#Onsite Mix Concrete Service

Explore tagged Tumblr posts

Text

Revolutionizing Construction: Onsite Mix Concrete Service

In the realm of construction and civil engineering, precision and efficiency reign supreme. The foundation of every solid structure begins with the quality of concrete used. No matter how well-laid the plans are or how skilled the laborers are, it all boils down to the fundamental element - concrete. And in this ever-evolving world, the need for innovative solutions has paved the way for Onsite Mix Concrete Service to take center stage, redefining the way we build, one pour at a time.

The Traditional Conundrum

Traditional concrete procurement is often riddled with inefficiencies and complications. The process of ordering pre-mixed concrete, transporting it to the construction site, and managing the concrete slump can be a logistical nightmare. The sheer volume of ready-mix concrete required can result in wastage, escalating costs, and even environmental concerns.

Moreover, time constraints are a persistent issue in the construction industry. Delays can snowball into considerable financial setbacks. The conventional method of procuring concrete can be sluggish, further exacerbating construction delays.

Enter Onsite Mix Concrete

Onsite Mix Concrete, as the name suggests, eliminates the need for ready-mix concrete deliveries. It revolutionizes the construction industry by bringing the concrete batching plant directly to your construction site. This innovative approach to concrete supply offers a myriad of benefits that are reshaping the construction landscape.

Unparalleled Convenience and Efficiency

Gone are the days of struggling with rigid delivery schedules and concrete slump adjustments. Onsite Mix Concrete Service provides a level of convenience that was previously unheard of. Your concrete is mixed, poured, and finished right where it's needed. No more concerns about premature setting, long wait times, or the hassle of adjusting the mix on-site.

Customization at Its Finest

Onsite Mix Concrete Service allows for on-the-fly adjustments. This means that the mix can be tailored to the specific requirements of your project. Whether you need high-strength concrete for structural elements or flowable concrete for intricate designs, Onsite Mix Concrete has you covered. This level of customization ensures that you get precisely the concrete you need for your project, no more and no less.

Reduced Waste and Costs

One of the significant advantages of Onsite Mix Concrete is the elimination of wastage. In traditional concrete procurement, any excess concrete often goes to waste, resulting in increased costs and environmental concerns. Onsite Mix Concrete Service eradicates this issue by preparing the exact amount of concrete needed for the project. This not only reduces costs but also minimizes environmental impact.

Environmental Sustainability

In an era where environmental concerns are at the forefront of every industry, Onsite Mix Concrete Service proves to be a sustainable choice. With reduced waste, fewer transportation emissions, and optimized batching processes, it is an eco-friendly alternative to traditional concrete procurement.

Optimal Utilization of Resources

Onsite Mix Concrete Service optimizes the use of resources. It minimizes the need for excess labor and equipment to handle concrete deliveries. This streamlines the construction process, allowing for better allocation of resources to other critical tasks.

Versatility in Application

Onsite Mix Concrete Service is not confined to a specific scale of construction. Whether you are working on a residential project, a commercial development, or a large-scale infrastructure project, the benefits remain consistent. The versatility of this service makes it a valuable asset across various sectors of the construction industry.

Seamless Integration with Technology

The construction industry has embraced technology in recent years, and Onsite Mix Concrete Service is no exception. Many service providers offer tracking systems and real-time monitoring, ensuring that you are always aware of the status of your concrete supply. This level of transparency and control is invaluable in modern construction projects.

Quality Assurance

The quality of concrete is paramount in any construction project. Onsite Mix Concrete Service maintains rigorous quality control measures, ensuring that the concrete you receive is of the highest standard. With professional expertise and state-of-the-art equipment, you can rest assured that the structural integrity of your project is in good hands.

Choosing the Right Onsite Mix Concrete Service

In a market where choices abound, it's essential to select the right Onsite Mix Concrete Service provider for your project. Consider the following factors to make an informed decision:

1. Reputation and Experience: Look for providers with a proven track record and a wealth of experience in the industry. Reputation is often a reflection of the quality of service.

2. Equipment and Technology: Ensure that the service provider employs modern equipment and technology for batching and delivery. This guarantees efficiency and accuracy.

3. Customization: Check whether the service provider can cater to your specific concrete requirements. Flexibility in mix design is a key factor.

4. Environmental Commitment: Evaluate their commitment to sustainability. Choose a provider that takes steps to reduce environmental impact.

5. Reliability and Transparency: Reliable delivery and real-time tracking are crucial for seamless project management. Transparency in the supply chain ensures that you are in control.

6. Cost-Effectiveness: While quality is paramount, consider the cost-effectiveness of the service. Find a balance between quality and affordability.

Conclusion

The construction industry is in the midst of a transformation, and Onsite Mix Concrete Service is at the forefront of this revolution. Its unique approach to concrete supply offers unparalleled convenience, efficiency, customization, and sustainability. It has the potential to save costs, reduce waste, and minimize the environmental footprint of construction projects.

In the quest for optimal construction solutions, choosing the right Onsite Mix Concrete Service provider is crucial. By considering factors such as reputation, equipment, customization, environmental commitment, reliability, and cost-effectiveness, you can ensure that your project benefits from the advantages of this innovative service.

Embrace the future of construction with Onsite Mix Concrete Service, and experience a new era of efficiency, precision, and sustainability in your projects.

0 notes

Text

High-Quality Ready Mix Concrete for Construction Projects

Experience the difference with The Thames Concrete's high-quality ready mix concrete tailored for all your construction needs. Engineered to deliver superior performance and durability, our mix ensures optimal strength and consistency for every project. From small-scale renovations to large-scale constructions, trust in our proven formula to provide reliable results that stand the test of time. With The Thames Concrete, you're not just getting concrete; you're investing in the foundation of your project's success. Build with confidence knowing you have the best ready mix concrete at your disposal.

#Ready mix concrete#concrete services#concrete supplier#volumetric concrete#onsite mixed concrete#on site concrete

1 note

·

View note

Text

Boosting Site Productivity Using Concrete Mixer on Rent Bhubaneswar

Construction demands precision, planning, and timely execution. Delays and inefficiencies affect every layer of progress. In a city like Bhubaneswar, where real estate and infrastructure projects continue to grow rapidly, companies need practical solutions that save time and improve output. Delta Engineering & Services addresses this gap with one of the most important assets on any site - a concrete mixer. Choosing a concrete mixer on rent Bhubaneswar is a smart step for contractors looking to reduce costs and maximise performance.

Simplifying Site Logistics

Managing labour and resources can often stretch project timelines. Manual concrete mixing slows down operations and increases the chance of inconsistency in quality. Delta Engineering & Services brings a clear solution to this challenge. Their rental concrete mixers are built to handle large volumes efficiently while ensuring uniformity in every batch.

With easy mobility and fast mixing cycles, these machines remove dependence on manual work. This simplifies site management, allowing the workforce to focus on execution rather than preparation. It keeps the work steady and aligned with project targets.

Cost Control with No Compromise

Owning heavy equipment can be expensive. There are costs related to purchase, maintenance, and storage. Delta Engineering & Services offers a better approach. A concrete mixer on rent Bhubaneswar helps contractors manage capital better. It reduces long-term investment and keeps maintenance off the client’s plate.

The machines available are modern and well serviced. This ensures consistent performance without sudden breakdowns. When clients rent, they receive reliable machines ready for immediate deployment. This cuts delays and prevents extra costs related to repairs or technical issues.

Faster Work, Better Results

Every hour matters on a construction site. The time spent on mixing can directly affect how fast the next stage begins. The concrete mixers provided by Delta Engineering & Services help cut downtime. High mixing capacity ensures that material is ready when required, keeping the workflow smooth.

The mixers are easy to handle. Workers do not need complex training. With simple operating systems, these machines are productive from the moment they reach the site. This ease of use adds speed without reducing quality.

A concrete mixer on rent Bhubaneswar allows project heads to scale work according to demand. Small and medium projects can benefit from the same efficiency as large ones without stretching budgets.

