#Multi-Axis CNC

Note

It's not erotic you're just a crazy robot fetishist (said with barely restrained lust)

Aww thank you for noticing 🥰

But the correct answer was "that multi axis CNC machine is so erotic and hot I need it to turn me into something beautiful"

Thanks for playing !

10 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Photo

This book is essential reading for researchers and practitioners in computer science, technical managers and software specialists This book provides a comprehensive treatment of the subject of sculptured surface machining in terms of user needs, CAM software solutions and theoretical research results and issues. State-of-the-art capabilities of the best commercial CAM systems are compared to user needs, and advanced academic research is presented. Among the topics covered are the following: Generative NC for dies and molds; 5-axis machining of impellers; Cutting simulation and NC verification; Virtual machining; CAPP for die and mold machining; NURBS-based CNC interpolators

Cutting Molds/Dies from Scan data

Experiences from a Quantum Leap Improvement in Turbine Manufacturing

A Generative Approach for Die Pattern Machining

Geometric Contributions to 3-Axis Milling of Sculptured Surfaces

Efficiency of Multi-Axis NC Machining of Sculptured Part Surfaces

Best-Fit of Sculptured Surfaces

Point-based Geometric Modelling

Virtual Machining and the Manufacturing Model

Virtual CNC with Performance Error Modeling

Fast Simulation of Sculptured Surface Milling with 3-Axis NC Machine

Simulation of Ball-nose End Milling Operations — Selection of Geometric Resolution Parameters

Machining Process Modeling for Intelligent Rough Machining of Sculptured Parts

Bridging the Gap Between Tool Path Generation for Sculptured Surface Machining and Computer Aided Process Modelling Techniques

Automatic Five-Axis CNC Feedrate Selection via Discrete Mechanistic, Geometric, and Machine Model Integration

Milling Simulation with an adaptive Strategy

Deformed Swept Volume Analysis to NC Machining Simulation with Cutter Deflection

Segmentation and Surface Fitting in Reverse Engineering

Surface Reconstruction from Point Clouds

Reverse Engineering Employing a Wrap-Around SurfaceTriangle Set

Manufacturability of Reverse Engineered CAD-models : a case study

https://archive.org/details/springer_10.1007-978-0-387-35392-0

3 notes

·

View notes

Text

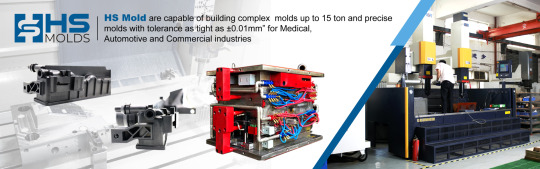

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

17 key tips for milling applications

Milling is the process of holding a blank in place and using a high-speed rotating milling cutter to travel over the blank to cut out the desired shape and features.

Conventional milling is more often used to mill simple shapes/features such as contours and slots. CNC milling machines can perform machining of complex shapes and features.

Milling and boring machining centers can perform 3-axis or multi-axis milling and boring for machining, molds, inspection tools, tire tools, thin-walled complex surfaces, artificial prostheses, blades, etc. In the selection of CNC milling and processing content, should give full play to the advantages and key role of CNC milling machine.

In the actual production of milling processing, including machine settings, workpiece clamping, tool selection and other aspects of application skills, this issue for you to briefly summarize the 17 points of milling processing, each point is worthy of in-depth mastery.

1. Power capacity

Check the power capacity and machine rigidity to ensure that the machine can use the required milling tool diameter.

2. Workpiece stability

Workpiece clamping conditions and considerations.

3. Overhang

Make the tool overhang on the spindle as short as possible during machining. 4.

4. Selecting the correct milling cutter tooth pitch

Use the correct tooth pitch of the milling cutter for the process to ensure that no excessive inserts are involved in the cut, which would otherwise cause vibration.

5. Cutter draft

For narrow workpieces or milling with gaps, ensure that there is sufficient insert draft.

