#Lean Six Sigma Green Belt Champion

Text

Value of Online Six Sigma Green Belt Certification for Employers

Businesses are always looking for methods to increase productivity, cut expenses, and improve quality. Six Sigma is one of the most well-known and successful approaches for accomplishing these objectives. Having Six Sigma certified team members can be very beneficial to businesses, especially if the certification is obtained online as a Six Sigma Green Belt. It makes Lean Six Sigma courses the go to course for professional development. This blog post will discuss the benefits of this certification for hiring managers and how it complies with the Council for Six Sigma Certification requirements.

Understanding the Online Six Sigma Green Belt Certification

Professionals that wish to show that they are knowledgeable about Six Sigma approaches can do so by earning the Six Sigma Green Belt competency. It addresses several different subjects, such as project management, statistical analysis, and methods for process improvement. Working individuals can finish the curriculum for the online Six Sigma Green Belt certification at their own leisure, which is an added benefit.

Key Components of Six Sigma

DMAIC Framework: Define, Measure, Analyze, Improve, Control is a five-step process that offers an organized method for tackling problems.

Statistical Tools: Six Sigma uses a variety of statistical techniques to examine data, spot patterns, and arrive at well-informed conclusions.

Roles and Responsibilities: To ensure unambiguous accountability, the system establishes roles inside projects, such as Champions, Black Belts, Green Belts, and Yellow Belts.

Benefits of Lean Six Sigma Courses for Employers

1. Enhanced Process Efficiency

The main objectives of Lean Six Sigma courses are to prepare aspirants for process improvement and waste elimination. Six Sigma Green Belt certified staff members are educated to spot inefficiencies, optimize processes, and put productivity-boosting ideas into action. Workflows become more effective as a result, and considerable cost reductions follow.

2. Improved Quality Control

Quality control is a fundamental component for any organization. The focus of Six Sigma approaches is on lowering process variability and faults. These guidelines can be used by certified staff members to guarantee that goods and services continuously live up to high standards.

3. Data-Driven Decision Making

Six Sigma employs a data-driven methodology. Workers who have earned a Green Belt certification are adept at analyzing data and coming to wise conclusions by applying statistical tools and methodologies. Making strategic judgments supported by empirical data is made easier with the aid of this analytical attitude.

4. Cost Reduction

Organizations can save money by working with Six Sigma Green Belt trained professionals to uncover inefficiencies and reduce waste. Several factors, such as less rework, fewer faults, and better resource use, can contribute to these cost savings.

5. Employee Development and Retention

Providing professional development options, like Lean Six Sigma training, can greatly improve employee retention and happiness. Employees are drawn to companies that support their professional development, and earning a Six Sigma certification can be a powerful incentive.

6. Competitive Advantage

Businesses that employ Six Sigma certified personnel enjoy a competitive advantage in the marketplace. A corporation can stand out from its rivals and draw in more business by effectively delivering high-quality goods and services.

The Role of the Council for Six Sigma Certification

An internationally renowned accrediting authority for Six Sigma certifications is the Council for Six Sigma Certification. Their accreditation guarantees that the certification and training programs adhere to strict quality and rigor requirements. Employers can feel secure knowing that workers who have earned a certification from the Council for Six Sigma Certification have the expertise needed to make valuable contributions to the company.

Why Choose Online Six Sigma Green Belt Certification?

1. Flexibility and Convenience

Online Six Sigma Green Belt certification programs the freedom to study on a timetable and at a pace that suits you. Professionals in the workforce who might not have the time to attend in-person sessions will especially benefit from this.

2. Cost-Effective

Online learning is frequently less expensive than traditional classroom instruction. They also save the need for travel and lodging costs, which makes them an affordable choice for companies and workers alike.

3. Access to Quality Content

Reputable online certification programs give you access to knowledgeable teachers, engaging materials, and top-notch content. This guarantees that workers receive thorough training equivalent to that of in-person classes.

Conclusion

Employers can gain a lot by investing in their employees' online Six Sigma Green Belt certification. The benefits of having Six Sigma trained personnel in an organization are indisputable, ranging from increased process efficiency and quality control to cost savings and competitive advantage. Employers can be assured that the certification satisfies strict standards of quality thanks to its approval by the Council for Six Sigma Certification.

Employers can promote a culture of continuous improvement and create sustainable growth by offering Lean Six Sigma training and encouraging staff members to achieve online Six Sigma Green Belt certification.

Resource: https://www.mindcypress.com/blogs/quality-management/value-of-online-six-sigma-green-belt-certification-for-employers

0 notes

Text

The Role of Lean Six Sigma Black Belts in Organizational Excellence

Introduction:

In today’s dynamic business world, organizations are constantly looking for ways to increase productivity, reduce waste and improve overall efficiency. One powerful approach that has emerged as a beacon of productivity is Lean Six Sigma. Central to this approach are individuals known as Lean Six Sigma Black Belt – highly trained professionals who play a key role in delivering organizational excellence In this blog we explore the key role of these black belts and how their skills contribute to success in different industries.

Understanding Lean Six Sigma Black Belts:

Lean Six Sigma Black Belt are individuals who have received rigorous training in the principles and techniques of Lean and Six Sigma. They have a deep understanding of statistical analysis, process improvement, and waste reduction. Unlike Green Belts, Black Belts play a comprehensive and strategic role within an organization, leading complex projects and influencing organizational culture.

Project Leadership and Management:

Black belts are assigned to pioneering high-impact projects aimed at improving productivity and eliminating deficiencies. Their leadership ensures that projects align with organizational objectives, and they are adept at managing cross-functional teams to achieve desired results.

Data-Driven Decision Making:

Using statistical tools and analysis, black belts make decisions based on data rather than theories. This data-driven approach enables organizations to identify the root causes of issues, leading to effective and sustainable solutions.

Continuous Improvement Champions:

Black belts are champions of continuous improvement theory. They promote a culture of continuous improvement within the organization and encourage a proactive approach to identifying and solving challenges.

Cost Reduction and Resource Optimization:

Using Lean Six Sigma principles, Black Belts identify opportunities for cost reduction and resource efficiency. This not only improves the organization’s financial performance but also increases competitiveness in the market.

Customer Satisfaction and Quality Assurance:

Black Belt Certification focuses on increasing customer satisfaction by improving products and services. Their work ensures that strategies meet or exceed customer expectations, contributing to long-term success and loyalty.

Knowledge Transfer and Training:

Black belts often play a role in training and mentoring Green Belts and other team members. This knowledge transfer ensures that the principles of Lean Six Sigma are embedded in the culture of the organization, resulting in a sustainable process of excellence.

Conclusion:

In conclusion, Lean Six Sigma Black Belt Certifications are key to achieving and sustaining organizational excellence. Their expertise in process improvement, data-driven decision-making, and project leadership positions them as drivers of positive business change As organizations navigate today’s market challenges, Lean Six Sigma plays a key role that is critical for black belts Investing in the development of Black Belts by adopting its principles can pave the way for a future where excellence is not just a goal but an integral part of the organizational DNA.

#LeanSixSigma#BlackBelts#OrganizationalExcellence#ContinuousImprovement#DataDrivenDecisions#ProjectManagement#Efficiency#CostReduction

0 notes

Text

Manufacturing & Production - 3139519

Job Description:

Our esteemed client, an industry-leading company with a strong track record of excellence, is currently seeking a dedicated Manager for their Continuous Improvement & Manufacturing team. This opportunity is based in the vibrant city of Horseheads, New York, and relocation assistance is available for eligible candidates within the United States.

What You'll Do:

In this pivotal role, you will lead and oversee various engineering and Continuous Improvement (CI) initiatives. You will have the opportunity to direct the efforts of the site's lean coordinator and tool champions, ensuring they drive plant-wide improvements, achieve business outcomes, and meet predefined assessment benchmarks.

Your responsibilities will include:

- Championing Operational Excellence in alignment with the client's Business Excellence criteria and their Lean Six Sigma methodology.