Trusted Support for Onsite Needs

Delta Engineering & Services is known for being responsive and client-focused. The company ensures timely delivery, technical support, and machine replacements when needed. Their systems are designed to reduce downtime and support client timelines.

They understand the ground challenges contractors face and provide services that remove unnecessary barriers. The goal is simple - deliver machines that help get the job done well and on time.

By offering smart rental solutions backed by dependable service, Delta Engineering & Services helps contractors shift focus to delivery and deadlines.

Choosing a concrete mixer on rent Bhubaneswar is no longer a compromise. It is a clear business decision that brings control, speed, and value to every project site.

#best construction equipment company in odisha#best construction machinery dealer#construction equipment manufacturers#construction equipment rental#heavy equipment supplier#construction equipment rental company

0 notes

Text

Ghaziabad has evolved from a quiet industrial suburb into one of the most dynamic residential and commercial hubs of the Delhi‑NCR region. Robust infrastructure projects, metro‑rail extensions, and the city’s strategic location on the Delhi‑Meerut Expressway have triggered an unprecedented demand for quality real‑estate. In this fast‑moving market, home‑buyers, investors, and institutional clients all face the same question: which construction company can truly deliver value, transparency, and long‑term quality?

For a growing number of Ghaziabad residents, the answer is Zenith Construction & Developers.

A Legacy Built on Trust and Craftsmanship

Best construction company Ghaziabad Founded by a team of civil engineers and visionary entrepreneurs, Zenith Construction & Developers began with a clear mission: to set a new benchmark for construction quality while keeping customer interests at the core. Over the last decade, Zenith has successfully delivered gated townships, luxury villas, commercial complexes, and industrial facilities across Ghaziabad’s most sought‑after micro‑markets—Indirapuram, Raj Nagar Extension, Wave City, and the fast‑rising NH‑24 corridor.

What distinguishes Zenith from other builders is the company’s three‑pillar philosophy:

Engineering Excellence – Every project is designed by a multidisciplinary team of architects, structural consultants, and MEP specialists who follow IS codes, NBC guidelines, and global green‑building standards.

Transparent Processes – From land acquisition to handover, Zenith provides real‑time updates, RERA‑compliant documentation, and milestone‑linked payment plans so clients can track exactly where their money goes.

Customer‑First Culture – A dedicated CRM desk answers queries within 24 hours, while the post‑handover team handles maintenance calls with a 48‑hour resolution SLA.

Signature Projects That Define Zenith’s Reputation

Project

Location

Key Highlights

Zenith Heights

Raj Nagar Extn.

15‑storey smart towers with rain‑water harvesting, rooftop solar panels, and EV‑charging bays

Zenith Corporate Park

NH‑24

Grade‑A office complex featuring column‑free floor plates and LEED‑Gold pre‑certification

Zenith Villas

Indirapuram

42 ultra‑luxury villas with private plunge pools, home automation, and concierge services

Zenith Industrial Hub

Meerut Road

Customised pre‑engineered buildings (PEBs) for SMEs, complete with logistics docking bays

Each development showcases Zenith’s commitment to premium materials, cutting‑edge technology, and on‑time delivery—a trio of promises rarely kept simultaneously in North India’s construction sector.

Technology‑Driven Quality Assurance

Zenith was among the first Ghaziabad builders to adopt:

M‑Sand & Ready‑Mix Concrete (RMC) for consistent mix design and reduced onsite pollution.

Aluminium Formwork for faster cycle times, superior finish, and minimal deviations.

Building Information Modelling (BIM) to detect clashes before ground‑breaking, cutting rework by up to 30 percent.

Drone‑Based Progress Monitoring that lets customers log in via a web portal and view weekly aerial snapshots of their tower or floor plate.

These tech integrations not only accelerate project timelines but also deliver structural integrity that withstands Ghaziabad’s shifting soil conditions and extreme temperature swings.

Sustainability at the Core

Modern buyers seek homes and offices that are future‑ready. Zenith addresses this through:

Low‑VOC paints, AAC blocks, and fly‑ash bricks to cut embodied carbon.

Dual plumbing lines for grey‑water recycling—particularly crucial in water‑stressed zones of Ghaziabad.

Smart lighting and motion sensors that reduce common‑area electricity consumption by up to 40 percent.

Extensive green belts: every project earmarks at least 25 percent of land for landscaped parks, urban forests, or podium gardens.

As a result, Zenith projects consistently earn higher IGBC and GRIHA ratings, translating to lower maintenance costs and healthier living environments for residents.

Why Clients Choose Zenith Construction & Developers

On‑Schedule Handover – A dedicated Project Management Office tracks critical paths daily, ensuring completion dates are met or exceeded.

Fair Pricing, No Hidden Extras – All inclusions—from modular kitchens to split AC conduits—are clearly listed in the Builder‑Buyer Agreement.

Bank & NBFC Tie‑Ups – Zenith is pre‑approved by major lenders, enabling swift loan disbursals and preferential interest rates for customers.

After‑Sales Peace of Mind – A 5‑year structural warranty and free one‑year defect liability period cover any unforeseen issues.

Community‑Driven Design – Clubhouses, co‑working lounges, creches, and elderly‑friendly ramps ensure every demographic feels at home.

Testimonials Speak Louder Than Claims

“We shifted to Zenith Heights six months ago, and the insulation quality is so good that our summer electricity bill dropped by 20 percent.” — Rohit B., Raj Nagar Extension resident

“Our manufacturing unit in Zenith Industrial Hub was operational two months ahead of schedule. Their PEB expertise saved us both time and cost.” — Anita S., SME owner

“Transparent paperwork and weekly drone updates made the buying journey remarkably stress‑free.” — Dr. Kavita M., Investor

The Road Ahead – Innovation & Expansion

Zenith Construction & Developers is currently lining up two ambitious mixed‑use projects near the upcoming RRTS (Rapid Rail) station, featuring skywalk retail, service apartments, and an integrated health‑and‑wellness center. The company is also piloting 3‑D concrete printing for low‑rise auxiliary structures, aiming to cut construction waste by 60 percent.

Conclusion – Building More Than Structures, Building Trust

In a city crowded with builders making tall promises, Zenith Construction & Developers consistently delivers measurable results—whether it’s sturdy workmanship, eco‑friendly features, or transparent customer engagement. For home‑buyers seeking long‑term asset appreciation, corporates eyeing efficient office spaces, or investors hunting for dependable rental yields, Zenith remains the best construction company in Ghaziabad.

0 notes

Text

Construction Made Easy: Ready Mix Concrete Services in Karachi

In the ever-evolving landscape of Pakistan’s construction industry, Allied Materials has emerged as a game changer—especially in the bustling city of Karachi. With infrastructure expanding rapidly and real estate development reaching new heights, contractors and builders now demand materials that are not only of high quality but also timely and cost-efficient. That’s where Ready Mix Concrete in Karachi becomes the ideal solution, and Allied Materials stands out as the trusted name to deliver it.

The Growing Need for Ready Mix Concrete in Karachi

Karachi, being Pakistan’s economic hub, hosts countless construction projects—residential, commercial, industrial, and infrastructural. Traditional methods of mixing concrete onsite are rapidly becoming outdated due to the inconsistency of quality, time delays, and high labor costs. In contrast, Ready Mix Concrete in Karachi offers superior control over quality, faster delivery, and reduced environmental impact. Allied Materials has tapped into this growing demand by providing modern concrete solutions that are custom-tailored for each project. Their production facilities and logistics operations are built to serve even the most demanding requirements of metropolitan construction.

What Is Ready Mix Concrete?

Ready Mix Concrete (RMC) is a type of concrete that is manufactured in a batch plant, according to specific mix designs, and then delivered to construction sites using transit mixers. Unlike traditional onsite mixing, RMC ensures consistency in proportions, minimizes wastage, and significantly cuts down construction time.