6. Insert groove type selection

Whenever possible, use positive front-angle slotted indexable inserts to ensure smooth cutting action and minimum power consumption.

7. Use the correct feed

Ensure proper feed of the insert used by using the recommended maximum chip thickness to achieve the correct cutting action.

8. Cutting direction

Use smooth milling whenever possible.

9. Part Considerations

Workpiece material and configuration, as well as the quality requirements of the surface to be machined.

10. Insert material selection

Select the slot type and material according to the type of workpiece material and type of application.

11. Vibration damping milling cutters

For longer overhangs exceeding 4 times the tool diameter, the tendency to vibrate becomes more pronounced and the use of vibration damping tools can significantly improve productivity.

12. Main deflection angle

Select the most suitable main deflection angle.

13. Milling tool diameter

Select the correct diameter according to the width of the workpiece.

14. Milling tool position

Position the milling cutter correctly. 15.

15. Milling cutter cut-in and cut-out

It can be seen that by circular plunge, the chip thickness during retraction is always zero, thus enabling higher feeds and longer tool life.

16. Coolant

Coolant is used only when deemed necessary. As a rule, milling is better executed without coolant.

17. Maintenance

Follow tool maintenance recommendations and monitor tool wear.

3 notes

·

View notes

Text

The different shafts of the Swiss lathe

Hello everyone, here at HANBS, I'm Sonya, and today I'm sharing with you the different shafts of the Swiss lathe, mainly to introduce the role of the shafts in the swiss lathe, why do we need so many shafts? What is its role embodied?

The swiss lathe (Swiss type cnc lathe/Sliding headstock cnc lathe) is known for its high precision and efficiency, and is especially suitable for small parts machining. They are divided into different types according to the number of axes and different configurations, today we will introduce 3-axis, 5-axis, 6-axis (Y2 axis) and so on. The following is a detailed explanation of each type.

1. 3-axis swiss lathe.

Involved axes: X1, X2, C-axis

Key features:

X1 axis: Controls the movement of the tool in the radial direction (perpendicular to the workpiece).

X2 axis: controls the movement of the tool in the longitudinal direction (along the length of the workpiece).

C-axis: Controls the rotation of the spindle for drilling and milling operations on the radial and end faces of the workpiece.

Although there are only 3 axes, it is possible to add other accessories to make it more unique by making it a specialized machine for parts.

APPLICATIONS:

This lathe is mainly used for simple turning, drilling and basic milling operations, and is suitable for machining cylindrical or slightly curved parts, but has limited ability to machine complex geometries.

2. 5-axis swiss lathe

Axes involved: X1, Y1, Z1, C1, C2 axes

Key Features:

X1, Z1: Used for turning and basic milling operations, similar to a 3-axis lathe.

Y1 axis: adds an extra lateral movement for eccentric milling and drilling operations.

C1/C2 axis: Controls the rotation of the main spindle (C1) and sub-spindle (C2) to realize machining of both ends of the workpiece.

The swiss lathe at this time can process the main and sub-spindles at the same time, which greatly improves the working efficiency.

Applications:

The 5-axis swiss lathe is capable of machining parts with more complex part geometries, and is especially suitable for parts that require multi-face milling, off-center drilling or contouring. Commonly used in aerospace, medical and other industries that require high precision and complexity.

3. 6-axis (Y2) swiss lathe

Axes involved: X1, Y1, Z1, X2, Y2, Z2

Key Features:

X1, Y1, Z1: Mainly used for turning and milling operations on the spindle side, providing complete machining freedom.

X2, Y2, Z2: Used for machining operations on the sub-spindle side, enabling simultaneous machining of both ends of the workpiece.

Y2 axis: Allows complete milling, drilling and contouring operations on the sub-spindle side.

Simultaneous machining: the main spindle and the subspindle can be operated independently of each other, allowing two different machining operations to be carried out in different positions on the same workpiece.

The 6-axis swiss lathe allows for simultaneous machining of the main and sub-spindles, and with the addition of the Y2 axis, allows both the main and sub-spindles to be independent machining fields, further reducing machining times.

