#Masterbatch

Explore tagged Tumblr posts

Text

Anti-static agent for plastics

Anti-static agent for plastics are used to reduce the static charge present in plastics.The accumulation of static charge can cause combustion and explosions as well as have an impact on how efficiently dust and electrostatic adsorption work . Therefore, it's important to get rid of static electricity buildup. Utilizing an antistatic agent can make a material's surface more resistive and decrease static electricity buildup.

Ammonium and phosphorus salts are the most common antistatic agents. Plastics frequently utilize this kind of antistatic substance. It performs well against static and has a strong affinity towards polar polymers. By reducing the material's resistance, anti-static chemicals are integrated into polymers to give static protection. Anti-static compounds are included into polymers to provide static protection by lowering the material's resistance. The majority of plastic materials are electrical insulators and can withstand significant static buildup.

Anti-static compounds help plastic surfaces resist the development of electrostatic charges. During the compounding phase of the manufacturing process, they are either applied directly to the surface or combined with additional materials. Leading supplier of anti-static materials for plastics is BS Masterbatches. Depending on your requirements, one can obtain a full list of additives that can be used on your product. To guarantee that the ideal solution is consistently supplied on time they have a R&D team that collaborates closely with clients. They are FDA-approved and their products adhere to a number of international standards for food contact and packaging.

For their clients, they are master producers of plastic masterbatches and experts in providing unique color matching solutions. They have a complete R&D department, allowing them to match every color masterbatch to the specifications of the client.

2 notes

·

View notes

Text

Water tank masterbatches are designed to offer improved color retention, thermal stability, and UV protection. They preserve the structural integrity and aesthetic attractiveness of tanks used in outdoor settings while assisting in extending their lifespan.

#masterbatches#masterbatch#masterbatches manufacturer#masterbatches for water tank#colour masterbatches#colour masterbatches manufacturer#water tank application

0 notes

Text

Sustainable Masterbatch Solutions: The Shift Towards Eco-Friendly Additives

The global masterbatch market size is expected to reach USD 9.65 billion by 2030 to expand at a CAGR of 6.6% from 2025 to 2030 as per the new report by Grand View Research, Inc. Increasing replacement of metal with plastic is projected to fuel the market growth. In addition, rising demand from the European region is expected to propel the demand over the forecast period.

Masterbatch Market Report Highlights

The black type dominated the market with a revenue share of 28.6% in 2024. This growth can be attributed to the increasing demand for black masterbatch and the high demand for tires, PVC containers, and other products for application in the automotive and transportation, building and construction, agriculture, and packaging industries.

The polypropylene (PP) carrier polymer segment dominated the global masterbatch industry with the highest revenue share of 26.7% in 2024, primarily driven by the excellent mechanical strength and flexibility offered by polypropylene.

The packaging masterbatch segment dominated the market with a revenue share of 27.0% in 2024. Its high share can be attributable to the packaging industry, which includes retail, industrial, and consumer packaging and includes flexible and rigid options.

Asia Pacific masterbatch market dominated the global market and accounted for the largest revenue share of 30.6% in 2024. This growth can be attributed to the presence of several end-use industries, including automotive and transportation, packaging, building and construction, and consumer goods.

For More Details or Sample Copy please visit link @: Masterbatch Market Report

In terms of revenue, black masterbatch was the largest type segment in 2022 and the trend is anticipated to continue over the forecast period. The increasing need for improving the surface appearance of plastic components in automotive and transportation, building and construction, and consumer goods is expected to contribute to the growth. Additive masterbatch is being widely used on account of various properties it imparts to plastics such as antistatic, antifoaming, antioxidant, antimicrobial, thermo-stabilizer, barrier properties, metal deactivators, anti-block, flame retardant, UV stabilizer, oxygen scavenger, and abrasion resistance. The growth of the packaging sector, especially plastic packaging, is anticipated to drive the demand.

