#Mini CNC Machine

Explore tagged Tumblr posts

Text

CNC Machining Center,CNC Machining Service,CNC Machining Parts

🔥Unlock the key to manufacturing miracles! 🚀 Walk into our CNC machining center and witness the birth of precision art! 🎯 From design drawings to precision parts, every process shines with the light of technology and craftsmanship. 🛠️ CNC machining service, customize your own miracle and make imagination within reach! ✨ Come and watch how we carve ordinary materials into extraordinary works! 🎬 #CNCMiracleMoment #CharmofPrecisionManufacturing #InnovationUnlimitedPossibilities

https://cnc-5-axis.com/cnc-machining-instant-quote/

#What Does CNC Machine Stand For#5 Axis CNC Machining#CNC Grinding Machine#CNC Machine projects#CNC Machine uk#CNC Machines For Sale#CNC Routing Machine#Desktop CNC Machine#Metal CNC Machine#Mini CNC Machine

0 notes

Photo

(通过 5款颠覆性的定制自行车部件:迷你自行车零件如何提升性能-亿鑫精密五金塑胶有限公司_金属_塑料)

#bicycle parts#CNC machining bicycle parts#mini bike parts#lowrider bike parts#Custom bicycle components#CNC machining#Cheap MTB Parts#ike wheel parts#Bicycle CNC parts manufacturer#bike parts#electric bike parts

0 notes

Text

Automatic Feeding Woodworking Lathe Wood Lathe Machine Wood Turning Mini CNC Wood Lathe Machine For Sale

0 notes

Text

I need $378 in 9 hours and idk what to do

I'm trying to find my car title so I can get a title loan but I can't find it ANYWHERE, which is weird because I keep all of my paperwork in one area - except for this one piece, apparently.

I need to pay my phone bill or I get shut off at midnight tonight! If I can get $400 I can buy a copy of my title online and then get a title loan and pay someone back. We would actually pay you back when Raven gets paid at the end of the month.

(I would ideally like to make some more money than that - Raven's birthday is today, and their party is this weekend, and I'd like to be able to get food and a cake.)

I've been applying to jobs left, right, and center - so I need the phone for that - but no one has been responding. They're all jobs I'm qualified for, but my job history of being unable to hold down a job long-term because of my executive dysfunction is NOT HELPING ME.

If you can help in any way, even just a few bucks, my Cashapp, PayPal, Ko-Fi, Chime? All $NovasPrime. Let me know if you need to be paid back and I will do so as soon as we get paid.