- Providing strategic guidance to the site's lean coordinator and lean tool champions to deliver business results and align with corporate objectives.

- Identifying and prioritizing engineering projects and Lean events. You'll be responsible for successfully driving these projects to completion, resulting in improved plant processes and performance metrics. Your role will also involve leading or participating in Kaizen events.

- Managing, directing, and coordinating the CI and manufacturing engineering functions, with a specific focus on enhancing safety, productivity, quality, customer satisfaction, and cost efficiencies.

- Overseeing a team of manufacturing engineers and engineering supervisors, providing them with leadership and direction. Together, you'll set meaningful goals aligned with plant objectives.

- Standardizing and consistently deploying manufacturing processes. Identifying and implementing innovative materials, equipment, processes, technology, and procedures to enhance product lines and optimize manufacturing processes.

- Managing capacity analysis, capital planning, and executing the annual capital plan. You'll also be responsible for preparing and managing the budget for the manufacturing engineering department. Additionally, you'll play a key role in Strategic Planning, preparing 5-year Quality, Manufacturing Technology, Lean, and Capital plans.

Qualifications:

Required Qualifications:

- Bachelor’s degree from an accredited institution.

- Three (3) years of experience in a Manufacturing environment.

- Two (2) years of management experience.

- Must have authorization to work in the U.S. without corporate sponsorship now or in the future.

Preferred Qualifications:

- Bachelor’s degree in engineering or manufacturing from an accredited institution.

- Lean certification and/or familiarity with Lean tools.

- Knowledge of financial management and cost optimization strategies.

- Five (5) years of experience in a Manufacturing environment.

- Six Sigma Green Belt or Black Belt certification.

- Experience in project management.

Our client is dedicated to providing equal employment opportunities to all job applicants and employees. Employment decisions are solely based on job-related qualifications and performance, regardless of factors such as race, color, religion, gender, sexual orientation, age, national origin, disability, marital status, genetic information, or veteran status, in accordance with applicable laws.

This opportunity offers a competitive bonus structure.

Job ID: 3139519

Read the full article

0 notes

Text

Top 10 Online Lean Six Sigma Courses in Delhi

Discover the top 10 online Lean Six Sigma courses that will help you gain the skills and knowledge to improve your career and increase your earning potential. These courses are taught by industry experts and offer practical, hands-on training that you can apply immediately to your work.

1) Lean Six Sigma Yellow Belt: This course covers the fundamentals of Lean Six Sigma, including the DMAIC process, tools and techniques, and how to apply them to solve business problems.

2) Lean Six Sigma Green Belt: In this course, you will learn the advanced skills required to lead Lean Six Sigma projects and deliver significant results to your organization.

3) Lean Six Sigma Black Belt: This course is designed for experienced Lean Six Sigma practitioners who want to take their skills to the next level and lead complex projects.

4) Lean Six Sigma for Service: This course is tailored specifically for service industries, teaching you how to apply Lean Six Sigma principles to improve service delivery and customer satisfaction.

5) Lean Six Sigma for Healthcare: Healthcare professionals will benefit from this course, which focuses on the unique challenges and opportunities in healthcare and how to apply Lean Six Sigma principles to improve patient outcomes.

6) Lean Six Sigma for Supply Chain: This course covers the application of Lean Six Sigma principles to optimize supply chain management, reduce costs, and improve efficiency.

7) Lean Six Sigma for IT: This course is designed for IT professionals, teaching you how to apply Lean Six Sigma principles to optimize IT processes, reduce downtime, and improve user satisfaction.

8) Lean Six Sigma for Manufacturing: This course focuses on applying Lean Six Sigma principles to manufacturing processes, reducing defects, increasing efficiency, and improving quality.

9) Lean Six Sigma White Belt: This course provides an introduction to Lean Six Sigma concepts and terminology, and is perfect for anyone new to the field.

10) Lean Six Sigma Champion: This course is designed for executives and leaders who want to understand the benefits of Lean Six Sigma and how to support and promote its implementation throughout their organization.

Investing in your Lean Six Sigma education will not only improve your earning potential but also demonstrate your commitment to your field and set you apart from your peers. Join the ranks of Six Sigma experts today with Gravitex Genesys.

At Gravitex Genesys, we offer a comprehensive online Lean Six Sigma training program that covers the DMAIC methodology and integrated lean content. Our courses bring both Green Belt and Black Belt participants together, ensuring consistent Green Belt-level knowledge of the principles and practices of Lean and Six Sigma.

#leansixsigmacertification#sixsigmacertification#careerboost#leansixsigmagreenbelt#sixsigmacombo#sixsigmablackbelt#leansixsigmablackbelt#earningpotential#Delhi

1 note

·

View note

Photo

Six Sigma Project team members roles and responsibilities explained with examples and infographics have a look

#six sigma#project#team members#dmaic#green belt#black belt#yellow belt#lean six sigma#master black belt#champion#sponsor

1 note

·

View note

Text

Materials World’s top feature of 2019

As 2019 is drawing to a close, the Materials World team wanted to highlight a couple of stories to end the year on a high note. On Wednesday we shared the news story that got the most clicks on our website in 2019.

Today, we are sharing the top feature. We hope you enjoy and Merry Christmas from the editorial team.

15 UNDER 30

By: Idha Valeur

IOM3 is looking to the future and celebrating young talent and ambition. Idha Valeur talks to the ones to watch in STEM.

Kyle Saltmarsh

Age: 27

Job: Robotics Engineer at Woodside Energy.

Education: PhD Engineering in Submarine Vibration and Acoustics, BSc in Physics and Applied Mathematics, BME (Honours).

Current project: Deployment of robotic technology onto Woodside’s oil and gas plant for surveillance, and performing tasks through robot manipulation.

Achievements: Best honours thesis, several hackathon wins, top IBM 2018 graduate in Australia/New Zealand, 2018 Young Persons’ World Lecture Competition Winner, world’s largest bungee jumper, blogger and hosting a podcast to inspire people in technology.

Ultimate goal: To positively impact the world through the power of technology.

Kyle Saltmarsh Image credit: Brent Campbell

Jennie Palmer

Age: 26

Job: Research Engineer.

Education: Undertaking an EngD in Structural Metals for Gas Turbine Applications, BEng in Aerospace Engineering, with a year in industry, Swansea University.

Current project: I am researching the development of bespoke test facilities and fundamental understanding of thermo-mechanical fatigue crack growth behaviour in titanium alloys.

Achievements: Graduating with a BEng in Aerospace Engineering with First-Class Honours, presenting my research at national and international conferences, having research published in an internationally recognised journal and a Green Belt Certificate in Lean Six Sigma.

Ultimate goal: To become a well-established, technical expert in my engineering field.

Jennie Palmer Image credit: Jemima Bond

Ilija Rašović

Age: 27

Job: Lecturer at University of Birmingham

Education: MEng in Materials Science at Corpus Christi College, Oxford. DPhil in Materials at St Cross College, Oxford.

Current project: The use of fullerenes — nanometre-sized balls of carbon — in biomedical applications. One of the methods I have devised, to make them soluble in water, helps in the formation of large self-assembled structures that hold great promise as multi-modal drug delivery vehicles.

Achievements: The IOM3 international Literature Review Prize in 2016. Final of the IOM3 Young Persons’ World Lecture Competition in 2017. I joined the P1 Graphene Solutions as an advanced materials engineer and became a lecturer at the University of Birmingham. In 2019, I joined IOM3’s Younger Members’ Committee.

Ultimate goal: To make a contribution to the wide deployment of transformative nanomedicine in a clinical setting within my lifetime. My broader vision is to continue to champion materials science and make more accessible the obfuscated world of academic research.

Ilija Rašović

Amanda Field

Age: 25

Job: Development Engineer.

Education: BEng Materials Science and Technology, University of Birmingham.

Current project: Trying to finish my PhD on additive manufacturing of tungsten for nuclear fusion reactors. It’s challenging but worthwhile because the success of nuclear fusion would go a long way to solving the energy crisis. I’m working in additive manufacturing.

