for reliable plastic injection molding in India, Clixroute is the name you can count on.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used to produce large volumes of plastic parts with high accuracy. It involves injecting molten plastic into a mold, where it cools and takes shape. This process is ideal for creating strong, lightweight, and detailed plastic products.

Why Choose Precision Plastic Injection Molding?

Precision molding ensures that every part is:

Accurate in size and shape

Consistent in quality across batches

Durable and made to perform under real-world conditions

Cost-effective for mass production

From small gears to complex medical devices, precision plastic injection molding is trusted for its performance and reliability.

Why Clixroute?

At Clixroute, we offer advanced plastic injection molding in India with a focus on precision, speed, and quality. Here’s what sets us apart:

✅ Advanced Technology

We use modern machines and tools to ensure high precision and fast turnaround.

✅ Skilled Team

Our engineers and technicians are trained to handle complex molds and custom requirements.

✅ Wide Range of Applications

From electronics and automotive to healthcare and packaging—we serve diverse industries.

✅ Quality Assurance

Every product is tested for strength, finish, and accuracy before delivery.

✅ Customer-Centric Approach

We work closely with clients to understand their needs and deliver the right solution on time.

Industries We Serve

Automotive – dashboards, clips, and connectors

Electronics – casings, switches, and housings

Medical – syringes, implants, and precision devices

Consumer Goods – containers, toys, and kitchen tools

Industrial Equipment – custom plastic components

No matter the size or complexity, Clixroute ensures your plastic parts are made to perfection.

Final Thoughts

If you’re searching for reliable and cost-effective precision plastic injection molding services, choose Clixroute. We are one of the leading providers of plastic injection molding in India, delivering high-quality parts that meet international standards. Let us help bring your ideas to life—accurately, efficiently, and affordably.

Visit us https://www.clixroute.com/

0 notes

Text

Superior Automotive OEM Solutions Tailored for Grand Rapids Excellence

In the heart of West Michigan’s manufacturing hub, precision and reliability are paramount for businesses seeking Automotive OEM Services Grand Rapids MI. Local enterprises thrive on partnerships with specialists who deeply understand the region’s industry standards and global market demands. By collaborating with seasoned experts, companies can optimize their production lines, reduce waste, and accelerate time‐to‐market. Whether developing cutting‐edge components or refining existing assemblies, entrusting projects to professionals familiar with Grand Rapids’ unique business ecosystem ensures both quality and consistency across every phase of development.

Innovation in metal fabrication, tooling, and assembly integration drives the sector forward, and only the most dedicated providers can deliver on stringent OEM requirements. These service partners leverage state‐of‐the‐art machinery and employ rigorous quality control protocols that comply with international automotive benchmarks. As a result, brands benefit from robust parts that withstand the rigors of testing and real‐world performance. The fusion of technical expertise, adaptive engineering teams, and collaborative project management yields a streamlined journey from prototype to full‐scale production, reinforcing why leading firms opt for top‐tier Automotive OEM Services Grand Rapids MI.

Choosing among the myriad Automotive Companies in Gand Rapids MI demands insight into each provider’s scope of capabilities and track record for on‐time delivery. Established leaders in the region offer end‐to‐end solutions, encompassing everything from material sourcing and CNC machining to surface finishing and assembly kitting. They also support continuous improvement initiatives, such as lean manufacturing and Six Sigma methodologies, ensuring that operational efficiencies evolve in lockstep with changing market needs. By aligning with a partner well‐versed in Grand Rapids’ manufacturing landscape, businesses can unlock new revenue streams and safeguard competitive advantage.

In addition to technical prowess, premier local firms prioritize transparent communication and agile responsiveness. Through dedicated project liaisons, customers receive regular progress updates and timely feedback loops, minimizing risk and fostering a true sense of partnership. This collaborative ethos not only expedites problem‐solving but also cultivates innovation, as multidisciplinary teams brainstorm solutions that blend regional specialties with global best practices. Such synergy underscores why discerning clients continue to seek out Automotive Companies in Gand Rapids MI that demonstrate both commitment and capability.

Finally, the confluence of expertise in advanced welding techniques, precision stamping, and injection molding positions Grand Rapids as a strategic center for automotive component production. Leveraging local infrastructure and a skilled workforce, the region’s OEM service providers deliver scalable solutions that adapt to demand fluctuations, regulatory changes, and evolving technological trends. By tapping into this vibrant ecosystem, companies can confidently navigate the complexities of modern automotive manufacturing and achieve sustainable growth. Whether launching a new vehicle line or enhancing existing component performance, the right partner in Grand Rapids provides the foundation for success in an increasingly competitive global market.

0 notes

Text

The Precision Powerhouse Behind Injection Molds in Dallas: Why Local Expertise Matters

In the heart of Texas, the manufacturing industry thrives with innovation, resilience, and precision. At the core of this industrial ecosystem lies a crucial element—injection molds. These meticulously crafted tools are vital for producing consistent, high-quality plastic parts used in countless applications, from automotive components to medical devices. For companies seeking top-tier injection molds Dallas, the region offers an impressive array of expertise, resources, and advanced machining capabilities.

Why Injection Molds Are Essential

Injection molds are the foundation of efficient and scalable plastic manufacturing. Precision is key: even a minor imperfection can compromise the integrity of a final product. That’s why businesses across Texas prioritize experienced partners that specialize in precision tooling, especially in fast-paced sectors like aerospace, electronics, and consumer products. Local manufacturers who understand the specific needs of Texas industries are better equipped to deliver consistent, high-performance results.

