#Nickel Alloy Tee

Text

Pipe Tee - Bu-Lok Pipe And Tube

A variety of Pipe Tee are produced and supplied by Bu-LOK. It is a leading manufacturer, exporter and supplier of reducing tees and straight tees in a variety of shapes and dimensions.We anticipate a growth rate of 5 % TO 10 % per year in the following 3 to 5 years and working towards it.

0 notes

Text

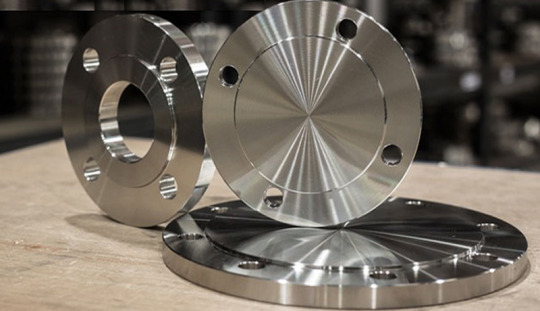

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Detailed Information about Steel Fittings

Pipe fittings involve rerouting the water supply via tees, elbows, and other pipe components. Reducing tees, reducers, and similar pipe fittings are used to modify pipe sizes. In addition to the countless variations of coupling, there are

ASME B16.9 bend

Schedule 40 ASME B16.9 bend Producer Steel Tubing Curves It is usual to have the pipe's diameter, wall thickness, and pressure contained within its program. The ASME B16.9 standard, for instance, applies to pipe and fitting diameters between 1/2 inch and 48 inches.

Steel Hollow Section

Tubular sections made from steel that have had their interiors hollowed down are called hollow steel. In addition to "structural steel tubes" and "Hollow Structural Sections," these terms can also be used interchangeably (HSS). steel hollow section suppliers are often used as beams in welded frames and columns because of their many advantages in building and mechanical applications.

Pipe Clamps

Pipe clamps, also known as pipe clips or saddle clamps, are standard, straightforward fixtures used in various do-it-yourself and professional installation scenarios. pipe clamps suppliers are channel support systems frequently used in HVAC, plumbing, and electrical installations.

Forged Fittings

Pipe fittings constructed from forged carbon steel, stainless steel, or high nickel alloys are known as "forged steel fittings." That's why Forged Fittings suppliers in uaeproductsso helpful to have a method of making sturdy fittings that forges steel.

Branch Fittings

Pipes that cross each other can be joined with branch fittings. T-fittings and 45- and 60-degree wyes are the two most common types of pipe produced by Branch Fittings suppliers. Considering the necessary sweep when choosing a branch suited for a specific sector is essential.

Heat Exchanger Tubes

One common type of tube produced by Heat exchanger tubes suppliers in UAE is the shell-and-tube type. It is the standard heat exchanger used in oil refineries and other large-scale chemical processes because it can withstand greater pressure.

Steel Angle

In most cases, hot-rolled carbon steel or high-strength low-alloy steel is used to create steel angle, also known as angle iron or Steel Angle supplier’sbar. It has an L-shaped section with two legs that can be the same length or different lengths, and the angle would be 90 degrees.

Sanitary Fittings

Cleanable tubing connections, known as Sanitary Fittings, are fitted in process piping systems to provide a germ-free environment. Sanitary Fittings suppliers in UAE like regular fittings, are used to regulate the flow of fluid by connecting different sections of piping systems.

Welding Electrode

Electrical arc welding requires electrodes and lengths of wire linked to a welding machine. A high amount of heat is generated by the arc created when current flows through this wire to melt and fuse metal for welding electrode suppliers in uae.

Fasteners

A mechanical tool or element, a Fasteners suppliers in UAE, firmly binds multiple items together. The pins can take apart or reassemble the parts without any problems. But they can also serve as fixed connections.

Conclusion

Tube fittings connect tubing segments to one another or to other tubes, pipes, hoses, or other components in various configurations, including in-line, offset, multi-port, and mounting. The straight components of a system are joined together by fittings, which are couplings and joints made from specialised materials.

2 notes

·

View notes

Text

Nickel 200 Forged Fittings Suppliers

Nickel 200 is a commercially pure nickel alloy (with a minimum of 99% nickel content), known for its excellent mechanical properties, outstanding corrosion resistance, and high electrical and thermal conductivity. Nickel 200 forged fittings are widely used in industries where purity, corrosion resistance, and operational integrity are essential, especially in extreme temperatures and harsh chemical environments.

Key Properties of Nickel 200 Forged Fittings

High Purity and Corrosion Resistance: Nickel 200 is highly resistant to a wide range of corrosive environments, particularly in reducing environments such as acids and alkalis. Its resistance to caustic soda, sulfuric acid, and other aggressive chemicals makes it ideal for the chemical and food processing industries.

Thermal and Electrical Conductivity: The high thermal and electrical conductivity of Nickel 200 makes it useful in applications requiring good heat transfer and electrical performance. This is why it is frequently used in electrical and electronic components.

Magnetic and Ductile: Nickel 200 retains its magnetic properties even at low temperatures and exhibits good ductility, allowing for easy fabrication and forming, making it suitable for many types of forged fittings.

Excellent Mechanical Properties: Even at elevated temperatures (up to 600°F or 315°C), Nickel 200 maintains its mechanical strength, while also performing well in low-temperature and cryogenic applications.

Applications of Nickel 200 Forged Fittings

Nickel 200 forged fittings are used in a variety of industries due to their excellent corrosion resistance, high thermal conductivity, and durability. Common applications include:

Chemical Processing: Nickel 200 is widely used in the handling of caustic alkalis, chlorine, and other aggressive chemicals in chemical processing plants. The fittings are used in pipe systems, reactors, and heat exchangers.

Food Processing: Due to its non-toxic and non-contaminating properties, Nickel 200 is used in food processing equipment, especially in environments where sodium hydroxide or other caustic solutions are present.

Electrical and Electronics: Nickel 200’s high electrical conductivity makes it ideal for electrical and electronic components like connectors, terminals, and batteries.

