Don't wanna be here? Send us removal request.

Text

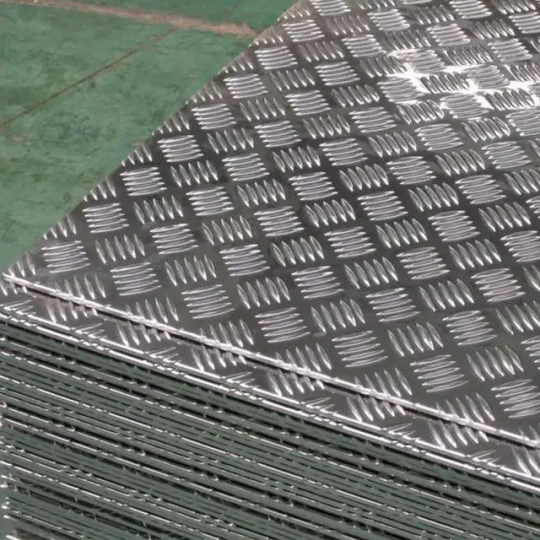

Aluminium 6082 Chequered Plates: Strength, Versatility, and Applications

Aluminium 6082 chequered plates, also known as tread plates or diamond plates, are renowned for their strength, lightweight nature, and corrosion resistance. This blog explores the properties, applications, and benefits of Aluminium 6082 chequered plates, emphasizing their importance in construction, transportation, and manufacturing sectors.

Properties of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates offer several key properties that make them suitable for diverse applications:

High Strength: Provides excellent structural integrity and load-bearing capacity, ideal for heavy-duty applications.

Lightweight: Aluminium's low density makes 6082 chequered plates easy to handle and install, reducing overall structural weight.

Corrosion Resistance: Resistant to corrosion and weathering, ensuring durability in outdoor and marine environments.

Skid-Resistance: Patterned surface design enhances grip and reduces slipping, making them ideal for flooring and stair treads.

Machinability: Easy to fabricate and machine, allowing for precise cutting and shaping in manufacturing processes.

Recyclability: Fully recyclable without loss of properties, supporting sustainability efforts in construction and manufacturing.

Applications of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates find extensive use across various industries and applications:

Transportation: Used in truck beds, trailers, and marine vessels for their durability and skid-resistant properties.

Construction: Ideal for flooring, stair treads, and walkways in commercial buildings, industrial facilities, and outdoor structures.

Manufacturing: Utilized as protective and decorative elements in machinery, equipment, and architectural applications.

Decorative Purposes: Applied in interior design and architectural projects for their aesthetic appeal and functional benefits.

Safety Applications: Employed in industrial settings and public spaces to enhance safety by reducing the risk of slips and falls.

Benefits of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates offer several advantages, making them a preferred choice in various applications:

Enhanced Safety: Provides a secure, non-slip surface, improving safety in high-traffic areas and industrial environments.

Longevity: Resistant to corrosion, abrasion, and wear, ensuring extended service life with minimal maintenance.

Versatility: Available in different patterns, thicknesses, and sizes to suit specific application requirements.

Cost-Effectiveness: Lower installation and maintenance costs compared to alternative materials, contributing to overall project savings.

Environmental Sustainability: Fully recyclable and energy-efficient during production, supporting green building initiatives.

Conclusion

Aluminium 6082 chequered plates are essential in industries where safety, durability, and aesthetics are paramount. Their unique patterned surface and robust properties make them versatile for various applications in transportation, construction, manufacturing, and decorative uses. Understanding the properties and benefits of Aluminium 6082 chequered plates underscores their significance in enhancing safety, efficiency, and sustainability across diverse sectors.

#Aluminium 6082 Chequered Plates#Tread Plates#Diamond Plates#Skid-Resistance#Construction Applications#Transportation Industry

0 notes

Text

Alloy Steel ASTM A182 F22 forged fittings are essential components in industrial piping systems known for their robustness, high-temperature resistance, and superior mechanical properties. These fittings are forged from chromium-molybdenum alloy steel, specifically designed to withstand corrosive environments and high-pressure conditions. This blog explores the properties, applications, and advantages of Alloy Steel ASTM A182 F22 forged fittings, highlighting their critical role in various industrial sectors.

Understanding Alloy Steel ASTM A182 F22 Forged Fittings

ASTM A182 F22 is a specification covering forged or rolled alloy steel pipe fittings intended for high-temperature service. The alloy composition includes chromium, molybdenum, and small amounts of other elements, enhancing the fittings' resistance to oxidation and corrosion. F22 forged fittings are available in a range of types such as elbows, tees, couplings, unions, and caps, providing versatility in piping system design.

Key Properties of Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings exhibit several key properties crucial for industrial applications:

High Temperature Resistance: F22 fittings maintain mechanical strength and integrity at elevated temperatures, making them suitable for high-temperature service.

Corrosion Resistance: The alloy composition offers excellent resistance to oxidation, sulfide stress cracking, and chloride environments, ensuring longevity in corrosive conditions.

Mechanical Strength: These fittings provide high tensile strength and toughness, capable of withstanding high-pressure applications without deformation.

Weldability: F22 alloy steel is readily weldable using standard welding techniques, allowing for secure and reliable joint connections.

Durability: Forged fittings are known for their durability and resistance to mechanical wear, ensuring reliable performance in harsh industrial environments.

Versatility: Available in various sizes, pressure ratings, and configurations, F22 forged fittings accommodate diverse piping requirements.

Applications of Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings find widespread use across industries requiring robust performance under challenging conditions:

Power Generation: They are essential in steam turbine systems, boiler assemblies, and heat exchangers in power plants.

Oil and Gas Industry: F22 fittings are used in refineries, pipelines, and offshore platforms for their resistance to corrosive fluids and gases.

Chemical Processing: They find application in chemical plants for processing acids, alkalis, and corrosive solvents.

Petrochemical Industry: These fittings are utilized in petrochemical plants for handling hydrocarbons and aggressive chemicals.

Shipbuilding: They are employed in marine applications for seawater systems, shipbuilding, and naval vessels.

Industrial Manufacturing: F22 forged fittings support fluid conveyance in manufacturing equipment, machinery, and industrial systems.

Benefits of Using Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings offer several advantages, making them a preferred choice in industrial applications:

Reliability: High mechanical strength and corrosion resistance ensure reliable performance under extreme conditions.

Safety: They meet stringent industry standards for safety and durability, reducing the risk of leaks or failures.

Cost-Effectiveness: Despite initial investment, F22 forged fittings provide long-term savings due to their durability and minimal maintenance requirements.

Flexibility: Available in various types and configurations, they offer flexibility in system design and adaptation to specific application needs.

Compliance: F22 fittings conform to ASTM A182 standards, ensuring quality and performance consistency.

Conclusion

Alloy Steel ASTM A182 F22 forged fittings play a crucial role in industrial piping systems where strength, durability, and resistance to corrosion are essential. Their ability to withstand high temperatures and corrosive environments makes them indispensable in power generation, oil and gas, chemical processing, and other critical industries. Understanding the properties and applications of F22 forged fittings highlights their critical importance in ensuring efficient, safe, and reliable operations in modern industrial settings.

#Alloy Steel ASTM A182 F22 Forged Fittings#High Temperature Service#Corrosion Resistance#Power Generation#Oil and Gas Industry

0 notes

Text

Exploring ASTM B619 Welded Pipe: Applications and Advantages

ASTM B619 is a standard specification for welded nickel-chromium-molybdenum-copper alloy (UNS N06022) and nickel-chromium-molybdenum-tungsten alloy (UNS N10665) pipe. These alloys are designed for use in corrosive environments, particularly those containing reducing and oxidizing chemicals. ASTM B619 welded pipes are critical in industries such as chemical processing, petrochemicals, pharmaceuticals, and power generation. This blog explores the properties, applications, and benefits of ASTM B619 welded pipes, emphasizing their importance in modern industrial applications.

