#Concrete Block and Brick Making Machine

Explore tagged Tumblr posts

Text

Hollow Solid Block Making Machine – Trusted Solutions by Ultra Tile Machine

In the construction industry, the demand for reliable and cost-effective building materials has never been higher. With infrastructure projects on the rise, both hollow and solid blocks are rapidly replacing traditional bricks due to their structural advantages, durability, and cost efficiency. At the core of producing these essential materials lies the Hollow Solid Block Making Machine, a critical asset for modern builders and manufacturers.

When it comes to choosing a dependable manufacturer, Ultra Tile Machine stands tall as an industry leader. With years of expertise and a reputation for quality and innovation, Ultra Tile Machine is your go-to partner for high-performance block making solutions.

What Is a Hollow Solid Block Making Machine?

A Hollow Solid Block Making Machine is a versatile industrial machine used to manufacture both hollow and solid concrete blocks. These machines compact a mixture of cement, sand, and aggregates into pre-defined molds using hydraulic or mechanical pressure. The result is uniformly shaped, high-strength blocks suitable for various construction needs.

Hollow blocks are lighter and used for non-load bearing walls, while solid blocks are denser and used in load-bearing structures. A machine that can produce both types offers manufacturers maximum flexibility and better ROI.

Why Hollow and Solid Blocks Are Gaining Popularity

Construction professionals are shifting towards hollow and solid concrete blocks due to their numerous advantages over traditional bricks. Some of these include:

Better thermal insulation

Faster construction speed

High load-bearing capacity

Reduced dead load on structure

Eco-friendly materials

Lower water absorption

Uniform shape and size

This shift has directly increased the demand for machines that can produce these blocks efficiently.

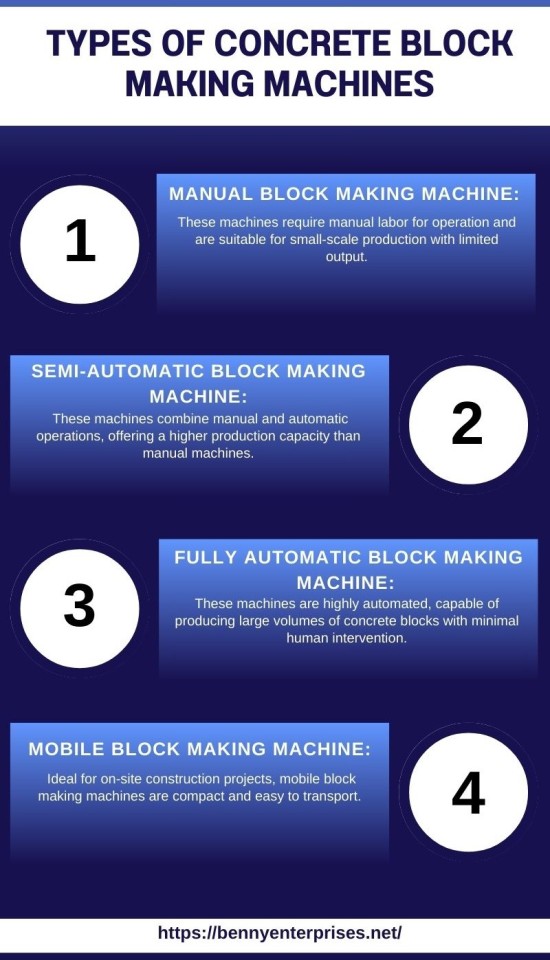

Types of Hollow Solid Block Making Machines

Depending on the scale and automation needs of your business, Ultra Tile Machine offers a range of machines such as:

Manual Block Making Machines

Semi-Automatic Machines

Fully Automatic Machines

Hydraulic Press Block Machines

Vibration Cum Compression Machines

Each type caters to a different production requirement, ensuring that businesses of all sizes can find the right fit.

Advantages of Investing in a Hollow Solid Block Making Machine

High Productivity

These machines are designed to produce hundreds or even thousands of blocks in a single shift, drastically improving output.

Versatility

Manufacturers can produce a wide range of block types, including hollow blocks, solid blocks, interlocking blocks, and more using different molds.

Cost Efficiency

Modern machines reduce labor dependency and minimize raw material waste, increasing overall profitability.

Better Quality Control

Precision engineering ensures consistency in size, strength, and shape, which is vital for large-scale construction projects.

Environmentally Friendly

These machines support the use of fly ash, slag, and other industrial waste, contributing to sustainable construction practices.

Why Choose Ultra Tile Machine as Your Manufacturer?

Industry Experience

Ultra Tile Machine has built a legacy of trust and excellence in the block making machinery sector. With decades of experience, the company understands the pulse of the construction industry and delivers solutions tailored to real-world challenges.

Advanced Technology

All machines by Ultra Tile Machine are designed using the latest technology to ensure high output and consistent performance. Key features include:

High-pressure hydraulic systems

Heavy-duty steel construction

Advanced vibration technology

Precision molds

User-friendly controls

Long service life

These features enable operators to run production smoothly with minimal downtime.

Wide Product Range

Ultra Tile Machine offers a full suite of machinery for every scale of operation:

Manual Machines: Ideal for startups and small-scale units

Semi-Automatic Models: A perfect mix of manual and automatic features

Fully Automatic Machines: Best suited for large-scale continuous production

Hydraulic Block Machines: Ensures greater compression and block durability

Whether you’re a beginner or a seasoned industrialist, there's a machine that suits your business needs.