Achievements: I have presented my work at international conferences. I was involved with an experimental parabolic flight campaign for the European Space Agency where we used a demonstrator device to 3D print metal in zero gravity. I came second in the IOM3 Young Persons Lecture Competition.

Ultimate Goal: To keep working in additive manufacturing. I’d like to stay in R&D as you get such variety in your role and you have the potential to make significant improvements to a product or a technology, or design new ones yourself.

Amanda Field Image credit: Luke Carter

Jack Saunders

Age: 25

Job: PhD Student in Materials Chemistry.

Education: MChem with a year in industry, University of Manchester.

Undertaking a PhD in Materials Chemistry, University of Manchester, in collaboration with AkzoNobel.

Current project: To analyse the impact of different polymers on the corrosion protection afforded by emulsion paints. I aim to achieve this by synthesising and testing polymer’s corrosion performance. This is to better understand how polymer chemistry can affect the corrosion protection offered by the dried paint.

Achievements: A First Class Master’s degree in chemistry. My PhD at the School of Materials at The University of Manchester. Awarded the President’s Doctoral Scholar Award. Presented my work at conferences such as the RSC’s MacroGroup YRM, Dublin, 2018. Won the regional Young Persons’ Lecture Competition this year.

Ultimate goal: To develop my research and management skills in order to have my own research group in the field of polymer chemistry and colloid science.

Jack Saunders Image credit: University of Manchester

Megan McGregor

Age: 25

Job: PhD Candidate at the Department of Materials Science & Metallurgy, University of Cambridge.

Education: MSci in Natural Sciences, University of Cambridge, specialising in Materials Science.

Current project: A PhD project investigating a new intermetallic alloy for commercial gas turbine engines. Specifically, trying to develop a novel coating material required to attach abrasives onto the end of rotating turbine blades, in pursuit of a more efficient sealing system.

Achievements: I enjoy teaching in the department, and was recently awarded the Departmental Demonstrator Prize. I talked at the Cambridge Science Festival and the inaugural Cambridge Soapbox Science event. I will be representing the South Eastern Region in the final of the IOM3 Young Persons’ Lecture Competition this year, selected for an RCUK Public Policy Internship at the Government Office for Science in 2018, where I got to contribute to government policy.

Ultimate goal: To see the material I am working on make it into a commercial gas turbine engine. I want to take my expertise in this area into industry, and be able to contribute to the development of the hybrid-electric aircraft sector.

Megan McGregor Image credit: Andrew Jeskins

Abigail Georgia Robinson

Age: 22

Job: Geology student.

Education: MGeol in Earth and Environmental Sciences, University of St Andrews, graduating in 2020.

Current project: I will co-lead an expedition to the Lofdal Complex, Namibia, which hosts a suite of carbonatitic and silicic igneous rocks, some of which are enriched in heavy rare earth elements. I aim to integrate geological field data with geochemical and isotopic datasets to model the petrogenesis of the scientifically interesting igneous rocks.

Achievements: I was awarded the prestigious Laidlaw Scholarship in Research and Leadership in 2018. This supported my field campaign in Armenia, to investigate the interplay between climate change, hydrology and medieval irrigation systems. I did a research placement at the Scottish Universities Environmental Research Centre where I learned to code in Python and used this to statistically investigate the geographical origin of lunar meteorites across the lunar surface. This work was included in Dr Marissa Tremblay’s published abstract and presentation at the 2019 Lunar and Planetary Science Conference, USA.

Ultimate goal: I plan to embark on a PhD on the tectonically imposed planet-wide cycling of the volatile elements. I plan to be an active communicator promoting an understanding of geoscience and the global scale problems that we, the geoscientists, can work to solve.

Abigail Robinson Image credit: Evan Margerum

Federica Rosaria Lisa

Age: 24

Job: Technical Graduate at British Steel.

Education: MChem Chemistry with Forensic Science with a year in industry, University of Leicester.

Current project: A variety of research and development projects – one on understanding and reducing the factors that influence power and electrode consumption at the ladle arc furnaces in the secondary steelmaking process.

Achievements: Graduated with a First Class Honours and secured a 12-month industrial placement and a place on a graduate programme. I succeeded in my secondary school exams after moving to a new continent and starting International School.

Ultimate goal: To work for a sustainable discovery/development that will improve lives and I would like to lead a company. I would also like to promote the importance of education, support developing countries in the construction of more schools and strengthen the educational system.

Frederica Lisa Image credit: Johnny Gallagher

Daniel Everington

Age: 26

Job: Materials Technologist – Surface Engineering.

Education: MEng Aerospace Engineering with a year in industry, University of Sheffield.

Current project: Surface engineering at Rolls-Royce. I’m involved with different projects across the engine, including compressor sealing systems, hot end environmental protection and anti-seize coatings.

Achievements: Developed a novel method to flow test ceramic filters used in the investment casting process. The technique contributed to a 3% improvement in casting yield and the reduced variation helps lower the amount of metal. Patents may be filed on the work.

Ultimate goal: I’d like to work with academia to co-develop novel coatings/surface treatments. I enjoy the challenges that come with working on new technology as the answers can’t simply be found in a textbook.

Daniel Everington Image credit: Alistair Coast-Smith

Louise Gale

Age: 28

Job: Materials Engineer at Rolls-Royce Plc.

Education: MSci & MA in Natural Sciences, specialising in Materials Science, University of Cambridge.

Current project: The development of ceramic matrix composites for introduction into aerospace gas turbine engines. My responsibilities include running mechanical testing programmes, supervising work at our university partners as well as the analysis and fractography of tested samples to elucidate damage mechanisms.

Achievements: Completing the Rolls-Royce Graduate Scheme, including obtaining funding for an international placement in the Materials Testing Department in Berlin. I became Technical Lead of a £2.5mln project which was part of a government-funded programme to develop SiC/SiC ceramic matrix composites. I developed the £7mln, three-year materials development component to the follow on project that was approved in late 2017.

Ultimate goal: To become an expert on ceramic and composite materials systems.

Louise Gale Image credit: Stephen Gale

James Grant

Age: 24

Job: EngD student with TATA Steel and M2A, Materials and Manufacturing Academy.

Education: School of Physics and Astronomy, Cardiff University, College of Engineering, Swansea University.

Current project: Development of novel coating solutions for the improvement of pre/post heat treatment of carbon steel conveyance tubes. My project aims to reduce high-temperature oxidation caused by the normalising process.

Achievements: I developed a novel anodisation system for fabricating alumina masks in the molecular beam epitaxy application. In addition to this, my placement with Merck successfully optimised electrophoretic fluids to further enhance the E-ink display technology. I’ve been competing in the 2019 IOM3 Young Persons Lecture Competition. Having won the SWMA heat and the South West Regional, presenting at the national final in May.

Ultimate goal: To educate and encourage the next generation of students to take up STEM subjects. I hope I can engage and excite a younger audience about materials science and demonstrate the opportunities available in engineering.

James Grant Image credit: James Grant

Vidya Chamundeswari Narasimhan

Age: 28 years

Job: Post-doctoral Research Fellow Department of Materials Science and Engineering, NTU.

Education: PhD in Materials Engineering.

Current project: Developing responsive nasogastric tubes for the elderly and using nature-derived biopolymers for biomedical applications.

Achievements: Young Scientist Award conferred by VIWA in India, Title Winner of the IOM3 Young Persons’ World Lecture Competition 2017, Women in Engineering Travel Grant in 2018, Chair of the Young Scientists Forum at the European Materials Research Society conference in Poland 2018.

Ultimate goal: To lead and manage a diverse team, foster interdisciplinary collaboration and offer R&D support for cutting edge research in the healthcare sector. I also want to contribute significantly towards mentoring the next generation of young girls towards pursuing exciting careers in STEM fields.

Vidya Chamundeswari Image credit: Dr Rohit Satish

Frederick Cooper

Age: 28

Job: Research Engineer and PhD student.

