#Manufacturing Module

Explore tagged Tumblr posts

Text

Odoo 18 has arrived, and it’s setting a new standard in manufacturing efficiency! Packed with innovative features, this update empowers businesses to streamline workflows, improve resource management, and achieve seamless project integration.

Key updates include:

Manufacturing Orders (MO): Directly link orders to projects for better workflow management and provide detailed instructions accessible from shop floor interfaces.

Bill of Materials (BoM): Easily add components from the catalog and connect BoMs to specific projects for enhanced production alignment.

Master Production Schedule (MPS): Enjoy a cleaner dashboard, dynamic schedule adjustments, and smarter replenishment rules to ensure efficient stock management.

Gantt View Enhancements: Navigate schedules with horizontal scrolling, zoom-in/out functionality, and flexible period selection.

Whether you’re focused on boosting shop floor productivity, managing demand forecasting, or improving scheduling flexibility, Odoo 18 delivers tools to transform your manufacturing processes.

As an official Odoo partner, Serpent Consulting Services specializes in implementing ERP solutions tailored to your unique business needs. Let us help you take advantage of Odoo 18’s powerful features. Reach out to us at [email protected] today!

#Odoo 18#Manufacturing Module#ERP Solutions#Manufacturing ERP#Odoo Features#Odoo Manufacturing Updates

0 notes

Text

How ERP Software for Engineering Companies Improves Operational Efficiency

In today's competitive market, engineering companies are under immense pressure to deliver innovative solutions, maintain cost-efficiency, and meet tight deadlines—all while ensuring the highest standards of quality. As the engineering industry becomes more complex and digitally driven, operational efficiency has become a key metric for success. One of the most transformative tools driving this change is ERP (Enterprise Resource Planning) software.

For companies seeking to streamline their operations, ERP software for engineering companies provides a centralized platform that integrates every function—ranging from procurement, design, production, finance, HR, and project management. In India, especially in industrial hubs like Delhi, the demand for such software is growing rapidly. Let us explore how ERP systems significantly enhance operational efficiency and why choosing the right ERP software company in India is vital for engineering enterprises.

Centralized Data Management: The Foundation of Efficiency

One of the major challenges engineering companies face is managing vast amounts of data across departments. Manual entries and siloed systems often lead to redundancies, errors, and miscommunication. With ERP software for engineering companies in India, organizations gain access to a unified database that connects all operational areas.

Real-time data availability ensures that everyone, from the design team to procurement and finance, is working with the latest information. This reduces rework, improves collaboration, and speeds up decision-making, thereby increasing efficiency.

Streamlined Project Management

Engineering projects involve numerous stages—from planning and design to execution and maintenance. Tracking timelines, resources, costs, and deliverables manually or via disparate systems often results in delays and budget overruns.

Modern engineering ERP software companies in Delhi provide robust project management modules that allow firms to plan, schedule, and monitor projects in real time. This includes milestone tracking, Gantt charts, resource allocation, and budget forecasting. Managers can gain visibility into bottlenecks early on and reallocate resources efficiently, ensuring timely delivery.

Automation of Core Processes

Automating routine tasks is one of the key advantages of implementing ERP software. From generating purchase orders and invoices to managing payroll and inventory, ERP eliminates the need for repetitive manual work. This not only saves time but also minimizes human error.

The best ERP software provider in India will offer customizable automation workflows tailored to the specific needs of engineering companies. For instance, when a material stock reaches a minimum threshold, the ERP system can automatically generate a requisition and notify the purchasing team. This ensures zero downtime due to material shortages.

Enhanced Resource Planning and Allocation

Resource planning is crucial in engineering projects where labour, materials, and machinery must be utilized efficiently. A good ERP software for engineering companies provides detailed insights into resource availability, utilization rates, and project requirements.

By analysing this data, companies can better allocate resources, avoid overbooking, and reduce idle time. This leads to significant cost savings and ensures optimal productivity across the board.

youtube

Integration with CAD and Design Tools

Many ERP solution providers in Delhi now offer integration with design and CAD software. This is particularly useful for engineering firms where design data is often needed for procurement, costing, and production.

