#Interlocking Tile Making Machine

Explore tagged Tumblr posts

Video

youtube

Paver Blocks / Interlocking Tiles Making Machine से कमाई Rs 6 लाख महीना!...

#youtube#Paver Blocks / Interlocking Tiles Making Machine से कमाई Rs 6 लाख महीना!... https://youtu.be/nB2VQo8yeIA?si=s7sgBKOtMHXGnOFD via @YouTube pa

0 notes

Text

#Paver Block Making Machine Manufacturers in Ghaziabad#Interlocking Tile Making Machine Suppliers#Paver Tiles Making Machine Wholesalers in Uttar Pradesh

0 notes

Text

Durable & Cost-Effective Interlocking Tiles Making Machine for Your Business

Transform your construction business with BTM Product's state-of-the-art interlocking tiles making machine that combines precision engineering with outstanding durability. Our machines are designed to meet the growing demands of the construction industry while ensuring maximum efficiency and profitability for your business.

Advanced Technology Meets Industrial Excellence

At BTM Product, we understand that investing in an interlocking tiles making machine is a crucial decision for your business growth. Our machines incorporate the latest technological advancements to deliver superior quality products consistently. The robust construction and innovative design ensure minimal maintenance and maximum output, making it an ideal choice for both small-scale and large-scale operations.

Versatility in Production

Our paver block making machine offers unmatched versatility in production capabilities. Whether you need to manufacture traditional rectangular blocks or intricate designer patterns, our equipment can handle it all. The flexible mold system allows you to:

- Create various shapes and sizes of pavers - Produce different thickness options - Switch between designs quickly - Maintain consistent quality across batches

Superior Quality Output

When you choose BTM Product's best fly ash brick making machine, you're investing in quality that speaks for itself. Our machines are engineered to produce blocks with:

- Precise dimensions and smooth finish - High compressive strength - Excellent durability - Uniform color distribution - Perfect interlocking capabilities

Cost-Effective Production Solutions

We understand the importance of operational costs in your business. Our paver block making machine is designed to optimize resource utilization and minimize waste, resulting in:

- Reduced power consumption - Minimal raw material wastage - Lower labor requirements - Increased production speed - Better return on investment

Technical Specifications and Capacity

The interlocking tiles making machine from BTM Product comes with impressive specifications:

- Production capacity: Up to 1000 blocks per hour - Power consumption: Energy-efficient motor system - Hydraulic pressure: Adjustable for different products - Vibration system: Advanced technology for proper compaction - Control panel: User-friendly interface with automatic features

Raw Material Flexibility

Our best fly ash brick making machine is compatible with various raw materials, including:

- Cement - Fly ash - Crushed sand - Stone dust - Industrial waste materials - Color pigments

After-Sales Support

BTM Product believes in building long-term relationships with our clients. We offer:

- Comprehensive installation support - Operator training programs - Regular maintenance services - 24/7 technical assistance - Spare parts availability - Warranty coverage

Quality Assurance

Each paver block making machine undergoes rigorous quality testing before delivery. Our quality control measures ensure:

- Structural integrity - Component durability - Performance consistency - Safety compliance - Production efficiency

Environmental Responsibility

At BTM Product, we're committed to environmental sustainability. Our interlocking tiles making machine incorporates eco-friendly features:

- Reduced carbon footprint - Energy-efficient operations - Waste material utilization - Water conservation systems - Noise reduction technology

Investment Benefits

Investing in BTM Product's machinery offers numerous advantages:

1. Quick Return on Investment - High production capacity - Low operational costs - Minimal maintenance requirements - Extended equipment life

2. Market Competitiveness - Superior product quality - Diverse product range - Consistent output - Cost-effective production

3. Business Growth - Scalable production - Market expansion opportunities - Enhanced reputation - Increased profitability

Installation and Setup

We ensure a smooth transition from purchase to production:

- Site preparation guidance - Professional installation - Initial testing and calibration - Operator training - Production optimization support

Customization Options

Understanding diverse business needs, we offer customization in:

- Production capacity - Mold designs - Automation levels - Control systems - Safety features

Conclusion

Choose BTM Product's machinery for a reliable, efficient, and profitable manufacturing solution. Our commitment to quality, innovation, and customer satisfaction makes us the preferred choice in the construction equipment industry. With our best fly ash brick making machine and comprehensive support system, your business is positioned for success in the competitive construction market.

Experience the difference with BTM Product's superior manufacturing solutions. Contact our team today to discuss your specific requirements and discover how our machines can transform your business operations. Let us be your partner in building a successful and sustainable construction materials manufacturing enterprise.

0 notes

Note

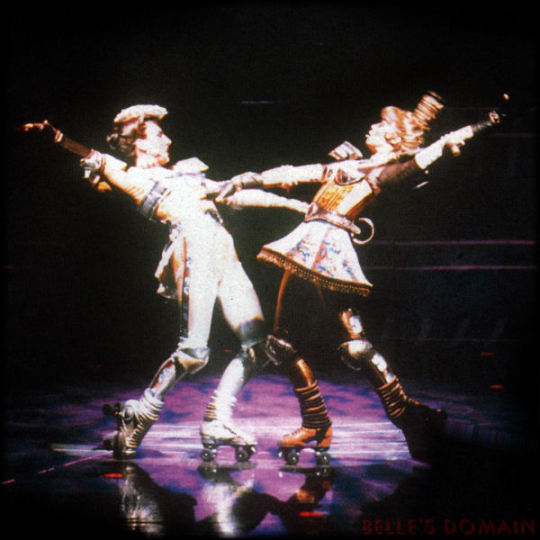

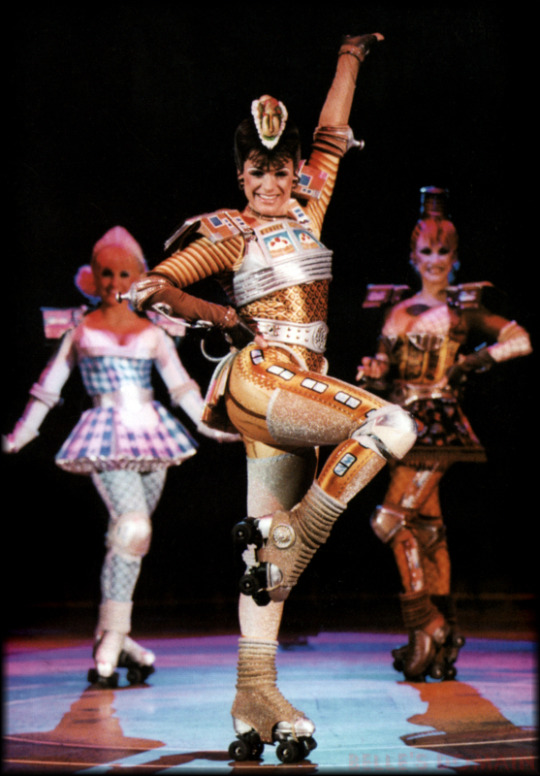

Would you be able to do a Buffy Broadway/Bochum costume breakdown?

Buffy! Yes! I think I've got quite a few refs for her, let's see... while photography has developed a lot, her costume really hardly changed at all from 1988 - 2018! Other than her wig, obviously.