Education: BEng with Honours, Swansea University.

Current project: Microstructural and mechanical characterisation of flow formed F1E – a novel, maraging steel.

Achievements: Used flow form to develop materials for detailed metallographic, micro-textural, and mechanical assessment. I run two small businesses, have an Associate Diploma from the National College of Music, and an Associate Fellowship of the Higher Education Academy and was appointed as a Yeoman of the Worshipful Company of Tin Plate Workers.

Ultimate goal: To complete my current project and transfer a comprehensive mechanical property database detailing static and fatigue performance to a major engineering sponsor – to enable novel component manufacture. Further, I would like to use my experience to develop a career in public engagement or education.

Frederick Cooper Image credit: Lauren Ednie Photography

Robert Hoye

Age: 28

Job: Royal Academy of Engineering Research Fellow.

Education: PhD, Cambridge University, BE(Hons).

Current project: I am looking at two areas that could accelerate the scale of photovoltaics. This makes an attractive technology for producing clean energy, especially in remote regions.

Achievements: Developed a recombination contact to couple a metal-halide perovskite top-cell with an n-type silicon bottom cell, which lead to new design rules to identify promising classes of materials that could tolerate defects, and an all-inorganic device structure that led to 80% external quantum efficiency in solar cells. This went on display in the Deutsches Hygiene-Museum in Dresden, Germany. 2018 Young Engineer of the Year Award by the Royal Academy of Engineering, which also awarded me £500,000 to start an independent group at the University of Cambridge. European Forbes 30 under 30 list.

Ultimate goal: To create new classes of defect-tolerant semiconductors that can be used as low-cost and efficient top-cells in tandem with silicon.

Robert Hoye Image credit: Zoe Chung

Matthew Wadge

Age: 24

Job: PhD Researcher.

Education: BSc(Hons) Biomedical Materials Science & PhD (ongoing), University Of Nottingham.

Current project: Exploring novel formation and ion-exchange reactions of titanate surfaces for biomedical applications.

Achievements: Achieved eight awards during my undergraduate degree including the Best Student Prize, Best Project Prize, and The Armourers and Brasiers’ Best Student Prize for achieving the highest project mark within the faculty. I have since won the Armourers and Brasiers’/TWI Best BSc/BEng Student of the Year Award, Best Oral Presentation Prize from the UK Society for Biomaterials Conference in 2018. Published my first journal paper during the first year of my PhD. I am one of the Nottingham coordinators for this year’s Pint of Science festival.

Ultimate goal: To try and improve a patient’s quality of life, from improving fixation of hip stems for improved longevity, through to antibacterial surfaces for minimising infections. I aim to continue on into academia post PhD to share my experiences, and hopefully train the next generation of bioengineers and biomaterial scientists.

Matthew Wadge Image credit: Matthew James

#engineering#materials science#innovation#15 under 30#top#science#STEM#research#young#professionals#iom3

40 notes

·

View notes

Text

Additional Six Sigma Green Belt Certification Mumbai

What is Six Sigma?

Six Sigma is a strategy used to correct business processes by practicing measurable examination as opposed to mystery. Processes are bettered by controlling variety and grasping the confusions inside them. This kaizen consulting in Mumbai in Mumbai is more unsurprising and beneficial business processes. Six Sigma is farther than "preparing "; it's a methodology predicated on information and intended for frameworks with quantifiable business issues. This demonstrated methodology has been executed inside an extensive variety of productivity to accomplish both hard and delicate industrialist reserve funds, while adding consumer loyalty. For case, in 1999 GE Capital was reasonable to save$ 2 Billion with Six Sigma.

6 Sigma is at the van of Six Sigma Green Belt Certification in Mumbai and counseling administrations. We assist relationship with all parts of the exhibition cycle from preparing Six Sigma champions to guaranteeing laborers at different belt circumstances. We can assist your organization with deciding the perfect singularities who might profit from preparing and encourage on the most proficient method to pick implied frameworks.

Six Sigma Training and Certification

Sigma.us is the initial Six Sigma supplier to offer the initial fourteen days of the Green Belt and Black Belt together. This 2 2 configuration takes into consideration Green Belts and Black Belts to go to preparing together, accordingly culminating interior local area while outfitting lower authoritative severity. We convey a full scope of on location Champion administration courses for kaizen training in Mumbai.

The public classes start at 900 am and end at 600 pm Monday through Thursday at most districts. Weeks with4.5 days will end at 0100 pm on Friday. This incorporates the JumpStart, as well as the primary seven day stretch of the Green Belt. The principal seven day stretch of the Master Black Belt likewise incorporates a ½ day on the main Friday.

DMAIC - The Best Six Sigma Process improve Methodology

During my Six Sigma instructional courses, continually I go over certain inquiries from entertainers

• How might we begin six sigma plan in our affiliation?

• When would it be advisable for us to begin six sigma plan in our affiliation?

• Do we remain for any client protest or any external view about process issues?

• Is six sigma truly pertinent, as we do n't notice any interaction imperfection?

The way of thinking behind six sigma approach is

• Anything that we measure; procures our concentration

• Anything that we concentrate; prompts improvement

Thus, recognize basic achievement factors for your business interaction. Characterize process models to gauge process execution. With six sigma system, you can correct this interaction execution. lean six sigma certification in Mumbai is a coherent organized way to deal with improve business processes.

The Greek letter "Sigma" a factual term; measures how much a given cycle veers off from flawlessness. Sigma is otherwise called standard divagation of the interaction from its mean. Six Sigma process empowers a relationship to quantify the quantity of " scars " in a cycle, styles to count them and draw near to " zero scars " however much as could reasonably be expected.

Chiefs face difficulties in idealizing the quality and viability of the business. To survive, they need to apply the wash procedure and devices to dissect and control the cycle. The wash method for amending the outcome is to correct the interaction.

#kaizen consulting in mumbai#six sigma green belt certification in Mumbai#kaizen training in mumbai#lean six sigma certification in Mumbai

0 notes

Text

Basic Knowledge of Six Sigma Green Belt Certification.

Six Sigma Green Belt is a certification course wherein participants will receive an introduction to tools and methods that are essential to participating in DMIAC improvement projects. This course focuses on the basic structure of DMAIC. By usurping this certification course professionals can identify the issues and implement solutions to eradicate them. The Six Sigma Green Belt Certification Course provides you with a practical perspective on learning Six Sigma tools. This is one of the Best Six Sigma Certification programs available online that not only helps you understand Six Sigma principles, Six Sigma tools, and Six Sigma examples but also helps you do a realistic Lean Six Sigma Green Belt case study in a step-by-step manner.

Who is it for?

Six Sigma is a people‐driven process. The Six Sigma project performance level tends to match the level of persistence, expertise, and commitment of the individual members of the team. While reviewing the roles that contribute to the project, most of them consider the champion and Black Belt's roles to deploy the project. However, to improve the performance of the projects, Green Belts will also play a critical role in the process improvement.

Green belts are skilled team players and their aim is to enhance process quality. They help to bridge the gap between the Six Sigma theory and real-world application. Six Sigma Green Belt candidates play an important role in improving the process, data inspection, or Project Management. Green Belt training teaches candidates the basic tools used by a project team and how to apply DMAIC skills that relate to a Six Sigma project.

Is It Right for you?

Six Sigma certification is for individuals who are interested in the terminologies like continuous improvement and waste reduction and work experience in any supply chain or business management. Six Sigma certification helps the professionals to boost their subject proficiency which leads to increased desirability by employers and salary. This certification for professionals is responsible for controlling costs, improving outputs, and contributing to better results.

0 notes

Text

Lean Six Sigma - A method of improving processes with a specific goal.

Lean Six Sigma combines two methodologies, Lean and Six Sigma, to help organisations accelerate specific processes in order to solve problems faster, reduce waste, and create more value for customers. It combines the Lean methodology's waste-reduction mentality with Six Sigma's defect and variance reduction focus. Lean Six Sigma, when combined, creates a powerful methodology for keeping businesses on time and on budget, allowing organisations to create processes that support the organisation and its employees while saving money, adding value, and improving productivity.

