#Liquid Silicone Rubber

Text

#Silicone Elastomers Market#Silicone Rubber#Silicone Injection Molding#Liquid Silicone Rubber#Silicone Rubber for Medical Devices

0 notes

Text

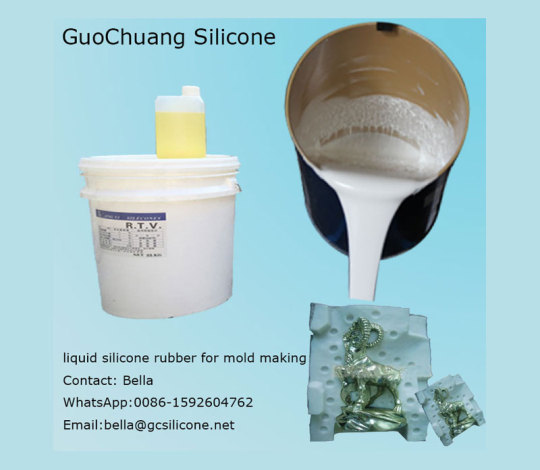

How Do You Make a Silicone Mold? A Step-by-Step Guide

"Learn to create silicone molds with precision. Start by cleaning your object, apply a mold release agent to avoid sticking, and use clay or tape to seal gaps for perfect detail replication."

#Silicone Rubbers#Silicone Molds#Silicone Mold Making#Mold-Making Techniques#Mold Release Agent#Mold Making Essentials#Mold Box Creation#Life Casting Materials#Liquid Silicone Rubber#Kastez Resin Applications#Culinary Arts Molding#Alginate Molds Crafting

0 notes

Text

#Liquid Silicone Rubber in Delhi#liquid silicone rubber price in delhi#Liquid Silicone Rubber#liquid silicone rubber price

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone supplies that are readily mixed and quickly heat-cured into durable elastomers. With superior processing time, decreased cycle occasions and decrease manufacturing costs, liquid silicone rubbers may help with your industrial and food contact formulation needs.

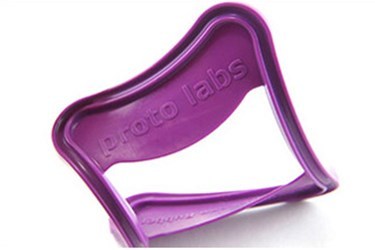

Appropriate fabrication methods for liquid silicone rubbers embody liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is particularly designed for 3D printing.

LSR properties:

Biocompatibility: Under in depth testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids and is hypoallergenic, making it a good choice for skin-contact products. In comparability to different elastomers, liquid silicone rubber is proof against bacteria development and will not stain or corrode different materials.

Tasteless and odorless: LSR is tasteless and odorless and can be formulated to adjust to stringent FDA standards required for meals and beverage and baby products..

Durable: Liquid silicone rubber parts can withstand excessive temperatures, making LSR a super selection for elements used in cars under the hood and in outdoor functions.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and some chemical solutions similar to acids and alkali. The material could be sterilized via a variety of methods, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and numerous different strategies used for medical and healthcare merchandise.

Temperature endurance: Compared to different elastomers, molded silicone can stand up to a variety of high to low-temperature extremes. It will remain stable in temperatures ranging from minus 60 degrees Celsius to one hundred eighty degrees Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, excessive tear and tensile power, wonderful flexibility, and a hardness vary mostly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber also has glorious insulating properties, helpful for a number of electrical functions. Compared to traditional insulating supplies, silicone can carry out in far higher and lower temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its natural shade is white and conducive to pigmentation for producing custom, molded products in a selection of colors.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing kinds and compositions. Each type has varying traits.

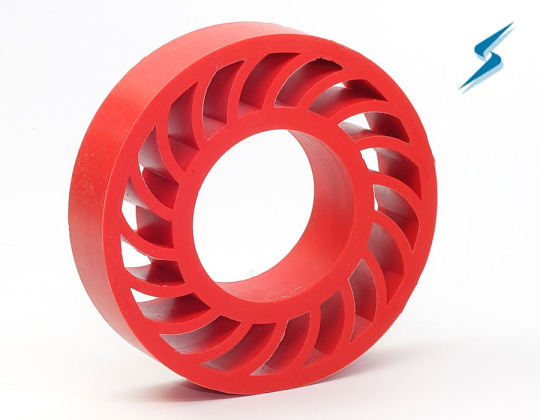

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used material with extensive functions because of its flexibility, biocompatibility, and heat resistance. Typical uses of common function LSR kind embody seals, gaskets, and industrial elements.

High-Temperature LSR

High-temperature liquid silicone rubber materials can face up to extreme warmth publicity without degrading or compromising its qualities. Common applications of this LSR include industrial gear, automotive elements, and digital elements.

Medical Grade LSR

This kind of liquid silicone rubber is formulated to satisfy the strict biocompatibility and safety requirements for medical and healthcare merchandise. Medical grade LSR supplies are sterilizable and biocompatible, making them appropriate for applications that require contact with the human physique.

Self-Bonding LSR

Self-bonding LSR material reveals wonderful properties of adhering to itself without using different adhesives. Therefore, it's perfect for making complicated assemblies without relying on conventional bonding techniques.