What is ASTM B619 Welded Pipe?

ASTM B619 specifies seamless and welded pipes made from nickel-chromium-molybdenum-copper (Alloy C276, UNS N06022) and nickel-chromium-molybdenum-tungsten (Alloy B-2, UNS N10665) alloys. These materials are highly resistant to corrosion in a wide range of aggressive environments, including acids, chlorides, and seawater. Welded pipes under ASTM B619 are manufactured using fusion welding processes, ensuring uniformity, strength, and integrity throughout the pipe length.

Key Properties of ASTM B619 Welded Pipe

ASTM B619 welded pipes exhibit several critical properties that make them suitable for corrosive environments:

Corrosion Resistance: Nickel-based alloys like C276 and B-2 offer exceptional resistance to a wide range of corrosive chemicals, including acids (sulfuric, hydrochloric), chlorides, and seawater.

High Temperature Performance: These alloys maintain their mechanical strength and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications.

Mechanical Strength: ASTM B619 welded pipes provide excellent mechanical properties, including high tensile strength and toughness, ensuring reliability in demanding conditions.

Weldability: The alloys are easily weldable using conventional welding techniques, allowing for easy fabrication and repair of piping systems.

Low Maintenance: Due to their corrosion resistance, ASTM B619 welded pipes require minimal maintenance, reducing downtime and operational costs.

Longevity: These pipes have a long service life in aggressive environments, offering reliable performance over extended periods.

Applications of ASTM B619 Welded Pipe

ASTM B619 welded pipes find extensive use in industries requiring resistance to corrosive environments:

Chemical Processing: They are used in chemical plants for transporting acids, alkalis, and other corrosive chemicals.

Petrochemical Industry: ASTM B619 pipes are employed in oil refineries, gas processing plants, and offshore platforms where exposure to corrosive fluids is common.

Pharmaceutical Industry: These pipes are used in pharmaceutical manufacturing processes that involve corrosive solvents and chemicals.

Power Generation: ASTM B619 pipes are utilized in power plants for handling corrosive cooling water, steam, and chemicals in boiler systems.

Waste Treatment: They are used in wastewater treatment facilities for conveying corrosive liquids and gases.

Pulp and Paper Industry: ASTM B619 pipes find application in pulp and paper mills for handling corrosive chemicals used in bleaching and processing.

Benefits of Using ASTM B619 Welded Pipe

ASTM B619 welded pipes offer numerous advantages, making them a preferred choice in corrosive environments:

Corrosion Resistance: Superior resistance to a wide range of corrosive chemicals ensures longevity and reliability.

High Performance: These pipes maintain their mechanical properties at high temperatures, ensuring consistent performance in demanding conditions.

Safety: Reliable corrosion resistance reduces the risk of leaks and failures, enhancing operational safety.

Cost-Effectiveness: Despite their initial cost, ASTM B619 welded pipes offer long-term savings due to reduced maintenance and extended service life.

Versatility: Available in various sizes and configurations, they can be tailored to meet specific application requirements.

Environmental Sustainability: Nickel-based alloys are fully recyclable, promoting environmental sustainability and compliance with green initiatives.

Conclusion

ASTM B619 welded pipes made from alloys such as C276 and B-2 play a crucial role in industries where corrosion resistance and reliability are paramount. Their exceptional properties make them ideal for handling corrosive chemicals in chemical processing, petrochemicals, pharmaceuticals, and power generation. Understanding the benefits and applications of ASTM B619 welded pipes underscores their critical importance in ensuring efficient, safe, and sustainable operations in modern industrial environments.

#ASTM B619 Welded Pipe#Nickel-Chromium-Molybdenum Alloys#Corrosion Resistance#Chemical Processing#Petrochemical Industry#Power Generation#Mechanical Strength#High Temperature Performance

0 notes

Text

Discovering the Advantages and Uses of DHP Copper Bars

DHP copper bars, known for their superior formability and excellent corrosion resistance, play a pivotal role in various industrial applications. DHP stands for Deoxidized High Phosphorus, indicating the specific treatment and composition that enhances the properties of this copper alloy. This blog explores the unique features, applications, and benefits of DHP copper bars, highlighting their importance in modern manufacturing and construction.

What are DHP Copper Bars?

DHP copper, designated as C12200, is a type of copper alloy that contains a small amount of phosphorus (around 0.015% to 0.040%) which acts as a deoxidizing agent. This deoxidation process reduces the oxygen content in the copper, improving its ductility and making it more suitable for welding and forming. DHP copper bars are solid, rectangular bars known for their excellent workability and corrosion resistance.

Key Properties of DHP Copper Bars

DHP copper bars possess several key properties that make them highly desirable for various applications:

Excellent Formability: The presence of phosphorus enhances the ductility of DHP copper, allowing it to be easily formed into different shapes without cracking.

Corrosion Resistance: DHP copper bars exhibit outstanding resistance to corrosion, particularly in moist and marine environments, making them ideal for outdoor applications.

Weldability: The deoxidized nature of DHP copper ensures superior weldability, making it a preferred choice for applications requiring strong, reliable joints.

Thermal Conductivity: DHP copper bars have high thermal conductivity, making them efficient in heat transfer applications.

Durability: These bars are durable and have a long service life, even in harsh conditions.

Applications of DHP Copper Bars

DHP copper bars find extensive use across multiple industries due to their versatile properties:

Plumbing and HVAC Systems: They are commonly used in plumbing and HVAC systems for tubing, fittings, and components due to their corrosion resistance and ease of joining.

Heat Exchangers and Radiators: The high thermal conductivity of DHP copper makes it ideal for heat exchangers, radiators, and other heat transfer equipment.

Marine Applications: DHP copper bars are used in marine environments for applications such as shipbuilding and offshore structures due to their excellent resistance to seawater corrosion.

Construction and Architecture: In the construction industry, DHP copper bars are employed in roofing, flashing, and decorative elements due to their durability and aesthetic appeal.

Electrical Applications: Although not as conductive as ETP copper, DHP copper bars are still used in certain electrical applications where weldability and formability are critical.

Benefits of Using DHP Copper Bars

DHP copper bars offer numerous advantages, making them a preferred material in various applications:

Enhanced Workability: The excellent formability of DHP copper allows for complex shapes and intricate designs, facilitating a wide range of manufacturing processes.

Superior Corrosion Resistance: DHP copper's resistance to corrosion ensures long-lasting performance, reducing maintenance costs and extending the lifespan of the products.

Reliable Weldability: The deoxidized composition of DHP copper bars ensures strong, reliable welds, enhancing the structural integrity of the applications.

Efficient Heat Transfer: High thermal conductivity makes DHP copper bars efficient in heat transfer applications, improving the performance of heating and cooling systems.

Sustainability: DHP copper is fully recyclable, contributing to environmental sustainability and reducing the carbon footprint of manufacturing processes.

Conclusion

DHP copper bars are indispensable in many industrial and construction applications, offering superior formability, corrosion resistance, and weldability. Their unique properties make them ideal for plumbing, HVAC systems, heat exchangers, marine applications, and more. Understanding the benefits and applications of DHP copper bars highlights their critical role in modern manufacturing and construction, ensuring efficient, durable, and sustainable solutions.