Customization Options

Ultra Tile Machine provides full flexibility in customizing:

Block size and mold design

Output capacity

Power source (electric or diesel)

Machine frame and configuration

Color and branding

Custom machines ensure that your production line aligns perfectly with market demand and your brand identity.

Quality Assurance

Ultra Tile Machine places strong emphasis on quality at every stage of manufacturing. Every machine undergoes rigorous quality checks to ensure:

Flawless operation

Durability and reliability

Resistance to wear and tear

Energy efficiency

Customers receive machines that perform consistently for years with low maintenance requirements.

Competitive Pricing

Despite offering premium features, Ultra Tile Machine maintains highly competitive prices. Their goal is to make quality machinery accessible to everyone, from small business owners to industrial giants. Transparent pricing, zero hidden costs, and a strong return on investment make them a clear choice.

Strong After-Sales Support

What truly sets Ultra Tile Machine apart is their dedication to customer satisfaction beyond the sale. They offer:

Installation and commissioning support

Operational training for staff

Routine maintenance and inspection services

Readily available spare parts

Prompt technical assistance

This helps ensure that your production stays uninterrupted and efficient.

Nationwide and Global Reach

Ultra Tile Machine serves clients across India and exports machinery to several countries. Their machines are built with global standards in mind and come with all necessary documentation, training materials, and remote support for overseas clients.

Positive Customer Testimonials

“Ultra Tile Machine gave us a powerful machine that revolutionized our block manufacturing process. Their service team was quick, professional, and helpful.” – Arjun, Hyderabad

“We use their hydraulic solid block machine, and the output is simply unmatched. Highly recommended!” – Neha, Pune

Feedback like this showcases the strong reputation Ultra Tile Machine enjoys in the industry.

How to Choose the Right Machine for Your Needs?

Before you invest in a Hollow Solid Block Making Machine, consider the following:

Production Volume: Assess how many blocks you need to produce per day

Automation Level: Go with automatic models for higher speed and lower labor costs

Block Types: Choose a model compatible with the kinds of blocks you plan to manufacture

Available Space: Some machines require more floor space for installation and raw material handling

Budget: Ultra Tile Machine offers machines in a variety of price brackets to fit your investment range

Applications of Hollow and Solid Blocks

Hollow and solid blocks produced by these machines are used in:

Residential and commercial buildings

Roadside pavements

Compound walls and fences

Industrial structures

Warehouses and godowns

Load-bearing and non-load-bearing walls

Their strength, cost-efficiency, and long lifespan make them a preferred material in construction across the globe.

Focus on Sustainability

Ultra Tile Machine is committed to promoting eco-conscious practices. Their machines support:

The use of fly ash, slag, and other industrial byproducts

Reduced water usage in block curing

Low energy consumption

Long-term recyclability of produced blocks

This not only aligns with green building standards but also appeals to environmentally responsible contractors and builders.

Conclusion

In the ever-evolving world of construction, the need for reliable, durable, and high-quality blocks is more important than ever. Investing in a Hollow Solid Block Making Machine is a strategic move that can transform your business by increasing efficiency, reducing production costs, and meeting the growing demand for sustainable construction materials.

Ultra Tile Machine, as a trusted manufacturer, offers unmatched expertise, top-tier machinery, and unwavering customer support. Whether you’re starting a new venture or expanding an existing one, Ultra Tile Machine provides everything you need to succeed in the block manufacturing industry.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Concrete Block Moulding Machine

Concrete block moulding machine QT series adopts German technology, with high efficiency, practical, reliable quality and so on. The main products models of concrete block molding machine are QT4-15, QT6-15, QT8-15, QT10-15, QT12-15, QT16-15, etc., the most suitable for the production of fly ash, shale, coal gangue, ceramic, sand, slag, cement, construction waste and other raw materials, the production of a variety of specifications of free-burning bricks, hollow blocks and other products.

When searching on the market, there are many concrete block moulding machine manufacturers and products, to ensure the normal and stable working condition, we should buy high quality concrete block molding machine, then how can we choose high quality block making machine? High quality concrete block molding machine should usually meet the following standards: 1.Production capacity: With stable production capacity, able to meet the requirements of concrete block production needed for the project. 2.Molding precision: Able to ensure the size precision and shape consistency of the concrete blocks, and make sure the joints between the blocks are close. 3.Degree of automation: With a certain degree of automation, easy to operate and reduce manual labor intensity. 4.Durability: The concrete block moulding machine equipment has a solid structure, excellent quality of parts and components, and has a long service life. 5.Safety: Equipment operation is safe and reliable, with the necessary safety protection devices. 6.Convenient maintenance: The concrete block molding machine equipment is easy to maintain, easy to carry out routine maintenance and maintenance work. 7.Environmental protection: Meet the requirements of environmental protection, no pollution in the production process, in line with relevant national standards and regulations. Choosing a high-quality concrete block molding machine can ensure the production of high-quality blocks and improve the quality and efficiency of the project. When purchasing the concrete block moulding machine equipment, it is recommended to choose products produced by regular manufacturers and pay attention to the performance parameters and warranty service of the equipment.

