#Lean Workflow Mapping Software

Explore tagged Tumblr posts

Text

Maximizing Efficiency: How to Streamline Workflow for Teams and Businesses

In now a days speedy-paced business surroundings, efficiency is prime to staying competitive. Streamlining workflow is a critical method that enables groups optimize productivity, lessen inefficiencies, and beautify overall performance. By figuring out bottlenecks, leveraging generation, and imposing powerful strategies, businesses can acquire better results with less effort. This article explores diverse methods to streamline workflow and beautify operational performance.

Best tools to streamline workflow for small businesses free

Understanding Workflow Streamlining

Workflow streamlining involves simplifying and optimizing tasks, approaches, and conversation within an organization to make certain smooth operations. The purpose is to dispose of needless steps, lessen redundancies, and enhance usual workflow performance. By streamlining workflow, organizations can limit errors, beautify employee productivity, and enhance customer delight.

Steps to Streamline Workflow

1. Analyze Current Processes

The first step in streamlining workflow is to investigate the contemporary strategies. Understanding how duties are currently being finished permits corporations to become aware of inefficiencies, redundancies, and regions that need improvement.

Conduct technique audits to map out workflows.

Identify bottlenecks that slow down operations.

Seek remarks from personnel worried within the workflow.

2. Define Clear Goals and Objectives

Setting clean objectives allows make certain that every one workflow optimization efforts align with the company’s dreams. Whether the intention is to lessen processing time, growth accuracy, or improve customer service, defining specific and measurable goals is important.

Establish key overall performance signs (KPIs) to degree achievement.

Ensure all crew participants apprehend the anticipated outcomes.

3. Automate Repetitive Tasks

Automation is a recreation-changer in terms of streamlining workflows. Leveraging generation to deal with repetitive tasks reduces human mistakes, saves time, and improves performance.

Use undertaking control tools like Trello, Asana, or Monday.Com.

Implement customer relationship control (CRM) software program to streamline purchaser interactions.

Utilize automation tools including Zapier or Microsoft Power Automate.

Four. Improve Communication and Collaboration

Ineffective verbal exchange can reason delays and misunderstandings. Streamlining conversation ensures that employees have get right of entry to to the records they need after they need it.

Establish clear verbal exchange protocols.

Encourage regular group conferences and check-ins.

5. Standardize Procedures

Having standardized techniques ensures consistency and reduces confusion. Clearly defined approaches assist personnel understand their roles and responsibilities, leading to extra performance.

Create fashionable operating approaches (SOPs) for ordinary obligations.

Train personnel on excellent practices and pointers.

Regularly evaluate and update procedures to preserve them applicable.

6. Eliminate Unnecessary Steps

Many workflows consist of redundant or needless steps that upload no fee. By eliminating those steps, organizations can improve efficiency.

Identify and take away non-critical obligations.

Optimize approval tactics to reduce delays.

Use lean control concepts to streamline operations.

7. Leverage Data and Analytics

Data-driven selection-making helps corporations optimize workflows by offering insights into performance metrics and ability regions for improvement.

Use analytics gear to music workflow efficiency.

Identify developments and patterns in operational performance.

Adjust techniques based totally on facts insights.

8 Delegate and Outsource When Necessary

Delegating duties ensures that the right humans manage the right duties, preventing overload and improving efficiency.

Assign duties primarily based on worker strengths and understanding.

Outsource non-center sports to 0.33-birthday celebration carrier carriers.

Encourage personnel to focus on excessive-fee duties.

9. Encourage a Culture of Continuous Improvement

Workflow optimization is an ongoing manner. Encouraging a way of life of continuous development guarantees that companies adapt to converting wishes and stay competitive.

Solicit worker comments on workflow upgrades.

Conduct ordinary schooling and improvement programs.

Stay updated with enterprise tendencies and excellent practices.

10. Monitor and Adjust Workflow Regularly

Even the maximum nicely-optimized workflow desires continuous tracking and modifications to maintain efficiency.

Use overall performance monitoring tools to assess workflow effectiveness.

Conduct periodic opinions to identify new challenges.

Make essential changes to improve operations.

Benefits of Streamlining Workflow

1. Increased Productivity

By casting off inefficiencies and automating repetitive responsibilities, personnel can awareness on extra valuable activities, leading to higher productivity.

2. Cost Savings

Streamlining workflow reduces wasted assets, minimizes mistakes, and improves performance, resulting in substantial cost savings for agencies.

3. Improved Employee Satisfaction

Simplified methods and clean suggestions reduce frustration and stress amongst employees, improving process delight and engagement.

4. Better Customer Experience

Efficient workflows permit agencies to respond to client wishes faster and with better accuracy, leading to stepped forward consumer satisfaction and loyalty.

5 Enhanced Decision-Making

With higher facts collection and evaluation, organizations can make informed decisions that power achievement.

2 notes

·

View notes

Text

Top Reasons ComputerWorks Clients Prefer Adagio Accounting Software

For growing businesses, choosing the right accounting software isn’t just about features—it’s about finding a solution that fits seamlessly with operations, scales with growth, and offers the control that finance teams demand. That’s why so many clients of ComputerWorks choose Adagio Accounting Software to power their financial operations.

Known for its reliability, modular structure, and batch-oriented processing, Adagio Accounting Software has become the preferred choice for mid-sized businesses that have outgrown basic bookkeeping tools like QuickBooks but aren’t ready for the complexity (or cost) of full-scale ERP systems.

1. Designed for Financial Precision and Audit-Readiness

One of the top reasons ComputerWorks clients lean toward Adagio Accounting Software is its robust audit trail. Adagio uses batch-style processing, meaning users must explicitly post transactions, which adds a layer of control and accountability. This setup reduces errors and ensures financial integrity—an essential feature for companies subject to regulatory audits or financial scrutiny.

With Adagio, every entry is traceable, making it easier for accountants and auditors to verify transactions without digging through disconnected systems or spreadsheets.

2. Powerful Financial Reporting Capabilities

While many accounting platforms require third-party tools for customized reporting, Adagio Accounting Software includes its own advanced financial statement generator. Clients appreciate the flexibility it provides—whether they need department-level reports, consolidated statements, or multi-year comparisons.

ComputerWorks ensures that each client’s reporting needs are mapped during implementation, allowing stakeholders to view financial data in the format that best supports their decision-making.

3. Modular and Scalable for Growing Companies

Adagio isn’t a one-size-fits-all solution. Its modular architecture allows businesses to choose only the components they need—such as Ledger, Payables, Receivables, Inventory, and more—then add on as they grow.

This modularity is a key reason clients stick with Adagio Accounting Software over time. With support from ComputerWorks, businesses can expand their system capabilities without needing to replace their core infrastructure.

4. Seamless Integration with Existing Systems

Many mid-sized businesses use vertical market software or industry-specific tools. Adagio Accounting Software can be configured to integrate with a variety of third-party platforms, giving clients the flexibility to maintain their existing workflows.

ComputerWorks plays a critical role here, leveraging its in-house technical expertise to tailor integrations that align with client-specific requirements.

5. Exceptional Support and Training from ComputerWorks

Adopting new accounting software can be intimidating, but ComputerWorks ensures that the transition is smooth. Their team offers personalized onboarding, training, and ongoing technical support—helping clients fully utilize the power of Adagio Accounting Software.

Many clients cite ComputerWorks’ responsiveness, depth of product knowledge, and real-world accounting experience as deciding factors in both choosing Adagio and staying with it long term.

Conclusion

Choosing accounting software is a strategic decision—and for many mid-sized organizations, Adagio Accounting Software strikes the ideal balance between control, functionality, and affordability. Combined with the expert guidance and implementation support from ComputerWorks, it becomes a powerful tool for financial management, compliance, and growth.

