#Ketchup Packaging Machine

Explore tagged Tumblr posts

Text

Tomato Paste and Ketchup Packaging Machine Africa

#tomato ketchup packaging machine#tomato ketchup pouch packing machine#tomato paste packing machine#tomato sauce#ketchup packaging machine supplier in africa#ketchup packaging machine#ketchup packaging machine africa

0 notes

Text

PDM Paketleme ve Dolum Makineleri

PDM Packaging and Filling Machinery

www.pdmmakina.com.tr

#paketleme#sıvı#süt#bal#ketçap#mayonez#viskoz#packing#packaging#filling#machinery#machine#makina#dolum#tesis#products#ketchup#mayonnaise#honey#icecream#pdmmachinery#turkey#yoghurt#ayran#performans#kalite#quality#performance

0 notes

Text

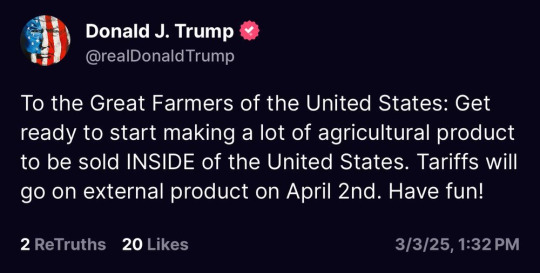

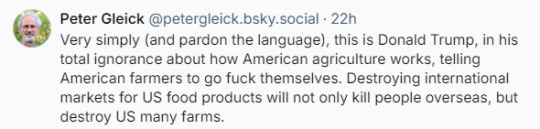

Donald fucked around, we get to find out

Via Narcity: "Starting Tuesday, Canada is slapping new counter-tariffs on U.S. products, targeting $30 billion worth of American goods. And that's just the beginning — Trudeau says an additional $125 billion in tariffs will roll out in the next three weeks if things don't de-escalate."

What follows is the full list of affected American products:

Food & drink

Poultry & eggs — chicken, turkey, goose, duck and their byproducts (fresh, frozen, preserved)

Dairy products — milk, cream, butter, ice cream, yogurt, cheese

Fruits & vegetables — tomatoes, beans, snap peas, citrus fruits, melons, peaches, nectarines, berries

Coffee & tea

Spices & flavourings — pepper, vanilla, dried spices (cinnamon, turmeric, curry, etc.)

Sauces & condiments — soy sauce, ketchup, mustard, mayonnaise, salad dressing, peanut and nut butters

Grains & baking essentials — wheat, rye, rice, barley, oats, flour, mixes and doughs

Oils & fats — canola, sunflower, safflower, palm, peanut and nut oils; margarine and butter substitutes

Sugars & sweeteners — honey, cane sugar, beet sugar, maple sugar and syrup, sugar syrups, molasses

Packaged foods — pasta, pizza, bread, cakes, biscuits, cereal-based foods, soup and broth, pickles, gum, candies, chocolate

Supplements — whey powder, casein, fish oil

Beverages & alcohol — orange juice, soda beer, wine, cider, spirits, liqueurs, coolers, bitters

Tobacco products

Raw & processed tobacco — unmanufactured tobacco, tobacco extracts, chewing tobacco, pipe tobacco

Cigarettes & cigars — cigars, cheroots, cigarillos and cigarettes

Nicotine products — vapes, e-cigarettes, nicotine patches and other smokeless tobacco products

Personal care products

Cosmetics & skincare — makeup, nail polish and manicure tools, hair care, deodorants, soaps and cleansers, razors, shaving products, bath products

Electronic tools — electric razors and clippers, hair dryers, curling irons, flatirons

Fragrances — perfumes, room deodorizers

Oral care — toothpaste, dental floss

Paper products — toilet paper, tissues, napkins

Home & office items

Kitchenware — paper and plastic tableware, storage containers, glassware, cutlery and utensils, kitchen knives, scissors

Furniture & home goods — metal, wooden and plastic furniture; chairs; mattresses and bedding; lighting; storage racks

Home textiles — carpets, rugs, blankets, bed linens, table and kitchen linens, curtains, cleaning cloths

Paper & books — stationery, notebooks, memo pads, binders, file folders, carbon sets, albums, printed materials

Office supplies — letter openers, pencil sharpeners

Artwork — paintings, drawings, pastels

Clothing & accessories

Clothing — shirts, pants, dresses, suits, underwear, hosiery, pyjamas, sweaters, activewear, swimwear, outerwear, baby clothes

Activity-specific attire — diving suits, ski suits, protective gear, life jackets, climbing harnesses, work belts, safety headgear, animal saddlery

Accessories — footwear, hats, gloves, scarves, belts, neckties, jewelry

Bags & luggage — handbags, wallets, suitcases, briefcases, backpacks

Electronics & appliances

Household appliances — refrigerators, freezers, dishwashers, washing machines and dryers, stoves, barbecues, fans, humidifiers, vacuum cleaners, fabric steamers

Countertop appliances & kitchen gadgets — blenders, food mixers, juicers, microwaves, grills, rice cookers, coffee makers, toasters

Gaming & entertainment — video game consoles, board games, card games

Vehicles & machinery

Motorcycles & recreational vehicles — motorbikes, sidecars, recreational boats, drones

Yard equipment — snowblowers, lawnmowers

Tools — saws, pliers, wrenches, spanners, hammers, drills, cutting tools, screwdrivers, staple guns, vices, lighters, pneumatic tools, padlocks

Rubber tires

Building materials

Silica & quartz sands

Plastic wall, floor & ceiling coverings

Window and door fixtures — window and door components and frames, shutters, blinds

Bathroom fixtures — plastic and ceramic baths, showers, sinks and wash basins, toilets, bidets, urinals

Plastic packaging

Wood products — planks, chips, veneer sheets, particle board, MDF, fibreboard, laminated wood, posts, beams, floor panels, wood pulp

Cardboard & paper — cartons, boxes, cases, paper bags

Textiles — tarps, tents, canopies, sails, woven fabric

Precious metals & gemstones — diamonds, silver, palladium

Weapons & ammunition

Firearms — pistols, revolvers, rifles, shotguns, air guns

Ammunition — bullets, cartridges, pellets

"Have fun!"

9 notes

·

View notes

Text

Fuck digital grocery labels. "We'll cut 20% of our paper waste". No, you're replacing an easily recycled renewable resource with electronic waste that almost certainly will not be recycled.

