#MachiningSolutions

Explore tagged Tumblr posts

Text

Upgrade your machining capabilities with our Universal Swivel Head Milling Machines. Designed for reliability and versatility, these machines are perfect for heavy-duty industrial operations as well as intricate precision tasks.

For more details, visit - https://www.bhavyamachinetools.com/products/universal-swivel-head-milling-machine

#bhavyamachinetools#MillingMachine#SwivelHeadMilling#UniversalMillingMachine#IndustrialMachinery#PrecisionMachining#HeavyDutyMachinery#MachiningSolutions#MetalworkingTools#EngineeringEquipment

0 notes

Video

youtube

Slant Bed vs. Flat Bed CNC Lathe: Which One is Perfect for You#SlantBedL...

Are you trying to decide between a Slant Bed CNC Lathe and a Flat Bed CNC Lathe for your machining needs?

In this video, we break down the ultimate comparison between these two CNC lathe designs—from performance and applications to costs and maintenance.

🎯 What You'll Learn in This Video:

Key differences between Slant Bed and Flat Bed CNC Lathes.

Which lathe suits high-speed production and which one is ideal for heavy-duty machining.

Cost analysis and ROI insights for smarter investments.

Expert tips to help you make the right choice for your business.

💡 Highlights:

✔️ Slant Bed Lathes are compact, fast, and precise, perfect for industries like automotive and aerospace.

✔️ Flat Bed Lathes are sturdy, durable, and powerful, ideal for oil, gas, and construction sectors.

👉 Read the full blog for more details:

Click here Video Outline Introduction Welcome to the video! Quick overview of why choosing the right CNC lathe design is critical for your business.

Mention the two CNC lathe types we’ll be comparing: Slant Bed and Flat Bed. Part 1: What Is a CNC Lathe? Brief explanation of CNC lathes and their importance in modern machining. Examples of industries where CNC lathes are indispensable (e.g., aerospace, automotive, oil, gas).

Key features of CNC lathes, such as precision, repeatability, and automation options. Part 2: Design Differences Slant Bed CNC Lathes: Angled bed design (30–45°) for better chip evacuation.

Compact footprint and ergonomic layout. Multi-tool setups with turret systems (e.g., 12-station turrets).

Flat Bed CNC Lathes: Horizontal bed for stability and heavy-duty machining. Larger swing diameters and higher load capacities (up to 5 tons).

Requires manual chip removal or conveyor systems.

Part 3: Performance Metrics Speed and Efficiency: Slant Bed: Up to 4,500 RPM, reducing cycle times by 15–20%.

Flat Bed: Lower speed (up to 2,500 RPM) but higher torque for heavy cuts. Precision and Accuracy: Both achieve tolerances of ±0.002 mm.

Slant Bed: Superior coolant flow reduces thermal expansion by 10%. Flat Bed: Excellent precision under heavy loads but requires frequent chip management.

Part 4: Applications Slant Bed Lathes: High-volume production, ideal for precision parts like pistons and aerospace fittings. Automation-friendly with bar feeders and robots.

Flat Bed Lathes: Heavy-duty machining, perfect for large workpieces like pump shafts and rollers. Popular in industries like oil, gas, and construction. Part 5: Cost and ROI Analysis Initial investment:

Slant Bed: $5,000–$50,000.

Flat Bed: $5,000–$40,000.

Operational Costs: Slant Bed: Lower energy consumption and maintenance costs. Flat Bed: Higher durability for long-term heavy-duty use.

ROI: Slant Bed recovers costs faster in high-production environments (3–4 years). Flat Bed suits long-term heavy-duty projects (4–6 years). Part 6: Final Thoughts and Recommendations Recap the pros and cons of each CNC lathe type.

Advice on choosing the right lathe based on: Workpiece size. Production volume. Industry requirements. Encourage viewers to explore Haishu Machinery’s blog for more details and insights.

#CNCLathe #SlantBedLathe #FlatBedLathe #MachiningSolutions #PrecisionMachining #HaishuMachinery #MetalMachining #CNCManufacturing #Engineering

#youtube#CNCLathe#SlantBedLathe#FlatBedLathe#MachiningSolutions#PrecisionMachining#HaishuMachinery#MetalMachining#CNCManufacturing#Engineering

1 note

·

View note

Text

Precision Meets Performance Graphite machining is powering the future of high-tech industries from aerospace to semiconductors.

At CreateProto, our cutting-edge graphite machining services deliver the accuracy, durability, and efficiency your advanced applications demand.

Why graphite?

