#Alloy 20 Pipe Fittings Exporters In India

Text

Hastelloy C2000 Pipe Fittings Exporters In India

Pipe fittings are utilised in different industries for various present-day and business applications. One of the most remarkable sorts of pipe fittings is Hastelloy C2000 pipe fittings, which have been getting notoriety because of their unmatched strength and deterioration impediment. Hastelloy C2000 pipe fittings are made using a nickel-based alloy anticipated for normal use in terms of obstruction and strength. This alloy has grand protection from an impressive number of heartbreaking media, including oxidising acids, diminishing acids, hot, dirtied seawater, and cruel water plans. Its phenomenal mechanical properties make it the ideal choice for applications involving high temperatures or strains. Hastelloy C2000 pipe fittings are generally utilised in chemical handling, thermal energy stations, oil and gas creation, food handling, and different industries where deterioration deterrents are major.

Hastelloy C2000 pipe fittings show up in several obvious shapes and sizes, including elbows, tees, reducers, couplings, and affiliations. They also come in different wall thicknesses ranging from Schedule 5 to Schedule XXS. This makes them reasonable for certain errands. Hastelloy C2000 pipe fittings can be utilised in applications including high temperatures and strains. They are commonly used in oil and gas production working environments, petrochemical plants, power plants, chemical handling plants, drug manufacturing working environments, water treatment frameworks, food handling plants, cooling designs, and more. Hastelloy B3 pipe fittings, Hastelloy C2000 pipe fittings, and essentially more grades are similarly accessible.

The fundamental advantage of using C-2000 hastelloy pipe fittings is that they are incredibly invulnerable to breaking down from different chemicals, including sulfuric disastrous, hydrochloric horrendous, and nitric damaging. In this way, they have astounding mechanical strength, which makes them reasonable for use in high-pressure structures. Moreover, they are not difficult to introduce and require less upkeep than different sorts of pipe-fitting materials, like treated steel or metal. Various types of things are accessible, such as mind-blowing bars, SMO 254 UNS S31254 pipe fittings, and so forth. UNS N06200 Nickel Alloy Pipe Fitting is a remarkable decision for applications that require huge, strong regions for a breaking-down-safe material. Its best opposition over harming media makes it reasonable for countless industries, including chemical handling, thermal energy stations, oil and gas creation, food processing, and more. Its phenomenal mechanical properties make it ideal for applications including high temperatures or tensions.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Hastelloy C276 Pipe Fittings Exporters In India#Hastelloy C2000 Pipe Fittings Exporters In India#Alloy 20 Pipe Fittings Exporters In India#Titanium Gr 1 Pipe Fittings Exporters In India#Titanium Gr 2 Pipe Fittings Exporters In India#Titanium Gr 5 Pipe Fittings Exporters In India

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Alloy Steel F11Forged Fittings Exporters in India

INTRODUCTION:

Manilaxmi Industrial, a prominent name in the manufacturing, supplying, and exporting of Alloy Steel F11 Forged Fittings, brings forth an array of high-quality forged fittings suitable for diverse industrial applications. Renowned for their exceptional block limit, mechanical properties, and weldability, Alloy Steel F11 fittings are the go-to choice for industries requiring robust and reliable components.

DESCRIPTION:

Alloy Steel F11, characterized by its excellent formability and superior resistance to harsh conditions, is widely used in the production of forged fittings. This steel variant, with its austenitic structure enriched with chromium and molybdenum, offers outstanding resistance to corrosion and mechanical stress. These properties make Alloy Steel F11 suitable for applications in extreme environments, ensuring durability and performance.

BENEFITS:

Superior Mechanical Properties: Alloy Steel F11 exhibits high tensile and yield strength, making it capable of withstanding significant mechanical stress.

Exceptional Weldability: The alloy's excellent weldability allows for easy fabrication using standard welding techniques.

Resistance to Corrosion: The chromium and molybdenum content provide enhanced resistance to oxidation and corrosion, even in aggressive environments.

Versatile Applications: Suitable for a range of applications, including the petrochemical, food management, oil and gas, and pharmaceutical industries.

High-Temperature Performance: Maintains structural integrity and strength at temperatures ranging from 600 to 900 degrees Celsius.

SPECIFICATIONS:

Standards: ASTM A182 / ASME SA182

Specifications: ASME B16.11, MSS SP-79, 83, 95, 97, BS 3799

Size Range: NPS 1/8″- 4″ (DN 6~100)

Rating Pressure:

Threaded End: 2000/3000/6000 LBS

Socket weld End: 3000/6000/9000 LBS

Type: Socket Weld, Screwed, BSP Threaded & NPT Threaded

Equivalent Grades:

WERKSTOFF NR.: 1.7338

UNS: K11597

Trade Name: 1-1/4Cr-1/2Mo

Chemical Composition:

C: 0.15 max

Mn: 0.3-0.6

Si: 0.5-1

P: 0.03 max

S: 0.030 max

Cr: 1-1.5

Mo: 0.044-0.65

Mechanical Properties:

Tensile Strength: 415 MPa

Yield Strength (0.2% Offset): 205 MPa

Elongation: 20%

PRODUCT OVERVIEW:

Manilaxmi Industrial produces an extensive range of Alloy Steel F11 Forged Fittings, including but not limited to:

Forged Socket Weld Equal Tee

Threaded Fittings

Forged Threaded 90° Elbow

Socket Weld Fittings

Forged Threaded Union

Plug and Hex Bushing

High-Pressure Forged Pipe Fittings

These fittings are meticulously manufactured to meet both domestic and international standards, ensuring reliability and quality. Available in various dimensions, these products cater to the specific requirements of different industrial applications.

CONCLUSION:

Manilaxmi Industrial stands out as a trusted manufacturer and supplier of Alloy Steel F11 Forged Fittings, delivering products that exemplify quality, durability, and performance. With a commitment to maintaining high standards and continuous innovation, Manilaxmi Industrial ensures that its fittings meet the evolving needs of various industries.

For inquiries or to place an order, contact us via email at [email protected] or call us at +91-7710800415. Visit our website at www.manilaxmifittings.com for more information.

1 note

·

View note

Text

Orifice Flanges Exporters in India

Introduction

Universe Metal & Alloys has extensive experience in manufacturing and supplying all types of pipe fittings. The entire manufacturing process is supported by trained professionals who have extensive experience in handling different types of pipe fittings and other products.

Description

Universe Metal & Alloy stands tall as one of the leading Manufacturers, Suppliers, Stockists, and Exporters of Orifice Flanges in India. With a rich legacy and a commitment to quality, we have carved a niche for ourselves in the competitive metal market. Our dedication to Suppliers to international and national quality standards sets us apart, making us a trusted name in the industry.

At Universe Metal & Alloy, we take pride in our Stainless Steel Orifice Flanges, which are meticulously designed and developed to meet the diverse needs of various industries. Crafted with precision and excellence, our ASTM A182 Stainless Steel Orifice Flanges are renowned for their durability and reliability, making them ideal for a wide range of piping applications across sectors such as Chemical, Petrochemical, Building, Construction, and more.

Benefits:

Accuracy and Reliability: Orifice flanges provide precise flow measurement, which is essential for process control and optimization.

Versatility: Suitable for a wide range of applications, including water, oil, gas, and steam.

Cost-Effective: They offer an economical solution for flow measurement, especially in large-scale industrial applications.

Durability: Made from robust materials, these flanges can withstand harsh operating conditions, ensuring long-term performance.