This resource is from http://www.haomeibatchplant.com/news/concrete-block-moulding-machine.html Should you be interested in buying our product, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it's imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

0 notes

Text

0 notes

Text

Brick vs Block: Which Construction Material Is Right for You?

Introduction

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

We brick machinery Manufacturer & Exporters of Hydraulic brick & PAVER Block Making Machines from Ahmedabad, India"

#paver block d molding machine in india#fly ash brick making machine#concrete block making machine#brick machine#brick making machine india

0 notes

Text

With Hydraform's Soil Diesel Brick Machine and build a sustainable future. It produces environmentally friendly bricks by harnessing the power of cement, dirt, and fuel. Reduce environmental impact while producing bricks that are effective, robust, and adaptable. With Hydraform's Soil Diesel Brick Machine, embrace sustainability, make a positive impact on the environment, and create the foundation for a brighter future. Visit us for more details.

#brick making machine#block making machine#hollow brick machine suppliers#interlocking brick making machine#hollow blocks machine for sale#automatic brick making machine#gmt pallet#concrete block machine price#paving brick making machine#manual block making machine#manual block making machine for sale#automatic block machine#automatic brick making machine price#Mobile Block Making Machine#Diesel Brick Machine

0 notes

Text

More modern Ebenezer/Constance!

These two are so delightfully awkward. <3

“Here you are, Mr. Scrooge,” she said politely. “One flat white. Oh, and here.”

She also handed him a small box, which she said was filled with pastries. It felt heavy and quite dense, requiring him to splay his fingers beneath the weight of the box to hold it.

“You work in an office, right?” Constance asked. “Please accept this. I hope you and the others enjoy them. Consider it a ‘thank you’ for your kind words.”

Without even looking inside to see what she was giving him, he could tell by the sweet, cinnamon-speckled aroma that the contents of the box likely came from the café’s bakery. “Oh, I couldn’t …”

“You must!” she insisted, her kind smile never faltering. “I’m sure there are some people in your office who skipped breakfast. It’s better to eat a pastry than nothing at all, I think.”

Seeing that he wasn’t going to deter the woman, and because he knew his coworkers would likely appreciate the baked goods in lieu of their coffee machine being broken, he surrendered with a thankful smile. “Well, that is exceptionally kind of you. I see the stereotype of American generosity is alive and well.”

It was her turn to stammer, and he watched in intrigue as she tucked a spiral of red hair behind one of her ears.

“Well, it was inspired by your kindness, sir,” Constance said. She bowed to him, her strawberry-blonde curls dropping over her shoulders as she did so. “Thank you again for being so sweet to me.”

With his hands now full, the woman followed Ebenezer to the door to hold it for him and make sure he got out safely. As he began his walk back down the sidewalk and toward his practice’s building, he glanced back over his shoulder and saw Constance standing in the doorway and waving to him.

The chilly, concrete streets of London’s financial district were a backdrop that only served to make everything about her form stand out more. From her coppery hair to her red corseted top to her, and even down to the glow of her tanned skin and smattering of freckles, everything about her radiated warmth. The juxtaposition was stark, like seeing a star glittering against a night sky.

He walked back to his office in a daze, barely noticing when he was thanked by the building’s other inhabitants for putting the pastries in one of the large communal kitchens.

When he made it back to his desk, coffee still in hand, Bob cast him a curious look from his station as he passed.

“You’re back!” he enthused. “Ah, looks like your trip was a success. The coffee smells good.”

“Hm?” Scrooge said, then broke out of his daydream with a laugh. “Oh! Yes, quite. It’s lovely.”

“Lovely?” the man asked, a brow lofting in amusement at the peculiar choice in adjective to describe a beverage. “Well, that’s quite a positive review!”

“Yes,” he parroted again. “It was certainly worth the trip out. Thank you for the recommendation.”

Taking a sip, the quality of the coffee was … quite good. It was a nicely brewed medium roast coffee with the proper amount of milk added. There was a touch of sweetness as well, which was far from unwelcome for a man who preferred to take his black tea with at least one lump of the granulated stuff. It was certainly better quality than what he would have gotten from the automated machine down in the lobby, and that was what mattered most, he supposed. Plus, he’d supported a local business, an initiative that had become much more near and dear to his heart in the past year.

Yet, as he sank into his seat and took another warm sip, he found it harder to descend back into the rhythm of work. Even as calls came in or meetings called him away, his caffeine-fueled brain kept drifting back to the brick coffee house a few blocks away.

The thoughts posed such an effective distraction that he never stopped to think why that could be.

For the next few weeks, Ebenezer found himself visiting New Grounds Coffee Co. every day on his morning walk into the office.

The first experience had been so pleasant after all that he felt obliged to support the business. Also, there was the small matter of thanking Constance for her kindness.

That next morning, he walked into the coffeehouse not knowing what to expect. Would she even be working? He hadn’t paid it much thought, but when he saw her smile and wave at him from behind the counter, the suddenly found himself with a spring in his step.

“Good morning, Mr. Scrooge!” she greeted positively, her voice as chipper as ever. He nodded in mutual greeting, unable to resist returning a matching smile.

He saw some of the other customers and workers wince at her loud American cadence, but he hardly minded. She was happy to see him, after all.

