#Open Stenter Machine

Explore tagged Tumblr posts

Text

Types of Textile Machinery Used in Textile Industries

The textile industry, a cornerstone of contemporary production, is predicated heavily on advanced equipment to produce fabrics and different textile products. As the era evolves, so does the range and class of textile equipment. Understanding these machines is crucial for all and sundry worries inside the industry. In this weblog, we will discover the varieties of fabric machinery utilised in fabric industries, that specialise in their roles and features, and how they contribute to the production method.

Introduction to Textile Machinery

Textile machinery encompasses a wide range of devices used to method raw fibres into completed merchandise. These machines perform numerous functions, from spinning and weaving to dyeing and finishing. Each system performs a vital role in ensuring the high-quality and performance of textile production.

Spinning Machines

1. Spinning Frames:

Spinning frames draw yarn out of uncooked fibres by twisting them, the fibres being cotton or wool. There are several grades in this technique: carding, drawing and roving. Spinning frames come in various forms; namely the ring spinning and rotor spinning, each having its advantages.

2. Open-End Spinning Machines:

These machines are recognised for his or her potential to course of yarn’s production at high pace and in giant portions successfully. These vary from the conventional spinning frames in a way that eliminate the use of roving; thus, making the process more efficient.

Weaving Machines

1. Power Looms:

Power loom is a mechanical weaving machine used for shedding and beats the warp and weft yarns to form material. They have in large part substituted handlooms mainly on the basis of velocity as they supply constant first-rate materials.

2. Rapier Looms:

Rapier looms are modern weaving units that are acknowledged for their flexibility. They are versatile for an extensive variety of yarn sorts and material patterns that make them suitable for complicated fabrics.

3. Air-Jet Looms:

These looms use air to propel the weft yarn through the warp shed, allowing for quicker and more green weaving. Air-jet looms are particularly appropriate for lightweight fabrics and excessive-velocity production.

Knitting Machines

1. Circular Knitting Machines:

Circular knitting machines create tubular fabric with the aid of knitting yarn in a non-stop round movement. They are commonly used for generating seamless garments, socks, and other hosiery products.

2. Flat Knitting Machines:

These machines knit fabrics in a flat form and are used for growing items like sweaters, scarves, and different flat-knit clothes. Flat knitting machines provide more flexibility in design and sample variations.

Dyeing and Printing Machines

1. Jet Dyeing Machines:

Jet dyeing machines are used to dye fabric in a closed system, wherein the dye liquor is circulated at excessive pressure. This method ensures uniform dyeing and is appropriate for diverse material types.

2. Rotary Screen Printing Machines:

Rotary display printing machines follow styles to material by forcing dye via a cylindrical display screen. They are recognised for his or her performance and ability to provide elaborate designs on a large scale.

Finishing Machines

1. Stenter Machines:

Stenter machines stretch and dry fabrics, ensuring they meet the desired dimensions and satisfactory requirements. This system improves the fabric’s texture, appearance, and stability.

2. Calendering Machines:

Calendering machines consist of heated rollers that press and easy fabric, enhancing their end and lustre. They are often used for fabric like cotton, polyester, and blends.

Embroidery Machines

Computerized Embroidery Machines:

These machines are used to create intricate embroidery designs on fabrics. With the aid of computer software, they can produce detailed and consistent patterns, making them essential for high-quality embroidery work.

Textile Testing and Quality Control Machines

1. Tensile Testing Machines:

Tensile testing machines measure the strength and elasticity of fabrics, ensuring they meet industry standards. They play a crucial role in quality control and product development.

2. Color Fastness Testing Machines:

These machines assess the colour fastness of dyed fabrics by subjecting them to various conditions, such as washing, light exposure, and rubbing. This ensures the durability and longevity of the fabric’s colour.

Generally, textile industry uses a broad category of equipment in the conversion process from textile material to the final product. All machines ranging from spinning and weaving to dyeing and finishing are very important in the process. It is worthwhile to study the functions as well as the capacities of these machines for anyone that is involved in the textile business.

It has been a well-known fact at Weavetech organisation that accurate textile machinery guarantees good fabric production. The awareness of the most recent innovations and the wide spectrum of machinery guarantees that clients get the most appropriate items and services.