÷÷÷÷÷÷÷÷÷÷÷÷

I'm also down to barter my skills for money! I can do 3D rendering for manufacture, and I have a 3D printer! Raven is also a very talented miniature painter, so if you need wargaming minis or D&D figurines designed, printed, painted, and shipped? Cat-Thulu Productions has your back!

~~~~~~~~~~~~~~~

I can also help polish a resume, I can write collegiate papers, I can tutor in English language (especially for writing for college), and I am pretty good at tutoring in sociology, machine/construction math, any kind of stagecraft stuff (behind the scenes stuff like wardrobe and set building - I am not an actor, although I can read scenes OK with you if you need practice).

I am a former journalist and can help format and write press releases, do page layout for print or online publishing (PDF format unless otherwise specified), and minor graphic design.

I CAN do metal stuffs, like writing code for CNC machines, but I don't have access to a full machine to test it out.

I have the stuff to make proxies for card games!

I want to earn money, but I can't find an employer who can accommodate my executive dysfunction, which is, frankly, understandable. So instead, get yourself a cool shiny, or help that you need!

So please, if you can help by commissioning me, or Raven, or both of us, please do! If you can help until we can get a title loan, let me know!

If not, please consider signal boosting. I can't lose my phone right now.

34 notes

·

View notes

Text

So I was watching Scott the Woz rant about his collection of Arcade1Up cabinets and how they're expensive for the little that you get and all I could think of was, "I think I could make that, but better!" And all I started kinda figuring it out, but I don't have all the tools for it, but like, you can make your own Nintendo Switch powered arcade cabinet!

All the complicated tech bits are off the shelf components that require no wiring or soldering or any of that. You've got 8BitDo's arcade controller plugged into a Switch dock where the coin mechanisms would be and then all that goes to a mini flat screen. You can plug those into a power strip mounted inside the cabinet near the back, and then the entire arcade cabinet runs on just one cable plugged into a wall.

I don't have the budget for the hardware or the tools required to fabricate the cabinet itself, but like, if you have the time and the tools, I'm pretty sure this could be built in a week especially with something like a laser cutter or a CNC machine.

Someone please build this!

#Taco talks#woodworking#Nintendo Switch#arcade#the only thing standing between you and the ultimate arcade cabinet is some fabrication and like $200 of tech bits

3 notes

·

View notes

Text

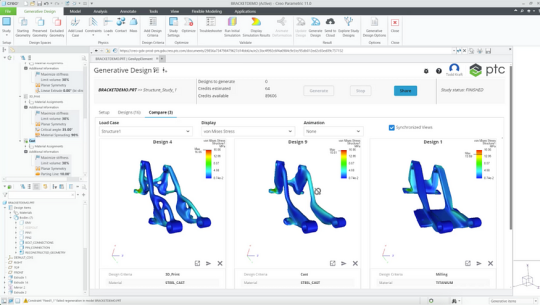

PTC Creo 12: New Tools for Smarter, Faster 3D Design

Discover what’s new in PTC Creo 12 — enhanced simulation, AI-driven design, MBD, and manufacturing tools. Upgrade now with ANH, the trusted PTC Creo reseller in the Delhi NCR region.

Top New Features in Creo 12

1. AI-Driven Design Guidance

Creo 12 takes intelligent design to the next level with built-in AI tools that offer real-time suggestions and improvements.

Get feedback during modeling

Reduce trial-and-error

Improve efficiency with every click

2. Enhanced Model-Based Definition (MBD)

Creo 12 makes MBD more practical and powerful, eliminating the need for traditional 2D drawings.

Improved PMI (Product Manufacturing Information)

Better GD&T annotation support

Clearer data for downstream users

3. Performance & Usability Upgrades

PTC has improved the overall speed, responsiveness, and ease of use:

Faster model regeneration

Smart mini toolbars

Enhanced model tree filters

Customizable dashboards for quick access

4. Creo Simulation Live — More Powerful Than Ever

Simulation Live has been expanded to cover:

Structural & thermal simulations

Better support for nonlinear materials

Real-time design feedback

5. Advanced Multi-Body Design

Creo 12 makes it easier to work with complex parts and assemblies:

Better control over multiple bodies in a single part

New body operations and organization tools

Improved part-to-part interactions

It’s ideal for high-detail engineering and intricate product development.

6. Additive and Subtractive Manufacturing Enhancements

Manufacturing has never been smoother in Creo:

More control over lattice structures

Enhanced 5-axis CAM functionality

New machine support and output formats

Whether you’re 3D printing or using CNC, Creo 12 has you covered.

7. Improved ECAD–MCAD Collaboration

With electronics becoming a bigger part of mechanical products, Creo 12 improves:

PCB visualization

Layer management

Synchronization between electrical and mechanical teams

This helps avoid costly errors during development.

Why Creo 12 is a Must-Have Upgrade

PTC Creo 12 isn’t just for big enterprises — it’s built for everyone who values smart, high-quality design. Whether you’re a design engineer, manager, or product innovator, Creo 12:

Saves time

Reduces errors

Encourages innovation

Supports industry 4.0 goals

Get Creo 12 from Delhi NCR’s Trusted PTC Reseller — ANH

Looking to upgrade your CAD tools or switch to Creo 12? ANH is a leading authorized PTC reseller in the Delhi NCR region. From licensing to training, we help businesses unlock the full potential of Creo.

Contact ANH today to get started with Creo 12!

✅ Conclusion: Welcome to the Future of Design

PTC Creo 12 is more than just an upgrade — it’s a gateway to smarter design, quicker development, and stronger innovation. With new AI tools, advanced simulations, and seamless usability, it’s built to give your team a competitive edge.

Design faster. Design smarter with Creo 12.

0 notes

Text

Drag Racing Differentials and Spools | Strange Engineering