“I’m quite impressed,” Ebenezer said as he stepped up to the counter, his gloved hands coming together to rest at his waist, “You remembered my name.”

She nodded; a gesture more confident than boastful.

“Well, I don’t often forget a face. Especially one of someone who was such a hero to me.”

Her sweet words inspired a rush of awe, but his brow furrowed in concern. “Now, surely what I did was nothing heroic. That man from yesterday was being shrill, and someone would have put him in his place eventually.”

A noncommittal hum answered his speculation. He noticed she didn’t look convinced, and suddenly felt self-conscious about not simply accepting the kind comment she’d given him. However, before he could reply, she added, “Well, you were the one who actually stopped him, so you were my hero for the rest of the day.”

For the first time in many years, a woman had made him blush. Although he was only 50 years of age, it had been a while since another person had complimented him well enough to make him go red in the face. Whether it was her sincerity, her cheerfulness, or her bright smile … he wasn’t sure, but the effect on his heart spoke for itself loudly against his ribcage.

“I-I’m happy to see you, Miss Constance,” he clumsily segued, hoping to distract from his embarrassment and carry on their conversation. “I wanted to thank you for yesterday.”

She cocked her head. “Thank me?”

“My coworkers did appreciate the pastries. I heard a lot of positive feedback, so hopefully you’ll have some more clients coming your way soon.”

“Oh, wonderful! I’m so glad to hear that!” she enthused. He heard the heels of her tall shoes click as she bounced behind the counter. Goodness, the woman was more excitable than some puppies he’d met.

It was ... cute.

29 notes

·

View notes

Text

Blacklight 1: Renegade

A little something I wrote a while back. I like this one.

Renegade

The rain was harsh and cold; could he not have picked another night? It hardly mattered when his feet hit the alleyway's concrete paving, to which he caught the beat in his step again and kept running. The sirens were still blaring in his head when he dashed around corner after corner, just barely clinging to the bricks when he almost slipped and fell. The scathed and torn flesh on his hands barely caught his attention, when he heard it again; the light tapping of his pursuer.

Scoffing, Nick sped into a tunnel, one he had used before. It would stretch towards the other end of the block, where he could hitch a ride, or so he thought. A headache tore through his mind when he remembered where he had left his car: Too far away. He cursed under his breath as he jumped into the tunnel, closing the hatch behind himself and engaging the arbitrary lock.

Nick: "Damn it! Fuck, fuck, fuck-"

He fumbled with the phone he quickly pulled from his pocket, still jogging as he dialled his brother.

Nick: "Heyyyy, Al, would you mind?"

Alex: "Where are you? Dinner was an hour ago."

Nick: "Yeah, sorry I couldn't make it, I texted Thom-"

Alex: "Did you?"

Nick: "I didn't? Look, Al, I could really use a ride right now, quickly."

Alex: "Who are you running from?"

Nick: "You'll see when you get here.

Alex sounded a tired sigh, before audibly shrugging and loudly closing a cupboard.

Alex: "Address?"

Nick: "Raze Street- You know the spot."

Alex: "Figures. Sit tight."

Nick whispered a thank-you-made-apology, before turning his phone off, hoping that the call was not intercepted. Before long, he would make his way to the other side of the tunnel, where he turned around to face his flank- Empty. Good. His head on a swivel, he glanced over his shoulder as he backed up towards the exit. To his surprise, an electronic lock blocked the way.

"Fuck!" He hissed with fleeting breath, as he tried to make out who had placed it there; to which he frustratingly recognised the logo of ForeverTech, the largest engineering corp in town. "That is karma for you," he whispered to himself, a chuckle following when he felt the tumbling flash drive in his coat. These locks were notorious for their anti-tampering mechanisms, which had caught many an unsuspecting burglar, but Nick was not unsuspecting. Guess I'm stuck here until Al arrives, he thought to himself as he put his ear to the metal plating.

After only a few minutes, Nick could hear the revving of an engine he recognised. A smirk slipped onto his face as he reached into his pocket, where he found a lighter. He took a deep breath, before pulling his coat's hood over his head again and triggering the lighter, before holding the yellow flame underneath the lock. After a few moments, the lock disengaged and triggered a fire alarm. The sound made Nick's ears ring as every sprinkler in the building activated as well. A grunt tumbled off Nick's lips as he climbed out through the newly opened escape hatch, which would lead him back onto the streets.

He was relieved to find his brother's motorcycle there, where Alex held out a helmet for Nick to put on. Nick wasted no time and took the headgear, before slipping it over his face and lowering the visor. Maybe he had hoped that they would have a little more time, until the siren sounded again. It was a deafening, alien noise that escaped from the vents of the peacekeeper's ribbed armour. There was no call to halt, no warning of arrest; Nick knew that if they lingered just a moment longer, they would be torn to shreds by a rifle. "Kick it!" He shouted, to which Alex wasted not another moment.

Alex hit the gas for all it had, sending the machine into a screeching galop. Alex bobbed and weaved through the late night traffic, until they were far enough out of sight to catch their breath.

Nick: "Alex, I-"

Alex: "Check the damn bike for trackers."

Alex' commanding tone always could tear through any fabric, and Nick knew better than to fight him then, so he reared his head and started carefully checking the cycle's frame for tracking devices as they drove down the freeway.