Applications:

The 6-axis (Y2) configuration is ideally suited for the machining of complex parts, especially those requiring multiple operations. The simultaneous machining function of the main spindle and the sub-spindle significantly reduces machining cycles and increases efficiency. Commonly used for mass production of medical devices, watch components and complex aerospace parts.

Summary

3-axis swiss lathe: for basic turning, drilling and face milling operations.

5-axis swiss lathe: offers greater flexibility in machining skills, the ability to machine complex geometries, support for eccentric milling, and the ability to control both the spindle and the subspindle simultaneously.

6-axis (Y2) swiss lathe: offers maximum flexibility, allowing simultaneous machining of both main and sub spindles, working in tandem, suitable for efficient machining of precise and complex parts.

Today's sharing is here, I hope to help those who need it, we will be the next chapter of these different types of axis machines for further derivation of the explanation. See you in the next installment.

www.hanbscnc.com

0 notes

Text

Future Trends of CNC Machining Technology

With the rapid development of science and technology, CNC machining technology plays an increasingly important role in modern manufacturing. Looking to the future, CNC machining technology presents a series of exciting development trends.

Higher precision and quality

Precision and quality have always been the core goals pursued by CNC machining technology. In the future, with the continuous advancement of sensor technology, measurement technology and control algorithms, the precision of CNC machining will reach a higher level. Nano-level machining accuracy will no longer be an unattainable dream. Through high-precision sensors, various parameters in the machining process, such as tool position, cutting force, temperature, etc., are monitored in real time, and timely feedback is given to the control system for adjustment, so that more precise machining can be achieved. At the same time, the continuous research and development of advanced machining technology and tool materials will further improve the machining quality, reduce surface roughness and reduce scrap rate. For example, in fields such as aerospace and medical equipment that have extremely high requirements for precision and quality, future CNC machining technology will be able to meet more stringent requirements.

Intelligence and automation

Intelligence and automation are the inevitable trends in the development of CNC machining technology. Future CNC machine tools will have stronger autonomous decision-making and adaptive capabilities. Through artificial intelligence technology and machine learning algorithms, CNC machine tools can automatically analyze processing tasks, optimize processing parameters, and select the best processing paths and tools. At the same time, CNC machine tools will also be more closely integrated with other automated equipment and robots to form an intelligent production system. For example, in an unmanned production workshop, CNC machine tools can work with automated logistics systems, robotic assembly systems, etc. to achieve fully automated production from raw materials to finished products. In addition, intelligent maintenance technology will also be widely used. CNC machine tools can detect potential faults in advance through self-diagnosis and predictive maintenance, and perform timely repairs to improve the reliability and availability of equipment.

High-speed and efficient processing

In order to meet the growing market demand, improving production efficiency is the eternal pursuit of the manufacturing industry. In the future, CNC processing technology will continue to develop in the direction of high-speed and efficient processing. High-speed spindle technology, fast feed system and efficient cutting tools will be further developed and applied. By increasing the spindle speed and feed speed, more material can be removed in a shorter time, greatly shortening the processing cycle. At the same time, multi-axis linkage processing technology will be more mature, able to achieve one-time processing and forming of complex-shaped parts, reduce the number of clamping times and processing errors, and improve processing efficiency. In addition, parallel processing technology will also be widely used, and multiple CNC machine tools can process a part at the same time, further improving production efficiency.

Green and environmentally friendly processing

With the continuous improvement of people's awareness of environmental protection, green and environmentally friendly processing will become an important development direction of CNC processing technology. Future CNC processing will pay more attention to energy conservation and emission reduction and the recycling of resources. By optimizing the processing technology, reducing the use of cutting fluid, reducing energy consumption and waste emissions. At the same time, new green cutting technologies, such as dry cutting and low-temperature cutting, will be widely used to reduce pollution to the environment. In addition, the recycling of waste tools and parts will also become an important part of future CNC processing. Through recycling and remanufacturing, resources can be recycled and production costs can be reduced.

