#Nickel Alloy

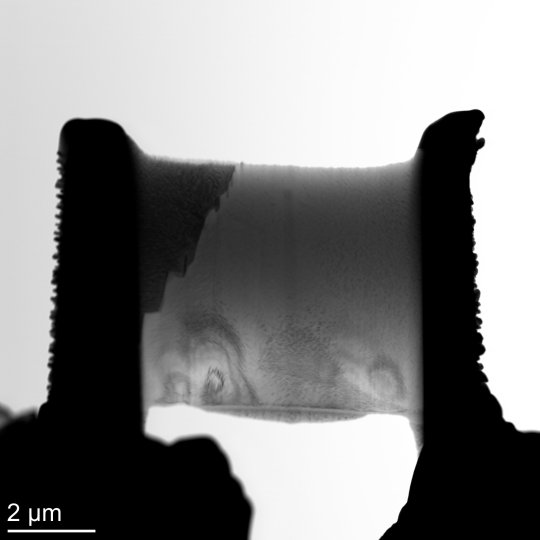

Photo

Harry Bertoia

Sonambient, 1970s

Nickel alloy with bronze base

52 × 11 3/4 × 11 3/4 in

5 notes

·

View notes

Photo

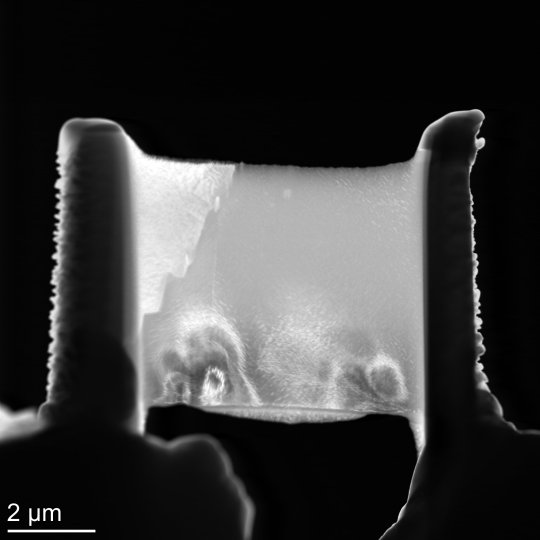

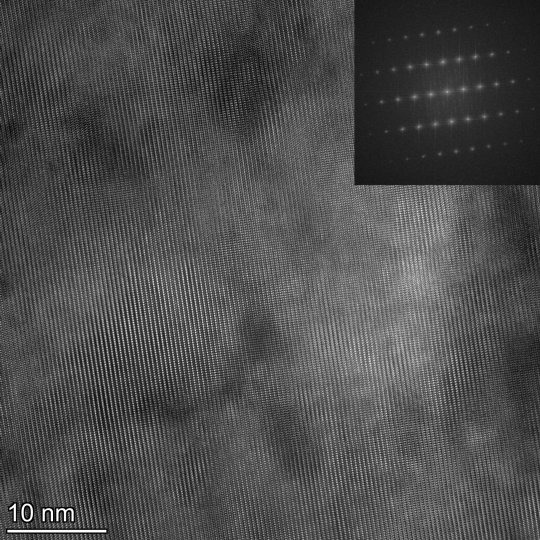

#transmission electron microscopy#bright field#dark field#HRTEM#Fourier transform#nickel alloy#scanning transmission electron microscopy#original content

5 notes

·

View notes

Text

KRYSTAL GLOBAL ENGINEERING LIMITED AT HEAT EXCHANGER WORLD AMERICAS - 2024

16 - 17 October 2024,

Houston, Texas

USA

HEAT EXCHANGER WORLD AMERICAS - 2024

Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024

Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions in high-performance Stainless Steel, Duplex, Super Duplex, Nickel Alloy, and Exotic-Grade Material Tubes, Pipes, and U-Tubes.