Food-Grade LSR

The food grade is just like the medical grade LSR. It meets strict necessities for contact with meals and beverages. Baby products, baking molds, and kitchen utensils are typical food-grade liquid silicone materials purposes.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) components that offer electrical conductivity properties. This grade is commonly used in purposes with electrical conductivity and flexibility of silicone rubber necessities, including EMI/RFI shielding and flexible circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is suitable for making merchandise like lenses, mild guides, and other optical elements and tools with transparency and optical readability requirements.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone supplies which would possibly be readily combined and rapidly heat-cured into durable elastomers. With superior processing time, lowered cycle instances and lower manufacturing costs, liquid silicone rubbers may help together with your industrial and meals contact formulation needs.

Appropriate fabrication strategies for liquid silicone rubbers embody liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is specifically designed for 3D printing.

LSR properties:

Biocompatibility: Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and physique fluids and is hypoallergenic, making it a good selection for skin-contact merchandise. In comparison to different elastomers, liquid silicone rubber is immune to bacteria growth and received't stain or corrode different supplies.

Tasteless and odorless: LSR is tasteless and odorless and may be formulated to comply with stringent FDA standards required for food and beverage and baby products..

Durable: Liquid silicone rubber components can face up to extreme temperatures, making LSR a super alternative for elements utilized in cars under the hood and in outdoor functions.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and a few chemical solutions corresponding to acids and alkali. The materials can be sterilized through a selection of methods, together with steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and quite a few other methods used for medical and healthcare merchandise.

Temperature endurance: Compared to different elastomers, molded silicone can face up to a extensive range of high to low-temperature extremes. It will remain secure in temperatures starting from minus 60 degrees Celsius to one hundred eighty levels Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, excessive tear and tensile energy, wonderful flexibility, and a hardness range mostly between 5 to 80 Shore A.

Electrical properties: Liquid silicone rubber additionally has glorious insulating properties, helpful for a bunch of electrical functions. Compared to traditional insulating materials, silicone can carry out in far greater and decrease temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its natural shade is white and conducive to pigmentation for producing custom, molded merchandise in a wide selection of colours.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing kinds and compositions. Each sort has varying characteristics.

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used materials with in depth purposes because of its flexibility, biocompatibility, and warmth resistance. Typical makes use of of general purpose LSR sort embrace seals, gaskets, and industrial parts.

High-Temperature LSR

High-temperature liquid silicone rubber supplies can stand up to extreme heat exposure without degrading or compromising its qualities. Common purposes of this LSR embody industrial tools, automotive parts, and digital components.

Medical Grade LSR

This sort of liquid silicone rubber is formulated to fulfill the strict biocompatibility and safety necessities for medical and healthcare products. Medical grade LSR materials are sterilizable and biocompatible, making them suitable for purposes that require contact with the human body.

Self-Bonding LSR

Self-bonding LSR materials exhibits glorious properties of adhering to itself without using other adhesives. Therefore, it's perfect for making advanced assemblies without relying on traditional bonding strategies.

Food-Grade LSR

The meals grade is much like the medical grade LSR. It meets strict necessities for contact with meals and beverages. Baby products, baking molds, and kitchen utensils are typical food-grade liquid silicone materials purposes.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) additives that supply electrical conductivity properties. This grade is usually utilized in applications with electrical conductivity and suppleness of silicone rubber necessities, together with EMI/RFI shielding and versatile circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is suitable for making products like lenses, gentle guides, and other optical elements and gear with transparency and optical clarity requirements.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone materials which may be readily mixed and rapidly heat-cured into sturdy elastomers. With superior processing time, decreased cycle times and lower production costs, liquid silicone rubbers can help with your industrial and meals contact formulation needs.

Appropriate fabrication methods for liquid silicone rubbers embrace liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is specifically designed for 3D printing.

LSR properties:

Biocompatibility: Under in depth testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and physique fluids and is hypoallergenic, making it a good selection for skin-contact merchandise. In comparison to other elastomers, liquid silicone rubber is proof against micro organism progress and will not stain or corrode other materials.

Tasteless and odorless: LSR is tasteless and odorless and can be formulated to comply with stringent FDA standards required for food and beverage and child merchandise..

Durable: Liquid silicone rubber parts can stand up to extreme temperatures, making LSR a perfect alternative for components utilized in vehicles under the hood and in outdoor purposes.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and some chemical solutions similar to acids and alkali. The material may be sterilized through a variety of strategies, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and numerous different methods used for medical and healthcare products.

Temperature endurance: Compared to different elastomers, molded silicone can withstand a extensive range of excessive to low-temperature extremes. It will stay steady in temperatures starting from minus 60 levels Celsius to 180 levels Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, high tear and tensile strength, excellent flexibility, and a hardness vary most commonly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber also has glorious insulating properties, useful for a bunch of electrical functions. Compared to traditional insulating materials, silicone can carry out in far greater and decrease temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure colour is white and conducive to pigmentation for producing custom, molded merchandise in a wide range of colours.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing kinds and compositions. Each sort has varying characteristics.

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used material with in depth functions because of its flexibility, biocompatibility, and warmth resistance. Typical uses of general purpose LSR sort include seals, gaskets, and industrial components.

High-Temperature LSR

High-temperature liquid silicone rubber materials can face up to excessive warmth publicity with out degrading or compromising its qualities. Common functions of this LSR include industrial equipment, automotive elements, and electronic parts.

