#Oil Filter Machine

Explore tagged Tumblr posts

Text

Understanding of the BETA factor

What is the Beta Ratio?

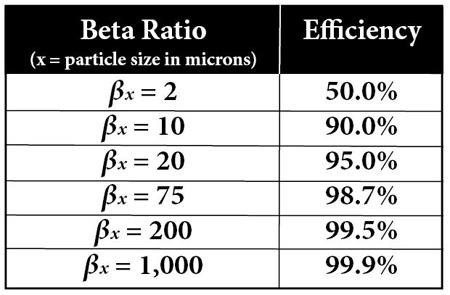

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

The Benefits of Using an Oil Filter Machine in Your Kitchen

In today's fast-paced culinary world, maintaining efficiency and quality in the kitchen is more important than ever. One key piece of equipment that can make a significant difference is an oil filter machine. Whether you're operating a busy restaurant or simply want to elevate your home cooking, understanding the benefits of this machine can help you make an informed decision.

An oil filter machine, such as those available from reputable brands like Chefs Shop, offers numerous advantages that contribute to a cleaner, more efficient kitchen. The primary function of an oil filter machine is to extend the life of your cooking oil by removing food particles and impurities. This not only improves the taste and quality of your fried foods but also reduces the need for frequent oil replacements, which can be both costly and wasteful.

One of the most notable benefits of using an oil filter machine is the improvement in food flavor. Over time, cooking oil accumulates residues from fried food, which can impart a burnt or rancid taste to your dishes. By filtering out these impurities, you ensure that each batch of fried food tastes fresh and delicious. For instance, if you’re using a bullet shape ice cube machine to make ice cubes for beverages, maintaining clean oil in your fryer ensures that your culinary creations—whether sweet or savory—are not tainted by undesirable flavors.

Another significant advantage is cost savings. Replacing oil frequently can become a major expense for any kitchen. By investing in an oil filter machine, you can extend the life of your cooking oil and reduce the frequency of replacements. This is particularly beneficial for commercial kitchens where oil consumption is high. With the Chefs Shop oil filter machine, you can ensure that your cooking oil remains clean and effective for a longer period, thus optimizing your overall kitchen budget.

In addition to cost savings, an oil filter machine contributes to better health standards. Reusing oil that has been properly filtered reduces the production of harmful compounds that can occur when oil degrades. This can lead to healthier meals with fewer unhealthy trans fats. For example, if you're preparing foods using a bullet ice cube machine for serving chilled drinks, you’ll benefit from healthier fried accompaniments, enhancing the overall quality of your meals.

Furthermore, using an oil filter machine improves the efficiency of your kitchen operations. Clean oil helps maintain the proper temperature and consistency of the oil, leading to more consistent cooking results. Whether you’re using a bullet shape ice cube machine or any other kitchen appliance, consistent cooking performance ensures that every dish is prepared to perfection.

For those who operate a busy kitchen, such as a restaurant or a catering service, incorporating an oil filter machine can greatly enhance productivity. With a reliable oil filter machine from Chefs Shop, you can ensure that your kitchen runs smoothly, without the frequent disruptions caused by oil changes. This can lead to a more streamlined cooking process and a better dining experience for your customers.

In conclusion, the benefits of using an oil filter machine in your kitchen are numerous and significant. From extending the life of your cooking oil and improving food flavor to reducing costs and promoting healthier meals, an oil filter machine is an essential piece of commercial kitchen equipment. Brands like Chefs Shop offer reliable options that can help you achieve these benefits efficiently and effectively. By investing in such equipment, you’re not only enhancing the quality of your food but also optimizing your kitchen’s overall performance.

0 notes

Text

Precision Filtration: Sumesh Service's Advanced Oil Filter Machine

Experience unparalleled precision in oil filtration with Sumesh Service's advanced oil filter machine. Engineered to deliver exceptional performance, this cutting-edge technology ensures that every drop of oil is meticulously filtered to the highest standards.

With state-of-the-art filtration mechanisms, it removes impurities, contaminants, and particulates with utmost accuracy, safeguarding your machinery and equipment from potential damage.

Visit for more info : https://www.sumeshservice.com/oil-filter-machine.html

Address : 276, G.I.D.C Estate., Makarpura, Vadodara - 390 010 Gujarat, India

Mail : [email protected]

Phone no : 9727705851

0 notes

Text

Do y’all crave the strength and certainty of steel like, platonically, or y’know. Carnally

#the eroticism of the machine#yk that phrase and ‘this is a girl to me’ have played havoc with me working on cars#lubricating an oil filter by making it kiss the old one. this is indeed yuri

3 notes

·

View notes

Text

Industrial Oil Filters in India – Efficient Filtration & Purification Solutions

At OilFilterMachineIndia.com, we offer high-performance Industrial Oil Filters in India designed for superior fluid cleanliness and equipment protection. Our systems are used across manufacturing, power, and hydraulic applications to extend oil life, reduce wear, and prevent system failures.