The major components of RMC include cement, water, fine aggregates (sand), coarse aggregates (gravel or crushed stone), and admixtures when required. The mixing process is carefully monitored under stringent quality controls to guarantee strength and durability.

Karachi’s Reliable Partner in Concrete Supply

Founded with a vision to revolutionize the construction supply chain in Pakistan, Allied Materials specializes in providing top-notch ready mix concrete services across Karachi. From small residential projects to large-scale commercial developments, the company’s expertise lies in delivering value through:

High-quality concrete mixtures

On-time delivery

Tailored solutions for diverse projects

Technical support and consultation

Environmentally responsible practices

Their commitment to excellence and innovation makes Allied Materials a preferred supplier for leading contractors, real estate developers, and government bodies.

Advantages of Using Ready Mix Concrete

1. Consistent Quality

RMC is produced under controlled conditions using state-of-the-art equipment. This minimizes errors in mix proportions and guarantees uniformity across batches.

2. Time Efficiency

By eliminating onsite mixing, projects can move faster. Workers focus on pouring and finishing rather than preparing the mix.

3. Labor Cost Reduction

No need for a full concrete mixing crew onsite. This reduces payroll costs and mitigates human error.

4. Reduced Wastage

Since the material is mixed in a central plant and delivered in required amounts, there is minimal surplus, saving both money and the environment.

5. Custom Mix Designs

Whether it’s for load-bearing walls, slabs, or roads, Allied Materials can create specific concrete grades suited to your structural needs.

Industries and Projects Served by Allied Materials

Allied Materials caters to a wide range of clients in Karachi. Their ready mix concrete services are ideal for:

Residential Developments: Apartments, villas, and housing societies

Commercial Buildings: Offices, malls, retail centers

Infrastructure Projects: Roads, bridges, flyovers, metro stations

Industrial Facilities: Warehouses, factories, cold storage units

Government Projects: Educational institutions, hospitals, and parks

The company’s versatility in handling both small and large-scale orders is what truly sets it apart.

Environmental Responsibility

In today’s world, sustainability in construction is no longer optional—it is a necessity. Allied Materials adopts environmentally friendly practices by:

Reducing dust and noise pollution through offsite mixing

Recycling unused concrete

Using admixtures that enhance durability and reduce cement content

Investing in fuel-efficient transport

This approach aligns with global standards and contributes to greener urban development in Karachi.

The Allied Materials Fleet: Mobility That Matters

Timely delivery is crucial in construction, and Allied Materials boasts a modern fleet of transit mixers, concrete pumps, and delivery trucks. Their logistics are strategically managed to ensure every batch reaches the site within the golden window of concrete usability—usually within 90 minutes from batching.

Additionally, their experienced drivers and pump operators ensure smooth operations onsite, reducing delays and ensuring safety.

Expert Consultation & Technical Support

One of the biggest advantages of working with Allied Materials is their end-to-end support. Their team includes civil engineers, material specialists, and logistics managers who work closely with clients to understand project requirements, design optimal mix solutions, and ensure compliance with construction codes.

From selecting the correct grade of concrete to advising on placement techniques, they are more than just suppliers—they are partners in progress.

Pricing and Packages

Allied Materials believes in transparent pricing. Clients are offered flexible packages based on:

Concrete grade (M10 to M40 and beyond)

Volume and frequency of orders

Location of the site

Special additives or accelerants

This pricing model makes it possible for small-scale builders and large construction companies alike to benefit from quality concrete at competitive rates.

How to Place an Order with Allied Materials

Ordering from Allied Materials is simple and efficient:

Initial Consultation: Share your project details and timeline.

Mix Design Approval: Confirm the required grade and performance.

Scheduling & Delivery Plan: Coordinate logistics with the Allied team.

Concrete Delivery & Pumping: Sit back and watch your project move forward with precision.

Their customer support team is available throughout the week to assist with queries, updates, and after-sales support.

The Future of Ready Mix Concrete in Karachi

As Karachi continues to grow, the demand for fast, reliable, and sustainable construction materials will rise exponentially. Ready mix concrete will be at the heart of this transformation.

With a strong foundation in quality and client satisfaction, Allied Materials is well-positioned to be a long-term leader in the ready mix industry. Their commitment to modernization, sustainability, and customer support ensures they’ll play a key role in shaping the city’s skyline for years to come.

Conclusion

If you’re a builder, developer, contractor, or even a first-time homebuilder in Karachi, choosing the right concrete partner can make or break your project. Allied Materials is not just a supplier it’s a name trusted by professionals for delivering consistent, high-strength Ready Mix Concrete in Karachi. With ethical business practices, expert consultation, and advanced logistics, they bring peace of mind to every pour. From the foundations of residential buildings to the soaring heights of commercial towers, Allied Materials is the name Karachi relies on for strength, reliability, and growth.

0 notes

Text

Maximizing Efficiency with High-Performance Concrete Pumps

In the fast-paced world of modern construction, time is money. Every hour saved on a job site can significantly reduce costs and accelerate project timelines. One of the most effective ways to enhance productivity is through the use of high-performance concrete pumps. In cities like Karachi, where rapid urban development is driving demand for efficient construction methods, integrating advanced pumping solutions with ready mix concrete services is becoming increasingly essential.

The Role of Concrete Pumps in Modern Construction

A concrete pump is a machine used to transfer liquid concrete through pumping. Unlike traditional methods that rely on manual labor or cranes and buckets, concrete pumps allow for a faster, more precise delivery of concrete. This equipment is particularly valuable for large-scale projects, high-rise buildings, or sites with limited access.

When using a concrete pump in Karachi, contractors can navigate complex urban environments more easily. Narrow streets, traffic congestion, and tight job sites are no match for modern boom or line pumps, which can deliver concrete directly to hard-to-reach areas with minimal disruption.

Why High-Performance Concrete Pumps Matter

Not all concrete pumps are created equal. High-performance models are designed to handle larger volumes, operate at greater speeds, and offer advanced features such as remote control, automatic pressure regulation, and improved safety systems. These benefits lead to:

Faster Placement: High-performance pumps can place concrete much faster than traditional methods, reducing labor hours and speeding up completion times.

Consistent Quality: They ensure a continuous flow of concrete, minimizing the risk of cold joints and inconsistencies in the mix.

Lower Labor Costs: With less manual handling and fewer workers needed for placement, labor costs can be significantly reduced.

Enhanced Safety: Minimizing manual work reduces the likelihood of onsite accidents.

In the context of Karachi's rapidly growing skyline, these advantages are more than just convenience—they're a necessity.

Synergy with Ready Mix Concrete in Karachi

Ready mix concrete in Karachi has become the standard for many construction projects, offering a consistent, quality-controlled product that saves time and reduces material wastage. When combined with a concrete pump, the efficiency of ready mix concrete is taken to the next level.

For example, a batching plant can produce high-grade concrete while a pump delivers it directly to the pour site, all within minutes. This synchronized operation reduces wait times, prevents concrete from setting before use, and ensures optimal workability on arrival.

Contractors working with both a reliable concrete pump and ready mix concrete in Karachi can streamline the entire process—from batching to final placement.

Choosing the Right Equipment for Your Project

When selecting a concrete pump in Karachi, consider the following factors:

Type of Project: Line pumps are ideal for smaller or residential projects, while boom pumps are suited for high-rise or commercial construction.

Concrete Mix Design: The pump should match the type and viscosity of the concrete being used. Some pumps handle mixes with larger aggregates better than others.

Job Site Conditions: Accessibility, space constraints, and elevation should all be considered.

Pump Output: Make sure the pump’s capacity aligns with the volume of ready mix concrete being supplied.

Partnering with experienced suppliers who understand the specific challenges of Karachi’s construction environment can make all the difference.

Reducing Environmental Impact

Another overlooked benefit of using high-performance concrete pumps is sustainability. Because they reduce concrete waste, optimize material usage, and lower energy consumption, they contribute to greener building practices.