#DHP Copper Bars#Deoxidized High Phosphorus Copper#Corrosion Resistance#Formability#Weldability#Thermal Conductivity

0 notes

Text

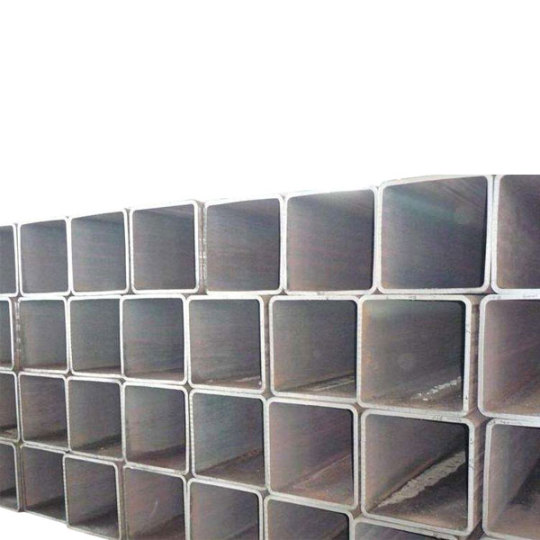

Exploring EN 10210 S235JRH Square Pipes

EN 10210 S235JRH square pipes are crucial components in various construction and industrial projects. Known for their strength, versatility, and ease of fabrication, these pipes are widely used for their superior mechanical properties. This blog delves into the specifics of EN 10210 S235JRH square pipes, highlighting their properties, applications, and the benefits they offer.

What is EN 10210 S235JRH Square Pipe?

EN 10210 is a European standard that specifies the technical delivery conditions for hot-finished hollow sections of non-alloy and fine grain structural steels. S235JRH is a grade under this standard, denoting specific mechanical and chemical properties. "S" stands for structural steel, "235" indicates the minimum yield strength in MPa, "JR" signifies impact testing at room temperature (20°C), and "H" stands for hollow section. The square shape of these pipes provides unique advantages in terms of load distribution and structural design.

Key Properties of EN 10210 S235JRH Square Pipe

EN 10210 S235JRH pipes are composed of non-alloy structural steel, providing a balance of strength and ductility. The minimum yield strength of 235 MPa ensures that the pipes can withstand significant stress without permanent deformation. They exhibit good impact resistance at room temperature, enhancing their suitability for structural applications. The chemical composition typically includes carbon, manganese, phosphorus, sulfur, and nitrogen, ensuring a combination of strength, weldability, and toughness. The hot-finished manufacturing process enhances the dimensional accuracy and surface quality of these pipes, making them reliable for precise applications.

Applications of EN 10210 S235JRH Square Pipe

In construction, EN 10210 S235JRH square pipes are widely used in building frameworks, columns, and support beams, providing essential structural integrity. They are ideal for infrastructure projects such as bridges, tunnels, and highways, where their strength and durability are indispensable. In industrial settings, these pipes are used in the fabrication of machinery, equipment, and various mechanical structures, ensuring reliability and performance. The square shape and smooth surface of these pipes also make them suitable for architectural applications, contributing to both structural and aesthetic elements of a design.

Benefits of Using EN 10210 S235JRH Square Pipe

One of the primary advantages of these pipes is their cost-effectiveness. The non-alloy steel composition keeps production costs relatively low, making them an economical choice for various projects. Their versatility allows for use in a wide range of applications, from structural frameworks to mechanical components. The combination of high yield strength and good impact resistance ensures that structures built with these pipes can endure heavy loads and adverse conditions. Moreover, the material's excellent weldability and formability simplify the fabrication process, reducing time and labor costs. The recyclability of steel also adds to the sustainability factor, making EN 10210 S235JRH pipes an environmentally friendly option for modern construction and industrial practices.

Conclusion

EN 10210 S235JRH square pipes are integral to the success of many construction and industrial projects. Their robust mechanical properties, coupled with their cost-efficiency and versatility, make them a preferred choice for engineers and builders. Whether it's for constructing resilient structures, developing infrastructure, or fabricating reliable industrial components, these pipes deliver the performance and durability required for long-lasting results. Understanding the properties and benefits of EN 10210 S235JRH square pipes can help professionals make informed decisions, enhancing the quality and sustainability of their projects.

#EN 10210 S235JRH Square Pipe#EN 10210#Structural Steel Pipes#Non-Alloy Steel Pipes#Construction Materials

0 notes

Text

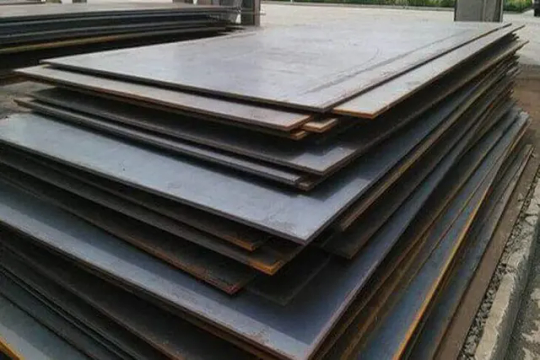

ASTM A516 GR. 60 HIC Plates: Ensuring Reliability in Pressure Vessel Applications

ASTM A516 GR. 60 HIC (Hydrogen Induced Cracking) plates are pivotal components in industries requiring robust materials for pressure vessels and boilers. These carbon steel plates are specifically engineered to withstand hydrogen-induced cracking, ensuring safety and durability in high-pressure environments. This blog explores the key features, applications, and advantages of ASTM A516 GR. 60 HIC plates, highlighting their critical role in maintaining structural integrity and reliability in industrial settings.

Introduction to ASTM A516 GR. 60 HIC Plates

ASTM A516 GR. 60 HIC plates are normalized carbon steel plates known for their excellent weldability and toughness. They are designed to resist hydrogen-induced cracking, a common issue in environments with high hydrogen content. These plates undergo a stringent heat treatment process to enhance their mechanical properties, making them suitable for use in pressure vessels and boilers operating at moderate temperatures.

Key Features of ASTM A516 GR. 60 HIC Plates

Hydrogen Induced Cracking Resistance: These plates are specifically formulated to resist hydrogen-induced cracking, ensuring long-term reliability and safety.

Good Tensile Strength: ASTM A516 GR. 60 HIC plates offer good tensile strength, providing structural integrity and durability under high-pressure conditions.

Normalized Heat Treatment: The plates undergo normalization to improve their mechanical properties and ensure uniformity across the thickness.

Excellent Weldability: They exhibit excellent weldability, facilitating ease of fabrication and assembly in pressure vessel manufacturing.

Applications of ASTM A516 GR. 60 HIC Plates

ASTM A516 GR. 60 HIC plates are widely used across various industries, including:

Oil and Gas: Used in storage tanks and pressure vessels for oil refining, gas processing, and offshore platforms.

Power Generation: Essential for boilers and heat exchangers in thermal power plants for generating electricity.

Chemical Processing: Ideal for chemical reactors and vessels handling corrosive substances and high-pressure gases.

Petrochemical Industry: Critical for storing and transporting petrochemical products under high-pressure conditions.

Advantages of ASTM A516 GR. 60 HIC Plates

Hydrogen Induced Cracking Resistance: Ensures safety and reliability in environments prone to hydrogen-induced cracking.

High Tensile Strength: Offers robust mechanical properties suitable for demanding industrial applications.

Reliability: Known for consistent performance under varying temperature and pressure conditions.

Cost-Effectiveness: Provides a cost-effective solution with long-term durability and low maintenance requirements.

Conclusion

ASTM A516 GR. 60 HIC plates play a crucial role in ensuring safety and reliability in pressure vessel applications across diverse industries. Their resistance to hydrogen-induced cracking, combined with good weldability and mechanical strength, makes them an ideal choice for critical applications where structural integrity is paramount. Understanding the unique features and applications of ASTM A516 GR. 60 HIC plates empowers industries to select materials that meet stringent safety standards and ensure operational efficiency.

#ASTM A516 GR. 60 HIC plates#hydrogen induced cracking resistance#pressure vessel steel#boiler plates#industrial applications#oil and gas#power generation#chemical processing

0 notes

Text

High-Speed Steel T42 Round Bar: Precision and Performance Redefined

High-speed steel (HSS) T42 round bars are revered in the realm of tooling and machining for their exceptional hardness, toughness, and heat resistance. Specifically designed for applications demanding high cutting speeds and prolonged tool life, T42 round bars represent a pinnacle in modern tool steel technology. This blog delves into the unique properties, diverse applications, and significant advantages of HSS T42 round bars, showcasing why they are indispensable in achieving precision and efficiency in machining operations.