Aerospace and Marine: Its resistance to saltwater corrosion makes Nickel 200 fittings suitable for marine environments and aerospace applications that involve high-performance requirements.

Pharmaceutical and Petrochemical Industries: Nickel 200 fittings are used in pharmaceutical manufacturing and petrochemical processing, where chemical purity and corrosion resistance are paramount.

Types of Nickel 200 Forged Fittings

Nickel 200 forged fittings are available in various types and configurations to accommodate different piping systems and operational needs. Some common types include:

Elbows: Used to change the direction of flow in piping systems.

Tees: Facilitate the branching of pipe sections to redirect flow.

Couplings: Join two pipes together, often used for easy pipe assembly.

Unions: Provide easy assembly and disassembly in piping systems, allowing for quick maintenance or replacement of parts.

Reducers: Help transition between different pipe sizes while maintaining flow efficiency.

Crosses: Enable a four-way junction for complex piping systems.

Specifications of Nickel 200 Forged Fittings

Nickel 200 forged fittings must adhere to specific industry standards and specifications to ensure their reliability in demanding applications. Below are some of the key specifications:

Chemical Composition

Nickel 200 has a simple and highly pure composition:

Nickel (Ni): 99.0% minimum

Cobalt (Co): 0.25% maximum

Manganese (Mn): 0.35% maximum

Carbon (C): 0.15% maximum

Sulfur (S): 0.01% maximum

Silicon (Si): 0.35% maximum

Iron (Fe): 0.40% maximum

This composition ensures the high purity of Nickel 200, which is key to its performance in corrosive environments.

Mechanical Properties

Tensile Strength (MPa): 415 MPa minimum

Yield Strength (MPa): 103 MPa minimum

Elongation: 40% minimum

Hardness: 110 HB (Brinell Hardness)

These properties allow Nickel 200 forged fittings to maintain strength and flexibility even under high-stress conditions.

Standards and Grades

Nickel 200 forged fittings are produced according to internationally recognized standards to ensure reliability in various industrial applications:

ASTM B564: This standard outlines the specifications for nickel alloy forgings.

ASME SB564: This is the corresponding ASME standard for nickel forgings used in pressure piping systems.

ASME B16.11: Specifies the dimensional standards for forged fittings used in pressure systems.

MSS-SP-79, MSS-SP-83, MSS-SP-95: Cover socket weld and threaded forged fittings.

Dimensional Specifications

Nickel 200 forged fittings are available in various pressure classes and sizes, depending on the requirements of the piping system:

Sizes: 1/8" NB to 4" NB

Pressure Classes: Class 2000, 3000, 6000, and 9000

Connection Types: Available in socket weld and threaded connection types.

Corrosion Resistance of Nickel 200 Forged Fittings

Nickel 200 exhibits excellent resistance to a variety of corrosive media, making it a superior choice for demanding environments:

Caustic Alkalis: Nickel 200 is particularly resistant to alkalis such as caustic soda, even at high concentrations and temperatures.

Acid Resistance: The alloy shows good resistance to neutral and mildly acidic environments.

Seawater Resistance: Nickel 200 performs well in marine environments due to its ability to resist saltwater corrosion.

Oxidizing Environments: In oxidizing conditions, Nickel 200 forms a protective oxide layer that prevents further corrosion.

Temperature Range

Nickel 200 forged fittings are designed to withstand a wide range of temperatures:

Operational Temperature Range: From cryogenic temperatures to around 600°F (315°C), Nickel 200 maintains its mechanical integrity and corrosion resistance.

Testing and Quality Control

To ensure the highest quality and safety standards, Nickel 200 forged fittings undergo rigorous testing, including:

Hydrostatic Testing: Ensures the fittings can withstand pressure without leaks or structural failures.

Non-Destructive Testing (NDT): Techniques such as ultrasonic or radiographic inspection ensure there are no internal defects.

Mechanical Testing: To verify tensile strength, yield strength, and elongation properties.

Chemical Composition Testing: Verifies the purity and chemical makeup of the alloy to ensure compliance with standards.

0 notes

Text

Top 3 Applications of Pipe Fittings

What are Pipe Fittings?

Pipe fittings are essential in many industries and systems where the handling of fluids-one form or other-is involved. Pipe Fittings are used for connecting, changing the direction of, controlling, and stopping the flow of a liquid, gas, or slurry inside a piping system. Their versatility and functionality make them indispensable across several fields. Some common applications and usages of pipe fittings are discussed below. Pearl Pipe Fittings is the leading Pipe Fittings Manufacturer in India and Flange Manufacturer in India.

Top 3 Applications of Pipe Fittings

1. Plumbing Systems

Probably the most common plumbing pipe fitting used serves to connect various sections of pipe in residential, commercial, and industrial buildings for water distribution and sewage systems. Standard elbows, tees, and couplers allow the flow of water to divert around obstructions or corners, while reducers change pipe sizes to comprehend any variation in pressure. We are also the best Carbon Steel Pipe Fittings Manufacturer in India and CS Flanges Manufacturers in India

2. Oil and Gas Industry

The oil and gas industry-operated pipe fittings are highly important to guarantee that crude oil, natural gas, or refined products are being moved around safely. Applications involving fittings under high-pressure conditions and requirements for corrosion resistance call for materials to be manufactured from carbon steel, stainless steel, or alloy for this purpose. Such fittings play an indispensable role in the process of connecting pipelines, flow rate control, and leak-proof applications at the stage of extraction, refining, and distribution.

3. Chemical and Pharmaceutical Industry

The chemical and pharmaceutical industries are one of the prime concerns in terms of precision with safety. The pipe fitting deployed within this industry needs to be resistant to corrosion and thereby not chemically reactive. Thus, this is used for transporting liquids, gases, and powders so that the substance being conveyed retains its integrity. Flanged connections, valves, and special fittings such as fittings for sanitary appliances ensure the process remains clean and free from contamination.