Ease of Installation and Maintenance: Orifice flanges are designed for easy integration into existing piping systems and require minimal maintenance.

Specification:

ASME B16.5 Orifice Flange Size Chart1/2" (15 NB) to 48" (1200NB) DN10~DN5000grooved Orifice flange StandardsANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092Spectacle Flange Pressure Rating ANSIClass 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Spectacle FlangeSpectacle Flange Pressure Calculation in DIN6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Spectacle FlangeJIS5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Spectacle FlangeUNI6Bar 10Bar 16Bar 25Bar 40Bar grooved Orifice flangeEN6Bar 10Bar 16Bar 25Bar 40Bar Forged grooved Orifice flangeCoatingOil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized ASME B16.5 Orifice FlangeMost common types of Orifice FlangeForged / Threaded / Screwed / PlateTest CertificatesEN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etcProduction technique

Forged, Heat treated and machined

Connect Type/ Flange Face TypeRaised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, GrooveSpecial designAs per your drawing

AS, ANSI, BS, DIN and JIS

15 NB (1/2″) to 200 NB (8″)

Equal and Reducing ConfigurationsTestDirect-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detectorEquipmentPress machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etcOriginIndian / West Europe / Japan / USA / KoreanManufacturer of

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

Spectacle Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

B.S: BS4504 , BS3293, BS1560, BS10

AS 2129: Table D; Table E; Table H

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

American standard (ANSI)

German (DIN)

British standard (BS)

DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 Forged grooved Orifice flange

The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276

grooved Orifice flange Uses & application

Bitumen upgraders.

Heavy oil refineries.

Nuclear power (mostly seamless).

Petrochemicals and acids.

Export toIreland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc

Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175

Product Overview:

At Universe Metal & Alloys, our orifice flanges are designed and manufactured to the highest standards. Each product undergoes rigorous quality control to ensure it meets the specific requirements of our clients. Our orifice flanges are suitable for a variety of applications, including chemical processing, petroleum refining, power generation, and water treatment. With a commitment to excellence, we provide detailed product information, technical support, and competitive pricing to meet the needs of our customers.

Conclusion:

Orifice flanges are an indispensable component for accurate flow measurement in industrial piping systems. Universe Metal & Alloys is dedicated to delivering high-quality orifice flanges that meet the exacting standards of various industries.

For more information or to place an order, please contact us at [email protected] or call us at +91-22-66363360 / 66393788.

0 notes

Text

Alloy 20 Sheets And Plates Exporters In India

INTRODUCTION:-

Shasan Piping Solution is a dependable Manufacturers, Exporters, and Suppliers of the a wide range of mechanically utilized items. We are giving the awesome nature of Alloy 20 Sheets and Plates to our regard benefactors for fulfilling their various requests. We are the client's aggressive industry that is giving something similar to our clients at various principles, details, sizes, wall thickness, surface gets done, and shapes.

BENEFITS:-

Alloys is the material that is chromium, nickel, and iron-based austenitic compound. It is made for guaranteeing the higher protection from the corrosive assaults, especially to the sulfuric corrosive. This material is having excellent opposition capacity to the overall consumption, cleft erosion and pitting too. Likewise, it opposes sulfuric corrosive, phosphoric corrosive, and nitric corrosive. Likewise, it is containing niobium for the adjustment against the sharpening.

SPECIFICATION:-

Alloy 20 Sheets and Plates Specification : ASTM B463 / ASME SB463

Dimension Standard : JIS, AISI, ASTM, GB, DIN, EN, etc

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 120 mm

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

PRODUCT OVERVIEW:-

The produced scopes of Alloy 20 Sheets and Plates are having numerous great properties to offer in view of which it has turned into an ideal fit for various purposes. The properties found in it are high elasticity, great layered precision, predominant surface completions, rough development, high strength, long usefulness, non-destructive body, endure high temperature, and so on.

CONCLUSION:-

Today Alloy 20 Sheets and Plates are widely utilized in numerous modern applications. It resembles heat exchangers, condensers, mash and paper industry, petrochemicals, drugs, specialty synthetics, substance industry, oil and gas handling, seawater applications, cars, building, and developments.

Alloy 20 Sheets and Plates are completely quality tried before dispatched from our industry. The tests are significantly finished for really looking at the item strength. The tests are pitting erosion tests, strength tests, positive material ID tests, and so on. The bundling of the equivalent is finished in wooden beds for more secure transportation.

CONTACT US:-

+91 22-6651 8642

EMAIL ID: [email protected]

WEBSITE: https://www.shasanpiping.com/alloy-20-sheets-and-plates-manufacturers-exporters-suppliers-stockists.html

#"Alloy 20 Sheets and Plates Manufacturers#Alloy 20 Sheets and Plates Suppliers#Alloy 20 Sheets and Plates Stockists

0 notes

Text

Forged Threaded Fittings Exporters in India

Forged Threaded Fittings, Forged Threaded Fittings Manufacturers, Forged Threaded Fittings Suppliers, Forged Threaded Fittings Exporters, Forged Threaded Fittings Stockists.

Forged Threaded Fittings in Mumbai, Forged Threaded Fittings Manufacturers in Mumbai, Forged Threaded Fittings Suppliers in Mumbai, Forged Threaded Fittings Exporters in Mumbai, Forged Threaded Fittings Stockists in Mumbai.

Forged Threaded Fittings in India, Forged Threaded Fittings Manufacturers in India, Forged Threaded Fittings Suppliers in India, Forged Threaded Fittings Exporters in India, Forged Threaded Fittings Stockists in India.

https://www.chhajedpipefittings.com/img/forged-threaded-fittings-manufacturers-suppliers-exporters-stockists.jpg

FORGED THREADED FITTINGS

We supply and fare manufactured strung fittings that display predominant working. These strung channel fittings are composed and created to meet different working conditions. These strung fittings give lasting welded associations with basic applications.DNNominal Pipe SizeCenter-to

-End

Elbows,

Tees,

Crosses, ACenter-to-

End 45

deg Elbow, COutside

Diameter

of Band, HMin.

Wall

Thickness, GMin

Length

of

Thread [Note (1)]200030006000200030006000200030006000200030006000BL261/82121251717192222253.183.186.356.46.781/42125281719222225333.183.306.608.110.2103/82528331922252533383.183.516.989.110.4151/22833382225283338463.184.098.1510.913.6203/43338442528333846563.184.328.5312.713.92513844512833354656623.684.989.9314.717.3321 1/44451603335435662753.895.2810.5917.018.0401 1/25160643543446275844.015.5611.0717.818.450260648343445275841024.277.1412.0919.019.2652 1/2768395525264921021215.617.6515.2923.628.980386951066464791091211465.998.8416.6425.930.510041061141147979791461521526.5511.1818.6727.733.0

SPECIFICATION

Grades :

Nickel Alloy:

ASTM / ASME SB 564 UNS 2200 ( NICKEL 200 ), UNS 4400 (MONEL 400 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) ASTM / ASME SB 160 UNS 2201 (NICKEL 201 ) ASTM / ASME SB 472 UNS 8020 ( ALLOY 20 / 20 CB 3 )

Copper Alloy:

ASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600. ASTM / ASME SB 151 UNS NO. 70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30), ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200.

Stainless Steel :

ASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel :

ASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.

Carbon Steel:

ASTM / ASME A 105. ASTM / ASME A 350 LF 2.

Alloy Steel:

ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91.