Event Details:

Date: 16 – 17 October 2024

Venue: Houston, Texas, USA

Booth Number: Stand 2110

Event Hours: 10:00 AM – 5:00 PM

Event Link: https://heat-exchanger-world-americas.com

KRYSTAL X HEAT EXCHANGER

2024

Manufacturer and Exporter of Seamless Stainless Steel, Duplex, Super Duplex, Nickel Alloy Tubes, Pipes & U Tubes.

At the trendsetting, ultimate networking event for the process industry, you will have an opportunity to connect with Krystal experts, tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics include the path beyond blue to green hydrogen, the latest decarbonization innovations, advances in electrolyser technologies with ITM Power and the role of services in future-proofing your plant.

About Krystal Global Engineering Limited:

Krystal Global Engineering Limited is your premier destination for top-quality tubes and pipes, serving industries worldwide including petrochemical, oil and gas, chemical processing, and power generation. We prioritize excellence and innovation, delivering superior products tailored to global standards.

What to Expect:

Extensive Product Showcase: Explore our comprehensive range of high-performance tubes, pipes, and U-tubes designed to endure extreme temperatures, corrosive environments, and high-pressure conditions.

Expert Consultation: Meet our team of industry specialists available to discuss your specific needs and provide tailored solutions.

Networking Opportunities: Connect with professionals, engineers, and industry leaders to exchange ideas, insights, and business opportunities.

Live Demonstrations: Witness live demonstrations highlighting the durability, reliability, and performance of our products in real-world applications.

Why Visit Us?

Quality Assurance: Our products undergo stringent quality control measures, ensuring compliance with international standards and specifications.

Customization: Benefit from our flexible manufacturing capabilities, allowing for customized solutions to meet your unique project requirements.

Global Reach: With a vast network of distributors and partners, we offer prompt delivery and comprehensive support worldwide.

Innovation: Stay ahead with our continuous investment in research and development, delivering cutting-edge solutions to address evolving industry challenges.

#16 - 17 October 2024#Houston#Texas#USA#HEAT EXCHANGER WORLD AMERICAS - 2024#Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024#Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions#Duplex#Super Duplex#Nickel Alloy#and Exotic-Grade Material Tubes#Pipes#and U-Tubes.#Event Details:#•#Date: 16 – 17 October 2024#Venue: Houston#Booth Number: Stand 2110#Event Hours: 10:00 AM – 5:00 PM#Event Link: https://heat-exchanger-world-americas.com#KRYSTAL X HEAT EXCHANGER#2024#Manufacturer and Exporter of Seamless Stainless Steel#Nickel Alloy Tubes#Pipes & U Tubes.#At the trendsetting#ultimate networking event for the process industry#you will have an opportunity to connect with Krystal experts#tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics in#the latest decarbonization innovations

0 notes

Text

The Versatile Strength of Nickel Alloy Plates

Nickel alloy plates are an unsung hero in many industries. Their unique combination of strength, corrosion resistance, and versatility makes them a go-to material for everything from aerospace to chemical processing.

Why Nickel Alloy Plates?

Corrosion Resistance: Perfect for harsh environments.

High-Temperature Stability: Ideal for aerospace and power generation.

Strength and Durability: Long-lasting performance under stress.

Versatility: Easily fabricated to meet diverse needs.

Where Are They Used?

Aerospace: Engines and critical components.

Chemical Processing: Reactors and heat exchangers.

Marine Engineering: Ship components and offshore platforms.

Power Generation: Turbines and boilers.

Nickel alloy plates are more than just metal sheets; they're the backbone of modern industry. As we push the boundaries of technology, their importance will only grow. 🛠️🌟

0 notes

Text

Leading Supplier Of Nickel Alloy 200 Pipes in Bengaluru

In the industrial panorama of Bengaluru, locating a dependable dealer of top notch nickel alloy pipes is vital for various packages throughout one-of-a-kind sectors. Among the myriad of options to be had, one call sticks out: Bhagya laxmi Industrial. Renowned for its commitment to first-rate and customer pride, we have emerged as a main Nickel Alloy 200 Pipes manufacturer, Nickel Alloy 200 Pipes stockist, Nickel Alloy 200 Pipes supplier, and Nickel Alloy 200 Pipes exporter in Bengaluru.