It is critical for any textile factory to ensure that they acquire the right textile factory machine that will make their production to be more efficient and of high quality as well as be versatile in use. Whether you operate within spinning, weaving, knitting, and finishing categories, it is very important that you are able to get the right equipment so as to also be able to compete in the complex textile market.

Read More:- Types of Textile Machinery Used in Textile Industries

0 notes

Link

Stenter Machine Stentex Manufacturer, Exporter, Supplier, heavy duty Stenter Clip, Stenter Pin bar, Stenter Pin Block, Cloth Guider, Stenter Machine Parts. Textile Machinery spare parts for desired Stenter Machines with high quality materials. Stenter Machine Monfort, Stenter Machine Clips, Textile Machines Parts, Monforts Stenter Machine, Hot Air Stenter Machine, Open Stenter Machine, Textile Stenter Machine, Stenter Machine, Pin bar Manufacturer, Stenter Machine Spare Parts, Cloth guider, Stenter Clip Manufacturer.

#Stenter Machine Stentex#Stenter Pin Bar#stenter clip#Stenter Machine#Pin bar Stenter Machine Spare Parts#Cloth guider#Textile Machines Parts#Monforts Stenter Machine#Hot Air Stenter Machine#Open Stenter Machine#Textile Stenter Machine#Stenter Pin Block

0 notes

Text

Caring for fabric and clothes

Clothes-800.jpg If you love fabric and clothes as much as I do you'll want to look after them. However excessive washing is often unnecessary and can mean your clothes wear out sooner. Here are some alternative suggestions to washing your clothes. Airing - by simply hanging out clothes in the fresh air or by an open window. This works especially well for woollen fabrics and clothing, the natural oil in wool repels the moisture that can carry bad smells. Essential Oils - when clothing looses that just washed smell try adding a few drops of Lavender, lemon or sage essential oil to a water spray and spritz your garment before airing. Baking or Bicarbonate of Soda - this is brilliant for musty smells especially if you buy vintage clothing or fabric and even works on suede and leather. Place the item in a carrier bag with a cup of soda and shake, leave over night, then shake out your item and brush off any soda. Coffee grains - I haven't tried this but I understand it can work in the same way as baking soda. Vodka - mix two-thirds vodka to one-third water spray on and then leave to dry. The vodka kills bacteria, removing the smell and dries odourless. Freeze your clothes - take a tip from denim aficionados, place your jeans in a canvas bag and leave in the freezer overnight. This kills the bacteria. This also works for cashmere and other wools and is excellent for moth prevention. Place your sweaters in a plastic bag and freeze for 48 hours; this kills the moth larvae. When you do wash your clothes try lowering the temperature and use a non-biological detergent. When I buy fabric, if it is washable, I always wash before making it up. If you are not sure a fabric is washable, cut a 20cm square and place it in your next 30-degree wash. Then when it’s washed and dried re-measure to check shrinkage and also to review the handle of the fabric. If you don���t like the result, make sure you only dry-clean the garment you are going to make. Before washing lengths of fabric, unfold them and iron out any creases. Loosely load into your machine and use a liquid detergent. These steps should avoid any unevenness in the colour fading especially with indigo and pigment dyed denim or coloured linens. The reason for pre-washing fabric is that during the manufacturing process, fabrics are often ‘stentered’. This is when they are pulled into a uniform width and length and a finishing chemical applied. The problem with this is, that when the fabric is subsequently washed, it ‘relaxes’ back or shrinks. So by washing it before making, you can make sure what you make doesn’t shrink. Untitled-1.jpg http://dlvr.it/R9bfwR

3 notes

·

View notes

Text

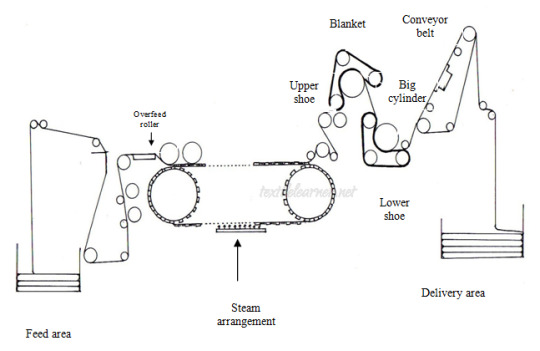

Open Width Compactor: Parts, Functions, Working Principle and Specifications

Open Width Compactor: Parts, Functions, Working Principle and Specifications #compactor #compacting #compactormachine #opencompactor #openwidthcompactor #compactingmachine