Understanding High-Speed Steel T42 Round Bars

High-speed steel T42 is a tungsten-based HSS alloy, known for its robust combination of elements that enhance cutting performance and tool longevity. It typically contains elements such as:

Tungsten (W): Enhances hardness and wear resistance.

Molybdenum (Mo): Improves strength and heat resistance.

Vanadium (V): Promotes fine grain structure and toughness.

Cobalt (Co): Enhances red hardness and overall tool life.

The composition and heat treatment of T42 round bars result in a material capable of withstanding high temperatures generated during high-speed machining without losing hardness or dimensional stability.

Key Properties of High-Speed Steel T42 Round Bars

Exceptional Hardness: T42 round bars typically exhibit hardness levels ranging from 63 to 67 HRC (Rockwell C Scale), ensuring sharp cutting edges and resistance to wear.

High Wear Resistance: The alloy composition provides superior resistance to abrasion and deformation, crucial for continuous and high-speed machining operations.

Excellent Heat Resistance: T42 round bars maintain hardness and toughness even at elevated temperatures, reducing thermal deformation and ensuring consistent performance.

Good Machinability: Despite its high hardness, T42 steel maintains moderate machinability, allowing for intricate and precise tool designs.

Applications of High-Speed Steel T42 Round Bars

High-speed steel T42 round bars find widespread application across various industries:

Metal Cutting Tools: Used for manufacturing drills, end mills, reamers, and taps due to their high hardness and wear resistance.

Automotive and Aerospace Industries: Essential for machining high-strength alloys and exotic metals.

Tool and Die Making: Employed in forming dies, punches, and extrusion tools where precision and durability are critical.

General Engineering: Used in gear cutting, milling cutters, and broaches for efficient metal removal and high-speed operations.

Advantages of Using High-Speed Steel T42 Round Bars

Extended Tool Life: T42 round bars offer significantly longer tool life compared to conventional tool steels, reducing downtime and tool replacement costs.

High Cutting Performance: They enable high-speed cutting operations with superior surface finish and dimensional accuracy.

Versatility: Suitable for a wide range of machining applications across various industries, providing reliable performance in demanding environments.

Cost Efficiency: Despite initial higher costs, T42 round bars deliver long-term savings through improved productivity and reduced maintenance.

Conclusion

High-speed steel T42 round bars exemplify the pinnacle of tool steel technology, offering unmatched hardness, wear resistance, and heat resistance for high-speed machining applications. Their ability to maintain sharp cutting edges and withstand extreme temperatures makes them indispensable in achieving precise and efficient machining operations across diverse industries. Understanding the unique properties and applications of T42 round bars empowers manufacturers and toolmakers to optimize processes, enhance productivity, and achieve superior results.

#High-speed steel T42 round bars#tool steel#HSS alloys#high-speed machining#cutting tools#tool and die making#wear resistance#heat resistance

0 notes

Text

Comprehensive Guide to IS 2062 E250C Plates: Features, Applications, and Benefits

Introduction

In the realm of structural engineering and construction, selecting the right materials is paramount to ensuring the strength and longevity of any project. IS 2062 E250C plates are a popular choice due to their exceptional mechanical properties and versatility. This blog will delve into the specifics of IS 2062 E250C plates, highlighting their features, benefits, and typical applications.

What is IS 2062 E250C?

IS 2062 is an Indian Standard that specifies the requirements for hot-rolled medium and high tensile structural steel. The "E250C" grade signifies a high-quality steel plate with a minimum yield strength of 250 megapascals (MPa). The "C" indicates that the material is suitable for use in structures where higher strength and better weldability are required.

Key Features of IS 2062 E250C Plates

High Strength: With a minimum yield strength of 250 MPa, IS 2062 E250C plates are capable of withstanding significant stress, making them ideal for structural applications.

Excellent Weldability: These plates exhibit superior weldability, which facilitates easy and robust construction.

Good Toughness: IS 2062 E250C plates maintain their toughness even at lower temperatures, ensuring reliability and durability under various environmental conditions.

Versatility: Suitable for a wide range of applications in construction, engineering, and industrial projects.

Chemical Composition

The chemical composition of IS 2062 E250C plates typically includes:

Carbon (C): 0.23% max

Manganese (Mn): 1.50% max

Silicon (Si): 0.40% max

Sulfur (S): 0.045% max

Phosphorus (P): 0.045% max

This balanced composition ensures a combination of strength, ductility, and resistance to wear and tear.

Mechanical Properties

The mechanical properties of IS 2062 E250C plates are as follows:

Yield Strength: 250 MPa min

Tensile Strength: 410 - 560 MPa

Elongation: 23% min

These properties make the plates suitable for high-stress environments where durability and flexibility are essential.

Applications of IS 2062 E250C Plates

Construction Industry: Widely used in building frameworks, bridges, and structural beams due to their high strength and durability.

Automotive Industry: Utilized in manufacturing parts and components that require high strength and resistance to impact.

Shipbuilding: Employed in constructing ship hulls and other marine structures owing to their toughness and corrosion resistance.

Engineering Projects: Ideal for various engineering applications, including machinery and heavy equipment fabrication.

Benefits of Using IS 2062 E250C Plates

Cost-Effective: The high strength-to-weight ratio of these plates ensures efficient material usage, leading to cost savings.

Versatility: Suitable for a wide range of applications, from construction to automotive, making them highly versatile.

Long-Lasting: Enhanced durability and resistance to environmental factors ensure long-term performance.

Ease of Fabrication: Their excellent weldability and formability make them easy to work with, reducing fabrication time and costs.

Conclusion

IS 2062 E250C plates are an essential material in the construction and engineering industries, offering a blend of strength, durability, and versatility. Whether for building robust structures or manufacturing resilient components, these plates provide a reliable solution that meets stringent quality standards. Understanding their properties and applications can help in making informed decisions for your next project, ensuring optimal performance and longevity.

0 notes

Text

Aluminium Alloys 5083 H111 Sheet Plate: Strength, Corrosion Resistance, and Marine Applications

Aluminium Alloy 5083 is a high-strength alloy known for its exceptional corrosion resistance and weldability, particularly in marine environments. When processed into sheet and plate forms with the H111 temper, Aluminium Alloy 5083 H111 offers robust mechanical properties and reliability, making it ideal for structural applications where durability and resistance to seawater are critical. This blog explores the unique features, applications, and benefits of Aluminium Alloy 5083 H111 sheet and plate, highlighting its significant role in marine engineering and other industries.

Understanding Aluminium Alloy 5083 H111

Aluminium Alloy 5083 belongs to the 5000 series of aluminium alloys and is distinguished by:

High Corrosion Resistance: Exhibits excellent resistance to corrosion in marine and industrial environments, including seawater and acidic conditions.

High Strength: Offers superior strength and toughness, suitable for structural components subjected to high loads and stresses.

Good Weldability: Aluminium Alloy 5083 H111 can be easily welded using conventional methods, ensuring ease of fabrication and assembly without compromising material integrity.

Key Features of Aluminium Alloy 5083 H111 Sheet Plate

Superior Corrosion Resistance: Aluminium Alloy 5083 H111 sheet and plate are highly resistant to corrosion, making them ideal for marine applications such as shipbuilding, offshore platforms, and coastal structures.

High Strength: The alloy provides excellent strength-to-weight ratio, offering structural integrity while maintaining lightweight properties. It is commonly used in hulls, superstructures, and other critical components of ships and boats.

