#PVC window frame making machine

Explore tagged Tumblr posts

Text

Curtains vs. Blinds: What Works Best for Bolton Properties?

When it comes to window treatments, the age-old debate of curtains vs. blinds continues to divide homeowners. For Bolton property owners, choosing between the two isn’t just a matter of aesthetics—it’s about functionality, insulation, privacy, and even energy efficiency. With Bolton’s ever-changing weather and diverse housing stock ranging from traditional terraces to modern new builds, making the right choice for your windows is essential.

In this article, we’ll compare curtains and blinds in terms of performance, style, practicality, and cost to help you decide what works best for your Bolton home.

The Key Differences: Curtains vs. Blinds

Before diving into the pros and cons, let’s clarify the core differences:

Curtains are fabric panels that hang vertically from a rod or track and are typically used for a soft, flowing aesthetic.

Blinds consist of slats or fabric that can be rolled, folded, or tilted to control light and privacy. They are generally more compact and modern-looking.

Both serve the same primary function—to cover windows—but they do so in very different ways.

1. Light Control

Curtains: Curtains, especially blackout or heavy-lined types, can block out a significant amount of light. However, they typically only offer two settings: open or closed.

Blinds: Blinds provide superior light control. Venetian and vertical blinds allow for precise light adjustment by tilting the slats, while day and night blinds offer dual fabric layers for tailored illumination.

Winner for Bolton homes: Blinds, especially useful during those long summer evenings or early sunrises.

2. Insulation & Energy Efficiency

In Bolton, where winters are chilly and energy bills are a concern, insulation is key.

Curtains: Thick, thermal-lined curtains are excellent for keeping the cold out and the warmth in. They create a barrier between the window and your room, reducing drafts.

Blinds: While some blinds—like honeycomb (cellular) blinds—offer great insulation, most standard blinds fall behind heavy curtains in this area.

Winner: Curtains, particularly thermal or blackout types.

3. Style & Interior Design

Curtains: Curtains add softness, drama, and elegance to a room. From sheer voiles to velvet drapes, the design options are vast. They suit traditional Bolton homes and can make large bay windows stand out.

Blinds: Blinds offer a sleek, minimalist look that’s perfect for modern properties. Options like Roman, roller, Venetian, or faux wood blinds can be customised to match nearly any decor style.

Winner: Depends on the decor – curtains for classic or cosy interiors, blinds for modern or minimalist designs.

4. Space-Saving Considerations

Curtains: They take up more space due to the fabric bunching and need for tracks or rods. In smaller Bolton homes or flats, they might feel bulky.

Blinds: Blinds are compact and mounted within or just above the window frame, making them ideal for smaller rooms or tight spaces.

Winner: Blinds for space-conscious properties.

5. Ease of Cleaning and Maintenance

Curtains: They often require dry cleaning or machine washing, depending on the material. Cleaning can be cumbersome, especially for floor-length or lined curtains.

Blinds: Blinds are generally easier to maintain. Wipeable materials like PVC, faux wood, or aluminium are perfect for Bolton’s dustier urban areas or rooms like kitchens and bathrooms.

Winner: Blinds, especially for those seeking low-maintenance options.

6. Cost and Budgeting

Curtains: Prices vary based on material and length. Custom-made curtains can be expensive, particularly if you’re covering large or unusually shaped windows.

Blinds: Blinds are usually more affordable, especially roller or vertical blinds. Custom options still exist, but overall, they’re a cost-effective solution.

Winner: Blinds for budget-conscious Bolton homeowners.

7. Privacy

Curtains: Offer excellent privacy when closed but little flexibility otherwise.

Blinds: Allow for partial or full privacy by adjusting slats or fabric layers—ideal for ground-floor or street-facing Bolton properties.

Winner: Blinds, particularly Venetian, vertical, and day & night styles.

When to Choose Curtains for Your Bolton Home

You live in a period or character property and want to maintain its traditional aesthetic.

You’re looking for maximum thermal insulation, especially in drafty rooms.

You want to add a cosy or luxurious touch to living rooms or bedrooms.

When to Choose Blinds for Your Bolton Home

You live in a modern property or apartment with a contemporary design.

You need precise light control and privacy, especially for south-facing rooms.

You’re furnishing small rooms, bathrooms, or kitchens.

You want a low-maintenance solution for busy areas.

Best of Both Worlds: Layering Curtains and Blinds

Many Bolton homeowners are now choosing to layer blinds with curtains for a stylish, flexible solution. For example:

Use roller blinds for privacy and light control.

Pair with sheer curtains for softness and style.

Combine blackout blinds with thermal curtains for bedrooms needing darkness and warmth.

Layering adds depth to your interior design and ensures your windows are functional and beautiful year-round.

Conclusion: What’s Best for Bolton Homes?

There’s no one-size-fits-all answer—the right window treatment depends on your needs, property style, and budget.

Choose blinds if you value modern style, flexibility, and practicality.

Opt for curtains if you’re seeking insulation, traditional charm, or a plush aesthetic.

Combine both for maximum versatility and comfort.