0 notes

Text

10 Tips for Choosing the Right pipe clamp fittings for your Industry.

Pipe clamp fittings, which include numerous pipe clamp types, play a crucial function throughout diverse industries via making sure the steadiness and integrity of piping systems. Whether you're in construction, manufacturing, or any other area requiring robust piping solutions, choosing the proper pipe-fitting clamp is paramount. As a main pipe clamp fittings Manufacturer and exporter, Arcellor Controls India is familiar with the importance of choosing the proper clamp pipe fittings in your specific industry wishes, inclusive of PVC pipe clamp and other material solutions.

In this weblog post, we will discuss 10 tips that will help you make knowledgeable choices when selecting clamp fittings in your projects.

10 Tips for Choosing The Right Pipe Clamp Fittings for your Industry

Evaluate Material Compatibility:

Ensure that the pipe fitting clamp you select from Arcellor Controls India are well suited with the material being conveyed thru your pipelines. Our extensive range of gadgets air header fittings are synthetic using first rate materials and grades to provide terrific corrosion resistance and sturdiness.

Consider Pressure Ratings:

Check the pressure ratings of our clamp fittings to make sure they are able to resist the operating pressures of your industrial applications. Whether you want Pipe Clamp Applications for low-pressure systems or heavy-obligation Rail Nut Pipe Clamps for high-pressure environments, we have you ever blanketed with dependable solutions.

Explore Temperature Constraints:

We offer clamp fittings designed to resist extreme temperature variations, making them suitable for numerous industrial settings. Whether your venture requires fittings for excessive-temperature strategies or cryogenic applications, we've the information to provide tailor-made answers.

Opt for Quality and Durability:

Our clamp fittings are made from top class materials and undergo rigorous exceptional checks to make certain superior performance and toughness. Investing in top notch fittings from Arcellor Controls India ensures minimal preservation requirements and long-term reliability to your pipelines.

Prioritize Hygiene and Sanitation:

Industries which include pharmaceuticals, meals and beverage, and biotechnology demand clamp fittings that meet strict hygiene standards. Our sanitary finishes and easy surfaces facilitate smooth cleansing and sterilization, making sure compliance with industry rules.

Assess Installation Compatibility:

Choose clamp fittings that seamlessly integrate together with your existing infrastructure to minimize set up time and expenses. Our Pipe Clamp Single Port, Pipe Clamps 2 Port, and different variants are designed for clean set up, presenting convenience and efficiency in your initiatives.

Ensure Regulatory Compliance:

We are devoted to adhering to enterprise guidelines and standards, making sure that our clamp fittings meet all vital compliance requirements. You can consider our products to supply top-rated performance at the same time as maintaining protection and regulatory compliance.

Consider Customization Options:

We recognize that every project is particular, which is why we offer customization options to satisfy your particular desires. Whether you require bespoke sizes, materials like Stainless Steel, Duplex and Super Duplex Steel, Carbon Steel, Low-Tempreture, Alloy Steel, Copper Alloy, Nickel Alloy including Monel, Inconel, Hastelloy and Alloy 20 Steel, aluminum, MS (Mild Steel Grades), pipe clamp pvc and extra. Our crew at we will offer personalized solutions tailor-made in your assignment requirements.

Seek Expert Guidance:

When doubtful, depend upon the expertise of our team at Arcellor Controls India. Our skilled specialists are to be had to offer steerage and assist, helping you pick out the right clamp fittings on your enterprise with confidence.

Materials & Grades Offered by Us - Pipe Clamps Fittings

Materials

Grades

Stainless Steel ASME B16.5

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel ASME 16.5

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel ASME B16.5

ASTM / ASME A/SA 105 ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low-Temperature Carbon Steel ASME B16.5

ASTM A350, LF2, LF3

Alloy Steel ASME B16.5

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel ASME B16.5

ASTM SB 61, SB62, SB151, SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy ASME B16.5

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201)

Monel

Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500)

Inconel

Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601)

Hastelloy

Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

Additionally, we offer pipe clamp fittings made from aluminum, MS (Mild Steel Grades), and more.

Uses and Applications of Pipe Clamp Fittings

Piping System

Support Systems

Temporary Structures

Custom Fabrications

Exhibition and Event Installations

Greenhouses and Agricultural Structures

Safety Barriers and Guardrails

Modular Racking Systems

Other Applications

Final Words!

Selecting the proper pipe fitting clamp on your enterprise is an essential decision that can effect the overall performance, protection, and efficiency of your piping systems. By following these 10 recommendations and deciding on clamp fittings from a trusted pipe clamp fittings manufacturer like Arcellor Controls India, you could ensure that your tasks are prepared with dependable and durable fittings that meet your unique necessities. Get in contact with us today at [email protected] or [email protected] / [email protected] to discover our extensive range of clamp pipe fittings and find the appropriate answer to your enterprise needs.

#pipe clamp types#pipe fitting clamp#pipe clamp fittings#clamp pipe fittings#pvc pipe clamp#pipe clamp pvc

0 notes

Text

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

When it comes to industrial piping systems, the choice of flange material plays a pivotal role in ensuring peak performance and long-lasting functionality. Among the myriad materials available, Monel stands out as one of the most popular and reliable options. As the leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, we take pride in offering a wide range of options to cater to diverse project requirements. Our Monel Flanges come in various sizes, specifications, standards, and grades, including the popular Monel 400 Flanges and Monel K500 Flanges.

Moreover, we offer different types of flanges, such as Slip On Flanges, Weld Neck Flanges, Socket Weld Flanges, Blind Flanges, Orifice Flanges, Reducing Flanges, Ring Type Joint Flange, Spectacle Blind Flanges, and Lap Joint Flanges, ensuring that you find the perfect fit for your projects. With our expertise and dedication as suppliers of Monel 400 Flanges and other products, we strive to meet the highest industry standards and be your preferred partner for all your Monel Flange needs in India and beyond.

In this blog post, we will explore the unique advantages of Monel Flanges over other flange materials, demonstrating why they are the preferred choice for critical applications across various industries.

Understanding Flanges and Their Role in Industrial Piping

Before we dive into the comparison, let's briefly understand what flanges are and why they are vital in industrial piping systems. Flanges are flat, circular discs with evenly spaced bolt holes used to connect pipes, valves, and other equipment in a piping network. Their primary functions include providing support, facilitating alignment, and allowing for easy assembly and disassembly of components.

Exploring Monel Flanges

Monel Flanges are a class of nickel-copper alloy flanges renowned for their exceptional properties. The composition primarily consists of nickel and copper, with additions of small amounts of iron, manganese, and other elements. This alloy's chemical composition results in a combination of impressive characteristics, including excellent corrosion resistance, high tensile strength, and exceptional temperature stability.

The corrosion resistance of Monel Flanges is particularly noteworthy, making them suitable for use in harsh and corrosive environments. They perform exceptionally well in marine applications, offshore drilling, and chemical processing industries where exposure to seawater, acids, and alkalis is common. The resistance to localized corrosion, such as pitting and crevice corrosion, adds to their popularity.

Comparing Monel Flanges with Other Flange Materials

To make an informed decision, it is essential to compare Monel Flanges with other commonly used flange materials, such as stainless steel, carbon steel, Inconel, and Alloy 20.

Stainless Steel Flanges

Stainless steel flanges are widely used due to their general corrosion resistance and cost-effectiveness. However, when compared to Monel Flanges, they may fall short in highly corrosive environments. Monel Flanges, with their higher nickel content, exhibit superior resistance to chloride-induced stress corrosion cracking, a common concern in stainless steel.