"We'll be able to do in minutes what might take employees a week to do". No, it only takes a week because you don't hire enough staff to keep your store functioning properly and they're always being dragged away by customers who can't find anyone to help them because you've eliminated the customer service desk and you've instituted policies where the stocker has to physically walk the customer to the item instead of just telling them.

"You'll be able to scan a QR code to find out if a product has gluten in it" It takes five seconds to go to google, do a voice search for "Heinz Ketchup Gluten" and get an answer using tech we already have.

"Coca-Cola did surge pricing on their vending machines in the 1990s and it failed so store owners won't do surge pricing" No, people just bought non-vending machine coca-cola because they had the ability to go elsewhere and they knew the price was inflated because it's easy to monitor one machine's prices. If every grocery store is practicing surge pricing, there's no alternative, and we'll lose touch of what a "normal" price is because while it's possible to keep a single cola machine's prices in mind, it's impossible to commit every item in the store to memory and know when you're being price gouged. It's price fatigue and the corporations know this. "Surge pricing will work in reverse, if a bunch of milk is about to go bad, stores will discount the milk" No, stores are going to get lazier about buying excess product because they know that if the gamble of buying excess product doesn't lead to more sales, they can offload bad food onto customers who are just trying to catch a break, and in turn those customers will have to make a return trip for full-priced non-expired milk. That's not reducing waste, that's creating waste.

Also, you KNOW these motherfuckers are gonna price products real low sometimes to encourage bulk buying and then five minutes later when 20 people have 60 units in their cart but have not reached the checkout stands yet, they'll jack up the price suddenly, and exhausted consumers will have to remain vigilant at checkout to spot the difference and then have to go through the humiliation of asking the cashier to put those items back.

Grocery shopping is exhausting. It's a constant fight to not give into deceitful packaging, nonsensical '4 jumbo rolls = 10 regular rolls" label math, psychological pressure to buy buy buy, constant vigilance for bargains, the uptempo music trying to put you in a manic purchasing state...... They really are just trying to push even normal people into such exhaustion that they will pay extra just to fucking escape.

Fuck everything about this.

3 notes

·

View notes

Text

Pouch Filling Machine: The Definitive Guide for Modern Packaging Solutions

What is a Pouch Filling Machine? A pouch filling machine is an automated packaging system designed to fill pre-formed pouches with liquid, powder, granules, or paste-based products. These machines are engineered to perform multiple tasks such as pouch feeding, product dosing, filling, sealing, coding, and sometimes even cutting or perforating—all in a single streamlined process.

Pouch filling machines are critical to ensuring speed, hygiene, product integrity, and cost efficiency in modern production lines.

Types of Pouch Filling Machines

Vertical Form Fill Seal (VFFS) Machines These machines form pouches from a roll of film, fill them vertically, and then seal them. Ideal for products like snacks, rice, sugar, and detergents.

Horizontal Form Fill Seal (HFFS) Machines Pouches are formed horizontally, making them perfect for solid and fragile items like biscuits, chocolates, and wrapped confectionery.

Pre-Made Pouch Filling Machines These handle pre-formed pouches (like doypacks or zipper bags), filling and sealing them. They are widely used for liquids, sauces, oils, and ready-to-eat foods.

Rotary Pouch Filling Machines Known for their compact design and high speed, rotary machines handle all pouch filling stages in a circular layout, offering consistent performance and versatility.

Applications Across Industries Food & Beverage Fruit juices, milk, water, ketchup, sauces, oil, spices, flour, snacks, grains

Use of food-grade contact parts, anti-drip nozzles, and nitrogen flushing for extended shelf life

Pharmaceutical & Nutraceutical Oral liquids, powders, capsules, herbal supplements

Requires adherence to GMP and FDA standards

Cosmetic & Personal Care Lotions, shampoos, gels, creams, serums

Need high viscosity handling and anti-leak sealing

Chemical & Agrochemical Liquid pesticides, fertilizers, and industrial chemicals

Involves corrosive resistance materials like SS316L or PTFE coatings

Key Features of Modern Pouch Filling Machines

Servo-Driven Dosing System Allows precise product fill levels with minimal variation, enhancing consistency.

Touchscreen HMI with PLC Control Offers easy recipe changes, fault diagnostics, and real-time performance data.

Automatic Pouch Detection The machine detects pouch presence and alignment before initiating filling.

Nitrogen Flushing Used to remove oxygen from the pouch, increasing product shelf life.

Zipper Opening and Closing Mechanism Essential for resealable pouches such as those used for dry fruits, coffee, and snacks.

High-Speed Operation Modern machines can fill up to 120 pouches per minute, depending on pouch size and product type.

Advantages of Using a Pouch Filling Machine Hygienic Packaging: Contactless filling and sealing in a clean environment

Reduced Labor Cost: Fully automated lines require minimal manpower

Higher Output: Consistent speeds and reduced downtime boost production

Versatile Packaging: Can handle stand-up, flat, zipper, gusseted, or spouted pouches

Enhanced Brand Appeal: Clean, wrinkle-free sealing with clear date coding

Minimal Wastage: Drip-proof nozzles and accurate dosing reduce overfilling or spillage

Top Considerations Before Buying

Product Type Is it a powder, granule, paste, or liquid? Each needs different dosing systems (auger filler, piston filler, volumetric cup filler, etc.).

Pouch Format and Size Ensure the machine supports your pouch type: flat, stand-up, zipper, three-side seal, or four-side seal.

Production Volume Calculate your expected pouches per hour and match it with the machine's speed.

Space Availability Rotary machines are compact, while VFFS may need vertical clearance.

Compliance and Certifications Machines for food and pharma should follow GMP, ISO 22000, or FSSAI standards.

Estimated Pricing in India (2025) Machine Type Price Range (INR) Capacity (Pouches/Min) Manual Pouch Filler ₹70,000 – ₹1.5 lakh 10–20 Semi-Automatic Machine ₹1.5 – ₹4 lakh 20–40 Automatic VFFS Machine ₹5 – ₹18 lakh 30–100 Rotary Pre-Made Pouch Filler ₹20 lakh – ₹1 crore+ 60–120

Prices depend on machine materials, number of filling heads, pouch size, and customization.