Whether you're in a Bolton city centre flat or a detached home in the suburbs, thoughtful window dressing can make a major difference to your living environment.

Ready to Transform Your Windows?

If you're still unsure which option to go for, consult a local window treatment specialist in Bolton. Many offer free consultations, measuring services, and tailored recommendations based on your space, budget, and needs.

Learn more

Contact us: Harmony Blinds Bolton Unit A1, Edge Fold, Ind Est, Plodder Ln, Bolton BL4 0LR, United Kingdom +44 1257 581571

1 note

·

View note

Text

Top 7 Blinds Buying Tips for First-Time Innisfil Homeowners

Buying blinds in Innisfil for the first time can be overwhelming with so many styles, materials, and features available. Whether you’re considering roller shades, Roman blinds, vertical blinds, or zebra blinds, making the right choice depends on your needs, budget, and home décor. To help you navigate this decision, we’ve compiled the top 7 blinds buying tips tailored for Innisfil homeowners. From measuring correctly to selecting the perfect fabric, these expert tips will ensure you find the ideal window treatments that combine functionality, aesthetics, and durability.

1. Measure Your Windows Accurately:

Ill-fitting blinds can ruin both functionality and aesthetics. Follow these steps:

Use a steel tape measure for precision.

Note down width and height in three places (top, middle, bottom).

Decide between inside or outside mount based on your window frame.

2. Consider Your Privacy & Light Needs:

Blackout blinds (ideal for bedrooms).

Light-filtering shades (great for living rooms).

Sheer vertical blinds (perfect for patio doors).

3. Choose the Right Material:

Fabric – Soft, elegant (best for Roman blinds).

Vinyl/PVC – Durable, easy to clean (great for vertical blinds).

Wood/Faux Wood – Classic, insulating (suits traditional homes).

4. Match Blinds to Your Home’s Style:

Modern homes → Zebra blinds or roller shades.

Traditional décor → Roman blinds or wooden shutters.

5. Prioritize Easy Maintenance:

Dust-friendly options: Vertical blinds or aluminum shades.

Machine-washable fabrics: Certain roller shades.

6. Set a Realistic Budget:

Affordable: Vinyl vertical blinds.

Mid-range: Roller shades.

Premium: Custom Roman blinds or smart motorized options.

7. Explore Energy-Efficient Options:

Insulated blinds help regulate indoor temperatures, reducing energy costs—a smart choice for Innisfil’s varying climate.

Selecting the perfect blinds in Innisfil doesn’t have to be stressful. By following these 7 expert tips, you can find stylish, functional, and durable window treatments that suit your home. Whether you prefer roller shades, Roman blinds, or zebra blinds, the right choice enhances both comfort and aesthetics. Ready to upgrade your windows? Start exploring today and give your home the flawless finish it deserves!

Explore the more details right here.

0 notes

Text

The Backbone of Every Build: Why Building Materials Suppliers Matter in the UAE

In the UAE’s fast-paced construction industry, where innovation meets architectural ambition, the quality of building materials used can make or break a project. While designs and concepts drive creativity, the real foundation lies in the materials chosen—and more importantly, in the supplier providing them.

Reliable building materials suppliers in UAE play a vital role in keeping projects on track, ensuring quality, and supporting every phase from planning to execution. Whether it’s a residential compound, a commercial fit-out, or a government facility, builders rely heavily on trusted suppliers to deliver performance-ready products on time and within budget.

Why Quality Building Materials Are Non-Negotiable

In the harsh climate of the UAE—marked by high temperatures, humidity, and dust—the strength and durability of construction materials are critical. Materials must not only meet global standards but must also be suitable for regional conditions. Substandard or mismatched materials lead to structural issues, frequent maintenance, or even safety hazards.

That’s why choosing the right supplier is more than a transaction—it’s an investment in the safety, longevity, and efficiency of a structure.

Core Products Offered by Leading Suppliers

Trusted suppliers in the UAE typically stock a wide selection of construction and interior finishing products. Below are some of the essential categories that professionals consistently look for:

1. Aluminium Profiles

Aluminium profiles are commonly used in framing, structural elements, partitions, and windows. Known for being lightweight, corrosion-resistant, and aesthetically adaptable, aluminium is an ideal solution for both interior and exterior applications. Suppliers offer them in various sizes, colors, and finishes to match modern design needs.

2. Tile Cutting Machines

For perfect tile installations, accurate cutting is a must. Professional tile cutting machines help achieve clean edges and precise alignment, which is essential for both functional and visual appeal. High-quality machines also reduce material waste and increase installation speed.

3. LED Profiles

With modern lighting trends leaning toward efficiency and style, LED profiles help house and protect LED strip lights while offering a clean and uniform finish. From under-cabinet lighting to architectural highlights, LED profiles are used in both commercial and residential interiors.

4. PVC Profiles

PVC profiles offer excellent resistance to moisture, chemicals, and weather changes. They are widely used for wall and ceiling cladding, cable channels, and protection trims. Their low maintenance and ease of installation make them a favorite among contractors and installers.