Karachi, like many other major cities, is facing increasing pressure to adopt more sustainable construction methods. By using advanced pumping technology and ready mix concrete solutions, builders can meet environmental standards without compromising on quality or speed.

Real-World Applications in Karachi

The city is already seeing a surge in projects utilizing these modern methods. From commercial high-rises in Clifton to infrastructure developments near the Super Highway, the combination of a concrete pump Karachi service with high-quality ready mix concrete is becoming a preferred strategy.

Developers are reporting reduced project durations, fewer delays due to weather or labor shortages, and a noticeable improvement in finished structural quality. It’s a shift that reflects a broader trend toward modernization in the construction industry.

Conclusion

Maximizing efficiency on the job site isn’t just about working harder—it’s about working smarter. High-performance concrete pumps represent a key step forward in construction technology, especially when integrated with ready mix concrete in Karachi. By adopting these tools and methods, contractors can increase productivity, reduce costs, and deliver superior results, all while keeping up with the demands of a fast-evolving urban landscape.

Whether you're a small contractor or a major developer, investing in the right equipment today can yield substantial benefits tomorrow. And in a growing city like Karachi, where every project matters, staying ahead with efficient concrete pumping solutions is more important than ever

ADDRESS

HeadOffice Location

21/3, Sector 22. Korangi Industrial Area, Karachi.

Korangi Creek Plant Office

Survey No. 423, Ibrahim Hydri, behind Bol head quarter, Korangi creek road, Karachi-74900

Highway Plant Office Address

Naclass (NC) No. 119, Deh Tore, Karachi-Hyderabad Motorway, Tappo Konkar, Malir Gadap Town, Karachi Near Karachi Toll Plaza

Location: Survey No. 423, Korangi Creek Rd, behind Bol head quarter, Ibrahim Hyderi Korangi Creek, Karachi, 74900, Pakistan

0 notes

Text

Top Ready Mix Concrete Suppliers in Pakistan (2025)

As Pakistan continues to experience rapid urbanization and infrastructure development, the demand for high-quality construction materials has surged — and among them, ready mix concrete stands out as a vital component in both residential and commercial projects. Whether you're constructing a multi-story building in Lahore or laying the foundation for a shopping mall in Karachi, choosing the right ready mix concrete supplier can make all the difference.

In 2025, the competition among suppliers in Pakistan has grown fiercer, and innovation in delivery, mixing technology, and service quality has significantly improved. This article will highlight some of the top ready mix concrete suppliers in Pakistan and also explore the growing importance of services like concrete pump Karachi and ready made concrete Karachi for smoother project execution.

What Is Ready Mix Concrete?

Ready mix concrete is a tailor-made concrete produced in a batching plant according to a specific mix design. It is then delivered to construction sites using transit mixers. This method ensures consistent quality, saves time, and reduces labor costs — all of which are critical factors for modern construction projects.

Why Ready Mix Concrete Is Gaining Popularity in Pakistan

Over the past few years, Pakistan’s construction sector has embraced ready mix concrete for a variety of reasons:

Time Efficiency: Unlike site-mixed concrete, ready mix is prepared offsite, reducing delays.

Consistent Quality: Professional batching ensures precision in the concrete mix.

Waste Reduction: Pre-measured mixes reduce material waste on construction sites.

Labor Optimization: Less reliance on manual labor at the construction site.

The convenience and quality of ready mix concrete have made it the preferred choice for builders across the country.

Top Ready Mix Concrete Suppliers in Pakistan (2025)

Let’s look at some of the most reputable suppliers currently dominating the Pakistani market.

1. Bestway Concrete (Ready Mix Division)

Bestway is one of Pakistan’s largest cement manufacturers, and their ready mix division is well-known for delivering high-quality concrete solutions across major cities. They are particularly active in Islamabad, Rawalpindi, and Lahore, offering reliable on-time delivery and superior concrete strength.

2. Maple Leaf Concrete

Maple Leaf has earned a strong reputation for its durable and weather-resistant concrete. Their ready mix service includes customized mix designs and onsite technical support. Their facilities are equipped with the latest batching technology.

3. Lucky Ready Mix Concrete

Based in Karachi, Lucky Ready Mix has become a go-to option for commercial builders and contractors. Their services include concrete pump Karachi, ensuring the concrete is placed efficiently, even in high-rise buildings or difficult-to-reach areas.

4. Crescent Ready Mix Concrete

Operating in Lahore and Faisalabad, Crescent offers quick delivery, flexible mix options, and competitive pricing. They also focus on sustainability, using eco-friendly practices in concrete production.

5. RAAZ Concrete

RAAZ has gained traction in southern Pakistan for its commitment to high-performance mixes. They provide ready made concrete Karachi solutions that are pre-tested and certified, minimizing construction risks and delays.

Importance of Concrete Pump Karachi in Construction

In a bustling city like Karachi, construction sites often face logistical challenges like narrow access roads or high-rise placements. This is where concrete pump Karachi services come into play. Concrete pumps allow for:

Precise Placement: Easily deliver concrete to the top floors of buildings or deep foundations.

Speed: Reduce the time required to pour concrete.

Labor Savings: Minimize the number of workers needed to transport concrete manually.

Top suppliers like Lucky and RAAZ include concrete pump Karachi options with their packages, making them highly competitive in the city’s fast-paced construction environment.

Advantages of Choosing Ready Made Concrete Karachi

Builders in Karachi are increasingly turning to ready made concrete Karachi due to the following benefits:

Reduced On-Site Hassles: Since the mixing is done offsite, projects run cleaner and more efficiently.

Enhanced Quality Control: Each batch is tested before delivery.

Scalability: Whether it’s a small residential home or a mega commercial project, ready made concrete Karachi can be customized to fit any size.

Major projects in Clifton, DHA, and Gulshan are now relying heavily on ready made concrete Karachi services to meet their deadlines and quality standards.

How to Choose the Right Ready Mix Concrete Supplier

When selecting a ready mix supplier, consider the following:

Reputation: Look for established names with proven track records.

Mix Design Customization: Ensure the supplier offers a variety of mix options tailored to your project.

Delivery and Pumping Services: Opt for companies that offer both concrete pump Karachi and delivery support.

Technical Support: On-site engineers or technicians can help maintain mix consistency.

Certifications: Choose suppliers who follow industry standards and offer certified quality assurance.

Final Thoughts

The construction industry in Pakistan is evolving fast, and ready mix concrete is at the center of this transformation. Whether you're building in the capital or on the coastline, relying on top suppliers for ready made concrete Karachi and leveraging concrete pump Karachi services can significantly streamline your workflow.

By partnering with the right ready mix concrete company, you're not just buying a product — you're investing in long-term quality, efficiency, and peace of mind.

HeadOffice Location

21/3, Sector 22. Korangi Industrial Area, Karachi.

Korangi Creek Plant Office

Survey No. 423, Ibrahim Hydri, behind Bol head quarter, Korangi creek road, Karachi-74900

Highway Plant Office Address

Naclass (NC) No. 119, Deh Tore, Karachi-Hyderabad Motorway, Tappo Konkar, Malir Gadap Town, Karachi Near Karachi Toll Plaza

Location: Gadap Town, Karachi, Pakistan

0 notes

Text

What You Need to Know About Concrete Delivery Services in Derby and Nottingham

When it comes to construction projects in Derby and Nottingham, having a reliable concrete delivery service is crucial. Whether you're working on a small residential project or a large commercial development, the right concrete supplier can make all the difference. In this article, we'll explore everything you need to know about concrete delivery services in Derby and Nottingham, including the benefits they offer and how to choose the right supplier for your needs.

What is Concrete Delivery?

Concrete delivery involves the transportation of freshly mixed concrete from the supplier's plant to the construction site. This ensures that the concrete is delivered promptly and is ready to be used immediately. With concrete delivery services in Derby and Nottingham, you can save time and labor by having the concrete delivered directly to your project site, eliminating the need for onsite mixing.