Carbon Steel Flanges

Carbon steel flanges are widely used in various industries due to their affordability and mechanical properties. However, they lack the corrosion resistance required for aggressive environments. Monel Flanges outshine carbon steel in corrosive atmospheres, making them the preferred choice for applications where durability and longevity are crucial.

Inconel Flanges

Inconel is another popular nickel-based alloy known for its high-temperature strength. While Inconel Flanges offer excellent performance in extreme heat, they may not provide the same level of corrosion resistance as Monel Flanges. For applications where both heat and corrosion resistance are essential, they prove to be the optimal choice.

Alloy 20 Flanges

Alloy 20, also known as Carpenter 20, is a nickel-chromium-molybdenum stainless steel alloy that offers excellent resistance to corrosion and pitting. While Alloy 20 is suitable for many corrosive environments, it may not match the overall corrosion resistance and mechanical properties of Monel Flanges.

Advantages of Monel Flanges

The advantages of using Monel Flanges extend far beyond their corrosion resistance. Let's explore the various reasons why they are a preferred choice in different industries and applications.

High Tensile Strength and Temperature Stability

Monel Flanges are known for their high tensile strength, which ensures they can withstand significant mechanical stress without deformation. This property makes them suitable for applications where the flanges are exposed to high-pressure conditions, such as in oil and gas pipelines, chemical reactors, and high-temperature environments.

Durability and Longevity

Monel Flanges exhibit exceptional durability and longevity, even in the most demanding conditions. Their ability to withstand extreme weather conditions, abrasive elements, and frequent exposure to corrosive substances makes them a reliable choice for critical applications with long operational lifespans.

Resistance to Biofouling and Microbial Corrosion

In marine and offshore industries, biofouling and microbial corrosion can pose significant challenges. Monel Flanges possess inherent resistance to these issues, making them ideal for use in seawater desalination plants, offshore platforms, and shipbuilding.

Excellent Weldability and Formability

Monel Flanges are known for their excellent weldability and formability. They can be easily welded, machined, and formed into complex shapes, allowing for greater design flexibility and ease of installation.

Low Risk of Contamination

For industries dealing with sensitive materials such as pharmaceuticals and food processing, Monel Flanges offer a low risk of contamination. Their non-reactive nature ensures that they do not leach any harmful substances into the conveyed fluids or products.

Key Considerations for Choosing Flange Materials

Selecting the appropriate flange material is crucial to ensuring the success and safety of your projects. Here are some key considerations to keep in mind when choosing flange materials:

Operating Conditions

Evaluate the temperature and pressure conditions under which the flanges will operate. Monel Flanges, with their excellent high-temperature and pressure capabilities, are an ideal choice for applications where these factors are critical.

Corrosive Environment

Consider the nature of the fluid being transported and the corrosive environment in which the flanges will operate. Monel Flanges excel in corrosive atmospheres, providing reliable performance and extended service life.

Industry Standards and Certifications

Ensure that the chosen flange materials meet industry standards and certifications. At Jay Steel Corporation, we take pride in adhering to global standards, providing our customers with the assurance of top-quality products.

Cost-Effectiveness

While Monel Flanges may have a higher initial cost compared to some other materials, their long-term durability and low maintenance costs make them a cost-effective choice in the long run.

Expert Guidance

Seek expert guidance from professionals who can analyze your project requirements and recommend the most suitable flange material. At Jay Steel Corporation, our team of experts is always ready to assist you in making the right choice.

Applications of Monel Flanges

Monel flanges are essential components used in various industries due to their unique properties and corrosion-resistant nature. Monel is a group of nickel-copper alloys known for their excellent resistance to seawater, acids, alkalis, and various corrosive environments. Here are some of the common applications:

Marine industry

Oil and Gas industry

Chemical processing

Aerospace industry

Power generation

Seawater desalination

Food processing

Pharmaceutical industry

Water treatment

Nuclear industry

Other Application

Final Thoughts!..

Monel Flanges emerge as the ideal choice for critical applications where corrosion resistance, high strength, and temperature stability are paramount. Their exceptional properties and performance set them apart from other flange materials, making them the preferred option for industries such as marine, offshore, chemical processing, aerospace, and so on.

As India's leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, Jay Steel Corporation is committed to delivering top-notch products that cater to your specific project requirements. Our Monel Flanges are not only highly regarded in India but are also in demand across the globe, with exports to countries such as Singapore, Malaysia, Nigeria, the USA, France, Saudi Arabia, Kuwait, Tunisia, Qatar, and more. Our products have gained international acceptance due to their unmatched quality, reliability, and adherence to global standards and certifications.

0 notes

Text

Stainless Steel Buttweld Fittings to ASME B16.9 - Metal Forge India

Stainless Steel Buttweld Fittings to ASME B16.9

In the realm of piping systems, selecting the right fittings is crucial to ensure seamless operation and durability. At Metal Forge India, we take immense pride in being the premier manufacturer, supplier, stockist, and exporter of top-notch stainless steel buttweld fittings conforming to the ASME B16.9 Standard. Our commitment to excellence extends beyond stainless steel, encompassing a diverse range of materials and grades such as Alloy 20, SMO 254, UNS N06600, Hastelloy C276, Stainless Steel 904L, and Inconel 600 Buttweld Fittings. Our comprehensive selection caters to varied project needs, offering a perfect fit for every requirement.

This blog post sheds light on the significance of stainless steel buttweld fittings manufactured in accordance with the ASME B16.9 standard.

Understanding Stainless Steel Buttweld Fittings to ASME B16.9

Stainless steel buttweld fittings to ASME B16.9 are essential components in various industries. These fittings offer exceptional corrosion resistance and durability, making them ideal for demanding environments. Let's explore the key features of these fittings:

Precision Engineering: Stainless steel buttweld fittings are designed with precision to ensure a secure and leak-free connection between pipes. This engineering precision reduces the risk of leaks and enhances overall system integrity.

Diverse Applications: These fittings find application in industries such as oil and gas, petrochemical, chemical processing, and more. Their versatility makes them suitable for both high-pressure and high-temperature environments.

Material Options: The buttweld fittings are available in different grades, such as Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings, each offering specific properties. This variety allows engineers to choose fittings that align with the requirements of their projects.

ASME B16.9 Compliance: ASME B16.9 is a standard that outlines the requirements for factory-made wrought buttwelding fittings. Stainless steel buttweld fittings that adhere to this standard ensure consistent dimensions and reliable performance.

The Advantages of Using Stainless Steel Buttweld Fittings

Stainless steel buttweld fittings offer numerous advantages, making them a preferred choice for many industries. Here's a look at some of their key benefits:

Corrosion Resistance: Stainless steel is known for its exceptional resistance to corrosion, rust, and oxidation. This property ensures the longevity of buttweld fittings, even in harsh environments.

Strength and Durability: Stainless steel possesses impressive mechanical properties, including high tensile strength and toughness. These qualities contribute to the overall durability and reliability of the fittings.

Hygienic Properties: In industries like food and beverage and pharmaceuticals, stainless steel's hygienic properties are crucial. The smooth surface of stainless steel buttweld fittings prevents the accumulation of contaminants and ensures the integrity of the fluid being transported.

Ease of Maintenance: Stainless steel fittings are relatively low-maintenance, requiring minimal upkeep to retain their appearance and functionality. This factor adds to their cost-effectiveness over the long term.

