#Logistics automation and smart warehouses

Explore tagged Tumblr posts

Text

The future of logistics is now: AI & Automation trends to watch in 2025

Problem: Traditional Logistics Can’t Keep Up Anymore

The logistics industry has always been the backbone of global trade. But in 2025, old systems are simply not fast, smart, or flexible enough to keep up. Rising fuel costs, unpredictable demand, labor shortages, and supply chain disruptions have pushed logistics companies to rethink operations.

Manual tracking, slow warehouse operations, and disconnected systems lead to delivery delays, increased costs, and unhappy customers. To stay competitive, logistics providers need more than just manpower, they need intelligence and automation.

Promise: Ai and automation are transforming the game in 2025

The good news? AI-powered logistics and smart automation are no longer futuristic concepts , they’re reality in 2025. From autonomous delivery vehicles to predictive inventory and smart route optimization, AI in logistics is unlocking new levels of efficiency, speed, and visibility.

Companies adopting logistics automation in 2025 are seeing:

Up to 30% faster deliveries

Real-time tracking with 99% accuracy

Reduced fuel and labor costs

Smarter demand forecasting and fewer stockouts

📊 Proof: real-world applications of Ai in logistics (2025)

Let’s break down how AI and automation are actively reshaping logistics today:

1. Smart warehousing and robotics

Modern warehouses in 2025 use AI-powered robots to pick, pack, and sort packages. These systems reduce human error and boost throughput.

Example: Amazon’s AI-driven robotic warehouses process thousands of orders per minute with near-perfect accuracy.

2. Predictive Analytics and Inventory Management

AI tools now predict demand trends based on historical data, weather patterns, and customer behavior helping companies avoid overstocking or stockouts.

Stat: Companies using predictive logistics AI report up to 40% reduction in excess inventory.

3. Autonomous Delivery Vehicles & Drones

Self-driving trucks and drones are no longer pilot projects; they're actively delivering goods in urban and rural areas.

Example: FedEx and UPS are deploying AI-guided autonomous trucks for regional deliveries in the U.S.

4. AI Route Optimization

AI platforms like ClearMetal and Locus use real-time data to optimize delivery routes in minimizing fuel consumption and delivery time.

Result: Businesses save thousands monthly by avoiding traffic, delays, and inefficient planning.

Proposal: Why you should embrace logistics automation in 2025

If you’re in the logistics business or rely heavily on shipping and supply chains, now is the time to act.

Here’s what you can do:

Audit Your Current Tech Stack

Identify where manual systems are costing you time and money. Focus on warehouse operations, delivery tracking, and customer service.

Invest in Scalable AI Solutions

Start with tools that offer immediate ROI such as AI route planners or automated inventory systems.

Partner with a Logistics Tech Expert

Don’t go it alone. Collaborate with a logistics software development company that understands AI in logistics 2025 and can build custom automation solutions for your business.

Train your team for the Ai shift

Technology is only powerful if your people can use it. Upskill your staff in AI-powered systems and digital tools.

Conclusion :

The logistics industry in 2025 is smarter, faster, and more data-driven than ever thanks to AI and automation. Businesses that invest today in intelligent logistics solutions will gain a competitive edge, reduce operational costs, and exceed customer expectations.

Don’t let outdated systems slow you down. Embrace the AI revolution in logistics now.

#“latest logistics innovations 2025”#“AI and automation in supply chain”#“future of logistics industry”#“transportation tech innovations”#logistics mobile app development trends”#Logistics innovations 2025#Supply chain trends 2025#Future of logistics industry#Smart logistics solutions#Emerging logistics technologies#Top logistics tech trends for 2025#Logistics automation and smart warehouses#Sustainable logistics practices in 2025

1 note

·

View note

Text

Guide for Importers on Manufacturing Control

Efficient Manufacturing Control in China

1. Understand the Chinese Manufacturing Environment:

Diverse Ecosystem: China offers a vast range of manufacturers, from small workshops to large factories. This variety is beneficial but also poses challenges in ensuring consistent quality.

IP Concerns: Despite improvements, IP protection in China can be inconsistent, requiring robust measures to safeguard your innovations.

Regulatory Landscape: China’s complex and changing regulations make compliance crucial to avoid fines and reputational damage.

Quality Control: While quality has improved, some sectors still prioritize quantity over quality. Rigorous quality protocols are essential.

Labor & Costs: Labor costs are rising, pushing manufacturers toward automation. Infrastructure is robust, but supply chains can be disrupted by natural disasters or policy changes.

Government Policies: China’s government heavily influences manufacturing through policies and incentives, which can affect costs and market access.

2. Build a Strong Foundation:

Supplier Selection: Choose reliable suppliers through thorough due diligence, including factory visits and financial checks.

Clear Communication: Provide detailed specifications and maintain open communication to avoid misunderstandings.

Quality Management: Implement a Quality Management System (QMS) and conduct regular audits to ensure consistent product quality.

Strong Relationships: Develop long-term partnerships with suppliers to build trust and collaboration.

3. Implement Effective Control Strategies:

QA & QC: Establish a robust QA/QC framework to ensure consistent product quality.

Supplier Development: Invest in your suppliers’ capabilities to improve quality and efficiency.

Risk Management: Prepare for disruptions with backup plans and diversified suppliers.

Contractual Coverage: Clearly define product specifications and include IP protections in contracts.

Third-Party Verification: Use third-party inspections to ensure compliance and quality.

4. Manage Logistics & Supply Chain:

Transportation: Choose the best transport mode and routes to minimize costs and delays.

Warehousing & Inventory: Optimize warehouse locations and use management systems to track inventory.

Customs & Documentation: Ensure compliance with customs regulations and prepare accurate documentation.

Supply Chain Visibility: Use technology to monitor shipments and collaborate with suppliers.

Risk Assessment: Develop contingency plans for disruptions like natural disasters or strikes.

5. Overcome Common Challenges:

Language & Cultural Barriers: Hire experts to bridge gaps in communication and cultural understanding.

IP Protection: Secure your IP with patents, trademarks, and NDAs; monitor for infringements.

Regulatory Compliance: Stay updated on regulations and partner with local experts for compliance.

Supply Chain Disruptions: Diversify suppliers, maintain sufficient inventory, and use smart tools for monitoring.

6. Continuous Improvement:

Use data analytics to track trends and improve processes.

Regularly evaluate supplier performance and invest in employee training.

Embrace technology to enhance communication and efficiency.

7. Build a Culture of Quality:

Encourage employees to propose improvements.

Reward contributions to quality enhancement.

Focus on exceeding customer expectations.