Drag Racing is a competitive sport where drivetrain stability and component performance matter a lot. Differentials or spools play an important role in providing the power to the wheels, helping the drivetrain take quick turns with maximum stability. Strange Engineering is globally known for building high-quality drag racing differentials and spools, and other components with the latest technologies that help drivers stay ahead of their competition during rigorous track conditions.

Strange Engineering drag racing parts are precision-machined from the finest materials, including chrome-moly steel, aircraft aluminum, and heat-treated alloys to provide each component with the ability to withstand the harsh torque loads and constant shock of professional drag racing.

Whether racing in Top Sportsman, Pro Mod, Bracket Racing, or Street/Strip classes, their product offerings include both spools for maximum power transfer and differentials for limited-slip control, providing the racer the ability to build for their specific application and conditions.

Product Features & Benefits

Lightweight Spools for Pure Power Transfer Strange provides full spools and mini spools that are intended to remove slip completely, transmitting equal torque to both wheels. Straight-line performance and high-horsepower drag cars that require consistent traction are perfect for these.

S-Trac Helical Gear Differentials For street/strip applications, Strange's S-Trac differentials offer a smooth, controlled limited-slip operation. These helical-gear diffs, unlike clutch-type units, are quiet and low-maintenance while enhancing traction on acceleration and gear changes.

Precision Engineering and Fit Every component is CNC-machined to precise tolerances, providing flawless fitment to popular rear-end housings such as Ford 9", GM 12-bolt, Dana 60, and others.

Material Superiority Strange spools are manufactured from high-strength 4140 steel or 9310 alloy, offering unbeatable strength without unnecessary weight, key for reducing rotating mass and improving ETs.

Durability You Can Count On All products are race-tested under real-world conditions and trusted by professional drivers, drag racing teams, and weekend warriors alike. Strange Engineering components are built to last season after season.

Easy Integration & Upgrade Paths Designed to work seamlessly with Strange axles and other drivetrain parts, these differentials and spools offer easy upgrade paths for racers growing into faster, more powerful cars.

Why Choose Strange Engineering?

Strange Engineering has decades of experience in building the best auto parts for the racing industry and has a proven track record in delivering top-notch products that are built with precision to provide maximum stability and performance during racing. Their drag racing differentials and spools are one of those products that are known for their ability to provide maximum support to the drivetrain and help racers win any kind of racing.

Explore Now

Ready to upgrade your rear-end setup? Browse the full range of Drag Racing Differentials and Spools at: StrangeEngineering.net

Give your race car the competitive edge it deserves—engineered by racers, for racers.

#drag racing differentials#racing spools#Strange Engineering spools#drag car rear ends#high performance differentials#9 inch Ford spools#lightweight spools#competition differential parts#racing drivetrain components#locked rear differential#drag racing differentials and spools#Strange Engineering drag spools#high strength racing spools#drag car differential components#spool rear end setup#Ford 9 inch racing differential

1 note

·

View note

Text

SCAR-CQB MINI-14 STOCK Clyde Armory Inc CNC machined aircraft grade grey alluminum alloy stock for Mini-14/AC-556 Ruger rifles. Factory 6 position collapsible stock. Magpul pistol grip installed. Quad rail fully vented forend.

0 notes

Text

The Secrets Behind Accuracy Thermoforming Molds Created in China

Vacuum forming and thermoforming have come to be vital production methods throughout sectors, and much of their success exists in the precision of the molds used. In China, a hub for sophisticated manufacturing, thermoforming molds producers have actually created very efficient systems to make sure every mold satisfies limited resistances and exacting standards. From custom thermoforming molds to bespoken vacuum forming molds, precision is constructed right into every stage of the process to assure constant and trusted results for clients all over the world.

Advanced Engineering and also Mold Design

Precision begins with professional preparation. Every trustworthy thermoforming molds manufacturer in China counts on a seasoned engineering team to craft comprehensive CAD-based vacuum forming mold designs. These blueprints form the foundation for extremely precise production. Modern thermoforming tools makers also use simulation software application and 3d print vacuum form molds for prototyping, permitting improvements prior to final machining. This technique makes sure that each customized thermoforming mold aligns flawlessly with client specifications, making Chinese providers reputable companions in the international market.

Use Top Quality Products and Precision Machining

A reputable vacuum forming molds manufacturer understands that premium products are non-negotiable for lasting performance. Whether it's pure light weight aluminum, copper, or composite FRP, makers use only high-grade products for boosted mold toughness and precision. From there, CNC machining brings these products to life with micro-level accuracy. Leading vacuum forming tools producers in China integrate this with automated evaluation systems to guarantee that each mold is prepared for rigorous industrial usage, specifically in sectors requiring regular and reputable results.

Rigorous Examining and Quality Control

