#Manual Edge Banding Machine

Explore tagged Tumblr posts

Text

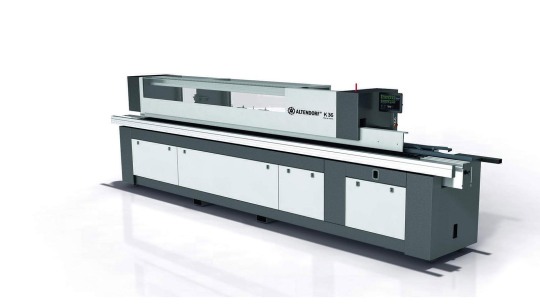

Troubleshooting Edge Banding Nightmares: Common Problems and How to Fix Them

Ah, the pursuit of the perfect edge. Edge banding, the process of applying a pre-veneered material to raw panel edges, elevates your woodworking projects with a touch of professionalism. But even the most seasoned woodworker can encounter occasional edge banding woes. Fear not, fellow crafters! This guide explores common edge banding problems and solutions, empowering you to troubleshoot these nightmares and achieve flawless results.

The Bane of Beautiful Edges: Common Edge Banding Nightmares

Let's delve into some of the most frequent edge banding challenges and how to overcome them:

Uneven Glue Application: This can lead to poor adhesion and visible gaps between the edging material and the panel.

Solution:

Manual Edge Banding: Ensure even glue spread with a dedicated glue spreader or a notched trowel.

Automatic Edge Banding Machines in India: Check the glue application settings and ensure proper roller pressure for consistent glue distribution.

Poor Adhesion: If the edging material peels off easily, the glue bond might be weak.

Solution:

General: Use a high-quality wood glue suitable for veneer application and ensure both surfaces are clean and free of dust before applying glue.

Manual Edge Banding: Apply sufficient clamping pressure to ensure a tight bond while the glue dries.

Rough or Chipped Edges: Uneven trimming can leave jagged edges or chipped veneer.

Solution:

Manual Edge Banding: Invest in a sharp, dedicated router bit for veneer trimming. Use a scrap piece of wood as a fence to guide your router for a straight cut.

Automatic Edge Banding Machines: Ensure the trimming blades are sharp and properly adjusted.

Wrinkles or Air Bubbles: These imperfections can detract from the overall finish.

Solution:

Manual Edge Banding: When using the glue and clamp method, carefully smooth out any air bubbles with a pressing tool before clamping.

Automatic Edge Banding Machines: Check the tension settings of the edging material feed system to avoid wrinkles.

Burning of Edging Material: Excess heat during trimming can scorch the veneer.

Solution:

Manual Edge Banding: Use a router with adjustable speed settings and a light touch while trimming.

Automatic Edge Banding Machines: Adjust the trimming speed or temperature settings to avoid burning the edging material.

Beyond Troubleshooting: Pro Tips for Flawless Edge Banding

Here are some additional tips to ensure a smooth edge banding experience:

Choose the Right Edging Material: Select a material compatible with your chosen glue and project requirements. Consider thickness and flexibility for curved edges.

Practice on Scrap Wood: Before tackling your final project, experiment with your edge banding technique on scrap pieces to perfect your application and trimming skills.

Clean Work Area: Dust and debris can interfere with glue adhesion. Maintain a clean workspace throughout the process.

Read the Manual (Seriously!): Whether using a manual or automatic edge banding machine, familiarizing yourself with the manufacturer's instructions ensures optimal machine performance and helps avoid common pitfalls.

Embrace the Challenge, Achieve Flawless Edges

Edge banding might present occasional challenges, but with the right knowledge and these troubleshooting tips, you can overcome these nightmares and achieve professional-looking results on your woodworking projects. Remember, whether you're using a manual edge banding machine, a high-tech automatic option in India, or a good old-fashioned DIY approach, patience, practice, and a touch of problem-solving go a long way in achieving flawless edges. So, don't let edge banding woes hold you back. Embrace the challenge, and watch your woodworking creations transform with the beauty of perfectly finished edges!

0 notes

Text

Post Round 2 [Pt. 2] - Tov’s Log

————————————————————

A moment of silence passed.

Then another.

Elias’s arms were still tense.

Finally, he sighed.

It was different sounding than Prem’s sigh. Elias sighed like he knew this confrontation was inevitable.

“Sounds like a fine name to me.” He said. His tone gave nothing else away.

The elevator stopped its descent and the doors slid open.

Tov assumed Elias would turn to the right towards the main clinic area, but instead he went to the left.

She furrowed her brow, hesitating, but continued to follow behind him.

As if he’d sensed her confusion, Elias spoke up again, “We’re going to the medical technician room. We have proper equipment to recalibrate your band there.”

Tov felt like he was speaking to more than just her.

Probably so.

She wouldn’t doubt that every inch of the dorm was covered with hidden cameras and audio recorders.

There was really no such thing as privacy in Alien Stage.

Tov took two steps for each of Elias’s long and sure strides.

He walked to a rhythm.

One. Two. One. Two. One. Two.

Her pace was a little faster.

One. Two. Three. One. Two. Three.

Something about counting steps like this felt nostalgic to her.

They came to a stop in front of a set of white doors. Elias removed one of his gloves to place his thumb on the scanner next to them.

His skin was dark like hers. A large scar stretched across the back of his hand.

The doors swung open automatically.

Inside was a sterile white room filled with medical equipment and various machines Tov could recall seeing in the hospitals she frequented; all very expensive and equally as delicate.

Elias gestured for her to enter first and manually pulled the doors shut until a heavy lock clicked in place.

There were a few medical beds lined up in a row against the left wall. Tov sat on the edge of the nearest bed.

“We’ll be able to talk freely in here,” he said, forgoing a chair to lean against the counters across from her. “All of the equipment frequencies interfere with the audio listening devices used throughout the complex.”

Tov briefly glanced around the corners of the room, “What about cameras?”

“There’s a lot of proprietary medical technology down here. Cameras are forbidden in case of a breach.”

Huh. Good to know.

Elias tugged off his helmet, revealing black, tightly coiled hair cut close to the scalp. His jawline was sharp, but his eyes were sharper; ink black and stone cold.

He crossed his arms, meeting her gaze head on. “So,” he started. “Prem?”

Tov nodded once, “Prem.”

He sighed again and pinched the bridge of his nose.

Tov imagined that it was close to how she looked whenever she found out Nyx or Dian did something stupid, usually in the other’s company.

Elias muttered something under his breath before clearing his throat and addressing her, “Okay then. How much did he tell you?”

“He said you’re the one who wrote the notes and that you told him not to tell me. Then he gave me your name, the shift you work, and the code word.”

“Great, so, basically everything I told him.” Elias huffed. “Damn it, Prem.”

Probably should’ve worked alone.

Tov didn’t say that aloud.

“I’m sure you have a lot of questions. I’ll answer as much as I can before we need to go back upstairs to avoid suspicion.”

The openness was… odd.

She wasn’t expecting Elias to be so forthcoming. She thought she’d have to pry information out of him like she had to with Prem.

But this time, she didn’t have any leverage. It was for the best that she didn’t run into any resistance.

“You’re the original author of the notes?” She asked.

Elias nodded once, “I am.”

“Did every contestant get a note?”

“No. Only you.”

Tov frowned, “Why?”

“Because the information was only relevant to you.”

On its face, the answer made sense. Tov was close to Solei, Aurien, and Nyx. Of course she’d want to know they were alive and safe.

But Lang was also close to Nyx. Why was the information about him given to her and not Lang?

There had to be another reason.

“Why did you chose me specifically?” She asked.

Elias hesitated. Tov wanted to seize the moment by the throat.

“I— did it as a favor.” He said stiltedly.

She wanted to groan long and suffering in that way Tallis always hated to hear.

