#PTFE Gasket

Text

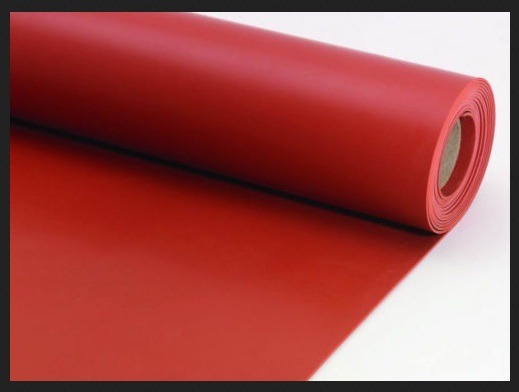

Sealing Solutions Redefined- Exploring Gaskets, Materials, and the Innovation of Silicone Sheets

In the intricate machinery of various industries, the humble gasket stands as a guardian, ensuring tight seals and preventing leaks that could disrupt operations. At the heart of these sealing solutions lie carefully selected materials, each chosen for its unique properties and suitability for specific applications. Among these materials, silicone sheets have emerged as a versatile option,…

View On WordPress

2 notes

·

View notes

Text

PTFE

PTFE products, processed parts, special-shaped parts

Please contact me for a quote if required.

Henan Sixfluorine Chemical Co.,Ltd

WhatsApp/Telegram:+(86)15038852660

Mail:[email protected]

1 note

·

View note

Text

Exploring The Excellence of PTFE Sheets- The Ultimate in Versatile and Durable Sealing Solutions

In the dynamic landscape of industrial applications, the demand for materials that offer superior performance, reliability, and versatility is ever-present. Polytetrafluoroethylene (PTFE) sheets stand out as a remarkable innovation, offering a unique combination of properties that make them indispensable in various sectors. This article delves into the world of PTFE sheets, exploring their…

View On WordPress

1 note

·

View note

Text

Factors to consider when choosing a PTFE Sheet gasket

Introduction

PTFE (Polytetrafluoroethylene) sheet gaskets are widely used in various industries due to their excellent chemical resistance and high-temperature capabilities. However, not all PTFE sheet gaskets are created equal, and choosing the right one for your specific application is crucial. In this article, we will discuss the important factors you should consider when selecting a PTFE sheet gasket to ensure optimal performance and reliability.

1. Material Quality

The quality of the PTFE material used in the sheet gasket is of utmost importance. It is essential to choose a gasket made from high-quality virgin PTFE or an engineered grade of PTFE that meets industry standards. High-quality PTFE ensures better resistance to chemicals, improved sealing properties, and longer service life.

2. Temperature and Chemical Resistance

Consider the temperature and chemical environment in which the gasket will be used. PTFE sheet gaskets are known for their excellent temperature resistance, but different grades of PTFE have varying capabilities. Ensure that the gasket you choose can withstand the specific temperature range and chemical exposure in your application to avoid premature failure or leakage.

3. Dimensions and Thickness

Accurate dimensions and proper thickness are vital for effective sealing. Measure the flange dimensions carefully and select a PTFE sheet gasket that matches those dimensions precisely. Additionally, consider the required thickness based on the flange gap to achieve the desired compression and sealing performance.

4. Surface Finish

The surface finish of the flanges in contact with the gasket is essential for a proper seal. Ensure that the flanges are smooth and free from any irregularities or damage. A rough or damaged flange surface can lead to leaks even with a high-quality PTFE sheet gasket. If necessary, perform surface preparations such as machining or sandblasting to achieve the required surface finish.

5. Pressure Rating

Consider the operating pressure of your application and choose a PTFE sheet gasket with a suitable pressure rating. The gasket should be able to withstand the maximum pressure without compromising its sealing performance. Higher pressure ratings are often achieved by using thicker PTFE sheet gaskets or incorporating reinforcing fillers.

6. Compressibility and Recovery

The compressibility and recovery properties of the PTFE sheet gasket play a crucial role in achieving a reliable seal. The gasket should be able to deform and conform to the flange surfaces under compression to fill any imperfections and ensure uniform contact. After compression, the gasket should have good recovery properties to maintain the sealing force even after thermal cycles or system vibrations.

7. Cost-effectiveness

While it's important to select a high-quality PTFE sheet gasket, it's also necessary to consider the overall cost-effectiveness. Evaluate the balance between the gasket's performance and its price to ensure you're getting the best value for your investment. Cheaper gaskets may compromise on material quality or long-term reliability, leading to frequent replacements and increased downtime costs.