Conclusion: Effective manufacturing control in China requires ongoing effort, attention, and adaptation. Invest in strong practices to improve product quality, reduce costs, protect your brand, and optimize your supply chain.

3 notes

·

View notes

Text

Larry Savage Birmingham About Logistics Challenges And How To Overcome Them

Logistics managers are now more aware of the need to obtain vital information instantly due to the pandemic. Additionally, it encouraged warehouse managers to be proactive in mitigating risks related to supply and demand. Today, machine learning software that analyzes real-time data can help prevent both overstock and out-of-stock. This is similar to IoT sensors assisting transportation businesses in tracking goods throughout the route. So, to learn more, read Larry Savage Jr Birmingham – Challenges That Necessitate The Need For An Organized Logistics Industry to level up your business performance.

Strengthen communication at all levels

A vital component of surviving in business is anticipating logistical obstacles and knowing how to overcome them. You should include improving communication with the participants in your global supply chain in your planning. You might even wish to create connections with far-off logistical companies to increase your marketing reach if your company is local. In order to stay informed about the state of the resources supporting your products and market, it's critical to keep in constant contact with your suppliers.

Establish standards for suppliers and partners

If businesses follow different standards, it could confuse some of them when arranging many deliveries daily with several supply chain managers. Logistics operations are considerably more streamlined and coherent when every service follows the same loading and unloading procedures. Supply chain visibility can also be maximized for all participants in this coordination through smart technology and interconnected electronic networks.

Invest in the right technology

Companies today are also overspending on the latest software and hardware developments due to the quick changes in business technology. Spending less on technology to achieve maximum efficiency is now possible if you use cloud technologies.

If your business is operating on a tight budget, cloud services offer the most economical options. A warehouse might think about collaborating with logistics industry specialists if it needs additional flexibility, scalability, or experience.

Using third-party logistics providers to carry goods to markets is one way for businesses that can't afford to invest in creating a logistics service that makes use of automation, robots, and artificial intelligence.

Reduce warehouse management errors

An infrastructure's likelihood of errors decreases as it becomes more digital through automation or improved access to pertinent real-time data.

Adopting warehouse management software with integrations to new and innovative technologies like 5G, AI, and IoT has become crucial in this century. You can use these technologies to gather and archive important logistics data.

Proper placement of warehouse inventory products is also crucial to avoid a cascade of disruptions.

Then, to prepare items for delivery, they must be carefully chosen and packed. Incomplete orders and incorrect delivery information are two common order fulfillment mistakes that still happen. Warehouse managers can effectively decrease these errors by using more vigilant supervision and enhanced picking and packing confirmation protocols.

Final thoughts

In the future, meeting customer needs will be the hardest task for the logistics industry. So, improving warehouse structure and layout by analyzing logistics will help you. Lastly, don’t read Larry Savage Birmingham — Know About The Basics Of Stock Options Trading to keep your fortunes thriving.

#Larry Savage Birmingham#Logistics Challenges#Logistics Expert#Logistics Industry#business owner#business ideas#business strategy

3 notes

·

View notes

Text

The Future of Warehouse Management: How WMS Fuels Growth

The warehouse industry is undergoing a major transformation. With the rapid growth of e-commerce, increasing customer expectations, and continuous advancements in technology, managing warehouses efficiently has never been more critical. In this shifting landscape, a powerful Warehouse Management System (WMS) like Warehouse Solutions for UAE has become an essential part of business success.

Meeting the Demands of Modern Customers

Today’s consumers expect fast delivery, accurate orders, and full visibility into their shipments. This means warehouses must operate with precision and speed. Rubicon WMS Dubai helps businesses meet these rising expectations by streamlining inventory management, improving order accuracy, and integrating smoothly with delivery platforms. The result? Higher customer satisfaction, repeat business, and long-term loyalty.

Keeping Up with E-Commerce Growth

The e-commerce boom has dramatically changed how warehouses function. Businesses now face higher order volumes, complex product assortments, and frequent returns. Warehouse Solutions for UAE is designed to handle these challenges. With smart features like batch picking and return management (reverse logistics), it helps businesses stay competitive and efficient in the fast-paced digital marketplace.

Embracing Automation and Smart Technologies

Automation and AI are redefining warehouse operations. Rubicon WMS seamlessly connects with modern warehouse technologies like robots, pick-to-light systems, and automated guided vehicles (AGVs). These tools minimize manual labor, reduce errors, and boost overall productivity. By automating repetitive tasks, businesses can focus more on strategy and growth.

Built for Growth: Scalable and Flexible

As your business grows, so do the demands on your warehouse. You need a system that can keep up. Warehouse Solutions for UAE is built to scale, handling increased inventory, new locations, and more complex workflows. Its flexible architecture allows for customization, ensuring the system aligns with your specific operational needs now and in the future.

Data-Driven Decisions for Continuous Improvement

In today’s data-driven world, insights are everything. Rubicon WMS provides powerful analytics tools that help identify inefficiencies, track performance, and forecast future needs. From uncovering bottlenecks to optimizing stock levels, these data insights support smarter decision-making and continuous improvement.

Conclusion: Ready for the Future?

The future of warehouse management lies in embracing innovation. By leveraging smart, scalable, and automated systems like Warehouse Solutions for UAE, businesses gain the tools they need to grow, adapt, and exceed customer expectations. Whether you're managing high order volumes or expanding into new markets, Rubicon WMS delivers the flexibility and power needed to stay ahead.

Is your warehouse ready for what’s next? Discover the potential of Rubicon WMS and future-proof your operations today.

0 notes

Text

Top 10 Key Goals of Objectives of Inventory Management Systems You Should Know

Top Inventory Management Systems 2025: AIDC’s Smart Solutions Overview

Inventory management is a core part of running a successful business. Whether you’re managing stock in retail, manufacturing, or logistics, keeping your inventory in control helps ensure smooth operations and cost efficiency. In 2025, AIDC Technologies India offers reliable inventory solutions designed to meet the modern needs of businesses across sectors.

The success of any system lies in how well it achieves the key objectives of inventory management. AIDC focuses on helping businesses reduce costs, improve stock accuracy, and streamline supply chains through its advanced inventory tools.

What Is an Inventory Management System? AIDC’s Simple Definition

An inventory management system is a software-based solution used to track stock levels, manage orders, and record inventory movements in real time. It helps businesses keep an accurate count of goods, track their location, and plan for future demand.

AIDC Technologies provides inventory systems that use barcode and RFID scanning to automate stock monitoring. These systems are designed to meet the objectives of inventory management, including reducing waste, improving accuracy, and maintaining stock availability at all times.

