#Manufacturing ERP module

Explore tagged Tumblr posts

Text

The Role of ERP in Managing Quality Control in Manufacturing

In the highly competitive manufacturing sector, maintaining stringent quality control is not just a necessity but a strategic advantage. In a landscape where efficiency and precision define success, integrating ERP for manufacturing companies in India has become a game-changer. The role of manufacturing ERP software in India extends beyond operational management; it plays a pivotal part in ensuring quality control throughout the production lifecycle.

Understanding the Need for Quality Control in Manufacturing

Quality control ensures that products meet predefined standards, adhere to regulations, and satisfy customer expectations. Without effective systems in place, manufacturing companies risk producing defective products, incurring financial losses, and damaging their reputation. This is where manufacturing enterprise resource planning software in India comes into play. By centralizing data and streamlining processes, ERP systems empower manufacturers to monitor, measure, and enhance quality at every stage.

How ERP Facilitates Quality Control in Manufacturing

1. Centralized Data Management

ERP systems consolidate data from various departments into a unified platform. This centralization is crucial for quality control, as it provides real-time access to critical metrics like raw material quality, production processes, and final product evaluations. ERP software companies in India ensure that manufacturers have a single source of truth, enabling faster and more informed decision-making.

2. Automation of Quality Checks

The manufacturing ERP module often includes automated tools for conducting quality checks. By automating repetitive tasks such as inspecting raw materials, testing products, and verifying compliance, ERP reduces human error and enhances efficiency. This capability is particularly valuable for industries with strict quality standards, such as automotive, pharmaceuticals, and electronics.

3. Compliance Management

Staying compliant with industry regulations is non-negotiable for manufacturing companies. ERP systems provide features that help monitor compliance parameters, generate audit reports, and track regulatory changes. ERP software providers in India offer tailored solutions to meet local and global compliance requirements, ensuring seamless operations.

4. Real-Time Analytics and Reporting

Real-time analytics is a cornerstone of modern ERP systems. These tools allow manufacturers to track quality metrics in real-time, identify deviations, and implement corrective actions instantly. The insights gained from these analytics not only improve quality but also drive process optimization.

5. Supply Chain Integration

Quality control begins with raw materials and extends through the supply chain. ERP systems facilitate end-to-end supply chain visibility, enabling manufacturers to assess supplier performance and ensure the quality of incoming materials. Many ERP solution providers in India offer integrated supply chain management modules to support this functionality.

6. Continuous Improvement through Feedback Loops

ERP systems support continuous improvement by capturing and analyzing feedback from quality control processes. This data is invaluable for identifying recurring issues, uncovering root causes, and implementing preventive measures. Top 10 ERP software providers in India have built-in tools for continuous quality enhancement, ensuring sustained excellence.

Benefits of ERP for Quality Control in Manufacturing

Integrating an ERP system offers several tangible benefits for quality control:

Enhanced Traceability: ERP systems provide traceability across the production process, making it easier to track and rectify defects.

Reduced Waste: By identifying inefficiencies and defects early, ERP reduces waste and optimizes resource utilization.

Improved Customer Satisfaction: Consistently delivering high-quality products strengthens customer trust and loyalty.

Cost Savings: Preventing defects and ensuring compliance minimizes the financial risks associated with recalls, fines, and reputational damage.

Choosing the Right ERP Software for Quality Control

Selecting the best ERP solution requires careful consideration of your manufacturing needs. Here are some factors to consider:

Industry-Specific Features: Look for manufacturing ERP software in India that offers modules tailored to your industry.

Scalability: Ensure the ERP system can scale with your business as it grows.

Integration Capabilities: The ERP should integrate seamlessly with your existing systems and technologies.

Vendor Expertise: Collaborate with an ERP software company in India with proven expertise in delivering quality solutions.

Why Indian Manufacturers Need ERP for Quality Control

India's manufacturing sector is poised for growth, driven by initiatives like Make in India and PLI schemes. However, this growth comes with increasing competition and stricter quality expectations. Leveraging ERP software providers in India can give manufacturers the edge they need to thrive in this evolving landscape.

A Trusted Partner for ERP Implementation

With numerous options available, finding the right ERP vendor is crucial. Leading ERP software companies in India offer customized solutions to meet the unique challenges of Indian manufacturers. These providers combine deep industry knowledge with cutting-edge technology to deliver exceptional results.

Shantitechnology: A Trusted Name in ERP Solutions

Shantitechnology, a renowned name among top 10 ERP software providers in India, specializes in delivering robust ERP solutions for manufacturing companies. Our comprehensive manufacturing ERP module is designed to address the intricacies of quality control, ensuring manufacturers achieve excellence with ease.

Conclusion

In the modern manufacturing landscape, quality control is not an isolated function but a core component of operational success. ERP systems empower manufacturers to seamlessly integrate quality control into their workflows, ensuring consistent product excellence. As one of the best ERP software providers in India, Shantitechnology is committed to helping manufacturers navigate the complexities of quality control with innovative ERP solutions. By embracing the right ERP system, Indian manufacturers can enhance their competitive edge, drive customer satisfaction, and achieve sustainable growth.

If you are looking to elevate your quality control processes, partner with a leading ERP software company in India like Shantitechnology. Contact us today to learn more about our customized ERP solutions and how they can transform your manufacturing operations.