Lean Six Sigma's main goal is to reduce waste by minimising variability in business processes and establishing a continuous flow between each step. The methodology classifies waste into eight categories: defects, overproduction, waiting, underutilised talent, transportation, inventory, movement, and extra-processing. Once your organisation eliminates this type of waste, you will be able to solve problems faster, reduce process inefficiencies, and increase productivity.

Principles of Lean Six Sigma

While both Lean and Six Sigma have their own sets of principles, Lean Six Sigma provides a unique set of principles that incorporates elements from both frameworks.

The five main principles of Lean Six Sigma, according to Purdue University, are:

• Work for the customer: Ensure that any changes you implement will benefit the customer and provide the highest quality possible in accordance with market demands.

• Locate and concentrate on your problem: Avoid getting sidetracked by other issues while working to improve organisational processes. Determine the problem to be addressed, stay focused on that area of business, and move on to other issues once the main problem has been resolved.

• Remove variations and bottlenecks: Optimize processes by reducing defects. Streamlining your processes will aid in the improvement of efficiency and quality.

• Communicate clearly and train team members: Implementing Lean Six Sigma can cause disruption in the workplace. To reduce the risk of project failure, ensure that everyone is trained and prepared to implement Lean Six Sigma.

• Be adaptable and responsible: As you begin Lean Six Sigma, you will almost certainly need to refine your approach and pivot your strategy. It makes no sense to cling to a failing strategy, so remain agile and flexible throughout the process if you want the best results.

Belts in Lean Six Sigma

Lean Six Sigma employs a structure similar to Six Sigma, which borrows from martial arts, to designate an individual's experience and proficiency in implementing the methodology. You'll earn different belts as you progress up the certification ladder until you reach the final "Champion" level.

• White Belt: As an entry-level position, you will report process issues to Green and Black Belts. You should understand the fundamentals of Lean Six Sigma, including common terminology as well as the methodology's basic structure and goals.

• Yellow Belt: You will continue to report to the Green and Black Belts. As a Yellow Belt, you must be well-versed in the guiding principles of Lean Six Sigma. You will also work on project teams and receive additional training.

• Green Belt: Green Belts are in charge of initiating and managing Lean Six Sigma projects, as well as training White and Yellow Belts. You should have a thorough understanding of the Lean Six Sigma methodology at this level.

• Black Belt: You report to Master Black Belts as a Black Belt and have advanced knowledge of Lean Six Sigma. For Lean Six Sigma projects, you will be viewed as a mentor, coach, and project leader.

• Master Black Belt: This rank is in charge of implementing and driving necessary cultural shifts. You'll report to executive management and be expected to coach, mentor, monitor, and lead Lean Six Sigma projects.

• Champion: The highest level of Lean Six Sigma certification is for executive leaders who assist in identifying and selecting the right projects and then ensuring teams have the support they need to succeed.

Tools for Lean Six Sigma

Lean Six Sigma tools are typically used to streamline processes, improve collaboration, and provide data analysis. DMAIC (define, measure, analyse, improve, control), data collection plans, scatter plots, SIPOC (suppliers, inputs, process, outputs, customers), stakeholder analysis, seven wastes, value stream mapping, flow, fishbone diagram, regression analysis, project management, visual workplace, statistical process control, and voice of the customer are examples of common Lean Six Sigma tools.

Lean Six Sigma software tools can assist you in effectively implementing the methodology. These solutions are usually centred on data reporting and analysis, as well as collaboration.

How to Combine Lean and Six Sigma

According to the American Society for Quality (ASQ), most successful implementations start with the Lean approach, which boosts efficiency and makes the workplace as efficient and effective as possible by reducing waste and using value stream maps to improve throughput. Following that, any remaining process issues can be addressed using "more technical Six Sigma statistical tools."

The overall goal is to build a well-rounded IT process improvement strategy by combining the best of both methodologies. Both methodologies have flaws when used separately, but when used together, it is easier to fill in the gaps. Six Sigma, for example, eliminates defects but does not teach organisations how to optimise process flow, according to the Business Process Management Institute (BPMI). Similarly, the BPMI claims that Lean provides a limited view of process defects because it lacks the "advanced statistical tools frequently required to achieve the process capabilities required to be truly 'lean.”

0 notes

Text

Learn Value Stream Mapping and Its Essentials for Success

Organizations are continuously looking for methods to increase customer value, reduce waste, and improve efficiency. Value stream mapping is an effective technique for accomplishing these goals (VSM). A visual technique called value stream mapping is used to examine and enhance the movement of data and materials through a system or process. We'll go through the essential ideas and factors for value stream mapping success in this blog, emphasizing the role it plays in promoting operational excellence and process improvement.

Understanding Value Stream Mapping

At its core, value stream mapping is a lean management technique that helps organizations identify and eliminate non-value-added activities, reduce lead times, and optimize process flow. The process involves creating a visual representation of the current state of a process, identifying areas of waste and inefficiency, and designing a future state that maximizes value for the customer. You can learn more about it by enrolling in top lean six sigma green belt certification courses to enhance your knowledge about VSM lean six sigma.

Key Concepts in Value Stream Mapping

Current State Map: The current state map provides a snapshot of the existing process, including all steps, activities, and flows from raw materials to finished product or service. It helps identify bottlenecks, delays, and waste in the process.

Value-Added and Non-Value-Added Activities: Value-added activities are those that directly contribute to meeting customer requirements and are willing to pay for. Non-value-added activities, on the other hand, do not add value to the product or service and should be eliminated or minimized.

Process Flow: Understanding the flow of materials and information through the process is critical for identifying opportunities for improvement. Process flow analysis helps identify areas of congestion, duplication, or inefficiency.

Future State Map: The future state map represents the desired state of the process after implementing improvements. It outlines the ideal flow of materials and information, as well as the elimination of waste and inefficiency.

Considerations for Success

Leadership Support: VSM lean six sigma requires strong leadership support to drive change and ensure that resources are allocated effectively. Leaders must champion the value stream mapping process and provide the necessary support and resources for implementation.

Cross-Functional Collaboration: Value stream mapping involves multiple stakeholders from different departments and functions. Effective collaboration and communication are essential for identifying opportunities for improvement and implementing changes across the organization.

Data Accuracy and Analysis: Accurate data collection and analysis are critical for identifying patterns, trends, and opportunities for improvement. Organizations must ensure that they have access to reliable data and the analytical capabilities to interpret it effectively.

Continuous Improvement Mindset: Value stream mapping is not a one-time exercise but rather an ongoing process of continuous improvement. Organizations must foster a culture of continuous improvement. They should empower employees to identify problems, propose solutions, and implement changes to drive positive outcomes.

Measurement and Monitoring: Establishing key performance indicators (KPIs) and metrics is essential for measuring the success of VSM lean six sigma initiatives. Organizations must monitor progress against established targets and adjust strategies as needed to achieve desired outcomes.

Conclusion

Value stream mapping is a powerful tool for driving process improvement and operational excellence in organizations. By understanding current state mapping, value-added activities, process flow, and future state mapping, organizations can identify opportunities for improvement. Organizations should consider factors like leadership support, data accuracy, continuous improvement mindset, and measurement and monitoring. It ensures the success of their VSM lean six sigma initiatives and achieve improvements in performance and customer satisfaction.

Do you want to learn more about Lean and six sigma green belt certification courses? You can enroll at MindCypress, an upskilling platform that supports professionals by providing personalized upskilling courses for career growth.