No mold leaves a trusted thermoforming molds supplier without comprehensive quality checks. Each tool is examined under practical forming conditions to verify warmth tolerance, vacuum stability, and dimensional precision. Licensed vacuum forming molds distributors follow worldwide requirements like ISO9001 and ISO13485, especially for clinical or digital applications. This level of analysis makes certain every item from a thermoforming tools manufacturer is resilient, reliable, and compliant - making them the best source for high-performance vacuum forming molds China throughout global markets.

Personalization and Customer Collaboration

What establishes a top-tier vacuum forming molds supplier apart is their technique to customization. These professionals don't just construct molds - they fix manufacturing issues. Whether you require a customized vacuum forming mold for food product packaging or a bespoken vacuum forming mold for auto components, Chinese vacuum forming tools manufacturers work closely with clients to adjust every information. A dependable thermoforming molds production will certainly lead you through material selection, surface coating, and part intricacy, making sure the last mold aligns with your business objectives.

Conclusion

Accuracy in vacuum forming molds China is not accomplished by chance. It's the result of careful vacuum forming mold design, cutting-edge machining, extensive screening, and solid customer relationships. As a trusted vacuum forming molds manufacturer, China has established the global standard for both quality and customization. Whether you require custom thermoforming molds, high-volume manufacturing molds, or experimental vacuum forming 3d published molds, Chinese suppliers offer trustworthy solutions. With a tested track record, companies like SME Plastic proceed to lead the means in supplying precision-engineered thermoforming solutions.

SME Thermoforming Molds

Address: No.10, 3rd st, Minying Industrial Zone,

Shawan Town,Panyu District, Guangzhou City, Guangdong, PRC

Mob: +86-13928889690

Location map: https://maps.app.goo.gl/2CfwLCx2WAPuEuCF8

0 notes

Text

𝐑𝐞𝐯𝐞𝐚𝐥𝐢𝐧𝐠 𝐭𝐡𝐞 𝐇𝐞𝐚𝐫𝐭 𝐨𝐟 𝐭𝐡𝐞 𝐂𝐚𝐫: 𝐇𝐨𝐰 𝐂𝐍𝐂 𝐂𝐚𝐫𝐯𝐞𝐬 𝐚 𝐒𝐭𝐞𝐞𝐫𝐢𝐧𝐠 𝐊𝐧𝐮𝐜𝐤𝐥𝐞

From a rough blank to a precision-finished product, every step in the machining process is a testament to the perfect fusion of technology and craftsmanship. In this post, we take you behind the scenes to explore:

🔩 How CNC machines transform raw materials with unparalleled precision.

🔩 The intricate steps involved in carving a steering knuckle.

🔩 The role of advanced tools and meticulous craftsmanship in achieving perfection.

Whether you’re passionate about automotive engineering or intrigued by manufacturing technologies, this deep dive showcases the artistry and innovation behind every steering knuckle.

𝐃𝐢𝐝 𝐲𝐨𝐮 𝐤𝐧𝐨𝐰? Precision machining ensures not just durability but also optimal performance for critical automotive components.

Check out the video and tell us: What part of the CNC machining process fascinates you the most? Share your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#Machining #CNC #ThreadTapping #Metalworking #Manufacturing #cncmachine #cncmachining #cncmachinist #cncmilling #cncturning #cncprogramming #foryou

#CNC Machining For Medical Imaging#CNC Milling Machine For Sale#CNC Routers Machines#CNC Screw-Machining For Aviation#Diy CNC Machine#Haas CNC Milling Machine#Laser CNC Machine#Mazak CNC Machine#Mini CNC Milling Machine#What Is CNC Milling Machine#What Is CNC Routers Machine#5 Axis CNC Milling Machine#Advantages Of CNC Machine#Budget CNC Machine

0 notes

Text

The Secrets Behind Precision Thermoforming Molds Created in China

Vacuum forming and thermoforming have become crucial manufacturing techniques across industries, and a lot of their success depends on the accuracy of the molds used. In China, a center for sophisticated manufacturing, thermoforming molds producers have developed very efficient systems to make certain every mold satisfies limited resistances and exacting criteria. From custom thermoforming molds to bespoken vacuum forming molds, accuracy is constructed into every stage of the procedure to assure regular and trustworthy results for clients all over the world.

Innovative Engineering as well as Mold Design

Accuracy starts with expert planning. Every reputable vacuum forming tools manufacturer in China counts on a seasoned engineering team to craft thorough CAD-based vacuum forming mold designs. These plans form the structure for highly precise production. Modern thermoforming tools manufacturers likewise use simulation software application and 3d print vacuum form molds for prototyping, permitting refinements prior to final machining. This approach makes sure that each personalized thermoforming mold aligns completely with client requirements, making Chinese providers reputable companions in the global market.

Use High-Quality Products and Accuracy Machining

A trustworthy vacuum forming tools manufacturer understands that premium materials are non-negotiable for lasting performance. Whether it's pure aluminum, copper, or composite FRP, suppliers make use of only top-grade materials for boosted mold toughness and precision. From there, CNC machining brings these products to life with micro-level accuracy. Leading vacuum forming tools manufacturers in China incorporate this with automated evaluation systems to assure that each mold awaits rigorous commercial use, particularly in sectors requiring consistent and dependable outcomes.

Extensive Testing and Quality Assurance

No mold leaves a reputable thermoforming molds supplier without comprehensive quality checks. Each tool is examined under practical forming conditions to verify warmth tolerance, vacuum honesty, and dimensional accuracy. Licensed vacuum forming molds providers adhere to global standards like ISO9001 and ISO13485, specifically for medical or electronic applications. This level of scrutiny ensures every piece from a thermoforming tools manufacturer is resilient, reliable, and certified - making them the go-to resource for high-performance vacuum forming tools across international markets.