Benefits of Concrete Delivery Services

Convenience: With concrete delivery services, you can eliminate the hassle of transporting and mixing concrete onsite. This saves time and labor, allowing your construction project to proceed more efficiently.

Quality Assurance: Professional concrete suppliers ensure that the concrete is mixed to the correct specifications, resulting in a high-quality end product. This reduces the risk of errors and ensures that your project meets the required standards.

Cost-Effectiveness: By outsourcing your concrete delivery needs, you can avoid the expense of purchasing and maintaining your own mixing equipment. This can result in significant cost savings over the course of your project.

On-Time Delivery: Reliable concrete delivery services ensure that your concrete arrives on time, allowing your project to stay on schedule. This is essential for meeting deadlines and avoiding costly delays.

What to Look for in a Concrete Delivery Service

Experience: Choose a concrete supplier with extensive experience in the industry. This ensures that they have the knowledge and expertise to meet your project's specific requirements.

Reputation: Research the reputation of the concrete delivery service by reading customer reviews and testimonials. A reputable supplier will have a track record of delivering quality products and excellent customer service.

Reliability: Look for a concrete supplier that offers reliable delivery services, with a fleet of well-maintained vehicles and experienced drivers. This ensures that your concrete arrives on time and in good condition.

Flexibility: Choose a supplier that can accommodate your project's schedule and requirements. Whether you need a small quantity of concrete for a residential project or a large volume for a commercial development, a flexible supplier can meet your needs.

Concrete Delivery in Derby

In Derby, construction projects ranging from residential renovations to large-scale infrastructure developments rely on dependable concrete delivery services. Whether you're building a new driveway, patio, or foundation, having access to quality concrete is essential for ensuring the success of your project.

Concrete Delivery in Nottingham

In Nottingham, construction projects are thriving, with new developments springing up across the city. From residential housing to commercial buildings, concrete is a fundamental building material for construction projects of all sizes. With reliable concrete delivery services in Nottingham, contractors can access the materials they need to complete their projects efficiently and effectively.

Choosing the Right Supplier

When choosing a concrete delivery service in Derby or Nottingham, it's essential to consider factors such as experience, reputation, reliability, and flexibility. By selecting a reputable supplier that meets your project's specific requirements, you can ensure that your construction project proceeds smoothly and successfully.

Conclusion

In conclusion, concrete delivery services play a vital role in construction projects in Derby and Nottingham. By outsourcing your concrete needs to a reliable supplier, you can enjoy the benefits of convenience, quality assurance, cost-effectiveness, and on-time delivery. When choosing a supplier, be sure to consider factors such as experience, reputation, reliability, and flexibility to ensure the success of your project. With the right concrete delivery service by your side, you can build with confidence and achieve outstanding results.

0 notes

Text

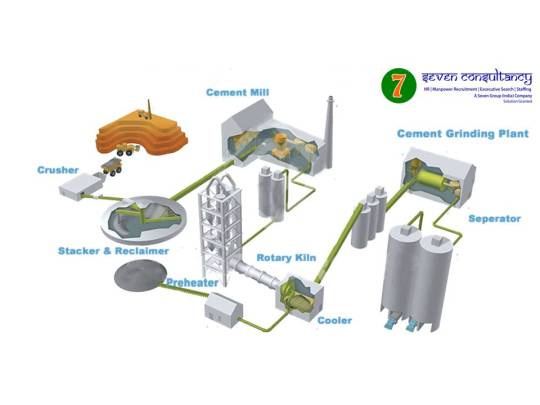

Being the top Cement plant recruiting nation, India provides the best workforce from different regions

Cement is a material that's used to build very strong, hard surfaces and structures. Cement is an ingredient in both mortar, which holds bricks together, and concrete, with which dams and roads and buildings are constructed. The making process of portland cement in the modern industry can be divided into the wet process, dry process, and semi-dry process. Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protection. The significant component in making cement is limestone which is first crushed then sent for pre-blending via belt conveyor. After this activity, the material is stored with other materials. These components are then extracted in precise proportions taking assistance of electronic weigh feeder. At the end the material is sent to raw mill for further fine grinding. The excavated materials are transported to the crushing plant by trucks, railway freight cars, conveyor belts, or ropeways. They also can be transported in a wet state or slurry by pipeline. Generally, limestone is 80% and remaining 20% is the clay. In the cement plant, the raw mix is dried, heavy wheel type rollers and rotating tables blend the raw mix and then the roller crushes it to a fine powder to be stored in silos and fed to the kiln.

As a leader in the cement and mining industries, they have taken on the responsibility of developing sustainable solutions. They have an ambition to engineer the zero emissions cement plant and the zero emissions mining process by 2030. And your know-how and innovative mindset will take them from idea to action. As Manager Standardization you will be heading a team of people who supports on the design automation across Mining products in the areas of Proposal, Pricing documents along with product optimization. Your responsibilities are estimate the time line and efforts required to complete the tasks or activities and communicate them to the counterpart, track the projects/tasks on its status and challenges with the onsite team, head the product Standardization team and execute various Standardization projects, organize gate meeting with stake holders and review the project progress, define the design automation required for the project/product and communicate with the team member, maintain the productivity and efficiency of the team, monitor the status of the projects/tasks and provide periodic update to the onsite team. Cement Plant Recruitment Agency in India provides services recruitment.

Recruitment is the process of actively seeking out, finding candidates for a specific position or job. The recruitment definition includes the entire hiring process, from inception to the individual recruit’s integration into the company. Searching out the sources from where required persons will be available for recruitment. If young managers are to be recruited then institutions imparting instructions in business administration will be the best source. Developing is the techniques to attract the suitable candidates. Best Cement Plant Recruitment Agency in India also provides consultancy service. They seek professionals through internal references from their employees, job postings on popular job search portals and recruitment consultants. You are invited to submit your resume on their website for current or future openings. They will maintain it in their database and will contact you in case your profile is suitable for a particular position. Outsourcing is an indirect source of talent. It is a major feature in the oil and gas and building sectors, with many key functions often subcontracted. Taken to the limit, the result is a virtual company directly employing little more than its directors. Finally, the cement industry needs people who can shape its future and create value. Looking to that future, leaders need to be aware that younger workers that they currently employ seek fulfillment, appreciation and being part of a greater goal, rather than just job security.

The last decade or so has seen a lot of growth in the outstanding capacity of cement production and consumption in India. Top Cement Plant Recruitment Agency in India also provides in consultancy sectors. They were already known to be one of the largest producers of cement in the world, and the future is only going to make that position stronger. With digitalization, a mystery can be revealed. Raw meal can be finely controlled to ensure the optimal mix to meet quality targets, while avoiding overspend on additives and higher-quality materials. This optimization brings benefits in terms of lower energy consumption and less wear on mechanical parts. All of which is great for the long-term sustainability of the industry. At higher levels of fuel substitution, such as those implied by BCG, that instability can only be controlled with the aid of digital control solutions.

#CementPlantRecruitmentAgencyinIndia#BestCementPlantRecruitmentAgencyinIndia#TopCementPlantRecruitmentAgencyinIndia

0 notes

Text

Efficiency and Reliability: The Key Characteristics of Concrete Delivery Services

In the realm of construction and infrastructure development, the timely delivery of materials is crucial to project success. Among these materials, concrete stands as a fundamental component, forming the backbone of structures worldwide. To ensure seamless progress on construction sites, the reliance on efficient and reliable concrete delivery services has become paramount.

Concrete delivery services play a pivotal role in the construction industry, offering a range of benefits that contribute to project efficiency and cost-effectiveness. From small-scale residential projects to large-scale commercial developments, these services facilitate the transportation and placement of concrete with precision and expertise.

Timely delivery is one of the primary advantages offered by reputable concrete delivery services. Construction projects often operate on tight schedules, with each phase intricately planned to minimize delays and maximize productivity. Delays in concrete delivery can disrupt these schedules, leading to costly setbacks and potential complications. By partnering with a reliable delivery service, construction teams can ensure that concrete arrives precisely when needed, avoiding unnecessary downtime and maintaining project momentum.