Personalized customized processing

With the increasing diversification of consumer needs, personalized customized processing will become an important trend in the future manufacturing industry. CNC processing technology will provide strong technical support for personalized customization. Through fast programming and flexible processing capabilities, CNC machine tools can quickly respond to customers' personalized needs and produce unique products. For example, the combination of 3D printing technology and CNC machining technology can realize the processing of more complex personalized parts. At the same time, the development of Internet technology will also enable customers to directly participate in the design and manufacturing process of products, realizing true personalized customization.

0 notes

Text

Computerized Numerical Control (CNC) Spinning Machines Market Opportunities, Analysis and Size by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Computerized Numerical Control (CNC) Spinning Machines Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Computerized Numerical Control (CNC) Spinning Machines Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Computerized Numerical Control (CNC) Spinning Machines Market?

The global computerized numerical control (CNC) spinning machines market size reached US$ 387.1 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 575.2 million in 2032, exhibiting a growth rate (CAGR) of 4.5% during 2024-2032.

What are Computerized Numerical Control (CNC) Spinning Machines?

Computerized numerical control (CNC) spinning machines are high-tech manufacturing tools that use computer systems to precisely control the metal spinning process. These machines rotate a metal workpiece while a tool systematically presses against it, shaping the material into the desired form with precision. CNC spinning machines are known for their accuracy, repeatability, and efficiency, making them ideal for producing complex metal components with minimal waste. Widely used in industries like aerospace, automotive, and metalworking, they are capable of creating symmetrical shapes such as cones and cylinders, with computer control ensuring consistency and flexibility in production.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1930

What are the growth prospects and trends in the Computerized Numerical Control (CNC) Spinning Machines industry?

The computerized numerical control (CNC) spinning machines market growth is driven by various factors and trends. The market for Computerized Numerical Control (CNC) spinning machines is witnessing consistent growth due to rising demand for precise metal forming across industries like aerospace, automotive, defense, and manufacturing. These machines provide high efficiency, precision, and cost savings in the production of complex, symmetrical metal parts, making them vital for sectors requiring customized, lightweight, and durable components. Advancements in CNC technology and increasing automation in manufacturing are further fueling market growth. Additionally, the emphasis on minimizing material waste and improving production speed is encouraging more companies worldwide to adopt CNC spinning machines. Hence, all these factors contribute to computerized numerical control (CNC) spinning machines market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Horizontal CNC Spinning Machines

Vertical CNC Spinning Machines

Multi-Axis CNC Spinning Machines

By Application:

Metal Forming and Spinning

Prototyping

Production Manufacturing

By End-Use Industry:

Automotive

Aerospace

Electronics

Energy

Healthcare

Others

Market Segmentation By Region:

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Amada Miyachi Co., Ltd.

Bystronic Inc.

DMG Mori Co., Ltd.

Emag Holding GmbH

Faccin S.p.A.

Forming Systems Inc.

Fujitsu Limited

Haas Automation, Inc.

JETCAM International s.a.r.l.

Mazak Corporation

Nakamura-Tome Precision Industry Co., Ltd.

Okuma Corporation

Prima Power Group

Salvagnini Group

View Full Report: https://www.reportsandinsights.com/report/Computerized Numerical Control (CNC) Spinning Machines-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Computerized Numerical Control (CNC) Spinning Machines Market share#Computerized Numerical Control (CNC) Spinning Machines Market size#Computerized Numerical Control (CNC) Spinning Machines Market trends

0 notes

Text

The Impact of OEM CNC Machine Manufacturers on Today’s Advanced Manufacturing

In the ever-evolving landscape of modern manufacturing, the role of OEM CNC machine manufacturers has become pivotal. Their influence extends beyond mere production capabilities, shaping the trajectory of technological advancements and operational efficiency in various industries. This article delves into how OEM CNC machine manufacturers, particularly those in Canada, are driving innovation and redefining the standards of precision and productivity.