When ERP is integrated with CAD, design changes automatically reflect across related departments. This seamless flow of information eliminates miscommunication and ensures that downstream processes such as procurement and manufacturing are aligned with the latest design specifications.

Real-time Cost and Budget Management

Keeping engineering projects within budget is a continuous challenge. Unexpected costs can arise at any stage, and without proper monitoring, they can spiral out of control. ERP software providers in India equip engineering companies with real-time budget tracking tools.

From initial cost estimation to actual expenditure, companies can monitor every aspect of the financials. Alerts can be configured for budget deviations, helping management take corrective action promptly. This financial control is a cornerstone of operational efficiency and long-term profitability.

Improved Compliance and Documentation

Engineering companies must adhere to various compliance standards, certifications, and audit requirements. Maintaining accurate documentation and audit trails is critical. ERP systems automate compliance tracking and generate necessary documentation on demand.

By partnering with trusted ERP software companies in Delhi, engineering firms can ensure they meet industry standards with minimal administrative overhead. Features like document versioning, digital signatures, and compliance checklists help organizations stay audit-ready at all times.

Scalable and Future-ready Solutions

One of the biggest advantages of working with a reputed engineering ERP software company in Delhi is access to scalable solutions. As engineering businesses grow, their operational complexities increase. Modern ERP systems are modular and scalable, allowing businesses to add new functionalities as needed without disrupting existing operations.

Moreover, cloud-based ERP solutions offer flexibility, remote access, and lower infrastructure costs. These are especially beneficial for engineering companies that operate across multiple locations or work on-site with clients.

Enhanced Customer Satisfaction

Efficient operations lead to improved delivery timelines, better quality products, and faster customer service—all of which directly impact customer satisfaction. With ERP, engineering companies can maintain accurate production schedules, meet delivery deadlines, and respond to customer queries with real-time information.

By choosing the right ERP software for engineering companies in India, firms not only improve internal operations but also build a strong reputation for reliability and professionalism among their clients.

Choosing the Right ERP Partner

With the growing number of ERP solution providers in India, selecting the right partner is crucial. Here are a few factors to consider:

Domain Expertise: Choose a vendor with experience in the engineering sector.

Customization: The software should be tailored to suit your specific workflows.

Scalability: Ensure the ERP solution grows with your business.

Support & Training: Opt for companies that provide ongoing support and employee training.

Integration Capabilities: Check whether the ERP can integrate with your existing systems, including CAD tools, financial software, etc.

Trusted ERP software companies in Delhi like Shantitechnology (STERP) stand out because they offer deep industry knowledge, scalable platforms, and dedicated customer support—making them ideal partners for engineering businesses seeking to transform operations.

youtube

Final Thoughts

In a rapidly evolving business landscape, engineering companies must adopt smart technologies to stay ahead. ERP software is not just an IT solution—it is a strategic tool that can redefine how engineering firms manage their projects, people, and performance.

From streamlining project workflows and automating routine tasks to enhancing collaboration and boosting resource efficiency, ERP solutions deliver measurable gains across the organization. For those looking to make a digital leap, partnering with a top-rated ERP software company in India can be the difference between stagnation and scalable success.

Looking for a reliable ERP partner? Shantitechnology (STERP) is among the leading ERP solution providers in Delhi, offering tailored ERP software for engineering companies to help you boost productivity, reduce costs, and grow sustainably. Contact us today to learn more!

#Engineering ERP software company#ERP software for engineering companies in India#ERP solution providers#ERP software for engineering companies#ERP software companies#ERP software providers in India#Gujarat#Maharashtra#Madhyapradesh#ERP solution providers in India#ERP for manufacturing company#Delhi#Hyderabad#ERP Software#Custom ERP#ERP software company#Manufacturing enterprise resource planning software#Bengaluru#ERP software company in India#Engineering ERP Software Company#Best ERP software provider in India#Manufacturing ERP software company#Manufacturing enterprise resource planning#ERP modules for manufacturing industry#Best ERP for manufacturing industry#India#Youtube