Medical Grade LSR

This sort of liquid silicone rubber is formulated to fulfill the strict biocompatibility and security necessities for medical and healthcare merchandise. Medical grade LSR materials are sterilizable and biocompatible, making them suitable for applications that require contact with the human physique.

Self-Bonding LSR

Self-bonding LSR materials reveals excellent properties of adhering to itself with out using different adhesives. Therefore, it is perfect for making complex assemblies without relying on conventional bonding strategies.

Food-Grade LSR

The meals grade is just like the medical grade LSR. It meets strict requirements for contact with food and beverages. Baby products, baking molds, and kitchen utensils are typical food-grade liquid silicone materials functions.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) additives that offer electrical conductivity properties. This grade is commonly utilized in applications with electrical conductivity and flexibility of silicone rubber necessities, including EMI/RFI shielding and versatile circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making merchandise like lenses, gentle guides, and different optical components and gear with transparency and optical readability requirements.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone materials that are readily combined and quickly heat-cured into durable elastomers. With superior processing time, lowered cycle occasions and decrease manufacturing costs, liquid silicone rubbers may help along with your industrial and food contact formulation wants.

Appropriate fabrication strategies for liquid silicone rubbers embody liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is particularly designed for 3D printing.

LSR properties:

Biocompatibility: Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and physique fluids and is hypoallergenic, making it a good selection for skin-contact merchandise. In comparability to other elastomers, liquid silicone rubber is resistant to micro organism development and received't stain or corrode different materials.

Tasteless and odorless: LSR is tasteless and odorless and may be formulated to comply with stringent FDA requirements required for food and beverage and baby merchandise..

Durable: Liquid silicone rubber elements can withstand excessive temperatures, making LSR an ideal alternative for parts utilized in automobiles under the hood and in outside purposes.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and some chemical options corresponding to acids and alkali. The materials can be sterilized via quite lots of methods, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and quite a few other techniques used for medical and healthcare merchandise.

Temperature endurance: Compared to different elastomers, molded silicone can face up to a wide range of high to low-temperature extremes. It will stay steady in temperatures ranging from minus 60 levels Celsius to a hundred and eighty degrees Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, excessive tear and tensile power, excellent flexibility, and a hardness vary mostly between 5 to 80 Shore A.

Electrical properties: Liquid silicone rubber additionally has wonderful insulating properties, useful for a host of electrical purposes. Compared to conventional insulating materials, silicone can carry out in far greater and lower temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure color is white and conducive to pigmentation for producing customized, molded products in a selection of colours.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has different types and compositions. Each kind has varying traits.

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used materials with in depth purposes because of its flexibility, biocompatibility, and heat resistance. Typical makes use of of common function LSR kind include seals, gaskets, and industrial elements.

High-Temperature LSR

High-temperature liquid silicone rubber materials can stand up to excessive warmth publicity without degrading or compromising its qualities. Common purposes of this LSR embrace industrial tools, automotive elements, and electronic components.

Medical Grade LSR

This sort of liquid silicone rubber is formulated to satisfy the strict biocompatibility and security necessities for medical and healthcare merchandise. Medical grade LSR materials are sterilizable and biocompatible, making them suitable for purposes that require contact with the human physique.

Self-Bonding LSR

Self-bonding LSR materials reveals wonderful properties of adhering to itself with out utilizing different adhesives. Therefore, it's excellent for making complex assemblies without relying on conventional bonding strategies.

Food-Grade LSR

The food grade is much like the medical grade LSR. It meets strict necessities for contact with food and beverages. Baby merchandise, baking molds, and kitchen utensils are typical food-grade liquid silicone materials applications.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) additives that provide electrical conductivity properties. This grade is commonly used in purposes with electrical conductivity and flexibility of silicone rubber necessities, including EMI/RFI shielding and flexible circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making merchandise like lenses, gentle guides, and different optical elements and gear with transparency and optical readability requirements.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone supplies which are readily blended and quickly heat-cured into sturdy elastomers. With superior processing time, lowered cycle occasions and lower manufacturing prices, liquid silicone rubbers can help along with your industrial and meals contact formulation needs.

Appropriate fabrication methods for liquid silicone rubbers embrace liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is particularly designed for 3D printing.

LSR properties:

Biocompatibility: Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and physique fluids and is hypoallergenic, making it a sensible choice for skin-contact merchandise. In comparison to different elastomers, liquid silicone rubber is proof against bacteria progress and will not stain or corrode different materials.

Tasteless and odorless: LSR is tasteless and odorless and could be formulated to comply with stringent FDA requirements required for food and beverage and baby products..

Durable: Liquid silicone rubber elements can withstand excessive temperatures, making LSR an ideal selection for elements utilized in vehicles beneath the hood and in out of doors functions.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and a few chemical solutions corresponding to acids and alkali. The material can be sterilized by way of a big selection of methods, together with steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and quite a few different strategies used for medical and healthcare products.