5. Skirtings

Skirtings are a finishing element used at the base of walls to cover expansion gaps and protect against impact. They are available in various materials and designs, making them both functional and decorative. Skirtings also help in creating a seamless transition between walls and floors.

What Sets the Best Suppliers Apart?

Not all suppliers offer the same value. While many might stock similar products, a few key qualities make some suppliers stand out:

Consistent Product Quality: Materials should be certified and tested for safety and durability.

Product Range: A broad selection allows builders to source multiple items from one place, saving time and coordination effort.

Expert Knowledge: Suppliers who understand product application can guide buyers on the best choices for specific projects.

Timely Delivery: Delays in materials can halt an entire project. Reliable suppliers ensure timely and accurate deliveries.

Competitive Pricing: Fair and transparent pricing allows project managers to stay within budget without compromising on quality.

After-Sales Support: Guidance on installation, maintenance, and technical information builds long-term trust.

Supporting All Stakeholders in the Construction Chain

A dependable building materials supplier serves not only contractors but also architects, interior designers, and developers. By providing detailed product specifications, customization options, and access to the latest materials on the market, suppliers can influence better design outcomes and construction methods.

For large projects, having a supplier who offers consistent communication, logistics support, and volume-based pricing can help streamline operations and reduce project risk.

Aligning with Sustainability and Innovation

Sustainability is becoming more than a trend in the UAE—it’s an expectation. Developers and government bodies are increasingly focused on green building certifications, energy efficiency, and low-waste practices. Suppliers who offer recyclable materials, energy-efficient lighting systems, and eco-friendly profiles support the region’s long-term sustainability goals.

Moreover, as the construction industry integrates smart building technologies and modern techniques, suppliers that adapt to innovation with new products and solutions are better positioned to serve future-ready projects.

Final Thoughts

Construction is not only about blueprints and labor—it’s about materials, quality, and the partners who support the process. The role of building materials suppliers in UAE is fundamental to the country’s construction growth, shaping everything from skyline-defining towers to efficient residential homes.

By working with a reliable supplier, project managers and contractors gain more than just access to materials—they gain confidence that their work will meet expectations, timelines, and performance standards. In an industry where time, budget, and quality are constantly being measured, the right supplier can make all the difference.

0 notes

Text

The Shape of Things to Come: How Plastic Extrusion Profiles Are Redefining Industries

In a world constantly seeking innovative solutions, the unassuming plastic extrusion profile is quietly revolutionizing how we design, build, and manufacture. From sleek architectural elements to intricate components in cutting-edge technology, these versatile shapes are no longer a niche – they're a trending force reshaping industries with their adaptability and efficiency. Let's dive into the fascinating world of plastic extrusion profiles and discover how they're shaping our future, with a nod to how PARKNONWOVEN supports this dynamic sector.

Beyond Basic Shapes: The Allure of Plastic Extrusion

Imagine the ability to create continuous lengths of plastic with virtually any cross-sectional shape imaginable. That's the power of plastic extrusion. By forcing molten plastic through a precisely designed die, manufacturers can produce complex profiles tailored to incredibly specific needs. This isn't just about making simple tubes or rods anymore; it's about crafting intricate components that integrate seamlessly into larger systems, offering solutions that were once complex or even impossible with traditional materials.

Why Plastic Extrusion Profiles Are Capturing Attention

Several compelling factors are fueling the rising popularity of plastic extrusion profiles:

Unleashing Design Freedom: Extrusion empowers designers and engineers to move beyond standard shapes. Complex geometries, interlocking mechanisms, and integrated features can be incorporated directly into the profile, reducing the need for secondary assembly and streamlining production.

Cost-Effective Innovation: For high-volume production, plastic extrusion often presents a significantly more economical route compared to machining, molding, or metal fabrication. Reduced material waste and faster production cycles translate to substantial cost savings.

Material Advantage: The sheer variety of plastics available for extrusion – from flexible PVC to robust ABS and high-performance polycarbonates – allows for profiles with tailored properties like weather resistance, chemical inertness, electrical insulation, and specific impact strength.

Lightweighting Solutions: In industries like automotive and aerospace, the demand for lightweight materials is paramount for fuel efficiency and performance. Plastic extrusion offers strong yet lightweight alternatives to traditional metals.

Sustainability Integration: The ability to utilize recycled plastics in the extrusion process is gaining traction, aligning with the growing global focus on sustainability and circular economy principles.

The Astonishingly Diverse Applications

The versatility of plastic extrusion profiles is evident in their ever-expanding applications:

Architecture & Construction: Window and door frames, seals, decorative trims, cable conduits, piping systems, and even structural elements.

Automotive Industry: Interior and exterior trims, weather stripping, seals, fluid transfer tubes, and wire harnessing channels.

Electronics: Cable management systems, housings, connectors, and insulating components.

Retail & Display: Shelving supports, signage frames, display fixtures, and point-of-sale materials.

Medical Devices: Tubing, profiles for diagnostic equipment, and components for medical furniture.

Consumer Goods: Appliance trims, furniture components, and sporting goods accessories.