If your business is ready to move beyond entry-level systems and gain deeper control over financial data, it’s time to explore how Adagio Accounting Software, supported by ComputerWorks, can deliver long-term value and confidence.

0 notes

Text

The Power of Lean: Why Every Professional Needs a Lean Implementer Certification in 2025

In a world where efficiency is everything, businesses are constantly looking for ways to do more with less. That’s why lean methodology has become a core strategy across industries and the need for skilled professionals with a Lean Implementer Certification is higher than ever. Whether you're in IT, manufacturing, finance, or healthcare, earning the Certified Lean Implementer credential gives you the skills to cut waste, improve processes, and become a true change-maker in your organization.

Why Lean Matters More Than Ever in 2025 💡

Organizations today face rising costs, increasing customer expectations, and pressure to deliver faster. That’s why companies are turning to lean certification programs to find leaders who can think strategically and act efficiently. With a lean implementer certification, you don’t just learn theory, you master tools that directly improve how work gets done.

From identifying non-value-added tasks to creating streamlined workflows, a certified lean implementer helps organizations stay competitive, responsive, and profitable in a fast-paced world.

What You’ll Gain from a Lean Implementer Certification 🎓

By taking the lean implementer course, you’ll gain practical, job-ready knowledge that includes:

✅ How to eliminate waste in processes ✅ How to drive continuous improvement ✅ How to apply Lean tools like 5S, Value Stream Mapping, and Kaizen ✅ How to lead process improvement initiatives across departments

And most importantly, the lean certification helps you become someone companies trust to boost performance and lead change.

Who Needs a Certified Lean Implementer? 🧑💼🏭

This certification is perfect for:

🔹 Project Managers 🔹 Business Analysts 🔹 Quality Specialists 🔹 Operations Managers 🔹 Engineers 🔹 IT Professionals 🔹 Healthcare Administrators

Whether you're early in your career or an experienced professional, the Certified Lean Implementer certification gives you a recognized edge in the job market.

Real Results from Lean in Action 🚀

✔️ A financial services firm saved $1.2 million in operational costs after a certified lean implementer redesigned their loan processing workflow. ✔️ A hospital reduced patient wait times by 35% through Lean-driven scheduling and resource allocation. ✔️ A software company improved product delivery speed by 40% using Lean tools combined with Agile frameworks.

Future-Proof Your Career with Lean Skills 🌐

As businesses continue evolving, lean skills will be essential not optional. Professionals who hold a lean implementer certification show they’re ready to handle real-world challenges, improve performance, and lead with confidence.

This isn't just another certificate it's a proven way to:

✔️ Grow your career ✔️ Make measurable impact ✔️ Stand out to top employers ✔️ Be part of strategic decision-making

Ready to Start Your Lean Journey?

Now is the perfect time to enroll in the Certified Lean Implementer Certification and join the ranks of professionals driving real change in their organizations.

For more information: https://www.gsdcouncil.org/certified-lean-implementer

Contact no: +41 41444851189

0 notes

Text

Common BPM Challenges and How Professional Services Can Solve Them

In today’s rapidly evolving business landscape, companies are constantly pressured to streamline operations, reduce costs, and improve customer satisfaction. This is where Business Process Management Services come into play. Organizations like Global Wave Dynamics offer expert solutions designed to optimize workflows, ensure regulatory compliance, and enhance overall performance. However, the road to effective BPM implementation is not without its challenges. Understanding these obstacles — and how professional services can overcome them — is key to leveraging the full potential of BPM.

1. Lack of Clear Process Visibility

One of the most prevalent challenges in BPM is the lack of end-to-end visibility into business processes. Without a clear view of how tasks flow from one department to another, inefficiencies and bottlenecks often go unnoticed. This can lead to delays, duplicated efforts, and missed opportunities for improvement.

How Professional Services Help: Business Process Management Services begin with comprehensive process mapping and analysis. Professionals use tools such as flowcharts, process modeling software, and performance dashboards to give stakeholders a clear, real-time view of operations. This transparency makes it easier to identify pain points and prioritize improvements.

2. Resistance to Change

Change management is one of the most difficult aspects of BPM implementation. Employees often resist new workflows due to fear of the unknown, concerns about job security, or simple inertia. This resistance can stall or even derail BPM initiatives.

How Professional Services Help: Experienced BPM consultants understand the psychology of change. They offer structured change management strategies, including communication plans, training programs, and employee engagement initiatives. By involving stakeholders early and often, they help foster a culture that embraces improvement rather than fearing it.

3. Poor Integration with Existing Systems

Many businesses struggle to align BPM solutions with legacy systems or other third-party platforms. This lack of integration can result in data silos, manual hand-offs, and reduced efficiency.

How Professional Services Help: Professional Business Process Management Services are designed with integration in mind. Service providers assess your current IT ecosystem and build custom connectors or APIs to ensure seamless data exchange between systems. This not only reduces redundancy but also enhances real-time decision-making by centralizing information.

4. Inadequate Performance Metrics

It’s difficult to improve what you can’t measure. Many organizations embark on BPM initiatives without establishing clear KPIs (Key Performance Indicators) to track progress and outcomes. As a result, they struggle to determine whether their efforts are delivering real value.

How Professional Services Help: Expert BPM providers start by defining success metrics aligned with business goals, such as cycle time reduction, error rate minimization, or customer satisfaction improvement. They then implement monitoring tools that allow for continuous performance tracking. With data-driven insights, businesses can adjust strategies in real-time and demonstrate ROI to stakeholders.

5. Complexity in Process Design

Designing optimal workflows that meet compliance standards, customer needs, and internal requirements can be overwhelming. In many cases, companies either over-engineer processes, leading to unnecessary complexity, or under-design them, resulting in ambiguity.

How Professional Services Help: Business Process Management Services include access to seasoned analysts and architects who specialize in process simplification. These experts apply lean methodologies, Six Sigma principles, and industry best practices to ensure that processes are both efficient and scalable. The result is a design that’s intuitive, robust, and adaptable to future needs.

6. Lack of Strategic Alignment

Sometimes BPM efforts are treated as standalone projects rather than integral components of business strategy. When BPM is isolated from overall corporate goals, it’s easy for initiatives to lose direction and fail to deliver long-term benefits.

How Professional Services Help: Professional BPM services ensure strategic alignment by involving executive leadership and aligning process objectives with business priorities. Whether the focus is digital transformation, cost reduction, or improved customer experience, the BPM strategy is tailored to support those high-level objectives. This alignment enhances both the relevance and sustainability of BPM efforts.

7. Difficulty in Maintaining Momentum

Even when BPM projects start strong, sustaining improvement over time is a common challenge. Teams may revert to old habits, or improvement initiatives may lose visibility after the initial excitement fades.

How Professional Services Help: Top-tier Business Process Management Services provide ongoing support through governance frameworks, periodic audits, and continuous improvement programs. Providers like Global Wave Dynamics not only help implement changes but also establish feedback loops and accountability structures to keep BPM efforts on track. With consistent review and iteration, businesses can maintain momentum and continue reaping the benefits of process optimization.

Conclusion

While the path to BPM excellence is riddled with challenges — from lack of visibility and employee resistance to integration issues and misalignment — each of these obstacles can be effectively addressed with the right professional support. Business Process Management Services offer more than just process redesign; they bring structure, expertise, and strategy to the table.

Organizations that partner with experienced providers such as Global Wave Dynamics position themselves to overcome operational hurdles and drive long-term innovation and growth. By investing in the right BPM services, businesses can transform challenges into opportunities and build a foundation for sustainable success.