Key Objectives of Inventory Management Systems Explained by AIDC

The primary purpose of using an inventory management system is to meet specific business goals. These goals, or objectives of inventory management, help businesses operate efficiently while meeting customer expectations.

Some of the major objectives of inventory management include improving stock accuracy, avoiding shortages, reducing holding costs, optimizing storage space, supporting production planning, and ensuring timely order fulfillment. AIDC integrates these goals into every system it develops, ensuring that businesses can maintain control over their inventory in every situation.

How AIDC Inventory Systems Work in Real-Time Business Environments

AIDC’s inventory systems are built to offer real-time visibility into stock movement. Every item is tagged with a barcode or RFID chip, and every entry or exit is scanned and logged instantly. These updates reflect immediately in the system’s dashboard, giving business owners and managers a clear picture of stock status.

This real-time tracking directly supports the objectives of inventory management, such as reducing data entry errors, minimizing stock losses, and improving decision-making. AIDC makes sure that businesses no longer rely on outdated methods or delayed reporting.

Features That Set AIDC Inventory Tools Apart in 2025

AIDC’s inventory solutions are packed with features to help meet both basic and advanced inventory needs. These include automatic stock alerts, real-time dashboards, inventory analytics, multi-location tracking, mobile access, and seamless integration with billing and ERP systems.

Each of these features supports the core objectives of inventory management by helping businesses avoid excess inventory, maintain adequate stock levels, and reduce overhead costs. The tools are built to be user-friendly and scalable, making them suitable for both small enterprises and large organizations.

Retail and Warehouse Inventory Control with AIDC Technologies

Retailers and warehouse operators rely heavily on accurate inventory data. AIDC’s solutions are designed to help them reduce errors, track inventory in real time, and maintain balanced stock levels. These solutions are especially helpful during peak sales periods or when managing multiple product categories.

By focusing on the objectives of inventory management, AIDC enables businesses to improve turnover rates, avoid missed sales, and streamline order fulfillment. The result is better customer service and higher profitability.

AIDC Inventory Software for Stock Tracking and Forecasting

Good inventory management goes beyond tracking stock. AIDC inventory software includes forecasting tools that analyze past trends and current demand to predict future inventory needs. This helps businesses plan smarter, reduce overstocking, and avoid running out of high-demand items.

By supporting proactive planning, AIDC’s systems fulfill long-term objectives of inventory management such as reducing holding costs, optimizing supply chain operations, and minimizing financial risks.

Comparing Traditional Systems vs AIDC’s Smart Inventory Tools

Many businesses still rely on manual inventory tracking, spreadsheets, or outdated software. These traditional systems are often slow, error-prone, and limited in scope. AIDC’s smart inventory tools offer automation, accuracy, and scalability that traditional systems cannot match.

Businesses that switch to AIDC’s solutions see a marked improvement in meeting the objectives of inventory management. Tasks that used to take hours can now be completed in minutes, and data is always current and reliable.

Industry Applications of AIDC Inventory Management Systems

AIDC’s inventory systems are used across a wide range of industries, including retail, manufacturing, logistics, warehousing, automotive, and healthcare. Each industry has unique needs, but the objectives of inventory management remain consistent.

For example, manufacturers use AIDC systems to track raw materials and production inputs. Retailers use them to monitor shelf stock and reorder levels. Healthcare providers rely on accurate inventory data for medical supplies. AIDC’s flexibility allows its systems to adapt to different sectors while delivering consistent results.

Book a Free Demo of AIDC Inventory Management Solutions Today

If you’re looking to improve your stock control and meet the real objectives of inventory management, AIDC Technologies India is ready to help. Their smart systems are trusted across India for their accuracy, speed, and ease of use.

Book now AIDC and get a free demo customized for your industry. See how real-time inventory visibility, automation, and reporting can transform the way your business operates.

#InventoryManagement2025#SmartStockControl#InventoryGoalsExplained#WarehouseAutomation#StockOptimization#InventoryEfficiency#RealTimeInventoryTracking#InventoryControlSystem#AIDCInventorySolutions

0 notes

Text

The Link Between Customer Satisfaction and Supply Chain Software

Businesses are constantly striving to improve customer satisfaction. One of the most overlooked yet critical areas that directly influences customer experience is the efficiency of the supply chain.Slow processes, frequent mistakes, and limited visibility can lead to customer dissatisfaction and weaken overall brand trust. This is where supply chain software becomes a game-changer. By automating and optimizing various logistics and fulfillment processes—especially demand planning and forecasting—companies can significantly enhance service levels, improve delivery accuracy, and create smoother customer interactions. When operations align with customer expectations, satisfaction becomes a natural outcome.

Enhancing delivery performance and accuracy

Customers now demand complete and timely deliveries. Any delays or errors can lead to dissatisfaction, damaging reviews, and a loss of trust in your brand. With the help of supply chain software, companies can monitor real-time data and track goods from the warehouse to the doorstep. Features such as automated inventory control, smart routing, and delivery status updates ensure that the right products reach the right place at the right time.

Moreover, integrating demand planning and forecasting into the supply chain system allows businesses to anticipate customer needs more effectively. By analyzing historical data and current market trends, companies can prevent overstocking or stockouts, which directly impacts customer satisfaction levels.

Improving inventory management for better service

Nothing frustrates a customer more than discovering a product is out of stock after they have placed an order. Efficient inventory management plays a vital role in reducing such scenarios. Supply chain software provides visibility into stock levels across multiple locations, enabling businesses to fulfill orders faster and more accurately.

Advanced demand planning and forecasting modules allow supply chains to respond proactively to seasonal demand, promotional campaigns, or sudden market shifts. This capability improves fulfillment rates, reduces backorders, and ensures customers receive what they want, when they want it.

Enabling proactive customer communication

Customers appreciate transparency. They want timely updates about their order status, expected delivery dates, and any disruptions that may arise. Through supply chain software, companies can automate notifications and updates via email or SMS, keeping customers informed throughout the fulfillment process.

In addition, modern supply chain software integrates advanced tracking and communication features that significantly improve transparency and ensure greater accountability across operations. This proactive approach builds trust and reassures customers, ultimately elevating satisfaction and retention.

Supporting long-term loyalty and brand reputation

Efficient supply chains do more than just fulfill orders—they shape the overall brand experience. When deliveries are reliable, returns are hassle-free, and inventory is always available, customers are more likely to stay loyal. Implementing robust demand planning and forecasting practices within the supply chain helps ensure consistency in service, which is crucial for building long-term trust.