Nick: "None on the back, but Alex-"

Alex: "I don't want to hear it. Not here. Now keep your head down, for Nòll's sake."

Nick did as he was asked and kept his gaze on his brother's back, as they drove all the way to the other side of town. Alex would not slow down one bit, until they left the freeway and pulled into the suburbs on the outskirts of Coredam. It would take no more than another minute or two for them to turn into the driveway of their childhood home, where the garage door responded to their arrival and opened up on its own. Alex carefully brought the bike to a halt and waited for Nick to get off, before doing the same. Nick removed his helmet and placed it on a workbench that stood by the wall. Alex was soon to follow, his deep blue eyes piercing the night as he sought eye contact with his brother, which Nick stubbornly denied.

Still, he said nothing as he nudged Nick out of the garage and had the door close behind them, before opening the home's front door and heading inside. Nick was the one to close the door this time, hesitant to hang up his coat in case he was still being kicked out. Alex had already left the hall and headed into the dining room, but Nick lingered for a moment, thinking of anything and everything he could say. After a few moments, he fixed his blond hair as much as he could and decided to hang up his coat anyway. After that, he headed after his brother, into the dining room where Alex was taking the dishes into the kitchen.

Alex stacked four dirty plates onto a clean one, before picking them up and leaving an empty table behind. Nick briefly checked the living room, yet could not see Thomas, the youngest, anywhere. He figured that Thom had simply gone to bed. Nick hesitated once more, before carefully following Alex into the kitchen, where the water was running. Alex was scrubbing the plates he had brought in just a few moments ago, glancing over his shoulder only briefly when Nick walked in.

Alex: "You're a mess."

Nick: "You love me when I'm a mess."

Alex scoffed, shaking his head as he stacked the now clean plates. He was nothing if not efficient.

Nick: "You still love me, right?"

Alex: "You stole from a corp. Again."

Nick: "You know as well as I do that-"

Alex: "I know what's at stake, which is exactly why I can't have you keep doing this, not when you live under this roof!"

That last part was what hurt Nick. He would have left, if he could.

Nick: "That's not fair and you know it."

Alex: "What's not fair is that you keep putting Thomas in danger. We had a deal."

Nick: "I haven't forgotten."

Alex: "Then act like it!"

The silence was deafening.

Alex: "Who is it for this time?"

Nick: "The Collective."

Alex: "You are running for those rats again?"

Nick: "They are not rats."

Alex: "They will just sell the damn thing to the Militia!"

Nick: "I would bloody hope so!"

Alex: "I can't believe that you're okay with that."

Nick: "Dad would have supported me."

Alex: "Yeah, well, if you keep this up you can ask him what he thinks of it."

Nick: "I'm going to bed."

Just as Nick started to turn around and leave, Alex grasped his arm tightly and yanked him back into the kitchen.

Alex: "There's nothing you can do. Let it go."

Nick: "Oh, that's right, you would know all about letting go, wouldn't you?"

Alex only responded with a frown, to which his grip weakened. Nick slipped out of his grasp and retreated into the darkness of the hallway, before heading down the stairs and into the basement.

Alex backed up to stand against the counter, where he rested his hands in his lap as he leaned back a bit. He looked out through the kitchen window to see the burning tower in the distance, knowing what there was still to come; knowing that Nick hardly knew at all.

#writeblr#writers of tumblr#writerscommunity#writing#original character#writers and poets#writers on tumblr#short story#fiction#scifi#dystopia

2 notes

·

View notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

Best Paver Block and Brick Making Solutions from Ultra Tiles Machine

When it comes to producing high-quality paver blocks, bricks, and other concrete products, having the right equipment is crucial. Ultra Tiles Machine has established itself as a leading name in the industry, providing top-notch machinery for all your block and brick-making needs. With a wide range of machines designed to meet the demands of various construction projects, we cater to businesses that require efficiency, reliability, and precision in their manufacturing processes.

In this blog, we’ll explore the different types of machines offered by Ultra Tiles Machine, including Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, and Automatic Brick Making Machine Manufacturer.

Paver Block Making Machine

A Paver Block Making Machine is essential for creating durable, aesthetically pleasing paving stones used in roads, driveways, walkways, and other outdoor spaces. At Ultra Tiles Machine, we offer advanced paver block machines that produce high-quality interlocking paver blocks in various shapes and sizes.

Our machines are designed to cater to both small and large-scale production needs, ensuring consistent output with minimal labor.

These machines are designed for optimal performance, ensuring that each paver block produced has the desired strength, texture, and finish.

Whether you need blocks for residential, commercial, or industrial projects, our Paver Block Making Machine will meet your specific requirements, ensuring efficiency, precision, and cost-effectiveness.

The Hollow Solid Block Making Machine offered by Ultra Tiles Machine is designed for producing high-strength blocks that are both cost-effective and versatile. Hollow blocks are widely used in the construction of walls, foundations, and other structures, offering excellent insulation and soundproofing properties. Our machine can produce both hollow and solid blocks, depending on your project’s requirements.

The machine is engineered with precision and advanced technology, ensuring that the blocks produced are uniform in size and shape. This ensures a smooth construction process, reducing material wastage and improving overall building quality. Additionally, our Hollow Solid Block Making Machine is designed to be durable, ensuring a long service life with minimal maintenance.