#ERP software in India#Top 10 ERP software providers in India#ERP software company in India#Engineering ERP Software company in India#ERP software for engineering companies#Engineering ERP software solution#ERP software for engineering companies in India#ERP software providers in India#ERP software companies in India#ERP solution providers in India#Best ERP software provider in India#ERP for manufacturing company in India#Manufacturing ERP software in India#Manufacturing enterprise resource planning software in India#Manufacturing ERP module

5 notes

·

View notes

Text

A Quick Guide to SAP Business One for the Manufacturing Industry – Modules & Implementation

SAP for Manufacturing Industry can significantly accelerate time-to-market (TTM), boost production efficiency, and cut down operational expenses. In simple terms, SAP ERP empowers manufacturing companies by bringing automation and adaptability across various operations. Consequently, manufacturers can utilize available resources more effectively while maximizing productivity.

Globally, the manufacturing sector plays a pivotal role in shaping our everyday lives. To keep up with rising product demands, manufacturers are constantly on the lookout for efficient and scalable solutions. This is where SAP ERP comes into the picture, offering transformative automation for the industry. In this blog, we’ll explore the pivotal role SAP plays in the manufacturing sector, its various modules, and the key benefits it brings. But first, let’s understand:

What is SAP for Manufacturing?

As with many other key industries, automation and digital transformation are reshaping the future of manufacturing. These forward-looking trends help businesses address complex challenges like shrinking delivery timelines, evolving consumer demands, and disrupted supply chains. The SAP Business One manufacturing solution steps in as a powerful enabler, making operations more agile and future-ready.

SAP is a comprehensive and scalable Enterprise Resource Planning (ERP) platform, offering robust features, modular integration, and high adaptability for both small and large enterprises. Its intuitive design simplifies usage while drastically reducing implementation time. SAP manufacturing modules empower real-time monitoring of the production lifecycle, ensuring better oversight and control.

Through built-in intelligence, integration, and analytics tools, SAP’s digital manufacturing suite refines processes for peak performance. For a successful implementation, partnering with a trusted global SAP provider is essential.

Problems Facing Manufacturing Industries

The manufacturing domain is evolving rapidly, but rising competition and global uncertainties pose several hurdles. Here are the primary challenges manufacturers face:

Prediction of Demand

Forecasting demand remains a major concern. The absence of real-time data analytics tools leads to inaccurate estimates, making it difficult for manufacturers to align supply with market needs.

Efficiency Issues

Managing remote production facilities presents its own set of hurdles. Many manufacturers struggle to maintain cost-efficiency and consistent output quality, occasionally compromising on standards.

Lead Management

Prioritizing and managing sales leads effectively is a pain point. Due to the lack of a strategic lead management approach, all leads are often treated uniformly, resulting in missed opportunities.

Inventory Management

Manual stock tracking invites errors and inefficiencies. This outdated approach can lead to stock-outs or excessive inventory levels, both of which hinder operations.

ROI Challenges

Maximizing Return on Investment (ROI) quickly is a universal industry goal. However, manufacturers often encounter numerous roadblocks in their quest for faster, sustainable gains.

This is where SAP ERP Solutions proves invaluable, empowering manufacturers to overcome these barriers with greater ease.

How SAP Helps in Manufacturing Industries

SAP ERP offers numerous advantages tailored to the manufacturing ecosystem. Whether it's inventory control or multi-level bill of materials management, SAP is an indispensable tool. Here are some of the top ways SAP supports the industry:

Streamlined, end-to-end automation

Optimal resource utilization

Decreased turnaround time and operational costs

Real-time feedback and insights

Secure tracking of all functions

These advantages translate into elevated productivity and operational excellence. Let’s now dive into the core SAP Manufacturing ERP Modules that make this possible.

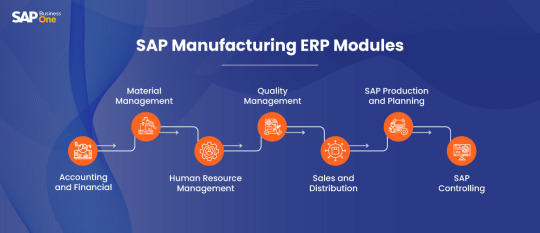

SAP Manufacturing ERP Modules

SAP offers a mix of functional and technical modules, each delivering powerful results for the manufacturing process:

1. Accounting and Financial

Manages financial transactions and audit trails efficiently across all business sizes. Integrates all financial data in one dashboard for quick, accurate decision-making.

2. Material Management

Ensures raw material availability by streamlining procurement, storage, and inventory processes. Also supports automated invoice creation and vendor interactions.

3. Human Resource Management

Manages workforce operations with care and structure, boosting employee engagement and overall efficiency. Critical for fostering a productive workplace culture.

4. Quality Management

Maintains quality standards at every stage—from raw material intake to final product delivery. Ensures compliance with industry norms.

5. Sales and Distribution

Tracks sales orders and delivery schedules with ease, while aiding inventory and revenue forecasting. A vital tool for smooth distribution.

6. Production and Planning

Offers centralized planning by leveraging real-time data, streamlining sales, operations, and material requirements efficiently.