1 note

·

View note

Text

3D Modeling Games on a Budget Free Tools That Compete with Industry Giants

In the ever-expanding world of game development, 3D modeling plays a crucial role in shaping immersive experiences. From crafting realistic 3D game assets to developing expansive 3D game environments, the need for high-quality 3D content is more prominent than ever. However, premium tools like Autodesk Maya, 3ds Max, and ZBrush often come with steep price tags, creating barriers for indie developers, hobbyists, and students. Fortunately, a range of free 3D modeling tools now provide professional-level features that allow you to build games without burning a hole in your wallet.

This blog explores how to create 3D modeling games using free tools that can rival industry standards. Whether you're working on Hard Surface Modeling, designing a car 3D model, or developing detailed 3D game environments, you'll find the right tool to bring your vision to life.

Why Choose Free Tools for 3D Modeling Games?

Before diving into the tools, it's important to understand why choosing free software is not a compromise in today’s game development scene. Open-source and community-driven platforms have matured significantly, offering robust capabilities such as:

High-poly and low-poly modeling

UV mapping and baking

Rigging and animation

Sculpting and texturing

Real-time rendering

Free 3D modeling software can help you build professional 3D game assets and props 3D model without compromising quality, making them ideal for game studios on a budget.

Top Free Tools for 3D Modeling Games

Let’s look at some free tools that can help you build stunning 3D game environments, realistic vehicles, or detailed props for any game genre.

1. Blender – The Ultimate All-Rounder

Blender is the king of free 3D software and a favorite among indie developers and professionals.

Key Features:

Industry-standard 3D environment modeling, sculpting, and UV unwrapping

Built-in Cycles and Eevee render engines

Add-ons for game export formats like FBX, glTF, and OBJ

Blender excels at creating everything from stylized 3D game environments to realistic car 3D model structures with excellent polygon optimization.

2. SketchUp Free

For those new to 3D modeling games, SketchUp Free offers an intuitive browser-based interface ideal for basic Hard Surface Modeling and quick asset prototyping.

Ideal For:

Simple architectural or environmental layout

Early-stage 3D game environment blockouts

Basic 3D vehicle modeling and structures

While it lacks the depth of Blender or other professional suites, it’s perfect for beginners and level designers looking to experiment without a steep learning curve.

3. MagicaVoxel – Voxel Art for Stylized Games

If your game leans toward pixel art or voxel-based aesthetics, MagicaVoxel is an outstanding free choice. It allows you to create props 3D model, characters, and environments with a retro-inspired look.

Key Advantages:

Lightweight and easy to learn

Ideal for mobile and indie games

Exports to common 3D formats for game engines

Voxel games like Crossy Road and Minecraft-inspired titles have shown that stylized 3D modeling games can be just as engaging as hyper-realistic ones.

4. Wings 3D

While it lacks animation capabilities, it’s perfect for crafting game-ready props 3D model or vehicles.

Use Cases:

Modeling car 3D model for racing games

Creating a clean topology for export into game engines like Unity or Unreal

Low-poly 3D game assets are ideal for mobile optimization

5. ArmorPaint – Free Texturing Alternative to Substance

ArmorPaint is an open-source alternative to Substance Painter that allows for real-time 3D painting with PBR workflows.

Key Features:

Layer-based texturing

Real-time preview of materials

Integration with Blender and Unreal Engine

Perfect for those looking to polish their 3D game environment with realistic or stylized surface textures.

Creating Game Assets on a Budget: Best Practices

While using free tools helps reduce costs, maximizing efficiency in asset creation is just as important. Here are a few best practices:

1. Start with Modular Design

Design modular 3D game assets like walls, doors, and props that can be reused across your 3D game environments. This saves time and optimizes memory usage in the game engine.

2. Optimize for Performance

Games demand optimized geometry. Avoid unnecessarily high polygon counts, especially for mobile games. Even for 3D vehicle modeling, consider LOD (Level of Detail) techniques to maintain frame rates.

3. Utilize Free Libraries

Leverage community libraries like Sketchfab, CGTrader (free section), and Blend Swap.

Industry Examples of Games Using Free Tools

Some successful games and developers started their journey with free 3D tools:

"KRKAL 2" used Blender exclusively for character and level modeling.

"Supraland", a hit indie title on Steam, was created by a solo developer using Blender and UE4.

Voxel-based mobile games like The Sandbox started with tools like MagicaVoxel for content creation.

These games stand as testimony that free tools can produce stunning visuals and gameplay experiences when used skillfully.

Challenges and How to Overcome Them

While free tools offer a lot, they may lack certain features found in paid software. However, you can overcome these limitations through:

Community Plug-ins: Blender’s massive community offers add-ons for rigging, hard surface modeling, and exporting to engines like Unity and Unreal.

YouTube Tutorials: Free courses and tutorials can speed up your learning curve, especially for complex tasks like 3D hard surface modeling.

Combining Tools: Use Blender for modeling, ArmorPaint for texturing, and Unity for scene building to create an effective game pipeline—all at zero cost.

Conclusion: Create Without Limits

You don't need an expensive subscription to start your journey into 3D modeling games. With powerful free tools like Blender, MagicaVoxel, and SketchUp, you can build high-quality 3D game assets, realistic 3D vehicle modeling, and immersive 3D game environments without spending a dime.

From Hard Surface Modeling to designing a props 3D model that fits perfectly into your fantasy world, these tools empower creators to bring their vision to life on any budget. As technology advances and communities grow, expect even more capabilities from free 3D software shortly.

#Hard Surface Modeling#3d game environments#game assets#3d vehicle modeling#props 3d model#3d modeling games#3d modeling services

0 notes

Text

What is Lean Project Management? Understanding the 5 Principles

In today's fast-paced business environment, efficiency, agility, and value to the customer are the pillars of effective project delivery. One approach that has found favor for espousing these characteristics is Lean Project Management. What was initially a derivation from lean manufacturing processes developed by Toyota has found widespread use across sectors from software development to healthcare and construction. This piece explores what Lean Project Management is and examines the five fundamental principles that are the pillars of this methodology. What is Lean Project Management? Lean Project Management is a methodology centered on delivering maximum customer value with minimum waste. As opposed to traditional project management, which tends to focus on strict timelines and budget, lean revolves around maximizing processes, eliminating inefficiencies, and continually improving the manner in which work is accomplished. Lean" was made popular for the first time by the book written by James P. Womack and Daniel T. Jones, The Machine That Changed the World, back in the 1990s. Although manufacturing was what the term was actually about, the philosophy and means have been fantastically effective across project management applications. Essentially, Lean Project Management invites teams to create greater value with less means through making things more efficient and building a culture of continuous improvement. It's as much about the mindset as it is about the methodology.

Why Lean Project Management? Delays, cost overruns, and customer expectations misalignment are all too familiar in traditional projects. Lean mitigates these issues by: • Improving process efficiency • Cutting costs by eliminating waste • Increasing delivery speed • Improving product or service quality • Aligning team efforts with actual customer needs Whether software development, construction of infrastructure, or product introduction, lean practices can significantly enhance results. The 5 Core Principles of Lean Project Management Embedded within Lean Project Management are five basic principles. They were articulated by Womack and Jones and form the core of introducing lean into any given environment. 1. Identify Value Understanding what the customer values is the key to initiating any lean process. This implies avoiding the sole intention of task accomplishment and aiming for delivering outcomes of value to customers and to which they subscribe with expectations. Value is customer-defined, not team-defined. So, what are the features, functions, or services customers really care about? What will they pay for or value? By knowing value: • Projects align with customer expectations • Resources go to high-impact work • Teams don't waste time on work that won't add value This principle guarantees that each step in the project leads to a goal that is important. 2. Map the Value Stream Once value is established, the second step is to map the value stream — the entire life cycle of a product or service from conception to delivery. This entails: • Writing down every step in the process • Examining which steps create value and which do not • Determining bottlenecks, redundancies, and delays The intention here is to be able to see the workflow and to identify opportunities where waste can be eliminated. Waste in lean speak may be defined as overproduction, waiting, excess motion, untapped talent, overprocessing, unnecessary inventory, and defects. Mapping the value stream allows teams to have a clear view of how the work operates and where there is room for improvement.