Understanding the Significance of Nickel Alloy 200 Pipes & Tubes

Nickel Alloy 200 is a commercially natural wrought nickel alloy known for its fantastic resistance to many corrosive environments. It offers fantastic mechanical properties even at excessive temperatures and reveals appropriate electrical conductivity. These residences make Nickel Alloy 200 Pipe & Tube fantastically perfect for a huge range of applications in industries along with chemical processing, petrochemicals, marine engineering, strength technology, and greater.

Reliable Manufacturer and Supplier

As a trusted manufacturer and provider of UNS N02200 Pipes & Tubes, we guarantee that its merchandise adhere to the very best exceptional requirements. The employer makes use of advanced satisfactory uncooked substances and employs superior manufacturing techniques to produce pipes and tubes that meet the stringent requirements of various industries.

Unparalleled Quality Assurance

Quality warranty is paramount, each Nickel Alloy 200 Pipe and Tube undergoes rigorous testing strategies to make sure its integrity and performance. From dimensional accuracy to mechanical homes, each thing is thoroughly examined to assure compliance with global first-rate requirements. This unwavering commitment to pleasant has earned us the loyalty of its customers.

Customization Options

Recognizing that each assignment has particular requirements, we offer customization alternatives for Nickel Alloy 200 Pipe & Tube. Whether it is precise dimensions, tolerances, or surface finishes, the business enterprise works closely with its customers to supply tailor-made answers that precisely meet their wishes. This flexibility units from its competitors, making it the desired desire for discerning customers in Bengaluru and beyond.

Competitive Pricing

Despite offering top rate-great merchandise, we maintain aggressive pricing to make sure affordability for its clients. The organisation believes in imparting value for cash without compromising on great, making its UNS N02200 Pipes & Tubes available to a huge range of industries and organizations.

Exceptional Customer Service

The company’s dedicated group of specialists goes above and past to offer outstanding provider, from supporting with product choice to making sure timely delivery. Whether it is a small-scale mission or a massive business software, clients can depend upon Bhagyalaxmi Industrial for spark off and personalized attention

Conclusion

In conclusion, for groups in Bengaluru searching for a dependable dealer of Nickel Alloy 200 Pipes & Tubes, Bhagyalaxmi Industrial emerges as the top preference. With its unwavering dedication to high-quality, giant product variety, customization alternatives, aggressive pricing, and terrific customer support, Bhagyalaxmi Industrial sets the benchmark for excellence inside the industry. Contact us today to experience the difference firsthand and discover why it is the main provider of Nickel Alloy 200 Pipes & Tubes in Bengaluru.

Contact us for all of your UNS N02200 Pipes & Tubes necessities and experience unrivaled quality and provider.

#bhagya laxmi industrial#nickel alloy#nickel alloy 200 pipes#nickel alloy pipes supplier#nickel alloy pipes Manufacturer

0 notes

Text

As a professional supplier and manufacturer of nickel alloys materials in China, HZW provides a quite wide range of nickel alloys products to our global customers.

The forms of our supply come into four categories: Pipes, Strips, Bars, Sheets. Monel, Inconel, Incoloy, Hastelloy are our four major grades.

At HZW, you buy trustworthy quality nickel alloys.

0 notes

Text

What are industrial applications of Nickel Alloy?

Aerospace Industry: Nickel alloys are extensively used in aircraft components and aerospace structures due to their high strength, corrosion resistance, and ability to withstand extreme temperatures encountered during flight.

Chemical Processing: In chemical plants, nickel alloys are utilized in equipment such as reactors, vessels, and piping systems due to their exceptional corrosion resistance to harsh chemicals and acids.

Power Generation: Nickel alloys play a crucial role in power generation applications, including gas turbines, steam turbines, and nuclear reactors, where they offer resistance to high temperatures and corrosion in aggressive environments.