Personalization and Customer Collaboration

What establishes a top-tier vacuum forming molds supplier apart is their strategy to customization. These specialists don't simply construct molds - they fix producing issues. Whether you require a personalized vacuum forming mold for food product packaging or a bespoken vacuum forming mold for automobile parts, Chinese vacuum forming tools suppliers work carefully with customers to fine-tune every detail. A trustworthy thermoforming molds manufacturing will certainly direct you via material selection, surface area coating, and part complexity, making certain the final mold aligns with your business goals.

Verdict

Accuracy in vacuum forming molds China is not attained by opportunity. It's the result of thorough vacuum forming mold design, sophisticated machining, extensive screening, and strong customer partnerships. As a reputable vacuum forming molds manufacturer, China has established the global criteria for both quality and personalization. Whether you need custom thermoforming molds, high-volume manufacturing molds, or speculative vacuum forming 3d published molds, Chinese manufacturers use reliable solutions. With a proven track document, companies like SME Thermoforming Molds proceed to blaze a trail in supplying precision-engineered thermoforming solutions.

SME Thermoforming Molds

Address: No.10, 3rd st, Minying Industrial Zone,

Shawan Town,Panyu District, Guangzhou City, Guangdong, PRC

Mob: +86-13928889690

Location map: https://maps.app.goo.gl/2CfwLCx2WAPuEuCF8

0 notes

Text

The Secrets Behind Accuracy Thermoforming Molds Made in China

Vacuum forming and thermoforming have actually come to be necessary manufacturing techniques throughout industries, and much of their success lies in the precision of the molds made use of. In China, a hub for advanced production, thermoforming molds suppliers have established highly efficient systems to make certain every mold fulfills tight tolerances and exacting standards. From custom thermoforming molds to bespoken vacuum forming molds, precision is built right into every phase of the process to guarantee consistent and trustworthy results for customers all over the world.

Sophisticated Engineering and Mold Design

Accuracy begins with expert preparation. Every respectable thermoforming molds supplier in China counts on an experienced engineering group to craft detailed CAD-based vacuum forming mold designs. These plans form the foundation for extremely precise manufacturing. Modern thermoforming tools manufacturers also utilize simulation software program and 3d print vacuum form molds for prototyping, allowing refinements prior to final machining. This strategy makes certain that each custom thermoforming mold aligns perfectly with customer specifications, making Chinese distributors trustworthy partners in the worldwide market.

Use High-Quality Products and Accuracy Machining

A reputable vacuum forming tools manufacturer recognizes that premium products are non-negotiable for lasting efficiency. Whether it's pure light weight aluminum, copper, or composite FRP, suppliers make use of just top-grade materials for improved mold stamina and accuracy. From there, CNC machining brings these materials to life with micro-level accuracy. Leading vacuum forming tools producers in China incorporate this with computerized assessment systems to ensure that each mold awaits strenuous commercial use, particularly in fields demanding constant and reliable results.

Rigorous Examining and Quality Assurance

No mold leaves a reputable thermoforming molds supplier without extensive quality checks. Each tool is evaluated under practical forming conditions to confirm heat resistance, vacuum integrity, and dimensional accuracy. Licensed vacuum forming molds distributors follow global requirements like ISO9001 and ISO13485, specifically for medical or electronic applications. This level of scrutiny ensures every piece from a thermoforming tools manufacturer is sturdy, reputable, and certified - making them the go-to source for high-performance bespoken vacuum forming molds across worldwide markets.

Customization and Customer Collaboration

What establishes a top-tier vacuum forming molds supplier apart is their strategy to personalization. These professionals do not simply construct molds - they solve manufacturing troubles. Whether you require a customized vacuum forming mold for food packaging or a bespoken vacuum forming mold for auto components, Chinese vacuum forming tools suppliers work closely with customers to fine-tune every detail. A trustworthy thermoforming molds manufacturing will lead you via product option, surface area finish, and component intricacy, ensuring the last mold aligns with your business goals.

Conclusion

Precision in vacuum forming molds China is not attained by possibility. It's the outcome of meticulous vacuum forming mold design, cutting-edge machining, rigorous testing, and strong client connections. As a reputable vacuum forming molds manufacturer, China has established the global benchmark for both quality and personalization. Whether you require custom thermoforming molds, high-volume manufacturing molds, or experimental vacuum forming 3d published molds, Chinese makers offer dependable solutions. With a proven track document, companies like SME Plastic continue to lead the method in supplying precision-engineered thermoforming solutions.

SME Thermoforming Tools

Address: No.10, 3rd st, Minying Industrial Zone,

Shawan Town,Panyu District, Guangzhou City, Guangdong, PRC

Mob: +86-13928889690

Location map: https://maps.app.goo.gl/2CfwLCx2WAPuEuCF8

0 notes

Text

Customised Fabrication for Mining Equipment: Enhancing Efficiency and Safety

India’s mining industry is a powerhouse of activity, relying on highly specialised mining equipment to meet growing demands. From huge excavation to precise material handling, the efficiency of heavy equipment machinery is the foundation of any mining operation.