Good Formability and Machinability: Aluminium Alloy 5083 H111 exhibits good formability, allowing for easy shaping and forming into complex structures. It also offers good machinability, facilitating precise machining operations for customized applications.

Reliability in Extreme Conditions: Maintains mechanical properties at low temperatures, making it suitable for cryogenic applications and environments where temperature fluctuations are significant.

Marine Applications: Aluminium Alloy 5083 H111 sheet and plate find extensive use in marine industries due to their corrosion resistance and durability:

Shipbuilding: Used in ship hulls, decks, and bulkheads to withstand harsh marine conditions.

Offshore Structures: Employed in offshore platforms, oil rigs, and coastal infrastructure where corrosion resistance and reliability are crucial.

Applications of Aluminium Alloy 5083 H111 Sheet Plate

Aluminium Alloy 5083 H111 sheet and plate serve critical roles across various industries:

Marine: Primary applications include shipbuilding, yacht construction, and marine equipment due to its corrosion-resistant properties and strength.

Transportation: Used in the construction of truck trailers, railway cars, and other transport vehicles requiring lightweight materials with high strength.

Industrial: Applied in structural components for bridges, building facades, and industrial equipment where corrosion resistance and durability are essential.

Benefits of Using Aluminium Alloy 5083 H111 Sheet Plate

Corrosion Resistance: Provides exceptional resistance to seawater, reducing maintenance costs and extending service life in marine environments.

High Strength-to-Weight Ratio: Enhances structural integrity while minimizing overall weight, contributing to fuel efficiency and operational performance in marine and transportation sectors.

Versatility: Suitable for various manufacturing processes including welding, forming, and machining, allowing for versatile design options and customized solutions.

Environmental Sustainability: Aluminium Alloy 5083 H111 is recyclable and environmentally friendly, supporting sustainable manufacturing practices.

Conclusion

Aluminium Alloy 5083 H111 sheet and plate combine superior corrosion resistance, high strength, and excellent weldability, making them indispensable materials in marine engineering and structural applications. Their ability to withstand harsh marine environments while maintaining structural integrity ensures they play a crucial role in shipbuilding, offshore platforms, and other demanding industries. By leveraging the features, applications, and benefits of Aluminium Alloy 5083 H111 sheet and plate, industries can enhance efficiency, durability, and sustainability in their projects.

0 notes

Text

Duplex S32205 Flanges

In the realm of industrial piping systems, Duplex S32205 flanges are integral components known for their robustness, corrosion resistance, and versatility. These flanges, crafted from a duplex stainless steel alloy, play a crucial role in ensuring secure connections and reliable performance across various industries. This blog delves into the features, applications, and benefits of Duplex S32205 flanges, highlighting their significance in modern engineering and construction projects.

Understanding Duplex S32205 Flanges

Duplex S32205, also known as UNS S32205 or Alloy 2205, is a duplex stainless steel alloy characterized by its dual-phase microstructure of ferrite and austenite. This composition provides Duplex S32205 flanges with superior mechanical properties and resistance to corrosion, making them ideal for demanding applications in aggressive environments.

Key Features of Duplex S32205 Flanges

Corrosion Resistance: Duplex S32205 flanges offer excellent resistance to corrosion, including stress corrosion cracking, pitting, and crevice corrosion. This makes them suitable for use in marine environments, chemical processing plants, and offshore oil and gas platforms.

High Strength: The duplex microstructure imparts high mechanical strength to S32205 flanges, enabling them to withstand high pressures and mechanical loads without deformation or failure. This strength is crucial for maintaining integrity in critical piping systems.

Versatility and Adaptability: These flanges are versatile and adaptable to various applications across industries such as oil and gas, chemical processing, marine, and power generation. They can withstand a wide range of temperatures and corrosive environments, ensuring reliable performance in diverse conditions.

Weldability: Duplex S32205 flanges exhibit good weldability, allowing for ease of fabrication and installation. Proper welding practices ensure the retention of corrosion resistance and mechanical properties during assembly.

Cost-Effectiveness: Despite their superior properties, Duplex S32205 flanges offer a cost-effective solution compared to other high-performance alloys. They provide a balance of performance and affordability in critical industrial applications.

Applications of Duplex S32205 Flanges

Duplex S32205 flanges find widespread use in various industrial sectors for critical applications:

Oil and Gas Industry: Used in pipelines, subsea equipment, and offshore platforms due to their corrosion resistance and strength.

Chemical Processing: Ideal for reactors, storage tanks, and process equipment handling corrosive chemicals and acids.

Marine and Shipbuilding: Employed in ship hulls, desalination plants, and seawater handling equipment for their resistance to chloride corrosion.

Power Generation: Utilized in turbine components, boilers, and heat exchangers where high temperature and pressure resistance are required.

Benefits of Using Duplex S32205 Flanges

Reliability: These flanges ensure reliable performance in critical applications, contributing to operational efficiency and safety.

Durability: Duplex S32205 flanges are known for their durability and longevity, requiring minimal maintenance over their service life.

Environmental Sustainability: The recyclability and sustainability of Duplex S32205 support eco-friendly practices in industrial manufacturing and construction.

Conclusion

Duplex S32205 flanges exemplify strength, corrosion resistance, and versatility, making them indispensable in modern industrial applications. Their ability to withstand harsh environments while maintaining structural integrity ensures optimal performance and longevity in critical infrastructure projects. By understanding their features, applications, and benefits, industries can leverage Duplex S32205 flanges to enhance the efficiency, reliability, and sustainability of their operations.

0 notes

Text

Navigating Stainless Steel Rectangular Pipe Weight Charts

Stainless steel rectangular pipes are versatile and widely used in various industries for structural support, architectural accents, and fluid transportation. Understanding the weight of stainless steel rectangular pipes is crucial for design, engineering, and installation purposes. In this blog, we'll delve into the intricacies of stainless steel rectangular pipe weight charts, exploring how to interpret dimensions, calculate weights, and leverage this information for practical applications.

Deciphering Stainless Steel Rectangular Pipe Weight Charts

Stainless steel rectangular pipe weight charts provide valuable information regarding the dimensions and corresponding weights of rectangular pipes. Let's break down the key elements of these charts

Dimensions: Stainless steel rectangular pipe weight charts typically include dimensions such as

Outer Width (W): The width of the rectangular pipe's outer surface.

Outer Height (H): The height of the rectangular pipe's outer surface.

Wall Thickness (T): The thickness of the pipe's walls.

Length (L): The length of the pipe segment.

Weight per Meter: The weight per meter (or weight per foot) column in the chart specifies the weight of the rectangular pipe per unit length, typically measured in kilograms per meter (kg/m) or pounds per foot (lbs/ft). This value is crucial for determining the total weight of the pipe based on its length.

Calculations: The weight of a stainless steel rectangular pipe can be calculated using the formula: Weight = (W - T) * T * 0.0246615 * L Where

W: Outer Width of the pipe (in mm)

T: Wall Thickness of the pipe (in mm)

L: Length of the pipe (in meters)

0.0246615: Conversion factor for density of stainless steel (in kg/mm³)

Practical Applications and Considerations

Structural Design: Engineers and designers use stainless steel rectangular pipe weight charts to determine the weight of structural elements in buildings, bridges, and infrastructure projects, ensuring structural integrity and load-bearing capacity.

Material Procurement: Stainless steel fabricators and manufacturers refer to weight charts to estimate material requirements and calculate costs for purchasing stainless steel rectangular pipes.

Transport and Handling: Understanding the weight of rectangular pipes helps logistics professionals plan for transportation, storage, and handling of these materials, ensuring safe and efficient operations.

Installation Planning: Contractors and installers use weight information to assess the feasibility of lifting, positioning, and securing stainless steel rectangular pipes during installation, minimizing risks and ensuring workplace safety.