These are used in various end-use industries, such as packaging, building and construction, consumer goods, automotive and transportation, and agriculture, as it imparts useful functional properties such as smooth surface finish and desired hardness. The increasing spending capability of customers toward purchasing attractively packaged consumer goods is expected to trigger the need for various plastic componentss to improve the appearance and other properties. These factors together are anticipated to boost the market demand over the forecast period.

In terms of revenue, polypropylene (PP) was the largest carrier polymer segment in 2022 and the trend is anticipated to continue over the forecast period. Polypropylene offers excellent electrical resistance and does not present stress-cracking problems at high temperatures and strong chemicals. As such, it is useful in both rigid and flexible packaging applications. The demand for polypropylene as a carrier polymer is projected to increase owing to its excellent mechanical strength and flexibility offered by it. Polypropylene also enhances the quality of surfaces. It is lightweight and therefore, is used to replace metal components in the automotive industry.

List of Key Players of Masterbatch Market

Schulman, Inc.

Ampacet Corporation

Cabot Corporation

Clariant AG

Global Colors Group

Hubron International Ltd.

Penn Color, Inc.

Plastiblends India Ltd.

PolyOne Corporation

Tosaf Group

We have segmented the global masterbatch market on the basis of type, carrier polymer, end use, and region

#Masterbatch#PlasticsIndustry#ColorMasterbatch#AdditiveMasterbatch#FillerMasterbatch#PolymerSolutions#PlasticAdditives#SustainablePlastics#PackagingIndustry#AutomotivePlastics#PlasticManufacturing#InnovationInPlastics#RecyclablePlastics#MasterbatchMarket#SmartMaterials

0 notes

Text

Masterbatch Manufacturer & Supplier | Anant Polymers

Nanocoppers is a leading Masterbatch Manufacturer and Masterbatch Supplier, offering a wide range of high-quality masterbatches to meet the diverse needs of the plastics industry. Our Masterbatch products include color masterbatch, white and black masterbatch, and additive masterbatch, which are used to enhance the performance and aesthetic appeal of plastic products. These masterbatches are meticulously formulated by combining pigments, dyes, and additives with a polymer carrier to ensure consistent, vibrant coloration and functional properties. As a trusted Masterbatch Manufacturer, we focus on providing superior color consistency, improved processing efficiency, and enhanced durability for plastic products. Whether you're involved in extrusion, injection molding, or blow molding, our masterbatches are designed to optimize the quality of your end products while maintaining cost-effectiveness. Our Masterbatch solutions help to streamline the manufacturing process by reducing the need for expensive raw pigments, offering higher accuracy in dosing, and minimizing production variances. Our Masterbatch Supplier services are backed by cutting-edge technology and a deep understanding of customer needs, ensuring that we deliver top-notch products that meet industrial standards.

For More Details Clicks Here - https://www.nanocoppers.com/masterbatch.html

0 notes

Text

Masterbatch Prices: Trends, Factors, and Future Projections

Masterbatch, a concentrated mixture of pigments and additives encapsulated during a heat process into a carrier resin, plays a pivotal role in the plastics industry. Used for coloring or imparting various properties to polymers, masterbatch is an indispensable material for manufacturers worldwide. However, like many raw materials, its price is subject to various factors, including supply-demand dynamics, raw material costs, and global economic conditions.

Recent Trends in Masterbatch Prices

In recent years, the masterbatch market has seen significant price fluctuations driven by the global economic environment. For instance, the COVID-19 pandemic caused disruptions in supply chains, leading to increased costs of raw materials such as polymers and pigments. As economies recovered, there was a surge in demand for plastics in packaging, automotive, and construction, further influencing masterbatch prices.

In 2024, the masterbatch market witnessed a mixed trend. While the prices of color masterbatches remained stable due to steady demand from the consumer goods sector, additive masterbatches saw an uptick in costs. This increase was attributed to growing requirements for advanced properties like UV resistance, flame retardancy, and antimicrobial functionalities in packaging and healthcare applications.