Standards & Specifications of Buttweld Pipe Fittings

Size

1/8” NB – 48” NB

Standards

ASME/ANSI and DIN

Schedules

5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS with NACE Certifications

Types

45 Degree elbow, 90 Degree elbow & 180 Degree elbow, Cross, Caps, Tee, Concentric Reducers, Eccentric and Stub End

Materials

Stainless Steel & Alloy 20 Steel, Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, and 254 SMO

Forms

Seamless, Welded & Fabricated

Grades

Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings

Selecting the Right Stainless Steel Buttweld Fittings

Choosing the appropriate stainless steel buttweld fittings for a project involves considering various factors. Let's explore the key considerations when selecting these fittings:

Fluid Compatibility: Different grades of stainless steel are suitable for different types of fluids. Understanding the fluid's corrosiveness and temperature will help in selecting the right grade of stainless steel.

Pressure and Temperature: Stainless steel buttweld fittings are designed to withstand specific pressure and temperature ranges. Ensuring that the fittings can operate safely within the intended conditions is crucial.

Size and Configuration: The size and configuration of fittings play a significant role in their compatibility with existing piping systems. Accurate measurements and fittings that match the piping system are essential.

Quality and Compliance

Opting for stainless steel buttweld fittings from reputable Stainless Steel Buttweld Fittings manufacturers like Metal Forge India ensures quality and compliance. Look for certifications such as Material Test Certificates (MTC) in accordance with EN 10204 3.1 and EN 10204 3.2, along with Test Certificates certifying NACE MR0103 and NACE MR0175. These certifications guarantee traceability and adherence to industry standards.

Project Budget: While stainless steel buttweld fittings offer numerous advantages, it's important to consider budget constraints. Balancing the benefits of stainless steel with project costs is key.

Installation and Maintenance of Stainless Steel Buttweld Fittings

Proper installation and maintenance practices are essential to ensure the optimal performance and longevity of stainless steel buttweld fittings. Here's a guide on installing and maintaining these fittings:

Preparation: Before installation, ensure that all components are clean and free from contaminants. Proper preparation prevents issues such as leaks and faulty connections.

Welding Techniques: Stainless steel buttweld fittings are typically welded to the pipes. Utilizing appropriate welding techniques, such as TIG or MIG welding, is crucial to maintaining the fittings' integrity.

Inspection and Testing: After installation, perform thorough inspections and pressure tests to identify any potential leaks or defects. Timely detection and rectification of issues are essential to prevent system failures.

Regular Maintenance: While stainless steel requires minimal maintenance, periodic inspections are still recommended. Check for signs of corrosion, wear, or damage, and replace fittings as needed.

The Future of Stainless Steel Buttweld Fittings in Industry

Stainless steel buttweld fittings continues to evolve in response to changing industry needs. Here's a glimpse into the future trends and innovations in this field:

Advancements in Materials: Ongoing research and development are leading to the creation of new stainless steel alloys with enhanced properties, opening up new possibilities for fittings in extreme conditions.

Digitization and Automation: Industry 4.0 trends are making their way into fitting manufacturing. Digitized processes and automation are improving precision and efficiency in production.

Sustainability: As environmental concerns grow, manufacturers are exploring ways to make stainless steel production and usage more sustainable, aligning with global green initiatives.

Final Words!

The stainless steel buttweld fittings offered by Metal Forge India meet ASME B16.9 standards and cater to a wide range of project needs. Furthermore, We do also export our ASME B16.9 Stainless steel buttweld fittings to various countries, including the United Arab Emirates, the USA, Germany, South Korea, Russia, Singapore, France, Thailand, Turkey, Vietnam, and Indonesia. Our worldwide delivery capabilities ensure that customers around the world can benefit from our high-quality products.

0 notes

Text

How are flanges manufactured?

Flanges, those unassuming yet indispensable components in piping systems, play a crucial role in connecting pipes, valves, and other equipment. As a leading Flanges Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP takes pride in offering a diverse range of flanges to cater to various industrial needs.

In this blog post, we delve into the fascinating world of flange manufacturing, shedding light on the intricate processes that give rise to these versatile components.

Understanding Flanges!

Flanges are common components in industrial piping systems that provide a strong, leak-proof connection between pipes or equipment. Essentially, a flange is a disc-shaped fitting with evenly spaced holes for bolts and is designed to be attached to the end of a pipe or any other object that requires a joint. Flanges can be made of various materials such as Stainless Steel, Hastelloy, Carbon Steel, Nickel, Duplex Steel, Alloy Steel, Super Duplex Steel, Titanium, Aluminium, Tantalum, Monel, Alloy 20 Steel, SMO 254, Inconel, and Incoloy Flanges. One of the primary functions of a flange is to facilitate the ease of maintenance, repair, or replacement of the equipment that is connected to the piping system. Flanges also help in minimizing leakage, as they create a tight seal between two pipes or equipment.

The Step of how flanges are Manufactured!

Selecting the Right Raw Materials

The durability and reliability of flanges hinge on meticulous material selection. We recognize the significant impact that material choice has on the performance and longevity of the final product. Our extensive range of flanges is forged from an array of materials, each boasting distinct properties that determine compatibility with specific applications and environmental conditions.

Forging: A Cornerstone of Flange Manufacturing

The forging process takes center stage in the production of flanges. This method involves shaping the flange by heating a metal billet and applying controlled pressure to deform it. The sequential steps include billet heating, shaping using a die, and controlled cooling. Forged flanges exhibit exceptional strength and durability, making them ideal for demanding applications. However, it's important to note that forging is a time-intensive process that demands skilled labor.

Casting: An Alternate Path to Flange Creation

Casting stands as another prevalent method for manufacturing flanges. In this process, a mold is created with the desired flange shape, and molten metal is poured into the mold. As the metal cools and solidifies, the mold is removed, leaving behind the cast flange. Casting allows for intricate shapes and is particularly cost-effective for large quantities. However, it's important to consider that cast flanges may possess slightly lower strength compared to their forged counterparts, necessitating additional quality control measures.

Machining for Precision and Customization

Machining involves removing material from a pre-formed flange blank to achieve the desired shape. This method is frequently employed for specialized or customized flanges. Machined flanges offer precise dimensions and tight tolerances, achieved through cutting, drilling, and shaping processes. While machining ensures flexibility and accuracy, it might not be the most cost-effective solution for high-volume production.

Drilling and Threading for Secure Connections

Flanges require strategically placed holes and threads to accommodate bolts and gaskets. Specialized machines execute the drilling and threading process with precision, ensuring accurate alignment for a secure and leak-free connection.

Enhancing Properties Through Heat Treatment

To elevate the mechanical properties of flanges, they undergo various heat treatment processes such as annealing, quenching, or tempering. Heat treatment imparts increased strength, hardness, and resistance to wear and tear, enhancing the overall performance of the flanges.

Surface Finishing for Protection and Appeal

Flanges receive surface finishing treatments to enhance their aesthetic appeal and safeguard against corrosion. Processes such as pickling, passivation, electroplating, or coating are applied based on the material and specific customer requirements.

Rigorous Quality Inspection

Our unwavering commitment to quality control permeates every manufacturing stage. Our flanges undergo meticulous inspections to validate dimensions, surface quality, and material integrity, ensuring that our customers receive products of the utmost quality.

Concluding the Manufacturing Journey

Following the completion of manufacturing and rigorous quality control processes, the flanges undergo a final inspection to ensure they conform to all specifications. Subsequently, they are meticulously packaged and readied for shipping to their intended destinations.