Interpreting Stainless Steel Rectangular Pipe Weight Charts:

Accuracy: Ensure that the weight chart is sourced from a reputable manufacturer or supplier to guarantee accurate dimensions and weight values.

Material Grade: Verify that the weight chart corresponds to the specific grade of stainless steel being used, as different grades may have varying densities and weight calculations.

Units of Measurement: Pay attention to the units of measurement (e.g., millimeters, meters, kilograms) used in the weight chart to avoid errors in calculations and conversions.

Conclusion

Stainless steel rectangular pipe weight charts serve as invaluable tools for engineers, designers, fabricators, and installers involved in various industries. By understanding the dimensions, calculations, and practical applications of these weight charts, professionals can make informed decisions regarding structural design, material procurement, transportation, handling, and installation of stainless steel rectangular pipes. Embrace the insights provided by weight charts to streamline processes, optimize resources, and ensure the successful execution of projects involving stainless steel rectangular piping systems.

0 notes

Text

Elevate Your Space with Stainless Steel Decorative L Profiles - Understanding Prices and Benefits

Stainless steel decorative L profiles have become a popular choice for enhancing the aesthetics and functionality of interior and exterior spaces. These sleek and versatile profiles offer a combination of durability, corrosion resistance, and contemporary design, making them ideal for architectural accents, trimmings, and edgings. In this blog, we'll explore the world of stainless steel decorative L profiles, shedding light on their benefits, applications, and factors influencing prices to help you make informed decisions for your design projects.

The Allure of Stainless Steel Decorative L Profiles

Stainless steel decorative L profiles are crafted from high-quality stainless steel alloys, such as 304 or 316, known for their exceptional corrosion resistance and longevity. These profiles feature a sleek L-shaped design, offering clean lines and modern aesthetics that complement various architectural styles, from minimalist to industrial.

Key Benefits of Stainless Steel Decorative L Profiles

Durability: Stainless steel decorative L profiles are highly durable and resistant to corrosion, rust, and environmental elements, ensuring longevity and low maintenance requirements.

Versatility: These profiles can be used in a wide range of applications, including wall cladding, door frames, countertops, staircases, and furniture, adding a touch of elegance and sophistication to any space.

Easy Installation: Stainless steel decorative L profiles are designed for easy installation, with options for adhesive, screw, or clip-on mounting, allowing for hassle-free integration into your design projects.

Hygiene and Cleanliness: Stainless steel is inherently hygienic and easy to clean, making it suitable for use in areas where cleanliness is paramount, such as kitchens, bathrooms, and healthcare facilities.

Factors Influencing Stainless Steel Decorative L Profile Prices

Grade of Stainless Steel: The price of decorative L profiles can vary depending on the grade of stainless steel used. Higher-grade alloys, such as 316 stainless steel, which offer superior corrosion resistance and durability, may command a higher price compared to standard grades like 304.

Finish and Surface Treatment: The choice of finish, whether brushed, polished, satin, or mirror, can influence the price of decorative L profiles. Additional surface treatments such as etching or embossing may also add to the cost.

Dimensions and Thickness: The size, dimensions, and thickness of the L profiles can affect the price, with larger or custom-sized profiles typically commanding higher prices due to material and manufacturing costs.

Quantity and Customization: Bulk orders of standard profiles may qualify for volume discounts, while customizations such as special finishes, patterns, or perforations may incur additional costs.

Supplier and Brand: The reputation and reliability of the supplier or brand can also impact the price of stainless steel decorative L profiles. Established brands known for quality craftsmanship and customer service may offer premium-priced products.

Conclusion

Stainless steel decorative L profile prices offer a perfect blend of functionality and aesthetics, adding sophistication and style to interior and exterior spaces. By understanding the benefits, applications, and factors influencing prices, designers, architects, and homeowners can make informed decisions when selecting stainless steel L profiles for their projects. Whether you're renovating a residential kitchen, designing a commercial space, or creating a bespoke furniture piece, stainless steel decorative L profiles are sure to elevate the ambiance and leave a lasting impression.

0 notes

Text

Unveiling the Excellence of Stainless Steel 304L Pipe

Stainless steel has revolutionized the world of engineering with its exceptional corrosion resistance, durability, and versatility. Among the array of stainless steel grades, 304L stands out as a popular choice for various applications, including piping systems. Stainless Steel 304L pipes offer remarkable strength, reliability, and corrosion resistance, making them indispensable in industries such as petrochemical, pharmaceutical, food processing, and more. In this blog, we'll delve into the features, applications, fabrication methods, and advantages of Stainless Steel 304L pipes, shedding light on their significance in modern engineering.

Understanding Stainless Steel 304L Pipe

Stainless Steel 304L is an austenitic stainless steel alloy with low carbon content, offering enhanced weldability and corrosion resistance compared to standard SS 304. Stainless Steel 304L pipes inherit these advantageous properties, making them ideal for applications requiring superior corrosion resistance, longevity, and structural integrity in diverse operating conditions.

Key Features of Stainless Steel 304L Pipe

Corrosion Resistance: Stainless Steel 304L pipes exhibit excellent resistance to corrosion, oxidation, and chemical attack, ensuring durability and reliability in aggressive environments exposed to acids, alkalis, and corrosive media.

Weldability: The low carbon content in 304L enhances its weldability, allowing for easy fabrication of welded joints with minimal risk of sensitization and intergranular corrosion, making it suitable for welding without post-weld annealing.

Strength and Durability: Stainless Steel 304L pipes offer high tensile strength, impact resistance, and structural stability, enabling reliable performance in high-pressure and high-temperature applications without deformation or failure.

Versatility: Stainless Steel 304L pipes are versatile and adaptable to various fabrication techniques, including seamless and welded manufacturing methods, catering to diverse application requirements.

Applications of Stainless Steel 304L Pipe

Petrochemical Industry: Stainless Steel 304L pipes find extensive use in petrochemical plants for conveying corrosive fluids, gases, and hydrocarbons in pipelines, reactors, and storage tanks, ensuring safe and efficient operation.

Food and Beverage Industry: In the food processing and beverage industry, 304L pipes are utilized for transporting potable water, beverages, dairy products, and food-grade liquids, maintaining hygienic conditions and product purity.

Pharmaceutical Sector: Stainless Steel 304L pipes are employed in pharmaceutical manufacturing facilities for transporting pharmaceutical-grade chemicals, solvents, and sterile fluids in compliance with stringent quality standards and regulatory requirements.

Architectural and Construction: In architectural and construction applications, 304L pipes serve as structural components, handrails, and decorative elements in building facades, bridges, and infrastructure projects, offering aesthetic appeal and durability.

Fabrication Methods for Stainless Steel 304L Pipe

Seamless Pipe Manufacturing: Seamless Stainless Steel 304L pipes are produced through hot extrusion or piercing of solid billets, ensuring uniform composition, dimensional accuracy, and smooth surface finish, ideal for high-pressure and critical applications.

Welded Pipe Fabrication: Welded Stainless Steel 304L pipes are manufactured through processes such as TIG (Gas Tungsten Arc Welding), MIG (Gas Metal Arc Welding), or ERW (Electric Resistance Welding), offering cost-effective solutions for various applications.

Advantages of Stainless Steel 304L Pipe

Corrosion Resistance: Stainless Steel 304L pipes provide superior corrosion resistance, ensuring longevity and reliability in corrosive environments, reducing maintenance requirements and lifecycle costs.

Weldability: The weldability of 304L pipes facilitates ease of fabrication and installation, allowing for efficient assembly of piping systems with minimal risk of weld defects or failure.

Hygiene and Cleanliness: Stainless Steel 304L pipes offer hygienic properties, making them suitable for applications requiring sanitary conditions, such as food processing, pharmaceutical, and beverage industries.