Temperature endurance: Compared to other elastomers, molded silicone can stand up to a wide range of high to low-temperature extremes. It will remain steady in temperatures starting from minus 60 degrees Celsius to one hundred eighty degrees Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, high tear and tensile strength, glorious flexibility, and a hardness vary mostly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber additionally has glorious insulating properties, useful for a bunch of electrical purposes. Compared to conventional insulating supplies, silicone can carry out in far larger and lower temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure colour is white and conducive to pigmentation for producing custom, molded products in a big selection of colors.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing kinds and compositions. Each sort has varying traits.

silicone rubber liquid for making bushings

General Purpose LSR

This is a widely used materials with intensive functions due to its flexibility, biocompatibility, and warmth resistance. Typical uses of common objective LSR kind embody seals, gaskets, and industrial parts.

High-Temperature LSR

High-temperature liquid silicone rubber materials can stand up to excessive heat publicity without degrading or compromising its qualities. Common purposes of this LSR embody industrial equipment, automotive elements, and electronic parts.

Medical Grade LSR

This kind of liquid silicone rubber is formulated to meet the strict biocompatibility and security requirements for medical and healthcare merchandise. Medical grade LSR supplies are sterilizable and biocompatible, making them appropriate for purposes that require contact with the human physique.

Self-Bonding LSR

Self-bonding LSR materials displays wonderful properties of adhering to itself without using other adhesives. Therefore, it is good for making complicated assemblies with out relying on conventional bonding strategies.

Food-Grade LSR

The meals grade is much like the medical grade LSR. It meets strict requirements for contact with food and beverages. Baby merchandise, baking molds, and kitchen utensils are typical food-grade liquid silicone material applications.

Electrically Conductive LSR

It incorporates electrostatic discharge (ESD) components that offer electrical conductivity properties. This grade is commonly used in functions with electrical conductivity and flexibility of silicone rubber requirements, including EMI/RFI shielding and versatile circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making products like lenses, mild guides, and other optical components and gear with transparency and optical readability necessities.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone supplies which are readily combined and rapidly heat-cured into durable elastomers. With superior processing time, decreased cycle instances and lower manufacturing prices, liquid silicone rubbers may help along with your industrial and meals contact formulation needs.

Appropriate fabrication strategies for liquid silicone rubbers embrace liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is particularly designed for 3D printing.

LSR properties:

Biocompatibility: Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and physique fluids and is hypoallergenic, making it a sensible choice for skin-contact products. In comparability to different elastomers, liquid silicone rubber is immune to micro organism growth and will not stain or corrode different supplies.

Tasteless and odorless: LSR is tasteless and odorless and may be formulated to comply with stringent FDA standards required for food and beverage and baby merchandise..

Durable: Liquid silicone rubber parts can face up to excessive temperatures, making LSR a perfect selection for components used in automobiles beneath the hood and in out of doors functions.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and some chemical solutions such as acids and alkali. The material could be sterilized through a selection of methods, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and quite a few other strategies used for medical and healthcare products.

Temperature endurance: Compared to other elastomers, molded silicone can withstand a extensive range of high to low-temperature extremes. It will stay secure in temperatures ranging from minus 60 levels Celsius to a hundred and eighty degrees Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, high tear and tensile strength, excellent flexibility, and a hardness vary mostly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber additionally has glorious insulating properties, helpful for a bunch of electrical applications. Compared to conventional insulating supplies, silicone can carry out in far greater and decrease temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure colour is white and conducive to pigmentation for producing customized, molded merchandise in quite lots of colors.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has different types and compositions. Each kind has varying traits.

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used material with intensive purposes as a outcome of its flexibility, biocompatibility, and warmth resistance. Typical makes use of of basic purpose LSR sort embody seals, gaskets, and industrial components.

High-Temperature LSR

High-temperature liquid silicone rubber materials can stand up to excessive warmth exposure without degrading or compromising its qualities. Common purposes of this LSR embody industrial equipment, automotive parts, and electronic components.

Medical Grade LSR

This sort of liquid silicone rubber is formulated to meet the strict biocompatibility and security requirements for medical and healthcare products. Medical grade LSR supplies are sterilizable and biocompatible, making them appropriate for functions that require contact with the human body.

Self-Bonding LSR

Self-bonding LSR materials reveals glorious properties of adhering to itself with out utilizing different adhesives. Therefore, it is excellent for making complicated assemblies with out depending on conventional bonding strategies.

Food-Grade LSR

The food grade is much like the medical grade LSR. It meets strict requirements for contact with meals and drinks. Baby products, baking molds, and kitchen utensils are typical food-grade liquid silicone materials purposes.

Electrically Conductive LSR

It accommodates electrostatic discharge (ESD) components that supply electrical conductivity properties. This grade is usually utilized in functions with electrical conductivity and flexibility of silicone rubber necessities, including EMI/RFI shielding and flexible circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making merchandise like lenses, mild guides, and different optical components and gear with transparency and optical readability requirements.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone materials which may be readily blended and rapidly heat-cured into durable elastomers. With superior processing time, reduced cycle occasions and decrease manufacturing costs, liquid silicone rubbers may help along with your industrial and meals contact formulation needs.

Appropriate fabrication methods for liquid silicone rubbers embody liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is particularly designed for 3D printing.

LSR properties:

Biocompatibility: Under in depth testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and physique fluids and is hypoallergenic, making it a good choice for skin-contact products. In comparability to other elastomers, liquid silicone rubber is resistant to bacteria development and received't stain or corrode different materials.

Tasteless and odorless: LSR is tasteless and odorless and could be formulated to comply with stringent FDA standards required for food and beverage and child merchandise..