3. Build Flow Having a streamlined value stream, smooth flow building is next in focus. Smooth flow entails designing processes and resources so work flows through the system without interruptions, delays, or rework. Some key practices to build flow are: • Reduction in batch sizes • Dividing work into small pieces of manageable work • Standardization of processes • Minimization of handoffs between teams Establishing flow typically involves cross-functional teamwork and eliminating conventional silos. As work flows smoothly, teams become more productive, delivery is quicker, and customers receive value sooner. 4. Create Pull The pull concept focuses on the fact that work should be started only when there is actual demand, not projections or internal timetables. That is, nothing is started or made unless there is an evident need for it. This avoids overproduction and makes sure that only those tasks that are actually needed by the customer or the next process step are being executed by the team. In practice, this could mean: • Visualizing workflow using Kanban boards • Prioritizing work items using customer input • Giving downstream processes the ability to "pull" resources when they are ready Pull systems keep steady flow going and prevent waste through a lack of overcommitment and less backlog clutter. 5. Pursue Perfection The last principle is one of promoting a culture of ongoing improvement, or "Kaizen" for short. There is never going to be a perfect process, and there will always be potential to improve the way work gets done. This includes: • Asking team members to make suggestions for improvement • bReviewing processes and results regularly • Making decisions based on data • Iterating on lessons learned Striving for perfection doesn't involve fixating on trivialities—it involves developing a culture in which all individuals are enabled to recognize and seize opportunities to make things better. In Lean Project Management, striving for perfection is not an end point, but a continuous process.

Lean Tools and Techniques Lean Project Management is supported by various tools and techniques that help in implementing its principles successfully. Some of them are: • Kanban: Visual method of controlling work flow and limiting work in progress • Value Stream Mapping: Diagram illustrating process steps and indicating waste • 5S System: Work area organization technique for making efficiency smooth • Root Cause Analysis: Techniques like the "5 Whys" to delve into problems • Lean Metrics: Cycle time, lead time, throughput, and other efficiency measures These tools provide shape and facts to lean thinking and decision-making. Challenges of Lean Project Management Lean has many benefits, but it's not without its challenges. Lean Project Management implementation requires: • A cultural shift towards transparency and continuous improvement • Patience and persistence as new processes are rolled out • Leadership commitment to enable lean transformation Resistance to change, poor training, or undefined customer requirements may also hinder lean implementation. However, through good leadership and team effort, these hindrances can be eliminated.

Final Thoughts Lean Project Management is not a collection of tools or a process—it's a mindset that values, efficiency, and learning. By using the five lean principles—Identify Value, Map the Value Stream, Create Flow, Establish Pull, and Pursue Perfection—organizations can achieve better outcomes, quicker, and with less. Whether you’re managing a large-scale software development project or a small internal workflow, Lean Project Management provides a powerful framework for driving continuous improvement and customer satisfaction.

Website: https://www.icertglobal.com/course/lean-management-certification-training/Classroom/50/3416

0 notes

Text

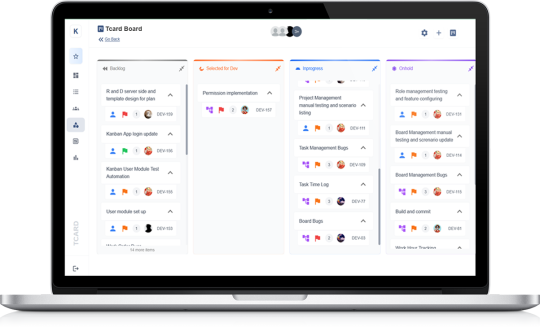

How Does T Card Software Support Continuous Improvement and Lean Principles?

Visit Us : https://kanbanboard.co.uk/how-tcard-software-continuous-improvement-lean-principles

Book Free Demo : https://kanbanboard.co.uk/contact-us

T Card software helps organisations improve continuously by supporting Lean principles and making workflow management more efficient. It provides a simple visual way to track tasks, monitor progress, and identify areas for improvement.

One key benefit is better organisation. The software allows teams to map out processes, assign tasks, and set priorities. This ensures that work is done in a structured manner, reducing delays and improving efficiency. By having a clear visual overview, teams can quickly spot bottlenecks and take action to keep operations running smoothly.

T Card software also promotes continuous improvement by supporting real-time tracking. Managers and employees can see the status of tasks at any moment, helping them make informed decisions. If an issue arises, it can be addressed immediately, preventing bigger problems down the line.

Lean principles focus on reducing waste and improving productivity. T Card software helps with this by eliminating the need for manual tracking, reducing paperwork, and cutting down on errors. Automating task updates ensures that time is used effectively and that valuable resources are not wasted.

Another advantage is better communication and teamwork. The software enables teams to share updates, assign responsibilities, and track performance together. This fosters a culture of accountability, where employees take ownership of their tasks and strive for continuous improvement.

Furthermore, T Card software helps businesses set clear performance targets. By tracking key metrics over time, organisations can measure success, identify trends, and make necessary adjustments. This supports long-term growth and efficiency.

In summary, T Card software supports continuous improvement and Lean principles by improving organisation, reducing waste, enhancing communication, and enabling real-time tracking. This leads to more efficient processes and better overall performance.

0 notes

Text

Streamlined Workflows for Success: Tips for Optimizing Your Operations

In today's fast-paced business environment, maintaining efficiency is crucial for success. Streamlined workflows play a vital role in enhancing productivity and reducing unnecessary tasks, allowing businesses to focus on core operations. Here, we'll explore the tips for optimizing your operations with streamlined workflows, focusing on strategies to streamline small business workflow and leveraging streamlined tools.

Benefits of Streamlined Workflows

Increased Cost Efficiency:

By automating tasks and reducing manual labor, businesses can save resources and allocate them more effectively.

Benefits: Streamlined workflows help minimize costs associated with paper usage, staffing, and data entry.

Improved Productivity:

Employees become more productive when processes are simplified, allowing them to focus on high-value tasks.

Benefits: Streamlined workflows enhance employee engagement and satisfaction by eliminating redundant tasks.

Enhanced Communication:

Streamlined management systems improve communication between departments, ensuring timely task completion.

Benefits: Better communication reduces confusion and enhances collaboration among team members.

Better Time Management:

With fewer tedious tasks, businesses can manage time more effectively, prioritizing critical tasks.

Benefits: Streamlined workflows allow for buffer time between tasks, reducing stress and improving overall efficiency.

Minimized Risk:

Streamlined processes provide greater transparency, making it easier to track progress and identify potential issues.

Benefits: This transparency helps in complying with regulations and meeting business obligations on time.

Strategies to Streamline Small Business Workflow

Assess Existing Processes:

Identify areas that can be improved by listing current processes and their benefits.

Benefits: Helps pinpoint unnecessary tasks and streamline workflows effectively.

Leverage Lean Principles:

Apply methodologies like continuous improvement and value stream mapping to eliminate waste and enhance efficiency.

Benefits: Encourages ongoing improvement and optimizes resource use.

Use Streamlined Tools:

Implement tools like workflow automation software to optimize routine tasks and reduce manual interventions.

Benefits: Enhances operational efficiency, reliability, and scalability.

Automate Repetitive Tasks:

Use low-code/no-code platforms to automate processes without extensive technical expertise.

Benefits: Supports collaborative development and maintains governance while improving efficiency.

Tips for Implementing Streamlined Workflows

Use Integrated Tools: Choose tools that combine multiple functions to streamline workflows efficiently.