7. SAP Controlling

Provides oversight and real-time monitoring of business processes. Supports budgeting, forecasting, and performance tracking.

Each of these modules plays a significant role in helping manufacturers optimize operations and achieve growth.

Benefits of SAP Manufacturing

Here are the standout business benefits manufacturers can gain by adopting SAP Business One:

Better Traceability of Stocks

Minimizes manual tracking errors by maintaining accurate stock levels and providing insights into expiring components.

Improved Inventory Management

Automates and organizes warehouse logistics through advanced tools like bin location tracking for greater visibility and control.

Unified Data Access

Eliminates siloed systems by consolidating all critical data into one accessible platform, improving cross-departmental efficiency.

Smarter Planning

MRP Wizard enables scenario planning for procurement and production to ensure better preparedness and decision-making.

Enhanced Customer Satisfaction

Automates order processing and query handling, offering faster response times and more personalized service.

SAP ERP Supports Multiple Manufacturing Types

SAP solutions can be tailored for various manufacturing models:

Process Manufacturing – e.g., pharmaceuticals, chemicals, F&B

Repetitive Manufacturing – e.g., electronics, automotive parts

Discrete Manufacturing – e.g., toys, furniture, appliances

Features of SAP Business One for Manufacturing

SAP B1 offers a range of manufacturing-centric features, including:

Warehouse Management – Optimize stock movement and reduce surpluses.

Machine Planning – Minimize overspending and maximize ROI.

Production Planning – Integrated with PLC and dependent operations.

Costing Tools – Accurate margin analysis and forecasting.

Key Product Costing – Use HANA to drive structured cost calculations.

Production Management – Real-time status updates and cross-functional reporting.

Planning & Consumption – Support for JIT and FIFO strategies.

Quality Control – Built-in compliance tools and automatic certifications.

Production Cycle Monitoring – End-to-end tracking and optimization.

SAP for Small Manufacturing Businesses

Small manufacturers can benefit immensely from SAP’s automated, scalable ecosystem. It helps manage all aspects—production, inventory, procurement, and sales—within a single, intuitive platform.

SAP Digital Manufacturing

SAP Digital Manufacturing Cloud enhances operations by providing:

Performance Visibility – Unified analytics to assess productivity.

Process Transparency – Real-time data integration via MOM.

Consistent Reporting – Actionable insights for instant decisions.

Adaptive Manufacturing – Flexibility to meet diverse market demands.

Resource Efficiency – Minimized downtime and optimized output.

Key Functional Areas of SAP in Manufacturing

Major functionalities include:

Financial operations (A/R, A/P, cash flow)

Inventory & SCM (lot tracking, raw materials)

Real-time shop floor control and costing

BI tools for workflow and attendance tracking

BOMs, routing, logistics, and CRM integration

Why You Should Adopt SAP for Manufacturing

SAP Business One offers:

Streamlined operations with real-time insights

Automation across functions, boosting agility

Enhanced supply chain and customer management

Seamless warehouse and eCommerce integration

Long-term scalability and efficiency

Why Choose Silver Touch for SAP Implementation?

Silver Touch Technologies is a seasoned SAP Business One partner. Here’s what sets us apart:

Deep domain knowledge and process consulting

End-to-end SAP solution planning and execution

Custom add-ons tailored to your operations

Integration with MES and legacy systems

Trusted by SMEs and large enterprises globally

24x7 technical support as a certified SAP Partner

Conclusion: SAP in Manufacturing

In conclusion, SAP ERP is a transformative solution for small and mid-sized manufacturing businesses. It supports intelligent, connected, and scalable manufacturing with features designed for modern industrial needs. Partnering with a reliable SAP provider like Silver Touch ensures your manufacturing unit is ready for the future.

Source - https://sap.silvertouch.com/blog/sap-business-one-for-manufacturing

#SAP Business One Manufacturing#SAP Business One Manufacturing Industry#SAP Business One manufacturing solution#SAP Manufacturing ERP Modules

0 notes

Text

Odoo 18 has arrived, and it’s setting a new standard in manufacturing efficiency! Packed with innovative features, this update empowers businesses to streamline workflows, improve resource management, and achieve seamless project integration.

Key updates include:

Manufacturing Orders (MO): Directly link orders to projects for better workflow management and provide detailed instructions accessible from shop floor interfaces.

Bill of Materials (BoM): Easily add components from the catalog and connect BoMs to specific projects for enhanced production alignment.

Master Production Schedule (MPS): Enjoy a cleaner dashboard, dynamic schedule adjustments, and smarter replenishment rules to ensure efficient stock management.

Gantt View Enhancements: Navigate schedules with horizontal scrolling, zoom-in/out functionality, and flexible period selection.

Whether you’re focused on boosting shop floor productivity, managing demand forecasting, or improving scheduling flexibility, Odoo 18 delivers tools to transform your manufacturing processes.

As an official Odoo partner, Serpent Consulting Services specializes in implementing ERP solutions tailored to your unique business needs. Let us help you take advantage of Odoo 18’s powerful features. Reach out to us at [email protected] today!