You may also like: Copper Nickel Flange Manufacturer in India

Product Source: Stainless Steel Flanges Manufacturer in India and SS Pipe Fittings Manufacturers in India

#Pipe Fittings Manufacturer in India#Flange Manufacturer in India#Carbon Steel Pipe Fittings Manufacturer in India#CS Flanges Manufacturers in India#Copper Nickel Flange Manufacturer in India#Stainless Steel Flanges Manufacturer in India#SS Pipe Fittings Manufacturers in India

0 notes

Text

Inconel 600 Buttweld Fittings Suppliers & manufacturers | Metalforgeindia

In the area of enterprise company agency business agency company applications wherein sturdiness, electricity, and resistance to immoderate environments are important, Inconel 600 buttweld fittings stand out as an outstanding choice. Known for their brilliant resistance to oxidation, corrosion, and excessive temperatures, Inconel 600 buttweld pipe fittings are considerably used within the route of numerous industries, collectively with chemical processing, aerospace, nuclear reactors, and electricity era.

For those looking to deliver the ones crucial components, choosing the right organization and manufacturer is important. In this weblog, we’ll find out the advantages of Inconel 600 buttweld fittings, why they will be a favored desire for demanding packages, and the way we are located as an excellent organization and producer within the market.

Understanding Inconel 600 Buttweld Pipe Fittings

Inconel 600 is a nickel-chromium alloy diagnosed for its wonderful resistance to oxidation and corrosion, particularly in environments subjected to immoderate temperatures. This alloy is well-known for extremely good mechanical houses, making it a remarkable material for fabricating buttweld pipe fittings, which might be vital in numerous business enterprise structures.

Buttweld fittings are used to trade the route, department off, or mechanically be a part of components inside a piping device. These fittings, which embody elbows, tees, reducers, caps, and crosses, are crucial in ensuring the integrity and normal everyday usual trendy fashionable performance of fluid and fuel transportation systems. When made from Inconel 600, the ones fittings provide terrific notable universal overall performance, in particular in environments that require resistance to immoderate warm temperature and corrosive substances.

Why Choose Inconel 600 Buttweld Fittings?

1. High-Temperature Resistance

One of the primary motives Inconel 600 is finished in buttweld fittings is its functionality to face as a whole lot as excessive temperatures. It can keep its mechanical houses and face up to oxidation in temperatures as amazing as 2000°F (1093°C). This makes it an incredible choice for industries like aerospace, wherein additives are uncovered to immoderate thermal pressure.

2. Excellent Corrosion Resistance

Inconel 600 offers advanced resistance to a large type of corrosive surroundings. It is especially obvious within the path of chloride-ion stress-corrosion cracking, a common hassle in masses of commercial enterprise agency business enterprise strategies. This makes it super for chemical processing industries wherein the tool is frequently uncovered to corrosive chemical substances.

3. Versatility in Applications

The versatility of Inconel 600 lets in it for use in numerous administrative center artwork, together with pipes, tubes, and fittings. In buttweld fittings, this versatility guarantees that they will be done in several applications beginning from immoderate-strain steam pipes to warm temperature exchangers, making sure reliability and sturdiness.

Applications of Inconel 600 Buttweld Pipe Fittings

Given their awesome homes, Inconel 600 buttweld fittings find out programs in numerous industries:

Chemical Processing: Inconel 600’s resistance to oxidation and corrosion makes it incredible for use in chemical processing vegetation, in which it may resist the aggressive chemical substances and immoderate temperatures.

Aerospace: Inconel 600 buttweld fittings are used within the aerospace company business company enterprise commercial enterprise corporation industrial organization industrial corporation business organization for additives that require strength and balance at excessive temperatures, which encompass exhaust systems and engine components.

Power Generation: The immoderate-temperature resistance of Inconel 600 makes it suitable to be used in strength era plants, especially in gasoline and steam generators.

Nuclear Reactors: Due to its capability to get up to oxidation and preserve its mechanical homes at immoderate temperatures, Inconel 600 is carried out in nuclear reactors, in which protection and reliability are paramount.

MetalForge India: Your Trusted Partner for Inconel 600 Buttweld Fittings

When it includes sourcing Inconel 600 buttweld fittings, we stand out as a prime company enterprise organization and manufacturer. With years of enjoy in the business enterprise, we've built a popularity for delivering exquisite merchandise that meet the stringent goals of several industries.

1. Extensive Range of Products

We offer an extensive form of Inconel 625 Round Bar, together with elbows, tees, reducers, caps, and crosses. These fittings are available in numerous sizes and thicknesses to fulfill the proper goals of your duties. Whether you need fashionable sizes or custom fittings, we've got the capability to supply.

2. Commitment to Quality

Quality is at the center of our operations. All Inconel 600 buttweld fittings are synthetic in compliance with global necessities which incorporate ASTM, ASME, and DIN. The employer’s power of will to incredible ensures that you get products that now do not outstanding meet but exceed your expectations.

3. Advanced Manufacturing Capabilities

We rent gift-day production facilities organized with present day- day generation. This permits the economic enterprise company employer business agency organization to deliver Inconel 600 buttweld fittings with precision and consistency. The use of superior machines moreover guarantees that the goods are loose from defects and prepared for use in essential packages.

4. Expertise and Experience

With a hard and fast of professional experts, we provide awesome information in the place of nickel alloys, which includes Inconel 600. The organization's experts are to provide technical manual and steerage, ensuring which you select out the right fittings for your precise applications.

5. Reliable Supply Chain

We are privy to the importance of well timed transport within the commercial enterprise corporation corporation corporation vicinity. The corporation employer has hooked up a dependable delivery chain that guarantees your orders are brought on time, each time. Whether you're sourcing for a small venture or a large-scale operation, you can anticipate us for regular delivery.

Conclusion

Inconel 600 buttweld pipe fittings are a vital detail in industries that require substances with wonderful resistance to excessive temperatures and corrosion. Their versatility, strength, and reliability stimulated them to be a desired preference for critical packages in chemical processing, aerospace, electricity generation, and nuclear reactors.

When sourcing those crucial components, it’s vital to select an enterprise and manufacturer with a tough and rapid up track file of handing over fantastic merchandise. We, with its massive form of Inconel 600 buttweld fittings, self-discipline to excellence, and advanced manufacturing capabilities, are counting on pals in ensuring the success of your duties.

