#LEHRA Fuel

Explore tagged Tumblr posts

Text

🏭Best Briquette Press Machine | Lehra Fuel⭐✨

A Lehra Fuel briquette press machine is a cutting-edge device designed to compress loose biomass materials like sawdust, wood chips, or agricultural residues into compact briquettes. These briquettes offer a more efficient and eco-friendly alternative to loose biomass, as they are easier to transport, store, and burn more cleanly, producing minimal smoke.

⭐✨Explore Lehra Fuel's Briquette Press Machine Range⭐✨

Mechanical Briquette Press Machines: Lehra Fuel's mechanical briquette press machines utilize mechanical force to compress biomass materials. While these machines are generally smaller and more cost-effective, they remain powerful enough to produce high-quality briquettes.

Hydraulic Briquette Press Machines: Lehra Fuel's hydraulic briquette press machines leverage hydraulic pressure for compressing biomass materials. Although these machines are typically larger and come with a higher price tag, they offer superior power and the ability to produce briquettes with higher density.

Don't wait Visit our website now🌍 www.lehrafuel.com/briquette-press 📞Call For More Information +91 991 520 0537

#lehra fuel#briquetting machine manufacturer#Briquette Press Machines#Briquette Press#Press Machines#Best Briquette Press Machine

0 notes

Text

Briquette Machine Manufacturer and Briquetting Machine | Lehra Fuel In the realm of sustainable energy solutions, Lehra Fuel stands as a beacon of innovation and excellence. As a prominent briquette machine manufacturer, the company has carved a remarkable niche for itself by providing state-of-the-art machinery that transforms biomass waste into valuable fuel briquettes. With an unwavering commitment to environmental preservation and resource optimization, Lehra Fuel has become a driving force in the transition towards cleaner energy alternatives. https://lehrafuel.com/

1 note

·

View note

Text

Biomass Briquetting Machine | Biomass Briquette Machine | Lehra Fuel

What is biomass briquetting?

Biomass briquetting, also known as biomass briquette pressing, is a process by which biomass material such as woodchips and agricultural waste is converted into compressed briquettes. This beneficial technique utilizes specialized machines, known as biomass briquetting presses, to produce these solid blocks of biomass. These briquettes can then be used as a fuel source to generate heat or electricity. The benefits of this technology are numerous; not only does it allow for efficient energy use, but it also helps to divert waste material away from landfills and recycle it into useful products.

How does a biomass briquetting machine work?

Biomass briquetting is the process of converting low density materials into high density briquettes. Biomass briquetting machine are used to produce briquettes from a wide range of Biomass materials, including sawdust, straw, paper, and more. The Briquetting process involves compressing the Biomass material under high pressure and temperature to create a denser, stronger briquette. Biomass Briquetting Machine can be used to produce a variety of different shapes and sizes of briquettes, depending on the specific application. For example, some Biomass Briquetting Machine are designed to produce square briquettes, while others may be designed to produce round briquettes. The specific design of the Biomass Briquetting Machine will dictate the shapes and sizes of briquettes that it can produce.

Check more Products here:

https://www.lehrafuel.com/biomass-briquetting-machine/

0 notes

Note

I don't mean to be thirsty on main but can I get a small fic where a gender neutral reader is admiring Xiao's muscles, and his tummy?

Bc g'damn the trailer splash art made me scream in the trailer 💀

Requesting a request okay— It seems we're continuing the Xiao fics week because I'm still braindead to do two fics daily hmmm. As per usual, these things are short still. But brainrot hours woohoo~

Admiring Xiao

Y'all so thirsty so here's you looking at that sweet, sweet Xiao musclesss... (masterlist)

You are looking respectfully.

Fueled by the fact that his attire and constitution are drastically different from the usual Liyue garb, there's no force mighty enough to stop you from oogling Xiao. Even before, even now.