Resource: https://www.mindcypress.com/blogs/quality-management/learn-value-stream-mapping-and-its-essentials-for-success

0 notes

Text

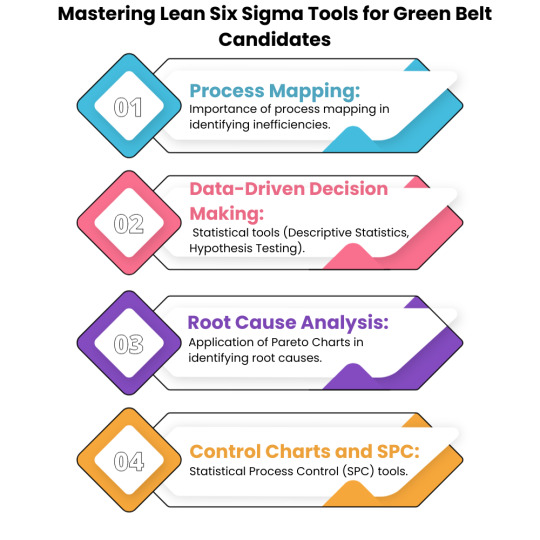

Mastering Lean Six Sigma Tools: A Deep Dive for Green Belt Certification Candidates

Introduction:

Lean Six Sigma, a well-known methodology for streamlining processes and increasing organizational productivity, empowers management with complex tools The mastery of these tools is critical to Greenbelt candidates who want to have more influence in their organizations. This blog will begin an in-depth analysis of the most important Lean Six Sigma tools. We will provide practical insights and guidance for Lean Six Green Belt candidates targeted to navigate their roles successfully.

1. Understanding DMAIC: The Foundation of Lean Six Sigma

At the core of Lean Six Sigma is the DMAIC process—Define, Learn, Evaluate, Improve, and Control. Each stage represents an important step in the journey of process improvement. We will break down the challenges in each category and shed light on their associated key objectives, strategies, and tools. With a better understanding of DMAIC, Greenbelt candidates can establish a structured and systematic approach to their development projects.

2. Process Mapping: Visualizing the Journey to Improvement

Process mapping is a key tool in the Lean Six Sigma arsenal. Through techniques such as flowcharts and value stream maps, Greenbelt candidates gain a visual understanding of existing processes. We explore how these maps not only identify inefficiencies but also foster collaboration among cooperatives. Deeper involvement in process mapping provides Greenbelts with the visual tools needed for effective problem-solving.

3. Data-Driven Decision Making: Statistical Tools for Green Belts

Statistical tools form the backbone of data-driven decision-making in Lean Six Sigma Green Belt candidates will benefit from descriptive statistical analysis, hypothesis testing, and regression analysis. Real-world examples will demonstrate how these tools enable data analytics, allowing for more informed and effective decision-making throughout the project lifecycle

4. Root Cause Analysis: Uncovering the Source of Problems

Identifying the root causes of problems is an important part of Lean Six Sigma Certification. Tools like the 5 Whys, fish skeleton diagrams, and Pareto charts make comprehensive root analysis easier. Through practical insights, Green Belt applicants will learn how to use these tools effectively, solving key problems that hinder implementation success.

5. Continuous Improvement with Kaizen Events

Kaizen processes are powerful tools for rapid, focused improvement. By organizing and facilitating Kaizen meetings, Greenbelt champions can drive change in their organizations. Success stories will demonstrate how these events can lead to significant improvements in processes, and foster a culture of continuous improvement.

6. Control Charts and SPC: Ensuring Sustainable Gains

Long-term sustainable improvement is a key consideration in Lean Six Sigma. Control charts and Statistical Process Control (SPC) provide tools to effectively monitor and control processes. Prospective Greenbelt developers will gain insight into the use of these tools to ensure that the gains made during the renovation are sustainable over the long term.

Conclusion: Empowering Green Belt Candidates for Impact

Mastery of Lean Six Sigma tools is not just a prerequisite for Green Belt certification; Being a problem solver and a system improvement expert is a journey. As Greenbelt candidates embrace the complexities of DMAIC, process mapping, statistical analysis, neuroanalysis, Kaizen events, control charts, and more, they position themselves as catalysts for innovation and efficiency This knowledge not only contributes to accurate certification but also Greenbelt continuous improvement in their organizations Also positioning themselves as cultural champions The ongoing journey to master these tools continues, marked by growth, learning, and commitment to positive change.

#LeanSixSigma#GreenBelt#ProcessImprovement#DMAICFramework#DataDrivenDecisionMaking#ContinuousImprovement#RootCauseAnalysis

0 notes

Text

How operational excellence through Lean, TQM, TOC and 5S help organisations improve performance? – Case Studies & Success Stories

Some of the case studies of our implementation as Lean, TQM, TPM, Six Sigma consultants in sites across India, Sri Lanka, Dubai, Saudi Arabia.

Case 1 – Industry: Material Handling equipment Manufacturing

Business Case : Not able to meet Customer demand on delivery time, due to constraint in fabrication. This resulted in adopting build to stock policy which added to inventory, last minute design corrections and rework costs

Project Goal : To reduce Chassis Fabrication time by 30 %

Approach used : Lean and Kaizen –- Studying and Mapping current process, -Analysing VA and NVA – Identifying and implementing solutions – Training on new methods – Standardization + more than 35 small improvements (kaizens)

Internal Customer Satisfaction measurement

Result Achieved : Previous : 9 Hrs/ Chassis

Target : 6 Hrs 30 Minutes Hrs /Chassis

Achieved: 4 Hrs 20 minutes/Chassis

Case 2 – Industry : Precision Tool Manufacturing

Business Case : Huge order backlogs and not able to meet customer expected delivery. Lead-time from order to Delivery was more than 12 weeks whereas customer expectation was less than 4 weeks.

The Challenge; It is a High Variety and Low Volume Business and Changeover time is much greater than Processing time.

Most tools are special tools and it was taking significant time at design stage

Project Goal : To Clear all Backlog orders

To reduce Lead-time in Phases to meet customer expectations (Both Manufacturing and Pre-Manufacturing Lead Times)

Approach used : Lean & Value Stream Mapping – Identifying the Bottlenecks – Developing should be Map and Implementation . ( Key tools: QCO, TPM, 5S, Standard work and Quality Improvement)

Result Achieved : Reduced overall lead-time in Phases from 12 weeks to 8 weeks in Phase 1 and from 8 weeks to 6 weeks in Phase 2.

Zero Backlog orders / Delighted Sales Team

Intangible Results : Internal Customer Satisfaction increased from 29 % to 76 % which improved cross-functional team work

Case 3 – Industry : Fiber Optic Cables for Telecom Industry

Business Case : Need to double Productivity as the demand increased in for exports

Challenges : It is completely manual process and productivity dependent on individual skills

Project Goal :

To Improve Productivity by 50 % from 430 ends per line per day to 650 ends per day per line

Approach used : Lean & Value Stream Mapping – TWI – 5S – Kanban

Hourly output monitoring and PDCA. Select pilot line and horizontal deployment to other lines

Result Achieved : Improved Productivity in Phases from 430 ends to 800 ends per line per day in 2 phases – 6 months duration.

This was achieved with existing workforce whose basic educational qualification is Class 10 or less

Case 4 – Industry : Apparel

Business Case : To meet demand of the export market . This could be met only if the lead-time from Cut-to-Pack is below 6 days.

Project Goal : To Reduce Lead-time from Cut to Pack from 9 days to less than 6 days

Approach used : A pilot line is selected, Takt time concept introduced,

VSM – Current and Future, Line Balancing , TWI, Heijunka + more than 25 small kaizens

Result Achieved : Achieved the goal of Lead-time reduction to less than 6 days in 2 phases

This company was also won Economics Times Manufacturing Excellence Award for best-in-Class Lean Implementation

Case 5 – Industry : Process – One of the Leading FIBC Bags Manufacturer in India

Business Case : It was a Mix of Labour and Process Oriented Industry. Labour Productivity was low compared to Benchmark companies in China. Quality and Delivery improvement at Optimum cost was the Goal

Project Goal :

To Improve Quality & Delivery and Reduce Cost through Total Employee Involvement

To reduce Wastage by 50 %

Approach used : 5S is used for Total Employee Engagement. Value Stream Mapping to identify the bottlenecks. Kaizen and AC story approached used for day today problem solving

Result Achieved : On Time Delivery >80 % achieved. Waste reduction Project is in progress

Case 6 – Industry : Process – Carbon Black

Business Case : Because of the Product the company is Manufacturing creating a healthy work environment was a challenge. Also the Machine Breakdowns were high due to dusty atmosphere

Project Goal :

To Improve work environment Score to 70 % +

Approach used : 5S , TPM and Visual Factory

Result Achieved : All the 15 zones in the organization achieved/exceeded the target score of 70 %. Employees felt happy about the better working environment. Indirect Benefits include Productivity, Employee Involvement and Customer delight

Case 7 – Industry : Automotive Machining

Business Case : Being in the Business of High precision parts for Automotive applications, quality and delivery are the top most priorities.