Oil and Gas Sector: Nickel alloys find applications in the oil and gas industry for components such as valves, tubing, and downhole tools, where they provide resistance to corrosion, erosion, and hydrogen sulfide cracking in demanding offshore and onshore environments.

Specialty Valves and Vacuum Systems: Nickel alloys are preferred materials for specialty valves, fittings, and vacuum systems in industries such as semiconductor manufacturing, where high purity, corrosion resistance, and reliability are essential.

Precision Components: In precision engineering applications, nickel alloys are used to manufacture components requiring high strength, corrosion resistance, and dimensional stability, such as bearings, springs, and fasteners.

Conclusion:

In conclusion, the industrial applications of nickel alloy span across a wide range of sectors, from aerospace and chemical processing to power generation and precision engineering. For reliable and high-quality nickel alloy products that meet the rigorous demands of these industries, consider sourcing from a trusted manufacturer like Ashapura Steel. As a leading Nickel Alloy Manufacturer, Ashapura Steel offers a diverse range of top-quality nickel alloy products tailored to your specific requirements, ensuring durability, performance, and reliability in critical applications.

0 notes

Text

Hastelloy has four properties

The alloy, Hastelloy C-276, is a special alloy material with excellent properties, its characteristics are as follows:

Chemical stability

In oxidizing and reducing environments, Hastelloy C-276 alloy can resist the erosion of various corrosive media, showing excellent corrosion resistance.

It has excellent resistance to pitting, crevices and stress corrosion, thanks to its high molybdenum (Mo) and chromium (Cr) content, which make the alloy resistant to chloride ions.

The addition of tungsten (W) further enhances the corrosion resistance of the alloy.

Hastelloy C-276 is one of the few materials that can withstand the corrosion of humid chlorine, hypochlorite and chlorine dioxide solutions, and it also exhibits significant corrosion resistance to high concentrations of chloride salt solutions, such as ferric chloride and copper chloride.

In addition, it is suitable for sulfuric acid solutions of various concentrations and is one of the few materials that can be applied to hot concentrated sulfuric acid solutions.

Physical properties

The material composition of Hastelloy C-276 consists of 57% nickel (Ni), 16% chromium (Cr), 16% molybdenum (Mo), 5% iron (Fe), 4% tungsten (W), a maximum allowance of 2.5% cobalt (Co), 1% manganese (Mn), 0.35% vanadium (V), 0.08% silicon (Si), and 0.01% carbon (C).

It complies with several international and regional standards, including UNS N10276, ASTM B575, ASME SB575, DIN/EN 2.4819 and others.

The alloy has a density of 8.90g/cm³.

Mechanical properties

The tensile strength of Hastelloy C-276 alloy reaches or exceeds 730Mpa, and the elongation is not less than 40%.

When hot forming, the alloy should be immediately annealed at 1150 ° C and water quenched.

Cold deformation processing can increase the strength of the alloy, but it should be noted that due to its high strength, compared with ordinary austenitic stainless steel, greater stress will be generated during the cold forming process.

Because the work hardening rate of Hastelloy C-276 alloy is faster than that of ordinary stainless steel, it is necessary to take intermediate annealing treatment in the extensive cold forming process to avoid excessive hardening.

Welding and heat treatment

The welding performance of Hastelloy C-276 alloy is similar to that of ordinary austenitic stainless steel. Before any welding method is adopted, measures must be taken to ensure that the corrosion resistance of the weld and the heat affected zone is minimized.

Suitable welding methods include tungsten gas shielded welding (GTAW), metal gas shielded welding (GMAW), submerged arc welding, etc. These methods help maintain the corrosion resistance of the weld and the heat affected zone.

Not suitable welding methods include oxy-acetylene welding and other methods that may increase the carbon or silicon content of the weld and heat affected zone of the material, as this will reduce the corrosion resistance of the material.