Open Width Compacting Machine: Open width compactor machine is used for compacting the open form fabric. Here, slitting machine is used for open the fabric from the tubular form. Open width compacting machine is a combination machine of pin plate stenter and felt compactor, it is used for the processing of 100% cotton, wool, hemp natural fabrics and chemical fabrics in open width form. It is also…

View On WordPress

0 notes

Text

Professional and Improving technology is the base of quality to ensure the machine good enough for your production and process

Professional and Improving technology is the base of quality to ensure the machine good enough for your production and process

New technology and new design to improve present machines, as our engineer’s self-motivated, always over customer’s expection. Now bigger and higher efficient Tubular Compactor produced, more fast with more processing capacity. Open fabric heat setting machine is more suitable for small factory, saving investment comparing with stenter machine. Also, Balloon Padder with new structure will give…

View On WordPress

0 notes

Text

Double Decker #Stenter for Open Width Fabric

Double Decker #Stenter for Open Width Fabric

#Stenter Machine/Function of Stenter Machine/Working process of Stenter Machine/ Technical specification of our stenter Stenter is a Textile Machine for Open-width Heat setting process in textile dyieng factories. The function of the stenter is as below: Heat setting for lycra fabric, polyester fabric and blended fabricsFabric width controlled by stenterFinishing chemical applied on fabric by…

View On WordPress

0 notes

Text

Open Type Rotary Screen Printing Machine Control System Requirements

The Open Type Rotary Screen Printing Machine is a method of printing using a seamless cylindrical screen. It began in the 1960s and developed rapidly, becoming a new printing method for fabrics. The rotary screen printing machine is characterized by the continuous rotation of the rotary screen for printing, which not only maintains the style of screen printing, but also improves the printing production efficiency.

In the control system of the rotary screen printing machine, the two main problems are solved. The first one is the synchronization between the feeding frame, the printing guide belt, the drying room conveyor belt and the falling frame, and the synchronization between them ensures the fabric. When passing through the four units continuously, they are neither stretched or even broken, nor wound. This kind of synchronization is given by the main motor as the other three way. The tension frame is used to realize the automatic adjustment of the closed loop speed, so as to achieve the synchronization between the four, usually by the simulation of "synchronous controller" or PLC. The output module is used to implement this synchronization.

The second synchronization is the synchronization between the rotation of the rotary screen printing machine (that from the professional Hot Air Stenter manufacturer - Licheng) and the movement of the conduction belt, which is one of the most critical technologies in the printing machine. The synchronization accuracy of the two determines the printing precision of the whole printing machine, how to improve the circle The synchronization between the net and the conduction band and the synchronization accuracy between the nets have become one of the most important problems in the system design. Compared with the independent transmission of the rotary screen, the traditional mechanical coaxial transmission has obvious gaps. The main differences are as follows:

