#Michoud Assembly Facility

Explore tagged Tumblr posts

Text

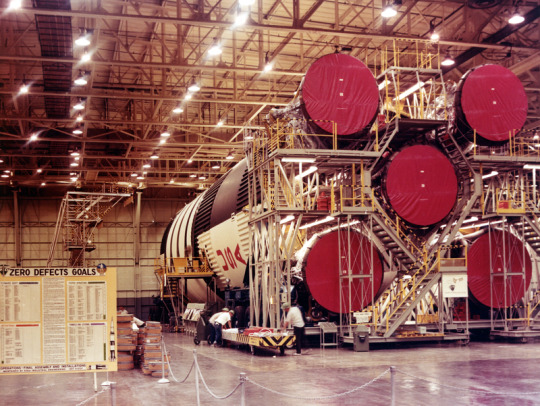

"This image depicts a Boeing worker installing an F-1 engine on the Saturn V S-IC flight stage at the Michoud Assembly Facility (MAF). The Saturn IB and Saturn V first stages were manufactured at the MAF, located 24 kilometers (approximately 15 miles) east of downtown New Orleans, Louisiana. The prime contractors, Chrysler and Boeing, jointly occupied the MAF. The basic manufacturing building boasted 43 acres under one roof. By 1964, NASA added a separate engineering and office building, vertical assembly building, and test stage building."

Date: November 1967

NASA ID: 6760478

#Rocketdyne F-1#F-1#Rocket Engine#S-IC#Saturn V#Rocket#NASA#Apollo Program#Construction#Michoud Assembly Facility#New Orleans#Louisiana#November#1967#my post

58 notes

·

View notes

Text

First engine installed on Artemis 2 Moon rocket

The installation of RS-25 engine E2059 at the base of the core stage for NASA’s second Space Launch System rocket. Credit: NASA Technicians have installed the first engine on the core stage of the second Space Launch System rocket, which is tasked with sending the first people to the Moon in more than a half century. Continue reading Untitled

View On WordPress

14 notes

·

View notes

Text

ALT: This video shows blades of grass moving in the wind on a beautiful day at NASA’s Michoud Assembly Facility in New Orleans. In the background, we see the 212-foot-core stage for the powerful SLS (Space Launch System) rocket used for Artemis I. The camera ascends, revealing the core stage next to a shimmering body of water as technicians lead it towards NASA’s Pegasus barge. Credit: NASA

The SLS (Space Launch System) Core Stage by Numbers

Technicians with NASA and SLS core stage lead contractor Boeing, along with RS-25 engines lead contractor Aerojet Rocketdyne, an L3Harris Technologies company, are nearing a major milestone for the Artemis II mission. The SLS (Space Launch System) rocket’s core stage for Artemis II is fully assembled and will soon be shipped via barge from NASA’s Michoud Assembly Facility in New Orleans to the agency’s Kennedy Space Center in Florida. Once there, it will be prepped for stacking and launch activities.

Get to know the core stage – by the numbers.

Standing 212 feet tall and measuring 27.6 feet in diameter, the SLS core stage is the largest rocket stage NASA has ever built. Due to its size, the hardware must be shipped aboard NASA’s Pegasus barge.

900 miles

Once loaded, the barge – which was updated to accommodate the giant core stage -- will travel 900 miles to Florida across inland and ocean waterways. Once at Kennedy, teams with our Exploration Ground Systems team will complete checkouts for the core stage prior to stacking preparations.

18 Miles + 500 Sensors

As impressive as the core stage is on the outside, it’s also incredible on the inside. The “brains” of the rocket consist of three flight computers and special avionics systems that tell the rocket what to do. This is linked to 18 miles of cabling and more than 500 sensors and systems to help feed fuel and steer the four RS-25 engines.

8.8 million

Speaking of engines… Our SLS Moon rocket generates approximately 8.8 million pounds of thrust at launch. Two million pounds come from the four powerful RS-25 engines at the base of the core stage, while each of the two solid rocket boosters produces a maximum thrust of 3.6 million pounds. Together, the engines and boosters will help launch a crew of four Artemis astronauts inside NASA’s Orion spacecraft beyond Earth orbit to venture around the Moon.

733,000 Gallons

Achieving the powerful thrust required at launch calls for a large amount of fuel - 733,000 gallons, to be precise. The stage has two huge propellant tanks that hold the super-cooled liquid hydrogen and liquid oxygen that make the rocket “go.” A new liquid hydrogen storage sphere has recently been built at Kennedy, which can store 1.25 million gallons of liquid hydrogen.