For greater statistics on Inconel 600 buttweld pipe fittings or to find out an order, contact us in recent times. Experience the distinction that superb, facts, and reliability also can additionally furthermore furthermore need to make to your commercial company operations.

0 notes

Text

Platinex: A Leading Supplier of Nickel Alloy Pipe Tees

Platinex has established itself as a premier manufacturer and supplier of high-quality nickel alloy pipe tees, renowned for their exceptional corrosion resistance, durability, and performance in demanding environments. With a strong commitment to excellence, the company offers products that meet the most stringent industry standards.

Why Choose Platinex for Nickel Alloy Pipe Tees?

Superior Corrosion Resistance: Nickel alloys are known for their excellent resistance to corrosion, making them ideal for applications in harsh environments, such as chemical processing, petrochemical, and marine industries.

High-Temperature Performance: Many nickel alloys can withstand high temperatures, making them suitable for applications involving extreme heat or corrosive media.

Excellent Mechanical Properties: Nickel alloy pipe tees offer excellent mechanical properties, including strength, toughness, and fatigue resistance.

Customization Options: Platinex can customize nickel alloy pipe tees to meet specific project requirements, including size, wall thickness, and end connections.

Industry Certifications: The company adheres to international standards and certifications, such as ASME, ANSI, and ASTM, demonstrating its commitment to quality and safety.

Excellent Customer Service: Platinex provides exceptional customer support, offering expert guidance and assistance throughout the entire process.

Timely Delivery: The company is committed to meeting customer deadlines and ensuring timely delivery of orders.

Applications of Nickel Alloy Pipe Tees

Nickel alloy pipe tees are widely used in various industries due to their superior corrosion resistance, high-temperature performance, and excellent mechanical properties. Some common applications include:

Chemical Processing

Petrochemical

Pulp and Paper Production

Marine and Offshore Engineering

Power Generation

Heat Exchangers

In conclusion, Platinex is a trusted supplier of high-quality nickel alloy pipe tees, renowned for their exceptional performance, durability, and corrosion resistance. By choosing Platinex, you can be confident in selecting products that meet the most demanding industry standards and ensure the success of your project.

0 notes

Text

Best Stainless Steel Tube Fittings Exporters in Nigeria

Best Stainless Steel Tube Fittings Exporters in Nigeria: Why Midland Alloys Inc. Stands Out as Your Ideal Partner

Introduction: The Growing Demand for Stainless Steel Tube Fittings in Nigeria

As Nigeria's economy expands, the demand for high-quality industrial materials, particularly stainless steel tube fittings, continues to rise. Essential in various sectors, including oil and gas, construction, and manufacturing, stainless steel tube fittings are prized for their durability, strength, and resistance to corrosion. In this context, selecting a reliable supplier becomes vital. Midland Alloys Inc. has emerged as a leading exporter of stainless steel tube fittings in Nigeria, committed to providing exceptional products and unparalleled service tailored to meet the diverse needs of various industries.

Midland Alloys Inc.: A Trusted Name in Stainless Steel Tube Fittings Exportation

Midland Alloys Inc., established in 1975, has been a leading manufacturer, supplier, and exporter of a diverse range of steel products. With 50 years of experience, the company has built a reputation for excellence in the steel industry. We offer a comprehensive product line including stainless steel, carbon steel, alloy steel, and nickel, in various forms such as pipes, tubes, fittings, flanges, and fasteners. Midland Alloys Inc. is committed to quality, timely delivery, competitive pricing, and exceptional customer service, aiming to meet and exceed client expectations globally.

Midland Alloys Inc. has built a solid reputation as a premier exporter of stainless steel tube fittings, not only in Nigeria but also across the globe. Our unwavering commitment to quality, innovation, and customer satisfaction sets us apart in this competitive industry. Here’s why Midland Alloys Inc. is the ideal partner for your stainless steel tube fittings needs:

Best Stainless Steel Tube Fittings Exporters in Nigeria

Exceptional Quality Assurance

At Midland Alloys Inc., maintaining high-quality standards is fundamental to our operations. We understand that the longevity and performance of stainless steel tube fittings are critical to the success of your projects. Therefore, we adhere to stringent international quality standards and implement thorough quality control processes at every stage of manufacturing. Each fitting is subjected to rigorous testing for strength, durability, and corrosion resistance, ensuring our products consistently meet the highest industry standards before they reach our customers.

Extensive Range of Products

We pride ourselves on offering a comprehensive selection of stainless steel tube fittings to meet the varied demands of different industries. Our product range includes various fittings such as elbows, tees, reducers, couplings, and flanges, available in multiple sizes and grades of stainless steel, including 304, 316, and 321. Whether you require standard fittings or customized solutions, Midland Alloys Inc. possesses the expertise and inventory to fulfill your specific needs.

Customized Solutions for Specific Applications

Every project comes with its unique challenges, and Midland Alloys Inc. is well-equipped to provide tailored solutions to meet your specific requirements. Our experienced team collaborates closely with clients to understand their project needs and deliver fittings that align perfectly with their specifications. From custom sizes and configurations to specialized finishes and coatings, we ensure our stainless steel tube fittings are a perfect match for your applications.

Advantages of Choosing Stainless Steel Tube Fittings from Midland Alloys Inc.

Opting for stainless steel tube fittings from Midland Alloys Inc. provides numerous advantages that enhance the reliability, efficiency, and longevity of your projects.

Best Stainless Steel Tube Exporters in Nigeria

Outstanding Durability

Stainless steel tube fittings are renowned for their durability and extended lifespan. They can withstand high pressures, extreme temperatures, and harsh environmental conditions without compromising structural integrity. This resilience makes them an ideal choice for industries like oil and gas, where tube systems are subjected to demanding operational conditions. With Midland Alloys Inc., you can be confident that you’re acquiring fittings designed to last.

Excellent Resistance to Corrosion

One of the standout features of stainless steel tube fittings is their remarkable resistance to corrosion. Unlike other materials, stainless steel does not rust or corrode when exposed to moisture, chemicals, or saltwater. This property is essential for applications in water treatment plants, marine environments, and chemical processing facilities. By choosing Midland Alloys Inc., you invest in fittings that maintain their performance and integrity, even in the most corrosive conditions.