⚙️ Advanced Industrial Oil Filters for All Applications

We specialize in Industrial Oil Filters and Industrial Oil Filtration Systems that meet the demands of heavy-duty operations. Our products are ideal for:

Hydraulic systems

Turbines

Gearboxes

Compressors

Power plant equipment

Industrial machinery

These oil purification filters in India ensure compliance with ISO cleanliness codes and industry safety standards.

🔩 Hydraulic Oil Filters in India – Built for Reliability

Our Hydraulic Oil Filters in India are used in critical hydraulic systems to protect pumps, valves, and actuators from contamination. We offer return line filters, pressure line filters, and suction filters tailored for every stage of hydraulic oil circulation.

With our specialized hydraulic system filtration technology, you can:

Improve operational efficiency

Reduce downtime and maintenance costs

Enhance system reliability

🛢️ Industrial Oil Filtration Systems – Clean Oil, Clean Operations

Our industrial oil filtration systems are engineered for maximum removal of dirt, sludge, water, and oxidation by-products from oil. These include:

✅ Offline filtration systems

✅ Inline and online filtration machines

✅ Mobile filtration trolleys

✅ Skid-mounted filter units

Each Industrial Oil Filter Machine is equipped with multi-stage filtration elements to ensure high purity and performance.

🇮🇳 Oil Cleaning Systems in India – Trusted Nationwide

As a recognized supplier of oil cleaning systems in India, we support industries in achieving long-term oil cleanliness and sustainability goals. Whether you're working with hydraulic fluids, gear oil, or turbine oil, our systems are proven to deliver results.

💡 Why Choose OilFilterMachineIndia.com?

✔️ India’s trusted manufacturer of industrial filters

✔️ Proven technology for oil purification filters in India

✔️ Custom solutions for every industry

✔️ After-sales service and technical support available pan India

📞 Contact Us for Industrial Oil Filters in India

Need hydraulic oil filters, oil purification filters, or a complete industrial oil filtration system? Contact OilFilterMachineIndia.com for durable and efficient industrial oil filters in India trusted by top industries nationwide.

#Industrial Oil Filters#Industrial Oil Filters in India#Hydraulic Oil Filters in India#Industrial Oil Filtration Systems#Industrial Filters#Oil Purification Filters in India#Hydraulic system filtration#oil cleaning systems in India#Industrial Oil Filter Machine

0 notes

Text

Advanced High-Vacuum Transformer Oil Filtration and Dehydration Solutions – ConserveYourOil.com

In industries where transformer performance and equipment longevity are non-negotiable, oil purity is a critical factor. At ConserveYourOil.com, we lead the way as a trusted High-Vacuum Transformer Oil Filtration manufacturer in India, offering innovative solutions that ensure optimal oil quality, extend equipment life, and reduce breakdowns.

🛢 Why High-Vacuum Oil Filtration Matters

Transformer oil acts as both an insulator and coolant. Over time, it absorbs moisture, gases, and particulates that compromise its insulating properties. Our high vacuum oil filter machines remove these impurities efficiently, restoring oil to its original dielectric strength and purity.

Our high vacuum transformer oil filtration and dehydration plants are engineered with precision to meet the demands of power plants, substations, transformer manufacturers, and heavy industries across India and abroad.

🏭 Our Expertise in High-Vacuum Oil Filtration

We are one of the leading high vacuum oil filter machines manufacturers in Pune, with a wide range of capacities and custom-built systems. Our equipment is compact, mobile, and easy to operate – making it ideal for both on-site and in-plant filtration.

Whether you need a mobile transformer oil filtration unit or a complete high-vacuum dehydration system, our machines deliver:

Efficient removal of water, gases, and particulate matter

Enhanced transformer life and performance

Compliance with international quality standards

Reliable operation in diverse environmental conditions

As trusted high vacuum oil filter machines suppliers in Pune, we provide full support from manufacturing to commissioning and after-sales service.

🔧 Vacuum Pressure Impregnation (VPI) & Trickle Impregnating Technology

In addition to filtration systems, ConserveYourOil.com is also a reputed Vacuum Pressure Impregnation Plant manufacturer in India. Our VPI systems are widely used for vacuum sealing electrical components, ensuring improved insulation and reduced operational failures.

We are also recognized as wholesale Pressure Impregnation Plant suppliers for various sectors like electrical, transformer, motor, and coil manufacturing.