Top Indian Manufacturers of Pouch Filling Machines Nichrome India Ltd.

Durga Packaging Machine

Uflex Limited

Sampack India Pvt. Ltd.

Mamata Machinery Pvt. Ltd.

These companies offer end-to-end solutions including pouch making, filling, sealing, and after-sales support with installation and operator training.

Common Accessories and Integrations Coding Machines (Inkjet/thermal) for MRP & date

Weighing Systems

Checkweighers and Metal Detectors

Nitrogen Flushing Units

Pouch Pick-and-Place Robots

Pouch Counting and Batching Units

Routine Maintenance Tips Lubricate moving parts every 15 days

Calibrate dosing systems monthly

Replace sealing jaws annually or as needed

Inspect sensors and PLC connections for moisture or dust

Clean nozzles and product pathways daily

Future of Pouch Filling Technology AI-Powered Fill Accuracy Adjustment

Self-Cleaning Filling Valves

Real-Time Batch Tracking

Smart HMI Panels with Cloud Storage

Recyclable Pouch Compatibility

Conclusion A pouch filling machine is an indispensable part of modern packaging automation. Whether you’re in the food, pharma, cosmetic, or chemical industry, the right machine can significantly improve productivity, reduce human error, and increase your product’s market appeal. With rising consumer demand for flexible and eco-friendly packaging, investing in the right pouch filling solution ensures long-term operational success and brand growth.

0 notes

Text

Boost Your Production Efficiency with the Right Paste Filling Machine

In the world of manufacturing and packaging, efficiency, precision, and hygiene are critical. One piece of equipment that meets all these standards is the paste filling machine. Whether you're in the food, cosmetics, pharmaceutical, or chemical industry, paste filling machines play a crucial role in streamlining production processes. In this blog, we'll dive deep into what a paste filling machine is, how it works, its types, and why choosing the right one can significantly benefit your business.

What is a Paste Filling Machine?

A paste filling machine is a type of packaging equipment designed specifically to fill thick, viscous substances into containers such as bottles, jars, or tubes. These substances can include products like sauces, creams, gels, honey, peanut butter, shampoo, ointments, adhesives, and other semi-solid materials.

Why Invest in a Paste Filling Machine?

Using a manual method to fill paste products can lead to inconsistency, waste, and longer production times. Here’s where a high-quality paste filling machine makes a difference:

Accuracy: Reduces product wastage by delivering precise quantities.

Speed: Increases production capacity with higher filling speeds.

Hygiene: Ensures cleanliness and product safety, especially important for food and pharmaceutical applications.

Ease of Use: User-friendly controls and minimal maintenance.

Cost-Effective: Reduces labor costs and boosts productivity over time.

Types of Paste Filling Machines

There are several types of paste filling machines available in the market, tailored for different needs:

Manual Paste Filling Machine Ideal for small businesses or startups. These machines are affordable and suitable for low-volume production. No electricity is required, and they are easy to operate.

Semi-Automatic Paste Filling Machine Suitable for medium-sized production. These machines need minimal manual intervention and offer a good balance between cost and efficiency.

Automatic Paste Filling Machine Perfect for large-scale industries. These machines work at high speeds, require very little human interaction, and are compatible with automated production lines.

Pneumatic Paste Filling Machine Operated with compressed air, these machines are commonly used for filling explosive or flammable materials. They are known for their precision and are widely used in chemical industries.

Applications of Paste Filling Machines

Paste filling machines are used in a variety of industries:

Food Industry: Tomato ketchup, mayonnaise, honey, sauces, spreads, etc.

Cosmetics Industry: Creams, gels, lotions, shampoo, etc.

Pharmaceutical Industry: Ointments, balms, gels, etc.

Chemical Industry: Adhesives, paints, waxes, etc.

How to Choose the Right Paste Filling Machine?

Here are a few factors to consider when selecting a paste filling machine:

Viscosity of the Product: Different products require different pump mechanisms.

Production Volume: Choose based on your daily production needs.

Container Type: Ensure the machine supports your specific container shapes and sizes.

Budget: Prices can range widely depending on the level of automation and capacity.

Brand and Support: Opt for a reliable paste filling machine manufacturer offering good after-sales service.

Paste Filling Machine Price in India

In India, the price of paste filling machines varies based on the machine’s type and features. A manual paste filling machine might start from ₹10,950, while automatic paste filling machines can go up to ₹1,41,999 or more. Always compare different options and reviews before making a purchase.

Conclusion

Investing in the right paste filling machine can transform your production line by ensuring speed, accuracy, and efficiency. Whether you're a small business or a large-scale manufacturer, there’s a filling solution to meet your needs. Don't forget to consider factors such as product type, volume, and budget when making your choice.

With rising demand for automation and improved hygiene standards, having a reliable paste filling solution isn’t just an option—it’s a necessity. Start exploring your options today and take your production quality to the next level!

1 note

·

View note

Text

Sauce Packaging Machines: Features and Advantages

In the food industry, packaging plays a critical role in preserving product quality, ensuring freshness, and enhancing shelf appeal. Sauce packaging machines are designed to meet the unique needs of liquid and semi-liquid food products, such as ketchup, mayonnaise, soy sauce, salad dressing, and hot sauce. These machines are essential for automating the packaging process, ensuring consistency, speed, and reliability.

In this blog, we will explore the features and advantages of sauce packaging machines and why they are a vital part of the modern food manufacturing process.

Key Features of Sauce Packaging Machines

1. Versatility in Packaging Sizes

One of the most significant features of sauce packaging machines is their ability to handle various container sizes. Whether it's small pouches, glass bottles, or large bulk containers, these machines can be adapted to accommodate a wide range of packaging formats. pouch packaging machines This flexibility allows manufacturers to cater to different customer preferences, from single-serving packages to family-sized containers.

2. Precise Filling Mechanism

Sauces often have varying viscosities, ranging from thin liquids to thicker, more paste-like textures. Sauce packaging machines are equipped with precise filling mechanisms, such as piston fillers or auger fillers, which ensure accurate portioning regardless of the consistency of the sauce. This eliminates the risk of overfilling or underfilling, which can lead to waste and product inconsistency.

3. Automatic Sealing and Capping

Sauce packaging machines come equipped with automated sealing and capping features. This helps prevent contamination, ensures product freshness, and extends shelf life. For example, many machines use induction sealing, which uses electromagnetic waves to create a hermetic seal on plastic containers, preventing leakage and spoilage. This feature is particularly important for sauces that require airtight packaging to maintain flavor and consistency.