Cost-Effectiveness and Long-Term Value

While the initial cost of stainless steel tube fittings may be higher compared to other materials, their long-term advantages make them a cost-effective choice. Their durability and resistance to wear significantly reduce maintenance and replacement costs over time. Additionally, the adaptability of stainless steel allows for quick installation and minimal downtime, which further contributes to cost savings. Midland Alloys Inc. offers high-quality fittings that deliver excellent value for your investment.

Best Stainless Steel Tube Fittings Exporters in South Africa

Our Commitment to Customer Satisfaction

Customer satisfaction is central to everything we do at Midland Alloys Inc. We believe that our success is closely tied to the success of our clients, and we go the extra mile to ensure your experience with us is smooth and rewarding.

Exceptional Customer Support

Our dedicated customer service team is always available to assist with any inquiries, concerns, or requirements you may have. From the moment you reach out to us, you’ll receive personalized attention and expert guidance to help you make informed decisions. We pride ourselves on our professionalism, responsiveness, and commitment to fostering long-term relationships with our clients.

Timely and Reliable Deliveries

Understanding that timely delivery is crucial for the smooth execution of your projects, Midland Alloys Inc. has established a robust logistics network and efficient supply chain management systems to ensure your orders are delivered on schedule, every time. Our strategic partnerships with reliable shipping companies allow us to provide prompt and secure delivery services throughout Nigeria.

Comprehensive After-Sales Service

Our relationship with you extends beyond the delivery of your products. Midland Alloys Inc. offers comprehensive after-sales service to ensure you get the maximum benefit from our stainless steel tube fittings. Whether you need technical assistance, maintenance advice, or additional supplies, our team is always available to support you. We value your feedback and continuously strive to enhance our products and services based on your input.

Best Stainless Steel Tube Fittings Exporters in Singapore

Success Stories: Meeting the Needs of Nigerian Industries

Over the years, Midland Alloys Inc. has had the privilege of collaborating with numerous clients across various industries in Nigeria. Here are some success stories that demonstrate our commitment to quality and customer satisfaction:

Case Study 1: Improving Efficiency in the Oil and Gas Sector

A prominent oil and gas company in Nigeria faced frequent pipeline leaks and corrosion problems with their existing fittings. They sought a solution from Midland Alloys Inc. We supplied them with high-quality stainless steel tube fittings specifically designed to withstand the demanding conditions of the oil and gas sector. The result was a significant reduction in maintenance costs and improved operational efficiency. The client expressed great satisfaction with the performance of our fittings and has since placed multiple repeat orders.

Case Study 2: Reliable Solutions for Water Treatment Facilities

A water treatment facility in Lagos required durable and corrosion-resistant fittings for their operations. They chose Midland Alloys Inc. based on our strong reputation for quality and reliability. We provided stainless steel tube fittings that precisely met their specifications. The installation went smoothly, and the fittings have been performing exceptionally well, ensuring the facility operates efficiently with minimal maintenance.

Case Study 3: Supporting Construction Projects with High-Quality Fittings

A construction company engaged in a large-scale infrastructure project needed customized stainless steel tube fittings for various applications, including plumbing and structural support. Midland Alloys Inc. worked closely with the client to understand their needs and provided tailored solutions that aligned perfectly with their requirements. The project was successfully completed, and the client praised our products and services for their quality and accuracy.

Best Stainless Steel Tube Fittings Exporters in Ethiopia

How to Partner with Midland Alloys Inc. for Your Stainless Steel Tube Fittings Needs

Collaborating with Midland Alloys Inc. is a straightforward and rewarding process. Here’s how to get started:

1. Reach Out: Contact our sales team via phone, email, or through our website. Share your project details and specific requirements with us. (Mobile No.: +91-9820238369 | E-mail: [email protected] | www. midlandalloys.com)

2. Consultation: Our experts will consult with you to understand your needs and recommend the best solutions available.

3. Quotation: We will provide a detailed quotation that includes product specifications, pricing, and estimated delivery timelines.

4. Order Placement: After you approve the quotation, place your order, and we will initiate the production process.

5. Delivery: Your order will be delivered to your specified location within the agreed timeframe.

6. After-Sales Support: Enjoy our comprehensive after-sales support to ensure the continued success of your projects.

Conclusion: Choose Midland Alloys Inc. for Quality and Dependability in Stainless Steel Tube Fittings

Midland Alloys Inc. is more than just a supplier; we are your trusted partner in achieving project success. Our unwavering commitment to quality, innovation, and customer satisfaction has established us as the preferred choice for stainless steel tube fittings in Nigeria. Whether you operate in the oil and gas, construction, water treatment, or manufacturing sectors, you can depend on us for superior products and exceptional service. Partner with Midland Alloys Inc. today and experience the difference that quality and reliability can make.

0 notes

Text

Hastelloy C22 Pipe Fittings Manufacturers In India

Hastelloy C22 is a versatile nickel-chromium-molybdenum-tungsten alloy known for its exceptional resistance to a wide range of corrosive environments, including pitting, crevice corrosion, and stress corrosion cracking. This alloy is particularly suitable for chemical processing, pollution control, and waste treatment applications. Hastelloy C22 pipe fittings are vital components in various industries requiring high corrosion resistance and reliability. This article explores the manufacturing process of Hastelloy C22 pipe fittings, current trends, their impact on industries, applications, future prospects, and recommendations for top manufacturers in India.

Background Process of Hastelloy C22 Pipe Fittings

The production of Hastelloy C22 pipe fittings involves several meticulous steps to ensure their quality and performance. The process begins with the selection of high-purity raw materials, followed by melting and alloying to achieve the desired composition. The alloy is then cast and forged into various pipe fitting shapes, such as elbows, tees, reducers, and flanges. Heat treatment is applied to enhance the mechanical properties and corrosion resistance of the fittings. Precision machining ensures the fittings meet the required dimensions and surface finish. Finally, rigorous testing and inspection are conducted to ensure compliance with stringent industry standards.