2 notes

·

View notes

Text

Top 10 Solar Module Manufacturers in India

#Top 10 Solar Module Manufacturers in Ahmedabad India#Best solar module manufacturers in Ahmedabad/Vadodara/Gujarat/India#Solar module prices in Ahmedabad/Vadodara/Gujarat/India#Solar module installation services in Ahmedabad/Vadodara/Gujarat/India#High-efficiency solar modules in Ahmedabad/Vadodara/Gujarat/India#Renewable Energy India#Solar Companies India#Solar Tech India#Sustainable Energy India#Green Energy India#Solar Innovation India#Clean Energy India#SolarCompanies AhmedabadIndia#SolarManufacturing India#SolarIndustry India#Solar PowerIndia

2 notes

·

View notes

Text

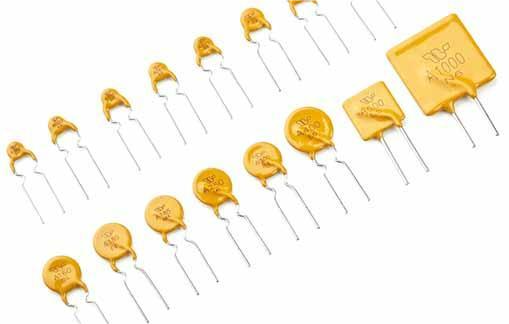

What Are PTC Resettable Fuses?

A PTC (Positive Temperature Coefficient) resettable fuse is a protective component designed based on the polymer's positive temperature coefficient effect. Its core material consists of a polymer composite embedded with conductive carbon black particles. Under normal conditions, the fuse maintains a low resistance state.

Get more details: What Are PTC Resettable Fuses?

#electronics#integrated circuits#semiconductor#components#electronic#module#chips#electronic devices#manufacturing#capacitors

0 notes

Text

How Lithium-ion Battery Packs Are Assembled: Techniques, Testing & Key Challenges?

The manufacturing of lithium-ion battery packs is a crucial step in delivering high-performance, reliable power solutions. It involves combining individual lithium-ion cells into functional battery modules, integrated with safety and monitoring systems.

These battery packs power a range of modern applications, including electric vehicles (EVs), renewable energy storage systems, and portable electronics.

Key Stages in Lithium-ion Battery Pack Manufacturing

1. Battery Cell Sorting and Grouping

Selection: Match cells with similar internal resistance, voltage, and capacity.

Grouping: Uniform cell groups promote balanced performance and longevity.

Testing: Evaluate cell capacity, voltage drop, and charge/discharge cycles.

2. Cell Assembly and Spot Welding

Fixture Placement: Accurately arrange cells using designated tools.

Spot Welding: Use automatic battery welding machines for strong, clean joints.

Quality Inspection: Check weld integrity to avoid electrical faults.

3. Battery Module Assembly

Module Connection: Configure cells in series or parallel for target voltage/capacity.

BMS Integration: Install a Battery Management System (BMS) to monitor temperature, voltage, and current flow.

4. Battery Pack Testing and Quality Control

Functional Testing: Validate module safety, performance, and reliability.

Leakage Testing: Ensure airtight, leak-free construction.

Visual Inspection: Spot physical defects or structural inconsistencies.

Challenges and Considerations in Battery Pack Manufacturing

Cell Consistency: Inconsistent cells can destabilize battery module performance.

Welding Quality: Poor welds may lead to short circuits and thermal hazards.

BMS Configuration: A well-calibrated BMS ensures safe energy management.

Compliance: Must meet global safety standards like UN 38.3, UL 2580, ISO 26262.

Conclusion

From cell sorting to final testing, every stage in lithium-ion battery pack assembly ensures the product is safe, efficient, and ready for deployment. When done correctly, this process delivers durable energy solutions for EVs, solar systems, and industrial battery applications.