Types of Flanges we do offer!

We offer a wide range of flanges to cater to diverse industrial needs. Here are some commonly used types:

Slip-on Flanges: These flanges slide over the pipe and are then welded in place. They are easy to install and provide excellent alignment.

Blind Flanges: Used to close the end of a pipe, blind flanges are solid discs without a bore. They are ideal for testing and inspection purposes.

Weld Neck Flanges: These flanges have a long, tapered hub that provides reinforcement and reduces stress concentration. They are widely used in high-pressure and high-temperature applications.

Threaded Flanges: Threaded flanges have internal threads that allow them to be connected to pipes with external threads. They are suitable for low-pressure applications.

Socket Weld Flanges: These flanges have a socket-like end that fits over the pipe, followed by fillet welding. They are commonly used for small-diameter, high-pressure piping.

Spectacle Flanges: Spectacle flanges consist of two discs attached to each other by a small section of metal. They are primarily used in applications where frequent inspection or cleaning is required.

Lap-Joint Flanges: Lap-joint flanges are used in combination with stub ends when dismantling is necessary. They allow easy alignment and disassembly of the piping system.

Orifice Flanges: Designed for orifice metering applications, these flanges feature a smaller bore and come with additional tapping holes and bolts.

Groove Flanges: Groove flanges have a groove machined into their face, which accommodates an O-ring or gasket. They are commonly used in industries requiring a tight seal.

Long Neck Flange: These flanges have an extended neck that provides reinforcement and reduces heat transfer to the flange. They are suitable for applications involving thermal expansion.

Flat Face Flange and Raised Face Flanges: These flanges have different face configurations. Flat face flanges are used in applications requiring low friction, while raised face flanges provide better sealing capabilities.

Materials & Grades We Offer - Flanges

Stainless Steel

304/304L/304H, 316,316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 & 904L

Titanium

Titanium Alloy Gr 2

Titanium Alloy Gr. 5

Titanium Alloy Gr. 7

Monel

Monel K500

Monel 400

Carbon Steel

Tantalum

Inconel

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium

Nickel

Nickel Alloy 200/201

SMO 254

Duplex Steel

Duplex UNS S32205

Duplex UNS S31803

Hastelloy

Hastelloy C22, B2

Hastelloy C276

Super Duplex Steel

Super Duplex Steel UNS S32750

Super Duplex Steel UNS S32760

Incoloy

Incoloy 825

Incoloy 800/800H/800HT

Alloy 20

Flanges Offered by Bullion Pipes & Tubes LLP: Your Trusted Partner

As India's foremost flanges manufacturer, Bullion Pipes & Tubes LLP takes immense pride in delivering a diverse array of top-notch flanges. Our unwavering commitment to excellence, extensive industry expertise, and rigorous quality control processes set us apart in the market.

We comprehend the unique needs of our clientele and offer flanges in a multitude of sizes, standards, grades, and materials. Whether your requirements span stainless steel, Hastelloy, carbon steel, or any other type of flange, we stand ready to fulfill them. Our flanges find applications across industries such as oil and gas, petrochemicals, power generation, water treatment, and many more.

Moreover, as reputable flanges exporters, we extend our services to clients across the globe, including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and beyond. Our global outreach, coupled with exceptional customer service, guarantees a seamless experience for international clients.

Applications of Flanges

Flanges are widely used in various industries for a range of applications due to their versatility and functionality. Here are some common applications of flanges:

Pipe Connections

Plumbing Systems

Oil and Gas Industry

Power Generation

Chemical Processing

Shipbuilding and Maritime Industry

HVAC System (Heating, ventilation, and air conditioning systems)

Food and Beverage Industry

Pharmaceutical Industry

Automotive Industry and many more.

Final Thoughts!..

The manufacturing of flanges is a complex and intricate process that demands expertise, precision, and a commitment to quality. Bullion Pipes & Tubes LLP, as a leading Flanges Manufacturer, Supplier, Stockist, and Exporter in India, takes pride in offering a diverse range of flanges that cater to a wide spectrum of industrial needs.

With an unwavering focus on raw material selection, manufacturing methods, and quality assurance, we provide flanges that stand the test of time, ensuring seamless and efficient piping systems for our valued clients worldwide.

0 notes

Text

Why use brass fittings?

Brass fittings are an essential component in various industries, offering durability, versatility, and reliable performance. As the leading brass fittings supplier, manufacturer stockist, and exporter in India, Instrumxx Industries takes pride in providing a wide range of brass fittings to cater to diverse project requirements.

In this blog post, we will explore the numerous advantages of using brass fittings and how they can enhance your project's performance and longevity.

Understanding Brass Fittings

Brass fittings are connectors used to join or redirect pipes, tubes, or hoses in plumbing, HVAC, industrial, and other applications. These fittings are made from high-quality brass alloy, which is primarily composed of copper and zinc. The inclusion of other elements, such as lead or tin, may be present in specific brass alloys to enhance specific characteristics.

Benefits of Brass Fittings

Durability and Strength

Brass fittings are renowned for their exceptional durability and strength. They can withstand high-pressure applications, making them ideal for plumbing systems, gas pipelines, and hydraulic installations. The robustness of these fittings ensures long-lasting performance, reducing the need for frequent replacements and minimizing maintenance costs.

Corrosion Resistance

One of the key advantages of brass fittings is their excellent resistance to corrosion. The combination of copper and zinc in the brass alloy creates a protective layer that prevents rust and corrosion, even when exposed to moisture or harsh environmental conditions. This corrosion resistance extends the lifespan of the fittings and ensures the integrity of the overall system.

Versatility:

Instrumxx Industries offers a comprehensive range of brass fittings, including brass compression fittings, brass hose fittings, brass pipe fittings, brass tube fittings, brass flare fittings, brass valves & cocks fittings, brass grease nipple fittings, brass sanitary fittings, and brass plumbing fittings. This versatility allows customers to find the perfect fitting for their specific project requirements, ensuring compatibility and ease of installation.

Excellent Thermal Conductivity

Brass fittings possess excellent thermal conductivity properties, making them suitable for applications that involve temperature regulation. Whether it's heating or cooling systems, brass fittings efficiently transfer heat, improving overall energy efficiency and performance.

Aesthetic Appeal

In addition to their functional advantages, brass fittings also add an aesthetic appeal to various applications. The warm, golden tones of brass create an elegant and timeless look, making them a popular choice for architectural and interior design projects.

Specifications of Brass Fittings

Materials

Brass

Size

1/8" outer diameter (O.D.) to 1" O.D

Technique

0.01 to 8mm

Brass Fittings Standard

JIS, ASNI, ASME and ASTM

Surface Treatment

NPT, BSP, and BSPT provide a range of tubing selections.

Thread Types

NPT/NPTF Threads, BSP Thread, JIS Tapered Pipe Thread-PT, SAE Thread, Metric Tapered/Parallel Thread.