#Odoo 18#Manufacturing Module#ERP Solutions#Manufacturing ERP#Odoo Features#Odoo Manufacturing Updates

0 notes

Text

Zillancer: Best Manufacturing ERP for Small Businesses

Small businesses in the manufacturing sector can now achieve better efficiency with ERP software solutions. Zillancer connects you with expert freelancers to help integrate customized ERP systems that simplify your processes, boost productivity, and foster growth. Get your manufacturing operations running smoothly with our tailored ERP solutions.

#Best ERP for Manufacturing#Best ERP for Small Manufacturing Business#Best ERP for Manufacturing Industry#Top 10 Manufacturing ERP Systems#Best Cloud ERP for Manufacturing#Manufacturing ERP#Manufacturing ERP for Small Business#Best ERP Systems for Manufacturing#ERP for Manufacturing Industry#ERP System for Small Manufacturing#Top 10 ERP Software for Manufacturing#ERP for Custom Manufacturing#Top ERP for Manufacturing#Cloud Based ERP for Manufacturing#ERP for Manufacturing Companies#ERP Manufacturing Module#ONEERP#Microsoft Dynamics 365#Microsoft Dynamics Business Central

0 notes

Text

How to Choose the Right ERP Software for Your Manufacturing Business

Selecting the right ERP software for a manufacturing business is a critical decision that can transform operations, boost efficiency, and drive growth. However, with many ERP options available, finding the perfect fit for your company’s unique needs can be challenging. In this blog, we’ll break down the essential factors to consider when choosing ERP software for manufacturing and guide you through the process to ensure a successful implementation.

1. Identify Your Business Requirements

Before exploring ERP options, clearly define your business needs and goals. Every manufacturing company has specific requirements, such as inventory management, production scheduling, quality control, or supply chain management. Create a list of your must-have features and functionalities based on the areas where your business needs the most support. This step helps narrow down your options to ERP systems designed for the manufacturing sector.

2. Look for Industry-Specific Features

Not all ERP systems are created equal. To fully benefit from an ERP solution, consider software designed specifically for manufacturing. Industry-specific ERP solutions typically include specialized features like:

Production Planning and Scheduling

Inventory and Warehouse Management

Quality Control

Supply Chain and Vendor Management

Bill of Materials (BOM) Management

By focusing on ERP systems with these manufacturing-specific tools, you ensure the software aligns closely with your operational needs.

3. Choose Between Cloud-Based and On-Premises ERP

ERP systems are available in cloud-based and on-premises versions, each with its advantages. Cloud-based ERP solutions, such as HostBooks ERP, offer accessibility from any location, scalability, and lower upfront costs. Cloud systems also frequently update, ensuring you benefit from the latest features without manual upgrades.

On the other hand, on-premises ERP systems provide greater control over data and may be preferable for companies with strict security requirements. Consider your company’s size, budget, and IT capabilities to determine which deployment method best fits your business.

4. Ensure Real-Time Data and Reporting Capabilities

Real-time data and reporting are essential for manufacturing companies, as they provide insights needed to make informed decisions. ERP systems with real-time data capabilities allow you to monitor production, inventory, and financial metrics as they happen. This visibility enables you to respond quickly to changes in demand, identify issues, and make data-driven decisions that improve overall efficiency.

Choose ERP software that offers customizable dashboards and robust reporting tools to track key performance indicators (KPIs) relevant to your business.

5. Evaluate Integration and Compatibility

Your ERP system must integrate smoothly with existing software and hardware in your organization. Whether you’re using CRM, financial software, or specialized production tools, compatibility with these systems is vital to streamline processes and avoid data silos. Look for ERP software with API capabilities and easy integration options to ensure a seamless flow of data across departments.

6. Prioritize User-Friendly Interfaces

A complicated, hard-to-use ERP system can slow down productivity and lead to user frustration. Choose an ERP solution with an intuitive, user-friendly interface that simplifies day-to-day tasks. Your team should be able to navigate the system, access the information they need, and perform their jobs efficiently. Additionally, consider ERP providers that offer comprehensive training and support to ensure a smooth transition.

7. Focus on Scalability and Flexibility

As your manufacturing business grows, your ERP software should grow with you. A scalable ERP system can adapt to handle increased production, new locations, and additional product lines. Look for ERP software that offers flexible configurations, allowing you to add new modules or features as your business evolves. This scalability helps future-proof your investment and ensures the ERP solution remains effective over time.

8. Assess Security and Compliance Features

Manufacturing companies often handle sensitive data, making security a top priority. When evaluating ERP solutions, assess the security protocols and compliance features of each option. Cloud-based ERP systems should offer data encryption, multi-factor authentication, and regular backups. For companies in regulated industries, look for ERP systems with compliance features that help meet specific industry standards, such as ISO or FDA requirements.

9. Evaluate the Vendor’s Support and Reputation

Your ERP provider should be a trusted partner in your business journey. Research each vendor’s reputation, read customer reviews, and check their industry experience. An ERP vendor with a strong track record in the manufacturing sector is more likely to understand your unique needs. Additionally, consider the level of support offered—reliable customer service, ongoing maintenance, and regular updates are essential for a successful ERP implementation.

10. Examples of Manufacturing ERP Software

Several ERP options cater to the specific needs of manufacturing:

HostBooks ERP: A versatile, cloud-based ERP solution designed to streamline operations for manufacturers. HostBooks ERP offers inventory management, order processing, and real-time reporting to enhance productivity and decision-making.