Fly Ash Brick Making Machine

Ultra Tiles Machine is a prominent Fly Ash Brick Making Machine manufacturer, offering state-of-the-art machines that are environmentally friendly and economically viable. Fly ash bricks are an eco-conscious alternative to traditional clay bricks, made from industrial waste products like fly ash, cement, and sand. These bricks are stronger, lighter, and more durable than conventional bricks, making them an ideal choice for modern construction projects.

Our Fly Ash Brick Making Machine uses innovative technology to ensure the production of high-quality fly ash bricks with consistent strength and size. This machine is perfect for businesses looking to reduce their environmental footprint while maintaining high standards of construction. With high automation and low energy consumption, it helps reduce production costs and enhances overall operational efficiency.

Concrete Block and Brick Making Machine

Our machines are designed to create blocks and bricks in various sizes, including standard, interlocking, and custom designs. The flexibility of our Concrete Block and Brick Making Machine ensures that it can cater to the specific needs of different construction projects. Whether you're building residential complexes, commercial buildings, or infrastructure projects, our machines deliver the perfect solution.

Chemical Hardener Manufacturers

In the production of paver blocks, bricks, and other concrete products, it’s essential to ensure high strength and durability. This is where the role of chemical hardeners comes into play. Ultra Tiles Machine is a trusted Chemical Hardener Manufacturer, offering top-quality hardening agents that improve the overall strength and resistance of concrete products.

Chemical hardeners are used to enhance the surface hardness of concrete products, providing them with greater resistance to wear, moisture, and weathering. By using the right chemical hardeners in your production process, you can ensure the longevity and durability of your paver blocks, bricks, and other concrete products.

Interlocking Paver Block Making Machine

At Ultra Tiles Machine, we ensure that the Interlocking Paver Block Making Machine we offer delivers precision and consistency in every block produced. With advanced technology and efficient production processes, these machines provide excellent results in a variety of sizes and designs to suit different project needs.

As an Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine offers machines that automate the process of brick production, resulting in reduced labor costs and increased efficiency. Our Automatic Brick Making Machines are designed to produce high-quality bricks with minimal manual intervention. These machines are ideal for businesses that need to produce large volumes of bricks quickly while maintaining high standards of quality.

Our automatic machines are equipped with advanced features such as automated brick molding, high-pressure forming, and easy-to-use control systems. This ensures that each brick produced meets the highest quality standards while reducing the need for manual labor and increasing overall productivity.

Why Choose an Ultra Tiles Machine?

At Ultra Tiles Machine, we are committed to providing our customers with the best machinery solutions for their block and brick-making needs. Here’s why you should choose us:

Advanced Technology: We use the latest technology to manufacture machines that deliver high-quality products with minimal labor.

Customization: We offer customized solutions tailored to your specific production needs, ensuring that you get the perfect machine for your requirements.

Durability and Reliability: Our machines are built to last, with high-quality materials and precision engineering ensuring long service life.

Eco-friendly Solutions: We are committed to providing eco-friendly machinery, including Fly Ash Brick Making Machines that help reduce your carbon footprint.

Customer Support: We offer excellent customer support, ensuring that you have the assistance you need at every step of the way.

Conclusion

Whether you're looking for a Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, or Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine is the trusted partner for all your block and brick-making needs.

With our high-quality machines, advanced technology, and exceptional customer service, we guarantee that your production process will be efficient, cost-effective, and reliable.

Contact Ultra Tiles Machine today to learn more about our products and how we can help you take your construction business to the next level.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Hollow Blocks Maker

Hollow blocks maker is a special equipment used to produce hollow bricks, which is widely used in construction material industry. The following is a detailed explanation of the introduction, principle and production capacity of hollow block machine: Hollow blocks maker is a new type of wall material production equipment, which is characterized by its ability to produce environmentally friendly, economical and effective hollow bricks. This kind of block making equipment is suitable for pressing fly ash, river sand, sea sand, mountain sand, mineral powder, slag, stone powder, cinder, coal gangue, tailing slag, chemical slag, etc. as the main raw material for no-burning bricks, steam-cultivated sand bricks, refractory bricks, porous bricks, colorful road bricks and hollow blocks and so on. It is an environmentally friendly building material equipment strongly advocated by the state, which provides an economical, environmentally friendly and practical new wall material solution for the construction industry.

The main structure of the hollow block making machine includes parts such as fabric mechanism, frame, silo, press head, plate supply mechanism, lifting table, control cabinet and brick discharge conveyor frame. These parts work together to realize the whole process of automation from raw material conveying to finished product output.

The working principle of the hollow blocks maker is mainly by feeding the mixture into the mold of the machine and applying a certain pressure, so that the mixture will form blocks with hollow structure inside the mold. This process includes the steps of uniform fabrication of the mixture, press molding of the mold, demolding and transferring of the bricks. The hollow block machine adopts the design of powerful combined unit, the bearing seat of the main shaft of the extrusion system and the mud cylinder are connected as one, which ensures the concentricity of the main shaft and is conducive to the effective and even extrusion, thus ensuring the quality and strength of the hollow blocks.

The production capacity of hollow block maker varies according to various factors such as block size, block model, equipment model, raw material type, working pressure, production efficiency and so on. Generally speaking, hollow block machine has high production efficiency and production capacity. The annual output range of the equipment is usually large, such as the annual output of standard bricks can be between 1000 to 10540 pieces per hour. The specific production capacity needs to be assessed according to the specific configuration of the equipment, the working condition and the production environment and other factors.