Regularly Review Processes: Continuously assess and refine workflows to ensure they remain optimized.

Enhance Communication: Ensure open communication channels to prevent confusion during process changes.

Conclusion

Optimizing your business with streamlined workflows can significantly enhance efficiency and productivity. Whether you're focusing on streamlining small business workflow or leveraging streamlined tools, these strategies provide the insights and efficiency needed to stay competitive. For more insights on optimizing your business processes and leveraging the best tools, visit our comprehensive guide at GMB Briefcase.

Contact Us

GMB Briefcase

STPI, T 16 - B, MIDC, opp. Garware Stadium, MIDC Industrial Area, Chikalthana, Chhatrapati Sambhajinagar, Maharashtra, 431210, India

+91 9822298988

https://gmbbriefcase.com

Find Us Online

Facebook

LinkedIn

Twitter

YouTube Channel

GMB Briefcase On Google Map

youtube

0 notes

Text

All About Process Diagrams: A Detailed Guide

Are you devising a fresh strategy for your business? Looking to improve in a particular area or pinpoint the reasons behind a project's challenges? In such cases, process diagrams can serve as a vital tool for analyzing the "hows" and "whys." These diagrams are essential for enhancing processes, offering a visual breakdown of workflows, and identifying potential problem areas. This guide explores the concept of process diagrams, their applications, various types, and tips for creating them effectively.

What Is a Process Diagram?

A process diagram, often called a flowchart, is a graphical representation of a process or workflow. It typically uses symbols and arrows to outline the sequence of steps. By visualizing the process, these diagrams help users understand and evaluate workflows holistically.

Process diagrams are widely used across industries such as engineering, project management, business improvement, and software development. They are also key components of methodologies like Six Sigma and Lean for quality management and process optimization.

A Brief History

Process diagrams trace their origins to the early 20th century. In 1921, industrial engineer Frank Gilbreth, Sr., introduced the "flow process chart" to the American Society of Mechanical Engineers (ASME). This innovation laid the groundwork for using visual tools to map workflows in various fields.

Over the decades, process diagrams gained popularity in industrial engineering and manufacturing, where they were instrumental in streamlining production processes. In business, they evolved into tools for enhancing operational efficiency. Additionally, data flow diagrams emerged to address information systems and data management. This evolution highlights the versatility of process diagrams in fostering understanding, improving efficiency, and optimizing systems.

The Purpose of Process Diagrams

Process diagrams simplify complex processes by breaking them into manageable steps, allowing users to identify areas for improvement and monitor progress. They facilitate better communication within teams and help detect potential bottlenecks.

The specific shapes and symbols used in these diagrams vary by type, but the overarching goal is to illustrate workflows in a logical sequence. Applications range from mapping out product manufacturing processes to planning everyday activities like preparing a meal.

Types of Process Diagrams

Different types of process diagrams cater to specific needs. The following are the most common:

Process Flowchart: Provides a basic overview of a process from start to finish, using standard symbols like ovals (start/end points), rectangles (steps), and diamonds (decisions). Ideal for spotting inefficiencies.

Workflow Diagram: Focuses on the flow of tasks between individuals or departments, clarifying roles and responsibilities for smoother operations.

Swimlane Flowchart: Organizes steps into lanes representing departments or individuals, making it easier to visualize inter-departmental coordination and detect inefficiencies.

Data Flow Diagram: Highlights how data moves within a system, often used in IT and software development for system analysis and troubleshooting.

Key Symbols and Elements in Process Diagrams

Understanding process diagrams requires familiarity with the symbols and elements that depict operations and flows. Common components include:

Equipment Symbols: Represent machinery or tools.

Process Piping: Shows material flow paths.

Arrows: Indicate the direction of the flow.

Valves: Highlight control points.

Operational Data: Displays information like pressure or temperature.

Stream Labels: Identify materials or data in the process.

What Not to Include

To maintain clarity, some details are excluded from process flow diagrams:

Pipe classes and line numbers

Detailed control instruments

Minor bypass valves

Maintenance vents and drains

Safety valves and relief systems

Steps to Create a Process Diagram

Define the Problem: Clearly identify the process to be mapped and its improvement goals.

List Activities: Determine all relevant activities to include.

Set Boundaries: Understand the process’s scope and the roles involved.

Identify Steps: Outline the sequence of steps to ensure clarity.

Use Basic Symbols: Represent processes, inputs, outputs, and decision points with standard symbols.

Refine the Diagram: Add details like annotations and swimlanes for better comprehension.

By following these steps, you can create a detailed and effective process diagram that serves as a valuable tool for analysis and improvement.

0 notes

Text

Bottleneck Processes in Manufacturing: Common Causes and Solutions

In the competitive world of manufacturing, operational efficiency is paramount. However, bottlenecks can severely disrupt production timelines and increase costs. A bottleneck occurs when a particular process or machine limits the overall output of a production line. Understanding and addressing bottlenecks is crucial for maintaining a smooth workflow and maximizing productivity. This article explores the common causes of bottlenecks in manufacturing and provides practical solutions to overcome them.

Understanding Bottlenecks in Manufacturing

Bottlenecks are points in a production process where demand exceeds capacity, causing delays and inefficiencies. These constraints often result from imbalances in production flow, equipment issues, or resource limitations. Identifying bottlenecks promptly is essential to minimize their impact on productivity and profitability.

Common Causes of Bottleneck Processes

Machine Downtime

Frequent equipment breakdowns or maintenance issues can disrupt production schedules.

Aging machinery or inadequate preventive maintenance practices exacerbate this issue.

Inefficient Workflow Design

Poorly designed workflows can create unnecessary delays and inefficiencies.

Lack of synchronization between processes often leads to idle time and backlogs.

Labor Shortages or Skill Gaps

Insufficient staffing or a lack of skilled workers can slow down production.

Employee fatigue or errors due to overwork can further compound delays.

Supply Chain Disruptions

Delays in the delivery of raw materials or components create bottlenecks.

Unreliable suppliers or inadequate inventory management often lead to production halts.

Overproduction or Underutilization

Overproduction in one area of the line can overwhelm downstream processes.

Underutilization of resources results in inefficiencies and wasted capacity.

Effective Solutions to Address Bottlenecks

Conduct a Workflow Analysis

Map out the entire production process to identify bottleneck points.

Use tools like value stream mapping or process flow diagrams for better visualization.

Implement Preventive Maintenance

Schedule regular maintenance to reduce unexpected machine downtimes.

Invest in modern equipment with higher reliability and efficiency.

Optimize Resource Allocation

Reallocate labor or machinery to underperforming areas to balance workloads.

Train employees to enhance skills and improve productivity.

Adopt Automation and Technology

Use automated systems to streamline repetitive or time-consuming tasks.

Implement manufacturing execution systems (MES) to monitor and optimize production in real time.

Enhance Supply Chain Management

Establish strong relationships with reliable suppliers to minimize disruptions.

Adopt just-in-time (JIT) inventory systems to ensure smooth material flow.

Implement Lean Manufacturing Practices

Use lean principles to eliminate waste and improve process efficiency.

Employ techniques like Six Sigma to identify and resolve inefficiencies systematically.

Case Study: Bottleneck Resolution in Action

A medium-sized manufacturing company experienced delays due to an outdated bottleneck machine in its assembly line. After conducting a workflow analysis, they identified the root cause and invested in a modern, automated machine. This upgrade reduced downtime by 30% and increased production capacity by 20%, leading to significant cost savings and improved customer satisfaction.'

youtube

Final Thoughts

Bottlenecks in manufacturing are inevitable but manageable with the right strategies. By identifying common causes and implementing targeted solutions, businesses can streamline their production processes, reduce delays, and improve overall operational efficiency.