Starting with her base layer - hand painted, of course. Her base is sewn into a single piece, despite looking like a leotard over leggings - nothing's gonna slip or move uncomfortably onstage! As a make though, it's pretty heavy on the spandex sewing skills.

I *think* her bodice is a heavier weight stretch satin than the rest of her costume, and her stockings are a stretch lurex, the rest seems to be standard spandex. Every inch of her is painted or dyed - even her lower sleeves which seem to have been handy paint samples while painting the rest of her bodice! This is, I think, the same technique used for the "Cats" costumes, that acid dye is mixed to a paintable texture, then set with steam. Even the lurex stockings are painted! The lurex bands on the edge of the leotard have padding, obviously, this has got to be something that will dry out super fast and hold its shape well - unless they have a better option, I've used filter foam for this in the past. like literally, sold for pond filters!

We can see she has a big patch of white velcro on her chest, that's gonna connect to her display case chest box.

Her chest box is a neat little vest, the back painted the same as her arms. We can see it zips up the centre back, and the shoulders connect at the front - very discreet fastenings, but still visible in hi-res photos! On this photo of the chest box on a hanger, I think we can see there's similar fastenings on the back. The other thing I think we're seeing here is that the fabric portion is attached by velcro and snaps to the metallic band and the display case panel - allowing the fabric to be washed! sounds wise!

So the "Chrome" band and the display case panel are foam, heavily worked with the glossy bands sewn down between the more matte fabric. I suspect the matte base fabric has some stretch to it, the super chromey shiny won't. It might be leather or leatherette to be that very, very shiny yet still machine stitched. I believe there's a thin plastic coating over her display case windows, so the frame is the top layer, then the plastic window, then the painted surface, then foam board for the shape. Then all the velcro! We can see the stitches that hold the display case panel to the ribbed chrome band. There's also some stitching on the left strap - I would guess that's mic related.

Shoulders - I realise I say "foam" a lot, but there's different types of foam, different densities, different uses. I don't know if I can really describe them properly... but the shoulders are not the same material is the padding in the leotard edge! But her shoulders would be the dense, easy to cut foam as used for yoga mats (but thicker) or interlocking floor tiles... I'd say it's covered in leatherette type material that's painted and trimmed, then hinges on the top, I think we can see connections between the ends and the middle at the back too, to stop the ends flipping up. There's also rivets on the back of the centre panel which line up with the reinforced spots on the jacket. And there's a padded fabric panel around the neck, for comfort!

Her belt is straightforward - apart from her napkins. At least, that's how I've always understood her pleated shiny butt flap! I think it's actually 8 panels - the top piece above the belt - then the wide centre, a two-stripe panel, then two single stripes. They're connected by a soft pleated fabric which is the colour contrast. Is it me or are her handles particularly wide-set? Staying clear of her napkin, I guess.

Her collar is just the simplest thing! Spandex, snap at the back, heat-set studs for decoration. Disconcertingly simple! She also sometimes has the same construction as stocking tops - but not always? I'm not sure why they're sometimes missing, but the extra 3D detail looks really good.

Gloves! How's this for a convenient reference? She has leather gloves, spandex "gauntlets" and matching, attached elbows - all with the added moulded latex decorations. On the pictures of the leotard hanging up, we can see metal bars on her sleeves - there's gotta be hooks inside the elbow pads to connect them. I suspect there's two bars for different fittings - longer or shorter arms - rather than two hooks to connect, but I might be wrong there.

I can NOT find a decent look at her kneepads! but Pearl and Dinah's are there, and the construction is gonna be the same. The heavy, dense foam bowl, a fixed middle strap and upper and lower adjustable straps all covered in the lurex, and the bowl covered in the decorative leather, then a hard plastic protective cover on top.

Her skate covers / springs / slinkies are painted ombre lurex - getting that effect might not be easy! - but it's sewn over triangular profile foam to get those sharp corners.

Finally, her hat! I'm not gonna cover her wig because she's had so many, but her hat remains much the same throughout. It's a curved base, covered in painted spandex like the rest of her main costume, and tucked in the top is some - err... delicious? looking fake food! Fabric lace represents the paper doily. There's mesh on the bottom edge to allow it to be pinned into the wig securely.

I think? that's everything? I've kinda glossed over some things I've described in more detail in other breakdowns, but if you have any more questions please ask!

24 notes

·

View notes

Text

Pebble Tiles: A Natural Touch for Stylish and Functional Spaces

Pebble tiles offer a unique way to add natural texture and organic beauty to both indoor and outdoor spaces. Whether used for a luxurious spa-like shower floor or a rustic outdoor walkway, these tiles bring a timeless and earthy elegance that enhances any design.

Crafted from smooth, rounded stones typically collected from riverbeds or coastlines, pebble tile is mounted onto mesh backing for easier installation. Available in a wide range of colors, shapes, and patterns, pebble tiles blend seamlessly with a variety of décor styles—from modern minimalist to tropical retreat.

What Are Pebble Tiles?

Pebble tiles consist of small, natural stones arranged on a mesh sheet. These stones are sorted for color and size, then hand-placed or machine-arranged in interlocking patterns. This ensures a seamless, flowing look when installed across larger surfaces.

Types of Pebble Tile:

Flat Pebble Tile: Stones are sliced on top for a more level surface.

Polished Pebble Tile: Stones are smoothed to a glossy finish.

Natural Pebble Tile: Retains the original round shape and matte texture.

Standing Pebble Tile: Stones are arranged upright for dramatic wall accents.

Where to Use Pebble Tile

1. Bathrooms and Showers One of the most popular uses of pebble tiles is in shower floors. The natural grip and slight irregularity of the stones make them ideal for wet areas, offering slip resistance and a comfortable feel underfoot. They’re also used for bathroom feature walls, backsplashes, and borders.

2. Kitchen Accents Pebble tile backsplashes bring a rustic or coastal charm to kitchens. Combined with stone countertops and wooden cabinetry, they create a cozy, earthy atmosphere.

3. Outdoor Spaces Ideal for patios, pool surrounds, walkways, and garden paths, pebble tiles are durable and weather-resistant. Their natural finish helps them blend into landscapes seamlessly.

4. Living Room or Entryway Features Use pebble tile on fireplace surrounds, accent walls, or entryway flooring for a statement that connects indoor design to nature.

5. Spa and Wellness Spaces Many wellness centers and spas incorporate pebble tile flooring and walls to create a calming, grounded environment that reflects natural elements.

Benefits of Pebble Tiles

Natural Aesthetic: No two tiles are the same, offering unique variation and texture.

Durability: Pebble tiles are strong and long-lasting, particularly in high-moisture areas.

Slip Resistance: Ideal for wet zones due to the non-slip properties of the textured surface.

Easy Maintenance: When sealed properly, pebble tile resists stains, mold, and mildew.

Eco-Friendly: Made from natural stone, often with sustainable sourcing practices.

Installation and Maintenance Tips

Preparation: Ensure the surface is clean, level, and dry. Use a high-quality thin-set mortar for a secure bond.

Grouting: Pebble tiles require careful grouting to fill the uneven spaces between stones. Sanded grout is typically recommended.