Moreover, an efficient and transparent supply chain showcases a company's reliability and operational excellence. In the long run, this strengthens brand reputation and fosters greater customer loyalty and support.

Customer satisfaction is no longer solely a function of marketing or customer service—it is deeply connected to operational efficiency. By investing in supply chain software and leveraging its demand planning and forecasting capabilities, businesses can streamline operations, respond to customer needs proactively, and exceed expectations. In a world where customer experience defines success, aligning supply chain performance with customer demands is not optional—it is essential.

1 note

·

View note

Text

Choosing the Right Pallet Conveyor Manufacturer: Key Factors to Consider

In the world of material handling and logistics, pallet conveyors play a critical role in streamlining operations, improving safety, and boosting efficiency. Whether you're managing a warehouse, distribution center, or manufacturing facility, choosing the right pallet conveyor manufacturer can significantly impact your productivity and ROI.

Here’s what you need to know when selecting a reliable manufacturer for pallet conveyor systems.

Why Pallet Conveyors Matter

Pallet conveyors are designed to transport heavy loads—typically pallets of goods—smoothly across production lines or storage areas. They are widely used in industries like:

Warehousing and logistics

Food and beverage

Pharmaceuticals

Automotive

FMCG and more

By automating material movement, these systems reduce manual handling, enhance safety, and ensure consistent workflow.

What to Look for in a Pallet Conveyor Manufacturer

1. Industry Experience and Expertise

Choose a manufacturer with a strong track record in designing and installing pallet conveyor systems. Years of experience often translate to better product knowledge, problem-solving capabilities, and tailored solutions.

2. Customization Capabilities

No two facilities are the same. A good manufacturer will offer custom conveyor solutions that fit your unique space, load requirements, and workflow.

Ask about:

System layout design

Weight/load capacity

Automation and integration options

Conveyor length and material type

3. Quality of Materials and Engineering

Durability is key. Ensure the manufacturer uses high-grade steel, rollers, motors, and controls that comply with international standards. The build quality will determine the longevity and maintenance needs of your conveyor system.

4. After-Sales Support & Maintenance Services

A good conveyor system is only as good as the support that comes with it. Check if the manufacturer offers:

Installation support

Staff training

Regular maintenance plans

Spare parts availability

Emergency response time

5. Technology Integration

Modern pallet conveyors often come with smart features like:

IoT-enabled tracking

Automated sensors

Integration with warehouse management systems (WMS)

Partner with a manufacturer who stays ahead of the tech curve.

Benefits of Working with a Trusted Manufacturer

Improved workflow efficiency

Reduced downtime and labor costs

Enhanced workplace safety

Scalable systems for future growth

Compliance with industry regulations

Final Thoughts

Investing in a pallet conveyor is a long-term decision. Take the time to research and compare different manufacturers. Look for one that not only delivers high-quality products but also becomes a strategic partner in your material handling journey.

Are you searching for a reliable pallet conveyor manufacturer in the UK or globally? Choose a company that combines engineering excellence with customer-focused service.

0 notes

Text

Santosh Kumar Sahu: A Visionary Revolutionizing India’s Agricultural Logistics

India’s agricultural landscape has long been plagued by inefficiencies — from post-harvest losses to fragmented supply chains. Enter Santosh Kumar Sahu, the driving force behind Go Green Warehouses, whose revolutionary vision and innovative strategies are transforming agri-logistics across the nation. Combining his deep agricultural expertise, technological insights, and commitment to sustainability, Santosh Kumar Sahu is spearheading a revolution, integrating AI-empowered systems to empower farmers and maximize efficiency.

From Rural Roots to Leadership in Agri-Tech

Born in a small village in Odisha, Santosh Kumar Sahu pursued agricultural sciences at OUAT, then honed his management skills with an MBA in IT and agriculture from DA-IICT. Over 18+ years, he amassed rich experience at Godrej Agrovet, Reliance Retail, NCML, and Krishidhan Seeds. But it was in 2018 that he teamed up with Maulik Shah to launch Go Green Warehouses — marking the turning point in India’s agri-logistics sector.

AI Meets Warehousing — A Smart Evolution

Under the leadership of Santosh Kumar Sahu, Go Green Warehouses is not just expanding its physical footprint; it’s innovating with digital infrastructure. By deploying AI-powered inventory management systems, predictive analytics for demand forecasting, quality control automation, and smart monitoring using IoT sensors, Santosh Kumar Sahu ensures that warehouses can dynamically optimize storage, reduce spoilage, and offer real-time dash boarding to farmers and traders.

These AI tools streamline operations, cut human error, and improve transparency — fostering trust among stakeholders while reducing costs and enhancing farm incomes.

Holistic Agri-Logistics — Beyond Storage

The ecosystem built by Santosh Kumar Sahu goes far beyond storage facilities:

Collateral Management & Commodity Finance: Enables farmers to leverage their stored produce as collateral for loans.

Post-Harvest Services: Sorting, grading, and quality assurance are embedded into each repository.

Market Linkages: Digital interfaces connect farmers and FPOs directly with buyers, avoiding exploitative middlemen.

Vertical Integration: Expansion into commodity testing, agro-processing, 3PL services, and agritech solutions powered by AI.

This end‑to‑end model not only slashes post-harvest losses but also empowers small and marginal farmers with financial inclusion and market access.

A Network of Green Warehouses

Under Santosh Kumar Sahu’s guidance, Go Green Warehouses has grown from a single operation in Gujarat in 2012 to a network spanning 600+ warehouses across 24+ states, serving over 4,000 farmers and FPOs. By 2025, the company aims to emerge as India’s largest agri-storage provider — and potentially expand globally. AI-driven expansion planning, risk monitoring, and operational efficiency are key to this ambitious roadmap.

Leadership Rooted in Trust and Sustainability

Trust forms the foundation of Santosh Kumar Sahu’s leadership. He emphasizes transparency through what they term the “8 Cs of Trust” (clarity, compassion, character, competence, commitment, connection, contribution, consistency). This philosophy ensures that every stakeholder — from warehouse staff to rural farmers — feels respected and heard.

He fosters a learning culture, empowering employees to experiment and innovate. Failures are treated as lessons — an empowering approach that fuels creativity and ensures continuous improvement in both logistics and tech.

Sustainability at the Core

Environmental stewardship is a non-negotiable for Santosh Kumar Sahu. Under his stewardship, Go Green Warehouses harnesses:

Renewable energy systems (solar panels, LED lighting)

Eco-friendly packaging and materials

Energy-efficient storage environments

Waste reduction initiatives

By integrating AI to monitor energy use and emissions, Santosh defines “green” not only as an aesthetic but as an operational ethos — saving both the environment and operational costs while enhancing brand image.