Our product portfolio includes:

Vacuum Impregnation Plant

Pressure Impregnation Plants

Batch Type Trickle Impregnating Machines

Varnishing Machines for motor windings and stators

These systems provide superior varnish penetration and curing, enhancing the thermal and electrical strength of your components.

🌐 Why Choose ConserveYourOil.com?

✅ Trusted Manufacturer in India ✅ Advanced Engineering & Custom Solutions ✅ Robust Quality Control & Timely Delivery ✅ Comprehensive After-Sales Support

Whether you are searching for a Vacuum Impregnation Plant manufacturer, Pressure Impregnation Plant supplier, or high vacuum oil filtration plant, we offer technology-backed solutions to meet every industrial need.

#"High-Vacuum Transformer Oil Filtration manufacturer in india#high vaccum oil filter machines#high vaccum oil filter machines manufacturer in pune#high vaccum oil filter machines suppliers in pune#Vacuum Pressure Impregnation Plant manufacturers#Vacuum Impregnation Plant manufacturer#wholesale Pressure Impregnation Plant suppliers#Vacuum Pressure Impregnation Plant#Pressure Impregnation Plant#Vacuum Impregnation Plant#Vacuum Impregnation Plants#Pressure Impregnation Plants#Varnishing Machines#Batch Type Trickle Impregnating Machine#Index Type Trickle Impregnating Machine#Vacuum / Pressure Impregnation Plants Manufacturer Exporter#Supplier#Satara#Vacuum Impregnation Plants manufacturer in pune#Vacuum Impregnation Plants manufacturer in india#vacuum pressure impregnation plant supplier in pune#vacuum pressure impregnation plant supplier in india#vacuum pressure impregnation plant exporter in india#vacuum pressure impregnation plant exporter in pune

0 notes

Text

When Should You Replace Your Oil Filter?

You should replace your oil filter every time you change your engine oil. For most vehicles, this is typically:

Every 3,000 to 5,000 miles with conventional oil

Every 7,500 to 10,000 miles with synthetic oil

Or as recommended in your vehicle’s owner’s manual

Why It Matters:

The oil filter traps dirt, metal particles, and sludge from your engine oil. Over time, it becomes clogged and can’t filter properly, which means dirty oil circulates through your engine. This can lead to wear, overheating, and long-term damage.

Signs You May Need to Change It Sooner:

Engine running hotter than usual

Dirty or dark oil on the dipstick

Reduced oil pressure

Unusual engine noise

0 notes

Text

How to Select the Best Commercial Atta Chakki for Your Flour Business?

Starting a new flour business or expanding an existing one is a wise and safe move in today's health-focused market. Consumer demand for fresh, chemical-free, high-nutrition flour is increasing and flour milling is a profitable market. What you choose as your commercial atta chakki (flour machine) can largely determine if you succeed.

With the number of models, brands, and specifications available on the market today, navigating the selection process can prove to be confusing. That is why we have developed this comprehensive guide for you to review as you go through the decision making process. Whether you are a new business or expanding your existing business, we will discuss everything you will need to know prior to investing.

Pinpoint Your Business Needs

Before you get into the technical details, let us first determine your needs from a business point of view. Some questions to ask yourself are:

What is your expected daily output?

What types of grains will you be milling?

Do you need the ability to chipatify (i.e. multi-grain)?

What is the available space for installation?

In general, a small business or startup may want to purchase a compact but effective small capacity machine, while a full-scale flour mill will need a heavy-duty machine capable of processing several tons a day of grains. Commercial Atta Chakki Manufacturers have equipment for every size of business, so knowing your needs is important.

Review the Machine’s Capacity

Capacity is one of the most important criteria when looking for a commercial atta chakki. Commercial atta chakki will range from 50 kg/hr and can go over 500 kg/hr. For small businesses a machine with a capacity of 100–150 kg/hr is usually sufficient; if your a medium to large business, you will probably want to get a machine that can achieve a higher output.

Always choose a machine that has slightly higher capacity than your now existing demand, so that you allow for future growth. Leading commercial atta chakki manufacturers offer customizable solutions that fit different capacity options.

Quality of Components and Build

The difference between a well-built atta chakki and one that is cheaply made can be seen in its durability, capacity to perform consistently over time, and reduced ongoing maintenance costs. Search for machines constructed with quality materials such as high-grade stainless steel or cast iron. Look for corrosion-resistant flour chambers and hardened material grinding blades that will retain their cutting ability and last longer.

Top commercial atta chakki manufacturers invest considerable capital into quality components so that their machines can last longer and provide a better ROI for your business. If you can, spend a bit more on a high-quality machine to reduce maintenance in future breakdown costs.