There is always a need to continual improvement to retain the share of Business.

Project Goal :

Reduce Customer Complaints, COPQ

Improve OEE and Value addition per employee

Improve Quality System Rating –Given by Customer

Approach used : 5S , Lean, TPM and Policy Deployment

Result Achieved : Achieved Zero Customer complaints and <100 ppm target . Exceeded target score in Quality System Audit. Reduction in Cost of poor Quality

Became a TOP rated supplier among all suppliers.

Achieved Platinum rating from OEM

Case 8 – Industry : High volume food manufacturing through automated machines – not for profit organisation sensitive in cost, hygiene, productivity and image of the organisation.

Business Case : This Industry feeds more than 1.5 million kids per day through Mid Day Meal scheme. Quality , Cost and Delivery are the key indicators to serve more and more hungry children. Operating more than 40 Kitchens throughout India. To improve the efficiency of the Kitchens The origination started TPM implementation with the help of Seven Steps.

Project Goal :

Reduce Customer Complaints, COPQ

Improve OEE of Key Equipments like Boilers, Roti Makers , RO units

Approach used : 5S & TPM

Result Achieved : Bellary unit successfully completed phase 1 TPM implementation in 18 months . Achieved targeted results in OEE, Water and Energy savings, Quality improvements and Employee engagement

Case 9 – Industry : Made to order and stock products needing Lean manufacturing for quick response and faster supplies

Business Case : MNC started its Operations in India a few years back . The Leadership team in India selected Seven Steps as their Strategic Partners to support their Vision 2022 project

The company supplies more than 25000 variety of Springs

Project Goal :

Facilitation of Business Excellence Initiatives by establishing Vision, Strategies, Roadmap and Key Milestones

Approach used : TQM , Lean and Policy Deployment

Result Achieved : Established good Daily Management Systems to reduce day to day Fire Fighting and focus on Break through Improvements. Backlogs brought close to ZERO using Lean approach

Machine Efficiencies improved to address High mix and low volume demands

Seven Steps Academy of Excellence is the training and development arm of Seven Steps Group having Headquarters in Bangalore, India. We provide training both inhouse and public programmes on globally recognized Lean Six Sigma Green Belt and Lean Six sigma black belt. Our reach is all over India and we serve cities such as Chennai, Mumbai, Hyderabad, Chennai, Hosur, Mysore, Ludhiana, Neemrana, Chandigarh, Pant Nagar, Nashik.

Other trainings being provided from Seven Steps academy include

Lean Six sigma professional training – Green belt and black belt

Lean experiential learning – training for Lean professional and Lean champions

Applied 5S and Visual Management for manufacturing, retail, logistics, Hospitals, Construction, Airports, Banking sector, power plants

Kanban and Supermarket implementation training for retail, manufacturing, hospitals, medical stores, warehouse, showrooms.

Total productive maintenance training – TPM, Autonomous maintenance – Jishu Hozen for manufacturing plants and continuous process plants.

Lean layout training.

Through our Consulting arm, we facilitate deployment of Lean manufacturing, Total Productive Maintenance, Policy deployment, 5S , Six Sigma consulting and implementation support. Our consultants are from multiple sector experience and we operate all over India.

Some of the flagship training programmes conducted at Seven Steps Academy of Excellence are:

Six sigma Green Belt

Six Sigma Black Belt

Six Sigma Yellow Belt

Skill development programme – Campus to Corporate – Precision Engineering

Applied 5S

TPM

Lean Experimental Learning Programme

#Business Excellence Consulting Companies in bangalore#Kaizen lean manufacturing companies in bangalore#lean healthcare consulting company in bangalore#Office lean kaizen services in bangalore#six sigma quality management in bangalore#kaizen implementation company in bangalore

0 notes

Text

Total Employee involvement through Quality circles and Kaizen Circles can take the organization to World Class levels.

For organizations to prosper, constant attention must be paid to quality control. This has become a well-known fact. The basic idea of quality control has been spread to all, but the implementation of it has not. The Japanese believe that caution is required for progress, but one who is overly cautious can never become a top manager.

Quality circles, if implemented correctly, can encourage and enable people at all levels of an organization to play meaningful roles in their organizations, hence improving the quality of their work. The concept of the quality circles was gotten from the Japanese, who believed that implementation of quality circles enabled problem solving at the front lines of their organizations.

To understand the concept of quality circles, we must first know

what quality is and how to achieve quality ?

Quality has been described by many people as many different things, but in reference to quality circles, quality is the state in which the entitlement of value is realized for both the customer and the provider in every aspect of the business relationship without majorly affecting the environment or the society.

To achieve quality, all levels of the organization must have the responsibility to maintain quality and must be responsible for the job assigned to them. To control and achieve quality, Statistical Quality Control gives the first approach. Statistical Quality Control has five stages of statistical integrity, each one sharing equal importance regarding achieving Statistical Quality Control.

Statistical quality control

Statistical Quality Control is an all-pervasive function to achieve quality control, but Statistical Process Control (SPC) aims at increasing knowledge and awareness about Statistical Quality Control and steers a process to behave in a particularly desired way. SPC measures, analyzes and controls variations in process through the application of statistical techniques. It aims to increase the output produced from a given amount of resource input. When implemented correctly, SPC reduces cost and increases profits majorly, though depending on the market, product and customer needs in many ways.

SPC also serves as a strategy for defect prevention in organizations. Total Quality Control -TQC is proven system for quality development, maintenance and improvement efforts and integrating various groups in an organization to enable production and service at the most economical levels. This in-turn allow the customer full satisfaction. TQC understands the necessity and importance of quality control by everyone in the organization being engaged in it. TQC requires the participation of all divisions in an organization. Though TQC is perfectly functional by itself, the involving of the Japanese did improve TQC by quite a bit. The Japanese began using SQC after the 2nd World War.

One could easily see that quality has always been an important element of competitive success. The initial approach for quality was final inspection and postproduction adjustment. Total Quality Management (TQM)is a new approach to improve quality and customer satisfaction on a continuous basis by restructuring traditional management practices.

Quality Circle

A Quality Circle had been described by professionals as a small group that voluntarily performs Quality Control within the same workshop/workspace for self-development, mutual development, control and improvement using Quality Control techniques with all the members participating equally and in harmony. The concept of Quality Circles has been spread in more than 130 countries, though it is mostly used in Asian countries such as Japan, South Korea, Taiwan, China and others.

For effective functioning of a Quality Circle, the following instructions must be strictly followed by the organization implementing it:

The upper management’s conviction and leadership for quality

Continuous education on developments taking place

Annual Quality improvement plans

Annual cost reduction plans and their implementation.

Implementation of this process shall bring about not an evolutionary change, but a revolutionary change in the functioning of organizations. The Quality circle is the best path towards the development of human resources. The Quality circle is not only a means of bringing about efficiency in a given organization, but also encourages employees at all levels to think about themselves, their families, associates and loved ones for improvement, as ‘the best help is self-help.

Many magazines have mentioned the Quality circle in their articles.