Current Trends in Hastelloy C22 Pipe Fittings

The demand for Hastelloy C22 pipe fittings is increasing due to their superior performance in highly corrosive environments. Industries such as chemical processing, pharmaceuticals, and pollution control are adopting these fittings for critical applications. The trend towards sustainability and cost efficiency is driving the use of Hastelloy C22, as it offers a longer service life and reduced maintenance costs. Additionally, advancements in manufacturing technologies are improving the quality and affordability of these fittings, making them more accessible to various industries.

Suggestions for Major Industries

For industries seeking reliable and durable piping solutions, Hastelloy C22 pipe fittings are an excellent choice. The chemical processing industry can benefit from their resistance to a wide range of corrosive chemicals, ensuring safe and long-lasting performance. In the pharmaceutical sector, these fittings provide exceptional resistance to various acids and solvents, crucial for maintaining the integrity of production processes. Pollution control and waste treatment applications also benefit from the excellent corrosion resistance and durability of Hastelloy C22.

Impacts on Industry Due to Hastelloy C22 Pipe Fittings

The widespread use of Hastelloy C22 pipe fittings has significantly impacted various industries by enhancing the reliability and longevity of piping systems. These fittings have reduced the frequency of maintenance and downtime, leading to increased operational efficiency and cost savings. Their superior properties also enable more innovative and flexible design solutions, allowing industries to address complex challenges and improve overall competitiveness.

Applications and Future Prospect

Hastelloy C22 pipe fittings find applications in numerous sectors, including:

Chemical Processing: Used in reactors, heat exchangers, and piping systems handling highly corrosive substances.

Pharmaceuticals: Employed in production processes involving aggressive chemicals and solvents.

Pollution Control: Applied in systems designed for pollution control and waste treatment.

Marine Engineering: Utilized in seawater handling systems and marine structures.

Food and Beverage: Suitable for applications requiring high corrosion resistance to maintain product purity.

Looking ahead, the future prospect for Hastelloy C22 pipe fittings is promising. Continuous advancements in material science and manufacturing techniques will further enhance their performance and cost-efficiency. As industries continue to seek high-performance materials for critical applications, the demand for Hastelloy C22 is expected to grow.

Conclusion

In summary, Hastelloy C22 pipe fittings are crucial components in various highly corrosive environments. Their exceptional properties and durability make them a preferred choice for industries aiming to enhance operational efficiency and reduce maintenance costs. For reliable and high-quality Hastelloy C22 pipe fittings, we recommend Manilaxmi Industrial. For more information, you can reach them at:

Manilaxmi Industrial

Email: [email protected]

Phone: +91-7710800415

Website: www.manilaxmifittings.com

#Hastelloy C22 Stub End#Hastelloy C22 Buttweld Elbow#ASTM B366 Hastelloy Alloy C22 Pipe Fittings#Hastelloy C22 Reducing Tee#Hastelloy® C22 Pipe Fittings in India#ASME SB366 Hastelloy® Alloy C22 Pipe Cap#Hastelloy C22 Buttweld Fittings#Hastelloy C22 45 deg.Elbow#Hastelloy C22 Reducer#Hastelloy C22 90 deg Elbow#ANSI B16.9 Hastelloy C22 Buttweld Pipe Fittings Suppliers in India

1 note

·

View note

Text

Article on : Stainless Steel 316H Buttweld Fittings Manufacturers in India

Stainless Steel 316H Buttweld Fittings are designed to provide superior performance in high-temperature and high-pressure environments. The "H" in 316H stands for "high carbon," indicating a higher carbon content compared to 316 and 316L, which enhances its strength at elevated temperatures. This article explores the properties, applications, and benefits of Stainless Steel 316H Buttweld Fittings in industrial settings.

Characteristics and Properties

Stainless Steel 316H, known as UNS S31609, is an austenitic stainless steel that contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, with a higher carbon content (0.04-0.10%). Key properties of Stainless Steel 316H include:

High-Temperature Strength: The increased carbon content provides higher creep, stress-to-rupture, and tensile strength at elevated temperatures, making it suitable for high-temperature applications.

Corrosion Resistance: The alloy offers excellent resistance to pitting and crevice corrosion, especially in chloride environments, due to the presence of molybdenum.

Oxidation Resistance: Stainless Steel 316H exhibits good oxidation resistance in intermittent service up to 870°C (1600°F) and in continuous service up to 925°C (1700°F).

Weldability: Despite the higher carbon content, 316H maintains good weldability, ensuring robust and reliable joints.

Applications of Stainless Steel 316H Buttweld Fittings

Stainless Steel 316H Buttweld Fittings are used in a variety of high-temperature and high-stress environments across different industries:

Petrochemical and Refining Industries: These fittings are employed in reformers, catalytic crackers, and other high-temperature processing equipment, where their strength and resistance to oxidation and corrosion are essential.

Power Generation: The power industry utilizes 316H fittings in boilers, superheaters, and heat exchangers, where high-temperature strength and resistance to thermal fatigue are critical for maintaining operational efficiency.

Chemical Processing: In chemical plants, 316H fittings are used in high-temperature reactors, heat exchangers, and other processing equipment that handle corrosive substances.

Industrial Heating Equipment: Stainless Steel 316H Buttweld Fittings are ideal for use in furnaces, kilns, and incinerators due to their ability to maintain structural integrity at high temperatures.

Aerospace Industry: The aerospace sector employs these fittings in various high-temperature applications, including engine components and exhaust systems, where their strength and oxidation resistance are vital.

Benefits of Using Buttweld Fittings

Buttweld fittings, particularly those made from Stainless Steel 316H, offer numerous advantages:

Leak-Proof Connections: The seamless design ensures leak-proof connections, essential for maintaining system integrity under high pressure and temperature.

Structural Integrity: Welded joints enhance the strength and durability of the piping system, reducing the likelihood of leaks and failures.

Versatility: Available in various shapes and sizes, including elbows, tees, reducers, and caps, these fittings can be customized to fit different piping configurations.

Efficiency: The smooth interior surface of buttweld fittings minimizes pressure drops and flow restrictions, improving the efficiency of fluid and gas transport systems.