Sealing: Sealing is crucial before and after grouting. It protects the tile from water absorption and discoloration.

Cleaning: Use mild, pH-neutral cleaners. Avoid acidic or abrasive products that may damage the surface or strip the sealant.

Choosing the Right Pebble Tile

When selecting pebble tile, consider the following:

Color Palette: Match the tile color to your existing décor—neutral tones for subtlety, dark stones for contrast, or mixed hues for a bold statement.

Tile Type: Flat pebble tiles offer smoother walking surfaces, while natural or standing pebble tiles add more texture and dimension.

Application Area: Choose the right finish (natural, polished, etc.) based on whether the tile will be used on the floor, wall, or outdoors.

FAQ:

Q1: Are pebble tiles comfortable to walk on? A: Yes. While they have a textured surface, properly grouted and sealed pebble tiles are comfortable, especially when used in barefoot areas like showers or spas.

Q2: How often do pebble tiles need to be sealed? A: It’s recommended to seal them every 1–2 years, or more frequently in high-moisture or high-traffic areas to preserve the finish and prevent water damage.

Q3: Can pebble tile be used outdoors? A: Absolutely. Pebble tiles are ideal for outdoor spaces like patios, pathways, and pool decks due to their natural weather resistance and durability.

Q4: Do pebble tiles require professional installation? A: While DIY installation is possible for experienced users, many choose professional installers to ensure even grout lines and proper sealing, especially for large or complex projects.

Q5: How do I clean pebble tile surfaces? A: Use a soft cloth or mop with a pH-neutral cleaner. Avoid harsh chemicals or acidic solutions, as they can damage the stone and sealant.

Conclusion

Pebble tiles are an exceptional choice for those looking to bring nature-inspired texture and warmth into their spaces. From luxurious shower floors to rustic garden walkways, the versatility and beauty of pebble tile make it a favorite for modern and timeless design alike. Whether you're starting a renovation or building new, investing in quality pebble tiles can elevate your space with organic charm and long-lasting function.

For best results, choose a reliable supplier and follow proper installation and care guidelines to enjoy your pebble tile surfaces for years to come.

1 note

·

View note

Text

Durable & Safe Flooring for Every Gym

Smart Gym Flooring Choices Setting up the perfect gym involves more than just machines and mirrors. One crucial aspect that determines comfort, safety, and functionality is the type of flooring. Whether it’s a home workout space or a full-scale commercial gym, choosing the right flooring is essential for shock absorption, injury prevention, and long-term durability. Among the top contenders for reliable gym floors are the best rubber gym flooring options and waterproof foam floor tiles. Both bring unique benefits to fitness environments and can significantly improve the quality of any workout space.

Why Rubber Flooring Stands Out Rubber flooring has long been the go-to choice for professional gyms. It's built to withstand heavy use, including the repeated impact of dropped weights and the wear and tear of high-traffic footfall. The best rubber gym flooring not only protects the subfloor from damage but also provides a firm yet cushioned surface for exercise. This reduces fatigue for users and minimizes joint strain during intense physical activities like weightlifting, HIIT, and cross-training.

What makes rubber particularly ideal is its non-slip texture. This becomes especially important in environments where sweat and moisture are present. Its grip helps reduce the risk of slips and falls, ensuring a safe workout environment for everyone. In addition to safety, rubber floors are easy to clean, odor-resistant, and extremely low maintenance, making them perfect for both home and commercial gyms.

The Role of Waterproof Foam Tiles While rubber is excellent for high-impact zones, waterproof foam floor tiles are a fantastic choice for lighter workout areas or multi-purpose spaces. They are softer underfoot, making them ideal for yoga, pilates, stretching, and bodyweight exercises. These tiles provide a balance of comfort and performance, especially in areas where flexibility and comfort are more important than heavy load-bearing.

One of the key benefits of waterproof foam floor tiles is their moisture resistance. Spills, sweat, or cleaning products won’t seep through or damage the surface, ensuring a clean and hygienic environment. This makes them particularly useful in basement gyms or areas prone to dampness. Additionally, their interlocking design allows for easy installation, customization, and portability. If a section gets damaged or needs replacing, it can be done quickly without replacing the entire floor.

Combining Both for Maximum Effect Many gym owners are now mixing flooring types to maximize their gym’s effectiveness. For example, placing the best rubber gym flooring in weightlifting or machine areas ensures durability and safety, while using waterproof foam floor tiles in stretching or warm-up areas enhances comfort and flexibility. This strategic combination creates a well-rounded space that caters to all types of workouts and fitness goals.

Visually, combining different textures and colors from both flooring types can add aesthetic appeal. It helps to define various workout zones, making the layout more organized and user-friendly. Whether it's a commercial gym or a compact home setup, layering different flooring solutions can lead to better workout experiences and long-term satisfaction.

Long-Term Investment and Sustainability Both rubber and foam flooring solutions are long-term investments. High-quality rubber flooring is often made from recycled materials, which adds an element of sustainability to your gym. It lasts for years without cracking, warping, or fading. Similarly, good quality waterproof foam tiles are durable enough to hold up under moderate use while maintaining their shape and integrity.

From an economic perspective, both options are cost-effective when considering their longevity and the protection they offer to underlying surfaces. They also save money on repairs, injury liabilities, and equipment wear over time.

Choosing between the best rubber gym flooring and waterproof foam floor tiles doesn’t have to be an either-or decision. By evaluating the needs of your space and workout routines, you can smartly combine both for the most efficient, safe, and comfortable gym environment.

0 notes

Text

Hollow Solid Block Making Machine – Trusted Solutions by Ultra Tile Machine

In the construction industry, the demand for reliable and cost-effective building materials has never been higher. With infrastructure projects on the rise, both hollow and solid blocks are rapidly replacing traditional bricks due to their structural advantages, durability, and cost efficiency. At the core of producing these essential materials lies the Hollow Solid Block Making Machine, a critical asset for modern builders and manufacturers.

When it comes to choosing a dependable manufacturer, Ultra Tile Machine stands tall as an industry leader. With years of expertise and a reputation for quality and innovation, Ultra Tile Machine is your go-to partner for high-performance block making solutions.

What Is a Hollow Solid Block Making Machine?

A Hollow Solid Block Making Machine is a versatile industrial machine used to manufacture both hollow and solid concrete blocks. These machines compact a mixture of cement, sand, and aggregates into pre-defined molds using hydraulic or mechanical pressure. The result is uniformly shaped, high-strength blocks suitable for various construction needs.

Hollow blocks are lighter and used for non-load bearing walls, while solid blocks are denser and used in load-bearing structures. A machine that can produce both types offers manufacturers maximum flexibility and better ROI.

Why Hollow and Solid Blocks Are Gaining Popularity

Construction professionals are shifting towards hollow and solid concrete blocks due to their numerous advantages over traditional bricks. Some of these include:

Better thermal insulation

Faster construction speed

High load-bearing capacity

Reduced dead load on structure

Eco-friendly materials

Lower water absorption

Uniform shape and size

This shift has directly increased the demand for machines that can produce these blocks efficiently.