Over the years, mining machinery has advanced from simple tools to sophisticated, automated systems that significantly improve productivity, safety, and speed. These machines are critical for the exploration, extraction, and transportation of resources. Excavators, drills, loaders, and haul trucks are key handling equipment for seamless operations across mining sites.

With rapid urbanisation and industrial expansion, India’s market for mining equipment is on a steady rise. The adoption of automation, robotic systems, and real-time monitoring is transforming how mining is carried out, making operations more efficient and environmentally responsible.

As these machines become more complex and capable, the need for reliable, durable, and precisely built components increases marking the vital role of metal fabrication in shaping the future of mining machinery.

Why Metal Fabrication is Indispensable in Mining Equipment

Metal fabrication services play a fundamental role in supporting the functionality and reliability of modern mining machinery. With demanding work environments and heavy workloads, mining equipment must be built to endure extreme conditions over long periods, making high-quality engineering fabrication essential.

Mining fabrication allows for custom-designed parts and structures tailored to specific site conditions. This customisation reduces idle time, lowers maintenance costs, and ensures faster repairs when problems arise. Precision techniques such as CNC machinery provide for faster turnaround and improved fault correction, which directly contributes to equipment uptime and efficiency.

The choice of material is just as critical as the design itself in heavy fabrication for mining applications:

Robust industrial fabrication techniques, combined with durable materials, ensure that mining equipment can withstand the toughest challenges of the field. Metal fabrication isn't merely a supporting infrastructure, but a driving force behind efficient, reliable, and durable heavy equipment machines.

Heavy Machinery That Powers Modern Mining Operations

Efficient mining begins long before extraction activities commence. It is primarily reliant on robust, purpose-built heavy equipment machines designed to withstand harsh environments. These equipment are essential for gaining access, eliminating overburden, and collecting precious resources effectively and safely. Each type of equipment has a distinct purpose in the mining lifecycle and is meticulously manufactured for strength and dependability using modern metal fabrication services.

Excavators:

Among the most frequently used machines in mining operations, excavators stand out for their versatility and power. These machines are typically used in open-pit mining and are capable of digging, scooping, and carrying large amounts of dirt or rock. They run on powerful excavator hydraulics and are frequently outfitted with enormous excavator buckets that may be replaced with other attachments depending on the task. From stripping overburden to loading haul trucks, excavators for mining come in various sizes, including compact mini excavators for tighter spaces, ensuring optimal efficiency across mining operations.

Loaders:

Loaders are also essential at the mine face, where they scoop, lift, and transfer loose materials. Their sturdy construction enables them to drive over uneven terrain while carrying debris, rocks, and soil. Wheel loaders are essential in clearing trails, loading trucks, and transferring material to crushers or sorting plants. Precision engineering fabrication has enabled loaders to have sturdy chassis and hydraulically operated arms, which make them capable of lifting heavy loads with ease and consistency.

Bulldozers:

A cornerstone of site preparation, bulldozers are built for brute strength. These crawler tractors feature a large blade at the front, which they use to push, level, or clear debris, rocks, and vegetation. Whether constructing access roads or preparing ramps for other equipment, bulldozers are vital in shaping a safe and accessible mining environment. Crafted through heavy fabrication, their steel frames and wear-resistant components allow them to function effectively in the harshest conditions.

Drills:

Drills are essential for rock blasting and creating passageways for extraction. Their structural integrity relies heavily on industrial fabrication. The tall mast or tower is fabricated to be stable and precise, ensuring safe drilling angles and depths. The frame, often mounted on tracks or wheels, supports the power unit and guide systems. While some components involve machinery, metal fabrication services are crucial for the fabrication of drill carriages, support structures, and load-bearing assemblies that ensure continued performance and durability in rugged mining conditions.

Each of these machines require precise custom metal fabrication to meet the unique demands of mining environments. Excavators, bulldozers, loaders, and drills are all modified through customised engineering from changing buckets, blades, and arms to strengthening undercarriages and operator cabins. Whether it's drilling masts being adjusted for depth, improving stability with counterweights, or adding dust control systems, these customised solutions make machinery work efficiently, safely, and reliably under intense operating pressures.

Conveyor Systems: Fabrication of Durable Conveyor Solutions

Effortless and cost-effective transportation of materials in today's dynamic mining machinery industry is critical. Efficient conveyor systems designed well play an instrumental part where this takes center stage. Successful operation in a mine heavily relies on how good materials can be transported from the point of departure to that of arrival, better accomplished with specialized conveyor system engineering.