8. Compliance with Industry Standards

Ensure that the PTFE sheet gasket you choose complies with relevant industry standards and regulations. Certifications such as FDA (Food and Drug Administration) approval or compliance with standards like ASTM (American Society for Testing and Materials) provide assurance of the gasket's quality and suitability for specific applications, such as food processing or pharmaceutical industries.

9. Manufacturer's Reputation and Support

Consider the reputation and expertise of the manufacturer when selecting a PTFE sheet gasket. Established manufacturers with a good track record are more likely to provide high-quality products and reliable customer support. Look for manufacturers who offer technical assistance, customization options, and responsive after-sales service.

Understanding the Different Types of PTFE Sheet Gaskets

PTFE sheet gaskets are available in various types, each designed to suit specific application requirements:

· Virgin PTFE Sheet Gaskets

Virgin PTFE sheet gaskets are made from pure PTFE material without any fillers. They offer excellent chemical resistance, low friction, and wide temperature capabilities. These gaskets are commonly used in applications where purity and resistance to aggressive chemicals are critical.

· Expanded PTFE Sheet Gaskets

Expanded PTFE (ePTFE) sheet gaskets are manufactured by expanding virgin PTFE. This process creates a unique microstructure with excellent sealing properties, even at low loads and moderate bolt stresses. ePTFE gaskets exhibit superior conformability, making them ideal for uneven or damaged flange surfaces.

· Filled PTFE Sheet Gaskets

Filled PTFE sheet gaskets are reinforced with fillers to enhance specific properties. Fillers such as glass fibers, carbon, graphite, or other materials can improve the gasket's strength, dimensional stability, or thermal conductivity. Filled PTFE gaskets are suitable for applications requiring higher pressure ratings or improved creep resistance.

Common Applications of PTFE Sheet Gaskets

PTFE sheet gaskets find applications in various industries, including:

· Chemical processing

· Petrochemical

· Pharmaceutical

· Food and beverage

· Power generation

· Oil and gas

· Automotive

· Electronics

These gaskets are used in flanged connections, pipelines, pumps, valves, heat exchangers, and other equipment where reliable sealing is critical.

Installation and Maintenance Tips for PTFE Sheet Gaskets

To ensure optimal performance and longevity of PTFE sheet gaskets, follow these installation and maintenance guidelines:

· Clean and inspect flange surfaces before installation to remove any debris or contaminants.

· Use compatible lubricants or anti-seize compounds on bolt threads and nuts to prevent galling and ensure proper tightening.

· Apply uniform bolt torque according to the manufacturer's recommendations.

· Regularly inspect the gasket for signs of wear, degradation, or leakage.

· Replace the gasket if it shows signs of damage or fails to provide an effective seal.

· Following these guidelines will help maximize the lifespan and reliability of your PTFE sheet gasket.

Conclusion

Choosing the right PTFE sheet gasket is crucial for achieving a reliable and long-lasting seal in various industrial applications. Consider factors such as material quality, temperature and chemical resistance, dimensions, surface finish, pressure rating, compressibility, cost-effectiveness, compliance with industry standards, and the manufacturer's reputation. By making an informed decision, you can ensure optimal performance, reduced downtime, and increased safety in your operations. To buy PTFE gasket sheets, visit our website at https://www.sealmax.in/. For any queries, you can call us at +91 8983059377 / +91 8983059366 or mail us at [email protected], or [email protected].

Resource: https://what-are-the-uses-of-ptfe-gasket.blogspot.com/2023/06/factors-to-consider-when-choosing-ptfe.html

0 notes

Video

undefined

tumblr

In today's industrial landscape, sealing solutions are vital for ensuring efficient and reliable operations across industries. One such solution that has gained immense popularity is the PTFE gasket. PTFE, or polytetrafluoroethylene, is a remarkable material known for its exceptional properties, making it an ideal choice for sealing applications.

0 notes

Text

The PTFE Ring Gasket Revolution

The PTFE ring gasket is a beacon of innovation and efficiency in the intricate world of industrial sealing solutions, where precision and reliability are paramount. Crafted from Polytetrafluoroethylene (PTFE), this specialized gasket offers a unique combination of properties that make it indispensable across many industries. In this blog post, we delve into the intricacies of PTFE ring gaskets, exploring their features, benefits, and transformative impact on industrial applications.