1. There are many transmission links, and the accumulated error is large, which affects the printing precision.

2. With the mechanical wear, it is easy to appear "running flowers", affecting the stability of the printing quality.

3. Variety adaptability is limited and it is not suitable for processing heavy structures.

4. The longitudinal versus flower range is limited.

0 notes

Text

DVCon 2019 at United States(San Jose) 2019-February

flat knitting business, collar knitting Trade Shows, dyeing Exhibitors, finishing Exhibitions, washing Trade Shows, rashing Exhibitors, brushing sueding business opportunities, polishing info, yarns business, yarn splicers business opportunities, boilers B2B Opportunities, steam presses Exhibitors, tumbler dryers business opportunities, dry-cleaning contact links, processing Exhibitors, compressors contact list, industrial sewing Business events, multi head computerizedembroidery Business events, linking Events, multicolor transfer/screen printing Events, antipilling info, fusing Exhibitors, lace and crochet knitting machines info, designing units Exhibitors, cad/cams Exhibitors, softwear Expos, electric motors companies, testing equipement contacts list, electronics scales B2C opportunities, threads Shows, buttons info, labels contact list, fabrics contact info, tapes companies, ribbons companies list, dyes business opportunities, chemicals B2B Opportunities, linings B2C opportunities, interlinings B2B ideas, gensets contact info, inverters contact info, pannels events, trade magazines companies contacts, fashion journals Trade Shows, etc. Exhibitors, textiles: rashchel Shows, shulzer contact links, wrap knitting machine Expos, loom network, winder companies contacts, double needle bar B2B ideas, processing machine Exhibitors, stenter machine Trade Shows, spinging machine companies, technical textile machine network, quality control Exhibitors, pollution controll Trade Shows, textile wrap beams events, ball wrapping B2C opportunities, fiber-making contacts list, non-woven fabrics contacts list, textiles testing contact info, high-speed carding top making machine Events, artificial fur card Shows, high-yyielding card. Meetings, manufacturer Events, suppliers companies, traders Exhibitors, distributors contacts list, retailers contact list, importers B2B Opportunities, exporters contact info, key decision makers B2C ideas 2019, February, United States, San Jose

DVCon 2019 at United States(San Jose) 2019-February

DVCon 2019 trade show event mainly focuses on:

flat knitting events, collar knitting Exhibitions, dyeing Exhibitions, finishing companies, washing business opportunities, rashing contact list, brushing sueding contact info, polishing Shows, yarns Meetings, yarn splicers contact list, boilers companies, steam presses Exhibitors, tumbler dryers Trade Shows, dry-cleaning info, processing companies contacts, compressors companies contacts, industrial sewing Exhibitors Directory, multi head computerizedembroidery contact links, linking contact list, multicolor transfer/screen printing contact info, antipilling Shows, fusing Trade Shows, lace and crochet knitting machines contact info, designing units business opportunities, cad/cams business opportunities, softwear B2C ideas, electric motors network, testing equipement Exhibitors, electronics scales B2B Opportunities, threads info, buttons Meetings, labels Events, fabrics network, tapes companies contacts, ribbons Shows, dyes Events, chemicals contact info, linings network, interlinings contact list, gensets Exhibitors Directory, inverters companies list, pannels business ideas, trade magazines B2B Opportunities, fashion journals business ideas, etc. events, textiles: rashchel Events, shulzer events, wrap knitting machine events, loom network, winder events, double needle bar directory, processing machine Exhibitions, stenter machine contact list, spinging machine business, technical textile machine Shows, quality control companies contacts, pollution controll Meetings, textile wrap beams Fairs, ball wrapping B2C opportunities, fiber-making B2B ideas, non-woven fabrics contacts list, textiles testing Exhibitions, high-speed carding top making machine business, artificial fur card Events, high-yyielding card. Fairs, manufacturer directory, suppliers business opportunities, traders B2C opportunities, distributors business contacts, retailers business ideas, importers contact links, exporters directory, key decision makers Shows

related products/services/industry/business. This trade show opens top business opportunities to exhibit products and services from flat knitting contact info, collar knitting B2C ideas, dyeing companies contacts, finishing Trade Shows, washing B2B ideas, rashing Trade Fairs, brushing sueding events, polishing contact info, yarns B2B ideas, yarn splicers Events, boilers Exhibitions, steam presses B2C ideas, tumbler dryers companies list, dry-cleaning B2B Opportunities, processing business opportunities, compressors B2B Opportunities, industrial sewing B2C opportunities, multi head computerizedembroidery business ideas, linking business contacts, multicolor transfer/screen printing Meetings, antipilling Exhibitions, fusing Exhibitors, lace and crochet knitting machines companies contacts, designing units B2C ideas, cad/cams Exhibitors, softwear events, electric motors contact list, testing equipement contact links, electronics scales contact links, threads companies, buttons contact info, labels Fairs, fabrics Exhibitors Directory, tapes business contacts, ribbons B2B ideas, dyes contact links, chemicals directory, linings contact info, interlinings B2B Opportunities, gensets companies contacts, inverters info, pannels info, trade magazines companies contacts, fashion journals B2B ideas, etc. contact links, textiles: rashchel Events, shulzer directory, wrap knitting machine Meetings, loom Trade Shows, winder network, double needle bar directory, processing machine Expos, stenter machine B2C ideas, spinging machine B2C opportunities, technical textile machine business ideas, quality control Exhibitions, pollution controll companies contacts, textile wrap beams Exhibitors Directory, ball wrapping B2C opportunities, fiber-making Exhibitors Directory, non-woven fabrics companies contacts, textiles testing network, high-speed carding top making machine companies, artificial fur card Expos, high-yyielding card. business ideas, manufacturer business opportunities, suppliers business contacts, traders contacts list, distributors business ideas, retailers network, importers business opportunities, exporters business opportunities, key decision makers Business events industry.