4. High-Speed Operation

The demand for fast production lines in the food industry is growing, and sauce packaging machines are designed to keep up with these demands. These machines operate at high speeds, ensuring that large quantities of sauces vacuum packaging machine can be packaged in a short amount of time. Whether it's for small batch production or large-scale manufacturing, high-speed packaging is essential for maintaining efficiency and meeting customer demand.

5. User-Friendly Interface

Modern sauce packaging machines come equipped with easy-to-use control panels that allow operators to manage and adjust settings without the need for specialized training. The digital interface typically features touchscreen controls, allowing for seamless operation. Additionally, the machines often offer automatic error detection and diagnostics, ensuring that any issues can be addressed quickly and without disrupting production.

6. Sanitary Design

In the food industry, hygiene is a top priority, especially when dealing with products like sauces that can easily spoil if contamination occurs. Sauce packaging machines are designed with sanitation in mind, featuring easy-to-clean surfaces and parts that meet food safety regulations. Many machines are made of stainless steel, a material known for its durability and resistance to corrosion, which is crucial for maintaining cleanliness during the packaging process.

7. Customization Options

Sauce packaging machines can be customized to meet the specific needs of a business. Whether it’s for small-batch artisanal sauces or high-volume production, manufacturers can adjust various parameters, such as speed, filling volume, and the type of packaging. Customization allows businesses to optimize their packaging lines and enhance productivity without compromising on product quality.

Advantages of Sauce Packaging Machines

1. Increased Efficiency

The automation provided by sauce packaging machines significantly boosts the efficiency of the packaging process. By reducing the need for manual labor, these machines streamline production lines and eliminate human error. This leads to faster production cycles, more consistent results, and ultimately, a more profitable operation. The reduction in labor costs also makes it easier for companies to maintain competitive pricing.

2. Enhanced Product Consistency

Consistency is key when it comes to sauce packaging. A manual packaging process can lead to variability in the amount of sauce per container, affecting the quality and consumer experience. Sauce packaging machines eliminate this inconsistency by ensuring that each container is filled with the precise amount of sauce. This is particularly important for businesses looking to maintain a strong brand image by offering products with consistent taste, texture, and presentation.

3. Reduced Waste

Waste reduction is another major benefit of using sauce packaging machines. With manual packaging, it's easy for sauces to spill or be overfilled, leading to wasted product. Automated machines are designed to minimize spillage, ensuring that each drop of sauce is utilized efficiently. In the long run, this reduces product loss and helps businesses improve their bottom line by making the most of their raw ingredients.

4. Improved Product Quality and Shelf Life

Sauces can be highly susceptible to contamination and degradation if not properly packaged. Sauce packaging machines help maintain the quality and shelf life of sauces by providing airtight seals and eliminating exposure to external contaminants. This extends the freshness of the product, which is particularly important for sauces that do not contain preservatives or have a short shelf life. Additionally, packaging machines ensure that sauces are handled gently during the process, preserving their delicate flavors and textures.

5. Cost-Effective

While the initial investment in sauce packaging machines may be substantial, the long-term savings can be significant. By increasing production efficiency, reducing waste, and minimizing labor costs, these machines pay for themselves over time. Furthermore, automated packaging processes often lead to a reduction in energy consumption, which contributes to overall cost savings.

6. Improved Hygiene and Safety

In the food industry, safety and hygiene are critical. Sauce packaging machines are designed to meet strict hygiene standards, preventing contamination during the packaging process. Features such as sealed systems and clean-in-place (CIP) functionality allow for easy sanitation and reduce the risk of foodborne illnesses. This is essential for complying with food safety regulations and maintaining consumer trust.

7. Scalability

For businesses looking to scale up production, sauce packaging machines offer the flexibility to expand production volumes without a significant increase in labor costs or time. Whether a company is moving from small-batch to large-scale production or adapting to seasonal demand fluctuations, these machines can be easily adjusted to accommodate growth. This scalability ensures that businesses can meet market demands without sacrificing quality or efficiency.

Conclusion

Sauce packaging machines are indispensable for modern food production lines. They offer numerous advantages, including increased efficiency, consistency, waste reduction, and improved product quality. These machines are essential for businesses in the sauce manufacturing industry looking to meet growing consumer demands while maintaining high standards of hygiene and product integrity.

By investing in a high-quality sauce packaging machine, businesses can streamline their operations, reduce costs, and improve customer satisfaction. Whether you're producing ketchup, hot sauce, or gourmet salad dressings, these machines are designed to optimize the packaging process, ensuring that your products are delivered in the best possible condition.

If you are considering upgrading your packaging process or entering the sauce manufacturing industry, investing in a sauce packaging machine is a step toward greater productivity, efficiency, and profitability.

0 notes

Text

Nichrome’s Ketchup Packaging Machine: Innovative & Precise Solutions

Nichrome’s ketchup packaging machine ensures precise filling, minimal wastage, and superior packaging quality for sauces and condiments.

Nichrome’s ketchup packaging machine offers high-speed, accurate filling and sealing for sauces and condiments. With advanced technology and minimal wastage, this machine ensures superior packaging quality and extended shelf life. Choose Nichrome for reliable ketchup packaging solutions tailored to your business needs.

Read Article:

0 notes

Text

Tomato Paste and Ketchup Packaging Machines | Africa | Nichrome

HFFS and Multitrack machines for 4 side seal pouches upto 100 gms; Pick Fill Seal machines; bottling lines and machines for packing Standy Pouch / DOYPACK Pouches- explore Nichrome's offerings for packing tomato paste/ketchup. For more infoarmation about tomato ketchup pouch packing machine visit us:https://africa.nichrome.com/applications/food/tomato-paste-ketchup-packaging-machine.php

#tomato ketchup pouch packing machine#tomato ketchup packaging machine#ketchup packaging machine#Sauces

0 notes

Text

The Minimalist's Guide to Maximum Parenting

In a world where more is often mistaken for better, what if the secret to raising well-adjusted, creative, and happy children lies in doing less? Welcome to the counterintuitive realm of simplicity parenting, where less stuff means more substance, and where the absence of clutter paves the way for the presence of mind.