Power Consumption and Energy Efficiency

Electricity is a recurring downstream cost for any flour milling operation. Therefore, when finding an atta chakki, it is imydously important to find one that provides a balance of performance and power performance. There are manufacturers today producing energy-saving models that don’t reduce your output.

When looking over products, you should check the wattage of the machine as well as the average weekly power consumption per kg of grain you milled. This will give you a more accurate picture of your monthly costs of operation. Efficiency ratings that you can find from commercial atta chakki manufacturers will be useful in procuring an economical option.

User-Friendly Operation and Maintenance of Atta Chakkis

Ease of use and maintenance is crucial in any flour milling operation, particularly if you would subsequently employ workers, or operate the equipment with just a couple of people. Where machines have automated feeding, digital controls, and are designed to be easy to clean then your business can be more efficient in time and labour, thus saving on labour costs.

Check with commercial atta chakki manufacturers if they provide a demo period, staff training, and an after-sales service. If you could find a good supplier, they will provide some operational guidance, additionally their access to spare parts should also be a benefit by reducing yours and potentially your customers' downtime.

Noise and Dust Control in Atta Chakkis

Noise and airborne dust can be a big issue in flour processing units. Many advanced machines now come with noise reduction technology built in and would have dust collector systems to manage the dust in the work area.

If your business is in a residential area where there may be noise regulations, or a unit which is shared in the same complex with other businesses, you should select machines that are noise dampened and/or fitted with filtration units. This is not only good for protecting the health and safety of your staff, but also enhancing your business reputation.

Evaluate Brands and Manufacturer Reputation

When looking at commercial machinery, the reputation of the manufacturer is really important. Always choose trustworthy commercial atta chakki manufacturer with a good history and excellent customer feedback with prompt service support.

To check the reputation of the manufacturer investigate their other machinery. Many commercial atta chakki manufacturers offer a range of other machinery, such as commercial oil filter machines, commercial oil expellers, Domestic Oil Maker Machine Manufacturers, and Domestic Oil Mill Machinery Manufacturers. If you buy your machinery from the same source you'll make your procurement process easier and have access to bundle deals and support plans.

Look for Value Added Features

Many of the modern commercial atta chakkis and newer models offer additional value-added features that greatly improve productivity and safety. Some features must haves include:

Automatic feeding system

Temperature control sensors

Emergency shutoff buttons

Overload protection

Grain cleaning attachments

Not only do these features improve productivity and efficiency, but they also help when making sure the machine meets safety guidelines for the industry.

Price versus Value

Although it is often easy to select the cheapest option available, it often results in greater expense down the road as it may force you into a cycle of repairs or inefficient operation. Evaluate the total value that is provided by the machine with respect to total output, energy used, maintenance required, and service availability.

Many of the recognized manufacturers of commercial atta chakki machines provide machines at various price points, and most have an easy EMI option of payment available. Ask for quotes from all of the vendors you are considering, and then do a side-by-side comparison of pricing and value.

Scalability and Upgradability

A major consideration for enterprises that are looking to grow is whether the atta chakki has the capability to grow with them. There are many models of the commercial atta chakki that are modular, which permits you to upgrade specific components or even increase the overall capacity of the machine without replacing it entirely.

If you are looking to branch into oil milling distances, or food processing aspects, then you would also want to check with manufacturers that supply Commercial Oil Expeller Manufacturers machines or commercial oil filter machines, or even domestic oil making machines, and domestic oil milling machines. Building a relationship with something that has more products helps you to create opportunities down the road.

Last Checklist Before You Buy

Before you finalize a purchase, ensure that you will:

See the manufacturer's plant or virtual demo.

Check the certifications for quality, safety and sustainability.

Confirm the warranty and service agreement.

Establish what installation and training will be provided.

Get a written quote including all terms and conditions.

Finding the right manufacturer is equally as important as finding the right machine. Top commercial atta chakki manufacturers are recognized not only for their heavy-duty equipment but also for their 360-degree customer assistance.

Conclusion

Choosing the right commercial atta chakki for your flour business is a decision that must be considering. The commercial grade machine's capacity and quality, the amount of power the machine consumes, and service support are elements of the business you must decide on to achieve success in your business.

Working with reputable commercial atta chakki manufacturers will help you obtain consistent quality for the flour you produce and will get your flour business headed in the right direction quickly. If you have or are thinking about expanding your business into other food processing areas, reputable manufacturers who also are Commercial Oil Filter Machine Manufacturers, commercial oil expeller manufacturers, domestic oil maker machine manufacturers, domestic oil mill machinery manufacturers will provide a one-stop solution for your industrial needs.