SAP ERP: A popular choice for large manufacturing enterprises, SAP ERP offers advanced features and customization options, making it ideal for complex operations.

Microsoft Dynamics 365: This ERP solution is well-suited for small to mid-sized manufacturers, offering robust integration with other Microsoft tools.

Oracle NetSuite: Known for its comprehensive cloud platform, Oracle NetSuite is ideal for managing everything from supply chain to finances.

Final Thoughts

Choosing the right ERP software for manufacturing involves careful evaluation of your business needs, industry-specific requirements, and long-term goals. By focusing on features like real-time reporting, integration, user experience, and scalability, you can select an ERP solution that drives efficiency and growth. A well-chosen ERP system not only optimizes your current processes but also positions your manufacturing business for future success.

#erp software#erp manufacturing#accounting#erp solution bd#manufacturing software#manufacturing erp modules#best erp for manufacturing industry#erp for manufacturing industry#erp software for construction industry#india#business#finance#ERP Software for Your Manufacturing Business

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--lighting-solutions--light-engine-led-assemblies--light-engines/ess015w-0350-42-erp-power-4089170

Outdoor Light, brightest light bulbs, LED lighting systems, retrofit LED lamp

100 - 277Vac, 14.7W, 350mA, 24-42V, [0-10V, TRI...], IP64 LED Driver

#Lighting Solutions#LED Assemblies#Light Engines#ESS015W-0350-42#ERP Power#Outdoor Light#brightest light bulbs#LED lighting systems#retrofit LED lamp#replacement bulbs#High Bay Lights#modules#Fiber Optic#LED manufacturers#Spot Lights

1 note

·

View note

Text

ERP Software Benefits for Private Label Manufacturing

Technology is changing with each passing day, and hence you get an upgraded/advanced version of the ongoing software/tools. Private labeling manufacturing is one of those manufacturing forms that has been helping process manufacturing companies for decades. Various challenges in private-label manufacturing need to be addressed with an ERP system.

Here are some of the benefits of using ERP software that can help solve all the challenges in private-label manufacturing;

Benefits of ERP Software for Private Labeling

Streamline Operations

ERP software integrates and centralizes various private labeling processes such as inventory management, production planning, order processing, and financial management. This streamlining of operations can lead to increased efficiency and reduced manual data entry.

Improved Inventory Management

Private label manufacturers must deal with a wide range of SKUs and inventory items. ERP software helps in tracking inventory levels in real-time, managing stock levels, and reducing carrying costs by preventing overstock or stockouts.

Enhanced Demand Forecasting

ERP systems often include modules for demand forecasting, it can also help private label manufacturers manage customer demand. It also helps in managing inventory and production scheduling.

Cost Control

ERP software provides better visibility into cost structures. It allows for cost tracking at various stages of production, helping companies identify cost-saving opportunities and optimize their pricing strategies.

Data Analytics

ERP software provides exact insights with valuable data and reports on various aspects of the business. Advanced analytics tools within ERP can provide insights for informed decision-making, performance tracking, and identifying areas of improvement.

Scalability

With ERP software, you can grow the business, accommodating increasing production volumes and complexity. This scalability helps private label manufacturers continue to meet the needs of expanding all the operations in an organization.

Improved Communication

Private manufacturers need to collaborate and communicate efficiently. With an ERP system, it is easier to communicate with real-time updates on production progress, order status, and inventory levels can improve client relationships.

Lot Traceability

Lot tracking is one of the most important tasks in private manufacturing. An ERP system supports traceability tracking requirements by tracking the origin of materials and components used in production, that particularly important in industries with strict traceability regulations.

Integration Capabilities

ERP software helps in integrating with other businesses, such as CRM and e-commerce platforms, creating a seamless and improving overall business efficiency.

Next Steps!

ERP software is helping private label manufacturers with a comprehensive and integrated solution for managing their operations, right from production, supply chain, inventory management, and other operations. It can also improve efficiency, cost control, and overall business performance, helping businesses deliver high-quality private-label products to their clients.

0 notes

Text

Farvision: The Ultimate ERP Choice - Superiority Unmatched!

In the fast-paced world of business, staying ahead of the competition is essential for success. An Enterprise Resource Planning (ERP) system plays a vital role in streamlining operations, enhancing efficiency, and driving growth. When it comes to ERP solutions, one name stands out amongst the rest – Farvision. In this blog, we’ll explore why Farvision is the best choice compared to other ERP…

View On WordPress

#construction erp#customized ERP#ERP application#erp for Construction industry#ERP software#erp software solutions#manufacturing erp modules#manufacturing erp software

0 notes

Text

Axolt: Modern ERP and Inventory Software Built on Salesforce

Today’s businesses operate in a fast-paced, data-driven environment where efficiency, accuracy, and agility are key to staying competitive. Legacy systems and disconnected software tools can no longer meet the evolving demands of modern enterprises. That’s why companies across industries are turning to Axolt, a next-generation solution offering intelligent inventory software and a full-fledged ERP on Salesforce.

Axolt is a unified, cloud-based ERP system built natively on the Salesforce platform. It provides a modular, scalable framework that allows organizations to manage operations from inventory and logistics to finance, manufacturing, and compliance—all in one place.