You’ve got to be kidding me…

“So you’re another middleman.” It was a statement, not a question.

“No, I’m the primary source.” He countered. “I’m the one who took the risk of gathering the information and writing the notes.”

“And you risked your position just to fulfill a favor? You don’t even get anything out of it?”

He looked away, rubbing the back of his neck, “Well, no. I do get something out of the agreement.”

Tov leveled him with a look that she could tell he was pointedly ignoring.

“If you’re getting something out of the agreement then it’s not a favor. It’s a transaction.” She said, voice flat.

“I don’t think I could put a price on what I’m getting.” He said.

Tov was getting really tired of everyone being so fucking cryptic all the time.

“Who asked you to write those notes and give them to me?”

“I can’t say.”

Oh fuck no—

Elias cut Tov off before she could even open her mouth to argue.

“—And no, I’m not as easy to crack as Prem. You can’t blackmail me into telling you who they are.” He spoke with such finality it made Tov want to draw blood.

“I made a promise and I plan to keep it.” He said. “A soldier’s word is his bond.”

By the way his set his jaw and narrowed his eyes, she knew he wasn’t going to yield. Normally, Tov wouldn’t either.

But there was still more she could learn from him, even if this was a dead end.

She relented with a sigh, breaking eye contact. “Fine.”

“Good.”

There was no way that ‘good’ wasn’t patronizing. But Tov let it go.

She needed answers about Lark.

“Do you know anything about the investigation into Lark’s poisoning?”

Elias’s expression turned grim.

“Unfortunately, no. But not for a lack of trying.” He sounded as disappointed as Tov felt. “As soon as the preliminary autopsy suggested poisoning, the AREPH swooped in and took over the whole case. They iced everyone out and pissed off some of the higher ranking guards.”

Tov mulled the new information over as she worried her bottom lip between her teeth.

Why would the AREPH get involved in a poisoning case?

There was nothing to suggest Lark’s death was connected to any of the security breaches or escapes.

It was a question that had been bothering her since she was interrogated by those AREPH agents the morning after Round 17.

Now it was gnawing.

“Have they made any official statements?”

Elias scoffed, “That’s not part of their operating procedure.” He said. “If guards lack transparency, then the AREPH is completely opaque by comparison. We know next to nothing about the extent of what they do and how they do it. Even their facility locations are classified.”

“No leaks, I assume?”

He shakes his head, “None that I know of. Medics tend to catch wind of most rumors.”

Tov knew she was coming up on yet another dead end.

“Is there anything else you can tell me about the AREPH?”

Elias thought it over for a moment, furrowing his eyebrows, “Well, there is one thing. But I don’t know if it’s relevant.”

I’ve got nothing to lose.

Tov gestured for him to continue.

“When the security breach during Round 6 happened, I got caught in the chaos with some other guards doing crowd control. We ended up crossing paths with a group of AREPH agents heading in the opposite direction, and there was a human with them.”

She blinked.

Wait.

What?

“A pet-human?” She asked.

“Maybe? I’m not sure.” Elias shook his head, “All I know is that they were wearing an AREPH uniform and badge.”

Tov couldn’t stop thinking of the possibility that the human was one of her classmates.

She tried to think all the way back to Round 6. Who was alive and who was dead?

Azure. Moran. Stasya. Min. Rose was still alive.

It couldn’t have been any of them… right?

“What did they look like?”

“Young, grey hair, black face mask, really fucking tall. You can’t miss them.”

The only person she knew close to that description was Nyx, and he was definitely not helping the AREPH.

Tov hoped he was somewhere resting peacefully, but still very much alive.

“Could the AREPH be recruiting humans now?” She asked.

“They could be, for all we know.” He muttered. “No clue why a human would work for those ghouls, though.”

Tov raised an eyebrow. “People probably say the same about you working as a guard.”

“I didn’t have a choice.” He said.

“Maybe they don’t either.”

Maybe as humans — no matter where they ended up in this system — would never have a choice.

Somewhere off to their right, a tone chimed.

Elias pushed away from the counter, sidestepping her loaded statement.

It was for the best.

“We should probably start heading back now. Any last questions?”

Tov shook her head, “None that can be answered right now.”

“Alright, do you mind if I ask you one then?”

“Sure, why not.”

“How did you get Prem to confess?”

“I faked a medical emergency to lure him into my room.” She said. “Once he was inside, I locked us both in and threatened to report him for writing the notes if he didn’t tell me who actually wrote them.”

Elias stopped halfway through putting his helmet back on.

He blinked.

Once.

Twice.

Then he doubled over laughing.

The joy ringing in his voice was so incongruous with his appearance and demeanor that it caught her completely off guard.

It reminded Tov of her own giddy, uncontrollable laughter after Nyx was rescued.

But she was still confused.

Tov tilted her head at him, “What’s so funny?”

Elias shook his head, waving her off as his laughter subsided, “Nothing. It’s nothing.” He was smiling now.

The stone cold look in his eyes had melted into something soft like putty. “You just reminded me of someone I know.”

“I see.” Tov didn’t know what else to say in the wake of such a genuine expression of emotion from a stranger.

Luckily, Elias kept talking.

“I think you would’ve made a good soldier.” He said. “You’ve got the mind for it.”

Tov thought for a moment, before asking, “If I agree, will you tell me who you’re working with?”

He chuckled again as he fastened his helmet on.

“Look, Tov. If you really want to find out who’s behind all of this, keep going.”

————————————————————

Tov got some answers (yay!), but they only led to more questions (boo!).

All will be revealed in due time. She just has to keep going…

Anyways, new relationship dynamic just dropped: Tov and Dian worsties (besties that have constant beef) 😁

Also, Eddy was the human AREPH agent that Elias saw during Round 6, so Tov sort of knows who they are now.

The next log will be post Round 24. I’m still trying to process Himei’s death and the extent it will impact Tov’s wellbeing (spoiler alert: it’s not good), so that might be a few days? We’ll see.

And then Round 26 is like… right after that. Big oof 🫠

Tallis and Eddy belong to @lookatmysillies.

Nyx and Dian belong to @rockwgooglyeyes.

Lang belongs to @pwippy.

#alien stage#alnst#alien stage oc#alnst oc#alnst oc: tov#alnst oc: elias#alien stage fan season#alnst fan season#alien stage season 39#alnst season 39#tov’s log

13 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Description: High Quality of Bench Cover: This Bench Cover made of 95% polyester and 5% spandex.Soft material,comfortable and wrinkle resistant,no ironing required.Stretchable Material,stretch that recovers quickly,secure fit with sewn-in elastic hem.Machine washable,easy to cleaning and wash. Suitable for Chair Size: The bench covers available in a variety of colors,Will fit most of regular size upholstered dining bench 42"" to 54” long,14"" to 18” wide,3.2"" to 4.7"" height. Fashion Design: Fashion classic rhombic lattice jacquard fabric design upgrades your older upholstered bench to give it a more sophisticated look and protect benches from scratches, spills, and stains.not only keep your new bench from getting dirty and slight scratches, but also giving your old damaged bench a new look. Widely Usage: dining bench cover protect your dining room bench from stains, spills, grime, and wear and tear with this dining bench slipcovers; these bench slipcovers are great for dining bench in the kitchen, bedroom, dining room, restaurant, living room, hotel and more. Easy to Use: The stretch dining room bench cover equipped with an elastic band and 2 straps with splicing buckles, secure fit with a sewn-in elastic hem so that it stays in place without shifting or moving, Just slip it over the bench seat and buckle it, durable fabric with elastic edge secures the cover, anti-slip. Machine washable,tumble dry low,no ironing needed. Package Includes: 1 Piece Stretch Bench Cover Note: Please allow 1-3mm measuring deviation due to manual measurement. Due to the different monitor and light effect,the actual color of the item might be slightly different from the color showed on the pictures.Thank you! This Bench Cover made of 95% polyester and 5% spandex.Soft material,comfortable and wrinkle resistant,no ironing required.Stretchable Material,stretch that recovers quickly,secure fit with sewn-in elastic hem.Machine washable,easy to cleaning and wash. Suitable for Chair Size The bench covers available in a variety of colors, Will fit most of regular size upholstered dining bench 42 to 54'' long,14 to 18'' wide, 3.2 to 4.7'' height. Fashion Design Fashion classic rhombic lattice jacquard fabric design upgrades your older upholstered bench to give it a more sophisticated look and protect benches from scratches, spills, and stains.not only keep your new bench from getting dirty and slight scratches, but also giving your old damaged bench a new look. Widely Usage dining bench cover protect your dining room bench from stains, spills, grime, and wear and tear with this dining bench slipcovers these bench slipcovers are great for dining bench in the kitchen, bedroom, dining room, restaurant, living room, hotel and more. Easy to Use The stretch dining room bench cover equipped with an elastic band and 2 straps with splicing buckles, secure fit with a sewn-in elastic hem so that it stays in place without shifting or moving, Just slip it over the bench seat and buckle it, durable fabric with elastic edge secures the cover, anti-slip. Machine washable,tumble dry low,no ironing needed. [ad_2]

0 notes

Text

Streamlining Production with Automated Woodworking Systems

Understanding Automated Woodworking Systems Core Components of Modern Automation Automated woodworking systems comprise key components that collaborate to deliver exceptional precision and efficiency. Central to these systems are CNC machines, robotic systems, and integrated software solutions, each playing a pivotal role in streamlining operations. CNC machines use precise computer controls to cut, shape, and mill wood, eliminating the potential for human error in intricate tasks. Moreover, advancements in technology, such as the incorporation of servo motors and high-speed spindles, enhance the performance of these machines, ensuring that woodworking processes are not only faster but also more accurate. Modern control systems provide real-time monitoring, allowing operators to make instant adjustments, thereby minimizing waste and ensuring profitability in today's competitive market.

How Automation Enhances Production Efficiency Automation revolutionizes production efficiency by significantly diminishing the need for manual labor. This reduction allows companies to redirect their workforce towards more strategic and creative tasks, boosting overall productivity levels. Automated systems, by ensuring consistency, reduce human errors and help sustain high quality standards, which are crucial for customer satisfaction. Research indicates that firms embracing automation have reported up to a 30% surge in output alongside a decrease in production costs, underscoring the financial advantages of automated systems. By standardizing processes and optimizing resource utilization, businesses can achieve exemplary productivity while maintaining their competitive edge in the woodworking industry.

Key Technologies Driving Woodworking Automation CNC Machinery for Precision Cutting CNC (Computer Numerical Control) technology has significantly impacted the woodworking sector by enabling precise cutting of materials that were previously challenging. Advanced CNC systems can manage complex designs, offering repeatable patterns crucial for both bespoke projects and mass production. By integrating CNC machines, the fabrication speed can increase by up to 50%, which greatly enhances workflow efficiency. This technology is pivotal for maintaining competitive quality standards and production speed in the industry.

Robotic Handling Systems for Material Flow Robotic handling systems have reshaped woodworking operations by optimizing material transfer, thereby improving safety and efficiency. These systems facilitate careful handling of wood panels, minimizing damage and waste during the manufacturing process. By integrating robotic handlers, manufacturers can expect up to a 40% increase in material handling efficiency. This improvement not only boosts productivity but also reinforces the arguments in favor of adopting automation technologies within the industry.

Integrated Dust Collection Solutions Effective dust collection is essential in automated woodworking to ensure adherence to health regulations and enhance equipment efficiency. Advanced integrated dust collection systems can capture up to 99% of wood dust, safeguarding workers and keeping workspaces clean. Investing in high-quality dust collection solutions can not only reduce maintenance costs related to dust accumulation but also prolong the lifespan of woodworking machines. By preventing potential downtime due to dust-related machine failures, these systems facilitate smoother, uninterrupted production cycles.

Featured Automated Woodworking Equipment STR Motorized Trimming Knife Spindle for Edge Banding The STR Motorized Trimming Knife Spindle is an exceptional tool engineered for high-speed edge banding applications. It ensures smooth, accurate finishes, significantly enhancing the aesthetic appeal of wood products. With its advanced motorization capabilities, this spindle minimizes trimming time and ensures consistent results across production runs. This makes it an ideal choice for modern woodworking businesses seeking to enhance their efficiency and product quality.

The spindle's technical specifications are impressive, operating at speeds up to 25,000 RPM. This allows for the optimization of edge banding processes, making it capable of handling a wide array of woodworking tasks with precision. The spindle is well-suited for various materials, offering versatility for multiple applications within the industry.

STR Motorized Trimming Knife Spindle for Edge Banding Machine 0.35\/0.75KW Air-Cooled Spindle for woodworking Equipment Achieve excellent edge banding results with the STR Motorized Trimming Knife Spindle, designed for precision and efficiency. Operating at up to 25,000 RPM, this equipment not only ensures smooth and accurate finishes but also reduces trimming time, offering modern woodworking businesses enhanced production consistency. STR MJW3000 CNC Panel Saw Machine The STR MJW3000 CNC Panel Saw Machine is lauded for its advanced technology, providing unparalleled reliability and precision in cutting large wood panels. This state-of-the-art CNC panel saw incorporates cutting-edge safety features and user-friendly interfaces, enabling operators to achieve high-quality cuts efficiently and securely.

Utilizing the advanced capabilities of CNC technology, the MJW3000 excels in delivering precise and consistent cuts, which are crucial for both custom projects and large-scale manufacturing. Its design supports ease of use, ensuring operators can maintain high productivity while ensuring safety. The integration of CNC technology with automated features makes it possible to achieve precision and improve workflow efficiency, reportedly providing a return on investment with a 20% increase in productivity over traditional saws.

STR MJW3000 Automatic Manufacturers Cnc Panel Saw Machine Table Saw Woodworking Sliding Table Panel Discover the STR MJW3000 CNC Panel Saw Machine, built for precision in cutting large wood panels with advanced safety features and user-friendly interaction. With its high-tech design, enhanced production efficiency is just a step away, promising improved throughput and reduced material waste compared to conventional saws by about 20%. STR 4-Side Hydraulic Composer Clamping System The STR 4-Side Hydraulic Composer Clamping System is indispensable in achieving precision and stability in woodworking processes. By applying a consistent force across all four sides of a wood piece, this clamping system enhances the accuracy of workpieces during complex woodworking operations. This reliability is crucial for ensuring that each component is precisely aligned, minimizing errors and material waste.

Hydraulic clamping is noted for improving production speeds, mainly by enhancing the setup efficiency of woodworking tasks. Consistent pressure and stable clamps mean fewer readjustments, allowing for faster workflow and increased productivity. The STR clamping system stands out in the industry for its unrivaled ability to adapt to a range of woodworking tasks, all while maintaining a high level of machining accuracy.

STR 4-Side Hydraulic Composer Woodworking Hydraulic Rotary Timber Clamping Machine for Solid Wood This cutting-edge machine offers precise and stable clamping for woodworking. The hydraulic system ensures uniform pressure across all sides of the workpiece, enhancing machining accuracy and reducing errors. Perfect for assembling panels, furniture, and other solid wood products, it provides efficiency and reliability in production. Optimizing Operations with ERP Integration Streamlining Design-to-Production Workflows Implementing ERP (Enterprise Resource Planning) software is a game-changer for integrating various departments and streamlining workflows from design to production. By seamlessly centralizing data, ERP systems provide real-time updates, enabling better coordination and swifter production processes. The immediate data flow ensures that all departments—design, manufacturing, and logistics—are aligned to enhance productivity. In fact, statistics reveal that organizations leveraging ERP solutions often reduce project completion times by up to 30%, significantly boosting customer satisfaction and operational efficiency.

Real-Time Inventory Management Solutions Real-time inventory management solutions are essential components of modern ERP systems, providing companies with the ability to meticulously track materials and avert production disruptions caused by shortages or surpluses. This aspect of ERP allows for more strategic decision-making, ensuring optimal stock levels and minimizing carrying costs. Research consistently shows that businesses adopting real-time inventory management can cut inventory costs by as much as 20%, which directly contributes to improved profitability and a competitive edge in the market. By maintaining a vigilant eye on inventory, companies can adapt more rapidly to demand fluctuations, ultimately supporting a more efficient and responsive supply chain.

Overcoming Challenges in Automation Adoption Balancing Initial Costs with Long-Term ROI While the upfront costs for automated woodworking systems can be significant, understanding the long-term return on investment (ROI) is essential. Advanced systems often come with a hefty price tag, but the efficiencies they introduce can yield substantial savings over time. A careful analysis shows that companies can recoup their investments in automation within 2-5 years through increased productivity and lower operating costs. For example, by utilizing technologies such as CNC machines or automated routers, businesses can maximize their production efficiency and reduce waste, which boosts both output and profit margins. Expert insights suggest that prioritizing automation in operations significantly enhances competitive advantage in the market, enabling companies to offer superior quality and maintain steadiness in supply chains.

Upskilling Teams for Advanced Systems With the introduction of automated systems, upskilling employees is critical to ensure they are equipped to manage and operate advanced machinery. Employees need to be able to transition from manual tasks to roles that require oversight of sophisticated equipment. Training programs focused on both technical skills and soft skills can improve employees' adaptability and job satisfaction. This includes comprehensive training on equipment like woodworking routers and saw blades, which increases their operational proficiency. Data from industry surveys reveal that companies investing in staff training experience lower turnover rates and higher overall productivity in automated environments. Providing employees with the necessary skills not only benefits the individual but also fortifies the company's operational foundation, making it more resilient in adapting to technological shifts.

0 notes

Text

PET Strapping Rolls: Durable, Eco-Friendly Solutions for Secure Packaging

In today's fast-paced shipping and logistics industry, securing goods during transit is more crucial than ever. Among the various packaging solutions available, PET strapping rolls have emerged as a top choice for businesses seeking reliable, strong, and environmentally friendly strapping options. This article explores what PET strapping rolls are, their advantages, applications, and why they are becoming the preferred material in modern packaging.

What Are PET Strapping Rolls?

PET (Polyethylene Terephthalate) strapping rolls are plastic bands made from a high-performance polyester resin. These straps are produced in roll form, allowing easy handling and efficient use in automatic and manual strapping machines. PET strapping offers superior tensile strength and flexibility compared to traditional steel or polypropylene straps, making it ideal for securing heavy loads and fragile items alike.

Key Benefits of PET Strapping Rolls

1. Exceptional Strength and Durability

PET strapping rolls are designed to withstand high tension without breaking or deforming. Their high tensile strength allows them to secure heavy pallets and bulky shipments effectively. Unlike steel straps, PET straps do not rust, chip, or cause injury, ensuring safer handling.

2. Eco-Friendly and Recyclable

As sustainability becomes a priority, PET strapping stands out for its environmental benefits. Made from recyclable polyester, these straps reduce plastic waste and contribute to a circular economy. Many manufacturers offer PET strapping made from recycled materials, further reducing the carbon footprint.

3. Lightweight and Cost-Effective

PET strapping rolls are significantly lighter than steel straps, which helps reduce shipping costs and makes manual handling easier. Their durability ensures fewer replacements and less downtime, translating to long-term cost savings for businesses.

4. Versatility Across Industries

PET strapping is suitable for a wide range of applications, from securing boxes and cartons to bundling construction materials, steel pipes, timber, and more. Its flexibility allows it to absorb shocks during transit, protecting goods from damage.

5. Enhanced Safety Features

Unlike steel strapping, PET straps do not have sharp edges, reducing the risk of injuries to workers during packaging and unloading. Moreover, PET strapping rolls do not cause damage to delicate or sensitive products.

Applications of PET Strapping Rolls

Logistics and Shipping: Ensuring cargo stability during long-distance transportation.

Construction: Bundling heavy materials like bricks, tiles, and metal rods.

Manufacturing: Securing finished goods on pallets for warehouse storage.

Agriculture: Bundling produce or agricultural tools safely.

E-commerce: Protecting parcels and fragile shipments.

How to Choose the Right PET Strapping Roll

When selecting PET strapping rolls, consider the following factors:

Width and Thickness: Depending on the load weight and size, choose the appropriate strap dimensions.

Tensile Strength: Opt for straps that can handle the tension required for your specific application.

Core Size and Length: Ensure compatibility with your strapping equipment for efficient operation.

Color Coding: Some industries use color-coded strapping for identification or branding purposes.

Installation and Handling Tips

Use proper tensioning tools to avoid over-tightening, which can damage both the strap and the goods.

Store PET strapping rolls in a cool, dry place to maintain their integrity.

Train staff on safe handling techniques to maximize safety and efficiency.

Why PET Strapping Rolls Are the Future of Packaging

With growing demand for sustainable, reliable, and cost-effective packaging solutions, PET strapping rolls offer a smart alternative to traditional materials. Their combination of strength, flexibility, and recyclability aligns perfectly with modern supply chain needs and environmental regulations.

0 notes

Text

Mattress Border Machine: Top 5 Advanced Systems for Edge Reinforcement in 2025

Mattress Border Machine: Top 5 Advanced Systems for Edge Reinforcement in 2025

What Is a Mattress Border Machine?

youtube

A mattress border machine is specialized equipment used in mattress manufacturing that handles the creation, quilting, and attachment of the vertical side panels (borders) of mattresses. These machines help streamline production by automating what would otherwise be labor-intensive processes.

Core Functions of Mattress Border Machines

The primary purpose of a mattress border machine is to create professionally finished edges for mattresses. These machines can perform several key functions depending on the model. Most border machines can quilt decorative patterns into the border material, adding both aesthetic appeal and structural integrity to the mattress sides.

Some advanced models like the M-4000 and M-4400 are designed for high-speed production, capable of quickly processing large volumes of mattress borders.

Border machines can also measure and cut border sections to precise specifications, ensuring consistency across production runs. This precision is crucial for creating professional-looking mattresses that meet quality standards.

Many modern border machines can also install zippers, which is essential for mattress protectors and mattresses with removable covers. This feature has become increasingly important as demand for accessible, cleanable mattress products grows.

Key Components and Structure

Border machines typically consist of several important components working together. The sewing head is one of the most crucial parts - machines like the DZ-52 feature multi-needle systems designed specifically for wider border sewing applications.

The feeding mechanism moves fabric through the machine at a controlled rate. Some advanced models include auto-feeding systems with edge-alignment technology that ensures borders remain straight and even.

Most border machines have pattern programming capabilities that allow manufacturers to create various decorative stitching patterns. These can range from simple rectangular designs to more complex triangle patterns, as seen in the CC-1A model.

Material detection sensors help prevent jams and ensure proper alignment throughout the sewing process. These sensors are particularly important when working with different fabric thicknesses or when attaching rubber bands in mattress protector production.

How Mattress Border Machines Work

The operation begins with loading the border fabric onto the machine. For roll-to-roll systems from Global Systems Group (GSG), this involves setting up continuous fabric rolls for high-volume production.

The machine then positions the fabric correctly using alignment tools and sensors. This step is crucial because even slight misalignments can result in visible defects in the finished mattress.

Next, the multi-needle sewing head creates decorative stitching patterns across the border material. This not only enhances the appearance but also reinforces the border for durability. Machines like the DZ-52 are specialized for this precise function.

For borders requiring zippers, specialized attachments on machines like the Richpeace Border Zipper Sewing Machine automatically position and attach zipper components. This automation dramatically reduces the time needed compared to manual zipper installation.

Finally, cutting mechanisms measure and cut the finished borders to the exact specifications needed for each mattress size. The precision of these cuts ensures proper fit when the borders are attached to the mattress panels.

Types of Mattress Border Machines

youtube

Mattress border machines come in several varieties, each designed to handle specific tasks in mattress manufacturing. These machines stitch designs, attach tapes, and create borders that give mattresses their finished look and structure.

Manual Mattress Border Machines

Manual border machines are the most basic type and require significant operator involvement. These machines need workers to guide the fabric through the stitching process by hand. While they're slower than other options, they offer great flexibility for custom work and small production runs.

Manual machines are usually more affordable, making them ideal for smaller mattress manufacturers or start-up operations. They typically include simple serging machines that finish the edges of the border fabric and basic stitching equipment.

The learning curve for manual machines is relatively short, but productivity depends heavily on operator skill. Most can handle various fabric types and thicknesses, though they lack the advanced pattern capabilities of automated systems.

Automatic Mattress Border Machines

Automatic border machines represent the cutting edge of mattress manufacturing technology. These sophisticated systems can create complex patterns and designs with minimal human intervention. They're programmable via touchscreens, allowing operators to select from pre-loaded designs or create custom patterns.

These machines dramatically increase production speed and consistency. Many automatic models can stitch logos, decorative patterns, and functional elements like handles or ventilation holes.

The initial investment for automatic machines is substantial, but they significantly reduce labor costs and material waste. Modern automatic border machines often include:

Multiple needle configurations

Automatic thread tension adjustment

Memory for storing numerous patterns

Precision cutting capabilities

Integrated tape-edge application

Semi-Automatic Mattress Border Machines

Semi-automatic border machines bridge the gap between manual and fully automatic systems. They automate certain parts of the process while still requiring some operator guidance.

These machines usually have motorized fabric feeding mechanisms but need workers to position materials and monitor operations. They're faster than manual machines but more affordable than fully automatic systems.

Semi-automatic machines often include features like:

Programmable stitch patterns

Automatic thread cutting

Adjustable speed controls

Guided sewing paths

They're ideal for medium-sized manufacturers looking to balance efficiency with budget constraints. Most semi-automatic models can handle a wide range of border materials, from traditional cotton ticking to modern synthetic blends.

Technical Specifications Explained

youtube

When selecting a mattress border machine, understanding the technical specifications is crucial for making an informed decision. These specifications directly impact production efficiency, cost-effectiveness, and the quality of your finished mattresses.

Sewing Speed and Performance

The sewing speed of a mattress border machine significantly affects your production capacity. Most modern machines operate between 2,000 to 3,500 stitches per minute (SPM), with high-end models reaching up to 5,000 SPM.

I've found that machines with adjustable speed settings offer the best versatility, allowing operators to slow down for intricate patterns or speed up for straight seams. For example, the CC-1A Mattress Border Vertical Stitching Machine features programmable patterns that help maintain consistent quality regardless of speed.

Look for machines with automatic thread tension adjustment systems. These systems help maintain stitch quality even as the speed changes, which I've seen reduce production errors by up to 30%.

Power and Energy Consumption

Power requirements for mattress border machines typically range from 0.75 kW to 2.5 kW, depending on the model and capabilities. Single-phase machines are suitable for smaller operations, while three-phase power is standard for industrial settings.

Energy efficiency has become a major consideration in recent years. I've noticed newer models incorporate energy-saving features like:

Servo motors instead of clutch motors (up to 70% more efficient)

LED lighting systems (reducing power consumption by 80% compared to traditional lighting)

Automatic sleep modes when idle for more than 5 minutes

When calculating operational costs, don't overlook power consumption. A machine using 0.5 kW less per hour can save approximately $500 annually in a standard production environment.

Sewing Thickness Capabilities

The ability to handle various material thicknesses is perhaps the most critical specification for a mattress border machine. Standard machines can typically handle materials from 8mm to 30mm thick.

I recommend looking for machines with:

Adjustable presser foot height

Strong needle penetration power

Variable feed dog settings

The best machines offer electronic thickness detection that automatically adjusts settings based on the material. This feature has saved me countless hours of manual adjustments when switching between different mattress types.

For specialized applications like pillow-top borders, ensure your machine can handle at least 40mm thickness. Some advanced Mattress Border Machines now incorporate ultrasonic sensors that measure thickness in real-time, adjusting thread tension accordingly for perfect stitches every time.

Key Features of Quality Mattress Border Machines

Modern mattress border machines come with several essential features that enhance production efficiency and product quality. These machines have evolved to include adjustable settings, precision cutting tools, and intuitive controls that simplify the manufacturing process.

Adjustable Fabric Width Options

When I shop for a mattress border machine, adjustable fabric width capability is one of the first features I look for. Quality machines offer width adjustments from 6 to 15 inches, accommodating different mattress sizes from twin to California king.

The best models include quick-change mechanisms that let operators switch between width settings in under a minute. This saves valuable production time when manufacturing different mattress models.

I've found that machines with digital width indicators provide more precision than manual adjustment systems. This precision prevents fabric waste and ensures consistent borders throughout production runs.

Some premium machines even offer programmable presets for different mattress models, eliminating setup errors when switching between products. This feature is especially valuable for factories that produce multiple mattress lines.

Advanced Cutting Mechanisms

The cutting system is what truly separates basic from quality border machines. Top-tier models use hardened steel blades that maintain sharpness through thousands of cutting cycles.

I prefer machines with automatic blade sharpening features that maintain cutting precision without production delays. This eliminates the jagged edges that can affect the final appearance of the mattress.

Laser-guided cutting systems provide accuracy down to 0.5mm, ensuring perfectly aligned fabric panels. This precision is crucial for creating professional-looking borders that enhance the mattress's visual appeal.

Many modern border machines incorporate servo-driven cutting mechanisms that reduce fabric waste by up to 15% compared to older mechanical systems. This efficiency translates directly to cost savings in material usage.

User-Friendly Control Systems

The control system forms the brain of any mattress border machine. I've worked with machines featuring touchscreen interfaces that display all critical operating parameters on a single screen.

Intuitive icons and color-coded controls make operation possible even for new workers with minimal training. This reduces the learning curve and helps maintain production speeds.

The best machines include memory functions that store settings for different border styles and fabrics. With a push of a button, operators can switch between quilted, plain, or decorative border types.

Error detection systems alert operators to problems like fabric jams or thread breaks before they cause production delays. These early warnings prevent damage to the machine and materials.

Remote diagnostics capability is becoming standard on premium models, allowing technicians to troubleshoot issues without visiting the factory floor. This minimizes downtime when technical problems arise.

Customization Options for Manufacturers

Mattress border machines offer a wide range of customization options for manufacturers looking to stand out in the competitive bedding market. These features allow production of unique mattress borders that can help establish brand identity and meet specific customer preferences.

Customizable Design Elements

The best mattress border machines let manufacturers create distinctive designs that reflect their mattress brand personality. I've seen machines that offer digital printing capabilities, allowing for vivid logos and patterns directly on borders. Some advanced models include screen printing and heat transfer options for more complex designs.

Border width adjustment is another key feature. Most modern machines can handle various border dimensions, typically ranging from 8 to 16 inches. This flexibility helps manufacturers create everything from slim, minimalist borders to plush, luxurious ones.

Color options are practically unlimited with today's technology. Many machines support multi-color stitching patterns and decorative elements that can be programmed through user-friendly interfaces.

Texture variations are also possible, with some machines offering quilting, embossing, or raised pattern capabilities that add both visual and tactile appeal to the final product.

Integration with Other Mattress Equipment

Modern mattress border machines are designed to work seamlessly with other production equipment. I've found that the most efficient setups include border machines that integrate directly with quilting systems, creating a streamlined workflow.

Compatibility with existing fabric feeding systems is crucial. The best machines accept materials from various sources and can be positioned in-line with cutting and sewing stations. This reduces handling time and minimizes production errors.

Digital connectivity features are becoming standard in high-end border machines. Many now include software that connects to central production management systems, allowing manufacturers to track efficiency, manage patterns, and schedule maintenance.

Some border machines can also be integrated with quality control systems that scan for defects while creating decorative elements, ensuring that only perfect borders move forward in the production process.

Essential Accessories and Attachments

Getting the most from your mattress border machine requires the right accessories. These attachments not only improve the quality of your finished mattress but also increase production efficiency and give you more creative options for border designs.

Guides and Feeders

The right guides and feeders make a huge difference in border production quality. Tape guides are essential for keeping the binding tape properly aligned as it feeds into the machine. I've found that adjustable guides work best since they can accommodate different tape widths.

Material feeders help maintain consistent tension on the border fabric as it moves through the machine. Most quality machines come with standard feeders, but upgrading to pneumatic feeders can dramatically improve consistency, especially when working with thicker materials.

Thread stands and holders are often overlooked but crucial accessories. Multi-spool stands allow for quick thread changes and reduce downtime between jobs. For high-volume production, I recommend investing in tension-controlled thread guides that prevent thread snapping and uneven stitches.

Cutting Attachments

Cutting attachments streamline the border finishing process by automating what would otherwise be manual cutting tasks. Automatic cutters with adjustable depth controls are essential for clean, consistent cuts across different fabric thicknesses.

The most valuable cutting attachment I've used is the programmable end cutter. This tool automatically cuts the border at predetermined lengths, eliminating measurement errors and saving significant time. Many models now include laser guides that ensure perfectly straight cuts every time.

Thread trimming attachments are also worth the investment. These small but mighty add-ons clip excess thread after sewing, giving borders a clean, professional finish without manual trimming. For mattress manufacturers producing hundreds of units daily, this small enhancement can save hours of labor.

Binding and Edge Trimming Devices

Binding devices are crucial for creating clean, durable mattress edges. Automatic binders fold and feed tape along the mattress edge while the machine stitches it in place. I've seen how upgrading from manual to automatic binders can cut production time nearly in half.

Edge trimming devices ensure uniform borders by removing excess material as the binding is applied. Look for adjustable trimmers that can handle different fabric types without fraying or damaging the material.

Decorative binding attachments allow for creating distinctive border designs like the faux tape edge mentioned in the search results. These specialized devices can apply decorative piping or create unique stitch patterns that make your mattresses stand out in the market.

Production Efficiency and Speed

Mattress Border Machines significantly boost manufacturing capacity while maintaining quality. Modern machines combine advanced technology with robust engineering to transform how mattress edges are sewn.

Increasing Throughput

The speed of a Mattress Border Machine is one of its most impressive features. Today's models can operate at up to 1600 RPM, drastically outpacing manual sewing methods. This rapid operation translates directly to higher daily production rates.

When I implemented a fully automatic border machine in my factory, our throughput increased by approximately 40%. The machine's ability to continuously operate without frequent stops for adjustments made a huge difference.

Power consumption is another factor worth considering. Many newer models balance high-speed performance with energy efficiency. I've found that despite the increased production speed, the power usage per mattress produced actually decreased compared to older methods.

Most machines now feature:

Quick-change tooling for different border styles

Automated tension control systems

Programmable stitch patterns

Multiple needle configurations

Maintaining Consistent Quality

While speed is impressive, the real advantage comes from maintaining quality at high production rates. The best Mattress Border Machines deliver consistently neat stitching even at maximum sewing speeds.

Automated systems control tension perfectly across the entire border, eliminating the variation that often occurs with manual sewing. This consistency is especially important for premium mattress lines where visible stitching is part of the product appeal.

I've noticed that properly calibrated machines produce almost zero defects. The precision of modern border machines means rejection rates typically stay below 1%, even when running at full capacity.

Many manufacturers report labor savings of 50-70% after implementing automated border machines. This reduction in labor hours doesn't just save money—it removes the variability that comes with different operators handling the same materials.

Physical and Environmental Requirements

Setting up a mattress border machine requires careful planning for utility connections and workspace arrangements. Proper installation ensures optimal performance and operator safety when handling these specialized machines.

Power Supply Considerations

Most mattress border machines require a stable 220V or 380V three-phase power supply. I've found that machines typically consume between 1-3 kW of total power, depending on their size and capabilities.

It's essential to have dedicated circuits with proper amperage ratings for these machines. In my experience, a 20-30 amp circuit breaker is usually sufficient, but always check the manufacturer's specifications for your specific model.

Power fluctuations can damage sensitive electronic components, so I recommend installing a voltage stabilizer or surge protector. This small investment can prevent costly repairs down the line.

Remember to have a qualified electrician handle the initial installation. Proper grounding is critical for operator safety and machine longevity.

Air Pressure Needs

Many modern mattress border machines incorporate pneumatic components that require compressed air to function properly. The typical air pressure requirement ranges from 0.4-0.6 MPa (58-87 PSI).

Your air compressor should deliver at least 10-15 CFM (cubic feet per minute) to ensure smooth operation. I recommend installing:

Air filters to remove moisture and contaminants

Pressure regulators to maintain consistent pressure

Lubricators for pneumatic components if required by the manufacturer

An inadequate air supply can cause erratic machine behavior or component failure. I've seen this happen firsthand when factories try to run too many pneumatic machines on an undersized compressor.

Check all air lines regularly for leaks, which can reduce efficiency and increase operating costs.

Space and Weight Considerations

Mattress border machines are substantial pieces of equipment. Most models weigh between 200-500 kg (440-1100 lbs) and require adequate floor support. I always ensure my factory floor can handle this concentrated weight.

Space requirements vary by model, but you'll typically need:

Machine footprint: 2.5 × 1.5 meters (8.2 × 4.9 feet)

Operational clearance: 3.5 × 2.5 meters (11.5 × 8.2 feet)

Ceiling height: minimum 2.5 meters (8.2 feet)

The workspace must accommodate both the machine and the mattress handling area. I've found that a clear path around the entire machine makes maintenance much easier.

Good lighting is essential for operators to see their work clearly. I recommend 500-750 lux of task lighting in the immediate work area.

Safety and Maintenance Best Practices

Keeping your Mattress Border Machine running safely and efficiently requires regular attention and proper care. I've found that following structured maintenance routines not only extends the life of the equipment but also creates a safer working environment.

Routine Cleaning Procedures

I always start my weekly maintenance by disconnecting the power supply. Safety first! The machine collects fabric particles and dust that can affect performance, so I use compressed air to clean hard-to-reach areas.

For the exterior surfaces, I wipe them down with a damp cloth—never soaking wet to avoid electrical components. The sewing heads need special attention, as lint buildup can cause thread breakage and skipped stitches.

I make it a point to clean and oil the needle bar assembly after every shift. This simple step has saved me countless headaches. For metal parts showing signs of rust, I use a manufacturer-approved rust remover followed by a thin coat of machine oil.

Monthly deep cleaning checklist:

Remove and clean bobbins and bobbin cases

Clean thread guides and tension discs

Vacuum motor vents

Inspect belts for wear and clean

Check and clean foot pedals

Essential Safety Precautions

I never operate my Mattress Border Machine without proper training. The fast-moving parts can cause serious injuries if mishandled.

I always wear close-fitting clothing and tie back long hair to prevent entanglement. Safety glasses are non-negotiable when operating or cleaning the machine, especially when using compressed air.

The emergency stop button location should be memorized by every operator. I test it monthly to ensure it's working properly. When performing maintenance, I use lockout/tagout procedures to prevent accidental startup.

Guards and safety shields must remain in place during operation. I've seen too many injuries from people removing these "for convenience." It's never worth the risk.

Machine modifications are a big no-no. I only use manufacturer-approved parts and attachments designed specifically for my model of Mattress Border Machine.

Troubleshooting Common Issues

When thread breaks frequently, I first check if the machine is threaded correctly. Then I inspect for rough spots on thread guides or tension discs. Dull or bent needles are often culprits too.

If the border looks uneven or puckered, I check the presser foot pressure and fabric tension. Sometimes adjusting the feed dogs solves this issue right away.

Unusual noises from the machine require immediate attention. I stop operating and check for loose parts or foreign objects. A grinding sound often indicates a lack of lubrication.

For motor issues, I check:

Power connections

Foot pedal functionality

Belt tension and wear

Motor brushes (if applicable)

Electrical problems like intermittent power require professional help. I never attempt to repair electrical components myself—that's a job for qualified technicians who understand the specific requirements of a Mattress Border Machine.

Selecting the Right Mattress Border Machine

Choosing an appropriate mattress border machine requires careful consideration of your specific manufacturing needs, technical capabilities, and ongoing support requirements. The right equipment can significantly impact production quality, efficiency, and your mattress brand's reputation.

Assessing Manufacturer Needs

Before investing in a mattress border machine, I recommend evaluating your production volume requirements. Small manufacturers might need a semi-automatic model that handles 50-100 mattresses daily, while large operations should consider fully automated systems capable of 300+ units per shift.

Budget constraints are crucial, but I've found that focusing solely on price often leads to higher long-term costs. Quality machines typically range from $25,000 for basic models to $150,000+ for advanced systems with multi-needle capabilities.

Consider your available floor space too. Some border machines require as little as 100 square feet, while comprehensive systems might need 300+ square feet with proper clearance for materials handling.

Your specific mattress designs matter significantly. If you produce customized borders with intricate patterns, look for machines with programmable stitching capabilities and adjustable sewing heads.

Comparing Technical Specifications

Speed and throughput should be top considerations when evaluating border machines. Look for models offering 2500-3000 stitches per minute with quick changeover capabilities between different mattress sizes.

Key Technical Features to Consider:

Sewing head type (single vs. multi-needle)

Stitch length adjustability (typically 2-6mm)

Border width capacity (standard is 6-15 inches)

Automation level (manual, semi-auto, or fully automatic)

Digital pattern storage capacity (modern systems store 100+ patterns)

Material handling capabilities vary significantly between machines. Some handle only standard fabrics, while premium models work with everything from basic polyester to thick quilted materials.

I've found that energy efficiency makes a substantial difference in operational costs. Newer border machines use 30-50% less power than older models while delivering superior performance.

Evaluating Supplier Support

Service availability is critical for minimizing downtime. I recommend choosing suppliers offering next-day technician visits and remote diagnostics capabilities. Ask about their average response time for emergency repairs.

Parts availability dramatically impacts maintenance costs and downtime. The best suppliers maintain at least 90% of common replacement parts in stock and can ship specialty items within 48-72 hours.

Questions to Ask Potential Suppliers:

What is your technician response time?

Do you offer operator training programs?

What's your warranty coverage period?

Can you provide references from similar manufacturers?

How long have you supported this specific model?

Training support varies widely between suppliers. Some offer only basic setup assistance, while others provide comprehensive multi-day programs that cover operation, maintenance, and troubleshooting.

Consider the supplier's industry reputation through customer reviews and professional associations. I've found that manufacturers with 10+ years in the industry typically provide the most reliable support.

Industry Trends and Innovations

The mattress manufacturing industry is evolving rapidly with new technologies reshaping how border machines operate. Companies are focusing on automation to increase productivity while also developing eco-friendly solutions to meet market demands.

Automation and Smart Technologies

Mattress Border Machines have undergone significant technological advances in recent years. Modern computerized systems can now increase output by 40-60% compared to traditional methods. I've noticed that manufacturers are integrating smart technologies that allow for remote monitoring and adjustment of production parameters.

The latest flanging machines feature advanced sensors that detect material thickness and automatically adjust tension. This reduces waste and improves consistency across production runs. Some models now include:

AI-assisted pattern recognition for precise border alignment

Touch-screen interfaces for easier operation

Cloud connectivity for production data analysis

Automated fault detection systems

Border Modular Systems like the BMS-1500 from Global Systems Group exemplify this trend. These versatile machines can quickly adapt to changing market requirements without lengthy retooling periods.

Sustainable Manufacturing Solutions

Sustainability has become a major focus in mattress border machine development. Manufacturers are designing equipment that uses less energy and produces minimal waste.

New border machines incorporate energy-efficient motors that reduce power consumption by up to 30%. I've seen systems that capture and reuse compressed air, significantly lowering their environmental footprint.

Material optimization features are now standard on premium models. These include:

Precise cutting algorithms that maximize fabric usage

Recyclable thread options for eco-conscious brands

Low-VOC adhesive applicators

Variable speed drives that reduce energy use during slower production periods

Many manufacturers are also offering retrofit packages for existing Mattress Border Machines. These upgrades help factories extend equipment lifespans while improving environmental performance.

Border machines now commonly use water-based lubricants instead of petroleum-based options. This reduces harmful emissions and makes maintenance safer for workers.

Frequently Asked Questions

Mattress border machines play a crucial role in mattress manufacturing, affecting quality, design, and production efficiency. These specialized pieces of equipment vary widely in features, cost considerations, and applications across the industry.

What factors determine the pricing of a mattress border machine?

The pricing of mattress border machines depends on several key elements. Brand reputation significantly impacts cost, with established manufacturers commanding premium prices for their proven reliability.

Machine capabilities also drive pricing - multi-needle models with programmable stitch patterns cost more than basic single-needle versions. Automation features like automatic thread cutting and pattern memory add to the price tag but improve efficiency.

New machines typically range from $8,000 to $30,000 depending on complexity and features. Imported machines from Asian markets may offer lower price points but sometimes with trade-offs in parts availability and support.

How does a used mattress border machine compare to a new one in terms of performance and longevity?

Used border machines can provide good value when purchased from reputable sources. Well-maintained used machines often deliver 5-8 years of service compared to 10-15 years for new equipment.

Performance differences may include slower operating speeds and fewer automated features. Older models typically lack the digital controls and programmable stitch patterns found in newer versions.

The key consideration is maintenance history. A properly serviced 5-year-old machine from a quality manufacturer often outperforms a newer budget model with inferior components.

In what ways does a border sewing machine contribute to mattress quality and design?

Border machines create the critical seams joining the mattress sides to top and bottom panels. Precise stitching ensures structural integrity and prevents premature seam failure during mattress use.

These machines enable decorative elements like distinctive border patterns that define brand identity. The quality of border stitching directly impacts consumer perception of craftsmanship and overall mattress quality.

Modern border machines offer variable stitch lengths and tensions that accommodate different fabric thicknesses. This versatility allows manufacturers to work with premium materials like organic cotton, cooling fabrics, or specialty blends.

Where can professionals in the mattress industry find reliable border machines for sale?

Industry-specific equipment suppliers like Mattress Machinery Direct and Global Systems Group specialize in mattress manufacturing equipment. These vendors typically offer both new and reconditioned models with technical support.

Trade shows such as ISPA EXPO and Interzum provide opportunities to compare multiple brands and negotiate directly with manufacturers. These events showcase the latest innovations and allow hands-on testing.

Online marketplaces for industrial equipment can yield good deals on used machines. Sites like MachineryTrader and Industrial Sewing Machine Exchange list pre-owned equipment, though careful vetting is essential.

What features set the best mattress border machines apart from the competition?

Superior border machines offer high-speed operation, typically 3000+ stitches per minute, significantly boosting productivity. This speed doesn't sacrifice stitch quality, maintaining consistency even at maximum rates.

Programmable stitch patterns and automatic tension control ensure uniform results across production runs. The best machines store multiple stitch profiles for different mattress models, reducing setup time.

Durability features like hardened feed dogs and reinforced frames justify the higher investment. Premium machines incorporate ergonomic design elements that reduce operator fatigue during long production shifts.

Could you explain the differences between a Mattress Flanging Machine and a Mattress border Handle Machine?

A Mattress Flanging Machine attaches the flanging tape that joins the mattress panel to the border. This specialized machine creates the foundation for a clean, professional edge and typically operates with a wider throat space than standard machines.

The Mattress Border Handle Machine, in contrast, is designed specifically for attaching handles to mattress borders. It features specialized guides and feed mechanisms optimized for handle materials and reinforced stitching patterns.

These machines serve distinct functions in the production process, though some manufacturers offer hybrid models. High-volume operations typically benefit from dedicated machines for each function rather than multi-purpose equipment.

1 note

·

View note

Text

A Comprehensive Guide to Foam Cutting Machines: Types, Applications, and Benefits

In industries that deal with polyurethane (PU) foam — such as furniture, automotive, packaging, and construction — having the right foam cutting machine is essential. Foam is not just used in refrigerators or electronics. It’s found in everyday products like mattresses, sofa cushions, car seats, insulation panels, and even bumpers.

Given its wide range of applications, PU foam production has grown rapidly in recent years. As a result, businesses are now investing in modern and efficient cutting machinery to meet industry demand with precision and speed.

This blog explores the various types of foam cutting machines, their real-world applications, and the benefits they offer across sectors.

Why Foam Cutting Machines Are Essential

PU foam is manufactured in large blocks or sheets, but for real-world use, it needs to be cut into specific sizes and shapes. That’s where PU foam cutting machines come in. These machines not only save time and labor but also ensure consistent results with minimal material waste.

A well-engineered foam cutting machine is a game-changer in mass production. It improves workflow and ensures that products meet industry and customer specifications with accuracy.

A S Enterprises is a trusted manufacturer of high-quality foam cutting machines in India, known for building durable, high-performance equipment for various industrial uses.

Types of Foam Cutting Machines

Let’s take a closer look at the most common foam cutting machines available in the market, their uses, and how they differ from each other.

### 1. Horizontal Foam Cutting Machines

Horizontal foam cutting machines are widely used to slice PU foam into sheets. These machines cut foam along a flat horizontal plane using a metal band knife or heated wire, depending on the model.

➤ Automatic Horizontal Foam Cutting Machine

This fully automatic version is PLC-controlled and allows precise sheet cutting from 2.5mm to 200mm. With just a press of a button, the operation can begin from any position. After each sheet is cut, the section lifts automatically for reverse table movement — boosting efficiency.

➤ Heavy Duty Horizontal Foam Cutting Machine

Designed for high-density bonded and flexible foam, this model ensures smooth cutting using a band knife mounted on two balanced wheels. It's touchscreen operated and ideal for industries where robust foam sheets are required.

➤ Belt Horizontal Foam Cutting Machine

This advanced heavy-duty machine not only cuts but also stacks foam sheets — saving manual labor. Equipped with a vacuum system, it efficiently handles sheet thickness from 2.5mm to 200mm.

These horizontal machines are perfect for applications in mattress manufacturing, packaging, and soft furnishing.

2. Vertical Foam Cutting Machines

Vertical foam cutting machines are used primarily for trimming the sides of foam blocks or cutting larger foam blocks into manageable pieces. With a typical accuracy of ±2mm, these machines are frequently used in making sofa cushions and thicker foam sheets.

Different models are available — from basic to fully automatic systems — depending on the level of control and automation required.

3. Circular Cutting Machines

These machines are designed for continuous, automated cutting of foam blocks into thinner sheets or mattresses.

Circular cutting machines can slice sheets as thin as 1.5mm, up to mattress-sized thicknesses of 200mm. The cutting is performed by an endless band saw blade rotating on four dynamically balanced wheels, ensuring precision and smooth edges.

These machines are ideal for bedding and upholstery industries, where uniform sheet thickness is critical.

4. Profile Cutting Machines

Profile cutting machines are used when foam needs to be cut into complex shapes or custom contours. These machines are often CNC-controlled and programmed to follow intricate cutting paths, producing unique profiles for various foam applications.

Common uses include:

Ergonomic seat shaping

Acoustic panels

Custom foam inserts for packaging

Industries looking for high-precision foam shaping should consider a reliable profile cutting machine from manufacturers like A S Enterprises, who offer tailored solutions for unique project requirements.

5. PU Foam Cutting Machines

PU foam cutting machines are specifically built for handling polyurethane foam, which is flexible yet requires precision during cutting to maintain structure and uniformity. These machines are widely used in:

Furniture and mattress manufacturing

Automotive seat production

Packaging and insulation industries

With programmable control systems, they ensure accurate cuts and smooth finishes — making them a preferred choice in high-volume operations.

6. Block Cutters

Block cutters are PLC-controlled machines that use a two-way guillotine mechanism. They cut large foam blocks into required sizes — often as the final step in the foam production line.

Advanced block cutters feature adjustable photo sensors for selecting block sizes and can perform top-to-bottom and bottom-to-top cuts automatically.

Applications of Foam Cutting Machines Across Industries

Foam cutting machines find applications across many sectors, such as:

✅ Furniture & Bedding

To cut foam into cushions, backrests, and mattresses. PU foam cutting machines are extensively used in this sector.

✅ Automotive

For shaping car seats, headrests, armrests, and even dashboard insulation components.

✅ Packaging

Profile and CNC machines are used to cut foam into customized shapes that fit and protect products during shipping.

✅ Construction

Foam panels for insulation and soundproofing are cut using large horizontal and vertical foam cutting machines.

✅ Textile & Upholstery

Foam rolls or pads used in textiles and interior design are cut using precision machinery to maintain consistency.

Benefits of Using Modern Foam Cutting Machines

Here are some reasons why industries are upgrading to automated, high-performance foam cutting systems:

High Cutting Precision – Especially with CNC and PLC-controlled models.

Faster Production Cycles – Automation reduces turnaround time.

Minimal Material Waste – Optimized cutting paths reduce foam wastage.

Reduced Labor – Automatic stacking and programmable cuts minimize manual effort.

Custom Cuts Possible – Ideal for profile and shaped foam products.

When investing in machinery, quality and reliability should be top priorities. AS designs foam cutting equipment with these principles in mind — ensuring long-term durability and minimal maintenance.

Conclusion

Whether you're manufacturing mattresses, automotive parts, or packaging inserts, the right foam cutting machine can make a massive difference in productivity and quality. From PU foam cutting machines for flexible applications to profile cutting machines for complex contours, each type serves a specific purpose in industrial production.

Businesses looking to streamline operations and boost output should explore the wide range of machines available at A S Enterprises. With proven expertise and a focus on performance, their foam cutting machines are among the best in India.

👉 Learn more about A S Enterprises foam cutting machines

1 note

·

View note

Text

Como Leather and Abrotape Finishes – Elevate Your Décor with Uro Veneer World

Discover the Art of Material Sophistication

In the world of interior design, materials are more than function—they define emotion, texture, and lifestyle. That’s why at Uro Veneer World in Bangalore, we bring together the tactile elegance of Como leather finishes and the seamless perfection of Abrotape edge bands, giving your spaces the richness and refinement they deserve.

Whether you're an architect designing luxury residences or a homeowner remodeling your space, these finishes offer a new level of aesthetic and structural finesse.