PARKNONWOVEN: Supporting Innovation in Extruded Plastics

While PARKNONWOVEN's core expertise lies in non-woven materials, their high-quality products play a vital supporting role in the broader manufacturing ecosystem, including the plastic extrusion industry. Their non-woven materials are utilized in:

Surface Protection: Providing protective layers for delicate plastic profiles during manufacturing, transportation, and installation, preventing scratches and damage.

Lamination Backing: Offering non-woven backings for laminated plastic profiles, enhancing their structural integrity and aesthetic appeal.

Filtration in Manufacturing: Supplying filtration media for air and liquid filtration systems used in plastic extrusion facilities to maintain clean operating environments and ensure product quality.

Packaging Solutions: Providing specialized non-woven materials for packaging extruded plastic profiles, offering cushioning and protection during transit.

Partnering with PARKNONWOVEN: A Commitment to Quality and Innovation

By choosing PARKNONWOVEN, businesses involved in plastic extrusion can benefit from:

Reliable and Consistent Materials: Ensuring the quality and performance of their final products.

Customizable Solutions: Tailoring non-woven materials to specific needs and applications.

Expert Technical Support: Accessing knowledgeable support for material selection and integration.

A Commitment to Sustainability: Utilizing materials from a company that values environmental responsibility.

The Future is Shaped in Plastic

Plastic extrusion profiles are more than just shaped plastic; they are the building blocks of innovation across countless industries. Their adaptability, cost-effectiveness, and material versatility are driving their increasing adoption. As we continue to push the boundaries of design and manufacturing, expect to see even more groundbreaking applications emerge. While PARKNONWOVEN may not be extruding the plastic itself, their commitment to providing high-quality non-woven solutions plays a crucial supporting role in ensuring the success and quality of these essential components.

[email protected] 0124-4816111 Corporate Office: Park Non Woven Pvt. Ltd., Gurugram, HR

#non woven battery gaunlets#breather fabric#compressor felt#fiber glass felt#high efficiency media#pet acoustic panel#light weight insulation#pp + pet felt#plastic extrusion profile#lint free wipes

0 notes

Text

The Art of Crafting a Wedding Tent: A Comprehensive Step-by-Step Guide

When planning an outdoor wedding, the tent is more than just a shelter; it’s the heart of the celebration, setting the stage for unforgettable memories. As leading Tent Manufacturers and Suppliers in Indore, understanding the meticulous process behind crafting these tents ensures the delivery of durable, stylish, and functional structures. From material selection to final assembly, here’s an inside look at how wedding tents are manufactured to perfection.

1. Material Selection: Laying the Foundation for Quality

The first step in crafting a top-tier wedding tent is selecting the right materials. Two fabrics dominate the industry: canvas and PVC (Polyvinyl Chloride), each bringing unique qualities to the table.

Canvas: Loved for its natural, rustic appeal, canvas is breathable and eco-friendly, making it ideal for outdoor weddings. However, it requires waterproofing treatments to handle weather conditions.

PVC Texture: For a smooth, present day see, PVC is the go-to alternative. Its weather-resistant and waterproof properties make it perfect for unpredictable climates. It’s also lightweight, allowing for both clear and opaque tent designs.

The tent's framework is equally important, typically made from corrosion-resistant aluminum or galvanized steel. These materials ensure the structure is lightweight yet sturdy, offering the stability required for large wedding gatherings.

2. Design and Customization: Tailoring the Tent to Perfection

Once the materials are chosen, the plan stage starts. Wedding tents can be customized to match the theme and scale of any event, making this stage crucial for creating the perfect ambiance.

Pole Tents: Featuring dramatic peaks supported by central poles, these tents are perfect for large, luxurious weddings, especially when paired with the Best Royal Wedding Furniture Set.

Frame Tents: Without center poles, these offer a flexible layout, allowing for elegant decor such as Wedding Flower Stage Decoration and spacious seating arrangements.

Clear-Span Tents: Ideal for maximizing space, these tents have no interior poles, making them the perfect choice for grand events that require a seamless, unobstructed flow.

With the help of CAD (Computer-Aided Design) software, manufacturers create custom designs that include essential features like windows, doorways, and decorative elements such as a Pink and White Wedding Gate, perfectly enhancing the overall aesthetic.

3. Precision Cutting and Sewing: Ensuring a Seamless Fit

Once the design is finalized, the fabric is cut to exact specifications. Precision is key here—laser cutters or automated machines ensure that each piece fits together flawlessly. This accuracy prevents any issues during assembly and guarantees a clean, professional look.

After cutting, the fabric pieces are sewn together using specialized machines. For fabrics like PVC, heat sealing is used instead of traditional stitching to create watertight seals, ensuring the tent remains leak-proof even in harsh weather conditions.

4. Crafting the Metal Frame: The Skeleton of the Tent

The frame of the tent forms its structural backbone. Aluminum or steel tubes are cut, bent, and welded into shape using high-tech machinery. These components are designed to easily interlock, allowing for quick assembly and disassembly on-site.

If the tent design includes clear sections, such as transparent windows or a decorative Wedding Flower Stage Decoration, clear PVC panels are added at this stage to allow natural light to fill the tent while maintaining a luxurious look.