Conclusion

Stainless Steel 316H Buttweld Fittings are crucial components for industries requiring high-temperature strength and superior corrosion resistance. Their unique properties make them suitable for a wide range of demanding applications, from petrochemical processing and power generation to chemical processing and aerospace.

#Stainless Steel 316H Buttweld Fittings Manufacturers#Stainless Steel 316H Buttweld Fittings Suppliers#Stainless Steel 316H Buttweld Fittings Stockists#Stainless Steel 316H Buttweld Fittings Exporters#Stainless Steel 316H Buttweld Fittings Manufacturers in India#Stainless Steel 316H Buttweld Fittings Suppliers in India#Stainless Steel 316H Buttweld Fittings Stockists in India#Stainless Steel 316H Buttweld Fittings Exporters in India

0 notes

Text

Incoloy Alloy 800/800HT/825 Forged Fittings

Introduction

In the world of industrial manufacturing and engineering, materials that can withstand extreme environments are crucial. Incoloy alloys, particularly Incoloy 800, 800HT, and 825, are known for their exceptional performance in high-temperature and corrosive environments. These alloys are widely used in various industries, including chemical processing, power generation, and oil and gas. Forged fittings made from these alloys are essential components in these industries due to their superior mechanical properties and resistance to oxidation and carburization. Ranflex Metals, a leading manufacturer in the field, specializes in producing high-quality Incoloy Alloy 800/800HT/825 forged fittings, ensuring reliability and durability in critical applications.

Understanding Incoloy Alloys

Incoloy 800

Incoloy 800 is an iron-nickel-chromium alloy with excellent resistance to oxidation and carburization at high temperatures. It maintains its structural integrity and strength even when exposed to extreme temperatures, making it ideal for applications such as furnace components, heat exchangers, and petrochemical processing equipment. Its composition typically includes 30-35% nickel, 19-23% chromium, and trace amounts of aluminum and titanium, which enhance its stability and resistance to scaling.

Incoloy 800HT

An enhanced version of Incoloy 800, Incoloy 800HT contains higher levels of carbon, aluminum, and titanium, providing improved creep and stress rupture properties. This makes Incoloy 800HT particularly suitable for applications requiring prolonged exposure to high temperatures. Industries that benefit from this alloy include nuclear power plants, where it is used in steam generators and heat exchangers, and petrochemical processing, where it finds applications in high-temperature reaction vessels and catalytic support grids.

Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This unique composition offers outstanding resistance to both reducing and oxidizing acids, as well as to stress-corrosion cracking. It is extensively used in environments where sulfuric and phosphoric acids are present. Typical applications of Incoloy 825 include chemical processing, pollution control equipment, and oil and gas well piping.

The Role of Forged Fittings

Forged fittings are critical components in piping systems, providing secure and leak-proof connections. The forging process involves shaping metal using compressive forces, resulting in a product with a dense and uniform grain structure. This enhances the mechanical properties of the fittings, making them stronger and more reliable than cast or machined fittings.

Ranflex Metals: Excellence in Forged Fittings

At Ranflex Metals, we pride ourselves on producing top-quality Incoloy Alloy 800/800HT/825 forged fittings. Our state-of-the-art manufacturing facility and stringent quality control measures ensure that each fitting meets the highest standards of performance and durability.

Our Product Range

Elbows: Available in various angles, our Incoloy elbows provide smooth directional flow in piping systems, reducing turbulence and pressure drop.

Tees: Our tees are designed to distribute fluid flow evenly, ensuring efficient operation of your piping network.

Reducers: Used to connect pipes of different diameters, our reducers ensure a seamless and secure transition.

Couplings: Our couplings provide a reliable connection between two pipes, ensuring leak-proof performance.

Quality Assurance

Ranflex Metals is committed to delivering products that meet or exceed customer expectations. Our Incoloy forged fittings undergo rigorous testing, including:

Chemical Analysis: Ensuring the precise composition of the alloy.

Mechanical Testing: Verifying tensile strength, hardness, and impact resistance.

Non-Destructive Testing: Detecting any surface or internal defects to ensure the integrity of the fittings.

Conclusion

Incoloy Alloy 800, 800HT, and 825 forged fittings are indispensable in industries where high-temperature and corrosion-resistant materials are required. Ranflex Metals stands out as a trusted supplier, providing high-quality forged fittings that meet the demanding requirements of various applications. Our commitment to excellence and customer satisfaction makes us a preferred choice for Incoloy forged fittings. When it comes to ensuring the reliability and durability of your piping systems, trust Ranflex Metals to deliver the best.

#Incoloy Forged Fittings#Incoloy Alloy 800/800HT/825 Forged Fittings#ASTM B564 Incoloy Alloy UNS N08800/11/25 Forged Fittings#825 Incoloy Alloy reducer#800 Incoloy elbow#800 stainless steel tee#601 Incoloy Alloy cross#825 Incoloy Alloy stub closes#825 Incoloy Alloy channel twist#800 Incoloy Alloy short range elbow Suppliers India

0 notes

Text

High Nickel Alloy Socket weld Fittings Exporters

Ganpat Metal Industries is one of the renowned Manufacturer & Exporter, of a qualitative range of High Nickel Alloy Socket Weld Forged Fittings that are being designed as per the national and international standard quality of raw materials.

As an acclaimed enterprise of the industry, Ganpat Metal Industries is involved in offering a vast array of Nickel Alloy Forged Socket Weld Pipe Fittings as a manufacturer, exporter, stockiest and supplier to our domestic and global clients.

ANSI/ASME Nickel AlloySocket Weld Pipe Fittings, Nickel Alloy UNS N02200, N02201 Forged Socket weld Fittings Exporter.