Picture this: You're standing in a toy store, surrounded by a cacophony of blinking lights and electronic chirps. Your wallet's trembling, your child's eyes are as wide as saucers, and you're wondering if you need a bigger house just to store all these "must-have" gadgets. Now, imagine walking out of that store empty-handed, feeling like you've just won the parenting lottery. Congratulations! You've just taken your first step into the world of simplicity parenting.

But wait, isn't denying your child the latest gizmo tantamount to setting them up for a lifetime of therapy? Won't they be the odd one out, the kid whose parents are stuck in the Stone Age? Fear not, for in this case, less truly is more. By curating your child's toy collection to a few high-quality, open-ended options, you're not depriving them – you're gifting them the most valuable currency of childhood: imagination.

Consider the humble cardboard box. To the untrained eye, it's packaging destined for recycling. But to a child armed with imagination, it's a spaceship, a castle, a time machine. By reducing material clutter, we're not taking away – we're making space for creativity to flourish. It's like Marie Kondo met Mary Poppins, and they decided to redecorate your child's playroom.

Now, let's talk about quality time. In the age of overscheduling, where toddlers have busier social calendars than most adults, simplicity parenting dares to ask: What if we just... hung out? Radical, I know. But hear me out. Instead of shuttling little Timmy from soccer to piano to underwater basket weaving, what if you spent an afternoon making a meal together? You might discover that your child is a budding chef, or at the very least, learn that spaghetti makes excellent hair gel.

This approach to family time isn't just about fun (although that's a delightful side effect). It's about building emotional intelligence, strengthening family bonds, and teaching life skills. It turns out that chopping vegetables together is not just meal prep – it's a masterclass in patience, coordination, and the art of conversation.

But simplicity parenting isn't all about what you do – it's also about what you don't do. It's about stepping back and letting your children explore their independence. It's the art of biting your tongue when your five-year-old insists on wearing rain boots on a sunny day or creates a breakfast smoothie with ketchup as the main ingredient. These moments of seeming chaos are actually laboratories of learning, where children experiment with decision-making and experience natural consequences.

Think of it as free-range parenting meets minimalism. You're not neglecting your parental duties; you're trusting in your child's innate ability to figure things out. It's like you're the director of a very low-budget, highly improvised play called "Life Skills 101."

Lastly, let's talk about emotional well-being. In a world that seems to run on stress and schedules, simplicity parenting advocates for creating pockets of calm. It's about making space for feelings, for reflection, for just being. Imagine a daily family "quiet time" where everyone gets to express their thoughts and feelings. It's like a group therapy session, but with more hugs and possibly cookies.

This focus on emotional well-being isn't just feel-good fluff. It's about equipping our children with the tools to navigate the complex emotional landscape of life. By creating a home environment that prioritizes mental clarity and emotional expression, we're essentially giving our kids a superpower – the ability to understand and manage their feelings.

So, dear parents, as you stand at the crossroads of excess and simplicity, remember this: In the grand department store of parenting philosophies, simplicity might not be the flashiest option on the shelf. It doesn't come with bells and whistles, or promise to turn your child into the next Einstein overnight. But what it offers is something far more valuable – the space for your child to grow, to imagine, to feel, and to become authentically themselves.

In embracing simplicity parenting, you're not just decluttering your home – you're clearing the way for a richer, more meaningful family life. And who knows? You might just find that in simplifying your approach to parenting, you've maximized your family's happiness. Now that's what I call a parenting hack worth sharing.

If you’ve enjoyed this article please consider sharing it or buy me a Coffee

0 notes

Text

Which equipment are used in the processing of tomato?

Divyom Process Machinery & Equipment offers a comprehensive range of equipment essential for the efficient processing of tomatoes into various products such as sauces, ketchup, puree, commercial sauce making equipment, tomato canning machine, tomato paste packaging machine, tomato processing equipment, industrial tomato sauce machine, commercial tomato sauce making machine and paste. Each piece of equipment is designed to ensure high-quality output, hygiene, and operational efficiency.

1. Tomato Washer: The first step in tomato processing is thorough washing. The tomato washer efficiently removes dirt, pesticides, and other impurities from the tomatoes, ensuring that only clean produce enters the processing line.

2. Tomato Crusher: After washing, the tomatoes are fed into a crusher, which breaks them down into smaller pieces. This step is crucial for preparing the tomatoes for further processing, such as pulping or juicing.

3. Pulper and Juice Extractor: The crushed tomatoes are then passed through a pulper, which separates the pulp from the seeds and skin. The juice extractor further processes the pulp to extract tomato juice, which can be used in various products like sauces and soups.

4. Preheater: The extracted tomato juice or pulp is passed through a preheater, where it is heated to a specific temperature. This process helps in reducing microbial load and enzyme activity, ensuring a longer shelf life for the final product.

5. Evaporator: For products like tomato paste or concentrate, the juice or pulp is transferred to an evaporator, which removes excess water content. This process increases the concentration of the tomato solids, giving the product a thicker consistency.

6. Sterilizer: The concentrated product is then sterilized to eliminate any remaining microorganisms, ensuring that it is safe for consumption and has an extended shelf life.

7. Filling and Packaging Machine: The final step involves the filling of the processed tomato product into bottles, cans, or pouches using automated filling machines. These machines ensure accurate filling and sealing, maintaining the product's freshness and quality.

8. Pasteurizer: After filling, the product may undergo pasteurization to further extend its shelf life by destroying any remaining pathogens.

Divyom Process Machinery & Equipment provides not only these essential machines but also customized solutions to meet the specific requirements of different tomato processing operations, ensuring efficient, high-quality production.

For more details, please contact us!

Website :- www.divyomprocessmachinery.com

Contact No. :- +91–8920336244

Email :- [email protected]

#Tomato Processing Machine#Tomato Processing Machine Manufacturer#Tomato Processing Machine Supplier

0 notes

Text

"Keeping It Clean: How SEPPA’s Rita SRM Series Meets the Demands of High-Volume Production"

Glass bottles continue to be a popular packaging solution in various industries due to their sustainability, durability, and aesthetic appeal. However, manufacturers are very concerned about how difficult it will be to clean and maintain these bottles, particularly when recycling is involved. SEPPA's Rita SRM Series Automatic Glass Bottle Washing Machines is an unmatched solution that combines high efficiency and state-of-the-art technology to serve a variety of industries such as ketchup, juice, soft drinks, brewers, and distilleries. We examine the salient characteristics and benefits of these devices below, which establish their superiority for companies that prioritize utmost productivity and hygiene.