Conveyors in the mining industry range from compact, straightforward assemblies to large-scale, intricate systems. Unlike generic, off-the-shelf conveyors, tailored solutions are created through engineering fabrication and heavy fabrication to meet the unique challenges of each mining site. From variable terrain to irregular tunnel layouts, custom-built conveyors account for site-specific inclines, declines, curves, and tight spatial constraints, ensuring a seamless material flow.

Customisation also ensures that each conveyor system is constructed to accommodate the nature of the material being transported whether it’s abrasive ore, dense coal, or moist minerals. Factors such as particle size, moisture content, and impact force guide the selection of belt materials, support frames, and pulley mechanisms. Conveyor belt manufacturers play a critical role here, ensuring each component is fabricated to withstand high-stress environments, reducing downtime and enhancing safety.

Moreover, fabricated metal conveyors are often integrated at multiple stages from the mining face to processing units demonstrating their flexibility and robustness. Customised conveyor systems not only increase efficiency but also improve longevity, reduce maintenance demands, and help streamline the entire mining workflow.

Custom-Fabricated Safety Solutions

In mining environments where high-risk operations are routine, standardised safety equipment often lacks the durability and precision required. For example, barriers around crushers or conveyor systems must be designed to match the layout and withstand harsh site conditions. Custom-built safety solutions provide the adaptability necessary to meet unique site demands while ensuring operational flow is not disrupted.

Fabricated safety components typically include protective barriers, walkways, access platforms, handrails, and machine guards. These systems are engineered for strength, stability, and corrosion resistance essential in mining settings. Adhering to updated safety regulations, these custom solutions help improve worker protection, reduce on-site accidents, and enhance maintenance access. Each piece is tailored to integrate seamlessly with existing infrastructure, providing safer operational zones without compromising efficiency.

Allmarc’s Advancement in Mining Equipment Fabrication

With the establishment of our new engineering facility at Ahmedabad, we are proud to strengthen our technological capabilities across industries. This development enables us to advance our fabrication processes and the quality of output under changing industry needs. In the mining equipment industry, we are introducing state-of-the-art metal fabrication services to assist one of the most demanding and performance-driven environments.

From heavy equipment machines like excavators and loaders to structurally complex components and handling equipment, our focus is on precision-built, durable systems that meet the unique challenges of mining environments. Our expertise also extends to the fabrication of conveyor systems, engineered to optimise material flow in tough terrains, and safety systems such as walkways and barriers that ensure compliance and worker protection.

By leveraging advanced engineering fabrication techniques, including CNC machinery, high-strength welding, and rigorous quality checks, we’re committed to building mining solutions that are efficient, long-lasting, and tailored to operational needs.

We’re not just fabricating parts, we're building the future of mining, one engineered solution at a time.

#mining equipment#heavy equipment machinery#handling equipment#metal fabrication#Metal fabrication services#engineering fabrication#Mining fabrication#heavy fabrication#industrial fabrication#heavy equipment machines#metal fabrication services#excavator hydraulics#excavator buckets#excavators for mining#bulldozers#precise custom metal fabrication#conveyor systems#Conveyor belt manufacturers#metal conveyors#Customised conveyor systems#mining equipment industry#rock drill#Bulldozers#Loaders#Excavators

0 notes

Text

In the heart of the UK’s bustling capital, where innovation meets tradition, Architectural Model Makers London are playing a crucial role in bringing some of the most ambitious architectural visions to life. These artisans blend precision, artistry, and cutting-edge technology to translate 2D concepts into tangible, three-dimensional masterpieces. Whether it’s a scale model of a residential development or a detailed replica of an urban cityscape, the art of model making remains an essential part of the architectural process.

A Vital Tool in the Design Process

Architectural model making is far more than a decorative craft. It serves as a critical communication tool between architects, clients, planners, and the public. Unlike digital renders, physical models offer a tactile and spatial perspective that allows viewers to truly understand the layout, scale, and context of a project. In a city as visually complex as London, where new developments must often integrate with heritage buildings and historical landscapes, these models help visualize potential outcomes long before a single brick is laid.

Model makers in London collaborate closely with architectural firms to ensure accuracy and artistic integrity. Every contour, façade, and landscape feature must reflect the intended design with remarkable detail. This high level of precision demands not only craftsmanship but also a deep understanding of architectural language.

The Evolution of Model Making in London

Gone are the days when model making was limited to foam boards, cardboard, and hand tools. Today, London’s model makers leverage a hybrid of traditional techniques and modern technologies. Laser cutting, 3D printing, CNC machining, and CAD design have become staples in the modern model-making studio.