Find More Details about DVCon 2019 event...

We help you to grow your business by providing the required contact details of all companies participating in this event and you can download the same data in excel format using the above links. Location of the Event:United States(San Jose) Year-Month:2019-February Official Website:Event Website source https://www.expomahal.com/2019/03/dvcon-2019-at-united-statessan-jose.html

0 notes

Link

If we compare the present business situation of knit sector with one decade earlier, FOB price significantly reduced, on the other hand, direct labor cost increased 4.8 times more, utility cost and crisis increased, the huge investment required to ensure occupational health & safety, have to face huge competition i.e. business environment become volatile, uncertain, complex and ambiguous day by day. Factories are falling in profitability crisis for different reasons, here I want to narrate a few management failure cases which impact greatly on profitability. Sometimes, factories fall in the sinking point from where turning back to the race become more and tougher. If leaders / CEO‘s decision was not appropriate, the amount of loses becomes huge. Surely it will impact profitability, in the long run, organizations have to pass a tough time to survive in the competition. I want to share a few case studies which will be an eye opener for others. Expansion: Many factories did not study the feasibility and consider Return on Investment before invest further to increase production capacity. One of a renowned factory KFMA (not really name), invest in a fabric manufacturing plant to make the capacity double by sanctioning loan from the bank. CEO does not take any advice from any technical expertise. He does not believe and rely on technical persons/subordinates. He loves to take a vital decision by himself. His dream was, by selling fabric to other RMG units, he will be able to pay the installments of bank loan. After completing the multistoried building and installed all the machinery, he found two drawbacks, All the machinery cannot run with existing approved gas connection. The government does not approve any connection for the industry at that moment. Gas consumption of boiler crossed the approved limit when all the dyeing machine runs. There is a chance of disconnection from Titas if repeatedly exceed the approved limit for consecutive months. So, the CEO decided to run 50% dyeing machines. Captive electricity is not sufficient to run finishing range as well as, 50% finishing line remains Stenter runs by CNG gas even though it was not economical. Managing the payment of monthly bank installment became tougher than ever. Dream broken just after installing all the machines. So the consequence of the above bad investment, disbursement of wages and salary of the workforce can’t maintain on time, due by several months. Huge credit on the supplier’s receivable, facing liquidity problems. Can’t open L/C for yarn, dyes, chemical etc. and on time shipment became a dream. The organization is passing a tough time. Many factories have also fallen in trouble with this type of immature investment. So, before any investment, we have to calculate the ROI. Project implementation: I know few factories, project implementation time takes more than 3-4 estimated times. By this way, the project cost has become much higher. Most of the cases entrepreneur himself follow up the project implementation activities. And implemented events not in the sequence, a few examples are like machinery arrives in factory before completion of new building, factory is ready for production but can’t obtain environmental clearance, factory is ready but gas connection was not obtained, lift or chiller arrived in the factory before the completion of the building etc. by this type of disorganization, the cost of manufacturing become high which leads to low profit. In case of new project implementation, Project evaluation and review technique (PERT) should follow by assigned technical persons. Who can help to implement the project on time, reduce the cost of the project & ROI will be less. Product Diversification: FOB price of all brands going down day by day. For our clear understanding, declined trend of FOB of legging orders of one of the top retailer in the county, 10 % price reduce within 4 years, in some case figures are higher. Minimum Wages of direct labor increase 51 % from 2013. Thousands of factories can produce basic products. All the buyers have alternative suppliers, due to unhealthy competition, the price of basic products are going down drastically. On the other hand, wages already increased 51%, which will be a big threat for textile industries. The organization should invest to increase the capability of doing value-added products. We should consider our workforce as a resource. We can covert our workforce into a strength by giving proper training. Most of the industries are focusing to train their people. By this way, we will be able to produce value-added higher price product which leads to higher profit. Own style Management: many entrepreneurs does not have enough knowledge on modern management. Successors are in the board immediately after completing the education. Entrepreneurs are thinking, their present successes indicate their previous strategy was right, they are more knowledgeable than professional employees. A renown textile industry KFMB, introduce the below strategy to increase accountability to their management staffs and workers. Everybody should submit their targets or to do lists to the concerned team in the morning. Before leaving the workstation in the evening, everybody again submits the job completion list to the concerned team. Salary & wages will be equivalent % of achieved average productivity. Every employee spends a noticeable amount of time and papers to comply above rules. 100% Verification of the performance cannot possible. Staff’s become demotivated after getting a repeated thread of salary deduction. Skill & talented staff’s leave the organization. After a few months, scrap the above strategy and try to adopt another new formula. Due to this type of experiment of management concept, productivity and profitability become low day by day. Many industries also practice their own management style, sometimes it gives positive results & sometimes gives negative results. We should follow the proven management philosophy like Lean/TQM/Six Sigma. Successors of entrepreneurs i.e. son/daughter should not be a board member after graduation. They should serve in the organization as a management trainee for a certain period so that he will become a mature leader. Unstable Management team: human beings are unique in all aspect, every top executive also have a unique concept and management techniques, many entrepreneurs want quick results even within 3-4 months from top executives. If results are not as per their desire, they change the executives. Found no consistent in any good practice causes a very frequent change in top position. Sometimes vital positions also changed when top executives leave the organization. Organizational reputation also fades. Recruitment of reputed performer become tougher than before. Failure of individuals, not for his capability, most of the causes due to systems/environments. All the transport drivers of Bangladesh will run the vehicle by maintaining 100% traffic rules in the cantonment area. Though same drivers are careless in other areas. So system and accountability is more important to ensure appropriate productivity as well as profitability.