5. Rigorous Quality Control: Ensuring Perfection

Before the tent is shipped, it goes through a rigorous quality control process. Each tent is fully set up in a designated testing area to ensure:

Fabric Integrity: Checking for any defects like holes or stitching errors.

Structural Strength: Ensuring the frame is strong enough to support the tent under various conditions.

Weather Resistance: Simulating wind and rain to ensure the tent is ready for outdoor use.

Adjustments are made as needed, ensuring the final product meets industry standards for Luxuries Tent Manufacturers and Suppliers in Indore.

6. Packaging and Shipping: Delivering the Dream Tent

Once the tent passes all quality checks, it’s carefully packaged for shipping. The fabric is folded and stored in waterproof containers, while the metal framework is securely bundled to avoid any damage during transport.

Whether shipped directly to the customer or a rental facility, manufacturers often provide on-site setup services or detailed assembly instructions, making the process hassle-free for event planners and coordinators.

Conclusion: The Craftsmanship Behind Wedding Tents

Crafting a wedding tent is an intricate blend of design, engineering, and craftsmanship. From choosing the highest-quality materials to ensuring every seam and joint is flawless, the process results in a tent that is both functional and stunning. For outdoor weddings, these tents become more than just shelters—they are the backdrop for life’s most cherished moments.

At Ranka Tent Suppliers, we pride ourselves on being the premier Tent Manufacturers and Suppliers in Indore. Whether you're in need of a tent with a Pink and White Wedding Gate, a Best Royal Wedding Furniture Set, or stunning Wedding Flower Stage Decoration, we ensure your event is covered with style and grace. By understanding the manufacturing process, you can be confident that your tent will provide the perfect setting for your special day, ensuring your celebration is sheltered in luxury and elegance.

#tent supplier#wedding tent suppliers#luxuries tent manufacturers and supplier in indore#best royal wedding furniture set

0 notes

Note

Roughly in order of scent prominence:

Raw woods, especially the pine they make cheaper, softer planks out of is very aromatic and is one of the dominant smells in most hardware stores, not only because there's sawdust around from cutting, but because the logs and planks are heated by cutting and still have moisture and sap in them.

Plywood, press board, and particle board also smell intensely of sawdust and adhesive and sometimes animal notes (some of these are treated with a urea compound from pig urine that is VERY noticeable to some people)

Go sniff around in the lumber section and see if wood smell is the bulk of what you're going for.

If it is, you might want to check out the perfumer Pineward. They're an independent American perfumer who specializes in wood and forest smells. They make more than a few amazing scents but specifically their scent Gristmill smells like a room full of fresh cut wood still hot off the mill.

Other scent elements prevalent in a hardware store are:

WD-40, obviously

Orange Soap (this is a rough soap used for cleaning grease off of stuff and often off of hands. A favourite of handy folks and mechanics)

Murphy's Oil Soap (for floors and other wood pieces)

Mineral Oil (this is what tool handles and other raw pieces of wood that are used without stain or lacquer coat get coated in to preserve them. It's also a good all purpose solvent for oil soluble things like adhesives, resins, and gums so you are likely smelling mineral oil having a chemical reaction with other things)

Metal polish/brasso (this stuff has a subtle smell unless you're actively using it, but if your hardware store sells things like drawer pulls and metal light fixtures it's likely everywhere)

Glass cleaner (especially if they sell windows and/or mirrors)

Potting Soil, fertilizer, and Peat Moss (each of these alone is distinct and pungent and maybe not as pleasant, but together they make the base of the comforting smell of the garden section)

Vinyl and PVC (there's piping, of course but also think window frames, flooring, and weather stripping. These offgas a lot)

Plastic and rubber hosing and irrigation tubing

Steel (seriously there's so much of it, also most hardware stores cut keys so there's often an element of hot metal in the air)

Coffee (this really cannot be understated as an element. Pretty much every person in a hardware store at any time is carrying the stuff, sweating the stuff and stained with the stuff, employees and patrons alike. My fav Ace store has a coffee machine directly behind one of the register counters and that thing chugs along all day)

I haven't tried either of these but apparently Solstice Scents - Sawmill and Olympic Orchids - Woodcut are beloved scents amongst the hardware store smell enthusiast perfume community. They're also both heavy on the cut wood notes, but have a mix of other stuff going on. Sawmill does list motor oil as a note.

If you're looking for something more comprehensive to the above notes than just wood, you might want to try layering a cut wood perfume with an adjacent favourite of the niche perfume world, the car mechanic/garage scent which will have those metal, rubber, and oil notes more prominently. Sadly, I don't have recommendations for these as my favorites have been discontinued, but there's a TON out there and perfume subreddits have plenty of recommendation threads about them.

One time I noticed that the ace hardware has a really good smell

and I’ve been trying to figure out what the smell was and how I can replicate it since?

possible leads

-Smells like WD-40 by MSCHF

-Sawdust by Demeter

Well I have GOT to say that I support this ambition, but I know zero things about smells. I live with someone (Dr Glass) who perceives scented stuff as highly threatening and, for example, won’t set foot in Lush.