1 note

·

View note

Text

Exploring the World of Nickel Alloys: What You Need to Know

Welcome to the fascinating world of nickel alloys! If you've ever wondered about the shiny, versatile metals used in various industries worldwide, then this blog post is for you. These alloys are not only durable and corrosion-resistant but also play a crucial role in modern technology and innovation. Let's dive into what makes nickel alloys so special and why they're essential materials in today's industrial landscape.

Advantages and Applications of Nickel Alloys

When it comes to using this alloy, there are numerous advantages that make them a popular choice in various industries. One of the main benefits is their exceptional resistance to corrosion and high temperatures, making them ideal for applications where strength and durability are essential.

This alloys are widely used in the aerospace industry for components such as turbine engines and aircraft structures. Their ability to withstand extreme conditions makes them crucial for ensuring safety and reliability in aviation.

In the medical field, this alloy play a vital role in manufacturing surgical instruments, implants, and medical devices due to their biocompatibility and resistance to bodily fluids.

The oil and gas industry also heavily relies on nickel alloys for equipment exposed to harsh environments like offshore drilling rigs. Their corrosion resistance helps prolong the lifespan of critical components in this sector.

The versatility of this alloy makes them indispensable across a wide range of industries where performance under demanding conditions is non-negotiable.

Common Types of Nickel Alloys

When it comes to nickel alloys, there are several common types that are widely used in various industries. One of the most popular ones is Nickel 200, known for its excellent resistance to corrosion and high thermal and electrical conductivity.

Another common type is Nickel 201, a low-carbon variant of Nickel 200 that offers similar properties but with improved ductility and lower carbon content.

Inconel alloys are also commonly used, offering outstanding oxidation resistance at high temperatures and excellent mechanical strength. Inconel 600, Inconel 625, and Inconel 718 are some well-known variations.

Monel alloys, such as Monel 400 and Monel K-500, are highly resistant to corrosion by acids and alkalis. These alloys find applications in marine engineering due to their exceptional strength.

Hastelloy alloys like Hastelloy C-276 exhibit great resistance to a wide range of chemical process environments including strong oxidizers. These versatile nickel-based superalloys are favoured in harsh industrial settings for their reliability.

Factors to Consider Before Choosing a Nickel Alloy

When selecting a nickel alloy for your project, there are several factors to consider. Think about the specific environment in which the alloy will be used. Will it be exposed to high temperatures, corrosive chemicals, or extreme pressures? Understanding the conditions will help you choose the right nickel alloy that can withstand these challenges.

Another crucial factor is the desired properties of the final product. Different nickel alloys offer varying levels of strength, ductility, and resistance to heat and corrosion. Assessing these requirements will guide you towards selecting an alloy that best suits your needs.

Cost is also a significant consideration when choosing a this alloy. While some alloys may offer superior performance, they might come at a higher price point. Balancing quality with affordability is key in making an informed decision.

Don't forget about availability and support from a reputable alloy’s supplier. Ensure that you can easily source the required materials and receive any necessary technical assistance throughout your project's lifespan.

Maintenance and Care for Nickel Alloys

Maintenance and care for these alloys are essential to ensure their longevity and performance. Regular cleaning with a mild detergent and water can help remove dirt and grime without causing damage to the alloy's surface. Avoid using abrasive cleaners or harsh chemicals that can scratch or corrode the nickel alloy.

To prevent tarnishing, it is recommended to dry the nickel alloy thoroughly after cleaning. Applying a coat of metal polish specifically designed for nickel alloys can help maintain its luster and protect it from oxidation. Inspecting the alloy periodically for any signs of wear or corrosion is also important in preventing further damage.

Storing these alloys in a cool, dry place away from direct sunlight can help preserve their appearance and structural integrity. Additionally, avoiding exposure to extreme temperatures or humidity levels can prevent potential degradation of the alloy over time. Regular maintenance routines will not only keep your nickel alloys looking great but also extend their lifespan significantly.