Four

The number four doesn’t just apply to the RS-25 engines. It’s also the number of astronauts who will fly inside our Orion spacecraft atop our SLS rocket for the first crewed Artemis mission. When NASA astronauts Reid Wiseman, Christina Koch, and Victor Glover along with CSA astronaut Jeremy Hansen launch, they will be the first astronauts returning to the Moon in more than 50 years.

Make sure to follow us on Tumblr for your regular dose of space!

966 notes

·

View notes

Text

Artemis III core stage receives thermal protection coating

NASA completed another step to ready its SLS (Space Launch System) rocket for the Artemis III mission as crews at the agency's Michoud Assembly Facility in New Orleans recently applied a thermal protection system to the core stage's liquid hydrogen tank.

Building on the crewed Artemis II flight test, Artemis III will add new capabilities with the human landing system and advanced spacesuits to send the first astronauts to explore the lunar South Pole region and prepare humanity to go to Mars. Thermal protection systems are a cornerstone of successful spaceflight endeavors, safeguarding human life, and enabling the launch and controlled return of spacecraft.

The tank is the largest piece of SLS flight hardware insulated at Michoud. The hardware requires thermal protection due to the extreme temperatures during launch and ascent to space—and to keep the liquid hydrogen at minus 423 degrees Fahrenheit on the pad prior to launch.

"The thermal protection system protects the SLS rocket from the heat of launch while also keeping the thousands of gallons of liquid propellant within the core stage's tanks cold enough. Without the protection, the propellant would boil off too rapidly to replenish before launch," said Jay Bourgeois, thermal protection system, test, and integration lead at NASA Michoud. "Thermal protection systems are crucial in protecting all the structural components of SLS during launch and flight."

In February, Michoud crews with NASA and Boeing, the SLS core stage prime contractor, completed the thermal protection system on the external structure of the rocket's liquid hydrogen propellant fuel tank, using a robotic tool in what is now the largest single application in spaceflight history.

IMAGE: Teams at NASA’s Michoud Assembly Facility in New Orleans move a liquid hydrogen tank for the agency’s SLS (Space Launch System) rocket into the factory’s final assembly area on April 22, 2025. The propellant tank is one of five major elements that make up the 212-foot-tall rocket stage. Credit: NASA/Steven Seipel

The robotically controlled operation coated the tank with spray-on foam insulation, distributing 107 feet of the foam to the tank in 102 minutes. When the foam is applied to the core stage, it gives the rocket a canary yellow color. The Sun's ultraviolet rays naturally "tan" the thermal protection, giving the SLS core stage its signature orange color, like the space shuttle external tank.

While it might sound like a task similar to applying paint to a house or spraying insulation in an attic, it is a much more complex process. The flexible polyurethane foam had to withstand harsh conditions for application and testing. Additionally, there was a new challenge: spraying the stage horizontally, something never done previously during large foam applications on space shuttle external tanks at Michoud. All large components of space shuttle tanks were in a vertical position when sprayed with automated processes.

Overall, the rocket's core stage is 212 feet with a diameter of 27.6 feet, the same diameter as the space shuttle's external tank. The liquid hydrogen and liquid oxygen tanks feed four RS-25 engines for approximately 500 seconds before SLS reaches low Earth orbit and the core stage separates from the upper stage and NASA's Orion spacecraft.

"Even though it only takes 102 minutes to apply the spray, a lot of careful preparation and planning is put into this process before the actual application of the foam," said Boeing's Brian Jeansonne, the integrated product team senior leader for the thermal protection system at NASA Michoud.

"There are better process controls in place than we've ever had before, and there are specialized production technicians who must have certifications to operate the system. It's quite an accomplishment and a lot of pride in knowing that we've completed this step of the build process."

The core stage of SLS is the largest NASA has ever built by length and volume, and it was manufactured at Michoud using state-of-the-art manufacturing equipment. Michoud is a unique, advanced manufacturing facility where the agency has built spacecraft components for decades, including the space shuttle's external tanks and Saturn V rockets for the Apollo program.

youtube

3 notes

·

View notes

Text

A Michoud Assembly Facility da NASA em Nova Orleans inclui 43 acres de espaço de fabricação sob o mesmo teto — um espaço grande o suficiente para conter mais de 31 campos de futebol profissional. Crédito: NASA

2 notes

·

View notes

Text

NASA Moon Rocket Stage for Artemis II Moved Prepped for Shipment

NASA is preparing the SLS (Space Launch System) rocket core stage that will help power the first crewed mission of NASA’s Artemis campaign for shipment. On July 6, NASA and Boeing, the core stage lead contractor, moved the Artemis II rocket stage to another part of the agency’s Michoud Assembly Facility in New Orleans. The […] from NASA https://ift.tt/WMDc1E2