The Role of Machining Services in Dallas

Behind every durable injection mold is a robust support system of machining services in Dallas. These services include CNC machining, turning, milling, and surface finishing—all critical steps in crafting high-tolerance molds. The region is home to advanced shops like Lowrance Machine, a trusted name known for its commitment to quality and fast turnaround times.

Lowrance Machine combines decades of hands-on experience with state-of-the-art equipment to produce some of the most reliable tooling and mold solutions in the industry. Their capabilities span far beyond just molds—they are a full-spectrum CNC machine shop in Dallas offering custom fasteners, cast inserts, and specialized parts tailored for unique production needs.

CNC Milling Dallas: Precision at Its Finest

A key technology used in mold making is CNC milling. In Dallas, the level of innovation in CNC milling has grown significantly, with shops offering 3-, 4-, and even 5-axis milling solutions. This allows for intricate mold designs, tight tolerances, and optimized production cycles. Whether you're producing thousands of parts or limited prototypes, precision milling ensures the mold performs perfectly, batch after batch.

The Importance of Versatility in Industrial Solutions

Beyond mold-making, facilities like Lowrance Machine play a broader role in the manufacturing landscape. Their expertise in industrial equipment repair in Dallas makes them a go-to resource for companies needing fast, reliable service to keep operations running smoothly. Downtime in manufacturing is costly, and having a partner who can swiftly diagnose and repair critical equipment is invaluable.

Moreover, services like producing custom fasteners in Dallas and cast inserts allow local manufacturers to streamline their supply chains and ensure compatibility and performance across their products.

Conclusion: Partner with the Best

Choosing the right partner for injection molds in Dallas means looking for precision, speed, and reliability. Lowrance Machine has earned a reputation as one of the best in the region for all-encompassing machining services in Dallas. From high-precision CNC milling to reliable industrial equipment repair, they offer a one-stop solution for manufacturers who demand excellence.

For companies that refuse to compromise on quality, partnering with a local expert like Lowrance Machine isn’t just a choice—it’s a competitive advantage.

1 note

·

View note

Text

Plastic Fabrication Company vs. Mass Manufacturing: What’s the Difference?

When it comes to creating plastic products or components, businesses often face a crucial decision: should they work with a plastic fabrication company or rely on mass manufacturing? While both approaches involve the production of plastic items, they differ significantly in scale, process, customization, and end-use. Understanding these differences can help businesses choose the most effective path based on their project goals, budget, and timeline.

Let’s explore the key distinctions between plastic fabrication company and mass manufacturing and what each method offers.

Customization vs. Volume Production

One of the most notable differences lies in the level of customization. A plastic fabrication company typically specializes in creating custom, made-to-order products. Whether it's a one-off prototype, a small production run, or a unique component with specific dimensions, fabrication shops are equipped to tailor solutions to client needs.

In contrast, mass manufacturing focuses on producing large volumes of identical items. Using methods such as injection molding or blow molding, factories can produce thousands or even millions of units efficiently. This process is ideal for businesses that require standard, high-volume parts at a lower per-unit cost.

Production Methods

Plastic fabrication uses techniques such as CNC machining, plastic welding, laser cutting, thermoforming, and routing. These methods are hands-on, flexible, and well-suited for intricate or specialized projects. They allow for quick design changes and accommodate a wide range of plastic materials.

Mass manufacturing, on the other hand, relies heavily on automated processes and tooling. Once a mold is created, it’s used repeatedly to produce the same item, which minimizes labor costs and increases speedbut also reduces flexibility. Any changes to the design often require new molds, which can be expensive and time-consuming.

Project Size and Turnaround Time

If your project involves small or medium-scale production, especially for prototypes or limited-edition products, a plastic fabrication company is likely the better choice. Fabricators can deliver faster turnaround times for low-volume orders and are more adaptable to changes during development.

Mass manufacturing excels when demand is high and consistent. Once setup is complete, the output is rapid and cost-effective over time, making it a smart option for companies that need to distribute products at scale.

Cost Structure

While mass manufacturing offers a lower per-unit cost in high-volume production, the upfront expenses can be significant. Mold creation, tooling, and setup require a substantial initial investment. This cost is usually justified only when producing in large quantities.

Plastic fabrication typically has lower initial costs because it doesn’t require extensive tooling. Although the per-unit cost may be higher, especially for larger orders, the flexibility and ability to produce limited runs often outweigh the expense especially for businesses prioritizing customization or testing new products.

Material Versatility and Design Flexibility

Plastic fabrication companies can work with a broader range of plastic materials and thicknesses. They can also handle complex geometries and design changes with ease. This is particularly important for industries such as medical, aerospace, or architectural design, where unique specifications are common.

Mass manufacturing processes, while efficient, often have limitations in terms of design complexity and material choice due to the constraints of mold design and production equipment.

Personalized Service and Collaboration

Another significant advantage of partnering with a plastic fabrication company is the level of personalized service. Clients often work directly with engineers and fabricators, receiving detailed feedback, design recommendations, and hands-on support throughout the process.

Mass manufacturing, due to its scale, may involve more standardized communication and limited customization. It’s typically a less collaborative environment, better suited for companies that already have finalized, mass-market-ready designs.

Choosing between a plastic fabrication company and a mass manufacturing provider depends largely on your project’s size, complexity, and long-term goals. If you need high-volume, low-cost production for a uniform product, mass manufacturing is likely your best option. However, if your business values flexibility, customization, quick prototyping, or lower initial investment, working with a plastic fabrication company can offer significant advantages.

Ultimately, understanding the strengths and limitations of each approach will help you make the right decision and ensure your product reaches its full potential.

0 notes