Farmer Empowerment Through Technology

AI-driven mobile apps and online dashboards roll out in regional languages, offering real-time info on:

Storage status

Quality grading results

Loan eligibility

Market trends and price forecasts

Under Santosh Kumar Sahu, these tools level the playing field for smallholders. Digital literacy training ensures that farmers actively use technology, driving adoption and inclusion.

H5: Collaborative Ecosystem Building

Collaboration lies at the heart of Santosh’s expansion strategy. Go Green Warehouses partners with:

Financial institutions for collateral-based lending

NABL-certified labs for quality assessments

Commodity exchanges and input vendors for market integrations

Agrotech start-ups for AI-driven hardware and data analytics

This networked model exemplifies Santosh Kumar Sahu’s vision of inclusive, tech-driven agricultural logistics.

Results and Impact

The integration of AI and sustainable practices under Santosh Kumar Sahu’s leadership has delivered impressive results:

Over 8000 crore INR worth of commodities stored

Farmer incomes increased through reduced spoilage and better pricing

Post-harvest losses slashed by up to 30–40%

600+ locations, servicing 4,000+ farmers and FPOs

Building trust with strong financial partnerships and premium clients

These metrics validate how Santosh Kumar Sahu’s model is not just visionary, but substantively transformative.

Looking Ahead

Santosh’s roadmap includes:

Further penetration into rural micro-warehousing

Full digital integration via AI and blockchain

Expansion into adjacent sectors — cold chain, pharma, FMCG storag

Exploring global partnerships at ports and logistic hubs

Santosh Kumar Sahu is also investing in R&D for novel agritech solutions — AI-based pest detection, predictive shelf-life analytics, and automated quality grading — all aimed at creating a smarter, more resilient agricultural ecosystem.

Leadership Advice from Santosh

Some key insights from Santosh Kumar Sahu:

1.Trust first — build value before pursuing profits

2.Patience and perseverance — renew focus even in the face of setbacks.

3.Empower your team — decentralize decision-making for innovation.

4.Listen and learn — stakeholder feedback fuels iterative improvements.

5.Aim for impact, not just scale — sustainability and empowerment are core success metrics.

Legacy of Transformation

More than a corporate leader, Santosh Kumar Sahu is an agent of socioeconomic transformation — uplifting rural communities, fostering sustainable development, and advocating for a digital agriculture revolution. His journey from a small village in Odisha to leading a pan-India agritech enterprise underscores the power of vision and purposeful execution.

0 notes

Text

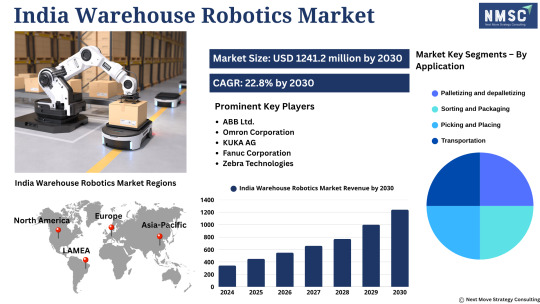

𝗗𝗜𝗗 𝗬𝗢𝗨 𝗞𝗡𝗢𝗪? 𝗜𝗻𝗱𝗶𝗮 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 is becoming one of the most underestimated goldmines in the automation space—and the smart capital is already flowing in.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗜𝗻𝗱𝗶𝗮 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗶𝘀 𝘀𝗰𝗮𝗹𝗶𝗻𝗴 𝗮𝘁 𝘄𝗮𝗿𝗽 𝘀𝗽𝗲𝗲𝗱

𝗛𝗲𝗿𝗲'𝘀 𝘄𝗵𝗮𝘁'𝘀 𝗳𝘂𝗲𝗹𝗶𝗻𝗴 𝘁𝗵𝗶𝘀 𝗺𝗼𝗺𝗲𝗻𝘁𝘂𝗺:

1. 𝗠𝗮𝘀𝘀𝗶𝘃𝗲 𝘄𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗲𝘅𝗽𝗮𝗻𝘀𝗶𝗼𝗻 —India will need 500+ million sq. ft. of warehousing space in the next 5 years. 2. 𝗟𝗮𝗯𝗼𝗿 𝗰𝗼𝘀𝘁𝘀 𝗿𝗶𝘀𝗶𝗻𝗴, 𝗲𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆 𝗱𝗲𝗺𝗮𝗻𝗱𝘀 𝗴𝗿𝗼𝘄𝗶𝗻𝗴 —robotics is no longer optional. 3. 𝗠𝗮𝗸𝗲 𝗶𝗻 𝗜𝗻𝗱𝗶𝗮 + 𝗣𝗟𝗜 𝘀𝗰𝗵𝗲𝗺𝗲𝘀 + 𝗜𝗻𝗳𝗿𝗮 𝗯𝗼𝗼𝘀𝘁 = major tailwinds. Early-stage startups & deep-tech firms are gaining real traction with global VCs.

Still think robotics is a luxury in India? Think again.

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: ABB Ltd., Omron Corporation, KUKA AG, Fanuc Corporation, JBT Corporation, GreyOrange, Bastian Solutions LLC, Zebra Technologies, Dematic, Honeywell International Inc, Vanderlande Industries B.V., Daifuku Co., Ltd., Murata Machinery, Ltd., YASKAWA ELECTRIC CORPORATION and others.

𝗧𝗵𝗶𝘀 𝗶𝘀 𝘆𝗼𝘂𝗿 𝘀𝗶𝗴𝗻𝗮𝗹.

If you're an investor looking for deep tech meets real-world scale, warehouse robotics is the entry point to India’s trillion-dollar logistics overhaul.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

𝗧𝗵𝗲 𝗻𝗲𝘅𝘁 𝘂𝗻𝗶𝗰𝗼𝗿𝗻 𝗺𝗮𝘆 𝗻𝗼𝘁 𝗯𝗲 𝗮𝗻𝗼𝘁𝗵𝗲𝗿 𝗦𝗮𝗮𝗦 𝗮𝗽𝗽—𝗶𝘁 𝗰𝗼𝘂𝗹𝗱 𝗯𝗲 𝗮 𝗿𝗼𝗯𝗼𝘁 𝘀𝗼𝗿𝘁𝗶𝗻𝗴 𝗽𝗮𝗿𝗰𝗲𝗹𝘀 𝗶𝗻 𝗮 𝘄𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗻𝗲𝗮𝗿 𝗗𝗲𝗹𝗵𝗶. Are you watching? Or investing?