#lithium-ion battery pack assembly#battery pack manufacturing process#lithium battery pack testing#battery pack assembly techniques#battery module assembly

0 notes

Text

Abb Imsed01 Gm9.0082.001.51 Seq. Of Events Digital Module - Auto2mation

The ABB IMSED01 GM9.0082.001.51 Sequence of Events Digital Module is a high-performance input module used in industrial automation systems. Designed for fast and accurate event recording, it ensures precise monitoring and fault detection in real time. Ideal for critical applications, it provides reliable digital input data to help improve safety and efficiency in operations. With its robust build and seamless integration into ABB control systems, it’s perfect for power plants, substations, and automation networks. Buy the ABB IMSED01 SOE Digital Module today from Auto2mation – your trusted source for industrial automation parts and solutions.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Abb#Digital Module#Plc Systems

0 notes

Text

Ladder cable tray cover

Ladder cable tray covers from Aparna Rollform are vital for safeguarding cables in industrial and commercial settings.

These covers, made from durable materials like galvanized steel, aluminum, or stainless steel, shield cables from dust, moisture, and mechanical damage, ensuring longevity and safety.

Their robust design supports heavy cable loads while allowing excellent ventilation to prevent overheating. Available in vented, perforated, or solid styles, they balance protection and airflow. Customizable to fit specific sizes and finishes, Aparna Rollform’s covers enhance cable management, simplify maintenance, and improve aesthetics.

Easy to install and corrosion-resistant, they’re ideal for harsh environments. Choose Aparna Rollform for high-quality, reliable ladder cable tray covers tailored to your needs. Visit aparnarollform.com for more.

#Solid Bottom Type Cable Trays#solid bottom cable trays#solid bottom tray#Cable Tray Manufacturer#cable tray manufacturer in Hyderabad#Cable Tray Covers#cable tray cover types#ladder type cable tray with cover#perforated cable tray cover#ladder cable tray cover#perforated cable tray with cover#cable tray manufacturers#cable tray manufacturers in Hyderabad#Raceway Cable Tray Manufacturer in Hyderabad#raceway cable tray#electrical cable tray#cable tray covers#solar module mounting structures#false ceiling sections#stainless steel grating manufacturers#steel reinforcement manufacturers#false ceiling channels types#Types of Ceiling Channels Used In False Ceiling

1 note

·

View note

Text

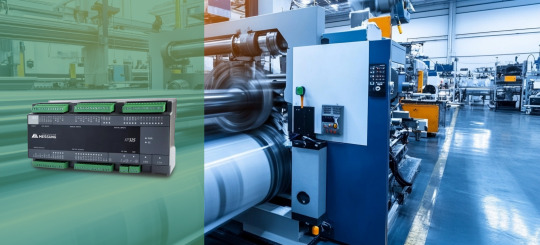

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung���s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

The Role of ERP in Managing Quality Control in Manufacturing

In the highly competitive manufacturing sector, maintaining stringent quality control is not just a necessity but a strategic advantage. In a landscape where efficiency and precision define success, integrating ERP for manufacturing companies in India has become a game-changer. The role of manufacturing ERP software in India extends beyond operational management; it plays a pivotal part in ensuring quality control throughout the production lifecycle.

Understanding the Need for Quality Control in Manufacturing

Quality control ensures that products meet predefined standards, adhere to regulations, and satisfy customer expectations. Without effective systems in place, manufacturing companies risk producing defective products, incurring financial losses, and damaging their reputation. This is where manufacturing enterprise resource planning software in India comes into play. By centralizing data and streamlining processes, ERP systems empower manufacturers to monitor, measure, and enhance quality at every stage.

How ERP Facilitates Quality Control in Manufacturing

1. Centralized Data Management

ERP systems consolidate data from various departments into a unified platform. This centralization is crucial for quality control, as it provides real-time access to critical metrics like raw material quality, production processes, and final product evaluations. ERP software companies in India ensure that manufacturers have a single source of truth, enabling faster and more informed decision-making.

2. Automation of Quality Checks

The manufacturing ERP module often includes automated tools for conducting quality checks. By automating repetitive tasks such as inspecting raw materials, testing products, and verifying compliance, ERP reduces human error and enhances efficiency. This capability is particularly valuable for industries with strict quality standards, such as automotive, pharmaceuticals, and electronics.

3. Compliance Management

Staying compliant with industry regulations is non-negotiable for manufacturing companies. ERP systems provide features that help monitor compliance parameters, generate audit reports, and track regulatory changes. ERP software providers in India offer tailored solutions to meet local and global compliance requirements, ensuring seamless operations.