Durable: Liquid silicone rubber parts can withstand extreme temperatures, making LSR a super alternative for elements utilized in automobiles underneath the hood and in outdoor functions.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and some chemical options corresponding to acids and alkali. The materials may be sterilized through a wide range of methods, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and quite a few other strategies used for medical and healthcare products.

Temperature endurance: Compared to different elastomers, molded silicone can face up to a extensive range of high to low-temperature extremes. It will stay secure in temperatures starting from minus 60 levels Celsius to one hundred eighty degrees Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, excessive tear and tensile strength, excellent flexibility, and a hardness vary mostly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber additionally has wonderful insulating properties, helpful for a host of electrical applications. Compared to traditional insulating materials, silicone can carry out in far higher and lower temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure colour is white and conducive to pigmentation for producing custom, molded products in a wide selection of colours.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing kinds and compositions. Each kind has various traits.

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used materials with extensive applications because of its flexibility, biocompatibility, and heat resistance. Typical uses of general purpose LSR kind embody seals, gaskets, and industrial parts.

High-Temperature LSR

High-temperature liquid silicone rubber supplies can face up to extreme heat exposure with out degrading or compromising its qualities. Common applications of this LSR embody industrial gear, automotive components, and electronic components.

Medical Grade LSR

This sort of liquid silicone rubber is formulated to satisfy the strict biocompatibility and safety requirements for medical and healthcare products. Medical grade LSR supplies are sterilizable and biocompatible, making them appropriate for functions that require contact with the human body.

Self-Bonding LSR

Self-bonding LSR materials displays glorious properties of adhering to itself with out utilizing different adhesives. Therefore, it is good for making complicated assemblies without relying on conventional bonding techniques.

Food-Grade LSR

The meals grade is much like the medical grade LSR. It meets strict requirements for contact with meals and beverages. Baby merchandise, baking molds, and kitchen utensils are typical food-grade liquid silicone materials functions.

Electrically Conductive LSR

It incorporates electrostatic discharge (ESD) components that offer electrical conductivity properties. This grade is usually utilized in functions with electrical conductivity and suppleness of silicone rubber requirements, including EMI/RFI shielding and versatile circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making products like lenses, mild guides, and other optical components and equipment with transparency and optical readability necessities.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone materials which are readily blended and quickly heat-cured into sturdy elastomers. With superior processing time, reduced cycle times and decrease production prices, liquid silicone rubbers might help together with your industrial and meals contact formulation needs.

Appropriate fabrication methods for liquid silicone rubbers embody liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is specifically designed for 3D printing.

LSR properties:

Biocompatibility: Under in depth testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids and is hypoallergenic, making it a good choice for skin-contact products. In comparability to different elastomers, liquid silicone rubber is resistant to bacteria growth and received't stain or corrode different materials.

Tasteless and odorless: LSR is tasteless and odorless and can be formulated to comply with stringent FDA standards required for meals and beverage and child products..

Durable: Liquid silicone rubber components can face up to excessive temperatures, making LSR an ideal selection for components utilized in vehicles under the hood and in out of doors purposes.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and some chemical solutions corresponding to acids and alkali. The material may be sterilized by way of a selection of methods, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and quite a few other techniques used for medical and healthcare merchandise.

Temperature endurance: Compared to different elastomers, molded silicone can withstand a broad range of excessive to low-temperature extremes. It will remain steady in temperatures ranging from minus 60 degrees Celsius to a hundred and eighty levels Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, high tear and tensile strength, excellent flexibility, and a hardness range most commonly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber also has excellent insulating properties, beneficial for a host of electrical applications. Compared to traditional insulating materials, silicone can perform in far greater and decrease temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its natural colour is white and conducive to pigmentation for producing custom, molded products in a selection of colours.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has different types and compositions. Each kind has varying traits.

silicone rubber liquid for making bushings

General Purpose LSR

This is a widely used material with extensive functions as a end result of its flexibility, biocompatibility, and heat resistance. Typical makes use of of common purpose LSR kind include seals, gaskets, and industrial components.

High-Temperature LSR

High-temperature liquid silicone rubber supplies can withstand extreme warmth exposure without degrading or compromising its qualities. Common purposes of this LSR embrace industrial tools, automotive components, and electronic components.

Medical Grade LSR

This type of liquid silicone rubber is formulated to fulfill the strict biocompatibility and safety requirements for medical and healthcare products. Medical grade LSR supplies are sterilizable and biocompatible, making them suitable for functions that require contact with the human body.

Self-Bonding LSR

Self-bonding LSR material displays wonderful properties of adhering to itself with out utilizing different adhesives. Therefore, it's good for making advanced assemblies with out relying on conventional bonding techniques.

Food-Grade LSR

The food grade is much like the medical grade LSR. It meets strict requirements for contact with food and beverages. Baby merchandise, baking molds, and kitchen utensils are typical food-grade liquid silicone materials purposes.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) components that provide electrical conductivity properties. This grade is usually utilized in functions with electrical conductivity and adaptability of silicone rubber necessities, together with EMI/RFI shielding and versatile circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making merchandise like lenses, mild guides, and other optical components and equipment with transparency and optical readability necessities.