#IndiaRobotics#WarehouseAutomation#VCIndia#DeepTech#SupplyChainRevolution#Logistics#InvestorAlert#IndiaGrowthStory#SmartCapital#RoboticsStartup

0 notes

Text

Leading the Future of Construction: Top PEB Manufacturers in India Revolutionizing Infrastructure

In the dynamic world of infrastructure development, Pre-Engineered Buildings (PEBs) have emerged as the most efficient, cost-effective, and sustainable solution for modern construction. From industrial warehouses to commercial complexes and institutional buildings, the demand for PEB structures is surging across India. At the heart of this growth are the PEB manufacturers who are transforming the construction landscape with innovation, precision, and speed.

What are Pre-Engineered Buildings?

PEBs are factory-fabricated buildings that are assembled on-site using pre-designed components such as steel frames, roofing sheets, wall cladding, and accessories. Unlike traditional construction, PEBs offer unmatched advantages including:

Faster construction timelines

Lower cost of materials and labor

Superior design flexibility

Eco-friendly building processes

High strength-to-weight ratio

These benefits make them ideal for industrial, commercial, agricultural, and institutional applications.

Role of PEB Manufacturers in India

PEB manufacturers in India play a pivotal role in designing, engineering, fabricating, and erecting pre-engineered building systems. With in-house R&D, automated production lines, and a skilled workforce, these companies are delivering tailor-made solutions that meet global standards.

Leading PEB manufacturers in India specialize in:

Industrial Sheds and Warehouses

Airport Hangars and Logistics Hubs

Retail Showrooms and Shopping Complexes

Cold Storage and Food Processing Units

Multi-storey Steel Buildings

Why Choose a Trusted PEB Manufacturer?

Choosing a reliable PEB manufacturer ensures:

Custom-engineered designs as per site and load requirements

High-quality materials like galvanized or color-coated sheets

Quick delivery and on-site support

Compliance with IS codes and international standards

Long-lasting, weather-resistant structures

Future of PEB in India

With government initiatives such as "Make in India" and a strong push for industrialization, the PEB industry is poised for exponential growth. The rise of smart cities, logistics parks, and e-commerce fulfillment centers will continue to drive demand.

As pioneers in steel structure solutions, PEB manufacturers in India are not just building warehouses—they're building the future.

Conclusion:

If you're planning an industrial or commercial project, partnering with an experienced PEB manufacturer can be a game-changer. Their expertise, innovation, and commitment to quality ensure that you get a structure that’s not only cost-effective but also durable and future-ready.

Visit:- https://www.pebmanufacturers.in/

0 notes

Text

The Unsung Heroes of Modern Warehousing

Efficiency is crucial in the hectic fields of logistics and production. Whether it's handling goods across countries or completing online purchases, companies depend on backend systems that silently handle the laborious tasks. Conveyor systems stand out among them; they are crucial but frequently disregarded.

What Exactly Are Conveyor Systems?

Conveyor systems are essentially mechanical devices that move goods from one location to another. Sounds easy? Not exactly. In factories, warehouses, and distribution centres, these systems are made to maximise speed, minimise manual handling, and establish smooth operation. They can be roller conveyors, belt-driven lines, or overhead conveyors, among other types.

The Significance of Roller Conveyors

One of the most widely used kinds, roller conveyors provide a useful and affordable means of moving things, particularly in settings involving manufacturing or packing. Consider them to be highways for pallets, crates, or boxes. Because the rollers lessen friction, moving big objects requires less effort and personnel. Additionally, because they are modular, companies can add, delete, or reroute pieces in response to changing needs.

While gravity roller conveyors rely on incline and basic physics, powered roller conveyors use motors to transport objects automatically. Both kinds provide safety, speed, and consistency, things that physical labour can't always provide.

Smart Conveyor Systems' Ascent

Conveyor systems change with the industry. Smarter than ever, today's setups frequently incorporate robotics, automation software, and sensors. These intelligent technologies notify operators of maintenance requirements prior to a breakdown, track goods in real-time, and modify speeds based on load.

Conveyor systems are now the foundation of dependable, scalable operations in the cold chain, pharmaceutical, and e-commerce industries. They guarantee that goods travel from point A to point B without interruption, harm, or misunderstanding.

Choosing Trustworthy Conveyor Belt Suppliers

If you plan to set up or change your system, working with experienced conveyor belt suppliers is crucial. When choosing a conveyor, the type of material, needed speed, load weight, and available space are all crucial factors to take into account. Whether it's belt conveyors for fragile goods or roller systems for bulk movement, effective design and component selection can have a big impact on long-term performance.

0 notes

Text

Top 5 Latest Technology Trends in 2025 That Are Reshaping the Future

As we move deeper into 2025, technology continues to evolve at an unprecedented pace, influencing how we live, work, and interact. From intelligent automation to immersive realities, the digital revolution is accelerating across every sector. Here are the top 5 latest technology trends in 2025 that are shaping the world of tomorrow.

Artificial Intelligence Everywhere

AI is no longer limited to virtual assistants. In 2025, AI powers real-time decision-making across industries—healthcare diagnostics, financial forecasting, autonomous vehicles, and customer service chatbots. AI-as-a-Service (AIaaS) platforms are making it easier for businesses to integrate AI without large-scale infrastructure.

Quantum Computing Breakthroughs

Quantum computing is taking a leap in 2025. Tech giants and startups are developing quantum processors that can solve problems traditional computers can’t handle. It holds immense promise in drug discovery, cryptography, climate modeling, and logistics.

Hyperautomation and Autonomous Systems

Organizations are rapidly embracing hyperautomation—a combination of AI, machine learning, and robotic process automation (RPA). In 2025, warehouses, customer support centers, and manufacturing lines are increasingly operated by autonomous systems, reducing errors and boosting productivity.

6G Connectivity Begins Rolling Out

While 5G is still being adopted globally, 2025 sees the first rollouts of 6G networks in some advanced regions. With speeds 100x faster than 5G and ultra-low latency, 6G enables more complex IoT ecosystems, real-time VR/AR experiences, and smart city integration.

Extended Reality (XR) in Daily Life

Extended Reality—which includes AR, VR, and MR—has moved beyond gaming. In 2025, XR is used in virtual offices, remote education, virtual tourism, therapy, and e-commerce. The metaverse continues to evolve as a space for both business and social interaction.

0 notes

Text

Enhancing Operational Efficiency with Inventory Tracking Systems and Modern Supply Chain Technology

In today’s fast-paced and hyper-competitive market, businesses can no longer rely on manual processes to manage their logistics. Precision, speed, and visibility are now vital components of successful operations. That’s why implementing an advanced inventory tracking system, leveraging intelligent Supply Chain Technology, and optimizing warehouse management are crucial for companies aiming to scale efficiently and meet rising customer expectations.