Regardless, take your time, gather your research, make the decision that fits your needs and invest wisely - your flour business deserves it.

#Commercial Oil Filter Machine Manufacturers#Commercial Oil Expeller Manufacturers#Domestic Oil Maker Machine Manufacturers#Domestic Oil Mill Machinery Manufacturers#Commercial Atta Chakki Manufacturers

1 note

·

View note

Text

Application instructions for lubricating oil purifier

Application of a lubricating oil filter

The lubricating oil filter is an important measure to improve and ensure the cleanliness of the system, especially for systems with high precision requirements or serious pollution.

Adding a lubricating oil filter has the advantages of large flow and high precision. Circulating filtration has been applied in high-precision systems designed at home and abroad.

Compared with the oil filter on the main circuit of the system, it can choose a higher precision oil filter without worrying about the oil filter being blocked due to excessive precision, affecting the work of the system, thereby improving the pollution control level of the entire system.

The lubricating oil filter is also equipped with a degassing and dehydration device, such as oil-water separation, which will not affect the system.

In order to obtain a good filtering effect, the circulation system selects full flow filtration, and the filtration flow matches the system working flow, so that the system working medium can be filtered in time.

For systems with insufficient filtering capacity, the method of adding or modifying a lubricating oil filter is adopted, and a filter element with higher precision is selected in the circulation loop.

0 notes

Text

How often should an oil filter be changed, and what happens if you don't replace it on time?

An oil filter plays a crucial role in maintaining engine health by removing dirt, metal particles, and other impurities from engine oil. Over time, the oil filter can get clogged, which is why replacing it regularly is essential for the smooth performance of your vehicle.

How often should an oil filter be changed?

It’s generally recommended to replace the oil filter every time you change your engine oil. This typically falls between 5,000 to 10,000 kilometers (or around 3,000 to 6,000 miles), depending on your vehicle’s make, model, and driving conditions. If you often drive in dusty areas, heavy traffic, or extreme weather, more frequent changes are advised.

For reliable and genuine oil filters, platforms like Liskart offer a wide range of high-quality options for different vehicle types. Whether you need filters for two-wheelers, cars, or commercial vehicles, Liskart makes it easy to find the right fit.

What happens if you don’t replace the oil filter on time?

Reduced Engine Performance: A clogged oil filter limits oil flow, affecting the engine’s efficiency.

Increased Engine Wear: Dirty oil continues to circulate, leading to faster wear and tear of engine parts.

Overheating: Poor oil circulation causes engine components to heat up more quickly.

Potential Engine Damage: Ignoring oil filter maintenance for too long can result in serious engine problems and expensive repairs.

Conclusion

Replacing your oil filter on time is a small but critical step in keeping your vehicle in top condition. With trusted platforms like Liskart, you can easily find and order genuine oil filters that meet your vehicle's needs. Regular maintenance, including timely oil filter replacement, helps extend engine life and ensures a smoother drive.

0 notes

Text

Are you trying to make your oil look better than it is?

However, a wrong sampling technique might not reveal the true condition of the machine and thus, leads to the wrong representation and pre-mature breakdown. Thus, MINIMAC SYSTEMS is starting this #knowyouroil series under which we will make you aware of:

How to collect a sample

Type of contaminants and how they are harmful for your machines

Oil analysis and how to decode it

Oil changes are mostly done under two conditions:

On the basis of time or operating hours

On the basis of oil condition

Most of the time, changing oil based on time or operating hours is expensive and hence, changing based on oil condition is more viable. At this juncture, an Oil Analysis Report is key to decision making. For accurate oil analysis, correct sampling is the pre-requisite. For queries related to Oil Testing: https://www.linkedin.com/company/minimacsystemsprivatetlimited

3 points to be considered while taking sample:

TURBULENCE: The best sampling point is the place like sharp elbows or bends where the oil turns a lot and thus, carries a lot of impurities. The point which are located where the flow is laminar tends to have lesser particle carrying tendency and as a result, makes the oil appear cleaner than what it is.

INGRESSION POINTS: Oil samples should be taken downstream of parts that have a lot of wear and tear and before the oil gets into the inlet to the main oil tank. As once the oil gets mixed with the rest of the oil, the contamination gets diluted and results in poor sample.

FILTRATION: Inline filters ensure that they provide cleaner oil to the machinery downstream of them. If a sample is taken downstream to the filters it will be a lot cleaner than what the actual sample is until unless the filter is not working and is in the by-passed condition. Hence, the sample at all times should be taken upstream to the filters.