It didn't help that his whole arm was littered with such beautiful tattoos. And when you once held his bicep to stop yourself from plummeting to the ground, his lean yet toned muscles flexed oh so deliciously under your hand. It took you a solid minute and a mental breakdown before you had the mind to pull away as he looks at you in pure confusion.

Ever since then you'd been hyperaware of his arms, or the visible one at least. When it's crossed by his chest. When it's resting by his side. When it's around you up close and protectively. Your fingertips trace from his elbow up to his shoulder as he leans closer to you.

Trapped between the balcony's railing and his protective body, Xiao grunts ever so slightly before his sleeveless arm slips around your waist to pull you against his chest. It was one of those rare and serene moments when the Yaksha would be the one requesting for cuddling sessions even if a huge space still lingers between you two.

His sleeved arm grips the railing behind you as his sunrise gaze looks over the tranquil view of Dihua Marsh. You on the other hand- if your cheeks weren't overheating beforehand, it sure is now. With your hands and chest pressed against his, it takes all your restraint not to molest him with your own two hands.

It was hard and toned more than you expected it to be. The ridges and dips of his packed abdomen are very defined against your stomach. And when he hums- the vibration against your frame sends you into shivers.

Working up the courage after a few more beats of silence, your hands ever so subtly graze over his chest to work around the back where it finds itself flat over the back window of Xiao's outfit. Smooth and very defined. You bury your face on his shoulder as you rub circles on his surprisingly soft skin, giving the suple skin soft pats between the blades of shoulder and the muscles engulfing it.

You didn't know just how much you've been indulging.

Until you were woken up from your mesmerized daze when the Adeptus produced a rare laugh, making your hand grip his exposed back again to feel the reverb on it. He shifts a bit to lean his head on yours, breath ghosting over the tip of your ear as he spoke,

"Are you done? Can we continue this somewhere private now?"

Your brain melts down again.

I want me muscles.

Little compensation for demolishing your hearts last time? uwu

@kookieyachi @struggljng @bunniesrorange @anormalguyreader @moaa @dandelion-dreams @witchsungie @lehra @zelos-simp @legionqueensav @snackgod @rxsalinee @cala-ran @wind-wheel @lilydewi22 @yellowflowre @traveler-lumine @nonniechan

#genshin impact#genshin impact x reader#Xiao x reader#gender neutral#exile.flower#exile.goblet#genshin impact Xiao#genshin impact imagines#genshin impact oneshots#mmmmm simp#Simp time#you guys are obsessed#anon 🥗

2K notes

·

View notes

Text

Growth Of Hammer Mill Market Is Expected To Expand At A CAGR Of 4.3% To Reach A Valuation Of US$ 1,016 Mn By 2032

The global hammer mill market is estimated to expand at a CAGR of 4.3%, reaching a valuation of more than US$ 1,106 Mn by 2032. Hammer mills are good for breaking down hard, dry materials like straw, maize cobs, wood chips, and other fibrous materials.

They are suitable for use in residential areas due to their low vibration and noise levels, but they are also an excellent investment for commercial applications due to their long life and low maintenance requirements. Because of their diverse processing capabilities, they can be used in a wide range of industries, and the speed can be adjusted to meet a variety of materials.

These days, hammer mills are becoming increasingly popular. The main reason for this is that they are highly adaptable devices. They can be used for a variety of things, including the production of biomass and feed. They are also extremely effective and capable.

“Increased machine utilization and demand for high-quality goods in various sectors, as well as the integration of smart devices into equipment, are driving the expansion of the hammer mill market,” says an FMI analyst.

To Know More@https://www.futuremarketinsights.com/reports/hammer-mill-market

Key Takeaways:

At a CAGR of 5.8%, the fastest-growing product type is Pneumatic Discharge from 2022 to 2032.

From 2017 to 2021, the market for Hammer Mill increased at 3.4% CAGR and is expected to grow by 4.3% in 2022

Over the forecast period, the hammer mill market in Germany is projected to grow at a significant CAGR of 3.9%.