4. Real-Time Analytics and Reporting

Real-time analytics is a cornerstone of modern ERP systems. These tools allow manufacturers to track quality metrics in real-time, identify deviations, and implement corrective actions instantly. The insights gained from these analytics not only improve quality but also drive process optimization.

5. Supply Chain Integration

Quality control begins with raw materials and extends through the supply chain. ERP systems facilitate end-to-end supply chain visibility, enabling manufacturers to assess supplier performance and ensure the quality of incoming materials. Many ERP solution providers in India offer integrated supply chain management modules to support this functionality.

6. Continuous Improvement through Feedback Loops

ERP systems support continuous improvement by capturing and analyzing feedback from quality control processes. This data is invaluable for identifying recurring issues, uncovering root causes, and implementing preventive measures. Top 10 ERP software providers in India have built-in tools for continuous quality enhancement, ensuring sustained excellence.

Benefits of ERP for Quality Control in Manufacturing

Integrating an ERP system offers several tangible benefits for quality control:

Enhanced Traceability: ERP systems provide traceability across the production process, making it easier to track and rectify defects.

Reduced Waste: By identifying inefficiencies and defects early, ERP reduces waste and optimizes resource utilization.

Improved Customer Satisfaction: Consistently delivering high-quality products strengthens customer trust and loyalty.

Cost Savings: Preventing defects and ensuring compliance minimizes the financial risks associated with recalls, fines, and reputational damage.

Choosing the Right ERP Software for Quality Control

Selecting the best ERP solution requires careful consideration of your manufacturing needs. Here are some factors to consider:

Industry-Specific Features: Look for manufacturing ERP software in India that offers modules tailored to your industry.

Scalability: Ensure the ERP system can scale with your business as it grows.

Integration Capabilities: The ERP should integrate seamlessly with your existing systems and technologies.

Vendor Expertise: Collaborate with an ERP software company in India with proven expertise in delivering quality solutions.

Why Indian Manufacturers Need ERP for Quality Control

India's manufacturing sector is poised for growth, driven by initiatives like Make in India and PLI schemes. However, this growth comes with increasing competition and stricter quality expectations. Leveraging ERP software providers in India can give manufacturers the edge they need to thrive in this evolving landscape.

A Trusted Partner for ERP Implementation

With numerous options available, finding the right ERP vendor is crucial. Leading ERP software companies in India offer customized solutions to meet the unique challenges of Indian manufacturers. These providers combine deep industry knowledge with cutting-edge technology to deliver exceptional results.

Shantitechnology: A Trusted Name in ERP Solutions

Shantitechnology, a renowned name among top 10 ERP software providers in India, specializes in delivering robust ERP solutions for manufacturing companies. Our comprehensive manufacturing ERP module is designed to address the intricacies of quality control, ensuring manufacturers achieve excellence with ease.

Conclusion

In the modern manufacturing landscape, quality control is not an isolated function but a core component of operational success. ERP systems empower manufacturers to seamlessly integrate quality control into their workflows, ensuring consistent product excellence. As one of the best ERP software providers in India, Shantitechnology is committed to helping manufacturers navigate the complexities of quality control with innovative ERP solutions. By embracing the right ERP system, Indian manufacturers can enhance their competitive edge, drive customer satisfaction, and achieve sustainable growth.

If you are looking to elevate your quality control processes, partner with a leading ERP software company in India like Shantitechnology. Contact us today to learn more about our customized ERP solutions and how they can transform your manufacturing operations.

#ERP software in India#Top 10 ERP software providers in India#ERP software company in India#Engineering ERP Software company in India#ERP software for engineering companies#Engineering ERP software solution#ERP software for engineering companies in India#ERP software providers in India#ERP software companies in India#ERP solution providers in India#Best ERP software provider in India#ERP for manufacturing company in India#Manufacturing ERP software in India#Manufacturing enterprise resource planning software in India#Manufacturing ERP module

5 notes

·

View notes

Text

Professional Camera Module Supplier

CBRITECH is a Professional Camera Module Supplier, offering cutting-edge imaging solutions for medical, industrial, and consumer applications. Explore our wide range of high-quality camera modules designed for precision and performance. Trust us for innovative designs and reliable products. Visit CBRITECH today for advanced camera module solutions.