The Power of a Modern Inventory Tracking System

An inventory tracking system plays a central role in ensuring businesses always know what stock they have, where it’s located, and how it’s moving. Gone are the days of spreadsheets and handwritten logs. Today’s systems use barcoding, RFID, and cloud-based software to deliver real-time visibility and accuracy across the entire supply chain.

Benefits of an Inventory Tracking System:

Real-Time Visibility: Track stock levels across multiple warehouses and locations

Reduced Stockouts and Overstocks: Maintain optimal inventory levels

Increased Accuracy: Eliminate human error through automation

Faster Order Fulfillment: Improve pick, pack, and ship processes

Data-Driven Decisions: Use analytics for better forecasting and inventory planning

An efficient inventory system not only minimizes waste but also improves the customer experience by ensuring timely and accurate order fulfillment.

Supply Chain Technology: Driving Innovation and Agility

Supply Chain Technology is the backbone of modern logistics. It integrates everything from procurement and production to fulfillment and reverse logistics. Smart supply chain platforms harness technologies like AI, IoT, machine learning, and blockchain to optimize processes and reduce operational risks.

Core Elements of Advanced Supply Chain Technology:

Automation of repetitive and labor-intensive tasks

Predictive analytics for demand planning and forecasting

End-to-end visibility from supplier to customer

Cloud-based collaboration tools for seamless communication across departments

Sustainability tracking to minimize carbon footprints and waste

With cutting-edge technology, businesses can respond faster to disruptions, reduce costs, and increase operational agility.

Optimizing Warehouse Management for Maximum Efficiency

Efficient warehouse management is key to reducing operational bottlenecks and enhancing order accuracy. Whether you’re managing a single distribution center or a network of warehouses, having the right warehouse management system (WMS) in place is essential.

Key Functions of Warehouse Management Systems:

Slotting optimization to improve picking speed

Real-time inventory updates across locations

Workforce productivity tracking

Returns management

Integration with eCommerce and ERP platforms

When combined with a robust inventory tracking system, effective warehouse management ensures that stock is received, stored, and shipped with maximum precision and minimum delay.

Conclusion

The success of any logistics or retail operation hinges on how well it manages its inventory, warehouse, and supply chain. Implementing an intelligent inventory tracking system, adopting modern Supply Chain Technology, and streamlining warehouse management can lead to increased productivity, reduced costs, and a significantly improved customer experience.

In a world where efficiency equals competitiveness, it’s no longer a question of if you should invest in advanced systems—but when. The sooner you do, the faster your business will thrive in a technology-driven economy.

For original post visit: https://pittsburghpenguinsclub.com/read-blog/24741_enhancing-operational-efficiency-with-inventory-tracking-systems-and-modern-supp.html

0 notes

Text

Top 10 RFID Definitions in 2025: Revolutionizing Industry

AIDC India’s 2025 Guide: RFID Definitions That Power Industry Efficiency

The future of business operations is driven by speed, accuracy, and automation. In 2025, RFID Definitions are more relevant than ever as industries look for smarter ways to track inventory, manage assets, and ensure security. RFID, or Radio Frequency Identification, uses wireless communication to identify and monitor tagged items.

At AIDC Technologies India, we specialize in providing advanced RFID solutions that help businesses improve their efficiency. This blog explores the top 10 RFID Definitions reshaping industries across India and how AIDC is leading the transformation.

1. RFID Definitions for Inventory Accuracy in Retail by AIDC

One of the most practical uses of RFID Definitions is in the retail industry. Retailers are constantly seeking better ways to manage inventory, reduce shrinkage, and improve the shopping experience.

AIDC provides RFID systems that let store owners scan hundreds of products in seconds without line-of-sight scanning. It means faster stock checks, better shelf management, and fewer lost items. This improves accuracy while reducing manual labor.

2. AIDC’s RFID Definitions in Warehouse & Logistics Automation

Warehousing and logistics rely on timing and accuracy. Traditional barcoding requires line-of-sight and manual scanning, which slows down processes. RFID Definitions offer real-time visibility of assets as they move through different stages.

AIDC India helps logistics firms deploy RFID tags that are read automatically as shipments enter, exit, or move inside a facility. This reduces human error, speeds up sorting, and ensures transparency across the entire supply chain.

3. RFID Definitions for Smart Manufacturing Efficiency

Manufacturing plants use RFID Definitions to monitor materials, machines, and workflows. AIDC integrates RFID into production lines, enabling real-time tracking of parts and products as they pass through each stage.

Whether it’s automotive, electronics, or food processing, RFID ensures that the right components are used at the right time. It helps reduce waste, improve quality control, and boost overall productivity.

4. RFID-Based Healthcare Tracking with AIDC Technologies

Healthcare is another sector where RFID Definitions bring massive improvements. Hospitals and clinics use RFID to track medical equipment, monitor patients, and manage pharmaceutical inventory.

With AIDC's RFID systems, medical staff can quickly locate critical devices, ensure medication accuracy, and improve patient safety. RFID wristbands for patients help in preventing mix-ups and ensuring accurate treatment.

5. RFID Definitions in Secure Access & Workforce Management

Security and workforce management are made easier with RFID Definitions. RFID badges allow companies to control access to offices, labs, or secure areas while keeping digital records of entry and exit times.

AIDC Technologies provides RFID access systems that are fast, contactless, and fully traceable. It helps reduce unauthorized access, monitor employee attendance, and improve workplace safety.

6. AIDC RFID in Public Transportation & E-Ticketing

From metro systems to buses, RFID Definitions are now a core part of public transportation. Smart cards embedded with RFID chips allow passengers to board quickly and pay electronically.

AIDC has helped many transit authorities implement RFID-based ticketing systems that reduce waiting time and eliminate fraud. These systems are scalable, reliable, and offer real-time data for authorities to manage routes and passenger flow efficiently.

7. RFID Definitions for Livestock & Agricultural Monitoring

Farming and livestock management are also benefiting from RFID Definitions. Farmers can use RFID ear tags and chips to identify, track, and manage livestock health records, movement, and feeding schedules.

AIDC India supplies robust RFID tags for agriculture that are weather-resistant and long-lasting. These solutions help improve farm productivity, reduce losses, and ensure compliance with animal health regulations.

8. Event Management Made Easy with RFID-Based Access by AIDC

Managing large crowds at events can be challenging. RFID Definitions simplify entry control, ticket validation, and real-time attendee tracking. With RFID wristbands, event organizers can allow fast, secure, and contactless access.