Over the forecast period, the hammer mill market in agriculture sector is projected to grow at a significant CAGR of 4.2%.

By Sales Channel, OEM is set to account for more than 95% of the global market

By 2032, East is estimated to have the largest share of the global market, accounting for more than 48%.

Competitive Landscape

Some of the key hammer mill manufacturers included in the report are Andritz, Sandvik AB, Manfredini & Schianchi Srl, Prater Industries, Kurimoto Group, Hosowaka Micron Corporation, Rasa Corporation, Lehra Fuel Tech Pvt Ltd, Perkin Elmer, Kahl & Schlichterle, Schenck Process Holding Ltd Gmbh, Gebr Bellmer Gmbh Maschinenfabrik and Doppstadt.

About FMI – Industrial Automation

The industrial Automation division of FMI offers a novel approach and innovative perspective in analyzing industrial automation market. Comprehensive coverage of capital, portable, process, construction, industrial and special purpose machinery across manufacturing sector and distinctive analysis about installed base, consumables, replacement, USP-feature-application matrix make us a pioneering voice in the industry. We are preferred associates with established as well as budding industry stakeholders and channel partners when it comes to sustain, grow and identify new revenue prospects.

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

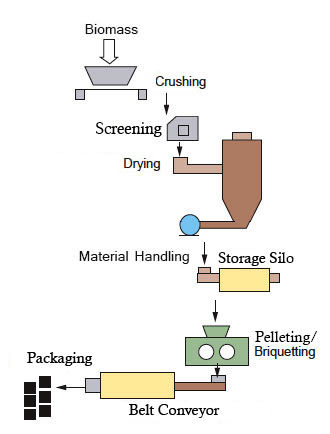

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

How does a briquetting machine work?

Briquetting machine raw material feeding:

The briquette press receives biomass waste via a speed-controlled screw conveyor. The speed of the screw determines the result of the machine's hardness of this briquette. The speed of the raw material is adjusted according to the specific gravity of the raw material. Therefore, a change in the specific gravity of the raw material will result in a change in the hardness of the agglomerate. We at Lehra always recommend that our briquetting presses be equipped with an automatic capacity adjustment system which will adjust the capacity up and down according to the raw material.

Briquetting machine biomass briquetting raw materials:

Any biomass and waste can be pressed into high-calorie fuel briquettes. It can be wheat straw, mustard waste, rice husks, Arhar straw, groundnut husks, pine needles Sarkanda, bagasse. Coffee husks, cotton straw, sunflower waste, sugar cane, bagasse, corn stover, bajra cobs and coconut dust in agricultural waste. Likewise, forest waste such as wood chips and chips, bark, twigs, sawdust, bamboo, wild grass, shrubs, leaves and litter can also be briqueted without any binder with the help of a briquetting machine.

Briquetting machine manufacturing process:

Raw materials such as sawdust are sieved, straw (forest and agricultural waste) is ground by chippers and grinders (single action) for the use of two or more types of materials, by mixing/hand mixing appropriate means. If the raw material has high moisture it should be reduced by sun drying or using a flash dryer, if the moisture is so high it can be reduced by a tumble dryer. Hammer mill grinders are used to grind materials to the desired particle size and are suitable for small models. The raw material (required particle size) is conveyed by a pneumatic system to a storage box fixed to the briquetting machine. Dust is collected directly to B.Pass by cyclone dust collector or screw conveyor. Through the screw conveyor, the material is discharged from the silo to the press. The material is compressed by the plunger through a tapered bore die. By compressing the temperature rises & lignin reaches the surface and binds the material through its natural binder. The briquettes are formed into log shapes and automatically pushed to the storage point by cooling lines.

Finished briquettes:

The finished briquettes have high specific density (1100-1200 kg/m3) and bulk density. These are inventories that can withstand long-distance transportation, with much lower handling and shipping costs and significantly lower requirements. Boiler efficiency of briquettes is much higher due to low moisture and higher density compared to burned wood or lost biomass.