Types of Hollow Solid Block Making Machines

Depending on the scale and automation needs of your business, Ultra Tile Machine offers a range of machines such as:

Manual Block Making Machines

Semi-Automatic Machines

Fully Automatic Machines

Hydraulic Press Block Machines

Vibration Cum Compression Machines

Each type caters to a different production requirement, ensuring that businesses of all sizes can find the right fit.

Advantages of Investing in a Hollow Solid Block Making Machine

High Productivity

These machines are designed to produce hundreds or even thousands of blocks in a single shift, drastically improving output.

Versatility

Manufacturers can produce a wide range of block types, including hollow blocks, solid blocks, interlocking blocks, and more using different molds.

Cost Efficiency

Modern machines reduce labor dependency and minimize raw material waste, increasing overall profitability.

Better Quality Control

Precision engineering ensures consistency in size, strength, and shape, which is vital for large-scale construction projects.

Environmentally Friendly

These machines support the use of fly ash, slag, and other industrial waste, contributing to sustainable construction practices.

Why Choose Ultra Tile Machine as Your Manufacturer?

Industry Experience

Ultra Tile Machine has built a legacy of trust and excellence in the block making machinery sector. With decades of experience, the company understands the pulse of the construction industry and delivers solutions tailored to real-world challenges.

Advanced Technology

All machines by Ultra Tile Machine are designed using the latest technology to ensure high output and consistent performance. Key features include:

High-pressure hydraulic systems

Heavy-duty steel construction

Advanced vibration technology

Precision molds

User-friendly controls

Long service life

These features enable operators to run production smoothly with minimal downtime.

Wide Product Range

Ultra Tile Machine offers a full suite of machinery for every scale of operation:

Manual Machines: Ideal for startups and small-scale units

Semi-Automatic Models: A perfect mix of manual and automatic features

Fully Automatic Machines: Best suited for large-scale continuous production

Hydraulic Block Machines: Ensures greater compression and block durability

Whether you’re a beginner or a seasoned industrialist, there's a machine that suits your business needs.

Customization Options

Ultra Tile Machine provides full flexibility in customizing:

Block size and mold design

Output capacity

Power source (electric or diesel)

Machine frame and configuration

Color and branding

Custom machines ensure that your production line aligns perfectly with market demand and your brand identity.

Quality Assurance

Ultra Tile Machine places strong emphasis on quality at every stage of manufacturing. Every machine undergoes rigorous quality checks to ensure:

Flawless operation

Durability and reliability

Resistance to wear and tear

Energy efficiency

Customers receive machines that perform consistently for years with low maintenance requirements.

Competitive Pricing

Despite offering premium features, Ultra Tile Machine maintains highly competitive prices. Their goal is to make quality machinery accessible to everyone, from small business owners to industrial giants. Transparent pricing, zero hidden costs, and a strong return on investment make them a clear choice.

Strong After-Sales Support

What truly sets Ultra Tile Machine apart is their dedication to customer satisfaction beyond the sale. They offer:

Installation and commissioning support

Operational training for staff

Routine maintenance and inspection services

Readily available spare parts

Prompt technical assistance

This helps ensure that your production stays uninterrupted and efficient.

Nationwide and Global Reach

Ultra Tile Machine serves clients across India and exports machinery to several countries. Their machines are built with global standards in mind and come with all necessary documentation, training materials, and remote support for overseas clients.

Positive Customer Testimonials

“Ultra Tile Machine gave us a powerful machine that revolutionized our block manufacturing process. Their service team was quick, professional, and helpful.” – Arjun, Hyderabad

“We use their hydraulic solid block machine, and the output is simply unmatched. Highly recommended!” – Neha, Pune

Feedback like this showcases the strong reputation Ultra Tile Machine enjoys in the industry.

How to Choose the Right Machine for Your Needs?

Before you invest in a Hollow Solid Block Making Machine, consider the following:

Production Volume: Assess how many blocks you need to produce per day

Automation Level: Go with automatic models for higher speed and lower labor costs

Block Types: Choose a model compatible with the kinds of blocks you plan to manufacture

Available Space: Some machines require more floor space for installation and raw material handling

Budget: Ultra Tile Machine offers machines in a variety of price brackets to fit your investment range

Applications of Hollow and Solid Blocks

Hollow and solid blocks produced by these machines are used in:

Residential and commercial buildings

Roadside pavements

Compound walls and fences

Industrial structures

Warehouses and godowns

Load-bearing and non-load-bearing walls

Their strength, cost-efficiency, and long lifespan make them a preferred material in construction across the globe.

Focus on Sustainability

Ultra Tile Machine is committed to promoting eco-conscious practices. Their machines support:

The use of fly ash, slag, and other industrial byproducts

Reduced water usage in block curing

Low energy consumption

Long-term recyclability of produced blocks

This not only aligns with green building standards but also appeals to environmentally responsible contractors and builders.

Conclusion

In the ever-evolving world of construction, the need for reliable, durable, and high-quality blocks is more important than ever. Investing in a Hollow Solid Block Making Machine is a strategic move that can transform your business by increasing efficiency, reducing production costs, and meeting the growing demand for sustainable construction materials.

Ultra Tile Machine, as a trusted manufacturer, offers unmatched expertise, top-tier machinery, and unwavering customer support. Whether you’re starting a new venture or expanding an existing one, Ultra Tile Machine provides everything you need to succeed in the block manufacturing industry.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Comprehensive Guide to Concrete Block Making Machines

Concrete block making machines play a crucial role in modern construction by enabling efficient, large-scale production of concrete blocks and pavers. These machines are widely used in residential, commercial, and industrial construction projects, providing durable and cost-effective building materials. This article explores the various aspects of concrete block making machines, their types, benefits, and applications.

What is a Concrete Block Making Machine?

A concrete block making machine is a specialized piece of equipment used to manufacture concrete blocks of various shapes and sizes. These machines are engineered to compact and mold concrete mixtures into high-quality blocks, ensuring uniformity and structural integrity.

Types of Concrete Block Making Machines

Concrete block machines come in various configurations to meet diverse production needs. The primary types include:

Manual Concrete Block Making Machine

Requires human intervention for mixing, molding, and curing.

Suitable for small-scale production.

Cost-effective but labor-intensive.

Semi-Automatic Concrete Block Making Machine

Partially automated with manual feeding and block extraction.

Offers a balance between automation and cost.

Suitable for medium-scale production.

Fully Automatic Concrete Block Making Machine

Features automated feeding, mixing, molding, and curing.

High efficiency and productivity.

Ideal for large-scale commercial block manufacturing.

Hydraulic Paver Block Making Machine

Uses hydraulic pressure to produce high-strength paver blocks.

Suitable for manufacturing interlocking pavers, driveway blocks, and decorative tiles.

Automatic Cement Block Making Machine

Specialized for producing cement-based blocks with precise composition.

Ensures consistent quality and durability.

Key Features of Concrete Block Making Machines

Modern block making machines incorporate advanced technology to enhance efficiency and quality. Some essential features include:

High Output Capacity

Designed for mass production, making them ideal for large construction projects.

Precision Engineering

Uses advanced vibration and compaction technology to ensure uniform density and strength in each block.