3 notes

·

View notes

Text

Moon and Flag at NASA Michoud

Monika Luabeya May 23, 2025 Just after sunrise, the waning gibbous moon sets just behind a waving United States flag on March 19, 2025, in this image from NASA’s Michoud Assembly Facility in New Orleans. The waning gibbous moon phase comes after the full moon. As the Moon begins its journey back toward the Sun, the opposite side of the Moon now reflects the Moon’s light. The lighted side…

0 notes

Text

Moon and Flag at NASA Michoud https://ift.tt/WY8k2zA The waning gibbous moon sets behind a flag at NASA’s Michoud Assembly Facility in New Orleans just after sunrise on Wednesday, March 19, 2025. via NASA Image of the Day https://ift.tt/6oujvzD May 23, 2025 at 09:02PM

0 notes

Text

Boeing and NASA Advance Artemis III with Key Milestone, But SLS Future Remains Uncertain

Teams at NASA’s Michoud Assembly Facility in New Orleans move a liquid hydrogen tank for the agency’s SLS (Space Launch System) rocket into the factory’s final assembly.Photo: Boeing / NASA NASA and Boeing have taken a crucial step forward in prepping the Space Launch System (SLS) rocket for Artemis III—the mission slated to return astronauts to the Moon—by completing thermal insulation on the…

0 notes

Text

Robots, Rovers, and Regolith: NASA Brings Exploration to FIRST Robotics 2025 - NASA

New Post has been published on https://sunalei.org/news/robots-rovers-and-regolith-nasa-brings-exploration-to-first-robotics-2025-nasa/

Robots, Rovers, and Regolith: NASA Brings Exploration to FIRST Robotics 2025 - NASA

What does the future of space exploration look like? At the 2025 FIRST Robotics World Championship in Houston, NASA gave student robotics teams and industry leaders a first-hand look—complete with lunar rovers, robotic arms, and real conversations about shaping the next era of discovery.

NASA engaged directly with the Artemis Generation, connecting with more than 55,000 students and 75,000 parents and mentors. Through interactive exhibits and discussions, students explored the agency’s robotic technologies, learned about STEM career paths and internships, and gained insight into NASA’s bold vision for the future. Many expressed interest in internships—and dreams of one day contributing to NASA’s missions to explore the unknown for the benefit of all humanity.

Multiple NASA centers participated in the event, including Johnson Space Center in Houston; Jet Propulsion Laboratory in Southern California; Kennedy Space Center in Florida; Langley Research Center in Virginia; Ames Research Center in California; Michoud Assembly Facility in New Orleans; Armstrong Flight Research Center in Edwards, California; Glenn Research Center in Cleveland; Goddard Space Flight Center in Greenbelt, Maryland; and the Katherine Johnson Independent Verification and Validation Facility in West Virginia. Each brought unique technologies and expertise to the exhibit floor.

Displays highlighted key innovations such as:

Space Exploration Vehicle: A pressurized rover prototype built for human exploration of planetary surfaces, offering attendees a look at how future astronauts may one day travel across the Moon or Mars.

Mars Perseverance Rover: An exhibit detailing the rover’s mission to search for ancient microbial life and collect samples for future return to Earth.

“These demonstrations help students see themselves in NASA’s mission and the next frontier of lunar exploration,” said Johnson Public Affairs Specialist Andrew Knotts. “They can picture their future as part of the team shaping how we live and work in space.”

Since the FIRST Championship relocated to Houston in 2017, NASA has mentored more than 250 robotics teams annually, supporting elementary through high school students. The agency continued that tradition for this year’s event, and celebrated the fusion of science, engineering, and creativity that defines both robotics and space exploration.

Local students also had the chance to learn about the Texas High School Aerospace Scholars program, which offers Texas high school juniors hands-on experience designing space missions and solving engineering challenges—an early gateway into NASA’s world of exploration.

As the competition came to a close, students and mentors were already looking ahead to the next season—energized by new ideas, strengthened friendships, and dreams of future missions.

“It was a true privilege to represent NASA to so many inspiring students, educators, and mentors,” said Jeanette Snyder, aerospace systems engineer for Gateway. “Not too long ago, I was a robotics student myself, and I still use skills I developed through FIRST Robotics in my work as a NASA engineer. Seeing so much excitement around engineering and technology makes me optimistic for the future of space exploration. I can’t wait to see these students become the next generation of NASA engineers and world changers.”

With the enthusiastic support of volunteers, mentors, sponsors, and industry leaders, and NASA’s continued commitment to STEM outreach, the future of exploration is in bold, capable hands.

See the full event come to life in the panorama videos below.