Get Real time Prices for Masterbatch: https://www.chemanalyst.com/Pricing-data/masterbatch-1117

Factors Influencing Masterbatch Prices

Raw Material Costs: The primary component of masterbatch, polymers, is derived from crude oil or natural gas. Fluctuations in crude oil prices directly impact polymer costs and, consequently, masterbatch prices. Additionally, pigments and additives used in masterbatch production are subject to market dynamics and availability, influencing overall costs.

Energy Costs: The production of masterbatch involves energy-intensive processes. Rising energy prices, especially in regions dependent on non-renewable energy sources, have pushed production costs higher.

Supply Chain Disruptions: Global events such as geopolitical tensions, trade restrictions, or natural disasters can disrupt the supply chain, causing shortages of raw materials and escalating prices.

Environmental Regulations: Increasing emphasis on sustainability has led to higher costs for eco-friendly additives and pigments. Manufacturers adhering to stringent environmental standards often face elevated production expenses, which reflect in the end-product price.

Market Demand: The demand for masterbatch varies across sectors like automotive, construction, and packaging. A surge in demand in any of these industries can drive prices upward, while a downturn can have the opposite effect.

Regional Variations

Masterbatch prices can differ significantly across regions. For instance, Asia-Pacific, being a hub for polymer production and manufacturing, often benefits from competitive pricing. On the other hand, regions like Europe and North America, with higher energy costs and stricter environmental regulations, may experience elevated prices.

Future Projections

To mitigate price volatility, many manufacturers are investing in research and development to create sustainable and cost-effective masterbatch solutions. Additionally, recycling and reusing masterbatch materials are gaining traction, offering potential cost benefits and environmental advantages.

Conclusion

Masterbatch prices are shaped by a complex interplay of factors ranging from raw material costs to market demand. While challenges such as supply chain disruptions and rising energy costs persist, innovations and sustainability efforts promise to reshape the market dynamics. For manufacturers and buyers, staying informed about these trends is crucial for strategic decision-making in this evolving landscape.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Masterbatch#Masterbatch Price#Masterbatch Prices#Masterbatch Pricing#Masterbatch News#Masterbatch Price Monitor#Masterbatch Database#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Introduction to basic knowledge of color masterbatch (color species)

1. What is color masterbatch? Color masterbatch is also known as color type. Color masterbatch is a new type of special colorant for polymer materials, also known as pigment preparation.It is composed of three basic elements: pigments or dyes, carriers, and additives. It is an aggregate obtained by uniformly loading an ultra-constant amount of pigment or dye in resin, which can be called a…

View On WordPress

0 notes

Text

Anti Bacterial / Silver Copper Antimicrobial | Anant Polymers

At Nanocoppers.com, we specialize in providing innovative Masterbatch solutions that enhance the performance and functionality of your products. Our diverse range of high-quality Masterbatches is designed to meet the unique demands of various industries. From vibrant Colour Masterbatches that ensure consistent and brilliant coloration to Anti-Bacterial Masterbatches that promote hygiene and safety, we have the ideal solution for your needs. Our Silver Anti-Bacterial Masterbatch delivers exceptional antimicrobial protection, making it the perfect choice for applications where cleanliness is critical. Infused with silver ions, this Masterbatch effectively inhibits bacterial growth, offering long-lasting defense against harmful microorganisms. Alternatively, our Copper Antimicrobial Masterbatch harnesses the natural properties of copper to provide an additional layer of hygiene and safety, ideal for industries looking to elevate their product standards.

For More Details Clicks Here - https://www.nanocoppers.com/

0 notes

Text

پرکاربردترین مستربچ ها در صنعت

دوستان عزیز در حال مطالعه یک مقاله در لینکدین بودم درباره اینکه کدام مستربچ ها بیشترین کاربرد را در صنعت تزریق پلاستیک دارند و هر یک از آنها چه ویژگی های خاص و منحصر به فردی دارد. برای مطالعه این مقاله روی این لینک The most widely used masterbatches in the industry کلیک کنید. از مزیت های مهم این مقاله این است که هر مستربچ کاربردی را از نظر ترکیبات به صورت خلاصه تشریح کرده و علت استفاده از آن در هر مورد را توضیح داده است.