✔️ High heat resistance ✔️ Ultra-precise tolerances ✔️ Ideal for EDM, molds & more

Dive into the tech that’s shaping innovation: https://createproto.com/services/graphite-machining-services/

#GraphiteMachining#HighTechManufacturing#AdvancedManufacturing#PrecisionEngineering#CNCmachining#CreateProto#EDMmachining#GraphiteEDM#ToolingSolutions#AerospaceEngineering#SemiconductorTech#CarbonMachining#ManufacturingInnovation#IndustrialTech#MachiningSolutions#FutureOfManufacturing#EngineeringExcellence

0 notes

Text

Stay Cool with EXAIR’s Cold Gun

Keep your tools cool and productivity high with EXAIR’s air-cooling system! Ideal for reducing heat in machining and grinding, the Cold Gun delivers spot cooling without messy liquids.

Shop Now: https://www.exair.com/cold-gun-sys2.html

0 notes

Text

Precision Machining with High Pressure Through Coolant Systems by Lex Technoaid

Lex Technoaid’s High Pressure Through Coolant System enhances CNC machining efficiency by delivering clean, pressurized coolant directly to the cutting zone. Designed for high-performance metal cutting applications, it helps extend tool life, maintain temperature control, and improve surface finish. Ideal for modern manufacturing setups seeking precision and productivity.

#CoolantSystem#HighPressureCoolant#CNCManufacturing#MachiningSolutions#IndustrialFiltration#ToolLifeExtension#PrecisionMachining#MetalCuttingTechnology#ManufacturingInnovation#LexTechnoaid

0 notes

Text

Cut Costs & Time with CNC Lathe Precision!

CNC Lathe Machines streamline manufacturing by automating complex cuts, reducing manual labor, and minimizing waste—delivering faster turnaround and lower production costs.

Efficiency starts here!

For more details, visit - https://www.yashmachine.com/blog/uses-of-cnc-lathe-machines-in-manufacturing-industry/

#yashmachinetools#CNCLathe#SmartManufacturing#CostEffectiveProduction#PrecisionEngineering#MachiningSolutions#ManufacturingExcellence

0 notes

Text

Boost Your Machining Efficiency with HP KOOLKUT 80!

Engineered by HP Lubricants for precision, long-lasting performance, and superior cooling during machining and grinding. 💎 Stay ahead with exceptional emulsion stability, pH balance, and unmatched reliability for all your industrial needs.

📞 Contact us: +91–9780305399 🌐 Website: lubetradeways.com 📍 Visit us on Google: https://maps.app.goo.gl/8PZRYo25yGZwN7kj9

#HPKoolkut80#CuttingFluids#MachiningSolutions#GrindingExcellence#IndustrialLubricants#PrecisionEngineering#MetalMachining#EfficientCooling#LongLastingPerformance#IndustrialSolutions#HPCLLubricants#SmoothOperations#MachiningExperts#CoolantPerformance#Himachal#punjab#Haryana#Chandigarh

0 notes

Text

youtube

UCAM proudly introduces the 5 Axis CNC Tilting Table, a state-of-the-art solution engineered to meet the precise shaping demands of a wide range of industries. Designed to elevate your 3-axis machine, this tool transforms it into a 5-axis system, allowing access to complex geometries and hard-to-reach areas with ease. The result is a substantial increase in both precision and efficiency during multi-face machining processes, making it an ideal choice for industries such as automotive, aerospace, and medical etc.

The 5 Axis CNC Tilting Table is equipped with a variety of advanced features. It offers options for pneumatic or hydraulic clamping, ensuring that workpieces are held securely in place while allowing flexibility in different operations. Its pre-loaded axial radial roller bearing delivers outstanding stability and accuracy during high-precision machining, and the dual lead worm gear set enables smooth and precise movements, further enhancing overall machining performance. UCAM's commitment to automation is evident in this cutting-edge machine, which automatically generates programs, turning raw materials into finely crafted finished products.

For customers seeking reliability, versatility, and performance in their machining operations, UCAM's CNC rotary tables are the solution. For more information, visit https://ucamind.com or contact us at 080 - 40744712 or [email protected].

0 notes

Text

Discover the fascinating world of CNC Machining Applications in Industries! Learn about its history, types, and wide-ranging applications. Dive deeper with Alshurooq for more insights!

#CNCmachining#CNCtechnology#IndustrialMachining#ManufacturingTech#CNCapplications#Alshurooq#PrecisionMachining#MachiningSolutions#IndustryInnovation#EngineeringExcellence#ManufacturingIndustry#TechInIndustry

1 note

·

View note

Text

Meet the WM Series Vertical Turning Lathe from Yash Machine Tools—your go-to solution for demanding metal turning tasks. Built with high-grade components, this versatile machine ensures long-term reliability and faster machining compared to traditional lathes.