0 notes

Text

Silicone Elastomers Market Expected to Hit $15.1 Billion by 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘Silicone Elastomers Market by Type (Liquid Silicone Rubber (LSR), High-temperature Vulcanize (HTV)), Process (Extrusion, Molding), End-use Industry (Automotive, Healthcare, Electrical & Electronics, Construction), and Geography - Global Forecast to 2031.’

According to the latest report from Meticulous Research®, the silicone elastomers market is forecasted to reach $15.1 billion by 2031, growing at a compound annual growth rate (CAGR) of 7.9% from 2024 to 2031. The market's expansion is fueled by the increasing use of silicone elastomers in medical devices, advancements in material science, and high demand in the electrical and electronics sectors. However, growth is hindered by environmental concerns, sustainability issues, and stagnation in developed countries.

Opportunities for market growth are anticipated through the integration of silicone elastomers with IoT devices and their increasing use in the automotive industry. Nonetheless, fluctuations in raw material prices present a significant challenge to market growth.

The silicone elastomers market is categorized by type, process, and end-use industry. The types include room-temperature vulcanize (RTV), liquid silicone rubber (LSR), and high-temperature vulcanize (HTV). In 2024, HTV is expected to hold the largest market share of over 52%, driven by advancements in manufacturing technologies and its extensive use in industries requiring high-temperature applications, such as automotive and electronics. Meanwhile, the LSR segment is projected to experience the highest CAGR due to innovations in material science and its increasing demand in high-volume production for sectors like automotive and healthcare.

By process, the market is segmented into extrusion, molding, calendering, and others. The molding process segment is anticipated to account for the largest share of over 45% in 2024, attributed to the demand for LSR injection molding for complex parts and advancements in molding technologies. This segment is also expected to register the highest CAGR during the forecast period.

In terms of end-use industry, segments include automotive, aviation & aerospace, consumer goods, electrical & electronics, healthcare, energy, industrial machinery, construction, and others. The electrical & electronics segment is expected to hold the largest share of over 35% in 2024, due to the increasing use of silicone elastomers in components like power supplies and circuit boards. The healthcare segment is projected to grow at the highest CAGR, driven by the demand for biocompatible materials and silicone elastomers in medical devices and implants.

Geographically, the silicone elastomers market is divided into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific is expected to dominate with a share of over 53% in 2024, driven by rapid economic development, particularly in China and India, and the growing healthcare and construction industries. This region is also projected to register the highest CAGR of over 9% during the forecast period.

Key players in the silicone elastomers market include Momentive Performance Materials, Inc. (U.S.), China National Bluestar (Group) Co., Ltd. (China), The Dow Chemical Company (U.S.), Shin-Etsu Chemical Co., Ltd. (Japan), Wacker Chemie AG (Germany), DuPont de Nemours, Inc. (U.S.), and several others.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5844

Key Questions Addressed in the Report:

What are the high-growth market segments by type, process, and end-use industry?

What is the historical market size for the silicone elastomers market?

What are the market forecasts and estimates for 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the silicone elastomers market?

Who are the major players in the silicone elastomers market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the silicone elastomers market?

What strategies are adopted by major market players?

What are the trends and high-growth countries?

Who are the local emerging players in the silicone elastomers market, and how do they compete with established players?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Silicone Elastomers Market#Silicone Rubber#Silicone Injection Molding#Liquid Silicone Rubber#Silicone Rubber for Medical Devices

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone supplies that are readily mixed and rapidly heat-cured into sturdy elastomers. With superior processing time, decreased cycle instances and lower production prices, liquid silicone rubbers might help along with your industrial and meals contact formulation needs.

Appropriate fabrication methods for liquid silicone rubbers embody liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is specifically designed for 3D printing.

LSR properties:

Biocompatibility: Under intensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and physique fluids and is hypoallergenic, making it a smart choice for skin-contact products. In comparison to other elastomers, liquid silicone rubber is resistant to micro organism development and will not stain or corrode other materials.

Tasteless and odorless: LSR is tasteless and odorless and may be formulated to comply with stringent FDA requirements required for food and beverage and child merchandise..

Durable: Liquid silicone rubber elements can stand up to extreme temperatures, making LSR an ideal choice for components utilized in vehicles beneath the hood and in outdoor functions.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and a few chemical solutions corresponding to acids and alkali. The materials may be sterilized via quite so much of strategies, including steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and numerous different strategies used for medical and healthcare merchandise.

Temperature endurance: Compared to different elastomers, molded silicone can withstand a variety of high to low-temperature extremes. It will stay steady in temperatures starting from minus 60 degrees Celsius to 180 levels Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, high tear and tensile energy, wonderful flexibility, and a hardness vary mostly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber additionally has wonderful insulating properties, helpful for a bunch of electrical purposes. Compared to traditional insulating supplies, silicone can carry out in far greater and lower temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure shade is white and conducive to pigmentation for producing customized, molded merchandise in a wide range of colours.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing kinds and compositions. Each sort has various traits.

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used materials with intensive functions because of its flexibility, biocompatibility, and heat resistance. Typical makes use of of common objective LSR sort include seals, gaskets, and industrial elements.

High-Temperature LSR

High-temperature liquid silicone rubber materials can withstand extreme heat publicity without degrading or compromising its qualities. Common applications of this LSR embody industrial gear, automotive components, and electronic components.