Understanding PTFE Ring Gaskets

PTFE ring gaskets are precision-engineered seals that provide tight and reliable sealing in various applications. These gaskets are composed of high-quality PTFE material and boast exceptional chemical resistance, temperature tolerance, and low friction properties. Their ring-shaped design allows for easy installation and ensures uniform compression, resulting in a secure seal that effectively prevents leaks and contamination.

Features and Benefits

Chemical Resistance: PTFE ring gaskets exhibit unparalleled resistance to various chemicals, acids, and solvents, making them ideal for sealing applications in corrosive environments.

Temperature Tolerance: Withstanding extreme temperatures ranging from cryogenic to high heat, PTFE ring gaskets maintain their integrity and sealing performance across various operating conditions.

Low Friction: PTFE's inherently low friction coefficient reduces the risk of gasket extrusion and ensures smooth operation even under high-pressure conditions, contributing to extended gasket lifespan and reduced maintenance requirements.

Versatility: PTFE ring gaskets are used in diverse industries, such as chemical processing, pharmaceuticals, food and beverage, oil and gas, automotive, and more. Their versatility makes them adaptable to a wide range of sealing challenges.

Conformability: PTFE ring gaskets conform well to irregularities in sealing surfaces, ensuring a tight and reliable seal even on uneven or rough mating surfaces.

Conclusion

In conclusion, PTFE ring gaskets represent a paradigm shift in industrial sealing solutions, offering unmatched performance, reliability, and versatility. With their exceptional chemical resistance, temperature tolerance, low friction properties, and conformability, PTFE ring gaskets ensure tight and reliable seals in the most demanding environments. As industries continue to evolve, PTFE ring gaskets stand poised to meet the challenges of tomorrow, driving efficiency, safety, and innovation.

For businesses seeking reliable sealing solutions backed by precision engineering and proven performance, PTFE ring gaskets emerge as the epitome of sealing excellence, ensuring optimal performance and peace of mind.

0 notes

Photo

Spiral Wound Gaskets in United States

Flexitallic Spiral Wound Gaskets are a precision-engineered solution for flanged joints. Proven to be the most reliable sealing element.

0 notes

Text

Manufacturer, Supplier, Exporter of PTFE Products like PTFE Sheets, Teflon Sheets, PTFE Gasket Sheets, PTFE Moulded Sheets

1 note

·

View note

Text

Modified/Reinforced PTFE Gasket

Shaoxing Sealgood gasket and sealing Co., Ltd. is a professional production enterprise in industrial sealing products R & D, manufacturing, sales, and engineering services, The company production and export all kinds of fluid sealing products and material, there are all kinds of sealing gaskets and packing, etc. Products are widely used in petrochemical. oil refining, electric power, iron and steel, shipbuilding and other industries, not only solve the domestic many power plants, chemical plants, pump, valve, pipeline leakage problems in various gas and chemical fluid conveying, many well-known enterprises designated and used, and has been exported to Europe and America, the Middle East, and Southeast pressure and many other countries and regions.

The company has advanced production and testing equipment, experienced staff, sufficient raw materials and product inventory for the customer provide products get a guarantee, the company holds the SGS asbestos-free license and ISO9001 certification is China’s packing and static sealing industry member enterprise. All products according to the domestic and international industry standards, such as GB, ASTM, DIN, JIS, ASME-ANSI, BS, CNS specification, and for sealing products customized special specifications.

Companies with “integrity, professional. pragmatic” as the guiding ideology, wholeheartedly provides high-quality sealing products and excellent service for the customers at home and abroad. At the same time also operates with the sealing industry well-known brands, such as the United States GORE,KINDER Australia, Japan, Germany, Spain, on card Frenzelit signs, and other various industrial sealing materials for customers on the seal product variety selection, give you the best sealing scheme.If you interest in our products, please click our website https://www.sealing-china.com/

Part No.:Modified/Reinforced PTFE Gasket SG-G1203

Company:Shaoxing Sealgood gasket and sealing Co.,Ltd.,

Your Name:Mr. Gao

E-mail:[email protected]

Tel:13588539608

PTFE modified gasket is made from PTFE suspension resin with proper fillers such as glass fiber, glass microsphere, graphite, barium sulfate, carbon fiber, molybdenum disulfide, polyphenyl, argil etc. in process of molding or skiving sheet Added a certain amount of filler, and the compression resistance and high temperature resistance will be greatly improved. It is especially suitable for using as the transmission sealing parts under the condition of-180℃-+260"℃ temperature range.

0 notes