Versatility

Adaptable to produce various block sizes and shapes, including standard bricks, pavers, and curb stones.

Energy Efficiency

Modern machines minimize power consumption, reducing operational costs and environmental impact.

Durability and Low Maintenance

Built with robust materials to withstand prolonged usage with minimal maintenance.

Materials Used in Concrete Block Production

Machine for concrete are typically made using a combination of the following materials:

Portland Cement: The primary binding agent that holds the aggregates together.

Sand and Fine Gravel: Provide structural integrity and improve workability.

Fly Ash: A by-product from coal combustion used as a partial cement replacement.

Recycled Aggregates: Such as post-consumer glass, slag cement, and crushed concrete, making production more sustainable.

Water: Essential for hydrating the cement and ensuring proper curing.

Advantages of Using Concrete Block Making Machines

Investing in a high-quality block making machine offers numerous benefits, including:

Cost-Effectiveness

Reduces reliance on manually produced bricks and lowers labor costs.

Produces blocks in bulk, reducing material costs.

Sustainability

Encourages the use of recycled materials in block production.

Produces minimal waste and contributes to environmentally friendly construction.

Strength and Durability

Concrete blocks offer excellent load-bearing capacity and weather resistance.

Ideal for long-lasting structures with minimal maintenance requirements.

Flexibility in Design

Machines can be adjusted to produce blocks of different shapes, sizes, and textures.

Suitable for architectural applications and decorative paving solutions.

Time Efficiency

Fully automatic machines significantly reduce production time.

Enables fast-track construction and large-scale project execution.

Applications of Concrete Blocks

Concrete blocks produced by block making machines are used in a variety of applications, including:

Residential Construction: Walls, partitions, and fencing.

Commercial Buildings: Shopping complexes, office buildings, and parking structures.

Industrial Infrastructure: Factories, warehouses, and loading docks.

Road and Pavement Construction: Paver blocks for driveways, footpaths, and public spaces.

Landscaping: Retaining walls, garden edgings, and outdoor seating arrangements.

Factors to Consider When Choosing a Concrete Block Machine

When selecting a concrete block making machine, consider the following aspects:

Production Capacity: Choose a machine that meets your required output volume.

Automation Level: Determine if you need a manual, semi-automatic, or fully automatic machine.

Material Compatibility: Ensure the machine supports the type of raw materials you plan to use.

Space Requirements: Check the installation space and layout compatibility.

Budget and ROI: Consider the initial investment versus long-term cost savings and production benefits.

Future Trends in Concrete Block Making Machines

The construction industry is continually evolving, with innovations in concrete block making machines shaping the future of block production:

AI-Integrated Machines: Smart automation for precise quality control.

Eco-Friendly Block Production: Machines designed to optimize the use of recycled materials.

3D Concrete Printing: New-age technology enabling customized block structures.

IoT-Enabled Monitoring: Remote tracking of machine performance and efficiency.

Conclusion

Investing in a concrete block making machine is a strategic decision for businesses in the construction sector. These machines offer enhanced efficiency, cost-effectiveness, and sustainability, making them indispensable for large-scale and small-scale projects alike. Whether you require automatic cement block making machines, hydraulic paver block machines, or high-volume production units, choosing the right equipment ensures superior quality and long-term benefits.

youtube

For businesses seeking high-performance block making solutions, advanced technology and precision engineering play a crucial role in meeting diverse industry demands. With continuous advancements, concrete block manufacturing continues to be a cornerstone of modern construction, paving the way for innovation and growth.

1 note

·

View note

Text

Garage Flooring

Our parking area has a showcase area that requires less upkeep than its sturdy competitors and heavy-duty garage flooring tiles. to increase the value of our house by adding locks to the sturdy floor tiles. Our deck tiles are sturdy enough to support automobiles and are composed of high-impact polypropylene. It cannot be a dependable, risk-free encounter that will satisfy all of your irrational demands. For a sign-up, we can just clean up spills and periodically remove dirt. Coin tops, gem tops, or pierced polypropylene plastic garage floor tiles can be used to create a unique and eye-catching floor.

Using floor tiles is one of the simplest and least expensive ways to cover your garage. You may choose a floor tile that matches the design and color scheme of your garage because they are available in a range of hues. Lay them down on the floor and assemble them according to the simple assembly directions. if you want to use your garage more frequently and have a more comfortable floor. They often possess sufficient resilience and impact resistance to shield you from severe harm if you trip and fall. The garage might feature tile flooring, just like the kitchen or bathroom.

If the tiles are positioned properly, this is a smart and durable decision. But eventually, they will deteriorate or peel. Debris will also collect in the gaps between tiles, where it could harbor mold or bacteria. Furthermore, when wet, the tile becomes incredibly slick and vulnerable to freeze-thaw cycle damage. Tiles are simple to install and can improve the appearance of the garage floor. However, they may incur significant costs. You should be able to choose one that blends in with the style of your garage thanks to the variety of materials, colors, and patterns that are offered.

It could be difficult to choose garage flooring for your remodeling job. How you want to use your garage will determine what kind of flooring is best for it. Because they provide us with choices and come in a variety of colors, materials, sizes, thicknesses, and other attributes, those tiles are fantastic. Covering any room of any size is simple due to its constructability, even if the space has an irregular shape. Their ease of self-assembly makes them ideal for both temporary and semi-permanent installations. When necessary, they are quite simple to replace or fix.

For your next do-it-yourself project, we are happy to offer a variety of interlocking floor tiles. We specialize in providing modular flooring for home renovations, such as damp basement flooring restorations, garage flooring makeovers, deck and patio flooring upgrading, and even backyard basketball courts. One of our most popular interlocking tiles is made of high-impact polypropylene. Large vehicles and machines can therefore be handled by these sturdy, lightweight tiles.

Our deck tiles are created from high-impact polypropylene and are sturdy enough to hold cars. You cannot count on it to be a reliable, certain adventure that will satisfy your high expectations. We can just mop up spills and sometimes clear away any dirt for a sign-up. For your unique floor, you can design an eye-catching pattern using punctured polypropylene plastic garage floor tiles, coin tops, or gem tops. Explore our collection of tiles in nine eye-catching hues with three unique models, as well as our unprecedented plans and tile offers. Numerous materials can be used to tile parking lot flooring.

0 notes

Text

Top Benefits of Using an Interlocking Tiles Making Machine for Your Business

In today's competitive construction and paving industry, efficiency and quality are paramount. One technology that has revolutionized the production of interlocking tiles is the interlocking tiles making machine. At BTM Product, we understand the importance of staying ahead in the market, which is why we offer top-quality equipment to boost your business productivity. Let's explore the numerous advantages of incorporating this innovative machinery into your operations.

Increased Production Efficiency

One of the primary benefits of using an interlocking tiles making machine is the significant boost in production efficiency. Traditional methods of creating interlocking tiles are time-consuming and labor-intensive. With our state-of-the-art machinery, you can dramatically increase your output while reducing manual labor.

BTM Product's interlocking tiles making machines are designed to operate continuously, allowing for 24/7 production if needed. This means you can meet larger orders and tighter deadlines without compromising on quality. The automated process ensures consistent results, minimizing errors and waste.