Where most ERPs are either too rigid or require costly integrations, Axolt is designed for flexibility. It empowers teams with real-time data, reduces manual work, and improves cross-functional collaboration. With Salesforce as the foundation, users benefit from enterprise-grade security, automation, and mobile access without needing separate platforms for CRM and ERP.

Smarter Inventory Software Inventory is at the heart of operational performance. Poor inventory control can result in stockouts, over-purchasing, and missed opportunities. Axolt’s built-in inventory software addresses these issues by providing real-time visibility into stock levels, warehouse locations, and product movement.

Whether managing serialized products, batches, or kits, the system tracks every item with precision. It supports barcode scanning, lot and serial traceability, expiry tracking, and multi-warehouse inventory—all from a central dashboard.

Unlike traditional inventory tools, Axolt integrates directly with Salesforce CRM. This means your sales and service teams always have accurate availability information, enabling faster order processing and better customer communication.

A Complete Salesforce ERP Axolt isn’t just inventory software—it’s a full Salesforce ERP suite tailored for businesses that want more from their operations. Finance teams can automate billing cycles, reconcile payments, and manage cash flows with built-in modules for accounts receivable and payable. Manufacturing teams can plan production, allocate work orders, and track costs across every stage.

86 notes

·

View notes

Text

Tally Training in Chandigarh: Build a Successful Accounting Career

In today’s fast-paced digital economy, proficiency in accounting software like Tally is no longer optional — it’s a necessity. Whether you’re a student, a working professional, or someone planning a career shift into finance, Tally training in Chandigarh offers a golden opportunity to build a solid foundation in business accounting. With growing business activity in the region, mastering Tally can set you apart in the competitive job market.

Introduction to Tally and Its Relevance

Tally is one of the most widely used business accounting software in India. It simplifies complex financial operations such as invoicing, inventory management, taxation, payroll processing, and financial reporting. Tally ERP 9, the earlier version, was known for its robust features, while Tally Prime — the latest iteration — offers an intuitive interface and smarter navigation for enhanced productivity.

In a country where small and medium enterprises form the economic backbone, Tally plays a critical role in helping businesses maintain compliance and streamline operations. From automating GST filings to tracking stock levels in real time, Tally’s capabilities are deeply aligned with the needs of modern Indian enterprises.

Why Choose Tally Training in Chandigarh?

Chandigarh has steadily grown into a major educational and business center in North India. With its well-connected infrastructure and proximity to Punjab, Haryana, and Himachal Pradesh, it attracts students and professionals from across the region.

The city boasts several reputed training institutes that specialize in job-oriented programs, including Tally training in Chandigarh. These institutes not only provide structured learning but also offer real-world exposure through internships and industry interactions. The business-friendly environment of Tricity — comprising Chandigarh, Mohali, and Panchkula — further enhances placement opportunities for Tally-trained individuals.

Key Features of a Good Tally Training Institute

Selecting the right institute can make a big difference in how effectively you master Tally. Look for the following features when choosing your Tally course:

Certified and experienced trainers ensure you’re learning from professionals who understand both the software and its industry applications. Practical exposure through case studies and real-time projects helps you gain confidence in using Tally in real-world scenarios.

Modern Tally courses now include essential modules like GST compliance, inventory control, payroll processing, MIS report generation, and taxation management. Institutes that regularly update their syllabus in sync with government norms and business trends are more valuable.

Personalized mentorship, flexible batch timings (weekend/evening), and career support services like resume building and mock interviews can significantly enhance your learning experience.

Career Scope After Tally Training

Completing a certified Tally course can unlock a variety of career paths. Common roles include:

Accountant

GST Consultant

Billing Executive

Finance Executive

Audit Assistant

Tally skills are especially in demand in sectors like retail, manufacturing, logistics, healthcare, and professional services. Small and mid-sized businesses across the Tricity area consistently hire Tally-certified professionals for daily bookkeeping, tax filing, and reporting.

The average starting salary for a fresher with Tally training ranges from ₹15,000 to ₹25,000 per month, with rapid growth potential as you gain experience and industry exposure.

Tally ERP 9 vs Tally Prime: What You’ll Learn

A well-rounded Tally training program in Chandigarh covers both Tally ERP 9 and the newer Tally Prime. While ERP 9 remains in use across many companies, Tally Prime introduces improved usability with a simplified menu structure, enhanced multi-tasking, and better data tracking.

Key modules you’ll explore include:

Financial Accounting and Ledger Management

Inventory Management and Stock Control

Payroll Setup and Salary Processing

GST and TDS Return Filing

MIS Reports and Business Intelligence

Data Backup and Security Features

You’ll also learn how to use Tally as a business management tool that integrates seamlessly with compliance and audit requirements.

Best Tally Training Institutes in Chandigarh

When choosing an institute, reputation matters. The best Tally training institutes in Chandigarh offer practical curriculum, certified trainers, placement assistance, and flexible learning schedules.

Bright Career Solutions Mohali stands out as a highly rated institute offering in-depth Tally training with practical exposure. With expert faculty, dedicated career support, and strong student feedback, BCS Mohali has become a trusted name in Tally education in the region.

Students regularly highlight the institute’s hands-on training approach, one-on-one mentorship, and successful placement records across local businesses and startups.