Nominal Diameter MM

1/8", 1/4", 1/2" 5/8", 3/4", 1", 1.25", 1.5", 2", 2.5",

Brass Fittings Temperature

-20°C-120°C

Brass Pipe Fittings Pressure Rating

PN25

Types of Brass Fittings

Brass 45° Elbow

Brass 90° Elbow

Brass 180° Elbow

Brass Equal Tee

Brass Concentric Reducer

Brass Eccentric Reducer

Brass Long Radius Elbow

Brass Short Radius Elbow

Brass End Cap

Brass Stub End

Brass Equal Cross

Brass Reducing Tee

Brass Female Elbow

Brass Hex Nipple

Brass Plumbing Fittings

Maintenance and Care of Brass Fittings

To ensure the longevity and optimal performance of brass fittings, proper maintenance is essential. Here are some tips to follow:

Regular Inspection: Periodically inspect the fittings for any signs of damage, leaks, or corrosion. Address any issues promptly to prevent further complications.

Cleaning: Clean the brass fittings regularly using mild soap and water. Avoid using abrasive cleaners that can scratch or damage the surface.

Lubrication: Apply a suitable lubricant to threaded fittings to prevent seizing and ensure smooth operation during installation or disassembly.

Other Types of Brass Fittings

Brass Compression Fittings

Brass Hose Fittings

Brass Pipe Fittings

Brass Tube Fittings

Brass Flare Fittings

Brass Valves & Cocks Fittings

Brass Grease Nipple Fittings

Brass Sanitary Fittings

Brass Plumbing Fittings

Applications of Brass Fittings

Brass fittings have a wide range of applications in various industries and everyday use. Here are some common applications:

Plumbing and Pipe Fittings

HVAC Systems

Pneumatic and Hydraulic Systems

Gas Distribution

Automotive and Marine Applications

Industrial Equipment

Furniture and Decorative Fittings

Electrical and Electronic Applications

Other Applications

Final Words!..

Brass fittings offer numerous advantages that make them a preferred choice for various industries and applications. With their durability, corrosion resistance, versatility, and aesthetic appeal, brass fittings from Instrumxx Industries provide reliable and long-lasting solutions for plumbing, HVAC, and industrial projects.

By choosing brass fittings, customers can enjoy the benefits of superior performance, reduced maintenance costs, and peace of mind knowing they are using high-quality components from a trusted Brass Fittings manufacturer.

0 notes

Text

M Pipe Fitting Solution Inc is a leading Alloy 20 Sheets Plates Manufacturer, Supplier, and Exporter in India.

1 note

·

View note

Text

Stainless Steel 304L High Precision Tubes Exporters in India

Introduction

Universe Metal & Alloys has extensive experience in manufacturing and supplying all types of pipe fittings. The entire manufacturing process is supported by trained professionals who have extensive experience in handling different types of pipe fittings and other products.

Description

Stainless Steel 304L High Precision Tubes stand as the cornerstone of modern industrial infrastructure, and at Universe Metal & Alloy, we take immense pride in being the leading Manufacturers, Suppliers, Stockists, and Exporters of this Stainless Steel 304L High Precision Tubes. Our commitment to quality, reliability, and innovation sets us apart in the stainless steel piping industry.

Crafted with precision and expertise, our Stainless Steel 304L High Precision Tubes boast a unique composition that includes nickel, chromium, and molybdenum elements. This composition not only ensures exceptional corrosion resistance but also guarantees longevity and reliability in various industrial applications. At Universe Metal & Alloy, we spare no effort in ensuring that our Tubes exceed industry standards in terms of quality and performance.

Benefits

Corrosion Resistance: 304L stainless steel offers superior resistance to corrosion, making it suitable for harsh environments and ensuring a long service life.

High Precision: Manufactured with exacting standards, these tubes provide precise dimensions and consistent performance.

Strength and Durability: The inherent strength of stainless steel 304L ensures that the tubes can withstand high pressures and temperatures.

Versatility: Suitable for a wide range of applications, including chemical processing, pharmaceuticals, and food industry.

Ease of Fabrication: The low carbon content allows for easier welding and forming, facilitating customization for specific requirements.

Specification

Dimensions - ASTM, ASME and API

Size Range - 6.35 mm-219 mm

Schedule - SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Thickness - 0.5-20 mm

Length - 1000-12000 mm or as Required

End - Plain End, Beveled End

Surface - pickled, bright and black

Material - Stainless Steel

Type - Seamless

Product Overview

Universe Metal & Alloys offers a comprehensive range of high precision Stainless Steel 304L tubes, tailored to meet the diverse needs of our clients. Our tubes are manufactured using advanced techniques and stringent quality control processes to ensure optimal performance and reliability. We offer customizable dimensions and finishes to meet the specific needs of various industries, including automotive, aerospace, and construction.

Our high precision tubes are meticulously tested to meet international standards, ensuring that each product delivered to our customers is of the highest quality. Whether you need standard sizes or custom specifications, we have the expertise and capability to fulfill your requirements efficiently and effectively.

Conclusion

Stainless Steel 304L high precision tubes from Universe Metal & Alloys represent the pinnacle of quality and reliability in the industry. With their superior corrosion resistance, precise dimensions, and robust performance, these tubes are the ideal choice for a variety of demanding applications.

For more information or to place an order, please contact us at [email protected] or call +91-22-66363360 / 66393788.

We look forward to serving your high precision tubing needs with excellence and dedication.

0 notes

Text

Hig Hub Flange

What is a high Hub blind flange?

high hub flange is a kind of round plate with no center hold but with all the proper bolt holes. It is used to close ends of piping systems. It is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles.

Material & Grades of High Hub Flanges :

Stainless Steel High Hub Flanges : ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L High Hub Flanges

Duplex & Super Duplex Steel High Hub Flanges : ASTM A182 / ASME SA182 F44, F 45, F51, F 53, F 55, F 60, F 61 High Hub Flanges

Carbon Steel High Hub Flanges : ASTM A105 / ASME SA105 ASTM / ASME A 350 , ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 High Hub Flanges

Low Temperature Carbon Steel High Hub Flange: ASTM A350, LF2, LF3 High Hub Flanges

Alloy Steel High Hub Flanges : ASTM A182 / ASME SA182 & A387 F1, F5, F9, F11, F12, F22, F91 High Hub Flanges

Copper Alloy Steel High Hub Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy High Hub Flanges : ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) High Hub Flanges

Application of High Hub Flange

ANSI B16.5 Class 150 High Hub Flanges uses in Industrial Boilers Industry

ASTM A182 Stainless Steel High Hub Flanges uses in Power Plants Industry

ASME B16.47 Series A and B High Hub Flanges uses in Nuclear Plants Industry

Stainless Steel High Hub Flanges uses in Oil & Gas Industry

Super Duplex Steel High Hub Flanges uses in Refineries Industry

Industrial High Hub Flanges uses in Ship Building Industry

Super Duplex Steel High Hub Flange Forged Flanges uses in Heat Exchanger Industry

Carbon Steel Industrial High Hub Flanges uses in Condensers Industry

Alloy Steel Industrial High Hub Flanges uses in Paper & Pulp Industry

Duplex Steel Industrial High Hub Flanges uses in Marine Applications

Stainless Steel Industrial High Hub Flanges uses in Nuclear Power Industry

Industrial High Hub Flange / Fittings System uses in Fossil Fuel Power Plants Industry

About Flanges And Nuts

Flanges nuts Is An ISO 9001:2015 licensed enterprise And Has A song file Of providing A wide variety Of Piping solution At Very competitive prices. In a totally brief time period, we've gained An tremendous national And international popularity.