Superior Quality and Consistency

Consistency is key in the production of interlocking tiles. Our machines are engineered to deliver uniform results with every batch. This level of consistency is difficult to achieve with manual production methods.

The precision of our interlocking tiles making machine ensures that each tile meets exact specifications. This results in easier installation, better interlocking, and a more durable final product. Your customers will appreciate the high-quality tiles that fit perfectly every time.

Cost-Effective Production

While the initial interlocking tiles making machine price may seem significant, the long-term cost savings are substantial. By automating the production process, you'll reduce labor costs and minimize material waste. The efficiency of the machine means you can produce more tiles with less raw material, further reducing your production costs.

Additionally, the durability of BTM Product's machines ensures a long lifespan with minimal maintenance costs. This translates to a lower cost per tile over time, improving your profit margins and competitiveness in the market.

Versatility in Design and Production

Modern interlocking tiles making machines offer incredible versatility. With our equipment, you can easily switch between different tile designs, sizes, and patterns. This flexibility allows you to cater to a wider range of customer preferences and project requirements.

BTM Product's machines come with customizable molds, enabling you to create unique designs that set your products apart from the competition. Whether you're producing tiles for residential driveways, commercial parking lots, or decorative pathways, our machines can handle it all.

Reduced Environmental Impact

Sustainability is becoming increasingly important in the construction industry. Interlocking tiles making machines contribute to a more environmentally friendly production process in several ways:

1. Reduced energy consumption compared to traditional methods 2. Minimal waste production due to precise measurements and molding 3. Ability to incorporate recycled materials into the tile mix

By using our machines, you're not only improving your business efficiency but also reducing your carbon footprint. This can be a strong selling point for environmentally conscious clients.

Enhanced Worker Safety

Safety should always be a top priority in any manufacturing environment. Interlocking tiles making machines significantly reduce the risk of workplace injuries associated with manual tile production. The automated process minimizes the need for heavy lifting and repetitive motions that can lead to strain or injury.

BTM Product's machines are equipped with safety features that protect operators and ensure a secure working environment. This not only protects your employees but also reduces the risk of work-related compensation claims and downtime due to accidents.

Scalability for Business Growth

As your business grows, your production capacity needs to keep pace. Interlocking tiles making machines offer excellent scalability options. You can start with a single machine and gradually expand your production line as demand increases.

BTM Product offers a range of machines with varying capacities to suit businesses of all sizes. Whether you're a small startup or a large-scale manufacturer, we have the right equipment to match your production needs and growth plans.

Competitive Edge in the Market

Investing in an interlocking tiles making machine gives your business a significant competitive advantage. The ability to produce high-quality tiles quickly and cost-effectively allows you to offer better prices and faster turnaround times to your customers.

Moreover, the consistent quality and unique designs you can achieve with our machines will help build your reputation as a reliable and innovative supplier in the industry. This can lead to increased customer loyalty and word-of-mouth referrals, driving business growth.

Easy Maintenance and Support

BTM Product understands that downtime can be costly for your business. That's why our interlocking tiles making machines are designed for easy maintenance and quick troubleshooting. We provide comprehensive training on machine operation and maintenance to ensure your team can keep the equipment running smoothly.

Additionally, we offer excellent after-sales support and readily available spare parts. This means you can count on minimal disruptions to your production schedule and maximum uptime for your investment.

Return on Investment

When considering the interlocking tiles making machine price, it's important to look at the long-term return on investment. The increased production capacity, reduced labor costs, and improved product quality all contribute to a healthy ROI.

Many of our clients report that their investment in BTM Product's machines pays for itself within a short period, thanks to increased sales and operational efficiency. As your business grows and production volumes increase, the value of your investment becomes even more apparent.

Conclusion

In today's fast-paced construction industry, staying competitive requires embracing innovative technologies. An interlocking tiles making machine from BTM Product offers numerous benefits that can transform your business operations. From increased efficiency and quality to cost savings and environmental benefits, the advantages are clear.

If you're looking to take your interlocking tile production to the next level, consider exploring our range of machines. With a paver block making machine for sale from BTM Product, you're not just purchasing equipment – you're investing in the future of your business.

Contact us today to learn more about how our interlocking tiles making machines can benefit your specific business needs. Let BTM Product help you pave the way to success in the interlocking tile industry.

0 notes

Text

Electrostatically Conductive PVC Tiles

In today’s industrial and commercial landscapes, controlling electrostatic discharge (ESD) is more critical than ever. From electronics manufacturing to healthcare facilities, environments sensitive to static electricity require robust solutions to maintain safety and efficiency. Electrostatically conductive PVC tiles emerge as an innovative flooring solution to meet these demands. Here at More Floor, we are committed to educating our clients on the benefits, applications, and features of these advanced tiles.

What Are Electrostatically Conductive PVC Tiles?

Electrostatically conductive PVC tiles are specialized flooring materials designed to dissipate static electricity. These tiles are manufactured with conductive materials embedded within their structure, allowing for the controlled flow of electrical charges. This property makes them ideal for environments where ESD can cause damage, injury, or operational disruptions.

Unlike traditional flooring solutions, conductive PVC tiles provide a combination of durability, aesthetics, and functionality, ensuring optimal performance in even the most demanding conditions.

Key Features of Electrostatically Conductive PVC Tiles

1. High Electrical Conductivity

Conductive PVC tiles incorporate carbon-based or metallic additives, enabling them to conduct electricity efficiently. The flooring connects to a grounding system, allowing static charges to safely dissipate.

2. Durability

These tiles are made from high-quality polyvinyl chloride (PVC), ensuring long-lasting performance. They are resistant to wear, scratches, and impact, making them suitable for high-traffic areas.

3. Chemical Resistance

Electrostatically conductive PVC tiles are resistant to a wide range of chemicals, including oils, acids, and solvents. This feature makes them a preferred choice in laboratories and industrial settings.

4. Easy Maintenance

The smooth surface of these tiles makes cleaning and maintenance hassle-free. Routine mopping with antistatic cleaning agents ensures they remain effective in controlling ESD.

5. Aesthetic Appeal

Available in various colors, textures, and finishes, these tiles blend functionality with aesthetics, enhancing the visual appeal of workspaces.

6. Ease of Installation

Modular designs and interlocking systems make installation quick and straightforward, minimizing downtime.

Applications of Electrostatically Conductive PVC Tiles

1. Electronics and Semiconductor Manufacturing

Electronics are highly susceptible to damage from static electricity. Conductive PVC tiles provide a controlled environment, ensuring the safety and integrity of sensitive components.

2. Healthcare Facilities

Hospitals, clinics, and laboratories rely on static-free environments to protect sensitive medical equipment and ensure patient safety. These tiles prevent ESD-induced malfunctions in devices like MRI machines and heart monitors.

3. Data Centers

In data centers, uncontrolled static discharge can lead to catastrophic hardware failures. Electrostatically conductive PVC tiles safeguard servers and other IT equipment.

4. Automotive and Aerospace Industries

These industries involve working with flammable materials and sensitive electronics. Conductive flooring reduces the risk of sparks and ensures compliance with safety regulations.