Briquettes are ideal because…

Environmentally friendly and renewable energy fuels. Economical and cheaper than other solid fuels (ie coal and wood). The high calorific value is about 3600-4800 K Cal/Kg and above. No pollution as there is no sulphur or any fly ash when burned. Consistently high combustion efficiency due to low moisture. Unique shape, easy to transport and feed. Burns more evenly than other coals.

Due to the high price of fossil fuels, the market demand is strong.

Why briquette:

Today, every country wants to protect their fossil fuels such as oil, gas, coal and wood. Not only is briquettes a great fuel, it's also good for nature, as it emits only the carbon dioxide needed for the plant and tree environment. In addition to energy, governments offer huge incentives and promotional tax breaks for installing briquetting presses and machines.

Yuke Machine is the best crusher rotary dryer manufacturer and briquetting machine suppliers in China, specialized in briquette machine, contact us!

0 notes

Text

Punjab farmers’ stir costs railways 26 crore a day

NEW DELHI/ PATIALA: The Indian Railways has so far incurred loss of at least Rs 1,670 crore, which is nearly Rs 26 crore a day, due to the ongoing farmers’ protest in Punjab. Moreover, because of the ongoing stalemate 3,090 freight trains could not be operated for transportation of essential commodities such as foodgrains, fertiliser, coal and petroleum products. Till Monday late night, there was no sign of the rail operations resuming in the state as the protesters were still in the circulation areas of stations at 25 sites even after vacating the railway tracks. “There is no assurance on the running of passenger trains. They want only freight trains to operate, but railways can’t let anyone pick and choose. It’s dangerous as well because many maintenance trains are passenger rakes. Threat of protestors coming in way of those trains can lead to disastrous consequences,” said a railway official, who did not wish to be identified. Sources said the situation is becoming more serious as the protests have a direct impact on the movement of essential commodities, including fuel to Jammu and Kashmir and of essential supplies to meet the requirement of defence forces. Official data show that because of the protest, the railways could not operate 520 rakes to transport coal and 1,150 rakes for movement of foodgrains. The last unit operational in the government-run Lehra Mohabbat thermal power plant has suspended operations on the instructions of Punjab State Power Corporation Ltd (PSPCL) to save coal for emergency situations. The power demand in Punjab has also declined to around 4,000 MW. Punjab has five thermal power plants, including two government-run. All three private plants have shut down operations due to non-availability of coal. The two state-run plants did keep a single unit operational to meet the power demand, but as fuel stocks depleted, Ropar plant suspended operations on Wednesday and the unit at Lehra Mohabbat plant packed up on Saturday evening. The deadlock has also started impacting the farmers as nearly 270 rakes could not be operated to transport fertiliser to the state. “There is no clue of whether normalcy will be back soon. There has been no improvement on the ground for more than a week. We could not operate nearly 600 rakes carrying containers. The impact is felt by every section in Punjab. We are ready to run trains provided the state ensures no protestor will be back on the tracks when we run freight and passenger trains,” said the railway official. Data from Northern Railway show that 1,565 passenger trains have either been completely or partially cancelled. Another 105 trains have been diverted since September 22. “Many trains had to be terminated at Ambala, which is known as short termination. Everyday trains were planned expecting the return of normalcy. But there has been no end to the crisis,” said another official.

The post Punjab farmers’ stir costs railways 26 crore a day appeared first on BreakingNews.

source https://bbcbreakingnews.com/2020/11/17/punjab-farmers-stir-costs-railways-26-crore-a-day/

0 notes

Text

🌿 Empowering Sustainable Energy with Lehra Fuel, the Premier Briquetting Plant Manufacturer 🌿

At Lehra Fuel, we stand at the forefront of innovation, crafting cutting-edge briquetting plants that transform biomass waste into eco-friendly fuel briquettes. Our expertise lies in designing and manufacturing briquetting plants tailored to meet the diverse needs of industries, from small-scale enterprises to large-scale production units.