With respect to different grades, we offer these Fittings in different types such as Nickel Alloy 200 Forged Socket weld & Threaded Fittings, Nickel Alloy 201 Forged Elbows, Nickel Alloy 200 Forged Equal & Unequal Tees, Nickel Alloy 201 Forged Equal & Unequal Cross, Nickel Alloy 200 Forged Couplings / Sockets, Nickel Alloy 201 Forged Unions, Nickel Alloy 200 Nipple (pipe, barrel, swage), Nickel Alloy 201 Bushing, and Nickel Alloy 200 Plug. With respect to national and international quality of raw materials, we also offer these UNS N02200 Forged Socket Weld Pipe Fittings / WNR 2.4066 Forged Socket Weld Pipe Fittings and UNS N02201 Forged Socket Weld Pipe Fittings / WNR 2.4068 Forged Socket Weld Pipe Fittings in customized sizes and thicknesses as per specific demands by our esteemed clients at market leading prices.

#High Nickel Alloy Socketweld Fittings Manufacturers#High Nickel Alloy Socketweld Fittings Suppliers#High Nickel Alloy Socketweld Fittings Stockists#High Nickel Alloy Socketweld Fittings Exporters

0 notes

Text

Hastelloy C2000 Pipe Fittings Exporters In India

Pipe fittings are utilised in different industries for various present-day and business applications. One of the most remarkable sorts of pipe fittings is Hastelloy C2000 pipe fittings, which have been getting notoriety because of their unmatched strength and deterioration impediment. Hastelloy C2000 pipe fittings are made using a nickel-based alloy anticipated for normal use in terms of obstruction and strength. This alloy has grand protection from an impressive number of heartbreaking media, including oxidising acids, diminishing acids, hot, dirtied seawater, and cruel water plans. Its phenomenal mechanical properties make it the ideal choice for applications involving high temperatures or strains. Hastelloy C2000 pipe fittings are generally utilised in chemical handling, thermal energy stations, oil and gas creation, food handling, and different industries where deterioration deterrents are major.

Hastelloy C2000 pipe fittings show up in several obvious shapes and sizes, including elbows, tees, reducers, couplings, and affiliations. They also come in different wall thicknesses ranging from Schedule 5 to Schedule XXS. This makes them reasonable for certain errands. Hastelloy C2000 pipe fittings can be utilised in applications including high temperatures and strains. They are commonly used in oil and gas production working environments, petrochemical plants, power plants, chemical handling plants, drug manufacturing working environments, water treatment frameworks, food handling plants, cooling designs, and more. Hastelloy B3 pipe fittings, Hastelloy C2000 pipe fittings, and essentially more grades are similarly accessible.

The fundamental advantage of using C-2000 hastelloy pipe fittings is that they are incredibly invulnerable to breaking down from different chemicals, including sulfuric disastrous, hydrochloric horrendous, and nitric damaging. In this way, they have astounding mechanical strength, which makes them reasonable for use in high-pressure structures. Moreover, they are not difficult to introduce and require less upkeep than different sorts of pipe-fitting materials, like treated steel or metal. Various types of things are accessible, such as mind-blowing bars, SMO 254 UNS S31254 pipe fittings, and so forth. UNS N06200 Nickel Alloy Pipe Fitting is a remarkable decision for applications that require huge, strong regions for a breaking-down-safe material. Its best opposition over harming media makes it reasonable for countless industries, including chemical handling, thermal energy stations, oil and gas creation, food processing, and more. Its phenomenal mechanical properties make it ideal for applications including high temperatures or tensions.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Hastelloy C276 Pipe Fittings Exporters In India#Hastelloy C2000 Pipe Fittings Exporters In India#Alloy 20 Pipe Fittings Exporters In India#Titanium Gr 1 Pipe Fittings Exporters In India#Titanium Gr 2 Pipe Fittings Exporters In India#Titanium Gr 5 Pipe Fittings Exporters In India

0 notes

Text

Inconel 625 Pipe Fittings

Buy Alloy 625 elbow and ASTM B366 UNS N06625 tee at affordable prices in Dubai, top 10 verified Inconel 625 pipe fittings suppliers in UAE, check Nickel 625 reducer price per KG.

Inconel 625 Pipe Fittings

0 notes

Text

Nickel 201 Forged Fittings

Nickel 201 is a commercially pure nickel alloy with similar properties to Nickel 200 but with a lower carbon content. This reduced carbon content enhances its performance in certain applications, particularly in environments where avoiding carbon embrittlement is crucial. Nickel 201 forged fittings are widely used in various industries due to their excellent mechanical properties, high ductility, and superior corrosion resistance.

Properties of Nickel 201

Nickel 201 boasts several key properties that make it suitable for forged fittings:

Corrosion Resistance: Nickel 201 exhibits excellent resistance to a wide range of corrosive environments, including alkaline solutions, organic acids, and neutral and alkaline salt solutions.

Thermal Stability: With a lower carbon content than Nickel 200, Nickel 201 provides better performance at elevated temperatures, reducing the risk of embrittlement.

High Ductility: The alloy maintains high ductility and toughness, even at low temperatures.

Magnetic Properties: Nickel 201 is non-magnetic in its annealed condition, making it suitable for applications where non-magnetic materials are required.

Ease of Fabrication: The material can be easily welded, machined, and formed into complex shapes, making it versatile for various applications.

Applications of Nickel 201 Forged Fittings

Nickel 201 forged fittings find applications across a variety of industries due to their unique properties. Common applications include:

Chemical Processing: The alloy's resistance to various chemicals makes it ideal for use in chemical processing plants, where it can handle caustic solutions and high-temperature environments.

Food Processing: Nickel 201 is often used in food processing equipment due to its corrosion resistance and ability to maintain purity in food-grade environments.

Electronics: The high electrical conductivity and non-magnetic properties of Nickel 201 make it an ideal choice for electrical and electronic components.

Marine Engineering: The alloy is used in marine applications where resistance to seawater and marine environments is essential.

Aerospace: Nickel 201 is employed in aerospace components that require high strength and resistance to harsh environmental conditions.

Types of Nickel 201 Forged Fittings

Forged fittings made from Nickel 201 come in various types to cater to different needs:

Elbows: Used to change the direction of flow within a piping system.

Tees: Allow for the splitting or combining of flow paths.

Couplings: Connect two pipes together, ensuring a secure and leak-proof joint.

Unions: Facilitate easy assembly and disassembly of pipelines.

Bushings: Used to join pipes of different diameters.

Caps and Plugs: Used to close the ends of pipes.

0 notes