Moreover, efficiency in transportation is a hallmark of professional concrete delivery services. Modern fleets equipped with advanced technology and logistical capabilities enable providers to optimize routes, minimize travel time, and maximize payload capacity. This efficiency not only reduces fuel consumption and environmental impact but also enhances overall project efficiency by streamlining the delivery process.

In addition to timely and efficient delivery, the quality of the concrete itself is paramount. Reputable delivery services prioritize the use of high-quality materials and adhere to industry standards and specifications. This commitment to quality ensures that the concrete delivered meets the structural requirements and performance expectations of the project, ultimately contributing to the longevity and durability of the finished structure.

Beyond the delivery itself, many concrete services offer value-added solutions such as onsite mixing and pumping. These capabilities eliminate the need for additional equipment and labor, simplifying the construction process and reducing costs. Furthermore, the flexibility to adjust mix designs on-site enables contractors to adapt to changing project requirements and optimize performance based on specific needs.

Safety is another critical aspect of concrete delivery services. Professional providers prioritize safety protocols and procedures to mitigate risks associated with transportation, handling, and placement of concrete. From trained drivers to secure packaging and handling practices, these measures ensure a safe working environment for construction crews and minimize the likelihood of accidents or injuries.

Ultimately, the success of any construction project hinges on the seamless coordination of various elements, and concrete delivery services play a vital role in this process. By prioritizing efficiency, reliability, quality, and safety, these services empower construction teams to overcome logistical challenges and achieve their project goals effectively.

For more info:-

concrete mixer rental services northern virginia

concrete delivery services near me

0 notes

Text

Revolutionizing Construction: Onsite Mix Concrete Service

In the realm of construction and civil engineering, precision and efficiency reign supreme. The foundation of every solid structure begins with the quality of concrete used. No matter how well-laid the plans are or how skilled the laborers are, it all boils down to the fundamental element - concrete. And in this ever-evolving world, the need for innovative solutions has paved the way for Onsite Mix Concrete Service to take center stage, redefining the way we build, one pour at a time.

The Traditional Conundrum

Traditional concrete procurement is often riddled with inefficiencies and complications. The process of ordering pre-mixed concrete, transporting it to the construction site, and managing the concrete slump can be a logistical nightmare. The sheer volume of ready-mix concrete required can result in wastage, escalating costs, and even environmental concerns.

Moreover, time constraints are a persistent issue in the construction industry. Delays can snowball into considerable financial setbacks. The conventional method of procuring concrete can be sluggish, further exacerbating construction delays.

Enter Onsite Mix Concrete

Onsite Mix Concrete, as the name suggests, eliminates the need for ready-mix concrete deliveries. It revolutionizes the construction industry by bringing the concrete batching plant directly to your construction site. This innovative approach to concrete supply offers a myriad of benefits that are reshaping the construction landscape.

Unparalleled Convenience and Efficiency

Gone are the days of struggling with rigid delivery schedules and concrete slump adjustments. Onsite Mix Concrete Service provides a level of convenience that was previously unheard of. Your concrete is mixed, poured, and finished right where it's needed. No more concerns about premature setting, long wait times, or the hassle of adjusting the mix on-site.

Customization at Its Finest

Onsite Mix Concrete Service allows for on-the-fly adjustments. This means that the mix can be tailored to the specific requirements of your project. Whether you need high-strength concrete for structural elements or flowable concrete for intricate designs, Onsite Mix Concrete has you covered. This level of customization ensures that you get precisely the concrete you need for your project, no more and no less.

Reduced Waste and Costs

One of the significant advantages of Onsite Mix Concrete is the elimination of wastage. In traditional concrete procurement, any excess concrete often goes to waste, resulting in increased costs and environmental concerns. Onsite Mix Concrete Service eradicates this issue by preparing the exact amount of concrete needed for the project. This not only reduces costs but also minimizes environmental impact.

Environmental Sustainability

In an era where environmental concerns are at the forefront of every industry, Onsite Mix Concrete Service proves to be a sustainable choice. With reduced waste, fewer transportation emissions, and optimized batching processes, it is an eco-friendly alternative to traditional concrete procurement.

Optimal Utilization of Resources

Onsite Mix Concrete Service optimizes the use of resources. It minimizes the need for excess labor and equipment to handle concrete deliveries. This streamlines the construction process, allowing for better allocation of resources to other critical tasks.

Versatility in Application

Onsite Mix Concrete Service is not confined to a specific scale of construction. Whether you are working on a residential project, a commercial development, or a large-scale infrastructure project, the benefits remain consistent. The versatility of this service makes it a valuable asset across various sectors of the construction industry.

Seamless Integration with Technology

The construction industry has embraced technology in recent years, and Onsite Mix Concrete Service is no exception. Many service providers offer tracking systems and real-time monitoring, ensuring that you are always aware of the status of your concrete supply. This level of transparency and control is invaluable in modern construction projects.

Quality Assurance

The quality of concrete is paramount in any construction project. Onsite Mix Concrete Service maintains rigorous quality control measures, ensuring that the concrete you receive is of the highest standard. With professional expertise and state-of-the-art equipment, you can rest assured that the structural integrity of your project is in good hands.

Choosing the Right Onsite Mix Concrete Service

In a market where choices abound, it's essential to select the right Onsite Mix Concrete Service provider for your project. Consider the following factors to make an informed decision:

1. Reputation and Experience: Look for providers with a proven track record and a wealth of experience in the industry. Reputation is often a reflection of the quality of service.

2. Equipment and Technology: Ensure that the service provider employs modern equipment and technology for batching and delivery. This guarantees efficiency and accuracy.

3. Customization: Check whether the service provider can cater to your specific concrete requirements. Flexibility in mix design is a key factor.

4. Environmental Commitment: Evaluate their commitment to sustainability. Choose a provider that takes steps to reduce environmental impact.

5. Reliability and Transparency: Reliable delivery and real-time tracking are crucial for seamless project management. Transparency in the supply chain ensures that you are in control.

6. Cost-Effectiveness: While quality is paramount, consider the cost-effectiveness of the service. Find a balance between quality and affordability.

Conclusion

The construction industry is in the midst of a transformation, and Onsite Mix Concrete Service is at the forefront of this revolution. Its unique approach to concrete supply offers unparalleled convenience, efficiency, customization, and sustainability. It has the potential to save costs, reduce waste, and minimize the environmental footprint of construction projects.

In the quest for optimal construction solutions, choosing the right Onsite Mix Concrete Service provider is crucial. By considering factors such as reputation, equipment, customization, environmental commitment, reliability, and cost-effectiveness, you can ensure that your project benefits from the advantages of this innovative service.

Embrace the future of construction with Onsite Mix Concrete Service, and experience a new era of efficiency, precision, and sustainability in your projects.

0 notes

Text

Efficient Volumetric Concrete Delivery Services for Your Construction Projects

Find the convenience of volumetric concrete delivery for your construction needs. Our services provide precise and on-demand mixing of concrete at your job site, ensuring optimal quality and consistency. With volumetric concrete delivery, you have greater flexibility and control over your project timelines and budgets. Say goodbye to overordering or wastage and streamline your construction process with our efficient delivery solutions.

1 note

·

View note

Text

Your Complete Guide to Choosing the Right Concrete Mixer of Ajax Fiori for Rent from J K Jain BuildTech India (JKJBIPL)

Concrete mixers are the workhorses of any construction project, ensuring that vital ingredients are meticulously blended for a sturdy and reliable foundation. When it comes to selecting the perfect mixer for your specific needs, J K Jain BuildTech India stands out as a trusted Ajax Fiori Machines brand delivering consistent performance and quality. JKJBIPL is one of India’s leading Self-Loading Concrete Mixer and Ajax Fiori Machine Rental Service providers with a head office in Delhi & branch office in Guwahati to specially cater to all seven states of North East including Assam, Arunachal Pradesh, Meghalaya, Nagaland, Mizoram, Manipur and Tripura empowers you to navigate the intricate world of concrete mixing with ease.