FAQs About Tally Courses in Chandigarh

Q. Is Tally useful for non-commerce students? Ans. Yes. Tally is designed to be user-friendly and can be learned by students from non-commerce backgrounds. Institutes usually begin with accounting basics before diving into software-specific training.

Q. What is the typical duration and cost of Tally training? Ans. The duration can range from 1 to 3 months depending on the course level (basic to advanced). Fees generally range from ₹5,000 to ₹15,000. Institutes like BCS Mohali also offer installment plans.

Q. Is a Tally certification necessary to get a job? Ans. While not mandatory, a certification adds credibility to your resume and significantly boosts your chances during hiring. Certified professionals are often preferred for finance and accounts roles.

Conclusion

Tally training in Chandigarh is more than just a short-term course — it’s a launchpad for a rewarding career in finance and accounting. With businesses increasingly relying on Tally for daily operations and compliance, skilled professionals are in high demand.

Whether you’re a student, job seeker, or professional looking to upgrade your skills, enrolling in a Tally course from a reputed institute like Bright Career Solutions Mohali can help you take a decisive step toward career success. The right training, combined with dedication and practice, can turn you into a valuable asset for any business.

2 notes

·

View notes

Text

2 notes

·

View notes

Text

How ERP Software for Engineering Companies Improves Operational Efficiency

In today's competitive market, engineering companies are under immense pressure to deliver innovative solutions, maintain cost-efficiency, and meet tight deadlines—all while ensuring the highest standards of quality. As the engineering industry becomes more complex and digitally driven, operational efficiency has become a key metric for success. One of the most transformative tools driving this change is ERP (Enterprise Resource Planning) software.

For companies seeking to streamline their operations, ERP software for engineering companies provides a centralized platform that integrates every function—ranging from procurement, design, production, finance, HR, and project management. In India, especially in industrial hubs like Delhi, the demand for such software is growing rapidly. Let us explore how ERP systems significantly enhance operational efficiency and why choosing the right ERP software company in India is vital for engineering enterprises.

Centralized Data Management: The Foundation of Efficiency

One of the major challenges engineering companies face is managing vast amounts of data across departments. Manual entries and siloed systems often lead to redundancies, errors, and miscommunication. With ERP software for engineering companies in India, organizations gain access to a unified database that connects all operational areas.

Real-time data availability ensures that everyone, from the design team to procurement and finance, is working with the latest information. This reduces rework, improves collaboration, and speeds up decision-making, thereby increasing efficiency.

Streamlined Project Management

Engineering projects involve numerous stages—from planning and design to execution and maintenance. Tracking timelines, resources, costs, and deliverables manually or via disparate systems often results in delays and budget overruns.

Modern engineering ERP software companies in Delhi provide robust project management modules that allow firms to plan, schedule, and monitor projects in real time. This includes milestone tracking, Gantt charts, resource allocation, and budget forecasting. Managers can gain visibility into bottlenecks early on and reallocate resources efficiently, ensuring timely delivery.

Automation of Core Processes

Automating routine tasks is one of the key advantages of implementing ERP software. From generating purchase orders and invoices to managing payroll and inventory, ERP eliminates the need for repetitive manual work. This not only saves time but also minimizes human error.

The best ERP software provider in India will offer customizable automation workflows tailored to the specific needs of engineering companies. For instance, when a material stock reaches a minimum threshold, the ERP system can automatically generate a requisition and notify the purchasing team. This ensures zero downtime due to material shortages.

Enhanced Resource Planning and Allocation

Resource planning is crucial in engineering projects where labour, materials, and machinery must be utilized efficiently. A good ERP software for engineering companies provides detailed insights into resource availability, utilization rates, and project requirements.

By analysing this data, companies can better allocate resources, avoid overbooking, and reduce idle time. This leads to significant cost savings and ensures optimal productivity across the board.

youtube

Integration with CAD and Design Tools

Many ERP solution providers in Delhi now offer integration with design and CAD software. This is particularly useful for engineering firms where design data is often needed for procurement, costing, and production.

When ERP is integrated with CAD, design changes automatically reflect across related departments. This seamless flow of information eliminates miscommunication and ensures that downstream processes such as procurement and manufacturing are aligned with the latest design specifications.

Real-time Cost and Budget Management

Keeping engineering projects within budget is a continuous challenge. Unexpected costs can arise at any stage, and without proper monitoring, they can spiral out of control. ERP software providers in India equip engineering companies with real-time budget tracking tools.

From initial cost estimation to actual expenditure, companies can monitor every aspect of the financials. Alerts can be configured for budget deviations, helping management take corrective action promptly. This financial control is a cornerstone of operational efficiency and long-term profitability.

Improved Compliance and Documentation

Engineering companies must adhere to various compliance standards, certifications, and audit requirements. Maintaining accurate documentation and audit trails is critical. ERP systems automate compliance tracking and generate necessary documentation on demand.

By partnering with trusted ERP software companies in Delhi, engineering firms can ensure they meet industry standards with minimal administrative overhead. Features like document versioning, digital signatures, and compliance checklists help organizations stay audit-ready at all times.