AIDC’s RFID event management tools are perfect for expos, concerts, and corporate gatherings. They also offer insights into visitor flow, helping organizers improve the event experience while keeping things secure.

9. RFID Definitions for Textile & Laundry Management Systems

Industries like hospitality, healthcare, and uniforms rely heavily on laundry and textile services. RFID Definitions enable automated tracking of linens, garments, and uniforms throughout the wash and delivery cycle.

AIDC provides washable RFID tags that help businesses monitor usage, prevent loss, and ensure timely returns. It’s an ideal solution for hotels, hospitals, and industrial laundries seeking better garment control.

10. Why AIDC Leads in RFID Definitions for Industrial Innovation

As RFID becomes the standard for tracking and identification, choosing the right solution provider matters. AIDC Technologies India stands out with its years of experience, reliable products, and customized services.

Our team understands the unique needs of each industry and provides complete RFID solutions—from tags and readers to software integration and support. We help businesses implement RFID Definitions that deliver real value and long-term efficiency.

Whether you're in retail, healthcare, manufacturing, or logistics, AIDC’s RFID technology is built to make your operations smarter and more agile.

Book now AIDC Technologies for RFID-Based Efficiency Solutions Today

Want to automate your workflow and increase productivity in 2025?

Conclusion: RFID Definitions Are Driving Industry Growth in 2025

In today’s digital-first world, businesses can’t afford delays, errors, or inefficiencies. RFID Definitions are the building blocks of a smarter, faster, and more connected future. They make it possible to track, manage, and optimize every aspect of operations—from inventory to people.

0 notes

Text

The Power of RFID in Warehouse Management: Efficiency, Accuracy & Beyond

In today’s fast-paced supply chains, RFID (Radio-Frequency Identification) is revolutionizing warehouse operations—replacing outdated barcode systems with real-time, touchless tracking. Here’s how RFID boosts speed, cuts costs, and minimizes errors in logistics:

🔍 Key Applications of RFID in Warehousing

Instant Inventory Tracking

Scan hundreds of items per second without line-of-sight (unlike barcodes).

No manual counting—reduce human error by up to 90%.

Automated Receiving & Shipping

RFID gates detect incoming/outgoing pallets instantly, slashing processing time.

Eliminate mismatched shipments with item-level visibility.

Smart Shelf & Stock Alerts

Sensors trigger low-stock warnings or detect misplaced items.

Perfect for high-value or perishable goods.

Forklift & Asset Tracking

Monitor equipment movement and optimize workflow paths.

Theft Prevention & Security

Tamper-proof tags alert unauthorized removals.

💡 Why RFID Outperforms Barcodes

✅ No scanning needed – Reads multiple tags through packaging. ✅ Durable – Withstands heat, dust, and moisture. ✅ Data-rich – Stores history, expiry dates, maintenance logs.

📈 ROI Spotlight

Companies like Amazon & Walmart cut inventory costs by 20-30% after RFID adoption.

Future-Proof Your Warehouse! From retail to pharmaceuticals, RFID is the backbone of Industry 4.0 logistics. Ready to upgrade?

0 notes

Text

Streamlining Growth with Ecommerce 3PL Canada: Your Guide to Choosing the Right Fulfillment Partner

In today’s ultra-competitive online marketplace, speed, efficiency, and reliability in order processing can make or break an eCommerce business. Canadian brands and international sellers looking to expand into North America are increasingly relying on professional third-party logistics (3PL) providers to manage warehousing and distribution. This is where the value of a trusted ecommerce 3PL Canada solution becomes crystal clear.

Whether you're a fast-scaling eCommerce brand or an established retailer, choosing the right fulfillment house Canada can dramatically improve delivery times, customer satisfaction, and operational efficiency. In this article, we explore why investing in professional fulfillment Canada services is essential for modern businesses.

What Is Ecommerce 3PL in Canada?

Ecommerce 3PL Canada refers to third-party logistics services specifically tailored for online retailers operating in or shipping to Canada. These providers handle critical logistics functions such as warehousing, order picking, packing, shipping, returns, and real-time inventory management.

Benefits of Partnering with an Ecommerce 3PL in Canada:

Faster shipping across Canada and into the U.S.

Reduced overhead on storage and labor

Seamless integration with eCommerce platforms like Shopify, Amazon, and WooCommerce

Real-time tracking and inventory updates

Flexible scalability during seasonal peaks

A reliable 3PL partner not only optimizes your supply chain but also helps you stay competitive by offering fast, accurate, and affordable shipping.

Fulfillment House Canada: The Backbone of Scalable Operations

A fulfillment house Canada is essentially your operational HQ for getting products into your customers’ hands. These fulfillment houses are strategically located near major Canadian cities—Toronto, Vancouver, Montreal, and Calgary—to maximize delivery speed and cost efficiency.

Services Typically Offered by Fulfillment Houses in Canada:

Warehouse storage and inventory management

Order picking, packing, and same-day fulfillment

Branded packaging and kitting services

Returns processing and reverse logistics

Freight forwarding and customs clearance support

Partnering with a well-equipped fulfillment house allows businesses to focus on growth, marketing, and customer engagement—while logistics are handled by industry professionals.

Why Fulfillment Canada Is a Smart Business Move

For brands looking to build or expand in North America, fulfillment Canada provides a reliable and efficient logistics base. Canada offers a stable business environment, excellent infrastructure, and a consumer base that values reliable delivery and local fulfillment.

Advantages of Fulfillment Canada:

Cross-border shipping advantage to U.S. markets

Compliance-ready operations for customs and import/export regulations

Bilingual support for both English and French-speaking customers

Strong network of domestic carriers for timely deliveries

Lower shipping costs for Canadian customers

Fulfillment services in Canada are also known for their strong tech adoption—using automation, real-time dashboards, and API integrations to keep businesses fully informed and in control.

Conclusion

In the fast-moving world of online retail, success depends on how well you manage logistics. Partnering with a trusted ecommerce 3PL Canada provider ensures you stay competitive by delivering products quickly and efficiently. A reliable fulfillment house Canada will not only support your current order volume but also scale with your business as you grow.

Whether you’re fulfilling hundreds or thousands of orders each month, investing in expert fulfillment Canada solutions is your key to building a more responsive, cost-effective, and customer-centric eCommerce operation.

Now is the time to streamline your fulfillment process and deliver on your brand promise—every single time.

For original post visit: https://alumeet.com/read-blog/11733_streamlining-growth-with-ecommerce-3pl-canada-your-guide-to-choosing-the-right-f.html

0 notes