Understanding OEM CNC Machine Manufacturers

Original Equipment Manufacturer (OEM) CNC machine manufacturers are specialized companies that produce CNC (Computer Numerical Control) machines for various applications. These machines are integral to precision machining, enabling manufacturers to create highly accurate and complex components used across multiple industries, from aerospace to automotive. OEM CNC machine manufacturers focus on designing and building machines that meet specific performance criteria, ensuring high-quality outputs and reliability.

Technological Advancements in CNC Machines

One of the key contributions of OEM CNC machine manufacturers is the continuous advancement in technology. Modern CNC machines are equipped with sophisticated controls, high-speed spindles, and multi-axis capabilities that allow for intricate and precise machining. OEM CNC machine manufacturers invest heavily in research and development to integrate cutting-edge technologies, such as advanced software algorithms and automation features, into their machines. This relentless pursuit of innovation has led to significant improvements in machining accuracy, efficiency, and overall production capabilities.

The Canadian Edge in CNC Manufacturing

Canada has established itself as a significant player in the CNC manufacturing sector, with several leading CNC machine manufacturers in Canada contributing to the global industry. These manufacturers leverage Canada's robust technological infrastructure and skilled workforce to produce high-quality CNC machines. The Canadian advantage lies in the country's commitment to maintaining high manufacturing standards and fostering innovation. CNC machine manufacturers in Canada are renowned for their emphasis on precision engineering and adherence to strict quality control measures, which enhance the reliability and performance of their machines.

Impact on Advanced Manufacturing

OEM CNC machine manufacturers have had a profound impact on advanced manufacturing practices. By providing cutting-edge machinery, they enable manufacturers to achieve higher levels of precision and efficiency. This, in turn, enhances the overall quality of products and reduces production costs. For instance, the use of advanced CNC machines allows for the creation of complex parts with minimal human intervention, reducing the likelihood of errors and increasing production speed.

Furthermore, the integration of automation and smart technologies in CNC machines has revolutionized manufacturing processes. Features such as real-time monitoring, predictive maintenance, and adaptive machining contribute to operational excellence and reduced downtime. OEM CNC machine manufacturers are at the forefront of these innovations, driving the transition towards more intelligent and autonomous manufacturing systems.

The Future of CNC Manufacturing

Looking ahead, the role of OEM CNC machine manufacturers will continue to evolve as manufacturing technology progresses. The focus is shifting towards enhancing machine intelligence, connectivity, and sustainability. The development of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is set to further transform CNC machining. OEM CNC machine manufacturers will play a crucial role in integrating these technologies into their machines, paving the way for smarter and more efficient manufacturing processes.

Conclusion

OEM CNC machine manufacturers are integral to the advancement of modern manufacturing. Their commitment to innovation and precision has reshaped the industry, driving improvements in efficiency, accuracy, and productivity. In Canada, CNC machine manufacturers continue to lead the charge, contributing to the global manufacturing landscape with their cutting-edge technology and expertise. As the industry evolves, OEM CNC machine manufacturers will remain at the forefront of technological advancements, ensuring that manufacturing practices continue to push the boundaries of what is possible.

0 notes

Text

Know About The Significance of CNC Machining Companies

An age of industrial accuracy like none before has arrived thanks to CNC machining. Traditional machining techniques sometimes require manual involvement, which might lead to irregularities and human mistakes. On the other hand, CNC machining uses computer-controlled instructions to accurately control tools and equipment. In addition to guaranteeing consistency in completed goods, this degree of precision also lessens the demand for frequent quality control inspections.

Unlimited Possibilities

CNC machining businesses provide a wide range of capabilities, from straightforward two-dimensional cuts to intricate multi-axis operations. This adaptability enables manufacturers to create complex geometries and forms that were previously thought to be impossible. CNC machining provides options for both sides of the spectrum, whether it's manufacturing a huge number of standardized components or developing prototypes with a specific design in mind.