However, some people I know on here have gotta be smart about this stuff, so I’ll toss it out to the general public and see if anyone knows how to smell like Ace Hardware. I think grass seed and rubber are probably strong pieces of it too.

323 notes

·

View notes

Text

Exploring the Versatility of Plastic Extrusion Products Directly from Manufacturers!

In Australia, plastic extrusion products are utilised primarily for safeguarding industrial machines in automobile development, electric and electronics, aviation and military, marine and boating, healthcare, agriculture, and a few other private sector businesses.

Because they specialise in producing plastic extrusions with remarkable endurance and flexibility, reputed manufacturers provide a guarantee of the product's effectiveness and security throughout usage.

On the other hand, the plastic extrusion process provides various benefits to firms looking to make high-quality items efficiently and cost-effectively. One of the primary benefits of plastic extrusion is its adaptability.

The procedure can be used to make everything from simple smooth tubes and profiles to sophisticated forms and designs including perforated tubes, circular wraps, heat-shrink, and solar conductors.

Reputable manufacturers frequently use substances such as polypropylene, LDPE, HDPE, ABS, polyamide, PVC (flexible & rigid), polycarbonate, thermoplastic polyurethane, PBT, and TPEs in the process of extrusion, enabling them to make a wide range of items for different industries.

The plastic protrusions, in particular, have a wide range of applications, including blow-moulded extrusion corrugators for corrugated tubing, standard plastic extruders for tube, cable, and profile-producing goods, vacuum testing for complex shapes, and co-extrusion for multi-layer or multi-coloured products.

Furthermore, plastic extrusion provides remarkable uniformity in product quality, allowing companies to produce large quantities of products with little variation.

The use of multiple materials in the extrusion process allows producers to develop top-quality UV-protected products with unique features, such as longevity and can withstand harsh weather and chemicals.

For instance, when these plastic extrusions are used in large transport vehicles, cars, or aircraft, they do not break down by changing their physical state and shape and never lose their natural elasticity.

These features make their plastic extrusion products appropriate for a wide range of applications from building door frames and window profiles to pipes and electrical enclosures.

Therefore, contact a reliable manufacturer and get suitable products for your business needs.

Source

0 notes

Text

Top 10 Must-Have Tools For Any DIY Project

Top 10 Must-Have Tools For Any DIY Project

Have you ever had an urge of wanting to build something? Something unique or something custom. But the cost of ordering a custom design is just too much. So you decide to take matters into your own hands. But don’t know where to begin? Well, we are here to help you. We can help you with this expedition of creating something custom and unique right at your home. This article will explore the top 10 tools you require for any DIY Project.

Top 10 Beginner Friendly DIY Tools

· Tape measure

A tape measure or measuring tape is a flexible tool, used for measuring length. Depending on whether you want to use it for general household DIY or for professional use you can either get the 30m tape measure or the 50m tape measure.

· Adjustable spanner

An adjustable spanner is an open-ended wrench with a movable jaw that can be adjusted to any size. It is advised to get an adjustable spanner set for home use as it saves you from getting an entire wrench set from which you will have to sort through to get to the right sized wrench that you need.

· Wrench

Having a wrench for home projects can come in very handy. They are generally used for gripping, fastening, turning, tightening and loosening things like pipes, pipe fittings, nuts and bolts. This not only assists you in your DIY urges but will also help in home renovations and fixing.

· Utility knife

A utility knife; also called a box cutter, a razor blade knife, a carpet knife, or a stationery knife; is a common tool used in various trades and crafts for a variety of purposes. It is a safe-to-use tool as it is covered with a PVC handle and can only open when certain buttons/levers are moved.

· Screwdriver

A screwdriver is used to insert or remove any screws. It is advised to have a screwdriver set for easy repair of any cracks or broken windows or hinges. Not only that, they can also be used for creating any connections in your DIY Projects and leave no loose screws.

· Hammer

A hammer for DIY Enthusiasts is as useful as their dominant hand. You can use this for used for general carpentry, framing, nail pulling, cabinet making, assembling furniture, upholstering, finishing, riveting, bending or shaping metal, striking masonry drills and steel chisels, and so on. With so many uses, it is a must-have item in your toolkit.

· Drill machine

Moving on to power tools, a safe-to-use drill machine is a must-have for all DIYers. Why? Because it is used to cut holes into or through metal, wood, or other materials. Not only that it can also be used to create small attachments and other home projects where you have to hang something on a wall.

· Circular saw

The most common function of a circular saw is to make cuts in a straight line on pieces of lumber. A circular saw is most suitable for any type of woodwork. Especially for people who are new to DIYing and don’t know how to cut straight pieces, this tool is very handy.

· Angle grinder

An angle grinder for home renovation can make your home look new and shiny. It is used for grinding, polishing, cutting and a lot more. This multi-use tool is a must for your DIY toolkit, especially if you want it to turn into a regular activity.

· Jigsaw

A jigsaw is used for cutting metal, wood, resin and almost all materials. As a result, when you want to create some funky shapes or some unique design that is only in your head, you can use this tool and bring it to life.