0 notes

Text

"Production facilities of the Boeing Aircraft Corporation at the Michoud Plant in New Orleans, Louisiana showing one of the first stages of the Saturn V vehicle in the final phases of assembly prior to shipment."

Date: April 1967

NASA ID: 97-1213

#Saturn V#S-IC#rocket#Apollo Program#NASA#construction#Michoud Assembly Facility#MAF#New Orleans#Louisiana#April#1967#my post

85 notes

·

View notes

Link

In this October 13, 2024, image, Comet C/2023 A3 (Tsuchinshan-ATLAS) is seen passing over NASA’s Michoud Assembly Facility in New Orleans. This comet hails from the distant Oort Cloud, far beyond Pluto and the outermost reaches of the Kuiper Belt. While Comet C/2023 A3 will remain visible through early November, the optimal time for observation [...]

1 note

·

View note

Text

NASA Michoud Continues Work on Evolved Stage of SLS Rocket for Future Artemis Missions

Manufacturing equipment that will be used to build components for NASA’s SLS (Space Launch System) rocket for future Artemis missions is being installed at the agency’s Michoud Assembly Facility in New Orleans, Louisiana. The novel tooling will be used to produce the SLS rocket’s advanced exploration upper stage, or EUS, in the factory’s new manufacturing […] Continue reading NASA Michoud…

0 notes

Text

A scathing report from NASA's Office of Inspector General (OIG) has highlighted several critical issues related to the development of the next version of the agency's Space Launch System megarocket, which will likely delay Artemis moon missions. The report, released by NASA's internal watchdog on Aug. 8, focuses on the gigantic Space Launch System (SLS) Block 1B and its Exploration Upper Stage (EUS). Block 1B is designed to increase the amount of cargo SLS can carry to the moon. The upgraded version is key to NASA's long-term lunar plans and will be used for Artemis 4, currently scheduled to launch in 2028. The OIG found that work being done by Boeing — the prime contractor for the SLS core and upper stages, as well as the rocket's flight avionics suite — at NASA's Michoud Assembly Facility in New Orleans does not meet international standards or agency requirements. This has led to numerous Corrective Action Requests (CARs) issued by the Defense Contract Management Agency (DCMA). A CAR, which can vary in level of severity, indicates that work has not conformed to specific contract requirements.

0 notes

Video

KSC-20240724-PH-JBP01_0034 by NASA Kennedy Via Flickr: In this aerial view, NASA’s Pegasus barge, carrying the agency’s massive SLS (Space Launch System) core stage, arrives at NASA’s Kennedy Space Center Complex 39 turn basin wharf in Florida on Tuesday, July 23, 2024, after journeying from the agency’s Michoud Assembly Facility in New Orleans. The core stage is the next piece of Artemis hardware to arrive at the spaceport and will be offloaded and moved to NASA Kennedy’s Vehicle Assembly Building, where it will be prepared for integration ahead of the Artemis II launch. Photo credit: NASA/Jamie Peer and Isaac Hutson NASA image use policy.

#Artemis#Artemis II#Core Stage#Crew#EGS#Exploration Ground Systems#Kennedy#Kennedy Space Center#Mars#Moon#NASA#Orion#Pegasus#Pegasus barge#SLS#Space Launch System#UAS#VAB#Vehicle Assembly Building#barge#drone#flickr

1 note

·

View note

Text

[Notícias da sede da NASA] AVISO: NASA convida a mídia para evento de lançamento do estágio do foguete lunar Artemis II N NASA há 18 minutosDetalhes 7 de junho de 2024

ASSESSORIA: M24-079

NASA convida a mídia para evento de lançamento do estágio do foguete lunar Artemis II

O estágio central é a espinha dorsal do foguete SLS (Sistema de Lançamento Espacial) que ajudará a impulsionar a missão Artemis II da NASA para enviar uma tripulação de quatro astronautas ao redor da Lua em 2025. Aqui, o estágio central está atualmente atrás de andaimes para permitir que o trabalho continue. no Michoud Assembly Facility da NASA em Nova Orleans. Os dois enormes tanques de propelente do palco comportam coletivamente 733.000 galões de propelente líquido para alimentar os quatro motores RS-25 em sua base. Após as análises de aceitação do hardware e as verificações finais, o palco estará preparado para entrega através da barcaça Pegasus da agência ao Centro Espacial Kennedy da NASA, na Flórida, para os preparativos do lançamento do Artemis II. (NASA/Eric Bordelon)

#tumblr#fotos#welberfotos#postar#photos#welberdesignershop#cars#photo#foto#carros#nasa#nasa photos#space

3 notes

·

View notes