Innovative Uses of Nickel Alloys in Various Industries

This alloy have found innovative applications across a wide range of industries, thanks to their exceptional properties and versatility. In the aerospace industry, nickel alloys are used in aircraft engines due to their high temperature resistance and corrosion protection. These alloys help enhance engine performance and durability while withstanding extreme conditions.

In the medical field, nickel-based materials are utilized for orthopaedic implants and surgical instruments. Their biocompatibility and strength make them ideal for long-term use within the human body. Additionally, in the automotive sector, nickel alloys play a crucial role in manufacturing components that require excellent heat resistance and mechanical strength.

Furthermore, the oil and gas industry rely on this alloy for equipment subjected to harsh environments such as deep-sea drilling operations. The outstanding resistance to corrosion makes these materials essential for ensuring safety and efficiency in extracting resources from challenging locations.

Conclusion: The Future of Nickel Alloys in Technology and Beyond

Nickel alloys have proven to be versatile and reliable materials with a wide range of applications across various industries. As technology continues to advance, the demand for nickel alloys is expected to grow even further. With their exceptional properties and capabilities, nickel alloys are poised to play a crucial role in shaping the future of technology and beyond.

As we look ahead, it is clear that nickel alloys will remain at the forefront of material science, providing essential support for advancements in technology, sustainability efforts, and beyond. By staying informed about the latest developments in this field and working closely with reputable suppliers of these alloys, industries can harness the full potential of these remarkable materials for a brighter future.

0 notes

Text

Inconel in the Chemical Industry: Defying Corrosion and Harsh Chemicals

In the vast world of the chemical industry, where the constant battle against corrosion rages on, the value of materials that can withstand harsh environments cannot be overstated. Among these resilient materials, Inconel alloys have risen to prominence, offering an impressive level of resistance to corrosion and harsh chemicals. This blog delves into the significance of Inconel in the chemical industry, shedding light on its distinctive properties and versatile applications.

Understanding Inconel Alloys

Inconel Alloys belong to a family of superalloys based on nickel and chromium. Renowned for their exceptional ability to withstand high temperatures, oxidation, and corrosion, these alloys consist of a combination of nickel, chromium, iron, and other elements. Their unique blend of mechanical strength and resistance to corrosion makes them highly suitable for a wide range of applications in the chemical industry.

The Corrosive Challenge

Chemical processing plants often grapple with corrosive substances that can wreak havoc on conventional materials. Corrosion refers to the gradual deterioration caused by chemical reactions that can result in equipment failure, safety risks, and costly downtime. However, Inconel alloys stand tall as formidable defenders against these corrosive challenges.

Applications of Inconel in the Chemical Industry

Aside from their impressive resistance to corrosion and harsh chemicals, Inconel alloys find diverse applications throughout various sectors within the chemical industry:

Chemical Processing Equipment

Inconel alloys are extensively used in manufacturing chemical processing equipment. Reactors, heat exchangers, and pipelines that come into contact with aggressive chemicals benefit greatly from Inconel's corrosion resistance properties. This ensures longevity and reliability for these vital components.

Catalyst Support Structures

Thanks to its ability to withstand high temperatures and aggressive chemical environments effectively; Inconel is a favored choice for catalyst support structures. These structures play a crucial role in catalytic processes where stability is paramount. And with its remarkable resistance, Inconel ensures the efficiency and durability of these processes over time.

Piping Systems

Transporting corrosive chemicals through pipelines requires materials that can withstand degradation. Inconel's corrosion resistance and exceptional strength make it an excellent option for constructing piping systems in chemical plants. This choice reduces the risk of leaks and failures, enhancing overall safety.

Inconel: A Key Player in Safety and Reliability

Ensuring Operational Integrity

In the chemical industry, maintaining operational integrity is of utmost importance. One key factor that contributes to this is the use of Inconel in critical components. By withstanding corrosive attacks, Inconel plays a crucial role in preventing equipment failures, leaks, and accidents. This not only ensures a safer working environment but also promotes overall operational integrity.