Investing in modern technology, training, and lean practices not only resolves current bottlenecks but also prevents future issues, ensuring sustained productivity and competitiveness in the market.

SITES WE SUPPORT

Software Processes - Wix

SOCIAL LINKS Facebook Twitter LinkedIn

0 notes

Text

Unlocking the Potential of Business Analysis

Unlocking the potential of business analysis involves understanding its core principles, tools, and techniques, as well as recognizing how it can bring value to an organization. Here’s how you can approach it effectively:

1. Grasp the Foundations

Definition: Business analysis is the practice of enabling change within an organization by identifying needs and recommending solutions that deliver value to stakeholders.

Key Objectives:

Understand business goals.

Bridge the gap between business needs and technical solutions.

Deliver actionable insights.

2. Master the Core Skills

To excel in business analysis, focus on the following skill sets:

Analytical Thinking: Break down complex problems into manageable components.

Communication Skills: Engage stakeholders and articulate findings clearly.

Problem-Solving: Identify root causes and propose practical solutions.

Technical Proficiency: Understand tools and systems used for analysis, like SQL, Excel, or specialized business analysis software.

3. Learn the Key Techniques

Some common techniques include:

SWOT Analysis: Evaluate Strengths, Weaknesses, Opportunities, and Threats.

Business Process Modeling: Visualize workflows to identify inefficiencies.

Requirement Gathering: Engage stakeholders through interviews, workshops, or surveys.

Gap Analysis: Compare current vs. desired performance or states.

4. Leverage Tools

Modeling Tools: Use tools like Visio, Lucidchart, or Bizagi for process mapping.

Data Analysis Tools: Familiarize yourself with Power BI, Tableau, or Excel for data-driven insights.

Project Management Tools: Collaborate using Jira, Trello, or Asana.

5. Align with Frameworks and Standards

Understanding industry-recognized frameworks ensures consistency and credibility:

BABOK® (Business Analysis Body of Knowledge): A guide by IIBA for best practices.

Agile Methodologies: Learn to adapt to iterative processes using Scrum or Kanban.

Lean Six Sigma: Focus on efficiency and quality in business processes.

6. Focus on Stakeholder Engagement

Build relationships with stakeholders at all levels.

Practice active listening to gather diverse perspectives.

Use storytelling and visualization to convey findings effectively.

7. Gain Certification

Certifications can boost credibility and demonstrate expertise:

Certified Business Analysis Professional (CBAP®): Advanced certification by IIBA.

PMI-PBA®: Focused on project management-oriented business analysis.

Agile Business Analyst Certification: Tailored for Agile environments.

8. Apply Business Analysis to Drive Value

Improve operational efficiency by optimizing processes.

Drive strategic initiatives by aligning solutions with organizational goals.

Enhance decision-making by providing actionable insights through data analysis.

By investing in these areas, you can unlock the full potential of business analysis, positioning yourself as a key player in driving organizational success. Let me know if you'd like resources or tailored guidance on any of these steps!

0 notes

Text

Process Improvement: The Secret to Boosting Efficiency and Success

In today's fast-paced world, businesses are constantly looking for ways to enhance their operations, improve productivity, and stay ahead of the competition. Enter Process Improvement, a game-changing approach to refining workflows, reducing waste, and achieving better outcomes. Whether you're a startup, a small business, or a global corporation, this concept has something to offer.

If you're new to the term, don't worry! We're here to break it down into simple, relatable terms that will leave you confident about how it can help transform your work and life.

What is Process Improvement?

At its core, Process Improvement is the practice of analyzing and enhancing existing processes to make them more efficient, cost-effective, and reliable. It’s all about identifying pain points, bottlenecks, or unnecessary steps in a workflow and finding better ways to tackle them.

Think of it this way: Imagine you’re baking a cake. The first time you try, you follow the recipe but take a lot of time measuring ingredients, preheating the oven, and cleaning up afterward. Over time, you find ways to streamline the process—pre-measuring ingredients, using tools to speed up mixing, and cleaning as you go. That’s Process Improvement in action!

Why is Process Improvement Important?

Businesses and individuals alike benefit from refining their processes. Here are some key reasons why it matters:

1. Saves Time

Time is money, right? Improving processes means tasks take less time to complete, freeing you to focus on what truly matters.

2. Reduces Costs

By eliminating inefficiencies, you can save resources like materials, labor, and energy. For businesses, this means higher profits.

3. Boosts Productivity

Streamlined workflows enable teams to accomplish more in less time, leading to happier employees and better results.

4. Enhances Quality

Consistently improving processes ensures fewer errors, better products, and more satisfied customers.

5. Encourages Innovation

When you actively look for better ways of doing things, you create a culture of creativity and continuous improvement.

Popular Process Improvement Techniques

There are several tried-and-true methods to improve processes. Here are some of the most commonly used ones:

1. Lean Methodology

Lean focuses on eliminating waste in processes. Waste can be anything that doesn’t add value to the final product or service. For example, reducing overproduction, unnecessary transportation, or excess inventory can significantly cut costs.

2. Six Sigma

Six Sigma aims to minimize errors and variability in processes. It uses data-driven techniques and statistical analysis to achieve near-perfect quality levels.

3. Agile

Though primarily used in software development, Agile principles can be applied to almost any field. Agile emphasizes adaptability and breaking work into smaller, manageable tasks.

4. Kaizen

Kaizen, a Japanese term meaning "continuous improvement," focuses on making small, incremental changes over time that add up to significant results.

5. Business Process Reengineering (BPR)

This technique involves rethinking and redesigning processes from scratch to achieve dramatic improvements in performance.

Steps to Implement Process Improvement

If you’re ready to embrace Process Improvement, here’s a simple step-by-step guide to get started:

Step 1: Identify the Process

Choose a specific process that needs improvement. It could be anything from how customer inquiries are handled to how invoices are processed.

Step 2: Analyze the Current State

Take a close look at how things are currently done. Map out the workflow, gather data, and identify bottlenecks or areas of waste.

Step 3: Set Clear Goals

Define what you want to achieve. Are you looking to save time? Reduce errors? Cut costs? Having a clear goal will guide your efforts.

Step 4: Brainstorm Solutions

Involve your team in brainstorming sessions to come up with potential improvements. Encourage creative thinking and open discussions.

Step 5: Implement Changes

Test the proposed solutions on a small scale before rolling them out company-wide. Monitor the results and make adjustments as needed.

Step 6: Measure Success

Use key performance indicators (KPIs) to evaluate the success of your improvements. Celebrate wins and document lessons learned.

Examples of Process Improvement in Action

Here are some real-life scenarios where Process Improvement can make a huge difference:

1. Customer Service

A company noticed long wait times for customer support. By implementing a chatbot for common inquiries, they reduced response times and freed up agents to handle complex issues.

2. Inventory Management

A retail store struggled with overstocked shelves. By adopting a just-in-time inventory system, they minimized waste and improved cash flow.

3. Team Collaboration

A marketing team used multiple tools for project management, leading to confusion. Switching to an all-in-one platform streamlined communication and boosted productivity.

Common Challenges in Process Improvement

While the benefits are clear, Process Improvement isn’t without its challenges. Here’s how to tackle some common obstacles:

1. Resistance to Change

Not everyone loves change. Involve employees early in the process, communicate the benefits, and provide training to ease the transition.

2. Lack of Resources

Improving processes can require time and money upfront. Prioritize high-impact changes that provide the quickest return on investment.

3. Poor Communication

Clear communication is key. Make sure everyone understands the changes and their role in the process.

Tools to Simplify Process Improvement

In today’s digital age, tools can make implementing Process Improvement much easier. Here are some popular ones:

1. Project Management Tools

Platforms like Trello, Asana, and Monday.com help teams manage tasks, deadlines, and communication.