When a true representative sample goes for oil analysis it can give answer to the following questions: (Call +91 8975150700 to book an appointment)

Whether the oil is suitable for further use or requires filtration, dehydration/flushing?

What are the types of contaminants in the oil? Are they in the limit as per ISO standards?

What is the condition of the rotating part? Is there excessive wear and tear?

Are there problems like Sludge/Varnish developing which requires flushing of the entire system.

Get your machine's oil check today with our technical expert by clicking on https://www.linkedin.com/company/minimacsystemsprivatetlimited or call +91 8975150700.

Like, Comment, Share this article to spread awareness in achieving Zero Mechanical Breakdown.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil dehydration systems#oil contamination#oil filter systems#transformer oil filter#oil filteration#oil filters#oil filter machine#hydraulic oil flushing#lube oil flushing#chemical cleaning#electrostatics lube cleaner#coalescer separator#diesel oil purification#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power generation#power industry#transformer oil filtration

0 notes

Text

Choosing the Right Commercial Oil Filter Machine for Your Needs

When it comes to maintaining the efficiency and quality of cooking oil in a commercial kitchen, selecting the right commercial oil filter machine is crucial. With the right equipment, you can extend the life of your oil, ensure consistent food quality, and even save on oil costs. But with numerous options available, how do you choose the best commercial oil filter machine for your needs? Here’s a guide to help you make an informed decision.

1. Understand Your Requirements

Before diving into specifics, it's essential to understand the unique needs of your kitchen. The volume of oil used, the type of food prepared, and the frequency of oil changes are all critical factors. For instance, if you run a busy fast-food restaurant, you might need a high-capacity commercial oil filter machine that can handle large volumes of oil quickly. On the other hand, a smaller café might be well-served with a more compact model.

2. Consider the Oil Filter Cart

An oil filter cart is a practical addition to your oil filtration system. It allows for easy mobility and convenience, enabling you to move the oil filter machine to different locations as needed. When selecting a commercial oil filter machine, consider whether it comes with an oil filter cart or if it can be paired with one. This flexibility can be beneficial in a busy kitchen environment where space and accessibility are always in flux.

3. Filter Quality and Efficiency

The quality of the filter is a key factor in maintaining the health of your oil. High-quality filters can remove impurities, carbon, and food particles more effectively, thus extending the life of your oil and improving the taste of your food. Look for a commercial oil filter machine that uses advanced filtration technology and offers easy filter replacement. Brands like Chefs Shop provide machines with reliable filters designed to deliver superior performance and durability.

4. Ease of Use and Maintenance

A commercial oil filter machine should be user-friendly and require minimal maintenance. Features like digital controls, automatic cleaning cycles, and easy-to-read indicators can make operating and maintaining the machine much simpler. Additionally, ensure that the oil filter machine you choose is easy to clean, as regular maintenance is crucial for optimal performance.

5. Capacity and Size

The capacity of the oil filter machine should align with your kitchen’s needs. Larger kitchens with high oil usage will benefit from machines with greater capacity, while smaller establishments may find that a more compact model suffices. Brands like Chefs Shop offer a range of sizes to suit different operational scales, ensuring you can find a machine that fits both your space and your oil volume requirements.

6. Durability and Build Quality

Investing in a durable and well-constructed commercial oil filter machine will save you money in the long run. Look for machines made from high-quality materials that can withstand the rigors of daily use. Stainless steel is a popular choice for its resistance to corrosion and ease of cleaning. Chefs Shop’s machines are known for their robust build quality and long-lasting performance.

7. Cost and Value

While cost is an important consideration, it's crucial to weigh it against the value the machine provides. Sometimes, spending a little more upfront on a high-quality commercial oil filter machine can lead to greater savings over time due to extended oil life and reduced maintenance costs. Compare different models and brands, including Chefs Shop, to find the best balance between cost and features.

Conclusion

Choosing the right commercial oil filter machine involves evaluating your kitchen’s needs, understanding the features and benefits of various models, and investing in quality equipment. Consider options like the oil filter cart for added convenience, and ensure that the machine aligns with your operational requirements. Brands such as Chefs Shop offer excellent choices that meet the high standards of commercial kitchen equipment. With the right commercial oil filter machine, you can maintain the quality of your oil, enhance food flavor, and streamline your kitchen operations.

0 notes

Text

Advancing Precision in Moisture Measurement: Sumesh Service Dew Point Meter Rental

In industries where precision is paramount, understanding and controlling moisture levels are critical for optimal performance and product quality and Dew Point Meter on rent. Sumesh Service, a pioneering player in the instrumentation rental sector, offers an unparalleled solution with their Dew Point Meter on rent services. This innovative approach not only addresses the diverse needs of industries but also introduces a cost-effective and flexible way for businesses to access cutting-edge technology.