0 notes

Text

For More Enquiry.. Visit us- www.bajajmb.com or call now on 7030924248

1 note

·

View note

Text

What is masterbatch?

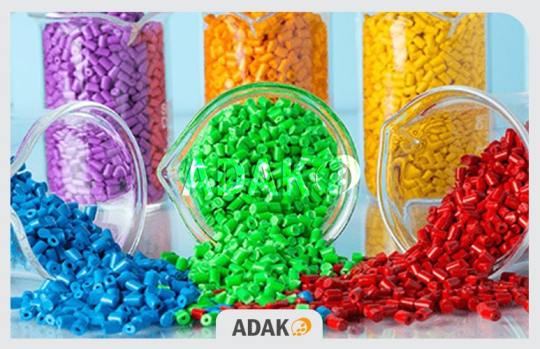

What is masterbatch? Masterbatch are similar to granular seeds. with the difference that unlike granular seeds, they are not made of polymer. Rather, they include additives, polymer base and compatibilizing agent. The polymer base and compatibilizing agent can make it better combined with granular grains. Additives can also include color, fillers, and compounds that ultimately change the properties of the final plastic. In fact, the additive part of Masterbatch is the most important factor that has led to the general changes of this material. Changing materials, color, fillers or other compounds that lead to changing properties are all added as additives. This factor has caused these materials to have various uses and functions.

source: adakeurope.com

1 note

·

View note

Text

Lifeline Technologies manufactures high-quality Rust Preventive Additive that is Effective on corrosion protection and packaging combined in one step and much more. Contact us for pricing and other details.

"Anti Corrosive Additive" & "VCI Masterbatch"

1 note

·

View note

Text

Masterbatch feito com PP: o que é e quais são as suas aplicações

Acesse https://jornalmontesclaros.com.br/2023/12/11/masterbatch-feito-com-pp-o-que-e-e-quais-sao-as-suas-aplicacoes/

Masterbatch feito com PP: o que é e quais são as suas aplicações

0 notes

Text

The purpose of each type of masterbatch is to meet industry-specific requirements, improve durability, and improve plastic processes. Manufacturing companies may produce high-performance, reasonably priced, and environmentally responsible plastic products by selecting the appropriate masterbatch.

#masterbatch#masterbatches#types of masterbatch#colour masterbatches#masterbatches manufacturer#masterbatches manufacturer near me#masterbatches manufacturer and supplier in india#masterbatches manufactrurer in india

0 notes

Text

Masterbatch Manufacturing Company for Sale - Explore a Lucrative Business Opportunity

Discover an exceptional business opportunity! This well-established masterbatch manufacturing company is up for sale on business deals. Tap into the thriving plastics industry with a turnkey operation, cutting-edge technology, and a loyal customer base. Don't miss out, inquire now!

0 notes

Text

Colour Masterbatches

With a range of more than 25000 colors in our databank we're almost sure we have a match for the color you are looking for - not only for commodity polymers but for engineering plastics as well.

Besides our databank and standard colors, we can match a color according to your physical sample, LAB values or even a Pantone or RAL shade card number. Our team of color technicians can practically match any color that you can dream of.

#Colour masterbatch#Masterbatch#Plastic Products#White Masterbatch#Black Masterbatch#Additive Masterbatch

0 notes

Text

Masterbatch Price | Prices | Pricing | News | Database | Chart

Masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin, used to color raw polymer materials or impart specific properties to plastics. The pricing of masterbatch fluctuates based on a variety of factors, including the type of additives, raw material costs, supply chain dynamics, market demand, and global economic conditions. These factors make masterbatch prices a topic of significant interest in industries that rely on plastics, such as packaging, automotive, electronics, and consumer goods. Understanding the intricacies of masterbatch pricing requires an in-depth look at the components that affect these costs.