Scalable and Future-ready Solutions

One of the biggest advantages of working with a reputed engineering ERP software company in Delhi is access to scalable solutions. As engineering businesses grow, their operational complexities increase. Modern ERP systems are modular and scalable, allowing businesses to add new functionalities as needed without disrupting existing operations.

Moreover, cloud-based ERP solutions offer flexibility, remote access, and lower infrastructure costs. These are especially beneficial for engineering companies that operate across multiple locations or work on-site with clients.

Enhanced Customer Satisfaction

Efficient operations lead to improved delivery timelines, better quality products, and faster customer service—all of which directly impact customer satisfaction. With ERP, engineering companies can maintain accurate production schedules, meet delivery deadlines, and respond to customer queries with real-time information.

By choosing the right ERP software for engineering companies in India, firms not only improve internal operations but also build a strong reputation for reliability and professionalism among their clients.

Choosing the Right ERP Partner

With the growing number of ERP solution providers in India, selecting the right partner is crucial. Here are a few factors to consider:

Domain Expertise: Choose a vendor with experience in the engineering sector.

Customization: The software should be tailored to suit your specific workflows.

Scalability: Ensure the ERP solution grows with your business.

Support & Training: Opt for companies that provide ongoing support and employee training.

Integration Capabilities: Check whether the ERP can integrate with your existing systems, including CAD tools, financial software, etc.

Trusted ERP software companies in Delhi like Shantitechnology (STERP) stand out because they offer deep industry knowledge, scalable platforms, and dedicated customer support—making them ideal partners for engineering businesses seeking to transform operations.

youtube

Final Thoughts

In a rapidly evolving business landscape, engineering companies must adopt smart technologies to stay ahead. ERP software is not just an IT solution—it is a strategic tool that can redefine how engineering firms manage their projects, people, and performance.

From streamlining project workflows and automating routine tasks to enhancing collaboration and boosting resource efficiency, ERP solutions deliver measurable gains across the organization. For those looking to make a digital leap, partnering with a top-rated ERP software company in India can be the difference between stagnation and scalable success.

Looking for a reliable ERP partner? Shantitechnology (STERP) is among the leading ERP solution providers in Delhi, offering tailored ERP software for engineering companies to help you boost productivity, reduce costs, and grow sustainably. Contact us today to learn more!

#Engineering ERP software company#ERP software for engineering companies in India#ERP solution providers#ERP software for engineering companies#ERP software companies#ERP software providers in India#Gujarat#Maharashtra#Madhyapradesh#ERP solution providers in India#ERP for manufacturing company#Delhi#Hyderabad#ERP Software#Custom ERP#ERP software company#Manufacturing enterprise resource planning software#Bengaluru#ERP software company in India#Engineering ERP Software Company#Best ERP software provider in India#Manufacturing ERP software company#Manufacturing enterprise resource planning#ERP modules for manufacturing industry#Best ERP for manufacturing industry#India#Youtube

2 notes

·

View notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

Searching for reliable Erp software?

Look no further than Hamro SAN. Designed for businesses such as restaurants, hotels, cafes, supermarkets, and manufacturing houses, Hamro SAN offers comprehensive modules for order processing, point of sale, inventory management, and accounting. The software features zero configuration, end-to-end encryption, and a user-friendly dashboard. Additionally, Hamro SAN provides 24/7 customer support, training materials, and flexible pricing plans to enhance productivity and operational efficiency. Choose Hamro SAN for a seamless and secure business management solution.

https://hamrosan.com/about/

2 notes

·

View notes

Text

Odoo ERP Customization || Transines Solutions

A successful Odoo ERP customization and implementation requires careful planning, technical expertise, and a collaborative approach with a trusted Odoo partner

With a dedicated team of experienced developers and odoo consultants. we work closely with businesses to understand clents requirements and provide customized solutions From custom module development to integration services,

6 REASONS TO PARTNER WITH US

Swift Solutions

Get your ERP implemented and supported promptly, eliminating the wait for an ERP expert to travel to your location. This not only saves you time but also cuts costs.

Seasoned Expertise

We have acquired expertise across diverse technologies, industries, and application types to extend the most efficient and timely assistance to you.

Deeds, not Words

Your questions deserve straightforward answers. Our ERP consultants will not confuse you with technical jargon. We are here to help you understand technicalities in plain language

Business Insight

We craft, assess, and endorse ERP solutions with a keen eye on the business benefits they bring to your company, ensuring a seamless integration of technology and business objectives.

All-in-One ERP Companion

Covering all facets of your business, our ERP software handles CRM, sales, purchase, inventory, HR, accounting, and manufacturing, making us your complete ERP partner.

Satisfaction Assured

100% Satisfaction is a Guarantee we offer. Our commitment is to ensure your complete satisfaction with our services, which instills us to go that extra mile to make you happy. Enjoy a hassle-free ERP experience with us

contact us by email at reagarding odoo related quaries feel free to contact us on [email protected]. we will get back to you as soon as possible with the help your your Odoo requirements.

2 notes

·

View notes

Text

#sales and distribution module in erp#erp software#erp manufacturing#accounting#erp solution bd#crm software#india#erp360#fnb360#erp software for construction industry#erp for manufacturing industry#manufacturing erp#erp software for manufacturing industry#manufacturing erp software#manufacturing software small business#manufacturing software

0 notes