1. Advanced Multi-Soak Tanks for Thorough Cleaning

One of the most notable aspects of the Rita SRM Series is the incorporation of 3 to 4 multi-soak tanks, which are intended to provide an extensive soaking procedure. Businesses that handle excessively unclean bottles will find this feature especially helpful. The prolonged soaking time ensures that all residues, whether from beverages or external contaminants, are loosened and ready for the subsequent high-pressure sprays. This is critical for companies that rely on flavor purity, such as breweries and distilleries.

2. High-Pressure Sprays for Comprehensive Washing

High-pressure sprays on the Rita SRM Series machines clean bottles on the interior as well as the outside. The constant movement of the main carrier chain exposes the bottles to these sprays for an extended length of time, maximizing cleaning efficiency. This function is critical for the dairy and juice sectors because any residue left behind can cause spoiling or contamination, reducing product quality and shelf life.

3. Automatic Label and Foil Removal

The removal of labels and foils poses a distinct problem in the bottle cleaning procedure. The SEPPA Rita SRM Series features label separators that successfully remove all labels and foils without the need for pre-washing. The machine is extremely efficient because of the labor and time savings provided by this automated procedure. This capability will be especially helpful to the ketchup and soft drink industries, as these bottles frequently have shrink wrap or numerous layers of labels that are difficult to remove by hand.

4. Energy-Efficient and Eco-Friendly Operations

All sectors of the economy are prioritizing waste reduction and energy conservation in the current ecologically conscious market. The Rita SRM Series meets this need with energy regeneration and water recycling devices that are built into every stage of the washing process. This results in a large reduction in steam and water use, making the machines both cost-effective and environmentally beneficial. This can result in significant electricity cost reductions and a smaller environmental imprint for large-scale enterprises like breweries and soft drink manufacturing.

5. Automatic Auto-Loader and CAM System for Efficient Bottling Line Integration

The Rita SRM Series is outfitted with a CAM system for out-feed and an automatic auto-loader for in-feed to guarantee smooth integration into current bottling lines. This automated procedure avoids manual handling, lowers the danger of bottle breakage, and assures a consistent flow of bottles through the cleaning process. This capability is especially helpful for high-output businesses, such as soft drinks and juices, because meeting consumer demand requires maintaining a fast-paced production line.

6. Cleaning In Place (CIP) and Optional Caustic Dosing

The Rita SRM Series also has Cleaning in Place (CIP) in the fresh water zone, which is critical for keeping the machine clean and free of pollutants. This system not only cleans but also disinfects, making it ideal for industries such as dairy, where cleanliness is critical. An Automatic Caustic Measuring and Dosing Device can also be included as an option. This makes it possible to precisely dose cleaning agents, which increases the cleaning efficiency of the machine and reduces the possibility of overuse—which can be expensive and possibly hazardous to the environment.

7. Versatility in Handling Different Bottle Sizes

The Rita SRM Series is designed to hold bottles up to 1 liter in capacity, making it versatile enough to handle a wide range of products from various industries. Whether you're working with small juice bottles or larger dairy containers, this machine delivers consistent, high-quality cleaning. Because of its versatility, the Rita SRM Series is an excellent choice for businesses wishing to streamline operations without having to invest in several machines for different bottle sizes.

8. High Output for Demanding Production Environments

The Rita SRM Series is designed to meet high-volume production requirements in many sectors. With its effective soaking and spraying cycles and constant movement of the main carrier chain, this machine can easily handle enormous volumes of bottles. This is especially helpful for soft drink and beer producers, as they must maintain a constant flow of production to meet market demand and downtime can be expensive.

9. Ready for Commissioning and Easy Integration

The fact that the Rita SRM Series machines are delivered ready for commissioning is one of their main benefits. This implies that they may be easily installed and integrated into your production line with little downtime after they are delivered. This capability is extremely useful in fast-paced industries like distilleries and juice makers, where any output delay can result in severe financial losses.

SEPPA’s Rita SRM Series - A Comprehensive Solution for Glass Bottle Cleaning

The ultimate efficiency and technology for bottle washing may be found in the SEPPA Rita SRM Series Automatic Glass Bottle Washing Machines. These machines provide unparalleled performance, energy economy, and ease of integration, with features tailored to meet the specific challenges faced by a variety of industries, including dairy and brewing. Companies who invest in the Rita SRM Series can ensure that their bottles are fully cleaned, pollutants are effectively removed, and production lines run as efficiently as possible.

#automatic glass bottle washer#glass bottle washers#automatic glass bottle cleaning machine#glass bottle cleaning machine#glass bottle cleaner#glass bottle washing#glass bottle washers machine#glass bottle washer machine#glass bottle washer#glass bottle washing machine#beer bottle cleaner machine#beer bottle washing machine#water bottle cleaner machine#bottle washer machine#bottle washing machine#bottle washer#automatic bottle washer

0 notes

Text

Sauce Pouch Packing Machine Manufacturer

Durga Packaging Machine specializes in crafting high-quality sauce pouch packing machines machine . designed to meet the diverse needs of the food and beverage industry. Our machines are engineered for precision, reliability, and efficiency, ensuring that each sauce pouch is filled and sealed to the highest standards. With a focus on user-friendly operation, our machines feature intuitive controls and easy maintenance, allowing for seamless integration into production lines.

Built with robust materials and advanced technology, Durga Packaging's sauce pouch packing machines offer exceptional durability and long-term performance. They are equipped with innovative filling systems that accommodate a range of sauce viscosities, from thin liquids to thick, chunky sauces. This versatility makes them ideal for various applications, including ketchup, mayonnaise, and specialty sauces.

0 notes

Text

Translations

The Forgetful

from Leena Krohn: Kadotus (Teos, 2018)

Some remember people's faces and forget their names, some remember people's names and forget their faces. I forget both the names and the faces. It is not that I have a bad memory. I simply think more about other things than people's things, such as the petrified footsteps of the dinosaurs, or Saturn's moonlight.

In a career guidance lesson we were asked what we wanted to become as adults, and many answered: "Most important thing is being allowed to spend time with other people."

I didn't know what I wanted, only what I did not: "Most important thing is being allowed not to."