Why Choose Lehra Fuel as Your Briquetting Plant Partner?

Unmatched Expertise: Our team of experienced engineers and technicians possesses in-depth knowledge of briquetting technology, ensuring you receive state-of-the-art solutions.

Custom-Designed Briquetting Plants: We carefully assess your requirements and craft briquetting plants that seamlessly integrate into your existing operations.

Unwavering Commitment to Quality: We adhere to stringent quality standards, guaranteeing the durability and efficiency of our briquetting plants.

Unlock the Potential of Briquetting with Lehra Fuel

Our briquetting plants offer a multitude of benefits, including:

Sustainable Fuel Source: Convert biomass waste into a renewable and environmentally friendly fuel source.

Reduced Operational Costs: Lower your energy expenses by utilizing briquettes as an alternative to traditional fuels.

Enhanced Environmental Footprint: Minimize your carbon footprint and contribute to a cleaner environment.

Join the Briquetting Revolution with Lehra Fuel

Embark on a journey towards sustainable energy solutions with Lehra Fuel, your trusted briquetting plant manufacturer. Contact us today to explore how our expertise can transform your biomass waste into a valuable fuel source.

Call: +91 991 520 0537

https://www.lehrafuel.com/about-us

0 notes

Text

Biomass Briquetting Machine | Biomass Briquette Machine | Lehra Fuel

What is biomass briquetting?

Biomass briquetting, also known as biomass briquette pressing, is a process by which biomass material such as woodchips and agricultural waste is converted into compressed briquettes. This beneficial technique utilizes specialized machines, known as biomass briquetting presses, to produce these solid blocks of biomass. These briquettes can then be used as a fuel source to generate heat or electricity. The benefits of this technology are numerous; not only does it allow for efficient energy use, but it also helps to divert waste material away from landfills and recycle it into useful products.

How does a biomass briquetting machine work?

Biomass briquetting is the process of converting low density materials into high density briquettes. Biomass briquetting machine are used to produce briquettes from a wide range of Biomass materials, including sawdust, straw, paper, and more. The Briquetting process involves compressing the Biomass material under high pressure and temperature to create a denser, stronger briquette. Biomass Briquetting Machine can be used to produce a variety of different shapes and sizes of briquettes, depending on the specific application. For example, some Biomass Briquetting Machine are designed to produce square briquettes, while others may be designed to produce round briquettes. The specific design of the Biomass Briquetting Machine will dictate the shapes and sizes of briquettes that it can produce.

Check more Products here:

https://www.lehrafuel.com/biomass-briquetting-machine/

0 notes

Text

LEHRA Fuel: Leading Rotary Drum Dryer Manufacturer in India

LEHRA Fuel, based in India, stands out as a prominent manufacturer of Rotary Drum Dryers, renowned for their cutting-edge technology and efficient performance. With a strong focus on innovation and customer satisfaction, LEHRA Fuel has established itself as a leader in the industry.

Expertise and Innovation: LEHRA Fuel's Rotary Drum Dryers are crafted with precision, incorporating the latest advancements in drying technology. Their team of skilled engineers and technicians ensures that each dryer is manufactured to meet international standards of quality and reliability. The company's innovative approach to design and engineering has resulted in highly efficient and energy-saving dryers.

Customized Solutions: One of the key strengths of LEHRA Fuel is their ability to provide customized solutions tailored to meet specific requirements. Whether it's agricultural products, minerals, biomass, or any other material that needs drying, LEHRA Fuel's Rotary Drum Dryers are designed to handle a wide range of materials efficiently.

Quality Assurance: LEHRA Fuel places great emphasis on quality assurance. Each Rotary Drum Dryer undergoes rigorous testing to ensure flawless performance before it reaches the customer. The company's commitment to quality has earned them a stellar reputation in the market.