For more details, visit - https://www.yashmachine.com/product/spm-heavy-machine/wm-series-vertical-turning-lathe

#yashmachine#VerticalTurningLathe#MetalTurning#PrecisionMachining#HeavyDutyLathe#MachiningSolutions#IndustrialMachinery#LatheMachines

0 notes

Text

Reliable Industrial Machining Component Solutions | AMASL

AMASL provides top-tier industrial machining component solutions, ensuring precision, durability, and efficiency for aerospace, automotive, and manufacturing industries. Our advanced machining technology delivers high-quality components tailored to your needs. Partner with us for superior engineering solutions. #MachiningSolutions #PrecisionEngineering #AMASL

0 notes

Text

Heavy Duty Lathe (Max Series) is built with high tensile casting, a latest design headstock, and hardened & ground bed and spindle, this machine ensures durability and exceptional performance for tough machining jobs. Perfect for industries that demand strength and precision in every cut.

For more details, visit - https://www.bhavyamachinetools.com/products/heavy-duty-lathe-max

#bhavyamachine#HeavyDutyLathe#IndustrialLatheMachine#PrecisionMachining#LatheMachine#HeavyMachining#MetalworkingMachine#LatheForIndustry#MachiningSolutions#CNCAlternative#EngineLathe

0 notes

Text

"Broaching Tools Revolution: Market Analysis and Projections (2024-2033)"

Broaching tools are at the forefront of modern manufacturing, providing unparalleled precision and efficiency in material removal processes. These tools are essential for creating intricate shapes and high-accuracy finishes in various materials, from metals to composites. With advancements in materials science and cutting-edge technology, broaching tools are now more durable and effective than ever, capable of handling the most demanding applications in automotive, aerospace, and industrial sectors. CNC broaching machines and automated systems enhance productivity by ensuring consistent quality and reducing manual labor. The integration of smart sensors and IoT in broaching equipment allows for real-time monitoring and predictive maintenance, minimizing downtime and optimizing performance. As manufacturers strive for higher standards and tighter tolerances, broaching tools continue to evolve, driving innovation and setting new benchmarks in the industry. Embrace the future of precision manufacturing with advanced broaching tools and stay ahead in the competitive landscape.

#BroachingTools #PrecisionManufacturing #CNCBroaching #MaterialScience #AdvancedMachining #ManufacturingInnovation #AerospaceEngineering #AutomotiveManufacturing #IndustrialMachining #SmartManufacturing #IoT #PredictiveMaintenance #CuttingEdgeTechnology #ToolDurability #HighPrecision #ManufacturingEfficiency #TechInManufacturing #Automation #ModernManufacturing #MachiningSolution

0 notes

Text

Are you facing inconsistent cooling performance from the water-cooled spindle?

1) Check for air pockets in the cooling system 2) Bleed the system if necessary 3) Maintain a stable water flow for consistent cooling . . . Enquire now at +919560500384 or via email at [email protected]. Website: https://www.kuvamtechnologies.com/water-cooled-spindle/ . . . #CoolingChecklist#SpindleMaintenance#WaterCoolingWoes#CNCcoolingFix#MachineMaintenanceTips#SpindlePerformance#CoolingSystemCare#MachiningSolutions#CNCMaintenance101#StableCoolingFlow#spindle#spindlemanufacturer#buyspindle#spindlesupplier#manufacturer#india#delhi#noida#ghaziabad#gujarat#haryana#kuvamtechnologies

0 notes

Text

We offer spindle repair, replacement, and rebuilding services to customers. When you work with us, you can rest easy knowing you’re getting the quality you deserve; we only employ the most skilled technicians in the industry, and we hold them to higher standards of precision.

🌐 https://unitedaxleofnm.com . . . .

precisionspindleservices #spindlerepairexperts #qualityworkmanship #skilledtechnicians #spindlereplacement #spindlerebuilding #industrystandards #reliablemachining #highprecision #machiningexcellence #spindlemaintenance #machinetoolrepair #precisionengineering #qualityassurance #expertcraftsmanship #machiningsolutions

0 notes

Text

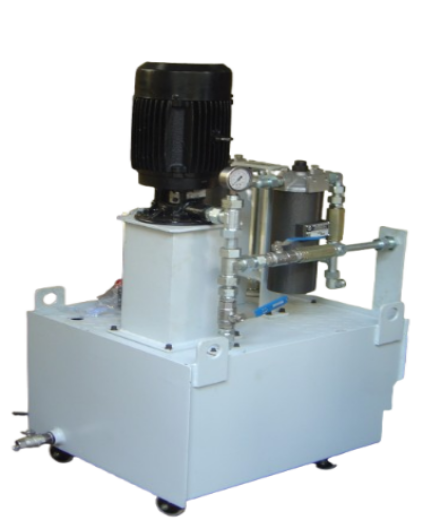

Centralized Coolant Filtration Systems by Lex Technoaid

Lex Technoaid's Centralized Coolant Filtration Systems are engineered to deliver coolant at optimal pressure, flow rate, temperature, and clarity to multiple machines. These systems enhance machining efficiency, reduce downtime, and promote sustainable operations by ensuring precise coolant management across various industrial applications.

#CoolantFiltration#IndustrialFiltration#MachiningSolutions#ManufacturingEfficiency#FiltrationTechnology

1 note

·

View note