Medical Grade LSR

This sort of liquid silicone rubber is formulated to meet the strict biocompatibility and safety requirements for medical and healthcare products. Medical grade LSR materials are sterilizable and biocompatible, making them appropriate for functions that require contact with the human body.

Self-Bonding LSR

Self-bonding LSR materials reveals glorious properties of adhering to itself without using different adhesives. Therefore, it's good for making complicated assemblies with out depending on traditional bonding strategies.

Food-Grade LSR

The food grade is much like the medical grade LSR. It meets strict requirements for contact with meals and drinks. Baby products, baking molds, and kitchen utensils are typical food-grade liquid silicone material purposes.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) components that offer electrical conductivity properties. This grade is often utilized in functions with electrical conductivity and adaptability of silicone rubber necessities, including EMI/RFI shielding and flexible circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making merchandise like lenses, gentle guides, and other optical parts and tools with transparency and optical clarity necessities.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone supplies that are readily blended and quickly heat-cured into sturdy elastomers. With superior processing time, reduced cycle instances and decrease manufacturing prices, liquid silicone rubbers may help with your industrial and meals contact formulation needs.

Appropriate fabrication strategies for liquid silicone rubbers embody liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is particularly designed for 3D printing.

LSR properties:

Biocompatibility: Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids and is hypoallergenic, making it a smart choice for skin-contact products. In comparability to different elastomers, liquid silicone rubber is proof against bacteria development and will not stain or corrode different materials.

Tasteless and odorless: LSR is tasteless and odorless and may be formulated to comply with stringent FDA requirements required for food and beverage and child products..

Durable: Liquid silicone rubber components can withstand excessive temperatures, making LSR a super selection for parts used in automobiles beneath the hood and in outdoor functions.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and a few chemical solutions similar to acids and alkali. The materials may be sterilized by way of a wide range of methods, together with steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and quite a few different techniques used for medical and healthcare merchandise.

Temperature endurance: Compared to different elastomers, molded silicone can face up to a variety of excessive to low-temperature extremes. It will stay steady in temperatures starting from minus 60 degrees Celsius to a hundred and eighty degrees Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, excessive tear and tensile strength, glorious flexibility, and a hardness range most commonly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber also has glorious insulating properties, helpful for a bunch of electrical applications. Compared to traditional insulating materials, silicone can perform in far larger and decrease temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure colour is white and conducive to pigmentation for producing custom, molded products in a wide range of colors.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing types and compositions. Each sort has varying characteristics.

silicone rubber liquid for making bushings

General Purpose LSR

This is a broadly used materials with in depth applications because of its flexibility, biocompatibility, and warmth resistance. Typical uses of basic purpose LSR kind embrace seals, gaskets, and industrial components.

High-Temperature LSR

High-temperature liquid silicone rubber supplies can stand up to excessive warmth exposure with out degrading or compromising its qualities. Common applications of this LSR embody industrial gear, automotive parts, and electronic components.

Medical Grade LSR

This kind of liquid silicone rubber is formulated to meet the strict biocompatibility and security requirements for medical and healthcare products. Medical grade LSR materials are sterilizable and biocompatible, making them appropriate for applications that require contact with the human physique.

Self-Bonding LSR

Self-bonding LSR materials displays wonderful properties of adhering to itself with out using other adhesives. Therefore, it is perfect for making complicated assemblies without relying on conventional bonding strategies.

Food-Grade LSR

The meals grade is much like the medical grade LSR. It meets strict requirements for contact with meals and beverages. Baby products, baking molds, and kitchen utensils are typical food-grade liquid silicone materials purposes.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) components that provide electrical conductivity properties. This grade is commonly utilized in functions with electrical conductivity and flexibility of silicone rubber necessities, together with EMI/RFI shielding and flexible circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is appropriate for making merchandise like lenses, mild guides, and other optical components and gear with transparency and optical clarity requirements.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone materials which might be readily blended and rapidly heat-cured into sturdy elastomers. With superior processing time, decreased cycle instances and lower production costs, liquid silicone rubbers can help together with your industrial and meals contact formulation wants.

Appropriate fabrication strategies for liquid silicone rubbers embrace liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is specifically designed for 3D printing.

LSR properties:

Biocompatibility: Under intensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids and is hypoallergenic, making it a sensible choice for skin-contact products. In comparison to different elastomers, liquid silicone rubber is proof against bacteria development and will not stain or corrode different supplies.

Tasteless and odorless: LSR is tasteless and odorless and may be formulated to adjust to stringent FDA requirements required for food and beverage and baby products..

Durable: Liquid silicone rubber components can stand up to excessive temperatures, making LSR a perfect choice for parts utilized in automobiles beneath the hood and in outside purposes.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and a few chemical solutions similar to acids and alkali. The material can be sterilized via a wide selection of strategies, together with steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and numerous different techniques used for medical and healthcare merchandise.

Temperature endurance: Compared to other elastomers, molded silicone can withstand a variety of excessive to low-temperature extremes. It will stay stable in temperatures ranging from minus 60 levels Celsius to 180 levels Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, excessive tear and tensile energy, glorious flexibility, and a hardness vary most commonly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber also has wonderful insulating properties, useful for a bunch of electrical purposes. Compared to conventional insulating supplies, silicone can carry out in far larger and lower temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure color is white and conducive to pigmentation for producing custom, molded products in a variety of colours.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has different types and compositions. Each type has various traits.

silicone rubber liquid for making bushings

General Purpose LSR

This is a widely used material with intensive purposes due to its flexibility, biocompatibility, and warmth resistance. Typical makes use of of common objective LSR sort embrace seals, gaskets, and industrial parts.