Some people have shared their views regarding the fact that Quality Circles should not be conducted at the command of a superior but instead must be conducted voluntarily at individual workplaces and organizations. They believe that if a worker wishes not to participate in the implementation of a Quality circle, he/she should not be forced into it. It must be noted that the Japanese started the implementation of Quality Circles long after every employee in their management had been thoroughly trained in quality control, at the end of the total program of implementation of quality control.

Not all companies require Quality Circles. To see whether they need the Quality Circle to increase the quality of the products, they should be clear about the following:

Whether they need such an introduction in their company,

Whether they are having the required conditions for such an introduction and

How they should introduce the Quality Circle in their company.

To smoothly introduce the Quality circle into their organization, the following steps must be followed.

Initiating an exposure program to senior executives,

Forming a Quality Council / steering committee and selecting a co-coordinator,

Working out an action plan,

Finding qualified trainers and facilitators,

Initiating an exposure program for workers and staff members

All together leading to successful quality circles.

Seven Steps academy of excellence is training and skill development arm of Seven Steps group which facilitates organization level deployment of Quality circles and Kaizen teams for ongoing improvements. Other trainings being provided from Seven Steps academy include

Lean Six sigma professional training – Green belt and black belt

Lean experiential learning – training for Lean professional and Lean champions

Applied 5S and Visual Management for manufacturing, retail, logistics, Hospitals, Construction, Airports, Banking sector, power plants

Kanban and Supermarket implementation training for retail, manufacturing, hospitals, medical stores, warehouse, showrooms.

Total productive maintenance training – TPM, Autonomous maintenance – Jishu Hozen for manufacturing plants and continuous process plants.

Lean layout training.

Through our Consulting arm, we facilitate deployment of Lean manufacturing, Total Productive Maintenance, Policy deployment, 5S , Six Sigma consulting and implementation support. Our consultants are from multiple sector experience and we operate all over India.

Some of the flagship training programmes conducted at Seven Steps Academy of Excellence are:

Six sigma Green Belt

Six Sigma Black Belt

Six Sigma Yellow Belt

Skill development programme – Campus to Corporate – Precision Engineering

Applied 5S

TPM

Lean Experimental Learning Programme

#Kaizen and Quality Circles#Statistical Quality Control#Seven Steps Academy#5s training in bangalore#lean six sigma#lean six sigma certification#lean six sigma green belt#lean six sigma black belt#lean six sigma yellow belt#lean six sigma training

0 notes

Text

All You need to know about Lean Six Sigma Certification

Lean Six Sigma has turned out to be the most celebrated tool in quality management spectrum. Although both Lean and Six Sigma have not witnessed much change individually, they have been widely accepted together.

While Lean methodologies aim at streamlining the process by eliminating wastes and variations, Six Sigma aims at refining a process until there is no issue left in it. Lean Six Sigma brings both these aspects together by reducing variations and detecting defects along with preventing defects. In this article, we will drill deep into the Lean Six Sigma and find all the minutes of Six Sigma.

Who governs Lean Six Sigma?

The first fact that you need to be acquainted with is that there is no Central certifying body for Six Sigma. The certification is provided by Master Black Belt through the organization he or she works for. This provides great flexibility to the Lean Six Sigma as organizations can streamline the course to suit their needs. Here are a couple of good reads on this topic.

The mystery of Central certifying body of Six Sigma!

The mystery of Central Certifying body of Six Sigma! What others have to say!

What is the base of LSS?

In layman’s term, the base working principle of LSS can be summed as:

Align all the efforts to fulfill customers’ requirements

Understand the steps that create the deliverables (value stream)

Improve the Value Stream

Eliminate elements that do not add value along with Wastes

Reduce variations in processes

Decide based on data not guess

Include employees in the improvement process and provide them the tools to find the solutions

What are the benefits of Lean Six Sigma?

Being the most potent quality management tool, the direct benefit of Lean Six Sigma to the organization is that it greatly improves the quality of products and processes thus increasing profitability. Professionals taking up the course enjoy multiple benefits like

Higher Pay structure: A Lean Six Sigma Certified professional gets a mean salary of $99,000 (Black Belt).

Improved opportunities: Lean Six Sigma Certification validates your knowledge in quality management. As quality management is a prominent aspect in every industry, new opportunities open up by hours.

Better performance: With the new learnings from the certification course, the performance gets a huge boost.

Nurture managerial skills: In general, Six Sigma helps nurture managerial skills in you and in due time you may become the face of change in your organization.

What are the various levels in Lean Six Sigma Certifications?

There are 6 levels in Lean Six Sigma which is represented in the form of belts. Each iterative belt digs deeper in Lean Six Sigma methodology and elaborates on methodologies and tools.

Lean Six Sigma White Belt: You are inducted to the structure of Lean Six Sigma along with the vocabulary used in it.

Lean Six Sigma Yellow belt: With the yellow belt, you will be able to work with the quality management team and will be able to identify and report process issues.

Lean Six Sigma Green Belt: You will gain the competency to manage the LSS based projects and provide a just-in-time trainer to the junior associates new to the quality management spectrum.

Lean Six Sigma Black Belt: You will have the mastery in LSS and will be able to drive LSS based projects along with extensively monitor and mentor the quality management team.

Lean Six Sigma Master Black Belt: You will work with the leadership team to identify major issues and design holistic solutions. You will also be responsible to integrate LSS into the working culture of the organization.

Lean Six Sigma Champion: You will work as an executive leader and will be responsible for any and all the change initiatives on an organizational level. You will also be the face of Cultural shift in the organization.

What are the prerequisites for taking up LSS certification?

The only prerequisite for getting LSS certification is the will to take active actions towards learning and shaping your future. Anyone working in quality management or project management spectrum can take up LSS certification. While you can take up any certification, it is advisable to follow the order of certification for maximum learning.

Where to get the LSS certification from?

Most of the prominent organizations provide in-house LSS training. These training modules are aligned towards the needs of the organization. If the organization you work for does not provide in house training, you can take up LSS certification from various training providers.

There are several training facilitators in the market who can assist you with the PMP certification course. We, Certification Planner are a leading training provider and are committed to connecting you with the best training solutions available. With our courseware being developed by Certified PMP instructors, we provide the best-in-class quality. Also get access to complimentary E-learning material, E-Book, A Guide to the Project Management Body of Knowledge (PMBOK® Guide - 6th Edition), Chapter end quizzes and much more.

If you want to know more, contact us at [email protected] or visit us at www.certificationplanner.com. You can also call us at +1 4084185586. Happy learning!

0 notes

Text

Top Benefits Of Lean Six Sigma Black Belt Certification

Lean Six Sigma Black Belt Program is one of the top 10 most sought after certification program in the world today. The reason being, over the last few decades Lean and Six Sigma methodologies, are being increasingly used across industries to improve the business profitability.

As the number of companies who look for ways to cut costs, improve efficiency and reduce waste increases, the adoption of Lean and Six Sigma will continue to increase.

Until today most of the large-scale Lean and Six Sigma deployments are done by the Consultants. But as the methodologies of Lean and Six Sigma are becoming the mainstream, companies are expecting their employees to become skillful in these.

The increased demand has led many professionals to opt for Lean Six Sigma Black Belt training program. These training programs not only enhance your career prospects but also augurs fully in business intelligence and problem-solving expertise.

As we can see from the list, Lean and Six Sigma methodology has a direct impact on 3 of the top 6 skills. They are,

Analytical Thinking

Strategic Thinking

Creative Problem-Solving

By doing the Lean Six Sigma Black Belt Program, you will have addressed the gaps in above skills and gained significant expertise.

Moreover, with rapid automation happening across industries, Problem Solving is one of the core skill, every professional should possess to survive and grow in the industry and Lean Six Sigma addresses this very core skill.

Producing Results: The overall purpose of becoming the champion in Lean Six Sigma Black Belt is to start producing results, right away at your Organization. Lean helps you to eliminate waste, improve the timeliness and productivity and Six Sigma reduces the variability, thus improving the overall quality. Hence, as a Black Belt you will be directly responsible for improving business profitability, customer satisfaction, customer loyalty and employee satisfaction.