This comprehensive guide equips you with valuable insights and expert tips for choosing the ideal concrete mixer of Ajax Fiori for rent from JKJBIPL, whether you’re tackling a small-scale DIY project or embarking on a large-scale construction endeavour.

1. Understanding Your Project Needs:

Scale and Scope: Before exploring your rental options, determine the project’s scale. Are you building a cosy patio or a towering skyscraper? Identifying the project size guides you towards the appropriate mixer capacity and type.

Concrete Mix Design: Different projects require specific concrete mix designs with unique mixing techniques and equipment. Consult your engineer or architect to understand the precise proportions of cement, aggregates, and water needed for your project. JKJBIPL’s knowledgeable team can also assist you in deciphering these specifications.

Project Timeline and Deadlines: Time is of the essence! Analyze your project’s timeline and deadlines to assess the ideal mixing and discharge speed required. Opting for a faster mixer might be crucial for projects with tight schedules.

2. Delving into the World of Ajax Fiori Mixers:

Self-Loading Concrete Mixers: These versatile machines, readily available at JKJBIPL, are equipped with a self-contained loading bucket, making them ideal for smaller to medium-sized projects. They simplify onsite operations by enabling convenient loading and mixing.

Transit Mixers: Designed for larger projects, transit mixers transport ready-mix concrete from the batching plant to your construction site. JKJBIPL’s extensive fleet ensures consistency and quality throughout the transportation process.

Site Dumpers: These workhorses facilitate efficient material movement within your site. From aggregates and sand to gravel, site dumpers, also available at JKJBIPL, keep your project running smoothly by transporting and dumping construction materials with ease.

3. Evaluating the Mixer’s Power and Capacity:

Mixing Capacity: Calculate the volume of concrete your project demands to determine the required mixing capacity. Choosing a mixer that can handle your desired output without compromising quality is essential. JKJBIPL offers a variety of capacities to suit your specific needs.

Power Source: Ajax Fiori mixers come in electric, diesel, and petrol options. Assess your construction site’s power availability and choose accordingly. Electric mixers are ideal for areas with consistent electricity supply, while diesel or petrol options provide flexibility for remote locations.

Mixing and Discharge Speed: Time matters! Consider the time constraints of your project and opt for a mixer that aligns with your desired mixing and discharge speed. Faster speeds can significantly improve efficiency, especially for projects with tight deadlines.

4. Renting with Confidence:

Reliable Rental Companies: Research and compare reviews before choosing a rental company. JKJBIPL, with its track record of providing well-maintained equipment and excellent customer service, is a trusted option in Delhi.

Rental Terms and Conditions: Carefully read and understand the rental terms and conditions. Pay close attention to the rental period, any additional charges, and the responsibilities of both parties. Ensure complete clarity before signing the agreement.

Availability and Delivery: Check the availability of your desired mixer and explore delivery options offered by JKJBIPL. Factor in any associated delivery costs to avoid unwanted surprises during the rental process.

5. Prioritizing Mobility and Maneuverability:

Wheelbase and Steering Mechanism: A mixer that moves effortlessly around your worksite is key! Choose a mixer with a sturdy wheelbase and responsive steering mechanism to navigate tight corners and rough terrain with ease. JKJBIPL’s diverse fleet caters to varied site requirements.

Turning Radius and Towing Capacity: Ensure the mixer can manoeuvre within your designated space. Check the turning radius and towing capacity before finalizing your choice. Remember, a mixer that gets stuck can significantly stall your project.

Weight and Dimensions: Consider the weight and dimensions of the mixer in relation to your site access points and towing vehicle capacity. Choosing a mixer that fits through your gates and can be handled by your truck avoids logistical headaches.

6. Safety First: Features and Maintenance:

Safety Features: Prioritize operator and site worker safety. Look for mixers equipped with emergency stop buttons, safety guards, and clear operating instructions. JKJBIPL prioritizes safety and offers mixers with these essential features.

Maintenance Guidelines and Service Support: Understanding the maintenance guidelines for the mixer is crucial. Ask about any required servicing intervals and ensure access to spare parts if needed. Additionally, inquire about JKJBIPL’s service support options in case of any issues during the rental period. Having readily available assistance can save you time and prevent project delays.

Safety Certifications and Compliance: Always verify if the mixer you choose complies with industry safety standards and possesses appropriate certifications. Choosing a certified mixer from JKJBIPL provides peace of mind and ensures you’re operating reliable and safe equipment.

7. Comparing Rental Costs and Terms:

Request Quotes: Don’t settle for the first option! Request quotes from multiple rental companies, including JKJBIPL, to compare pricing and terms. Consider factors like the rental period, delivery fees, and any additional charges when evaluating the total cost.

Negotiate: Depending on the duration of your rental or the volume of equipment you require, there may be room for negotiation. Speak to JKJBIPL’s representatives to explore potential cost savings.

8. Additional Tips for Success:

Ask Questions: Don’t hesitate to ask the rental company, like JKJBIPL, any questions you may have about the mixers, rental terms, or project specifics. Their expertise can guide you towards the best solution.

Plan Ahead: Book your mixer well in advance, especially during peak construction seasons, to ensure availability and avoid last-minute scrambling.

Inspect the Mixer: Before leaving the rental yard, conduct a thorough inspection of the mixer. Make sure all features are functioning properly and report any concerns to the rental company immediately.

Embrace the Rental Revolution!

Renting an Ajax Fiori concrete mixer isn’t just about convenience — it’s about working smarter, freeing yourself from the burdens of ownership, and focusing on creating something exceptional. Let J K Jain BuildTech, renting solution provider of Ajax Fiori be your partner in progress, offering the perfect blend of power, efficiency, and peace of mind, one project at a time.

Remember, turning your dream into reality doesn’t have to be an arduous task. Choose to work smarter, not harder, with Ajax Fiori concrete mixer rentals from J K Jain BuildTech.

Contact J K Jain BuildTech India Pvt Ltd, a leading Ajax Fiori Concrete Mixer Rental Services dealer, and unlock the potential of effortless construction!

FAQ

Can I rent an Ajax Fiori concrete mixer for small-scale projects?

Yes, JKJBIPL offers a range of concrete mixers suitable for small-scale projects.

2. Are safety features a crucial consideration when choosing an Ajax Fiori concrete mixer?

Safety should be a top priority in any construction project. When selecting an Ajax Fiori concrete mixer, it’s essential to assess the safety features it offers. Look for features such as emergency stop buttons, safety guards, and operator-friendly controls.

3. What are the advantages of renting an Ajax Fiori concrete mixer?

Renting an Ajax Fiori concrete mixer offers several advantages. Firstly, renting allows you to access high-quality equipment without the significant upfront investment of purchasing a mixer. Secondly, rental companies often provide maintenance and service support, ensuring that the mixer is in optimal condition throughout your project.

**Don’t forget to visit @J K Jain Buildtech (https://www.jkjainbuildtech.com/)

#ajaxforhireonrent #hirefiorimixer #ajaxfiorimachineonhire #hireajaxmachineonrent #ajaxfiorimachinerent #ajaxmachineonrent #ajaxmachineforrent #ajaxfiorimachineonrent #ajaxfiorionhire #ajaxfiorionrent #fiorionrent #Ajaxfiori #selfloadingconcretemixeronrent #concretemixerrental #constructionequipementonrent

#ajaxforhireonrent#hirefiorimixer#ajaxfiorimachineonhire#hireajaxmachineonrent#ajaxfiorimachinerent#ajaxmachineonrent#ajaxmachineforrent#ajaxfiorimachineonrent#ajaxfiorionhire#ajaxfiorionrent#fiorionrent#Ajaxfiori#selfloadingconcretemixeronrent#concretemixerrental#constructionequipementonrent

0 notes

Text

Onsite Mixed Concrete Supplier

If you're looking for an onsite mixed concrete supplier, you'll want to find a reliable company that can provide the right mix of concrete for your specific project. Here are some steps you can take to find and choose a suitable onsite mixed concrete supplier:

Research Local Suppliers:

Look for local concrete suppliers in your area. You can use online search engines, business directories, or ask for recommendations from construction professionals, contractors, or colleagues. Check Reviews and Reputation: Read reviews and testimonials from previous customers. This can give you an idea of the supplier's reputation, customer service, and the quality of their concrete. Verify Credentials: Ensure that the supplier has the necessary licenses and certifications to operate in your area. This helps ensure that they adhere to industry standards and regulations. Find onsite mixed concrete supplier.