0 notes

Link

Stenter Machine Monfort Clips, Stenter Machine Clips Manufacturer, and all types of stenter Machine spare parts manufacturer, exporter, and, supplier. Stenter Machine Monfort Manufacturer, We are a leading manufacturer, exporter, and supplier of Monfort with international standards. All types of Stenter Machine Spare parts and Textile Machinery Spare Parts Manufacturer. Stenter Machine Monfort, Stenter Machine Clips, Textile Machines Parts, Monforts Stenter Machine, Hot Air Stenter Machine, Open Stenter Machine, Textile Stenter Machine, Stenter Machine, Pin bar Manufacturer, Stenter Machine Spare Parts, Stenter Clip Manufacturer

#Stenter Machine Monfort#Stenter Machine Clips#Textile Machines Parts#Monforts Stenter Machine#Hot Air Stenter Machine#Open Stenter Machine#Textile Stenter Machine#Stenter Machine#Pin bar Manufacturer#Stenter Machine Spare Parts#Stenter Clip Manufacturer

0 notes

Text

Stenter for Fabric

#Stenter Machine/Function of Stenter Machine/Working process of Stenter Machine/ Technical specification of our stenter

Stenter Machine for Fabric Heat Setting Process

Stenter is a Textile Machine for Open-width Heat setting process in textile dyieng factories. The function of the stenter is as below:

Heat setting for lycra fabric, polyester fabric and blended fabrics

Fabric width controlled…

View On WordPress

0 notes

Text

Stenter for Open-Width Fabric Heat Settting Process

Stenter for Open-Width Fabric Heat Settting Process

#Stenter Machine/Function of Stenter Machine/Working process of Stenter Machine/ Technical specification of our stenter

Stenter is a Textile Machine for Open-width Heat setting process in textile dyieng factories. The function of the stenter is as below:

Heat setting for lycra fabric, polyester fabric and blended fabrics

Fabric width controlled by stenter

Finishing chemical applied on fabric…

View On WordPress

0 notes

Video

youtube

DEGUAN 8 Chambers Relax Dryer Machine

0 notes

Video

youtube

Deguan Auto Slitting Machine

0 notes

Video

youtube

DEGUAN Open Width Compacting Machine

0 notes

Video

youtube

DEGUAN Auto Slitting Machine

0 notes