5. Cleanrooms

Cleanrooms demand stringent control over environmental factors, including static electricity. Conductive PVC tiles meet these requirements, ensuring operational efficiency.

Benefits of Electrostatically Conductive PVC Tiles

1. Enhanced Safety

By eliminating the risks associated with ESD, these tiles create a safer work environment, protecting employees and equipment.

2. Regulatory Compliance

Many industries are subject to strict ESD control standards. Conductive PVC tiles help organizations meet these regulations with ease.

3. Cost Efficiency

Durable and low-maintenance, these tiles offer a long-term solution that reduces repair and replacement costs.

4. Versatility

With applications spanning diverse industries, these tiles adapt to various operational requirements without compromising performance.

Installation and Grounding of Conductive PVC Tiles

Proper installation is crucial to the performance of electrostatically conductive PVC tiles. The process typically involves:

Surface Preparation: Ensure the subfloor is clean, dry, and level to guarantee optimal tile adhesion.

Tile Layout: Plan the tile layout to minimize cuts and ensure an even appearance.

Adhesive Application: Use specialized conductive adhesives to secure the tiles in place.

Grounding: Connect the tiles to a grounding system using copper strips or grounding plates. This step ensures the efficient dissipation of static electricity.

Testing: Post-installation testing with an ESD meter confirms the conductivity and effectiveness of the flooring.

Maintenance Tips for Electrostatically Conductive PVC Tiles

Regular Cleaning: Use antistatic cleaning solutions to remove dust and debris, which can hinder conductivity.

Avoid Abrasive Tools: Use non-abrasive mops and pads to prevent surface damage.

Periodic Testing: Regularly test the flooring’s conductivity to ensure it remains within the desired range.

Prompt Repairs: Address any damage immediately to maintain the flooring’s effectiveness.

Why Choose More Floor?

At More Floor, we specialize in providing premium-quality electrostatically conductive PVC tiles tailored to your unique needs. Here’s why clients trust us:

Expertise: With years of experience, we understand the complexities of ESD control and flooring solutions.

Customization: We offer a wide range of tile options to suit diverse operational and aesthetic requirements.

Support: From consultation to installation and maintenance, our team ensures seamless service at every step.

Quality Assurance: Our tiles undergo rigorous testing to meet industry standards, delivering unmatched reliability.

Conclusion

Electrostatically conductive PVC tiles are an essential investment for industries where ESD poses a significant risk. Their unique combination of durability, functionality, and aesthetic appeal makes them a preferred choice across sectors. At More Floor, we are committed to helping you create safer, more efficient environments with our state-of-the-art flooring solutions.

Contact us today to learn more about our products and services. Together, let’s build a static-free future!

0 notes

Text

Rubber outdoor tiles

Our store offers interlocking rubber outdoor tiles designed for the home gym flooring market. The recycled rubber tiles, which are black with 10% of grey specks, give the impression of a high-end fitness floor. The 5/16-inch-thick, 8 mm-thick rubber tiles protect the flooring from vibrations from exercise equipment like treadmills. Their interlocking rubber technology makes them ideal for use in the installation of home gym floors. These rubber floor tiles snap together to cover a whole room or to create an exercise mat. Because they are made of recycled SBR rubber, they are environmentally beneficial. It is believed that each rubber floor tile created will stop one car tire from ending up in a landfill.

Because of their tight interlocking design, our rubber floor tiles are almost invisible once installed. Rubber floor tiles can be used to cover any kind of flooring, including wood, ceramic, and concrete. The tiles don't require glue to adhere, in contrast to rubber rolls. The flexible nature of the interlocking rubber floor tiles allows them to adjust to slightly uneven subfloors. Reduced vibration from your exercise machines while you use them is one benefit of putting rubber flooring in your home gym. A thicker rubber will absorb vibrations more fully. For home gym floors, 5/16-inch thick rubber tiles are usually utilized. Weightlifting experts may want to consider utilizing rubber matting or 3/4-tile flooring.

The primary benefit is how easy it is to install. The rubber roll flooring must be installed with glue, and the joints must be fitted and trimmed. It's not an easy task for the average homeowner to accomplish. The slightest mistake will negate the value of your investment and the appeal of the floor. Rubber rolls have applications in long-term installations as well. There is no way to reposition or shift them without causing damage to the rubber flooring. In comparison, it is easier to install interlocking rubber floor tiles. There's no need for adhesive because the factory uses precise cutting gear to cut the seams. If you need to rearrange the floor, you can even pick it up and put it somewhere else.

0 notes

Text

Best Paver Block and Brick Making Solutions from Ultra Tiles Machine

When it comes to producing high-quality paver blocks, bricks, and other concrete products, having the right equipment is crucial. Ultra Tiles Machine has established itself as a leading name in the industry, providing top-notch machinery for all your block and brick-making needs. With a wide range of machines designed to meet the demands of various construction projects, we cater to businesses that require efficiency, reliability, and precision in their manufacturing processes.

In this blog, we’ll explore the different types of machines offered by Ultra Tiles Machine, including Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, and Automatic Brick Making Machine Manufacturer.

Paver Block Making Machine

A Paver Block Making Machine is essential for creating durable, aesthetically pleasing paving stones used in roads, driveways, walkways, and other outdoor spaces. At Ultra Tiles Machine, we offer advanced paver block machines that produce high-quality interlocking paver blocks in various shapes and sizes.

Our machines are designed to cater to both small and large-scale production needs, ensuring consistent output with minimal labor.

These machines are designed for optimal performance, ensuring that each paver block produced has the desired strength, texture, and finish.

Whether you need blocks for residential, commercial, or industrial projects, our Paver Block Making Machine will meet your specific requirements, ensuring efficiency, precision, and cost-effectiveness.

The Hollow Solid Block Making Machine offered by Ultra Tiles Machine is designed for producing high-strength blocks that are both cost-effective and versatile. Hollow blocks are widely used in the construction of walls, foundations, and other structures, offering excellent insulation and soundproofing properties. Our machine can produce both hollow and solid blocks, depending on your project’s requirements.

The machine is engineered with precision and advanced technology, ensuring that the blocks produced are uniform in size and shape. This ensures a smooth construction process, reducing material wastage and improving overall building quality. Additionally, our Hollow Solid Block Making Machine is designed to be durable, ensuring a long service life with minimal maintenance.

Fly Ash Brick Making Machine

Ultra Tiles Machine is a prominent Fly Ash Brick Making Machine manufacturer, offering state-of-the-art machines that are environmentally friendly and economically viable. Fly ash bricks are an eco-conscious alternative to traditional clay bricks, made from industrial waste products like fly ash, cement, and sand. These bricks are stronger, lighter, and more durable than conventional bricks, making them an ideal choice for modern construction projects.

Our Fly Ash Brick Making Machine uses innovative technology to ensure the production of high-quality fly ash bricks with consistent strength and size. This machine is perfect for businesses looking to reduce their environmental footprint while maintaining high standards of construction. With high automation and low energy consumption, it helps reduce production costs and enhances overall operational efficiency.

Concrete Block and Brick Making Machine

Our machines are designed to create blocks and bricks in various sizes, including standard, interlocking, and custom designs. The flexibility of our Concrete Block and Brick Making Machine ensures that it can cater to the specific needs of different construction projects. Whether you're building residential complexes, commercial buildings, or infrastructure projects, our machines deliver the perfect solution.