Visit the Supplier:

If possible, visit the supplier's facilities. This allows you to assess their equipment, the quality of their materials, and their overall operation. It's also an opportunity to meet with their team and discuss your specific needs.

Ask About Mix Design and Testing:

Inquire about the supplier's mix design capabilities and testing procedures. A reliable readymix concrete supplier should be able to provide concrete mixes tailored to your project specifications and should conduct regular quality control tests.

Delivery Logistics:

Discuss the logistics of concrete delivery, including scheduling, delivery times, and any additional charges for delays or changes to the order.

Cost and Pricing Structure:

Obtain quotes from multiple suppliers and compare their pricing structures. Be sure to ask about any additional fees or charges that may apply, such as delivery fees, overtime charges, or fees for small loads.

Customer Service:

Evaluate the level of customer service provided by the supplier. A responsive and communicative supplier can help address issues promptly and ensure a smooth delivery process.

Environmental Considerations:

Inquire about the supplier's environmental practices, such as recycling of concrete waste. Some suppliers may offer eco-friendly options or recycled aggregates.

Contract Terms and Conditions: Review the supplier's contract terms and conditions. Ensure that you understand all aspects of the agreement, including payment terms, cancellation policies, and any warranties or guarantees. By taking these steps, you can make an informed decision when selecting an onsite mixed concrete supplier for your construction project.

#onsite readymix concrete#onsite readymix concrete supplier#readymix concrete supplier#ready mix concrete

0 notes

Text

Cement Contractors Near Me

If you’re looking for a concrete contractor, get at least three in-person estimates. Pick contractors that have extensive experience, relevant concrete industry certifications and glowing client testimonials.

Residential concrete companies install and repair driveways, sidewalks, patios, porches and garage floors. They can also make decorative concrete. These companies can add tinted coloring, stamped patterns and unique designs to ordinary concrete.

Residential Concrete Companies

Residential concrete companies install new and repair old concrete in residential spaces. They can make concrete onsite using a bagged cement mix for smaller-scale projects, such as landings and walkways, or pour concrete from a truck for larger-scale jobs like foundations and slabs. They also have the expertise to choose the right concrete mix, to set up formwork and to follow proper curing methods.

Some concrete contractors offer decorative concrete services as well. They can stain concrete in earth tones or in vibrant colors, which can give your home a more unique look. These concrete contractors can also polish your existing concrete floors, install countertops in a kitchen or bathroom remodel and create backyard retaining walls and patios.

Find the best concrete company for your project by reviewing images of their work and asking questions. You should also verify that the company has the necessary insurance, licensing and certifications for your job. You can learn more about finding a qualified contractor on the BBB’s website.

Commercial Concrete Companies

Concrete contractors typically work on larger projects, including commercial and industrial buildings. They may also be involved in the construction and repair of concrete sidewalks, driveways, and road surfaces. A contractor may stay on a project through its entirety or subcontract a portion of the work to another party.

Many companies specialize in a specific type of concrete construction. For example, Suntec Concrete is one of the largest commercial concrete contractors, with a significant presence across the Southwest United States and offices in Arizona, Colorado, Utah, and Texas. They describe themselves as a “full-service concrete construction company” that offers services such as preconstruction, concrete placement, pumping, foundation work, and facilities service.

A concrete contractor can also help rehabilitate existing concrete structures. A damaged section of concrete may need to be repaired using a process called concrete leveling, which involves drilling small holes into the top layer of the concrete and then injecting concrete to raise or lower it as needed.

Decorative Concrete Companies

Concrete is a very durable and economical material for floors, walls, patios & driveways. It can be formed into a wide variety of patterns and textures for aesthetic appeal or functional use. The surface can be stamped, etched, carved, grooved, drilled, scored, sandblasted or colored.

Residential concrete fabrication requires a lot of knowledge and experience. Knowing the right proportions of Portland cement, sand or aggregate and water for the specific project helps achieve a quality mix that is strong enough to handle the loads, allows for proper curing and drying without cracking and looks great when finished.

Decorative Concrete in Nyc provides cost effective alternatives to materials like wood, slate, granite, tile and marble. It is also much more durable against freezing and thawing, sand and salt damage, and is easier to maintain than many other types of flooring. Innovative options provide the design flexibility needed to satisfy performance goals while achieving your creative vision.

Concrete Repair Companies

Concrete is very durable, but it can crack, crumble or sink over time. Whether it’s caused by weather or poor construction, these problems need to be repaired quickly to keep the structure safe and prevent further damage.

There are many ways to repair concrete, and the best method depends on the severity of the cracks. For shallow, cosmetic cracks, a contractor can use filler or a skim coat to restore the concrete’s surface. This is usually a quicker and less expensive option than replacing the entire section of concrete.

A good concrete contractor will carefully evaluate the problem and choose a repair material that is right for the situation. Bagged concrete mix manufacturers like QUIKRETE offer repair products that are labeled for specific situations and designed with safety regulations in mind. Some products also include fibers or admixtures to improve strength and durability. These materials can help prevent chloride attack on the existing concrete and help the repair last longer.

source https://concretenewcastle.wordpress.com/2023/07/21/cement-contractors-near-me/

0 notes

Text

Finding Reliable Concrete Suppliers in Sydney: A Comprehensive Guide

Concrete is the backbone of modern construction, used in everything from residential homes and commercial buildings to roads, bridges, and infrastructure projects. Whether you’re a homeowner planning a small renovation or a contractor managing a large-scale development, choosing the right concrete suppliers in Sydney is critical for ensuring quality, durability, and efficiency.

With a range of suppliers available, it can be overwhelming to find the best option for your project. This guide will walk you through the importance of selecting a reputable concrete supplier , the types of concrete available, key factors to consider, and how to ensure a smooth and cost-effective supply chain.

1. Why Choosing the Right Concrete Supplier Is Essential

1.1 Ensuring High-Quality Construction

The strength and longevity of any construction project depend heavily on the quality of concrete used. Poor-quality concrete can lead to cracks, weak structures, and expensive repairs in the future. Trusted suppliers ensure that their products meet Australian Standards, providing high-strength, durable, and well-mixed concrete suitable for different applications.

1.2 Preventing Delays and Cost Overruns

Timely delivery of concrete is crucial in construction. Concrete must be mixed, transported, and poured within a specific timeframe to maintain its integrity. Delays in supply can disrupt schedules and lead to financial losses. Working with experienced suppliers helps prevent such issues by ensuring prompt and reliable deliveries.

1.3 Cost-Effective and Sustainable Solutions

Concrete is a major investment in any construction project, and choosing the right supplier can significantly impact overall costs. Reliable concrete suppliers in Sydney offer competitive pricing, efficient mixing solutions, and minimal material wastage, helping you get the best value for your money. Many suppliers also provide sustainable concrete options that reduce environmental impact without compromising quality.

2. Types of Concrete Available in Sydney

Concrete comes in various types, each suited for specific construction needs. Some of the most commonly used options include:

2.1 Ready-Mix Concrete

Ready-mix concrete is pre-mixed at a batching plant and delivered in a truck, ensuring uniform consistency and reducing onsite labour. It’s ideal for large-scale projects such as commercial buildings, roads, and high-rise apartments.

2.2 Exposed Aggregate Concrete