Still, to some extent I have had to, even here, in the lost-and-found office of this town, which I call Oblivion. This is, after all, an office, keeping an eye on lost items, a service occupation, though barely anyone's calling. This quiet office is where I ended up following a certain logic, inevitability, even. My days have flown in and joined one another in this Oblivion of forgotten items for so long that an entire life has become of them.

After yesterday's celebration, the last one of the summer, the streets and the parks were left littered. The yellowing lawns and the paving stones whitened by dust were speckled by wrappings stained by ketchup and grease, booze bottles and crushed beer cans, pizza boxes and cigarette butts. The sight doesn't please me, and I don't understand why people don't take the empty packages with them, as they have been able to carry them around full. In such nights as yesterday's, the townspeople forget and lose their belongings even more than usually; on park benches, trams, metro stations and the tables of cafés.

I call those people forgetters, and from their forgetting I earn my living. When someone bothers to bring in a lost item to this office, I register it, and it turns into a found item. Not everyone comes inside. On the wall of Oblivion there is a hatch, through which many items left behind by partygoers have been put during the night. I have a box in which I put all the freshly brought in items. Later I sort them according to their kind and place them on different shelves and into their own lockers. Right now there are fourteen items in the box: a key, an umbrella, an earring, an empty box, a leash, a watch, a wallet, a phone, a coffee spoon, a game, a ballet slipper, a snake skin, a pencil, and gold colored scissors.

They call them inanimate objects. I do not think that way. I believe that everything is alive, only in a multitude of ways. Everything that is has its own life and fate, and that's why even these items have to be handled with care. An item surely does not breathe, or move, or reproduce, it has no metabolism - and yet it receives, stores, gives away and radiates information. Even an item has its personal tastes and some of its own will. It can like its owner, or not. If it doesn't, it keeps falling from their hands and breaking; a light flickers, a machine's function is disturbed.

What is organic and what is inorganic, I ask. The elements that compose living objects are the same that the so called inanimate object are built of, and matter and thought are not the opposites, for every item has first been a thought and a vision.

Whereas thought, indeed, it is by no means only a thought but an arrow, a weapon, a tool, the first and the foremost instrument.

I look at items and I see their loneliness and their connections. Items are not merely matter. Even the simplest, most insignificant object manufactured by humans is a story, as it speaks about the hopes, the needs, and the works of humanity. Every man-made product from shoes to rifles, from books to vehicles has the imprints of human spirit in it. In the same way as natural objects, the artifacts have something to say about the laws of the universe, its resources, and the history of this star.

* * *

Baabelin kirjasto

kirjasta Jorge Luis Borges: Ficciones (Grove Press Inc., 1962)

Universumi (jota toiset kutsuvat Kirjastoksi) koostuu määrittelemättömästä, kenties äärettömästä määrästä kuusikulmaisia huoneita. Huoneet kiertävät parvimaisesti kuilua, jossa kulkevat varsin matalin kaitein ympäröidyt valtavat ilmastointikanavat. Tähyääpä kuiluun ylös- tai alaspäin, loputtoman kauas näyttävät huoneiden tasaväliset kerrokset ulottuvan. Kaksikymmentä kirjahyllyä - viisi pitkää hyllyä seinustaa kohden - peittää neljä seinää kuudesta lattiasta kattoon. Korkeudeltaan ne eivät juuri ylitä keskimääräistä kirjastonhoitajaa. Avoimella seinällä on kapea oviaukko, josta käytävä johtaa toiseen, täysin vastaavanlaiseen tilaan. Molemmin puolin käytävää on sijoitettu kaksi pientä huonetta. Toisessa on seisomatilaa nukkumista varten, toinen tarjoaa helpotusta aineenvaihdunnallisiin tarpeisiin. Käytävän läpi kulkevat myös korkeuksista tänne ja edelleen pohjattomuuteen syöksyvät kierreportaat. Sisäänkäynnin eteen on ripustettu peili, joka huolellisesti toisintaa tilan vaikutelman. Tämä on johtanut päätelmiin Kirjaston äärellisyydestä (jos se todella olisi loputon, miksi tämä illuusionomainen jäljennös?); minä kuitenkin haluan unelmoida kiiltävän pinnan olevan teeskentelyä, allaan lupaus äärettömästä...

Valo tulee pyöreistä hedelmistä, joita kutsutaan lampuiksi. Kussakin kuusikulmiossa niitä on kaksi vastakkaisilla puolilla. Niiden säteilemä valo on riittämätöntä, lakkaamatonta.

Nuoruudessani olen matkustellut, kuten kaikki Kirjaston asukkaat. Olen etsinyt kirjaa, kenties kaikkien teosten koontiteosta; nyt kun näköni tuskin riittää erottamaan mitä kirjoitan, valmistaudun kuolemaan täällä, muutaman tason päässä kuusikulmiosta jossa synnyin. Kuoltuani ei tule olemaan puutetta hurskaista käsivarsista heittämään minut yli kaiteen; muistomerkkini on oleva ilmasta tehty. Ruumiini tulee vajoamaan kauan ja mätänemään ja hajoamaan loputtoman putoamisen viimassa. Tulen osoittamaan Kirjaston olevan päättymätön. Idealistien mielestä kuusikulmaiset tilat ovat absoluuttisen avaruuden, tai ainakin meidän käsityksemme siitä, välttämätön muoto. He väittävät kolmi- tai viisikulmaisen tilan olevan käsityskykymme ulottumattomissa. (Mystikot väittävät hurmoksessaan heille paljastuneen pyöreän kammion, jonka seinämä on yhden suuren kirjan selkämys, mutta heidän todistuksensa on epäiltävä ja sanansa hämärän peittämät. Tuo kehämäinen kirja on Jumala.) Minulle toistaiseksi riittäköön klassinen opinkappale: Kirjasto on pallomainen tila, jonka keskus on mikä tahansa kuusikulmio, ja jonka ulkokehä on saavuttamaton.

* * *

To do something different to pass the remaining ALMS hours, I decided to try translating some prose texts. I chose to translate passages from Leena Krohn's novel Kadotus and from Jorge Luis Borges' short story The Library of Babel from the book Ficciones to get a taste of translating both from Finnish to English and from English to Finnish. Translation is something I am interested in as a kind of a creative puzzle, and had I had more time, I would've liked to take part in the translation support group. I expected translating to Finnish to be easier, but after all both had their own kinds of knacks.