Longevity and Cost-Efficiency

When it comes to making smart investments, choosing Inconel alloys proves to be a cost-effective choice in the long run. The extended lifespan of equipment constructed with Inconel translates to reduced maintenance costs, minimized downtime, and enhanced overall efficiency. It's clear that investing in Inconel pays off both in terms of longevity and cost-efficiency.

Invaluable Significance in the Chemical Industry:

The exceptional resistance of Inconel to corrosion and harsh chemicals solidifies its significance in the chemical industry. Acting as a stalwart ally against degradation, Inconel alloys contribute significantly to the longevity, reliability, and efficiency of critical components in chemical processing plants. Their role cannot be understated when it comes to ensuring smooth operations within this industry.

Alloyed Sustainables LLP: Your Trusted Inconel Partner

From chemical processing equipment to catalyst support structures and piping systems, Inconel alloys play an indispensable role in ensuring safety, reliability, and longevity within the chemical industry. At Alloyed Sustainables LLP, we find ourselves in a time where industries are constantly changing and evolving. The need for materials that can resist corrosion, like Inconel, has never been higher. We take great pride in being at the forefront of addressing this demand.

As one of the top importers and stockists of Inconel Alloys, we make sure to always have a steady and dependable supply of high-quality alloys. This allows us to meet the demanding requirements of different industries. With our support, businesses are empowered to keep their operations running smoothly, even in the face of corrosive challenges.

0 notes

Text

HEY

Does anyone know where I can buy or manufacture sheets of CrCoNi alloy?

I need it for uhhhh, scientific research....

I know it probably isn't commercially available but I thought I'd ask around

0 notes

Text

How Do You Find Seamless Nickel Pipe Suppliers

A flood of Nickel Alloy Tube Manufacturers in our market. Figuring out the right one is difficult for you because it consumes all your time. To avoid these circumstances, you should be aware of suitable methodologies to land on the perfect choice. For more information call us @ +86 178 58922973

0 notes

Text

Hastelloy-c276 Price In India

In the chemicals and petrochemicals business, hastelloy-c276 or alloy C-276 has a wide range of uses for both catalytic systems and parts in organic processes using chlorides.

0 notes

Text

Exploring the Mechanical Properties of Nickel Alloy

High Strength: Nickel alloy exhibits excellent strength characteristics, allowing it to withstand heavy loads and high-stress environments. This property makes it ideal for applications where structural integrity is crucial, such as aerospace components and marine equipment.

Corrosion Resistance: One of the most notable properties of nickel alloy is its remarkable resistance to corrosion and oxidation. This resistance ensures longevity and reliability, even in harsh environments exposed to corrosive substances or extreme temperatures.

Temperature Resistance: Nickel alloy maintains its mechanical properties at elevated temperatures, making it suitable for applications involving high heat or thermal cycling. Industries such as petrochemical, power generation, and automotive rely on nickel alloy for its ability to withstand extreme temperature fluctuations.

Fatigue Resistance: Nickel alloy demonstrates excellent fatigue resistance, allowing it to endure repeated loading and unloading cycles without experiencing structural degradation. This property ensures the durability and reliability of components subjected to dynamic loading conditions.

Machinability and Weldability: Despite its high strength and resistance properties, nickel alloy offers good machinability and weldability, allowing for ease of fabrication and assembly. This versatility makes it a preferred choice for manufacturers seeking efficient production processes without compromising on quality.

In conclusion, the mechanical properties of nickel alloy make it a valuable material in various industrial sectors, offering high strength, corrosion resistance, temperature resistance, fatigue resistance, and ease of fabrication. For premium-quality nickel alloy products tailored to your specific requirements, consider Om Steel as your trusted supplier. With their expertise and commitment to excellence, Om Steel ensures reliability and performance in every nickel alloy component. Explore Om Steel's offerings today and experience the difference in quality and service.

0 notes

Text

M Pipe Fitting Solution Inc is a leading Alloy 20 Sheets Plates Manufacturer, Supplier, and Exporter in India.

1 note

·

View note