High-Temperature LSR

High-temperature liquid silicone rubber materials can face up to extreme warmth publicity without degrading or compromising its qualities. Common purposes of this LSR include industrial equipment, automotive parts, and electronic elements.

Medical Grade LSR

This sort of liquid silicone rubber is formulated to meet the strict biocompatibility and safety requirements for medical and healthcare products. Medical grade LSR supplies are sterilizable and biocompatible, making them suitable for applications that require contact with the human body.

Self-Bonding LSR

Self-bonding LSR materials exhibits excellent properties of adhering to itself with out utilizing other adhesives. Therefore, it's perfect for making complex assemblies with out depending on traditional bonding techniques.

Food-Grade LSR

The food grade is similar to the medical grade LSR. It meets strict requirements for contact with food and drinks. Baby merchandise, baking molds, and kitchen utensils are typical food-grade liquid silicone materials purposes.

Electrically Conductive LSR

It incorporates electrostatic discharge (ESD) additives that provide electrical conductivity properties. This grade is often used in functions with electrical conductivity and adaptability of silicone rubber requirements, together with EMI/RFI shielding and versatile circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is suitable for making products like lenses, light guides, and different optical components and tools with transparency and optical readability necessities.

0 notes

Text

What is liquid silicone rubber (LSR)?

Liquid Silicone Rubbers are two-part dispensible silicone materials which might be readily mixed and quickly heat-cured into sturdy elastomers. With superior processing time, reduced cycle instances and lower production costs, liquid silicone rubbers might help along with your industrial and food contact formulation needs.

Appropriate fabrication strategies for liquid silicone rubbers include liquid injection molding and coating. Dow’s IMAGIN3D™ Liquid Silicone Rubber is particularly designed for 3D printing.

LSR properties:

Biocompatibility: Under intensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids and is hypoallergenic, making it a good choice for skin-contact merchandise. In comparability to different elastomers, liquid silicone rubber is immune to micro organism progress and gained't stain or corrode other supplies.

Tasteless and odorless: LSR is tasteless and odorless and may be formulated to adjust to stringent FDA requirements required for meals and beverage and child products..

Durable: Liquid silicone rubber components can withstand excessive temperatures, making LSR a super choice for elements used in automobiles beneath the hood and in out of doors purposes.

Chemical resistance: Liquid silicone rubber resists water, oxidation, and some chemical options corresponding to acids and alkali. The material may be sterilized via quite so much of methods, together with steam autoclaving, ethylene oxide (ETO), gamma, e-beam, and numerous different methods used for medical and healthcare merchandise.

Temperature endurance: Compared to other elastomers, molded silicone can face up to a variety of high to low-temperature extremes. It will remain secure in temperatures starting from minus 60 degrees Celsius to 180 levels Celsius.

Mechanical properties: Liquid silicone rubber has good elongation, high tear and tensile energy, excellent flexibility, and a hardness vary mostly between 5 to eighty Shore A.

Electrical properties: Liquid silicone rubber also has glorious insulating properties, beneficial for a host of electrical functions. Compared to standard insulating materials, silicone can perform in far higher and lower temperatures.

Transparency and pigmentation: Liquid silicone rubber is inherently translucent. Its pure shade is white and conducive to pigmentation for producing customized, molded merchandise in a wide range of colors.

Types Of Liquid Silicone Rubber

Liquid silicone rubber has differing kinds and compositions. Each kind has varying characteristics.

silicone rubber liquid for making bushings

General Purpose LSR

This is a extensively used materials with in depth purposes as a end result of its flexibility, biocompatibility, and heat resistance. Typical makes use of of general purpose LSR sort embrace seals, gaskets, and industrial parts.

High-Temperature LSR

High-temperature liquid silicone rubber materials can face up to extreme warmth publicity with out degrading or compromising its qualities. Common purposes of this LSR include industrial gear, automotive components, and digital parts.

Medical Grade LSR

This type of liquid silicone rubber is formulated to fulfill the strict biocompatibility and security necessities for medical and healthcare merchandise. Medical grade LSR supplies are sterilizable and biocompatible, making them appropriate for purposes that require contact with the human body.

Self-Bonding LSR

Self-bonding LSR materials displays excellent properties of adhering to itself with out using other adhesives. Therefore, it's excellent for making complicated assemblies with out depending on conventional bonding methods.

Food-Grade LSR

The meals grade is just like the medical grade LSR. It meets strict necessities for contact with meals and beverages. Baby products, baking molds, and kitchen utensils are typical food-grade liquid silicone materials purposes.

Electrically Conductive LSR

It contains electrostatic discharge (ESD) additives that provide electrical conductivity properties. This grade is often utilized in functions with electrical conductivity and suppleness of silicone rubber requirements, including EMI/RFI shielding and flexible circuits.

Optically-Clear LSR

Optically clear liquid silicone rubber is suitable for making merchandise like lenses, light guides, and different optical components and tools with transparency and optical readability necessities.

0 notes