0 notes

Text

0 notes

Text

What Are Power Line Filter Modules?

Power line filter modules are electronic components used in both AC and DC power systems. Their primary function is to suppress high-frequency noise interference either introduced from external sources or generated within the equipment itself, preventing these disturbances from propagating through the power lines. Typically, these modules integrate passive components such as inductors and capacitors, forming common-mode and differential-mode filter circuits. Advanced modules may also incorporate active compensation circuits to dynamically suppress high-frequency interference.

Get more details: What Are Power Line Filter Modules?

#electronics#integrated circuits#semiconductor#components#electronic#module#chips#electronic devices#manufacturing#capacitors

0 notes

Text

#solar module manufacturers in india#solar cell manufacturers in india#solar pv module manufacturers in india#solar panel factory in india#solar panel makers in india#solar panel producers in india#solar plate manufacturer in india

1 note

·

View note

Text

Unlocking Potential: Tailored Laser Diode Products for Advanced Applications

In the world of advanced applications, unlocking the full potential of laser diode technology is essential. That’s where tailored laser diode products come into play. These customized solutions are designed to meet the unique demands of advanced applications, offering precise performance and enhanced capabilities.

Tailored laser diode products are carefully crafted to address specific requirements and challenges. Whether it’s in the fields of research, medicine, industrial manufacturing, or beyond, these solutions are engineered to deliver optimal results. By understanding the intricacies of your application, a specialized manufacturer can develop a laser diode product that meets your exact needs.

One of the key advantages of tailored laser diode products is their ability to optimize performance. By customizing parameters such as wavelength, power output, and beam characteristics, the laser diode can be fine-tuned to match the specific requirements of your application. This ensures precise targeting, efficient energy delivery, and accurate results, enabling you to push the boundaries of what’s possible.

Furthermore, tailored laser diode products offer versatility and flexibility. They can be designed to integrate seamlessly into existing systems or workflows, making them a reliable and convenient solution for your application. Whether you require a compact form factor, specific mounting options, or compatibility with other components, the tailored design ensures a perfect fit.

Collaborating with a specialized manufacturer is crucial when seeking tailored laser diode products. These manufacturers have extensive expertise in laser diode technology and can provide valuable insights and recommendations throughout the customization process. Their in-depth knowledge allows them to optimize the product’s design, ensuring it meets your performance targets while maintaining reliability and durability.

Moreover, tailored laser diode products are built to withstand the demands of advanced applications. Robust construction, advanced thermal management, and reliable quality control measures are incorporated into the design to ensure long-lasting performance under challenging conditions. This reliability is essential for critical applications where precision and consistency are paramount.

By choosing tailored laser diode products, you unlock a world of possibilities for your advanced applications. These customized solutions provide the precision, performance, and capabilities needed to excel in your field. With the support of a specialized manufacturer, you can leverage their expertise to create a laser diode product that precisely matches your requirements and empowers you to achieve breakthrough results.

Tailored laser diode products offer a pathway to unlocking the full potential of laser diode technology in advanced applications. Through customization and collaboration with a specialized manufacturer, you can create a laser diode product that meets your specific needs. By optimizing performance, ensuring versatility, and delivering reliability, these tailored solutions open doors to new possibilities and advancements in your field.

0 notes

Text

Allen-bradley 1771-asb Remote I/O Adapter Module - Auto2mation

The Allen-Bradley 1771-ASB Remote I/O Adapter Module is a reliable solution for connecting I/O chassis to PLC systems. Designed for high-speed data exchange, it supports smooth communication between the processor and remote I/O devices. This module is ideal for industrial automation applications, ensuring accurate and timely data transfer. Easy to install in 1771 I/O chassis, it offers solid performance and durability.Perfect for upgrading or maintaining your control systems, this adapter module helps improve efficiency and reduce downtime in industrial environments. Shop now for fast delivery.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Allen-bradley#Adapter#io module

0 notes