Reduced Turnaround Times: The days of laborious hand setups and modifications in manufacturing are long gone. CNC machining services automate most of the manual work, streamlining the production process. Manufacturing lead times are greatly shortened as a result of this setup time reduction and the ability to conduct automated, uninterrupted operations. Now, businesses can react quickly to market needs and design modifications without compromising on quality or efficiency.

Cost-Effectiveness

The long-term advantages of CNC machining technology are without a doubt worth the initial financial outlay, which might be significant. Once set up, the devices can run independently with little assistance from humans. Reduced labor costs, fewer mistake rates, and improved resource utilization result from this. Additionally, the accuracy of CNC machining reduces material waste, which helps to reduce total costs.

CNC machining businesses are at the vanguard of innovation, according to Innovation Unleashed. They constantly push the limits of what is possible by integrating cutting-edge software, simulation tools, and additive manufacturing processes. Complex design creation and quick prototype iteration have enabled ground-breaking developments in industries including aerospace, healthcare, automotive, and electronics.

Personalization and Customization

Personalization and customization are crucial in today's consumer-driven environment. CNC machining companies that provide CNC machining meet this need by giving customers the freedom to design one-of-a-kind items or small batches that are suited to certain specifications. This degree of personalization boosts consumer satisfaction while also creating new market opportunities and specialized markets.

#CNC Machining#CNC Machining services#CNC Machining companies#Custom CNC Machining Service#Online CNC Machining Services#3 axis CNC machines

3 notes

·

View notes

Text

T-REX high-precision machine tools are developed by a team of German and Switzerland engineers, covering a range from 3-axis to 7-axis grinding machines and various tool machines. The company has achieved international certifications including ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018.

These machines feature high-quality mineral cast beds for rigidity and stability, precise linear guides, and ball screws for accurate positioning. Advanced spindle systems provide strong cutting power to meet various processing needs.

The T-REX team has also developed powerful CNC control software base on the hardware. It supports a variety of controllers to meet the needs of different users. The optimized processing algorithm and user-friendly operation interface have greatly improved the production efficiency and processing accuracy of the machine tool.

T-REX has a rich product line of machine tools, ranging from high-precision grinders to multi-axis composite grinders. The compact structural design maximizes the use of limited space. The modular design concept allows the machine tool to be flexibly configured according to customer needs.

T-REX machines are widely used in aerospace, automotive manufacturing, and mold making, earning global acclaim for their performance and reliability.

www.t-rexmachine.com

1 note

·

View note

Text

#ces laser marking machine#ces machine ahmedabad#laser cutting maching#automatic laser welding machine manufacturers#automatic laser welding machine

0 notes

Text

How much cnc lathe size?

Hello, everyone, this is HANBS, I am Sonya, recently I have been to the Mid-Autumn Festival ah, a while no share ah, of course, will not give up. So let's start today's sharing! Today I would like to share how much cnc lathe size. in fact, people who know cnc lathe know that there are still quite a lot of kinds of cnc lathe, so it is natural that its size will be a little different. cnc lathe size is varied, usually depends on their purpose, the size of the workpiece to be processed and the production needs. Here are a few key aspects of CNC lathe sizes:

1. Machining range

Maximum turning diameter: this is the maximum diameter of the workpiece that can be machined on a cnc lathe and usually varies between 150mm (6 inches) and 1000mm (40 inches). Small desktop grade cnc lathe usually machine diameters between 150mm-300mm, while large industrial grade cnc lathe can machine diameters up to 1000mm or more.

Maximum turning length:

This is the maximum length of the workpiece that the lathe can machine, usually from 200mm (8 inches) to 3000mm (120 inches) or longer. A small cnc lathe is suitable for shorter workpieces, while a large cnc lathe can machine long shafted parts (small ones also machine slender shafted parts).

2. cnc lathe external dimensions

The physical external dimensions of a cnc lathe depend on the machining capacity of its type:

Small desktop level cnc lathe: suitable for small parts processing, the general size of about 500mm * 1000mm * 1000mm.

Medium-sized cnc lathe: for medium-sized parts processing, with dimensions of about 2000mm*1500mm*1500mm.