These technological advances allow for faster production and enhanced precision while still maintaining the bespoke quality that handcrafting provides. At the same time, model makers continue to use manual sculpting and painting techniques to add realism and texture, especially when presenting landscapes, foliage, and terrain.

The result is a stunning blend of artistry and engineering — a physical manifestation of creativity and science working hand in hand.

Types of Architectural Models

Architectural models in London come in a wide variety of formats, each tailored to serve a specific function. Some of the most common types include:

Conceptual Models: Used early in the design process to explore shapes and massing.

Presentation Models: High-detail models used to impress clients, investors, or stakeholders.

Planning Models: Built for city planning committees to assess a project’s scale and impact on its environment.

Urban Context Models: Represent entire neighborhoods or city sections, showing how a new development fits within its broader context.

Each model type has different requirements in terms of materials, scale, and presentation. London's model makers are experts in advising architects on the most suitable model type based on project needs and audience.

A City of Diverse Architectural Styles

London is known for its eclectic mix of architecture — from the sleek modernism of the Shard to the neoclassical beauty of St. Paul’s Cathedral. This diversity presents both a challenge and an opportunity for model makers.

Reproducing the intricate details of historical buildings demands painstaking attention to detail and a nuanced understanding of architectural styles. At the same time, showcasing ultra-modern buildings requires technical precision and an eye for minimalist aesthetics. Model makers must be as versatile as the city itself, adapting their skills to suit a wide range of projects.

Sustainability and Innovation

Sustainability is becoming a top priority across all sectors, including model making. Many London studios now use eco-friendly materials such as recycled plastics, biodegradable composites, and sustainably sourced wood. Additionally, digital prototyping helps minimize waste and energy use during production.

Innovation also extends into interactive elements. Some models now include lighting, moving parts, and even augmented reality integration, offering dynamic ways to engage with a design.

Supporting Collaboration and Decision Making

Perhaps one of the most underappreciated benefits of architectural models is their ability to foster collaboration. When architects, engineers, clients, and city officials gather around a physical model, the design becomes a shared experience. Changes and improvements can be suggested in real time, and stakeholders often gain a much clearer understanding of a project’s potential.

This collaborative approach helps reduce costly errors down the line, speeds up approval processes, and builds confidence among investors and clients. In many cases, a well-made model can make or break the success of a project proposal.

The Future of Architectural Model Making

As London continues to evolve and expand, the demand for high-quality architectural models will only grow. With urban regeneration projects, new housing developments, and large-scale infrastructure plans underway, model makers will remain key players in shaping the future of the city.

Looking ahead, we can expect even more integration between digital and physical mediums, with models becoming smarter, more interactive, and even more immersive.

In conclusion, the craft of model making remains as relevant as ever, even in our increasingly digital world. It’s not just about constructing miniature buildings — it’s about telling a story, inspiring imagination, and transforming visionary concepts into something people can see, touch, and believe in. If you’re searching for precision, creativity, and expert craftsmanship, working with an experienced Architectural Model Maker London is a decision that brings your vision to life — from concept to creation.

0 notes

Text

Micro Mini Pistol

Discover the AR-15 Moriarti 5" Micro Mini Pistol in FDE at Moriarti Armaments. Choose your caliber and enjoy compact power with Centurion design and mag. Shop now!

Micro Mini Pistol

About us:-Moriarti Armaments is a licensed firearm manufacturer, dealer, and distributor located in Miami, Florida. Since 2014, we’ve been serving the firearms industry, with a growing presence not only across USA market but also in NATO countries and Latin America. We specialize in high-quality AR-style rifles, pistols, machine guns, and accessories.We offer a wide range of firearms, including AR-15 and AR-10 rifles, Pistol Caliber Carbines (PCC), silencers, machine guns, and handgun kits. Our in-house CNC manufacturing ensures top-tier quality and precision. Since 2022, we've supplied military and law enforcement agencies in Florida.Our mission is to provide customers with high-quality firearms at fair prices. We focus on exceptional customer service and stringent quality controls all backed by limited lifetime warranty. Our team of U.S. Veterans is committed to delivering the best products and support, whether you're a civilian, law enforcement, or a military customer.

Click Here For More Info-: https://moriartiarmaments.com/ar-15-6.5-grendel/complete-guns/pistols-1865864550/ar-15-moriarti-5-micro-pistol-fde-centurion-mag-choose-caliber.html

0 notes

Text

Colorful launched the motherboard CVN B850i Gaming Frozen for AMD Ryzen 7000, 8000, and 9000 Series

Colorful has just launched the MVN B850i Gaming Frozen Mini-Itx Not only impressed by the pitiful appearance with angular lines inspired by the military, this motherboard also possesses formidable strength it is equipped with a specialized 5.0 M.2 PCIe radiator with high -precision CNC machining grooves, improving heat sink performance while highlighting the strong and durable structure of the…

0 notes