Environmental Responsibility: Apart from delivering high-quality dryers, LEHRA Fuel is also dedicated to environmental sustainability. Their dryers are designed to minimize environmental impact by optimizing energy usage and reducing emissions. This eco-friendly approach aligns with global efforts towards a greener future.

Customer Support: LEHRA Fuel's dedication to customer satisfaction doesn’t end with the sale. Their excellent customer support ensures that clients receive timely assistance, be it for installation, maintenance, or troubleshooting. This proactive approach to customer service has fostered strong, long-lasting relationships with clients across India and beyond.

Conclusion: As a leading Rotary Drum Dryer manufacturer in India, LEHRA Fuel stands at the forefront of innovation, quality, and customer service. Their commitment to excellence and environmental responsibility makes them a preferred choice for businesses seeking reliable drying solutions. Choosing LEHRA Fuel ensures not just a dryer, but a partnership built on trust, quality, and innovation.

Call: +91 991 520 0537

Visit Our Website: www.lehrafuel.com/specification/rotary-drum-dryer/

#lehrafuel#rotary drum dryer manufacturers#rotary drum dryer price#rotary drum dryer working principle#rotary dryer manufacturers#rotary dryer manufacturers in india

#rotary drum dryer manufacturers#rotary drum dryer working principle#rotary dryer manufacturers#rotary drum dryer price#rotary dryer manufacturers in india#lehra fuel#briquette machine manufacturer#briquetting machine manufacturer

0 notes

Text

What is Briquetting Plant and Where To Buy The Best Briquette Machine?

BRIQUETTING PLANT & MACHINERY for converting agro-forestry waste into White coal; Bio-mass based Briquetting System & other energy equipment's.

Call +91 991 520 0537

https://lehrafuel.com/about-us/

#lehra fuel#briquetting plant#Briquetting plant Process#Briquetting Plant Manufacturer#Biomass Briquetting#LEHRA Fuel

0 notes

Text

Elevate Your Biomass Waste Management with Lehra Fuel Premier Briquetting Plant Manufacturer

Are you searching for a trusted Briquetting Plant Manufacturer to streamline your biomass waste management? Look no further than Lehra Fuel. With a sterling reputation in the industry, Lehra Fuel stands as a beacon of innovation and environmental responsibility.

Why Choose Lehra Fuel as Your Briquetting Plant Manufacturer?

Unparalleled Expertise: As a pioneering Briquetting Plant Manufacturer, Lehra Fuel brings decades of expertise to the table. Our seasoned engineers and technicians are well-versed in the intricacies of briquetting technology. Customized Solutions: We understand that one size doesn’t fit all. Lehra Fuel specializes in tailoring briquetting plant solutions to your specific requirements, ensuring maximum efficiency and ROI. Eco-Friendly Approach: At Lehra Fuel, we’re committed to sustainability. Our briquetting plants are designed to transform various organic waste materials into clean and eco-friendly briquettes, significantly reducing environmental impact. Cost-Efficiency: Waste management costs can be a significant burden. Our solutions not only benefit the environment but also provide substantial cost savings compared to traditional disposal methods. Versatile Applications: Lehra Fuel’s Briquetting Plants find applications across diverse sectors, including agriculture, forestry, biomass power plants, and more. Our technology empowers you to harness the potential of biomass waste effectively.

Discover Activities at Lehra Fuel’s Briquetting Plant:

Consultation: Tap into our extensive knowledge base. Our experts offer in-depth consultations to help you grasp the myriad advantages and applications of briquetting technology. Plant Tours: Step inside our cutting-edge manufacturing facility for an immersive experience. Witness firsthand the innovative processes driving our Briquetting Plant production. Product Demonstrations: See our state-of-the-art machinery in action. Understand how it efficiently transforms waste into valuable briquettes, contributing to a cleaner environment.

Contact us today to discuss your briquetting plant needs and embark on a greener, more cost-effective path. Lehra Fuel — Where Innovation Meets Sustainability.

Call: +91 991 520 0537

0 notes