It should be noted that the increase in production volume is not only dependent on the equipment itself, but also related to the skill level of the operator, the maintenance of equipment, the quality of raw materials and other factors. Therefore, when using the hollow blocks maker machine for production, various factors need to be considered comprehensively to achieve the best production results and economic benefits.

To summarize, the hollow blocks maker is an efficient and environmentally friendly wall material production equipment with a wide range of application prospects. By understanding its working principle and production capacity, you can better choose and use this equipment to contribute to the development of the construction industry.

This resource is from http://www.haomeibatchplant.com/news/hollow-blocks-maker.html Should you be interested in buying our product, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

Forklift Truck Hire Brisbane – Reliable, On-Site Material Transport with Mr Moffett Pty Ltd

When it comes to transporting heavy materials across Brisbane and South East Queensland, having the right equipment can make all the difference. Whether you’re a builder, landscaper, or supplier, moving bulky, pallet-ready goods like tiles, turf, bricks, or scaffolding efficiently and safely is essential to keeping your project on track.

At Mr Moffett Pty Ltd, we specialise in forklift truck hire across Brisbane and surrounding regions. With a 14-tonne truck and an all-terrain Moffett forklift on board, we offer a simple, flexible, and reliable solution for material transport—direct to your worksite.

What Is Forklift Truck Hire?

Forklift truck hire is the process of renting a truck that comes equipped with a mounted forklift—ideal for picking up, delivering, and unloading palletised materials without needing extra equipment on site. This service is a cost-effective and convenient option for businesses that need materials delivered and placed exactly where they’re needed.

Unlike traditional delivery trucks that require forklifts to be present at the destination, our Moffett-mounted forklifts travel with the truck and are ready to unload the moment we arrive—saving time, labour, and hassle.

Why Choose Forklift Truck Hire in Brisbane?

With so many active construction and landscaping projects across Brisbane and South East Queensland, timely and efficient material delivery is a top priority. That’s where forklift truck hire becomes a valuable asset.

Here are a few reasons why businesses choose forklift truck hire:

Saves Time and Labour: No need for manual unloading or waiting for site forklifts.

On-Site Unloading: Materials can be delivered exactly where you need them.

Cost-Effective: Pay only when you need it—no long-term equipment investment.

Flexible Hire Options: Ideal for both one-off deliveries and ongoing projects.

All-Terrain Capabilities: Suitable for rough or uneven worksites.

What Is a Moffett Forklift?

A Moffett forklift is a versatile, truck-mounted forklift that can be quickly unloaded from the back of a delivery truck. These machines are compact, lightweight, and highly maneuverable—perfect for job sites where space is tight or terrain is rough.

Benefits of using a Moffett forklift include:

Can operate on uneven or muddy surfaces

Doesn’t require a separate trailer or transport

Reduces delivery and unloading times

Offers precision placement of materials

Safe and easy to operate

With this setup, your materials arrive on a 14-tonne truck and are unloaded on-site with minimal disruption.

What Can You Transport With a Forklift Truck?

At Mr Moffett Pty Ltd, we’re equipped to handle a wide range of materials for different industries and projects, including:

✅ Construction Materials

We regularly transport and unload bricks, tiles, timber, steel, concrete blocks, and scaffolding directly onto construction sites across Brisbane.

✅ Landscaping Supplies

Need turf rolls, garden soil, mulch, pavers, or sleepers delivered to a backyard or outdoor project site? We’ve got it covered—no more double handling or backbreaking labour.

✅ Commercial Goods

We also assist businesses with palletised commercial deliveries for retail setups, event equipment, or bulk inventory moves.

✅ Building Projects

If you're working on residential or commercial developments, we’ll ensure your delivery schedule runs smoothly with professional, punctual service.

Why Hire from Mr Moffett Pty Ltd?

We’re not just a transport service—we’re your logistics partner. At Mr Moffett Pty Ltd, we specialise in forklift truck hire backed by years of hands-on experience, a commitment to safety, and a focus on customer satisfaction.

Here’s why customers across Brisbane trust us:

🚚 14-Tonne Capacity Truck

Our heavy-duty truck can carry large loads of materials, making fewer trips and saving you time.

🦾 Moffett All-Terrain Forklift

Perfect for construction zones, muddy landscapes, and uneven surfaces—ready to unload the moment we arrive.

📍 Wide Service Area

We proudly operate across Brisbane, Gold Coast, Sunshine Coast, Toowoomba, and Redland Bay.

📦 On-Site Pickup & Delivery

We collect materials from suppliers or depots and deliver them straight to your job site, hassle-free.

⏱ Flexible Hire Options

Need us for a day or a few weeks? We offer both short-term and long-term hire depending on your project requirements.

👷 Experienced Operators

Our professional team understands the challenges of heavy-load delivery and works safely and efficiently every time.

The Process – How It Works

Hiring a forklift truck from Mr Moffett Pty Ltd is simple and straightforward:

Get in Touch – Call or fill out our online form to request a quote.

Schedule Your Delivery – Tell us what you need moved and when.

We Pick Up & Deliver – Our driver arrives with the forklift onboard, ready to unload.