Headed through Mr. Ronak Bhansali (Director) And Supported by way of Our committed, expert team, we are able to fulfill The needs Of Our customers In A timely And Systematic manner. The Profound know-how And wealthy experience Of our crew within the Respective arena Of metal merchandise Has Assisted The business enterprise To gather outstanding role Amidst The reliable chrome steel, Pipe fitting In India.

we're Counted most of the nice manufacturer, Exporter Stockist & provider. We Export 60% Of Our range Of Flanges, shops, Pipe Fittings And solid Fittings To many nations Like u.s.a., united kingdom, Italy, Malaysia, Gulf and so on. we'd admire To Get Your Esteemed Enquires And look ahead to The delight Receiving Your precious response. we're often supplying these objects To Many main industrial gadgets inclusive of : ship constructing, Petrochemical flora, metallic flowers, Refineries, chemical substances, Fertilizers, electricity Plant, Pharmaceutical, Ports, Oil & gas, Railway, Mining, Cement vegetation, Paper mills, Sugar generators, Fabrication units and so on.

TO KNOW MORE ABOUT OUR PRODUCTS YOU CAN VISIT OUR WESITE

www.flangesnuts.com

Used in different industries by

Refineries Gas Processing Off-Shore Oil Drilling Companies Petrochemicals Hydro-Carbon Fertilizers Paper & Pulp Companies Power Generation Specialty Chemicals Pharmaceuticals Drugs Steel Cement Water Pipe Line Pesticides General Piping Construction Engineering Nuclear Food Processing & Dairy boiler & heatexchangers

0 notes

Text

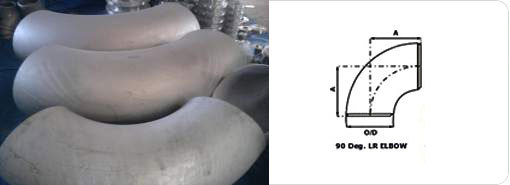

Elbow 90 Manufacturers

Elbow 90 Degree Buttweld Pipe Fittings, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers, Elbow 90 Degree Buttweld Pipe Fittings Suppliers, Elbow 90 Degree Buttweld Pipe Fittings Exporters, Elbow 90 Degree Buttweld Pipe Fittings Stockists.

Elbow 90 Degree Buttweld Pipe Fittings in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Exporters in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Stockists in Mumbai.

Elbow 90 Degree Buttweld Pipe Fittings in India, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in India, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in India, Elbow 90 Degree Buttweld Pipe Fittings Exporters in India, Elbow 90 Degree Buttweld Pipe Fittings Stockists in India.

90° ELBOW

We have earned presumed name in making of Elbow (90°) which is developed with the best of the materials accessible in the business sector. Stainless steel, composite steel and carbon steel and so forth are utilized for manufacturing this elbow. We give these funnel fittings at business sector driving ratesSPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type:

Seamless

ERW

Welded

Fabricated.

Material Type:

Stainless Steel

Alloy Steel

Carbon Steel

Nickel Alloys

Duplex

Grades :

Nickel Alloy:

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel:

ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel :

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Alloy Steel :

ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Carbon Steel:

ASTM / ASME A 234 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

0 notes

Text

Choosing the right Instrumentation Valves

Instrumentation valves play a essential role in diverse industrial packages, facilitating the manage and law of fluids and gases inside a gadget. Selecting the proper instrumentation valves is paramount to ensure most advantageous overall performance, safety, and toughness of your device. Arcellor Controls India, a main Instrumentation Valve manufacturer, supplier, and Instrumentation Valve exporter, offers a diverse range of valves tailor-made to meet various venture specs.

Understand Your Application Requirements:

Before diving into the arena of instrumentation valves, it's critical to have a clear understanding of your software necessities. Consider elements inclusive of fluid type, strain ranges, temperature tiers, and glide costs. This initial evaluation will manual you in selecting valves which can resist the needs of your precise environment.

Valve Types:

Instrumentation valves are available various kinds, each designed for particular purposes. The 8 primary types are Needle Valves, Ball Valves, Gate Valves, Globe Valves, Manifold Valves, Check Valves, Monoflanges Valves, and Valves Accessories.

Needle Valves:

Precision valves with a tapered factor for pleasant go with the flow manipulate, are usually utilized in applications requiring accurate adjustments in low-flow conditions.

Ball Valves:

Utilize a round closure detail for short on/off control with minimum pressure drop, broadly employed in fluid coping with systems and commercial approaches.

Gate Valves:

Control float via the raising or reducing of an internal gate, ideal for applications requiring straight-line flow and minimal strain drop.

Globe Valves:

Feature a disc-fashioned closure detail transferring perpendicular to the seat, providing unique manage of float quotes in applications consisting of HVAC and steam systems.

Manifold Valves:

Connect multiple units to a unmarried supply, streamlining piping preparations and facilitating centralized manipulate in compact designs.

Check Valves:

Allow go with the flow in one route only to save you backflow, essential in structures wherein opposite float should compromise performance or motive harm.

Monoflanges Valves:

Combine isolation and device mounting capabilities in a single unit, simplifying installation and reducing potential leak factors in pressure dimension programs.

Valve Accessories:

Components like positioners, actuators, and limit switches decorate valve performance and functionality, allowing customization primarily based on precise device requirements.

Material Selection:

The preference of material for instrumentation valves is crucial for their ordinary ordinary overall performance and sturdiness. Common substances encompass Stainless Steel (SS), Alloy Steel, Carbon Steel (C.S), Duplex & Super Duplex Steel, Nickel Alloys like Hastelloy, Monel, Inconel, and Alloy 20 Steel. Consider the compatibility of the fabric with the fluid being handled and the environmental situations.

Pressure and Temperature Ratings:

Pay close interest to the strain and temperature rankings of the valves. Ensure that the chosen valves can operate safely within the precise degrees of your application. Choosing valves with better strain and temperature rankings than important can provide a protection margin.

Connection Types:

Instrumentation valves include numerous connection kinds, inclusive of compression fittings, tube fittings, and pipe threads. Select the connection kind that aligns along with your present device or is suitable for your installation necessities.

Size and Flow Capacity:

Matching the dimensions and flow ability of the valves for your utility is vital. Consider the dimensions of the pipes and the specified go with the flow quotes to make sure that the valves can deal with the needs of your gadget without causing bottlenecks.

Considerations for Special Applications:

Some packages can also have specific necessities, which include corrosive or abrasive fluids. In such cases, choose valves specially designed to deal with these challenges. Additionally, for packages in dangerous environments, choose valves with appropriate certifications for safety.

Cost-Benefit Analysis:

While it is crucial to don't forget your budget, prioritize the long-time period benefits of investing in extremely good instrumentation valves. High-first-class valves may have a higher in advance fee but can result in progressed reliability, reduced renovation, and standard price financial savings over the years.

Uses and Applications of Instrumentation Valves

Here are some common uses and applications of instrumentation valves:

Process Control Systems

Oil and Gas Industry

Chemical Processing

Power Generation

Water Treatment

Aerospace and Defense

Laboratory and Analytical Instruments

Semiconductor Manufacturing

Pharmaceutical Industry

Food and Beverage Industry

Other Applications

Final Words!

Choosing the right instrumentation valve manufactures is crucial for the success of your venture. Arcellor Controls India offers a complete range of exquisite valves, ensuring which you locate the best healthy for your precise requirements. Explore our various offerings and trust in our knowledge as a main instrumentation valves manufacturer, supplier, and Instrumentation valves Exporter in various countries all across the globe including India, Oman, Qatar, USA, Germany, UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia. Contact us these days at [email protected] / [email protected] to speak about your mission needs and advantage from our aggressive fees and advanced-first-rate products.

0 notes