2. Data Analysis Tools

Google Analytics, Tableau, and Power BI provide insights to make data-driven decisions.

3. Workflow Automation

Zapier and Automate.io connect apps and automate repetitive tasks, saving you time.

Final Thoughts

Process Improvement isn’t just a buzzword; it’s a powerful approach that can revolutionize how you work. By identifying inefficiencies, streamlining workflows, and fostering a culture of continuous improvement, you can unlock new levels of success and satisfaction.

0 notes

Text

🦸♂️ Unlock the Power of Lean Implementer Certification!

Let’s be real — businesses today don’t need more managers; they need problem solvers. They need efficiency heroes 🦸♀️ who can eliminate waste, speed up processes, and boost profits. If you’re ready to be that person, then the Lean Implementer Certification is your next big move. 🚀

In a world where every second and every dollar counts, having a Certified Lean Implementer on the team can make the difference between success and struggle. And guess what? That Lean expert could be you! 😎

Why Lean? Why Now? ⏰

Lean is no longer just for factories. Whether it's software deployment, hospital workflows, supply chains, or customer service — the Lean mindset is changing the game. That’s why professionals across IT, healthcare, logistics, and finance are turning to the Certified Lean Implementer Certification to sharpen their edge. ⚙️💡

This isn't just a trend — it’s the future of work. Companies are on a mission to cut waste and streamline operations, and lean certification is your golden ticket to lead the charge.

What Makes This Certification So Powerful? 💥

Here’s what sets the Lean Implementer Certification apart:

✅ Real-World Tools & Techniques: Learn how to use proven Lean tools like 5S, Kaizen, and Value Stream Mapping to fix real business problems. ✅ Versatile & Industry-Neutral: Whether you’re in finance or healthcare, Lean applies. A lean certification makes you valuable anywhere. 🌍 ✅ Become a Change Leader: Don’t just join projects — lead them. Drive improvements that get noticed by leadership. ✅ Global Recognition: The Certified Lean Implementer program by GSDC is trusted by professionals and organizations across the globe. ✅ Fast Career Boost: This credential doesn’t just sit pretty on your LinkedIn — it gets results. Promotions, better roles, higher pay. 💼📈

What You’ll Actually Learn 📚

This isn’t a fluff course. It’s packed with knowledge that turns you into an operational powerhouse. You’ll master:

🔸 Identifying and removing process inefficiencies 🔸 Designing workflows that deliver results 🔸 Implementing a culture of continuous improvement 🔸 Using Lean tools to solve real business challenges 🔸 Leading Lean transformation across departments

Once certified, you’re not just skilled — you’re certified to transform organizations. That’s what makes this more than just another course.

Is It Worth It? 100% YES 🙌

The answer is simple: businesses are investing in Lean now more than ever. If you’re Lean-certified, you’re ahead of the curve and in demand. 🌐 The Certified Lean Implementer Certification helps you stand out in a crowded job market and makes you indispensable in your current role.

Final Thought 💭

In a world filled with chaos and inefficiency, be the person who brings clarity and results. The Lean Implementer Certification gives you the mindset, the tools, and the recognition to lead lasting change. Why wait? Become the Certified Lean Implementer every company wishes they had. 💼🔥

#LeanImplementer #CertifiedLeanImplementer #LeanCertification #ContinuousImprovement #ProcessExcellence #GSDC #CareerGrowth #EfficiencyExpert #LeanLeadership #LeanSixSigma #LeanThinking #OperationalExcellence

For more information: https://www.gsdcouncil.org/certified-lean-implementer

Contact no: +41 41444851189

0 notes

Text

Maximizing Operational Efficiency: Strategies for Sustainable Growth

Introduction

In today's competitive business environment, operational efficiency is no longer just an advantage—it's a necessity. Companies that prioritize efficiency can significantly reduce costs, improve productivity, and enhance customer satisfaction. This article explores the concept of operational efficiency, its importance, and various strategies that organizations can implement to achieve it.

Understanding Operational Efficiency

Operational efficiency refers to the ability of an organization to deliver products or services to its customers in the most cost-effective manner while maintaining high quality. It involves optimizing resources, processes, and workflows to minimize waste and maximize output. Companies with high operational efficiency can achieve more with less, enabling them to adapt quickly to market changes and customer demands.

The Importance of Operational Efficiency

Cost Reduction: Efficient operations can lead to significant cost savings. By streamlining processes and reducing waste, companies can lower operational costs and improve profit margins.

Enhanced Productivity: When operations are efficient, employees can focus on value-added tasks rather than spending time on redundant activities. This leads to higher productivity levels and improved employee morale.

Improved Customer Satisfaction: Efficient operations often result in faster delivery times and higher product quality, which can enhance customer satisfaction and loyalty.

Competitive Advantage: Organizations that can operate efficiently can offer competitive pricing or invest in innovation, setting them apart from competitors.

Sustainable Growth: By maximizing efficiency, companies can scale their operations more effectively and sustainably, ensuring long-term success in a dynamic market.

Strategies for Achieving Operational Efficiency

To enhance operational efficiency, organizations can adopt several strategies tailored to their specific needs:

Process Mapping and Analysis: Begin by mapping out existing processes to identify bottlenecks and inefficiencies. Use tools like flowcharts and value stream mapping to visualize workflows and pinpoint areas for improvement.

Lean Methodology: Lean principles focus on eliminating waste and optimizing processes. Implementing lean practices such as 5S (Sort, Set in order, Shine, Standardize, Sustain) can help streamline operations and create a culture of continuous improvement.

Automation and Technology Integration: Embracing technology can significantly boost efficiency. Automate repetitive tasks using software solutions and invest in tools that enhance communication and collaboration among teams.

Employee Training and Development: Well-trained employees are more productive and capable of identifying inefficiencies. Invest in ongoing training programs that equip staff with the skills needed to optimize operations.

Performance Metrics and KPIs: Establish key performance indicators (KPIs) to measure efficiency. Track metrics such as cycle time, defect rates, and employee productivity to assess the effectiveness of operational changes.

Cross-Functional Collaboration: Foster collaboration between departments to ensure that everyone is aligned on operational goals. Encourage open communication and teamwork to break down silos and improve overall efficiency.

Customer Feedback and Continuous Improvement: Actively seek customer feedback to identify areas for improvement. Use this input to refine processes and enhance the quality of products and services.

Inventory Management: Efficient inventory management is crucial for operational success. Implement just-in-time (JIT) inventory systems to reduce excess stock and minimize carrying costs.

Supply Chain Optimization: Analyze and optimize your supply chain to reduce lead times and enhance delivery reliability. Building strong relationships with suppliers can also improve overall efficiency.

Sustainability Practices: Incorporating sustainable practices can lead to operational efficiencies. For example, reducing energy consumption not only lowers costs but also enhances a company's reputation among environmentally conscious consumers.

Case Studies

Toyota: The automotive giant is known for its lean manufacturing practices, which focus on continuous improvement and waste reduction. By implementing the Toyota Production System, the company has achieved remarkable operational efficiency, allowing it to maintain its position as a market leader.

Amazon: Through advanced technology and automation, Amazon has revolutionized the supply chain and logistics industry. The company's investment in robotics and data analytics has enabled it to streamline operations and deliver products to customers faster than ever before.

Challenges in Achieving Operational Efficiency

While striving for operational efficiency, organizations may encounter several challenges:

Resistance to Change: Employees may resist new processes or technologies, fearing job loss or increased workloads. Effective change management strategies are crucial to overcoming this resistance.

Resource Constraints: Limited budgets or manpower can hinder efforts to implement efficiency improvements. Prioritizing initiatives based on potential impact can help organizations allocate resources effectively.