Chemical Hardener Manufacturers

In the production of paver blocks, bricks, and other concrete products, it’s essential to ensure high strength and durability. This is where the role of chemical hardeners comes into play. Ultra Tiles Machine is a trusted Chemical Hardener Manufacturer, offering top-quality hardening agents that improve the overall strength and resistance of concrete products.

Chemical hardeners are used to enhance the surface hardness of concrete products, providing them with greater resistance to wear, moisture, and weathering. By using the right chemical hardeners in your production process, you can ensure the longevity and durability of your paver blocks, bricks, and other concrete products.

Interlocking Paver Block Making Machine

At Ultra Tiles Machine, we ensure that the Interlocking Paver Block Making Machine we offer delivers precision and consistency in every block produced. With advanced technology and efficient production processes, these machines provide excellent results in a variety of sizes and designs to suit different project needs.

As an Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine offers machines that automate the process of brick production, resulting in reduced labor costs and increased efficiency. Our Automatic Brick Making Machines are designed to produce high-quality bricks with minimal manual intervention. These machines are ideal for businesses that need to produce large volumes of bricks quickly while maintaining high standards of quality.

Our automatic machines are equipped with advanced features such as automated brick molding, high-pressure forming, and easy-to-use control systems. This ensures that each brick produced meets the highest quality standards while reducing the need for manual labor and increasing overall productivity.

Why Choose an Ultra Tiles Machine?

At Ultra Tiles Machine, we are committed to providing our customers with the best machinery solutions for their block and brick-making needs. Here’s why you should choose us:

Advanced Technology: We use the latest technology to manufacture machines that deliver high-quality products with minimal labor.

Customization: We offer customized solutions tailored to your specific production needs, ensuring that you get the perfect machine for your requirements.

Durability and Reliability: Our machines are built to last, with high-quality materials and precision engineering ensuring long service life.

Eco-friendly Solutions: We are committed to providing eco-friendly machinery, including Fly Ash Brick Making Machines that help reduce your carbon footprint.

Customer Support: We offer excellent customer support, ensuring that you have the assistance you need at every step of the way.

Conclusion

Whether you're looking for a Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, or Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine is the trusted partner for all your block and brick-making needs.

With our high-quality machines, advanced technology, and exceptional customer service, we guarantee that your production process will be efficient, cost-effective, and reliable.

Contact Ultra Tiles Machine today to learn more about our products and how we can help you take your construction business to the next level.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Best Block Making Machine in India

Introducing the cutting-edge Block Making Machine, a game-changer in the construction industry. Designed to streamline and enhance the process of producing high-quality concrete blocks, this advanced machinery boasts unparalleled efficiency and precision, catering to the evolving needs of modern construction projects. The Block Making Machine offers a seamless blend of robust engineering and intelligent automation, ensuring consistent output while minimizing manual labor and operational costs. Equipped with state-of-the-art features, including precise mold filling mechanisms and customizable block specifications, it empowers construction companies to meet diverse project requirements with ease. With its versatile functionality, the Block Making Machine is ideal for a wide range of applications, from residential developments to large-scale infrastructure projects. Whether crafting paving blocks, bricks, or interlocking tiles, this innovative solution delivers superior performance and durability, contributing to sustainable and resilient structures.

For more details clicks here - https://www.indiantradebird.com/product/block-making-machine

0 notes

Text

Garage Flooring

Our parking area has a showcase area that requires less upkeep than its sturdy competitors and heavy-duty garage flooring tiles. to increase the value of our house by adding locks to the sturdy floor tiles. Our deck tiles are sturdy enough to support automobiles and are composed of high-impact polypropylene. It cannot be a dependable, risk-free encounter that will satisfy all of your irrational demands. For a sign-up, we can just clean up spills and periodically remove dirt. Coin tops, gem tops, or pierced polypropylene plastic garage floor tiles can be used to create a unique and eye-catching floor.

Our parking area has a showcase area that requires less upkeep than its sturdy competitors and heavy-duty garage flooring tiles. to increase the value of our house by adding locks to the sturdy floor tiles. Our deck tiles are sturdy enough to support automobiles and are composed of high-impact polypropylene. It cannot be a dependable, risk-free encounter that will satisfy all of your irrational demands. For a sign-up, we can just clean up spills and periodically remove dirt. Coin top, gem top, or pierced polypropylene plastic garage floor tiles can be used to create a unique and eye-catching floor.

Using floor tiles is one of the simplest and least expensive ways to cover your garage. You may choose a floor tile that matches the design and color scheme of your garage because they are available in a range of hues. Lay them down on the floor and assemble them according to the simple assembly directions. if you want to use your garage more frequently and have a more comfortable floor. They often possess sufficient resilience and impact resistance to shield you from severe harm in the event that you trip and fall. The garage might feature tile flooring, just like the kitchen or bathroom.

If the tiles are positioned properly, this is a smart and durable decision. But eventually, they will deteriorate or peel. Debris will also collect in the gaps between tiles, where it could harbor mold or bacteria. Furthermore, when wet, the tile becomes incredibly slick and vulnerable to freeze-thaw cycle damage. Tiles are simple to install and can improve the appearance of the garage floor. However, they may incur significant costs. You should be able to choose one that blends in with the style of your garage thanks to the variety of materials, colors, and patterns that are offered.

It could be difficult to choose garage flooring for your remodeling job. How you want to use your garage will determine what kind of flooring is best for it. Because they provide us choices and come in a variety of colors, materials, sizes, thicknesses, and other attributes, those tiles are fantastic. Covering any room of any size is simple due to its constructability, even if the space has an irregular shape. Their ease of self-assembly makes them ideal for both temporary and semi-permanent installations. When necessary, they are quite simple to replace or fix.

For your next do-it-yourself project, we are happy to offer a variety of interlocking floor tiles. We specialize in providing modular flooring for home renovations, such as damp basement flooring restorations, garage flooring makeovers, deck and patio flooring upgrades, and even backyard basketball courts. One of our most popular interlocking tiles is made of high-impact polypropylene. Large vehicles and machines can therefore be handled by these sturdy, lightweight tiles.

Our deck tiles are created from high-impact polypropylene and are sturdy enough to hold cars. You cannot count on it to be a reliable, certain adventure that will satisfy your high expectations. We can just mop up spills and sometimes clear away any dirt for a sign-up. For your unique floor, you can design an eye-catching pattern using punctured polypropylene plastic garage floor tiles, coin tops, or gem tops. Explore our collection of tiles in nine eye-catching hues with three unique models, as well as our unprecedented plans and tile offers. Numerous materials can be used to tile parking lot flooring.

0 notes

Text

#Paver Block Making Machine Manufacturers in Ghaziabad#Interlocking Tile Making Machine Suppliers#Paver Tiles Making Machine Wholesalers in Uttar Pradesh#Tiles Block Making Machine Manufacturers in Ghaziabad#Tiles Block Making Machine Suppliers in Uttar Pradesh#Tiles Block Making Machine Wholesalers in India

0 notes