Precision in Moisture Measurement

The Dew Point Meter, a sophisticated instrument designed to measure the dew point temperature, plays a pivotal role in various industrial processes. SumeshService rental service provides businesses with the opportunity to harness this advanced technology without the burden of upfront costs associated with purchasing such specialized equipment.

Industries such as pharmaceuticals, petrochemicals, food processing, and HVAC (Heating, Ventilation, and Air Conditioning) rely heavily on maintaining specific moisture levels for optimal efficiency and quality. The Dew Point Meter becomes a crucial tool in ensuring that these industries meet stringent standards and comply with regulatory requirements.

Flexibility in Instrumentation

SumeshService Dew Point Meter rental service stands out for its flexibility. Recognizing that different industries and projects have unique requirements, SumeshService offers a diverse range of Dew Point Meters available for rent. This allows businesses to choose the instrument that best aligns with their specific needs, ensuring they have the right tool for the job without unnecessary expenses.

The flexibility extends to the rental duration as well. Whether a business requires the Dew Point Meter for a short-term project, seasonal use, or an extended period, SumeshService accommodates diverse timelines. This adaptability is particularly beneficial for businesses with fluctuating instrumentation needs, providing them with a cost-effective solution without the long-term commitment of ownership.

Cutting-edge Technology at Your Fingertips

SumeshService takes pride in offering state-of-the-art Dew Point Meters equipped with the latest technology. These instruments employ precision sensors and advanced algorithms to deliver accurate and real-time dew point measurements. The reliability of SumeshService equipment ensures that industries can confidently monitor and control moisture levels in their processes, contributing to enhanced operational efficiency and product quality.

The cutting-edge technology embedded in SumeshService Dew Point Meters not only ensures accuracy but also simplifies the measurement process. User-friendly interfaces and intuitive controls make these instruments accessible to a broad range of operators, reducing the learning curve and increasing efficiency in industrial settings.

Cost-effective Solution for Industries

Investing in high-quality moisture measurement equipment can be a substantial upfront expense for many businesses. SumeshService Dew Point Meter rental service eliminates this financial barrier, allowing industries to access premium instrumentation without a significant capital outlay. This cost-effective solution democratizes access to advanced technology, enabling even smaller businesses to benefit from precise moisture measurement.

Additionally, by opting for a rental model, businesses can allocate their resources more strategically. The flexibility to scale instrumentation according to project demands and seasonal variations ensures that capital is not tied up in underutilized equipment. SumeshService Dew Point Meter on rent is a strategic choice for businesses looking to optimize their budgets while maintaining the highest standards in moisture control.

Comprehensive Support and Maintenance

Sumesh Service commitment to customer satisfaction extends beyond providing top-notch instrumentation. The company understands the importance of reliable equipment in industrial processes and offers comprehensive support and maintenance services as part of their Dew Point Meter rental package.

Customers can rest assured that the rented Dew Point Meters are well-maintained, calibrated, and ready for use upon delivery. Sumesh Service technical support team is available to address any queries or concerns, ensuring a seamless experience for their clients. This level of support adds significant value to the rental service, instilling confidence in businesses relying on precise moisture measurements.

Environmental Sustainability

In an era where environmental sustainability is a global priority, Sumesh Service incorporates eco-friendly practices into its Dew Point Meter rental service. By promoting the reuse of high-quality instrumentation, the company contributes to reducing electronic waste. The rental model aligns with the principles of a circular economy, emphasizing the importance of extending the lifespan of equipment through multiple uses.

Furthermore, Sumesh Service commitment to eco-conscious practices extends to its packaging and transportation processes. By optimizing logistics and minimizing waste, the company aims to make its Dew Point Meter rental service not only economically viable but also environmentally responsible.

Conclusion

Sumesh Service Dew Point Meter on rent is more than just a service; it is a strategic solution for industries seeking precision, flexibility, and cost-effectiveness in moisture measurement. The company's commitment to providing cutting-edge technology, coupled with flexible rental options and comprehensive support, positions Sumesh Service as a leader in the instrumentation rental sector.

In a world where industries face ever-increasing demands for efficiency, quality, and environmental responsibility, Sumesh Service Dew Point Meter rental service emerges as a beacon of innovation. By democratizing access to advanced instrumentation, Sumesh Service empowers businesses to elevate their moisture control processes without compromising on financial prudence or environmental sustainability. As industries evolve, Sumesh Service stands ready to support their instrumentation needs, ensuring a future where precision and sustainability go hand in hand.