Conclusion

Stainless Steel 304L pipes stand as versatile and reliable conduits in industrial piping systems, embodying durability, corrosion resistance, and performance excellence in diverse applications. By harnessing their advantageous properties and fabrication methods, engineers and plant operators can enhance the efficiency, safety, and sustainability of their processes across various industries. Embrace the craftsmanship and reliability of Stainless Steel 304L pipes to elevate your piping infrastructure and embark on a journey towards unparalleled performance and operational excellence.

0 notes

Text

Stainless Steel 304H Pipes

In the realm of industrial piping systems, stainless steel reigns supreme for its exceptional corrosion resistance, longevity, and versatility. Among the myriad stainless steel grades, 304H stands out as a high carbon variant renowned for its elevated temperature strength and enhanced creep resistance. Stainless Steel 304H pipes embody these qualities, serving as reliable conduits for conveying fluids, gases, and solids in diverse industrial sectors. In this blog, we'll delve into the features, applications, fabrication methods, and benefits of Stainless Steel 304H pipes, shedding light on their indispensable role in modern engineering.

Understanding Stainless Steel 304H Pipes

Stainless Steel 304H is an austenitic stainless steel alloy with a higher carbon content than its counterpart, SS 304. This increased carbon content enhances the alloy's high-temperature strength and creep resistance, making it suitable for applications involving elevated temperatures exceeding 500°C. Stainless Steel 304H pipes inherit these advantageous properties, making them preferred choices for demanding environments in industries such as petrochemical, chemical processing, and thermal power generation.

Key Features of Stainless Steel 304H Pipes

High Temperature Strength: Stainless Steel 304H pipes exhibit excellent mechanical properties at elevated temperatures, retaining their strength and structural integrity under thermal stress and cyclic loading conditions.

Corrosion Resistance: Like other stainless steel alloys, 304H pipes offer superior corrosion resistance, protecting against corrosion, pitting, and crevice corrosion in aggressive chemical environments and corrosive media.

Creep Resistance: The presence of carbon in SS 304H enhances its creep resistance, allowing the pipes to withstand prolonged exposure to high temperatures without deformation or failure.

Versatility: Stainless Steel 304H pipes are versatile and adaptable to various fabrication techniques, allowing for seamless integration into complex piping systems and assemblies.

Applications of Stainless Steel 304H Pipes

Petrochemical Industry: Stainless Steel 304H pipes are extensively used in petrochemical plants for conveying corrosive fluids, hydrocarbons, and chemical reagents at high temperatures and pressures.

Chemical Processing: In chemical processing facilities, 304H pipes serve as conduits for transporting acids, solvents, and corrosive solutions in reactors, distillation columns, and storage tanks.

Thermal Power Generation: Stainless Steel 304H pipes play a crucial role in thermal power plants, where they form essential components of steam pipelines, boiler tubes, and heat exchangers, ensuring efficient energy generation and distribution.

Aerospace and Automotive: In aerospace and automotive applications, Stainless Steel 304H pipes are utilized for exhaust systems, turbochargers, and engine components requiring high-temperature performance and durability.

Fabrication Methods for Stainless Steel 304H Pipes

Seamless Pipe Manufacturing: Seamless Stainless Steel 304H pipes are produced by hot extrusion or piercing of solid billets, ensuring uniform composition, dimensional accuracy, and smooth surface finish.

Welded Pipe Fabrication: Welded Stainless Steel 304H pipes are manufactured through processes such as TIG (Gas Tungsten Arc Welding), MIG (Gas Metal Arc Welding), or ERW (Electric Resistance Welding), offering cost-effective solutions for various applications.

Benefits of Stainless Steel 304H Pipes

Longevity: Stainless Steel 304H pipes exhibit exceptional durability and longevity, minimizing maintenance requirements and lifecycle costs over extended service periods.

Reliability: With their superior mechanical properties and corrosion resistance, 304H pipes offer reliable performance in harsh operating conditions, ensuring uninterrupted flow and process integrity.

Sustainability: Stainless Steel 304H pipes are recyclable and environmentally sustainable, contributing to resource conservation and eco-friendly manufacturing practices.

Conclusion

Stainless Steel 304H pipes stand as stalwart conduits in industrial piping systems, embodying durability, reliability, and performance excellence in high-temperature and corrosive environments. By leveraging their advantageous properties and versatility, engineers and plant operators can enhance the efficiency, safety, and sustainability of their processes across diverse industries. Embrace the resilience and craftsmanship of Stainless Steel 304H pipes to elevate your piping infrastructure and embark on a journey towards unparalleled performance and operational excellence.

0 notes

Text

A Comprehensive Guide to SS 304H Flanges

Stainless steel flanges are vital components in piping systems, offering secure connections, leak-proof seals, and ease of assembly in various industrial applications. SS 304H flanges, crafted from high-quality stainless steel alloy, exemplify durability, corrosion resistance, and superior performance in demanding environments. In this blog, we'll delve into the intricacies of SS 304H flanges, exploring their properties, applications, manufacturing standards, and installation considerations to unveil their significance in modern engineering.

Understanding SS 304H Flanges: Stainless steel 304H is a high carbon version of the widely used SS 304 grade, featuring enhanced strength and temperature resistance. SS 304H flanges inherit these exceptional properties, making them suitable for elevated temperature applications such as high-pressure steam systems, chemical processing, and thermal power plants. Let's delve deeper into the key aspects of SS 304H flanges:

Properties

High Temperature Resistance: SS 304H flanges exhibit excellent resistance to high temperatures, retaining their mechanical properties and corrosion resistance even at elevated temperatures exceeding 1000°C.

Corrosion Resistance: Like other stainless steel alloys, SS 304H flanges offer superior corrosion resistance, ensuring longevity and reliability in corrosive environments exposed to acids, alkalis, and moisture.

Strength and Durability: The high carbon content in SS 304H enhances its strength and hardness, making SS 304H flanges resilient against mechanical stresses, including pressure, vibration, and thermal cycling.

Applications

Petrochemical Industry: SS 304H flanges are widely used in petrochemical plants for connecting pipelines, reactors, and vessels handling corrosive fluids and high-temperature processes.

Power Generation: In thermal power plants, SS 304H flanges facilitate the assembly of steam pipelines, boiler components, and heat exchangers, ensuring efficient energy generation and transmission.

Chemical Processing: SS 304H flanges play a crucial role in chemical processing facilities, where they connect piping systems transporting aggressive chemicals, solvents, and corrosive gases.

Manufacturing Standards

SS 304H flanges are manufactured in compliance with international standards such as ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), and DIN (Deutsches Institut für Normung) to ensure dimensional accuracy, material quality, and performance consistency.

Common types of SS 304H flanges include weld neck, slip-on, threaded, socket weld, and blind flanges, each designed for specific applications and installation requirements.

Installation Considerations

Proper Surface Preparation: Before installation, ensure that flange mating surfaces are clean, smooth, and free from contaminants to achieve a leak-proof seal.

Bolt Tightening: Use appropriate torque values and bolt tightening procedures to uniformly distribute the load and prevent flange distortion or leakage.

Gasket Selection: Choose compatible gasket materials such as graphite, PTFE (Polytetrafluoroethylene), or spiral wound metallic gaskets based on the application requirements and temperature-pressure conditions.

Conclusion

SS 304H flanges stand as indispensable components in critical industrial processes, offering reliability, longevity, and performance excellence in high-temperature and corrosive environments. By understanding their properties, applications, manufacturing standards, and installation considerations, engineers and plant operators can harness the full potential of SS 304H flanges to ensure safe, efficient, and sustainable operation of piping systems across diverse industries. Embrace the craftsmanship and reliability of SS 304H flanges to elevate your engineering projects and pave the way for a robust infrastructure landscape.