Materials Delivered Safely – We place your items exactly where you need them—saving time and effort.

Who We Work With

We serve a wide range of clients, including:

Builders and construction companies

Landscapers and gardening professionals

Tile and brick suppliers

Event companies and commercial clients

Residential project managers

No matter the job, our mission is to help you move materials efficiently, safely, and with minimal disruption to your project.

Get in Touch Today

If you’re looking for forklift truck hire in Brisbane, trust Mr Moffett Pty Ltd for reliable service, competitive rates, and expert logistics support. Our Moffett-equipped trucks are ready to help you complete your project on time and on budget.

📞 Contact Details:

Business Name: Mr Moffett Pty Ltd Address: Hume Ct, Mount Ommaney QLD 4074, Australia Phone: 404 223 303 Website: https://mrmoffett.com.au Hours: Monday – Friday: 6:00 AM – 6:00 PM

🚛 Services We Offer:

Truck Rental with Moffett Forklift: 14-tonne truck hire with onboard forklift for easy loading and unloading

Construction & Building Material Delivery: Transport of bricks, tiles, sand, scaffolding, and more

On-Site Pickup and Drop-Off: We deliver directly to your worksite—no need to coordinate multiple contractors

Let Mr Moffett Pty Ltd take the heavy lifting off your hands. Contact us today to arrange your forklift truck hire in Brisbane and experience the convenience of safe, on-site delivery done right.

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

In the dynamic world of construction, innovative technologies are reshaping the way we build. One such groundbreaking advancement is the semi-automatic brick making machine. As the demand for efficient and cost-effective construction solutions continues to rise, these machines have become a game-changer in the industry. In this article, we’ll explore the benefits and features of semi-automatic brick making machines, and we’ll also shed light on the importance of choosing the right concrete block machine manufacturer.

Understanding Semi-Automatic Brick Making Machines:

Semi-automatic brick making machines have gained popularity for their ability to streamline the brick production process. These machines strike a perfect balance between manual and fully automatic systems, allowing for increased efficiency without compromising on control. With features like auto-material feeding and hydraulic pressing, these machines ensure consistent brick quality while minimizing labor requirements.

Key Features of Semi-Automatic Brick Making Machines:

a. Auto-material Feeding: The automated material feeding system reduces the need for manual intervention, enhancing overall efficiency.

b. Hydraulic Pressing: The hydraulic pressing mechanism ensures uniform and high-quality brick production, meeting industry standards.

c. User-Friendly Interface: Most semi-automatic brick making machines come equipped with user-friendly interfaces, making operation and maintenance hassle-free.

Benefits of Semi-Automatic Brick Making Machines:

a. Cost-Effective: These machines offer a cost-effective solution by reducing labor costs and increasing production rates.

b. Consistent Quality: The automation features ensure consistent brick quality, meeting the stringent requirements of construction projects.

Choosing the Right Concrete Block Machine Manufacturer:

When investing in a semi-automatic brick making machine, the choice of manufacturer plays a crucial role. Consider the following factors:

a. Experience and Reputation: Opt for a manufacturer with a proven track record and positive reviews in the industry.

b. Technology and Innovation: Choose a manufacturer that incorporates the latest technology and innovation into their machines.

c. After-Sales Support: Ensure the manufacturer provides comprehensive after-sales support, including maintenance and troubleshooting assistance.

Conclusion:

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it’s imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

View Source: https://medium.com/@raytoneblockm/revolutionizing-construction-with-semi-automatic-brick-making-machines-e8c57ff299f2

0 notes

Text

AAC Block Machine | Automatic & High-Efficiency Block Production

AAC (Autoclaved Aerated Concrete) block machines are advanced manufacturing systems designed to produce lightweight, durable, and energy-efficient building blocks that are widely used in modern construction. These machines utilize a combination of fine aggregates, cement, lime, gypsum, water, and a rising agent to create blocks that are cured in an autoclave under high pressure and temperature, resulting in highly porous and thermally insulating structures. AAC block machines come in various configurations, including semi-automatic and fully automatic models, to cater to different production capacities and operational needs. They offer significant advantages such as faster construction time, reduced dead load on structures, superior fire resistance, sound insulation, and improved seismic performance. Their eco-friendly manufacturing process, which generates minimal waste and uses recyclable materials, makes AAC technology a sustainable alternative to traditional clay bricks and concrete blocks. These machines are ideal for producing a range of products including blocks, panels, and lintels for both residential and commercial construction projects. With PLC-based controls, automated material handling, and precision molding, modern AAC block machines ensure consistent quality and high output with minimal labor. Widely adopted by construction companies, real estate developers, and infrastructure firms, AAC block machines are a valuable investment that enhances productivity and meets the growing demand for green building materials. Whether for a startup business or an established manufacturer, investing in a reliable AAC block machine offers long-term benefits in terms of cost savings, product quality, and environmental compliance.

#aac plant manufacturer#aac block machinery manufacturer#aac block plant cost#AAC block manufacturing machine cost#aac block machine#aac block#aac bricks plant cost

0 notes

Text

Selecting the right concrete block making machine for your construction business is a significant decision that can impact your productivity, profitability, and overall success. Benny Enterprises is the best choice for all your needs, we are the finest Concrete Brick Making Machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes