#Manual Lifting Column

Explore tagged Tumblr posts

Text

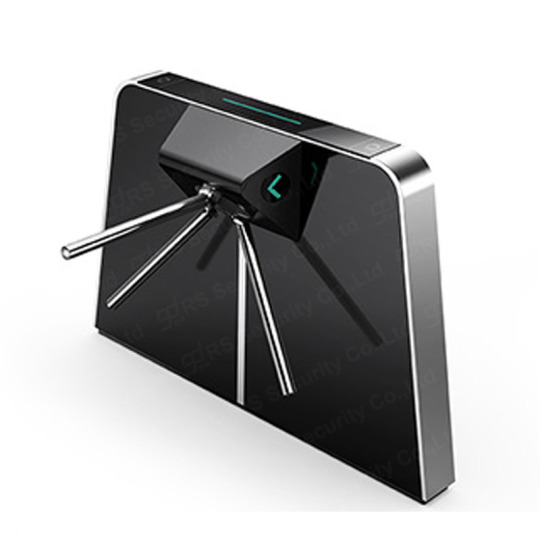

Tripod Turnstile Overview Tripod Turnstile, Swing Turnstile, and also Flap Turnstile( RS Security Co., Ltd: www.szrssecurity.com) are modern control devices for pedestrian passages. They are used in position where the entrance and departure of individuals need to be managed, such as clever neighborhoods, canteens, hotels, galleries, gyms, clubs, subways, terminals, docks, and so on area. Using Tripod Turnstile, Swing Turnstile, and Flap Turnstile can make the flow of individuals organized. Tripod Turnstile, Swing Turnstile, Flap Turnstile are used in mix with smart cards, fingerprints, barcodes as well as other recognition system tools to form an intelligent access control network control system; they are used in mix with computers, accessibility control, presence, billing monitoring, ticket systems and other software application to create a The intelligent Turnstile Gate extensive management system can understand functions such as accessibility control, attendance, usage, ticketing, and current limiting. This Turnstile Gate management system belongs to the "all-in-one card" and also is mounted at flows such as areas, factories, smart buildings, canteens, etc. It can finish numerous monitoring functions such as worker card traveling control, presence at get off job and also meals, and eating. Tripod Turnstile system features Fast and practical: check out the card in and out with one swipe. Utilize the licensed IC card and also wave it before the clever Tripod Turnstile viewers to finish the Tripod Turnstile gate opening and also cost recording work. The card analysis is non-directional and also the reading and also composing time is 0.1 secs, which is practical and also rapid. Safety and security and also discretion: Use background or local verification, authorized issuance, and special identification, that is, the card can just be made use of in this system, and it is private as well as secure. Dependability: Card superhigh frequency induction, dependable and also stable, with the ability to judge and think. Flexibility: The system can flexibly establish entrance and also leave control employees consents, period control, cardholder credibility as well as blacklist loss coverage, including cards and also other features. Flexibility: Through authorization, the customer card can be utilized for "one-card" administration such as car park, presence, accessibility control, patrol, intake, and so on, making it very easy to recognize several uses one card. Simpleness: Easy to install, straightforward to attach, the software has a Chinese interface and also is easy to operate. Tripod Turnstile, Swing Turnstile, and also Flap Turnstile( RS Security Co., Ltd: www.szrssecurity.com) are modern control devices for pedestrian flows. The use of Tripod Turnstile, Swing Turnstile, as well as Flap Turnstile can make the flow of people organized. Utilize the authorized IC card as well as wave it in front of the wise Tripod Turnstile reader to complete the Tripod Turnstile gate opening and cost recording work.

#Tripod Barrier Turnstile#Systeme Anpr#Qr Code Scanner#Manual Turnstile#Barrier Gate 4 6m#Electric Bolt Lock#Qr Code Scanner Box#Uhf Rfid Reader Chip#Manual Lifting Column#Turnstile Barrier Gate

0 notes

Note

i dare you to act upon the lh44 x assistant thoughts. 😍😍😍

no bc i am DISGUTING W MYSELF I NEED TO STOP I NEED TO CALM THE FUCK DOWN (here's a snippet of a lil something im working on hehehehe):

the spreadsheet had glitched again. a flicker in the dark, a stab in the back, a fucking betrayal. your breath hitched as the screen panned to white.

"tell me we didn’t just lose everything," you whispered, voice low. tight. rather hastily restrained. barely held together by the fraying thread of three restless hours of sleep and six hours of logistical level-headedness, of suzuka transport schedules (confirmed), red-eye flights (booked), sim runs (scheduled)—

behind you, lewis exhaled. heavy with sleep. worn. (you'd begun to resent it—his way of saying things without saying them.)

"you didn’t save it," he said. not accusatory. not cruel. just… flat.

you refused to look up. "you didn’t save it. this is your laptop. which, by the way, is a hundred years old." then, under your breath: "no one manually saves anything anymore."

a beat. the window was cracked open an inch, tokyo air damp and warm and electric, buzzing with the neon heartbeat of a city that never really slept. you'd turned off the lights an hour ago, the dim glow of the laptop screen on your lap painting your features in panic. (you always wondered when the day would come. the day you took it too far.)

"i’ll redo it," you said after a long moment. "it won’t take long."

you heard lewis shift on the bed, sheets rustling beneath his weight as he lifted himself to his feet. he hadn’t meant to fall asleep. you hadn’t meant to watch him. you could still feel the ghost of it lingering: his body stretched taunt across white cotton, shirt bunched around his navel, jaw slack with exhaustion. the way his mouth twitched in his sleep. (you couldn't help but wonder what he had been dreaming about.)

he was behind you, now. close enough to feel. close enough to touch. "you should rest."

you snorted softly. "that’s rich. coming from you."

somewhere down below, a car horn blared, then faded. lewis didn’t move. didn’t speak. not at first. and yet, the heat of him, the weight of his presence, stifled the words sitting limply in your throat.

"take the bed." his voice was gravel under velvet. something scraped from the bottom of a glass you weren’t supposed to drink from. "i'll do it."

your fingers began to fly across the keyboard in professional earnest, but you were simply typing gibberish. anything to keep from facing the slight downturn of his lips, the languid, sleep-mused drop of his eyes. "don't even think about it."

soft footsteps (one, two, three, four). then the slow press of his chest against your back, the tingling heat of his frame against yours. he didn’t really touch you. not yet. but his arms bracketed yours, palms flat on either side of the laptop, caging you into the desk without force. your eyes dropped to the ink on his fingers.

"tell me to stop," lewis murmured, his words ghosting over the back of your neck. (oh. oh. oh, god.)

your voice didn't seem to be yours. "we have an early call time."

"tell me. to stop."

"i can't."

"you never can," he said, breath ghosting over your jaw, your temple, the shell of your ear. "don't know why i asked." and then his mouth was against your neck, a press of lips just beneath your pulse, soft and scorching. feeling for the racetrack of your heartbeat. (and that's light out and away we—)

"that's not fair," you whispered, fingers stilling against the keyboard. "i'm just trying to do the right thing." (the clock on the desk read 2:43 am. too late for sense. too early for sleep. what else was bound to happen besides this?)

"this is the right thing," he said, mouth tracing a line down the column of your neck, the curve of your jaw. memorizing the shape of this mistake. your eyes slipped closed; you let it happen.

this couldn’t happen. it couldn’t.

(which meant, of course, that it would.)

♡

am i ever gonna post this fr?? prob no BUT OMG LET'S CHAT ABOUT THIS CONCEPT I LOVE IT MWAH 💫

64 notes

·

View notes

Text

Revolutionizing Urban Mobility: The Rise of Car Stack Parking Systems in Mumbai

In a dynamic metropolis like Mumbai, where real estate is scarce and traffic congestion is a daily battle, the need for smart, efficient, and space-saving parking solutions has never been greater. As the number of vehicles continues to rise, conventional parking facilities are no longer sufficient. Enter Car Stack Parking Systems a game-changing solution that is transforming urban parking infrastructure in the city.

What is a Car Stack Parking System?

A Car Stack Parking System is a type of automated or semi-automated parking solution that utilizes vertical space to park multiple vehicles in a single footprint. Unlike traditional parking setups, which require extensive horizontal space, stack parking structures use platforms to elevate and lower vehicles, allowing cars to be stacked one above the other.

This technology is particularly beneficial in crowded cities like Mumbai, where available land for parking is extremely limited and expensive. By adopting stack parking solutions in Mumbai, builders, developers, and city planners are able to optimize existing areas and cater to growing parking needs without the burden of constructing large parking lots.

Why Mumbai Needs Stack Parking Systems

Mumbai, often referred to as the financial capital of India, is home to over 20 million residents. With this booming population comes an ever-growing fleet of personal and commercial vehicles. Unfortunately, the city’s infrastructure has not expanded at the same pace.

Some of the biggest challenges Mumbai faces today include:

Severe traffic congestion

Limited land availability

Illegal and road-side parking

Rising vehicle ownership

Increased carbon emissions

The solution lies in technology-driven innovations like the Stack Parking System in Mumbai, which offers a smarter, cleaner, and more efficient way to deal with parking issues.

How Stack Parking Systems Work

The Stack Parking System operates on hydraulic or mechanical lifts that raise and lower vehicles to different levels. There are different types of stack parking, including:

Two-Level Stack Parking – Accommodates two cars, one above the other.

Three-Level Stack Parking – Holds three cars in a vertical stack.

Puzzle Parking Systems – Offers multiple rows and columns with a sliding mechanism for vehicle retrieval.

Tower Parking Systems – Fully automated with a high-rise structure for multiple car storage.

These systems are easy to operate and require minimal manual effort, making them suitable for both residential complexes and commercial areas.

Benefits of Car Stack Parking Systems

1. Space Efficiency

The most obvious advantage is the massive space-saving capability. A Car Stack Parking System can double or triple the number of cars parked in the same ground area.

2. Cost-Effective Infrastructure

Compared to constructing a full-fledged multi-storey parking lot, installing a stack parking unit is faster and more cost-effective.

3. Enhanced Safety

Since cars are mechanically parked, there's minimal human intervention, reducing the risk of accidents, dents, or theft.

4. Eco-Friendly Solution

By reducing the space needed for parking and eliminating the time drivers spend searching for parking spots, stack parking systems help lower fuel consumption and carbon emissions.

5. Ease of Operation

Most systems are equipped with user-friendly control panels and safety locks, making them accessible to people of all age groups.

Stack Parking Solutions in Mumbai: A Growing Trend

In recent years, stack parking solutions in Mumbai have gained massive traction. Builders and developers are incorporating automated parking as a key feature in their commercial and residential projects.

Several high-rise apartments, malls, office complexes, and even hospitals have now adopted Car Stack Parking in Mumbai as a modern and practical alternative to traditional parking lots.

Additionally, government bodies and municipal corporations are also taking steps to encourage the use of automated stack parking systems to curb illegal parking and ease traffic flow.

Stack Parking System in Mumbai: Applications Across Sectors

● Residential Societies

Multi-level parking systems are becoming increasingly common in gated communities to maximize parking without sacrificing landscape or play areas.

● Commercial Spaces

Offices, IT parks, and corporate hubs are embracing stack parking for efficient use of space and to maintain organized parking zones for employees and visitors.

● Shopping Complexes & Malls

Retail spaces, which attract large crowds, are implementing Car Stack Parking Systems to accommodate high traffic during peak hours.

● Public Infrastructure

Government buildings, transport hubs, and metro stations are planning for Stack Parking Systems in Mumbai as part of their smart city initiatives.

Choosing the Right Stack Parking Solution

Not all parking systems are created equal. When selecting a Car Stack Parking System, consider:

Space availability

Number of vehicles to be accommodated

Level of automation required

Budget and maintenance

Manufacturer’s experience and reliability

Always choose a vendor with proven experience in delivering stack parking solutions in Mumbai and the ability to offer customized configurations based on your site needs.

The Future of Parking in Mumbai

As Mumbai continues to grow vertically with high-rise buildings and compact plots, the demand for intelligent parking will only rise. Stack Parking Systems in Mumbai are not just a luxury anymore they’re fast becoming a necessity for modern urban living.

The integration of AI and IoT in future stack parking systems may even allow for app-based car retrieval, real-time availability tracking, and enhanced user convenience. Smart parking is not just about space it’s about transforming the way we experience mobility.

With its unmatched ability to save space, reduce congestion, and support sustainable development, the Car Stack Parking System is redefining how Mumbai parks its cars. Whether you’re a real estate developer, business owner, or policymaker, investing in stack parking solutions in Mumbai is a step towards a more organized and efficient city. So, as the city grows and vertical living becomes the norm, it’s time to look beyond conventional parking and embrace the future one level at a time.

0 notes

Text

Hydraulic Column Lift System: A Smart Solution for Efficient Material Handling

In the rapid-moving contexts of industry and logistics, speed, safety, and reliability are the foremost concerns. Among the many tools that support efficient material handling, the Hydraulic Column Lift System has emerged as a key solution for lifting and transporting heavy loads with minimal effort and maximum control.

Whether used in warehouses, delivery trucks, or factories, this system offers unmatched performance, adaptability, and safety—making it a must-have for businesses focused on streamlining operations.

What is a Hydraulic Column Lift System?

A Hydraulic Column Lift System is a vertical lifting platform typically mounted on the rear end of trucks, vans, or inside industrial facilities. It uses hydraulic power to raise or lower goods between different levels, such as from ground level to the vehicle bed, or vice versa. The system comprises vertical columns, a platform, hydraulic cylinders, and control mechanisms to ensure smooth, controlled movements.

This lift system is particularly useful for transporting goods that are too heavy or bulky to be handled manually, reducing the need for forklifts or manual labor.

Key Features and Components

Hydraulic Mechanism: The heart of the system, responsible for generating the power needed to lift heavy loads effortlessly.

Vertical Columns: These guide the platform smoothly and ensure stability during lifting or lowering.

Sturdy Platform: Intended to support a range of cargo, the platform features anti-slip surfaces and safety flaps.

Control Panel: The operator can raise or lower the lift accurately and safely using simple controls.

Safety Switches: Most systems are equipped with upper and lower limit switches to prevent over-extension or mechanical failure.

Benefits of Using a Hydraulic Column Lift System

Improved Efficiency

With a Hydraulic Column Lift System, loading and unloading tasks become much faster and less labor-intensive. This effectiveness results in speedier turnaround times for delivery vehicles and enhanced productivity in warehouse activities.

Enhanced Safety

Injuries can occur in the workplace as a result of lifting heavy objects manually. By automating the lifting process, these systems significantly reduce the risk of accidents and protect workers from strain and fatigue.

Versatile Applications

These systems are appropriate for a range of sectors, such as logistics, manufacturing, construction, and retail. They can handle anything from pallets and heavy equipment to delicate cargo, offering excellent flexibility.

Space Optimization

Hydraulic column lifts are space-efficient and can be mounted on current vehicles or fitted into narrow warehouse areas. Their vertical design helps save valuable floor space while improving operational flow.

Customization Options

Manufacturers often provide customized solutions to match the specific needs of a business, including platform size, load capacity, and integration with existing equipment or vehicles.

Use Cases of Hydraulic Column Lift Systems

Delivery Trucks: Ideal for loading and unloading packages, appliances, or other goods in e-commerce and retail distribution.

Medical Supply Transport: Safe handling of oxygen cylinders or other sensitive medical equipment.

Construction Sites: Lifting tools, materials, or machinery components to higher levels.

Warehouses: Moving goods between different levels or from storage to shipping areas.

Maintenance and Longevity

A properly maintained Hydraulic Column Lift System can last for years without major repairs. Regular inspections, oil changes, and component checks help ensure peak performance and safety. Some systems also come with maintenance kits and service support, reducing downtime and enhancing overall reliability.

Partnering with an experienced manufacturer or supplier ensures you get the most reliable and tailored system for your operational needs.

Conclusion

A Hydraulic Column Lift System is more than just lifting equipment—it’s an investment in safety, efficiency, and long-term operational success. By automating one of the most labor-intensive aspects of material handling, it not only saves time and money but also improves workplace safety and employee satisfaction.

Whether you’re managing a logistics fleet, operating a busy warehouse, or transporting delicate materials, the hydraulic column lift can transform the way you move goods—one lift at a time.

0 notes

Text

Unlocking Efficiency: Exploring the Best Gantry Lift for Sale

Gantry cranes are becoming an indispensable tool across industries, from construction to manufacturing, due to their versatility and strength. If you're searching for a gantry lift for sale, it's essential to understand how these systems function, what variations exist, and how to choose the right one to optimize productivity and ensure safety.

What is a Gantry Lift?

A gantry lift—often referred to as a gantry crane—is a type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels or along a track. These cranes are widely used for lifting and transporting heavy materials in open spaces or factories where building columns or beams are absent.

Unlike fixed cranes, a gantry crane hoist offers mobility and adaptability. Whether you're repositioning loads across a warehouse or unloading cargo in a shipyard, a gantry lift simplifies the process with minimal infrastructure investment.

Benefits of Using a Gantry Crane

Cost-Effective: Installation costs are lower since gantry cranes don’t require permanent support structures.

Flexible Placement: Their mobility allows for temporary or semi-permanent setups.

Customizable: They come in different load capacities and heights, accommodating a range of material handling tasks.

What to Look for in a Gantry Crane for Sale

When browsing for a gantry crane for sale, the following factors are key:

1. Load Capacity

Ensure the crane can handle the heaviest load it’s expected to lift. Common capacities range from 0.5 tons to 15 tons.

2. Span and Height

The size of the area where it will operate influences both the span and lifting height. Measure carefully to avoid clearance issues.

3. Mobility Needs

Do you require fixed-leg support or rolling casters for easy repositioning?

4. Hoist Mechanism

The gantry crane hoist can be electric, manual, or hydraulic. Each type offers unique advantages depending on your operational speed and power requirements.

Choosing the Right Gantry Crane Supplier

A reputable gantry crane supplier can be the difference between operational success and costly downtime. Look for:

Proven expertise in the material handling industry

Custom engineering capabilities

Compliance with safety standards, such as ISO or OSHA

Post-sale support, including installation and maintenance services

Real-World Insight: What Users Say

“After integrating a 5-ton mobile gantry lift into our assembly line, we cut load-moving time by 40% without modifying our floor layout.” — A. Morrison, Plant Manager, ToolForge Inc.

“Our construction site needed a lifting solution that didn’t require permanent structures. The portable gantry crane gave us just that—simple setup, maximum lift.” — M. Patel, Operations Head, SkyLift Construction

FAQs: Everything You Need to Know

Q1: Are gantry lifts suitable for outdoor use?

Yes, many gantry cranes are designed for rugged outdoor environments with corrosion-resistant coatings and weatherproof materials.

Q2: Can I upgrade the hoist mechanism later?

In many cases, yes. However, consult your gantry crane supplier to ensure compatibility with existing structural components.

Q3: What safety certifications should I look for?

Always verify that the crane complies with recognized standards like ASME, ANSI, or CE. These certifications ensure safe lifting operations.

Q4: Do I need a permit to operate a gantry lift?

Regulations vary by region, but generally, operators must be trained and certified, especially for cranes handling heavy loads.

Final Thoughts

Investing in a gantry lift for sale and overhead crane for sale means more than just acquiring machinery—it's about improving operational efficiency and workplace safety. Whether you’re a logistics manager, a warehouse owner, or an industrial contractor, understanding the core components and choosing the right gantry crane supplier will ensure you make a smart, scalable investment.

0 notes

Text

unfortunately the majority of vehicle systems are being replaced with electronic "upgrades". in a lot of places like engine control it can be beneficial because it offers a greater deal of control over things like ignition timing and valve lift, but in many ways it's being implemented almost for no reason other than to prove we can. I've heard of vehicles being tested with wireless remote steering, for example

in my opinion it's mostly being pushed by the advent of self-driving vehicles—this idea that comfort and convenience trump control. soon you're not going to have a steering column so why bother with manual gear shifting?

electronic technology is more reliable than most people are afraid of (in some cases even moreso than physical linkages which wear and rust and crack), but the electronification of our lives only further removes responsibility and control from human operators in a way that can, will, and has already become very dangerous

Touchscreens do not belong in cars

136K notes

·

View notes

Text

Exploring Concrete Pumping Solutions for Residential Projects in Karachi

As Pakistan’s commercial capital, Karachi is experiencing rapid urbanization, and with it comes a growing demand for smarter, faster, and safer construction techniques. Whether it’s a multi-story house in DHA or a villa in Bahria Town, efficiency and quality are key in residential construction. One solution that is quickly gaining traction in Karachi’s construction industry is the use of concrete pumps. These machines are transforming how concrete is delivered and poured at job sites. Allied Materials, a leading supplier of construction materials and machinery, is at the forefront of offering reliable and efficient Concrete Pump Karachi solutions. In this article, we explore how concrete pumping is benefiting residential projects, why it's essential in Karachi's dynamic construction landscape, and what makes Allied Materials a preferred name in the industry.

What Is Concrete Pumping?

Concrete pumping involves the use of machinery to transport freshly mixed concrete from the mixing site to the actual point of placement. Instead of relying on manual labor or wheelbarrows, a concrete pump streamlines the process and ensures that the concrete is placed precisely where it is needed.

There are two major types of concrete pumps commonly used in residential and commercial projects:

Boom Pumps – Ideal for high-rise or hard-to-reach areas.

Line Pumps – Perfect for smaller residential jobs and ground-level pours.

The Growing Demand for Concrete Pumping in Karachi

Residential construction projects in Karachi, especially in densely populated areas or upscale gated communities, present unique logistical challenges. Tight streets, limited space for equipment, and time constraints require innovative solutions.

Here’s why Concrete Pump Karachi services are becoming indispensable:

Efficiency: Speeds up the delivery and pouring of concrete, saving time on-site.

Precision: Ensures accurate placement with minimal waste or mess.

Safety: Reduces the risks associated with manual labor and heavy lifting.

Cost-Effectiveness: Lowers overall labor costs and minimizes material waste.

Applications of Concrete Pumps in Residential Projects

From foundations to roofs, concrete pumping offers versatility for a wide range of tasks in residential projects. These include:

Laying foundations for homes

Pouring concrete slabs and driveways

Constructing beams and columns

Roof decks for multi-story buildings

Swimming pools and water tanks

In Karachi’s high-end residential projects, the need for fast-paced and clean construction has led to a surge in demand for these applications.

Advantages of Using Allied Materials for Concrete Pumping in Karachi

Allied Materials stands out in the industry for offering high-quality and well-maintained concrete pumps, along with professional operators and technical support.

1. Modern Equipment Fleet

Allied Materials uses advanced concrete pumping machines capable of handling both large and small projects efficiently. Their equipment meets international safety and performance standards.

2. Professional Operators

Each machine is operated by skilled personnel trained in site safety, equipment handling, and efficient concrete placement.

3. Timely Delivery

In the construction business, time is money. Allied Materials ensures prompt service and timely equipment dispatch to keep your project on schedule.

4. Custom Solutions

Whether it's a tight urban neighborhood or an open suburban plot, Allied Materials tailors its pumping solutions to meet specific project needs.

5. Full Support and Maintenance

From initial planning to on-site support, the company provides comprehensive customer service, ensuring a smooth construction process.

Safety Considerations When Using Concrete Pumps

Safety is a top priority when using mechanical systems on residential job sites. Allied Materials emphasizes strict safety protocols to minimize risks:

Regular maintenance and inspection of equipment.

Training sessions for operators and site supervisors.

Use of personal protective equipment (PPE).

Clear communication on-site during pump operation.

Compliance with local construction and safety regulations.

Their adherence to these protocols has earned Allied Materials a strong reputation for reliability and safety.

Environmental Benefits

Concrete pumping also has environmental advantages. It reduces the number of truck trips needed on-site, which lowers emissions and noise pollution—an important consideration in residential neighborhoods.

Moreover, because the placement is more controlled, there is significantly less material waste, which contributes to a more sustainable construction process.

Cost Breakdown

Some builders may initially hesitate due to the rental costs of concrete pumps. However, when you consider the labor savings, reduced wastage, and increased speed of project completion, the value is clear.

Concrete pumps help complete tasks that would typically take several laborers and hours of work in a matter of minutes. This makes them a smart investment for projects on a tight timeline or budget.

Residential Project in Clifton

A recent residential project in Clifton used Allied Materials’ line pump to pour concrete for a 12-marla home’s roof slab. The pump helped deliver over 20 cubic meters of concrete in just under two hours. Compared to traditional methods, the project saved:

25% in labor costs

30% in time

15% less material waste

The homeowner praised the clean and hassle-free process, particularly in a neighborhood with strict construction regulations.

Future of Concrete Pumping in Karachi

As Karachi continues to urbanize and modernize, the demand for efficient construction practices will only grow. With increasing labor shortages, safety concerns, and time constraints, technologies like concrete pumping are no longer optional—they are essential.

Allied Materials is investing in newer and smarter machinery, training its staff, and expanding its services to meet this growing demand.

A Trusted Name in Karachi

Choosing the right partner for your construction equipment needs is vital. Allied Materials not only supplies industry-standard concrete pumps but also ensures customer satisfaction through technical support, transparency, and professionalism.

Whether you're building a single-family home or a multi-unit residential complex, you can count on Allied Materials for consistent and high-quality service.

To learn more about Concrete Pump Karachi services or to book a consultation, visit their official website.

Conclusion

Concrete Pump in Karachi has become an indispensable tool for modern residential construction in Karachi. Its ability to enhance efficiency, ensure precision, and reduce risks makes it ideal for today's competitive construction environment. With its commitment to excellence, modern fleet, and customer-first approach, Allied Materials is helping reshape Karachi’s residential construction one project at a time. By investing in advanced concrete pumping solutions, the company is ensuring that builders, homeowners, and contractors can achieve faster, safer, and better construction results.

0 notes

Photo

37-70 Inch Manuel Lifting Adjustable AV Trolley Telescopic Height Adjustable TV Cart - For most 37"-70" LED/LCD Flat Panel TVs This single display TV cart with stylish, technical, and functional design to provides a solid presentation solution for most 37''-70'' LED, LCD flat panel TVs up to 50kg/110lbs (each bracket). Its flat panel TV brackets vertically allow effortless height adjustment of max. height of 2069 mm to match different viewing needs at times. +5°~-12° freely tilting allows easy angle adjustment and reduces glare from lights or windows to obtain optimal viewing comfort. A solid base provides additional security by removing the possibility of being tripped over and ensures reliable performance for years of use. Internal cable management hides wires from view to keep a clutter-free appearance. Ideal for conferencing, public displays, or other professional presentation. FEATURES: Height adjustable TV mount Free-Tilting Design: for multiple monitor viewing angles Quick-Release Spring Lock: adjusts height effortlessly. Quick Assembly Shelf: assures easy post-installation and height adjustable. Cable Management: keeps everything organized. Heavy-Duty Casters: offer smooth mobility with quality that lasts a lifetime. SPECIFICATION: Product Category: TV Cart Rank: Premium Material: Steel, Plastic, Aluminum Metal Sheet Thickness: Bracket Arm THK=2mm cold-rolled sheet (Bracket Arm THK=0.079" cold-rolled sheet) Surface Finish: Sand-blasted Aluminum Anodic Oxidation, Powder Coating Color: Black, Silver Dimensions: 828x700x1669~2069mm (32.6"x27.6"x65.7"~81.5") Column Size (Main Column/Extension Column): 140x95x1.8x850mm,110x61x1.8x785mm (5.5"x3.7"x0.071"x33.5",4.3"x2.4"x0.071"x30.9") Fit Screen Size: 37"-70" VESA Compatible: 600x400,400x400,200x200,400x200,300x300 TV Weight Capacity: 50kg (110lbs) Strength Tested: 4 times approved. Screen Qty: 1 Tilt Range: +5°~-12° Screen Rotation: 0°~-90° TV Height Adjustable: Yes Shelf Weight Capacity: 5kg (11lbs) Shelf Height Adjustable: Yes Camera Rack Weight Capacity: 5kg (11lbs) Cable Management: Yes Base Type: Caster 10 Degree Slope Testing: Yes Accessory Kit Package: Compartment Polybag Instruction Manual Included: Yes Patent: 2015205699309

#TV_BRACKET_AND_MOUNT#ELECTRONICS#TV#AV_TROLLEY#BRACKET#BRK_TTV04_46TW#HEIGHT_ADJUSTABLE#MOUNT#TV_BRACKET#TV_MOUNT

0 notes

Text

How Automated Storage and Retrieval Systems (ASRS) Are Redefining Modern Warehousing

In today’s high-speed, high-demand world, traditional warehousing methods are struggling to keep up. Businesses are looking for smarter ways to store, manage, and move goods with greater efficiency. Enter the automated storage and retrieval system (ASRS), one of the most transformative technologies revolutionizing supply chain operations today.

Whether you’re managing a sprawling distribution center or a compact urban warehouse, ASRS systems offer a way to streamline operations, maximize space, and drive serious productivity gains. But what exactly are automated storage systems, and why are they becoming an industry standard? Let’s dive in.

What is an Automated Storage and Retrieval System?

An automated storage and retrieval system is a type of technology that uses robotics, conveyor belts, and computerized controls to store and retrieve goods automatically. Instead of relying on workers to locate and transport items manually, ASRS systems handle the heavy lifting, literally and figuratively.

These systems are made up of several key components: storage racks, retrieval machines, conveyors, and a sophisticated software platform that manages inventory and movement. Depending on the design, automated storage systems can handle pallets, totes, cartons, or even individual items with incredible precision.

Key Benefits of ASRS Systems

1. Space Optimization Traditional warehouses leave a lot of vertical and horizontal space unused. ASRS systems are engineered to maximize every inch. By building upwards and minimizing the need for wide aisles, companies can dramatically increase their storage capacity without expanding their physical footprint.

2. Speed and Efficiency Speed is the name of the game in modern logistics. With automated storage and retrieval system, goods are located, retrieved, and delivered in a fraction of the time it would take manually. Faster picking and storage times mean quicker order fulfillment and happier customers.

3. Improved Accuracy Human error is one of the biggest challenges in warehousing. Misplaced items, wrong picks, and inventory inaccuracies can cost businesses time and money. Automated storage systems offer near-perfect precision, reducing errors and ensuring that inventory records are always up-to-date.

4. Labor Savings While ASRS doesn't eliminate the need for human workers, it does shift them away from repetitive, labor-intensive tasks. This not only reduces labor costs but also allows employees to focus on more value-added activities like quality control, inventory management, and customer service.

5. Enhanced Safety Warehouses can be dangerous environments. ASRS systems reduce the need for forklifts, ladders, and manual handling of heavy goods, leading to fewer accidents and a safer working environment.

Different Types of Automated Storage Systems

There isn’t a one-size-fits-all solution when it comes to automated storage systems. Depending on your needs, you might choose from several types of ASRS setups:

Unit Load ASRS: Designed for handling large pallets or heavy loads, commonly used in manufacturing and large distribution centers.

Mini Load ASRS: Ideal for small items stored in bins or totes, often used in e-commerce or retail operations.

Vertical Lift Modules (VLMs): Space-saving systems that store items in vertical columns and automatically bring trays to an operator at an ergonomic height.

Horizontal Carousels: Great for high-speed picking of small items, often used in pharmaceutical or parts distribution.

Each type of automated storage and retrieval system can be customized to fit a specific workflow, making ASRS highly adaptable across industries.

Is ASRS the Right Choice for Every Warehouse?

While ASRS systems offer incredible advantages, they are a significant investment. Factors like warehouse size, inventory type, order volume, and business goals all play a role in determining whether an automated storage system is the right fit.

Small warehouses with low SKU counts might not benefit as much from a full-scale ASRS as a high-volume fulfillment center would. However, with modular solutions like VLMs or mini load systems, even smaller businesses can tap into the power of automation.

Future Trends: Where Are Automated Storage Systems Heading?

The future of automated storage systems looks even more promising with advancements in artificial intelligence, machine learning, and IoT integration. Modern ASRS platforms are becoming smarter, capable of predictive maintenance, dynamic inventory optimization, and even autonomous decision-making based on real-time data.

Additionally, as e-commerce continues to skyrocket, the demand for flexible, scalable, and high-speed automated storage and retrieval systems will only grow. Warehouses of the future will rely heavily on ASRS, not just for storage, but as intelligent hubs that drive overall supply chain performance.

Investing in an automated storage and retrieval system is more than just a move toward efficiency, it’s a strategic decision that future-proofs your operations. Whether you’re looking to optimize space, boost accuracy, cut costs, or enhance safety, ASRS systems offer a proven path to better, smarter warehousing.

As supply chains become more complex and customer expectations rise, companies that embrace automated storage systems will be better positioned to compete, and win, in the marketplace. The future of warehousing isn’t just automated; it’s intelligent, scalable, and powered by innovation. Are you ready to make the move?

0 notes

Text

Application, Features & Benefits of Hydraulic Goods Lift

The hydraulic goods lift is a non-scissor hydraulic lifting mechanical tool. It is used to move items between the second and third floors of industrial plants, restaurants, and snack bars. The reduced height is 150-350mm, especially appropriate for the website where you cannot dig a pit to mount the lift. Places, and no top lifting factors, varied kinds (dual column, four column, eight column).

The overview rail of the hydraulic goods lift is normally made of H-beams of light, network steel, and square pipe welding. The operation is straightforward and trustworthy. The transmission is economical and convenient.

Application of Hydraulic Goods Lift

We can tailor the hydraulic goods lift for clients according to the problem, such as the setup space being too narrow. The item has a solid structure, huge bearing capability, secure lifting, and simple, hassle-free installation and upkeep. It is an economical and useful low-floor elevator to replace the excellent freight communication devices. This item is mainly used in explosion proof ventures such as chemical markets, high temperatures, high pressures, power plants, nuclear sector bases, and dynamites.

Features of Hydraulic Goods Lift

Larger capacity of 30 loads, multi-point control, interactive interlocking of top and lower floors to attain risk-free use.

Multi-point control, interactive interlocking of top and lower floors, to accomplish secure use.

High lifting elevation, making use of side-mounted oil cylinders or dual measuring oil cylinders, steady operation, no noise, hassle-free upkeep, and long service life.

Manual reducing after power failing, emergency quit button, hassle-free, rapid, and useful.

The depth of the pit is generally 15 cm-30 cm, and the elevation of the leading layer is not restricted, and it can be tailored according to the site environment.

The flooring door can be passed through, and the inside and beyond the workshop can be opened equally, which is convenient and saves space; it is particularly ideal for 2-3 floors of steel framework workshops, both inside and outdoors.

Item Benefits of Hydraulic Goods Lift

Low Failure Rate: Because of the advanced hydraulic system and good control approach, the failure rate of elevator operation can be decreased to a low degree.

Reduced Power Consumption: When the hydraulic lift drops, it is driven by the stress generated by its own weight, which significantly saves energy.

Safety & Security Advantages

Safety Valve: Can protect against the system pressure from being excessive during upward movement.

Emergency Guide: When the power fails, the car can be dropped to the closest floor to open the door.

Hands-on Pump: When the system stops working, the manual pump can be operated to pump high-pressure oil to raise the auto rise to a more detailed flooring placement.

Oil Temperature Level Protection: When the oil temperature level in the oil tank exceeds the conventional set value, the oil temperature level defines tool creates a signal to suspend the use of the elevator and only begin the lift when the oil temperature decreases. BOB Engineering Co. is the best manufacturer of goods lift.

0 notes

Text

The JIB Crane: A Compact Powerhouse for Lifting and Material Handling

When it comes to material handling, businesses often need efficient and reliable tools to manage heavy lifting in tight spaces. Enter the JIB crane—a versatile, cost-effective, and space-efficient solution for a variety of industries. Whether it's for lifting heavy materials in a workshop, transferring components across a production line, or assisting with construction tasks, JIB cranes deliver significant value in boosting productivity, improving safety, and saving time. In this blog, we’ll take a deeper dive into what makes JIB cranes an essential piece of equipment in material handling operations.

What is a JIB Crane?

A JIB crane is a type of lifting equipment that consists of a horizontal arm (the "jib") which extends out from a vertical column. This setup allows the crane to lift and move materials within a specific area, usually in a circular or semi-circular motion. The lifting mechanism (typically a hoist or winch) runs along the jib, and materials can be raised or lowered within a designated radius.

Unlike large overhead cranes that require significant floor space, JIB cranes are compact and highly maneuverable, making them perfect for tight working environments. Whether mounted on the floor or attached to a wall, JIB cranes can be customized to suit specific operational needs.

Types of JIB Cranes

JIB cranes are designed with flexibility in mind, and there are several variations to fit different needs. The most common types include:

Free Standing JIB Cranes: These cranes are mounted on their own vertical column, often bolted to the floor. They offer a high level of mobility and can rotate 360 degrees, which is ideal for a workspace that requires the movement of materials in multiple directions. Their independent structure allows for use in smaller workshops or factory settings.

Wall-Mounted JIB Cranes: Wall-mounted JIB cranes are attached to an existing building or structure, allowing the jib to extend outward while the crane rotates along the wall. These are ideal for environments where floor space is limited but there is available support from a wall. Commonly used in warehouses and smaller industrial applications, wall-mounted cranes help maximize floor area.

Articulating JIB Cranes: Articulating (or knuckle boom) JIB cranes have a jointed arm that allows for greater flexibility in reaching around obstacles. This makes them ideal for areas with limited space or when precise positioning of materials is required. The articulation of the crane allows for the lifting mechanism to be moved in tight angles, making it suitable for intricate work.

Gantry JIB Cranes: A gantry JIB crane combines the features of a JIB crane with the stability of a gantry system. The crane is mounted on a gantry frame, which makes it a good option for applications that involve heavier loads or outdoor environments where greater stability is needed. This type of crane is often used in large warehouses or construction sites.

Benefits of JIB Cranes

JIB cranes are a valuable addition to any industrial operation due to their numerous benefits. Here are some key advantages:

Space Efficiency: One of the most attractive features of JIB cranes is their compact size. Unlike large overhead cranes that require extensive space, JIB cranes are designed to work in tight spaces. This makes them perfect for small workshops, factories, and warehouses where maximizing floor space is critical.

Increased Productivity: By automating material handling, JIB cranes can significantly improve workflow efficiency. Workers can quickly load, unload, or position items, reducing the need for manual lifting and minimizing downtime. This increased speed and efficiency lead to higher productivity and streamlined operations.

Improved Safety: Lifting heavy loads manually is a common cause of workplace injuries, particularly in industries like manufacturing and construction. JIB cranes help reduce these risks by allowing heavy materials to be lifted mechanically, preventing strain injuries, muscle fatigue, and accidents.

Flexibility and Maneuverability: JIB cranes can rotate, extend, and adjust their reach to suit specific tasks. The flexibility of the crane arm allows it to access hard-to-reach areas and move loads efficiently around a designated work area. Additionally, some models offer 360-degree rotation, which enhances their versatility even further.

Cost-Effectiveness: Compared to larger cranes, JIB cranes are relatively inexpensive to install and maintain. Their smaller size and simpler design make them a cost-effective solution for many companies, especially in environments that don't require large-scale lifting systems. For small and medium-sized businesses, JIB cranes are a great way to automate processes without breaking the bank.

Customizability: JIB cranes can be tailored to specific lifting needs, from adjusting the lifting capacity to determining the reach of the jib. These cranes are available in various sizes and configurations, allowing them to meet the unique demands of different industries and applications.

Applications of JIB Cranes

JIB cranes are used across a variety of industries, thanks to their adaptability and efficiency. Some common applications include:

Manufacturing and Assembly: In factories and assembly lines, JIB cranes are used to lift heavy components, such as motors or parts, into place. They help streamline assembly and reduce manual labor, ensuring a faster production process.

Warehouses and Distribution Centers: JIB cranes are commonly used in warehouses for picking and placing goods. They can assist with unloading containers, moving items from one location to another, or handling bulk materials.

Construction Sites: On construction sites, JIB cranes are used for lifting tools, materials, and construction equipment. Their ability to function in tight spaces makes them perfect for small construction projects or sites where space is limited.

Automotive and Aerospace: In industries like automotive manufacturing and aerospace, JIB cranes are often employed to lift and position large, heavy parts. This includes tasks like assembling vehicle chassis or moving aerospace components during production.

Maintenance and Repair: In maintenance workshops, JIB cranes are used to handle machinery and equipment during repair or maintenance. They make it easier to move heavy or cumbersome items, improving efficiency and safety.

Conclusion

JIB cranes are essential tools for many industries, offering a simple yet highly effective solution to material handling challenges. Whether you’re operating in a warehouse, construction site, or manufacturing plant, these cranes can enhance productivity, improve safety, and save valuable time. Their compact design, flexibility, and ability to be customized to suit specific needs make them an indispensable part of modern material handling systems.

For businesses looking to streamline their operations without the significant investment of larger cranes, a JIB crane is a smart choice—proving that sometimes, bigger isn’t always better. With their space-saving design, cost-effective operation, and versatile functionality, JIB cranes remain an essential tool for efficient and safe lifting.

0 notes

Text

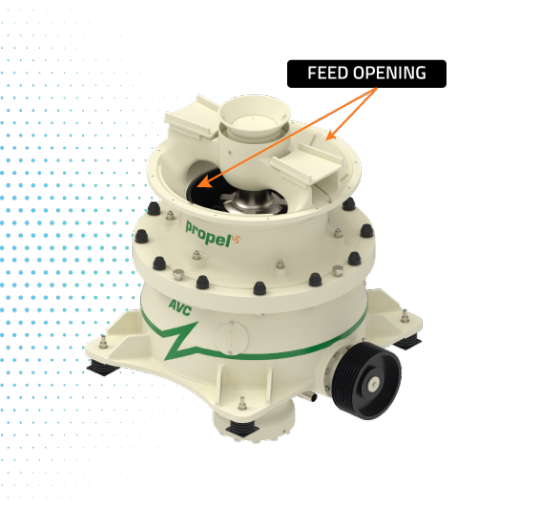

In depth – Avc Cone Crusher

Inside-Out | April 29, 2022

In the last issue, the In-Depth column focused on Jaw Crusher. This time, the spotlight turns on to our Cone Crusher. Some of the factors that R&D department considered before getting to make the Cone Crusher

The product must meet the customer’s unique requirement.

Cutting – edge technology must be put to work.

The product must cater to the 100 TPH to 350 TPH segment and serve the crushing industry.

The product must be in a position to evolve.

CONE CRUSHER MODEL

AVC 125 / AVC 160 / AVC 220 / AVC 250 / AVC 350

SM 100 / SM 150 / SM 200 / SM 250

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crushers are the most commonly used crusher type for the secondary and tertiary crushing stages. AVC Cone Crushers can be easily adjusted to different types of production requirements with change of chambers, eccentric strokes, and counter shaft speeds.

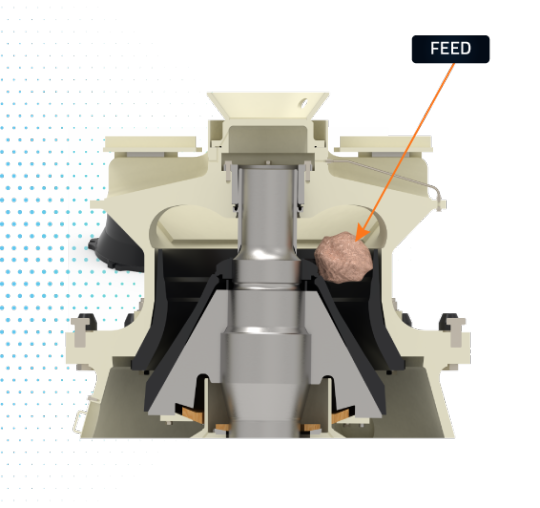

CONE CRUSHER WORKING PRINCIPLE

Both cone and gyratory crushers have an oscillating shaft.

The material is crushed in a crushing cavity, between an external static element (Concave) and an inner moving element (Mantle) mounted on the oscillating shaft assembly.

An eccentric shaft rotated by a gear and pinion produces the oscillating movement of the main shaft.

The eccentricity causes the cone head to oscillate between o.s.s. (open side setting) and c.s.s. (closed side setting) discharge opening.

In addition to c.s.s., eccentricity is one of the major factors that determine the capacity of cone crushers.

The Cone crushers are equipped with a hydraulic setting adjustment system, which adjusts c.s.s. and thus affects product gradation.

CRUSHER TERMINOLOGY

Feed: The raw material that is to be crushed.

Capacity: The output of the crusher computed in tons per hour (mtph/stph).

Product Size: The size of the screened material.

Feed Opening: The largest distance between the top of the crushing members as measured when the two crushing members are at their farthest relationship during one revolution of the eccentric. As a general rule the maximum size of feed should be 60 to 80% of the open side feed opening depending of the crusher type and the raw material to be crushed.

Discharge setting (S): The distance between the bottoms of the crushing members as measured at the point where the two crushing members are at their closest relationship during their gyrating circle (CSS-Closed Side Setting). The discharge setting regulates product sizes.

Minimum discharge setting: The smallest permissible distance between the bottom of concave and mantle as measured at the point where the two crushing members are at their closest relationship during their gyrating circle.

Stroke: The difference between open side setting (OSS) and closed side setting (CSS).

Open circuit operation: The type of operation where precise uniformity of product size is not considered to be of prime importance and the feed is run through the crusher only once.

Closed circuit operation: The type of operation where precise uniformly of the product size is important and the product is screened as it is being discharged and the material which does not pass through screen is returned to the crusher.

SAFETY

Safety of our operators, service engineers and customers has always been our top priority and to ensure that, Propel Cone Crusher comes with

Limited numbers of service points.

Special lifting tools are given to ease maintenance.

Cone crushers designed by Propel Industries have the following features for better maintenance

Closed Side Setting (CSS)

V Belt change

Lubrication

Liners change

We have given set of recommended maintenance procedures in Operation & Maintenance Manual which is absolutely safe to practice.

SALIENT FEATURES

Sturdy construction – strong in all directions and ensures excellent durability against shock-loads.

Setting adjustment made with wedge & traditional shim plates.

Quick and easy installation of Concave & Mantle to the crusher.

Designed with sacrificial parts to protect the main components of the crusher such as top shell, bottom shell and head. This reduces total lifecycle costs and increases uptime, as it is less expensive to change the sacrificial parts than the main components.

Ensured top shell, bottom shell, head and main shaft strength by Finite Element Analysis

IE2 Electric drive motor enabling energy saving

WHY CUSTOMERS OPT FOR OUR CONE CRUSHERS?

Robust construction design for durability

Dynamic setting adjustment

Stable capacity throughout liner life

Same machine can be used as secondary, tertiary machine with a liner change

Easy maintenance

0 notes

Text

Applications of Tail Gate Lifts

A Tail Gate Lift is an essential addition to modern transport vehicles, offering substantial improvements in loading efficiency, safety, and operational productivity. Built to simplify the movement of heavy or bulky goods from ground level to the vehicle bed and vice versa, tail gate lifts have become standard in many logistics, delivery, and service industries.

1. Improved Efficiency in Loading and Unloading

One of the key benefits of using a tail lift is the ability to load and unload goods more quickly and with greater ease. The hydraulic mechanism does the heavy lifting, allowing goods to be raised or lowered at the touch of a button. This automation minimizes manual labor and reduces the time spent at each stop, allowing businesses to handle more deliveries or pickups within the same working hours. For companies managing time-sensitive logistics, this improvement in efficiency can significantly enhance daily output.

2. Enhanced Safety for Operators and Goods

A tail gate lift is designed with safety at its core. It helps reduce the physical strain on workers by eliminating the need for manual lifting of heavy cargo. This not only improves workplace ergonomics but also lowers the risk of injuries such as back strain or slips and falls. Most tail gate lifts are equipped with non-slip platforms, safety rails, and control features that prevent overloading or sudden drops, ensuring secure handling of goods during operation. For employers, this translates into fewer incidents and reduced liability, contributing to a safer working environment.

3. Versatile Applications Across Industries

While commonly associated with transport and logistics, tail gate lifts are also widely used in industries such as healthcare, construction, retail, and waste management. Their ability to handle a range of load types—from delicate medical supplies to construction tools or commercial waste—makes them highly adaptable. Whether mounted on a small delivery van or a large freight truck, a tail gate lift can be customized to meet specific business needs, making it a valuable investment across diverse sectors.

4. Cost-Effectiveness Over Time

Although the upfront cost of installing a tail lift might seem significant, the long-term savings can be considerable. Businesses benefit from reduced labor costs due to less manual handling and shorter loading times. Additionally, the controlled lifting mechanism helps minimize damage to goods, leading to fewer returns or losses. The reliability and durability of a well-maintained tail gate lift mean fewer breakdowns and lower repair costs, making it a smart financial decision in the long run.

Choosing the Right Tail Gate Lift

When selecting a tail gate lift for your vehicle or fleet, several key factors should be evaluated:

Lifting Capacity: Consider the typical weight of the loads you’ll be transporting. Tail lifts are available in a range of capacities to suit different operational requirements.

Platform Size: The platform must be sufficiently large to ensure the safe accommodation of your cargo.

Vehicle Compatibility: Ensure the lift integrates properly with the type of vehicle you’re using, whether it’s a van, truck, or lorry.

Durability and Maintenance: Look for products built with high-quality materials and ensure that replacement parts and servicing options are readily available to maintain performance over time.

Real-World Applications of Tail Gate Lifts

Many businesses have already experienced measurable success after implementing tail lifts in their operations. Here are a few practical examples:

Medical Gas Distribution: A hydraulic column tail gate lift installed at the rear of the delivery vehicle enhanced the efficiency and safety of transporting medical gas cylinders.

Heavy Material Handling: Construction companies use tail gate lifts to move heavy materials from truck beds to job sites. The stability and lifting power of the equipment have improved handling speed and reduced workplace injuries.

Commercial Gas Supply: A specialized column tail lift designed for loading and unloading gas cylinders has optimized daily operations, particularly in urban areas where space and efficiency are key.

Conclusion

In today’s fast-moving business environment, investing in a tail gate lift is not just about convenience—it’s a strategic move toward improving efficiency, safety, and operational control. From increasing the speed of deliveries to ensuring the well-being of your workforce, a tail gate lift offers wide-ranging benefits that support long-term growth. Whether your business handles frequent deliveries or transports heavy cargo, integrating a reliable tail gate lift system into your fleet can help streamline operations and deliver consistent performance across the board.

0 notes

Text

Jib Crane for Sale: A Comprehensive Guide to Choosing the Right Solution

When it comes to lifting and moving heavy loads efficiently, jib cranes are an indispensable asset in various industries. Whether in manufacturing, construction, or warehouses, these cranes enhance productivity and safety. If you're searching for a jib crane for sale, understanding the types, benefits, and how to choose a reliable jib crane supplier is crucial.

This guide explores everything you need to know before making an investment in a jib crane hoist and how to find the right supplier for your needs.

What is a Jib Crane?

A jib crane inspection is a type of lifting equipment designed for material handling within a specific work area. Unlike overhead cranes, they are compact and ideal for localized lifting.

Types of Jib Cranes

Type

Description

Ideal For

Freestanding Jib Crane

Mounted on a concrete foundation, providing full 360-degree rotation.

Heavy-duty lifting, warehouses, outdoor work.

Wall-Mounted Jib Crane

Fixed to a structural wall or column, offering 180-degree rotation.

Workstations, assembly lines, factories with space limitations.

Mast-Type Jib Crane

Requires both floor and overhead support but offers high load capacity.

High-ceiling facilities, manufacturing plants.

Articulating Jib Crane

Features two swiveling arms for increased flexibility.

Precision lifting, confined spaces, maneuvering around obstacles.

Key Benefits of Using a Jib Crane Hoist

Enhanced Productivity: Reduces manual labor and speeds up material handling processes.

Space Optimization: Unlike gantry or bridge cranes, jib cranes occupy minimal space.

Safety & Ergonomics: Minimizes workplace injuries caused by manual lifting.

Customizable Options: Can be tailored to specific industrial requirements.

Cost-Effective Solution: Lower operational costs compared to larger crane systems.

Testimonial: What Industry Experts Say

"We installed a freestanding jib crane hoist in our warehouse, and it significantly improved our workflow. The lifting process is smoother, and worker fatigue has reduced dramatically." — Michael T., Warehouse Operations Manager

How to Choose the Best Jib Crane Supplier

Selecting the right jib crane supplier ensures you get a durable and high-performing product. Here are key factors to consider:

1. Industry Experience & Reputation

Look for suppliers with a proven track record and industry expertise. Established suppliers provide better quality control and after-sales support.

2. Customization & Product Range

A reliable jib crane supplier should offer various crane types and customization options to meet specific needs.

3. Quality & Compliance Standards

Ensure the crane meets international safety standards, such as: ✅ OSHA (Occupational Safety and Health Administration) ✅ ANSI (American National Standards Institute) ✅ ISO Certifications

4. Installation & After-Sales Support

A reputable supplier should provide professional installation, maintenance, and support services.

5. Pricing & Warranty

Compare prices, but don’t compromise on quality. Check warranty terms to safeguard your investment.

Testimonial: Customer Experience Matters

"We partnered with a top jib crane supplier who offered customization for our facility. Their support team was responsive, and the installation process was seamless!" — Sarah L., Manufacturing Plant Supervisor

Final Thoughts: Making the Right Investment

Investing in a jib crane hoist is a game-changer for industries looking to enhance operational efficiency. Whether you need a freestanding, wall-mounted, or articulating model, choosing a reliable jib crane supplier is key to ensuring long-term performance and safety.

Before purchasing a gantry crane for sale, assess your lifting needs, workspace constraints, and supplier credibility. A well-informed decision will maximize productivity and operational success.

0 notes

Text

Pompa FLUGO GMS 0500

Pompa Dosing Pump Flugo GMS Series

Pendahuluan:

Flugo GMS Series adalah pompa dosing dengan sistem Mechanical Diaphragm Metering yang dirancang untuk memenuhi kebutuhan industri yang membutuhkan dosis bahan kimia secara presisi dan efisien. Pompa ini menggunakan mekanisme diafragma mekanis yang digerakkan oleh motor, sehingga mampu memberikan dosis yang konsisten dan akurat tanpa kebocoran, menjadikannya pilihan yang handal untuk aplikasi di berbagai sektor industri, termasuk pengolahan air, pengolahan limbah, kimia, dan petrokimia.

Cara Penggunaan:

Persiapan Alat dan Bahan:

Pastikan pompa, pipa, dan konektor sudah terpasang dengan benar.

Periksa bahan kimia yang akan digunakan dan pastikan sesuai dengan spesifikasi pompa (misalnya, viskositas dan sifat korosif).

Pemeriksaan Awal:

Periksa pompa untuk memastikan tidak ada kerusakan fisik atau kebocoran sebelum digunakan.

Pastikan semua katup dan sambungan pipa sudah terpasang dengan kencang.

Pengaturan Kapasitas Dosis

Sesuaikan pengaturan kapasitas aliran sesuai kebutuhan proses.

Untuk pengaturan yang lebih presisi, ikuti petunjuk pengaturan yang terdapat dalam manual pengguna.

Prosedur Pengisian Cairan:

Isi tangki atau saluran masuk pompa dengan cairan kimia yang akan dipompa.

Pastikan tidak ada udara yang terperangkap di dalam sistem.

Manfaat:

Akurasi Dosis yang Tinggi: Flugo GMS Series dirancang untuk memberikan dosis bahan kimia yang sangat akurat, sehingga memastikan proses produksi atau pengolahan berjalan efisien dan sesuai dengan standar yang diinginkan.

Cocok untuk Berbagai Jenis Cairan: Ini membuatnya ideal untuk industri kimia, pengolahan air, pengolahan limbah, dan berbagai aplikasi industri lainnya.

Operasi Tanpa Kebocoran: Dengan mekanisme diafragma yang kuat, Flugo GMS Series memastikan tidak ada kebocoran selama operasi, menjadikannya lebih aman untuk digunakan dalam menangani bahan kimia berbahaya.

Mudah Dioperasikan dan Disesuaikan; Pompa ini dilengkapi dengan sistem pengaturan kapasitas dosis yang mudah diatur, memungkinkan operator untuk menyesuaikan aliran sesuai dengan kebutuhan proses tanpa kesulitan.

Biaya Perawatan Rendah: Karena desain mekanis yang sederhana dan tahan lama, Flugo GMS Series membutuhkan perawatan yang minimal. Selain itu, komponen-komponennya mudah diakses dan diganti jika diperlukan, mengurangi downtime dan biaya operasional.

Tahan Lama dan Andal: Ini menjadikannya pilihan yang andal untuk penggunaan jangka panjang di berbagai aplikasi industri.

Spesifikasi:

Maximum inlet pressure : 2bar

Maximum flow : 2040L/h

Maximum ambient temperature : +40˚C

Maximum outlet pressure : 12bar

The suction-lifting elevation may reach 3m water column

Adjustment range : 30%-100%, steady-state accuracy -+1%

Cara Kerja:

1. Penggerakan Diafragma:

Motor Listrik menggerakkan mekanisme eksentrik (cam atau crankshaft) yang terhubung ke batang pendorong (push rod).

Gerakan eksentrik ini menghasilkan gerakan maju mundur yang menggerakkan diafragma ke depan dan ke belakang.

2. Langkah Isap (Suction Stroke):

Ketika diafragma tertarik ke belakang, tekanan dalam ruang pompa (chamber) berkurang, menciptakan tekanan rendah.

Tekanan rendah ini menyebabkan katup inlet (suction valve) terbuka, sehingga cairan dari tangki atau sumber cairan ditarik masuk ke dalam ruang pompa.

3. Langkah Tekan (Discharge Stroke):

Setelah ruang pompa terisi cairan, diafragma bergerak maju (ke depan) karena dorongan dari mekanisme eksentrik.

Pada saat yang sama, peningkatan tekanan ini membuka katup outlet (discharge valve), sehingga cairan terdorong keluar dari ruang pompa menuju sistem atau saluran yang dituju (pipa distribusi).

4. Pengaturan Kapasitas Aliran:

Kapasitas aliran pompa dapat diatur dengan mengubah panjang langkah (stroke length) dari diafragma atau frekuensi gerakan.

Pada pompa Flugo GMS Series, pengaturan ini biasanya dilakukan melalui knob atau dial pada bagian pengatur pompa, memungkinkan pengguna untuk mengatur dosis yang sesuai dengan kebutuhan proses.

Kelebihan:

1. Akurasi Dosis yang Tinggi:

Hal ini sangat penting dalam aplikasi industri yang memerlukan dosis kimia yang tepat untuk mengoptimalkan proses dan mengurangi limbah.

2. Operasi Bebas Kebocoran:

Pompa ini menggunakan diafragma mekanis yang mencegah kebocoran cairan, bahkan saat menangani bahan kimia agresif.

3. Tahan terhadap Bahan Kimia Korosif:

Ini memungkinkan pompa untuk menangani cairan korosif seperti asam dan alkali tanpa kerusakan, memperpanjang umur alat.

4. Perawatan Mudah dan Biaya Rendah:

Komponen-komponennya mudah diakses, sehingga pemeliharaan dan penggantian bagian dapat dilakukan dengan cepat dan efisien.

Kesimpulan:

Dosing Pump Flugo GMS Series adalah solusi ideal untuk aplikasi yang memerlukan dosis cairan presisi tinggi dalam berbagai industri, termasuk pengolahan air, industri kimia, dan farmasi. Dengan desain yang sederhana namun kuat, Flugo GMS Series mempermudah perawatan dan memiliki biaya operasional yang rendah. Banyak digunakan dalam industri petrokimia, obat-obatan, makanan, pembangkit listrik tenaga panas, pembangkit listrik tenaga nuklir, tambang mineral, perlindungan lingkungan, pengolahan air, pertahanan nasional dan bidang penelitian dan produksi ilmiah terkait lainnya.

Info supplier Dosing Pump Flugo GMS Series - Mechanical Diaphragm Metering Pump 0813-3535-3290

PT. Hefram Asasta Indonesia

Jl. Raya Cikaret komplek ruko salsabila no 105, Pabuaran, Kec. Cibinong, Kab.Bogor 16915

Website:https://www.tokopedia.com/heframid/dosing-pump-flugo-gms-series-mechanical-diaphragm-metering-pump

Alamat:https://maps.app.goo.gl/XHtDvZAHB7ZxjkVDA

Facebook:https://www.facebook.com/heframasastaInstagram:https://www.instagram.com/heframid/

0 notes

Text

How to Choose the Right Portable Column Lift for Your Needs?

Choosing the right portable column lift involves several key considerations to ensure it meets your specific needs. First, assess the lift's capacity determine the maximum weight you need to lift, ensuring it exceeds your requirements. Next, consider the height adjustment range to accommodate various vehicles or equipment. Evaluate the power source whether electric or hydraulic, based on your work environment and preferences. Portability is crucial; look for models with wheels or compact designs for easy movement and storage. Additionally, check for safety features such as automatic locking mechanisms and overload protection. Lastly, review brand reputation and customer reviews to ensure reliability and service support. By carefully evaluating these factors, you can select a portable column lift that best fits your applications and enhances productivity.

What is a Portable Column Lift?

A portable column lift is a versatile lifting solution designed for easy mobility and flexibility in various environments. These lifts are commonly used in automotive repair shops, commercial garages, and industrial settings. Unlike traditional stationary lifts, portable column lifts can be moved around, allowing users to adjust their setup based on the task at hand. This makes them particularly useful for lifting heavy vehicles, equipment, or machinery.

Key Features of Portable Column Lifts

Portable column lifts come with a range of features that make them both functional and user-friendly. Some key features include adjustable lifting height, mobile capabilities, and high lifting capacity. Many models are equipped with hydraulic or electric motors offering efficient operation. Safety features like automatic locks and overload protection systems ensure that the lift operates securely under heavy loads.

Advantages of Using a Portable Column Lift

The flexibility of portable column lifts offers several advantages over traditional lifts. One of the main benefits is their portability allowing for use in multiple locations without being fixed in one spot. Additionally, these lifts save space in garages or workshops where floor space is limited. They can also handle large lifting capacities making them suitable for various types of vehicles, from light cars to heavy-duty trucks.

How to Select the Right Portable Column Lift for Your Needs?

Choosing the right portable column lift depends on factors like weight capacity power source and height range Start by determining the maximum weight you'll be lifting and ensure the lift has adequate capacity. Next, decide between electric or hydraulic models depending on your environment. Some lifts come with wireless controls providing extra convenience. Additionally, consider the space and mobility requirements, ensuring the lift fits your specific needs.

Safety Considerations for Portable Column Lifts

Safety is paramount when using portable column lifts. Many modern lifts are equipped with safety locks pressure sensors, and manual release mechanisms Always follow the manufacturer’s guidelines to ensure the lift is operated safely. Regular maintenance checks should also be performed to identify wear and tear or any potential hazards. Proper training for operators is key to preventing accidents.

Portable Column Lift Maintenance and Care

Routine maintenance is essential for extending the lifespan of a portable column lift. This includes regular lubrication of moving parts, checking for hydraulic leaks and ensuring electrical components are functioning correctly. Periodic inspections by a certified technician can help identify problems early and prevent costly repairs. Proper storage, especially in environments prone to rust or dust, also plays a crucial role in maintaining the lift's performance.

Applications of Portable Column Lifts in Different Industries

Portable column lifts have widespread applications across multiple industries. In the automotive industry they are used to lift vehicles for repair and maintenance tasks. In industrial settings they assist in moving heavy equipment, while in the construction and transport sectors, they are used for handling large machinery. Their versatility and portability make them a valuable tool across a range of professional environments

Conclusion

In conclusion, portable column lifts offer unmatched versatility, safety, and efficiency, making them an excellent investment for both commercial and industrial uses. Their portabilityallows for flexible workspace arrangements, and their heavy lifting capacity ensures they can handle a wide range of tasks. With proper maintenance and attention to safety, these lifts provide a long-term, cost-effective solution for lifting needs in workshops, garages, and industrial environments. When selecting the right model, consider your specific requirements, ensuring it meets your lifting capacity, power preferences, and mobility needs.

0 notes