Must Haves In Your Safety Kit

Safety is the most important thing when it comes to any and all types of DIYing. You need to make sure that you are taking care of yourself and are using safety equipment like goggles, gloves, etc. As the saying goes, “Safety First”, you must have a safety kit wherever you are doing some form of home renovation or DIY Project. Along with that make sure you also have a medical kit with bandages, gauze, and disinfectant at your place, in case of any injuries.

Links:

https://atozshop.co.in/?s=tape%20measure

0 notes

Text

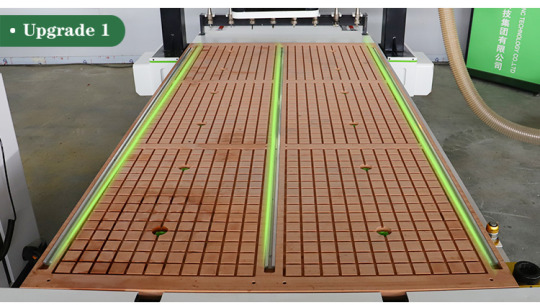

4 X 8 Linear Atc CNC Router with Automatic Tool Changer

This is the 2022 latest linear ATC CNC router machine, this machine has CNC router tool changer, so its tool change time is very short, which can save a lot of tool change time and improve machine processing efficiency. It has built-in eject pins and a controllable dust cover with built-in machine lubrication system for accurate material loading every time. So this machine can process wood, MDF, particleboard, plywood, OSB, melamine board, etc. It is widely used in cabinet manufacturing industry. It can also process acrylic, plastic, soft metals and many other different materials.

4x8 cnc router with vacuum table

CNC linear cutting machines is used for decorations, musical instruments, wood crafts, wood furniture, wood door making, cabinet making, windows, and tables. Now the best linear ATC wood CNC machine for sale at affordable price.

The ATC CNC router machine is equipped with a 9.0kw air-cooled spindle, and two tool change methods are available: linear tool change and disc tool change. Usually used in conjunction with labelling machines and automatic loading and unloading platforms.

This 4x8 CNC machine has a rotary device equipped on the one side of working table. When users need to process cylindrical materials, they can clamp the cylindrical piece onto the rotary device. Then rotary device rotates and at the same time the spindle engraves on the surface of the work piece. This machine with rotary device is suitable to process cylindrical materials. Users can design and make beautiful cylindrical sculpture crafts with it.

This is the professional linear ATC CNC router, this ATC CNC router with tool changer, so this machine has very high machining speed and cutting precision, and this 4x8 CNC router is equipped with a 9KW(12HP) air-cooled spindle and a 12 High-speed tool changers, these can be used to perform complex and diverse machining tasks. If you would like to own a linear ATC CNC router, then please contact us.

Hot applications of Industrial CNC Router With Auto Tool Changer:

>Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

>Wooden crafts industry: clock and watch frames, craft photo frames, calligraphic cards, electrical counter-tops, sporting equipment, thin aluminum plate engraving and carving;

>Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

0 notes

Text

#PVC window frame making machine#PVC window profile machine#PVC window frame production line#PVC door frame making machine

1 note

·

View note

Text

Cabinet Making CNC Machine/ CNC Kitchen Cabinet Wooden Door

The cabinet making cnc machine is our newly-developed CNC Router with combined function of material loading and unloading for cabinet-making, widely used in home decoration, shop and office furniture. It is equipped with Italy HSD Spindle, Italy Boring unit and advanced Syntec control system, Japanese Yaskawa servo and Taiwan reducers.

Custom and general Cabinet Making Machineis one of the most popular applications for CNC routers. IGOLDENCNC CNC routers have brought industry standards to a new level with our quality and components, delivering what you would find in much higher-priced CNC routers at a cost competitive with the less industrial designs.

📷

Features of Cabinet Making Machine:

* Square tube lathe bed with more solid structure and strong stability because of low center of gravity.

• Vacuum table in 4zones can fix materials of different sizes effectively.

• Taiwan TBI balls screws, HIWIN square guide rails, high precision, large load bearing and stable running.

• Gantry-travelling, sturdy, reliable and stable, non-deforming, high locating accuracy.

• Mach3 control system, with computer controlled, very stable.

• Unique ability to save several point of origin on several workpieces.

• No engraving saw-tooth, smooth undersurface, legible contour, by high-power spindle.

• Auto seeking original point system, a good way to improve the working effeciency.

• Large compatibility of drawing software, such as Type3, artcam and some other CAD or CAM.