One of the primary drivers of masterbatch prices is the cost of raw materials, specifically pigments and polymers. Pigments, especially those that are rare or difficult to produce, can greatly influence the cost of masterbatch. For example, metallic pigments or those used for special effects tend to be more expensive than basic colorants. The price of polymers, used as the carrier resin in masterbatch, also plays a critical role. Common polymers like polyethylene (PE) and polypropylene (PP) are heavily dependent on crude oil prices, which fluctuate based on geopolitical conditions, oil production levels, and market demand. Any volatility in crude oil prices directly impacts the cost of these polymers, and consequently, the cost of masterbatch.

Get Real Time Prices for Masterbatch : https://www.chemanalyst.com/Pricing-data/masterbatch-1117

Market demand is another crucial factor influencing masterbatch prices. When demand for certain plastics rises—whether due to an increase in consumer products, medical equipment, or packaging needs—the need for masterbatch also increases. In particular, sectors like the automotive and electronics industries, which often require specialized and high-performance masterbatches, tend to exert significant pressure on prices when demand spikes. On the other hand, periods of low demand can lead to price stabilization or even decreases, as manufacturers seek to offload inventory or remain competitive in a tight market. Global economic trends also play a role; in times of economic downturn, industries that consume large volumes of plastic may reduce their output, affecting masterbatch demand and pricing.

Another factor to consider is the type of masterbatch being produced. There are several kinds, including color masterbatches, additive masterbatches, and combination masterbatches. Color masterbatches typically have a more straightforward pricing structure because they primarily involve pigments and polymers. However, additive masterbatches, which include UV stabilizers, flame retardants, or antimicrobial agents, tend to be more expensive due to the complexity of their formulations and the cost of the additives themselves. Combination masterbatches, which incorporate both color and functional additives, can be even pricier because they provide multiple benefits in a single product.

Sustainability trends are also shaping the masterbatch market, influencing prices in unexpected ways. As industries move towards greener, more sustainable practices, demand for eco-friendly masterbatches is rising. These masterbatches, made with biodegradable polymers, recycled content, or natural pigments, often come with a premium price tag due to the higher cost of sourcing sustainable materials and meeting strict environmental regulations. However, the long-term benefits of using eco-friendly masterbatches, such as reduced carbon footprints and enhanced product appeal to environmentally conscious consumers, are making them an increasingly popular choice. This trend could lead to a more significant price divergence between conventional and sustainable masterbatches in the future.

Technological advancements in masterbatch production also influence pricing. As manufacturers invest in newer, more efficient production technologies, the initial costs of these investments may lead to a temporary rise in masterbatch prices. However, in the long run, these innovations can lead to greater efficiencies, reduced waste, and lower production costs, which could eventually bring down the price of masterbatches. For instance, the use of advanced compounding equipment or digital manufacturing techniques can improve the consistency and quality of masterbatches, giving producers a competitive edge without necessarily inflating prices.

Lastly, regional differences in masterbatch pricing are worth noting. Countries with well-developed petrochemical industries, such as those in the Middle East or the United States, may benefit from lower raw material costs, which can make masterbatches cheaper to produce in these regions. In contrast, countries that rely heavily on imported raw materials may experience higher production costs, resulting in pricier masterbatches. Trade policies, tariffs, and international relations also play a role in shaping these regional pricing differences, as duties on raw materials or finished goods can either raise or lower costs depending on the specific situation.

In conclusion, masterbatch prices are influenced by a complex web of factors, including raw material costs, supply chain dynamics, market demand, and regional conditions. Fluctuations in oil prices, technological advancements, and the increasing focus on sustainability are all contributing to the evolving landscape of masterbatch pricing. For manufacturers and consumers alike, staying informed about these trends is crucial to making well-informed decisions in industries that depend on plastics and polymer-based products. As the world shifts toward more sustainable practices and the global economy continues to evolve, the masterbatch market is likely to see further changes in pricing, driven by innovation and environmental considerations.

Get Real Time Prices for Masterbatch : https://www.chemanalyst.com/Pricing-data/masterbatch-1117

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Masterbatch#Masterbatch Price#Masterbatch Prices#Masterbatch Pricing#Masterbatch News#Masterbatch Price Monitor

0 notes