Complexity of Operations: As organizations grow, their operations may become more complex, making it difficult to identify inefficiencies. Regular audits and assessments can help maintain focus on efficiency.

Balancing Quality and Efficiency: Organizations must ensure that efforts to improve efficiency do not compromise product or service quality. A balanced approach that prioritizes both aspects is essential for long-term success.

Conclusion

Maximizing operational efficiency is vital for organizations looking to thrive in a competitive landscape. By implementing strategies such as process mapping, lean methodologies, technology integration, and employee training, companies can enhance productivity, reduce costs, and improve customer satisfaction. While challenges may arise, a commitment to continuous improvement and a focus on sustainable practices can help organizations navigate the complexities of operational efficiency, ultimately leading to long-term success and growth.

Call to Action

As you reflect on your organization’s operational processes, consider conducting a thorough analysis to identify areas for improvement. Engage your team in discussions about efficiency and foster a culture of innovation and collaboration. Remember, operational efficiency is not a one-time goal but a continuous journey toward excellence.

4o mini

0 notes

Text

Top Tools and Techniques for Improving Turnaround Time

In today’s fast-paced business environment, improving turnaround time (TAT) is crucial for maintaining a competitive edge. Turnaround time refers to the total time taken to complete a process or fulfill a request, impacting customer satisfaction and operational efficiency. To streamline processes and enhance TAT, organizations can leverage various tools and techniques. This blog will explore some of the most effective strategies to improve turnaround time.

1. Process Mapping and Analysis

One of the first steps to improving turnaround time is understanding the current processes. Process mapping involves visually representing workflows to identify bottlenecks, redundancies, and inefficiencies. Tools like Lucidchart or Microsoft Visio can help create detailed flowcharts that outline each step in the process. By analyzing these maps, teams can pinpoint areas for improvement, leading to more efficient workflows and reduced turnaround times.

2. Automation Tools

Automation plays a pivotal role in enhancing turnaround time. By automating repetitive tasks, businesses can reduce the time spent on manual processes. Tools like Zapier, Integromat, or Microsoft Power Automate allow organizations to create automated workflows between different applications, minimizing the need for human intervention. For instance, automating data entry can significantly cut down processing time, enabling employees to focus on more strategic tasks.

3. Project Management Software

Efficient project management is key to improving turnaround time. Tools such as Trello, Asana, and Monday.com facilitate better task management, team collaboration, and project tracking. These platforms help teams prioritize tasks, set deadlines, and monitor progress in real-time. By providing clarity on responsibilities and timelines, project management software ensures that projects are completed more swiftly and efficiently.

4. Lean Methodology

Adopting Lean principles can drastically improve turnaround time by eliminating waste and enhancing value. The Lean methodology focuses on continuous improvement, emphasizing customer value and efficient processes. Techniques such as Value Stream Mapping (VSM) can identify non-value-adding activities, allowing teams to streamline operations. By fostering a culture of continuous improvement, organizations can achieve significant reductions in turnaround time.

5. Time Tracking Tools

Monitoring time spent on various tasks is crucial for identifying inefficiencies. Tools like Toggl or Harvest enable teams to track time effectively, providing insights into where bottlenecks occur. By analyzing time logs, managers can assess productivity levels, identify areas for improvement, and implement strategies to enhance turnaround times. Time tracking not only helps in improving efficiency but also aids in better resource allocation.

6. Communication and Collaboration Tools

Effective communication is vital for improving turnaround time. Tools such as Slack, Microsoft Teams, or Zoom facilitate real-time communication and collaboration among team members. By fostering open lines of communication, organizations can ensure that information flows seamlessly, reducing delays caused by miscommunication. Additionally, these tools support remote work, allowing teams to collaborate efficiently, regardless of location.

7. Performance Metrics and KPIs

Establishing performance metrics and key performance indicators (KPIs) is essential for measuring turnaround time improvements. Organizations should define specific metrics, such as the average time taken to complete a task or the number of tasks completed within a set timeframe. Regularly reviewing these metrics allows teams to assess their progress and make data-driven decisions to optimize processes further.

8. Employee Training and Development

Investing in employee training can significantly enhance turnaround time. Providing team members with the skills and knowledge necessary to perform their roles efficiently can lead to improved productivity. Regular training sessions, workshops, and skill development programs can empower employees to work smarter, ultimately reducing turnaround times.

youtube

Conclusion

Improving turnaround time is a multifaceted endeavor that requires a combination of the right tools and techniques. By implementing process mapping, automation, effective project management, Lean methodologies, time tracking, collaboration tools, performance metrics, and employee training, organizations can streamline their processes and enhance operational efficiency. As businesses continue to evolve in a competitive landscape, focusing on reducing turnaround time will be crucial for achieving sustainable growth and ensuring customer satisfaction.

SITES WE SUPPORT

Turnaround Process - Wix

SOCIAL LINKS Facebook Twitter LinkedIn

0 notes

Text

How Businesses can save Funds and Time?

In today's fast-paced business environment, optimizing operations to save time and funds is essential for maintaining competitiveness and ensuring long-term success. Companies of all sizes must adopt strategies that promote efficiency and reduce unnecessary costs. This article explores effective ways businesses can save funds and time.

1. Embrace Automation

Automation is a powerful tool for increasing efficiency and reducing labor costs. By automating repetitive tasks, such as data entry, invoicing, and customer support, businesses can free up employee time for more strategic activities. Implementing automated systems can lead to significant time savings and reduced human error, ultimately saving money.

2. Optimize Processes

Conducting a thorough analysis of existing processes can uncover inefficiencies. Mapping out workflows and identifying bottlenecks allows businesses to streamline operations. Lean methodologies, which focus on reducing waste and improving flow, can be implemented to enhance efficiency and lower costs.

3. Invest in Technology

Investing in modern technology can yield substantial returns in terms of time and cost savings. Tools like project management software, customer relationship management (CRM) systems, and collaboration platforms enhance communication and organization. These technologies can help teams work more efficiently, reducing the time spent on administrative tasks.

4. Outsource Non-Core Functions

Outsourcing non-core functions, such as payroll, IT support, or customer service, can significantly reduce overhead costs. By partnering with specialized service providers, businesses can leverage expertise without the need for in-house resources. This allows companies to focus on their core competencies while saving time and funds.

5. Implement a Remote Work Policy

Allowing employees to work remotely can lead to cost savings on office space, utilities, and other overhead expenses. Additionally, remote work often leads to increased employee satisfaction and productivity, as team members can work in an environment that suits them best.

6. Monitor and Control Expenses

Regularly reviewing expenses and implementing budget controls can help businesses identify areas where costs can be reduced. Utilize accounting software to track spending and set alerts for budget overruns. Implementing strict approval processes for expenditures can also help control costs.

7. Foster a Culture of Continuous Improvement

Encouraging employees to contribute ideas for process improvements can lead to significant time and cost savings. Implementing a culture of continuous improvement fosters innovation and empowers team members to seek efficiencies within their roles.

8. Train Employees Effectively

Investing in employee training can improve efficiency and productivity. Well-trained employees are more confident and capable in their roles, leading to faster problem resolution and better customer service. Consider ongoing training programs that keep employees updated on industry best practices and technological advancements.

Conclusion

In conclusion, businesses can save funds and time by embracing automation, optimizing processes, investing in technology, outsourcing non-core functions, implementing remote work policies, monitoring expenses, fostering a culture of continuous improvement, and training employees effectively. By adopting these strategies, companies can enhance their efficiency, reduce costs, and position themselves for long-term success.

youtube

SITES WE SUPPORT

Direct Mail Service and Snail Mail API – Wix

SOCIAL LINKS

Facebook

Twitter

LinkedIn

Instagram

Pinterest

0 notes