This of course has a lot to do with the texts in question as well. As I found out, it was not easy to picture the exact details of the architecture of the Library of Babel that Borges might have had in mind. In particular, the positioning of the mirror was quite a puzzle, as it was simply described to hang "in the entrance way". But as the mirror was described to create an illusion of extended space, I decided that it must be hung "in the way of the entrance", as it wouldn't make much sense for it to be hung on the wall of the corridor between rooms. I am not even sure whether there is a corridor, or only a doorway, but I couldn't imagine the two small rooms and the staircase positioned any other way. Also I couldn't for the life of me decipher what it meant for the lamps to be "running transversally", so I just settled for them to be located on the opposite sides of the room.

When translating to Finnish I of course have more control of the nuances, and I found it easier to take more freedoms in order to better convey the ideas behind the text. The first draft was pretty quick to write, but editing out the most flagrant anglicisms and suiting the sentence structures to Finnish took a lot of time. But I like that kind of fine-tuning.

The translation to English was in some ways more straightforward. For one thing the source text was simpler, and also my ability to adjust the result is more limited. I found that when translating from Finnish to English the problem is that the sentences tend to become long because of the compactness of Finnish with respect to English. For example, in Finnish it is possible to list things while adding quite expressive attributes to them, such as "jo kellastuvia nurmikoita ja katukiviä, joiden värit pöly on vaalentanut", in English having the exact same information content can easily make the sentence very bloated. The relative straightforwardness is likely for a great part due to my blissful ignorace about registers and nuances, and the nature of the source text, but I found the sentence structures to be easier to translate from Finnish to English. English is perhaps more liberal in that aspect.

ALMS progress: 4 h 50 min

89 h 30 min

0 notes

Text

Stick and Sachet Packing Machine Market Size, Share, Trends Analysis with Forecast 2024-2033

The global stick and sachet packing machine market was valued at US$ 7.2 billion in 2021 and it is anticipated to grow up to US$ 12.4 billion by 2031, at a CAGR of 5.5% during the forecast period.

Packaging machines are used for packaging products or components. The need for packaging machines to integrate with upstream manufacturing processes has resulted in the development of automation techniques for several sectors. This product area includes equipment that forms, fills, seals, wraps, cleans, and packages at different levels of automation. Packaging machines also include related machinery for sorting, counting, and accumulating.

To Know More@ https://www.globalinsightservices.com/reports/stick-and-sachet-packing-machine-market/?utm_id=Pranalip

A stick pack machine is a single lane vertical form fill seal packaging machine where a roll of film is cut, multiple small stick pack bags are formed, and products are filled and sealed inside it. The main applications include small packagings such as sugar sachet, small ketchup sachet, and coffee stick packing machine.

Sachet packaging is extensively used in the cosmetics & personal care, food & beverages, and pharmaceutical industries. Sachets are small, sealed, flexible pouches manufactured from paper, plastic, aluminum foil, and cellulosic and contain liquid, powder, or capsule products. As they are cheaper than large-size packets, sachets are generally used either for promotional trial packs or to cater to low-income or price-sensitive customers who prefer economical packs.

Market Drivers and Trends

Sugar sachet packing machines, milk sachet filling machines, sachet stick packs, and tea sachet packing machines are some examples of sachet packaging machines that are increasing in demand, and the demand for small sachet packing machines is expected to drive the market’s revenue growth due to the presence of many food and beverage manufacturers.

Sachet packing machine is most extensively used in medicine packaging. Sachet packing machines can easily produce blister foils, slip packs, and easy-open pouches at high speed which has increased manifold due to the growing demand for pharmaceutical products are expected to drive the growth of the sachet packaging machine market.

Therefore, increasing demand in food and pharmaceutical sectors are boosting the global stick and sachet packing machine market growth.

Request Sample@ https://www.globalinsightservices.com/request-sample/GIS10460/?utm_id=Pranalip

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS10460/?utm_id=Pranalip

Global Stick and Sachet Packing Machine Market Segmentation

By Type

Stick Pack Packing Machine

Sachet Packing Machine

By Product Type

Powder and Granule

Liquid Products

Others

By End User

Food and Beverages

Pharmaceuticals

Chemicals

Cosmetics

Others

Major Players in the Global Stick and Sachet Packing Machine Market

The key players studied in the global stick and sachet packing machine market are ARANOW Packaging Machinery, S.L. (Spain), Duravant LLC (Spain), Ilapak International SA (Switzerland), Körber AG (Germany), Matrix Packaging Machinery, LLC (US), Nichrome Packaging Solutions (India), OMAG Srl (Italy), SmartPac Verpackungsmaschinen GmbH (Germany), Syntegon Technology GmbH (Germany), and Universal Pack S.r.l. (Italy).

COVID-19 Impact

In 2020, the COVID-19 pandemic resulted in economic challenges owing to subsequent lockdowns. In 2020, the manufacturing industry was severely affected due to a drastic decrease in product demand, falling prices, and storage shortages. A swift decline in manufacturing revenues due to virtually nonexistent manufacturing demand and slow production capabilities had limited the expenditure on the production of stick and sachet packing machines worldwide. Thus, the COVID-19 pandemic negatively affected the global stick and sachet packing machine market in 2020.

However, in 2021, the manufacturing industry started recovering from the significant labor and supply chain challenges that triggered the production of stick and sachet packing machines.

Buy your copy here@ https://www.globalinsightservices.com/checkout/single_user/GIS10460/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

TOMATO KETCHUP POUCH PACKING MACHINE MANUFACTURER DELHI

Durag Packing Machine stands out as a premier manufacturer and supplier of Tomato Ketchup Pouch Packing Machines in Delhi, offering unparalleled quality and reliability in the industry. With a commitment to innovation and excellence, Durag Packing Machine has earned a stellar reputation for its cutting-edge technology and precision engineering.

Their Tomato Ketchup Pouch Packing Machines are designed to meet the diverse needs of the food packaging industry, delivering efficient, hygienic, and high-speed packaging solutions. These machines are equipped with advanced features like automatic pouch filling, sealing, and labeling, ensuring consistent product quality and minimizing downtime.

read more:https://www.durgapackagingmachine.com/delhi/tomato-ketchup-pouch-packaging-machine

0 notes