Large industrial cnc lathe: can process large, heavy workpiece, size can reach 4000mm*2000mm*2000mm or even larger.

3.Spindle size

Spindle through-hole diameter: this refers to the diameter of the through-hole in the center of the spindle, determines the diameter of the bar that can be processed through the spindle. The diameter of the spindle through-hole of a small cnc lathe is usually 20-60mm, while the diameter of the spindle through-hole of a large lathe can exceed 100mm.

4.Lathe size

Bed length: determines the maximum workpiece length that the lathe can support. The longer the bed, the greater the length of the workpiece that can be processed. The bed can be from 500mm to 5000mm or even longer.

5. Other Considerations

Number and type of turret: small cnc lathes are usually equipped with a single turret, while large and versatile cnc lathes may be equipped with a double turret, or even have multi-axis control such as Y-axis, C-axis, and so on. Composite cnc lathe are usually equipped with multiple control axes.

Installation space: many people are actually concerned about this, so they ask for more details when purchasing a cnc lathe. When installing a cnc lathe, you need to consider the operating space. It is usually required to have at least 1-2m space around the lathe for operation and maintenance.

That's all for today's sharing, I hope it can help the people who need it, we will see you next time.

www.hanbscnc.com

0 notes

Text

5-Axis CNC Machining Services at BOEN – Precision for Complex Designs

At BOEN, we’ve been delivering cutting-edge 5-axis CNC machining services since 2014, using advanced German-imported DMG machines. Whether it’s for aerospace components, robotics parts, automotive, or medical devices, our high-speed precision equipment ensures every part meets your exact specifications.

What is 5-Axis CNC Machining?

Unlike traditional 3-axis machining (which operates on the X, Y, and Z axes), 5-axis CNC machining introduces two more axes – A and B. These extra axes allow for multi-directional cutting capabilities that make producing intricate designs easier, faster, and more efficient.

Benefits of 5-Axis CNC Machining:

Machining Complex Surfaces: Allows work on every surface apart from the clamping area.

Rotational Accuracy: Essential for precision designs.

Faster Material Removal: Reduces waste and saves time.

Improved Surface Finish: Enhances part quality.

Single Setup for Complex Shapes: Increases productivity, saving on labor costs.

Our service is ideal for prototypes, small production runs, or larger-quantity orders across multiple industries. With over 40 certified materials available (including plastics and metals), we offer on-demand machining to bring your designs to life. Whether it’s intricate medical devices or robust automotive parts, BOEN ensures quality and precision at every step.

Why Choose BOEN?

We combine advanced technology with expert craftsmanship. Our fully equipped facility handles both 3-axis and 5-axis machining, providing you with customized results for your unique projects.

Our experienced machinists and programmers can handle complex geometries, undercuts, and angles all in a single setup, minimizing errors and ensuring efficiency. By reducing setup times, overhead, and tooling costs, we deliver high-precision parts at the lowest possible cost per part.

Explore how our 5-axis CNC machining can elevate your project to the next level!

#CNCmachining#5AxisMachining#PrecisionEngineering#Aerospace#Robotics#Automotive#BOEN#ComplexDesigns#Manufacturing#Prototyping

0 notes

Text

Phillips India: Future CNC Trends in CNC Machine Development and Innovations

“The Future of CNC Machine: Innovations and Trends" delves into the evolving landscape of CNC machining. It highlights the integration of AI and IoT in CNC systems, enhancing precision and efficiency. The blog post discusses the rise of multi-axis machines, enabling complex designs and reducing production times. Emphasis is placed on the growing adoption of hybrid manufacturing, combining additive and subtractive processes for better versatility.

The blog also touches on the importance of sustainability, with innovations aimed at reducing waste and energy consumption. Furthermore, it explores advancements in software, enhancing machine usability and customization. Overall, the future of CNC machining is marked by increased automation, connectivity, and eco-friendly practices.

For more details, you can explore the full blog here: https://phillipscorp.com/india/the-future-of-cnc-machine-innovations-and-trends/

0 notes