#Oil Filter Machine#Oil Storage Tank#Transformer Oil Storage tank#Transformer Oil Filter Machine#Transformer Vacuum Pump#Vacuum Pump#Evacuation System#Dew Point Meter#PPM Meter#Transformer Oil Filter#Tools and Plant for Erection and commissioning of Transformer#Equipments for ETC of Transformer

0 notes

Text

Professional filter manufacturer

1 note

·

View note

Text

Industrial Oil Purification System Manufacturers & Exporters in India | Oil Filtration Machines

Looking for reliable Industrial Oil Purification System manufacturers in India? We are one of the leading Industrial Oil Purification System suppliers in India, offering high-performance oil filtration machines and oil filter plants for various industries.

✅ Specialized in Industrial oil filtration plant solutions ✅ Top-rated Oil filtration machines & filter machines ✅ Trusted Industrial Oil Purification Systems manufacturer in Pune ✅ Verified exporter of Industrial Oil Purification Systems in India

Our systems ensure maximum oil purity, enhanced machinery performance, and reduced downtime. Trusted by industries across manufacturing, power generation, steel, and transformer services.

#Industrial Oil Purification System Manufacturers#Industrial Oil Purification System Suppliers in India#industrial oil filtration plant#Industrial Oil Purification Systems manufacturer in pune#Industrial Oil Purification Systems suppliers in pune#Industrial Oil Purification Systems exporter in pune#Industrial Oil Purification Systems manufacturer in india#Industrial Oil Purification Systems exporter in india#Industrial oil filtration machines#Industrial oil filtration plant#Oil filter machines#Oil filteration plants#Oil filtration machines

0 notes

Text

Empowering Industries with High-Performance Oil Purification Solutions – ConserveYourOil.com

In today's industrial landscape, where reliability and efficiency are non-negotiable, oil purification and filtration systems play a vital role in maintaining machinery health and enhancing operational performance. At ConserveYourOil.com, we are proud to be among the leading VPI Plant Manufacturers and Vacuum Pressure Impregnation Plant Exporters in India, delivering advanced solutions to protect your oil and your equipment.

Trusted Manufacturers of Vacuum Pressure Impregnation (VPI) Plants

ConserveYourOil.com specializes in the design and manufacturing of high-performance Vacuum Impregnation Plants tailored to diverse industrial needs. Our VPI systems are engineered to provide superior insulation, reduced partial discharges, and extended operational life for electrical components. Recognized as one of the most reliable Vacuum Impregnation Plant Exporters in India, we serve both domestic and international markets with cutting-edge technology.

Superior Oil Filtration Machines & Purification Systems

Our range of oil filtration machines and oil filteration plants is built to meet the highest industry standards. Whether you're in power generation, transformer manufacturing, or heavy engineering, our systems ensure your oil remains contaminant-free. We manufacture efficient and robust industrial oil filtration machines that remove moisture, gases, and particulates to restore oil to its optimal working condition.

Our offerings include:

Transformer oil filtration machines in Pune

Oil purification plants for transformer and turbine oil

Oil purifiers designed for long-term industrial use

Portable oil filtration machines for field-based applications

Why Choose Us?

✅ Experience & Expertise – Backed by a strong technical foundation, we are one of the most respected oil filteration plant and oil purifier manufacturers in India.

✅ Global Reach – As Vacuum Pressure Impregnation Plant Exporters in India, we proudly serve clients across the globe, ensuring consistent quality and service excellence.

✅ Sustainability Driven – Our technology helps reduce oil waste, improve recycling capabilities, and minimize operational costs – all while protecting the environment.

✅ Custom Solutions – Whether you require small-scale oil filter machines or full-fledged oil purification plants, we offer tailored systems that meet your unique industrial requirements.

Serving Pune and Beyond

Our manufacturing facility in Pune is a hub for innovation in oil treatment technologies. From transformer oil filtration machines in Pune to large-scale oil purification machines, our solutions are trusted by industries nationwide and across continents.

#VPI Plant Manufacturers#Vacuum Impregnation Plant Exporters#Vacuum Pressure Impregnation Plant Exporters in India#oil filter machines#oil filteration plants#oil filtration machines#oil purification#oil purification machines#oil purification plants#oil purifiers#industrial oil filtration machines#Oil filteration plants#Transformer oil filtration machines in pune#Transformer oil filtration plants manufacturer in pune#high vaccum oil filter machines#transformer oil filtration machines#transformer oil filtration plants#Vacuum dehydration plant suppliers in pune#Vacuum impregnation plants manufacturer in pune#Vacuum dehydration plant exporter in pune#high vaccum oil filter machines manufacturer in pune. high vaccum oil filter machines suppliers in pune.

0 notes