0 notes

Text

Unveiling the Marvels of Aluminum Alloy 6061 Sheet

Aluminum alloys are celebrated for their remarkable combination of lightweight, strength, and corrosion resistance, making them indispensable in various industries ranging from aerospace and automotive to construction and consumer goods. Among the myriad of aluminum alloys, 6061 stands out as a versatile and widely used alloy renowned for its excellent mechanical properties and machinability. In this blog, we'll embark on a journey to explore the intricacies of Aluminum Alloy 6061 Sheet, uncovering its properties, applications, fabrication techniques, and key advantages.

Properties of Aluminum Alloy 6061 Sheet

High Strength: Aluminum Alloy 6061 Sheet exhibits exceptional strength, comparable to some low to medium carbon steels, making it suitable for structural applications where strength-to-weight ratio is critical.

Excellent Machinability: 6061 aluminum alloy can be easily machined, drilled, cut, and formed using conventional machining processes, making it favored for applications requiring intricate shapes and precise tolerances.

Corrosion Resistance: The addition of magnesium and silicon imparts corrosion resistance to Aluminum Alloy 6061 Sheet, allowing it to withstand exposure to moisture, atmospheric gases, and chemical environments without significant degradation.

Weldability: 6061 aluminum alloy offers good weldability using various welding techniques such as TIG (Gas Tungsten Arc Welding), MIG (Gas Metal Arc Welding), and resistance welding, enabling the fabrication of complex assemblies and structures.

Applications of Aluminum Alloy 6061 Sheet

Aerospace Industry: Aluminum Alloy 6061 Sheet finds extensive use in the aerospace sector for manufacturing aircraft components, fuselage panels, wing skins, and structural frames due to its lightweight properties and high strength.

Automotive Components: The automotive industry utilizes 6061 aluminum alloy for producing engine parts, chassis components, wheels, and body panels to reduce vehicle weight and improve fuel efficiency without compromising on performance and safety.

Marine Applications: Aluminum Alloy 6061 Sheet is employed in marine vessels, boat hulls, and marine equipment due to its corrosion resistance and durability, providing longevity in saltwater environments.

Structural Engineering: In the construction sector, 6061 aluminum alloy is utilized for fabricating architectural structures, bridges, support beams, and roofing systems, offering strength, versatility, and aesthetic appeal.

Fabrication Techniques for Aluminum Alloy 6061 Sheet

Cutting and Machining: Aluminum Alloy 6061 Sheet can be easily cut, drilled, and machined using standard machining tools and techniques, including milling, turning, drilling, and tapping.

Forming and Bending: With its excellent formability, 6061 aluminum alloy can be formed into complex shapes and profiles using techniques such as bending, rolling, stamping, and deep drawing.

Welding and Joining: Various welding methods such as TIG welding, MIG welding, and resistance welding are employed to join Aluminum Alloy 6061 Sheet to other components or structures, ensuring strong and durable weld joints.

Surface Finishing: Aluminum Alloy 6061 Sheet can be finished using processes like anodizing, painting, powder coating, or polishing to enhance its appearance, corrosion resistance, and durability.

Key Advantages of Aluminum Alloy 6061 Sheet

Lightweight: Aluminum Alloy 6061 Sheet offers a high strength-to-weight ratio, making it an ideal choice for applications where weight savings are critical, such as aerospace and automotive industries.

Corrosion Resistance: The alloy's corrosion resistance properties ensure longevity and durability in diverse environmental conditions, reducing maintenance requirements and lifecycle costs.

Versatility: Aluminum Alloy 6061 Sheet's versatility enables its use across a wide range of industries and applications, from structural engineering to consumer electronics, offering design flexibility and innovation opportunities.

Recyclability: Aluminum is highly recyclable, and Aluminum Alloy 6061 Sheet can be recycled repeatedly without losing its properties, making it an environmentally sustainable choice for manufacturers and end-users.

Conclusion

Aluminum Alloy 6061 Sheet exemplifies the pinnacle of engineering excellence, combining strength, machinability, corrosion resistance, and versatility to meet the demanding requirements of modern industries. Whether soaring through the skies in aircraft wings or forming the backbone of architectural marvels, 6061 aluminum alloy continues to shape the world we live in with its unparalleled attributes and endless possibilities. Embrace the power of Aluminum Alloy 6061 Sheet to unlock new horizons in design, innovation, and sustainability across diverse applications and industries.

0 notes

Text

Exploring the Wonders of Titanium Welding Wire

Titanium, renowned for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, is a highly sought-after material in various industries ranging from aerospace and automotive to medical and marine. Welding titanium presents unique challenges due to its reactive nature and high melting point. Titanium welding wire plays a crucial role in achieving high-quality welds with minimal defects. In this blog, we'll delve into the fascinating world of titanium welding wire, exploring its properties, applications, welding techniques, and key considerations.

Properties of Titanium Welding Wire

High Purity: Titanium welding wire is manufactured with high purity titanium to ensure excellent weldability and minimize impurities that can compromise weld integrity.

Corrosion Resistance: Like titanium itself, titanium welding wire exhibits exceptional corrosion resistance, making it suitable for applications in aggressive environments such as chemical processing plants and marine structures.

Strength and Ductility: Titanium welding wire possesses high tensile strength and ductility, allowing it to withstand extreme mechanical loads without failure or deformation.

Thermal Stability: Titanium welding wire maintains its mechanical properties even at elevated temperatures, making it ideal for welding applications involving high heat inputs.

Applications of Titanium Welding Wire

Aerospace Industry: Titanium welding wire finds extensive use in the aerospace sector for fabricating aircraft components, engine parts, and structural assemblies due to its lightweight properties and high strength.

Medical Devices: The biocompatibility of titanium makes it suitable for medical implants and surgical instruments. Titanium welding wire ensures precise and reliable welds in the production of orthopedic implants, dental prosthetics, and medical equipment.

Chemical Processing: Titanium's resistance to corrosion and chemical attack makes it an ideal material for manufacturing reactors, heat exchangers, and piping systems in the chemical processing industry. Titanium welding wire facilitates the fabrication of robust and leak-free weld joints in such applications.

Marine and Offshore Structures: Titanium welding wire is employed in the construction of marine vessels, offshore platforms, and subsea pipelines due to its resistance to seawater corrosion and fatigue loading.

Welding Techniques for Titanium Welding Wire

Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW is the preferred welding process for titanium due to its precise control over heat input and weld pool dynamics. The use of high-purity argon shielding gas ensures a clean weld environment and prevents contamination.

Plasma Arc Welding (PAW): PAW is another viable welding process for titanium, offering higher welding speeds and deeper penetration compared to GTAW. The focused plasma arc minimizes heat-affected zones and produces narrow, uniform weld beads.

Electron Beam Welding (EBW): EBW is suitable for welding thick titanium sections or dissimilar materials with minimal distortion. The concentrated electron beam generates intense heat, facilitating deep penetration welding without the need for filler material.

Key Considerations for Titanium Welding Wire

Cleanliness: Proper cleaning and degreasing of titanium surfaces and welding wire are essential to prevent contamination and ensure high-quality welds free from defects.

Shielding Gas: The use of high-purity argon or argon-helium mixtures as shielding gas is critical to protect the weld pool from atmospheric contamination and oxidation during welding.

Filler Material Selection: Matching the filler material composition to the base metal grade is crucial for achieving compatible weld properties and minimizing the risk of weld defects such as cracking and porosity.

Welding Parameters: Optimal welding parameters, including current, voltage, travel speed, and interpass temperature, must be carefully controlled to prevent overheating or underheating of the base metal and ensure sound welds.

Conclusion

Titanium welding wire plays a vital role in harnessing the unique properties of titanium and fabricating high-performance components across diverse industries. By understanding the properties, applications, welding techniques, and key considerations associated with titanium welding wire, welders and engineers can achieve superior weld quality, structural integrity, and longevity in titanium-based structures and assemblies. Embrace the versatility and reliability of titanium welding wire to unlock endless possibilities in engineering and manufacturing.

0 notes