Cabinet Making Machine application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Model

1325 CNC Nesting Machine

Working area

1300*2500mm

Spindle

ATC 9KW HQD air cooling spindle

Inverter

Fuling

Motor

Dorna servo motors

Driver

Dorna servo driver

Control System

Taiwan LNC control system

Table

Double layer Vacuum table + position cylinder + secondary dust collection + Pusher system

Oil lubrication

Automatic lubrication

Limit

Omron limit

Transmission

XY axis Taiwan helical rack Z axis Taiwan ball screw

Rail

X,Y,Z axis Germany Square guide rail

Screw

Z axis TBI ball screw

Bed

Thick steel welded big square tube

Gangry

Strong frame

Pillars

Steel pillar(Suitable for high-end customers)

Cabinet

Independent cabinet

Voltage

3 phase/380V

Color

As requirement

Tools

1 box(10 pieces)

Company Information

Jinan iGolden CNC Equipment Co.,Ltd. is a R&D,manufacturing,sales integration company that specializing in router cnc, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc.We adopt international advanced producing technologies to improve our products.Our products are widely used in advertising,woodworking, artworks, model, electric, CAD/CAM Industry Model, Clothing, Package Printing, Marking, Laser Sealing and so on.And welcome to visit us for more choices.

2 notes

·

View notes

Text

10 Amazing Things You Can Do With Custom Neon Signs

How much do you understand about custom LED neon sign; custom bar signs neon;

Neon signs are a staple of any modern business. Whether you’re promoting your new shop on the street or just want to add a little extra flare to your bar, neon signs are a great way to do so. But what if you don’t have any neon sign supplies at home? No problem! In this post, we’ll show you 10 amazing things you can do with ( custom neon signs ) that you might never have thought of before. So get creative and let your neon signs do all the talking!

What are custom neon signs?

Custom neon signs are perfect for any event. From weddings to birthday parties, they really add an extra level of excitement. Here are some amazing things you can do with custom neon signs: You can use them as a decoration for your party or event. You can use them as marketing tools. You can use them to promote your business.

Types of neon signs

Neon signs are a popular way to advertise and let people know about your business. Neon signs come in many different shapes and sizes, so there's bound to be a sign that would fit your needs. Here are some of the most common types of neon signs: -Decal neon signs: These are the simplest type of neon sign, where you just place a decal on a window or door. -Poster neon signs: These are similar to decals but instead of being attached to the surface, they're suspended from the ceiling or walls. -Plaque neon signs: These are similar to poster neon signs but they have metal frames that make them look more official. -Lighted neon signs: These are the fancier type of neon signs and they usually come with light fixtures inside them. They're perfect for businesses that want to give off an air of luxury or sophistication.

How to make a custom neon sign

Making a custom neon sign is a great way to show off your creative side and make a statement about your business. Here are some tips for making the process as easy as possible: 1. Choose the right material. Neon signs are typically made from PVC or metal, and both materials have their own advantages and disadvantages. PVC neon signs are cheaper and more versatile, but they can be less durable and may not last as long as metal neon signs. Metal neon signs are heavier and more expensive, but they're also more durable and look nicer. It's important to choose the right material for your business and budget accordingly. 2. Get started with sketching. Before you start cutting any fabric or tubing, it's important to have a rough idea of what you're aiming for. Draw out your design on paper or CAD software, then transfer it onto the material you'll be using. If you're using PVC, make sure to adjust the dimensions so that the seams will be hidden when the sign is installed. 3. Cut out the pieces with a laser cutter or CNC machine. Once you've got your design cut out, it's time to start assembling your neon sign! Use screws, nails or wire ties to attach the various pieces together, then secure them with painter's tape if necessary in order to avoid water damage later on. 4. Install your neon sign! Now all you need is some bright lights and your business will be ready for attention!

What to do with a custom neon sign once you have it

If you've ever wanted to create a one-of-a-kind neon sign, but weren't sure where to start, this guide is for you. In this article, we'll show you how to get started with custom neon signs and some of the amazing things you can do with them. First, decide what type of Neon sign you want to create. There are many different types of Neon signs available, from simple letters and numbers to full-blown graphics. Once you decide on the style of your Neon sign, find a supplier who can build it for you. Once your Neon sign is ready, it's time to get creative! You can use your Neon sign for all sorts of purposes - from advertising your business or event to adding a little bit of fun to your home. And don't forget - custom Neon signs make great gifts!

Conclusion

Neon signs are one of the most popular and versatile pieces of outdoor advertising out there. With all sorts of creative ways to use them, neon signs can be a powerful tool for your business or event. Here are 10 amazing things you can do with custom neon signs:

0 notes

Text

5 easy ways to create your home more energy efficient

Making your home more energy efficient can be fun as well as practical. Most people don't think about their energy consumption at home, but it's important to do your part to save on bills. Do you want to expect your home to be more energy efficient but feel like you don't have time? Here are five easy ways to create your home more energy efficient:

Five easy ways to create your home more energy efficient

1. Use a programmable thermostat

When I say programmable, I don't mean programs for pets or kids! Programmable thermostats allow users to set temperature schedules based on the time of day, weather conditions, and occupancy levels. You can use the built-in sensors to remotely control your heating and cooling system if you're away from home or asleep at night. Even if you're using them to save money (and who doesn't want that?), they'll help reduce the electricity you use and save you some cash.

2. Change out old bulbs

You've probably heard this tip before, but did you know that many traditional incandescent lightbulbs still work just fine? So long as they have not been changed in 15 years, they can hold their own against newer LED lighting and sometimes even CFLs. If you need to replace these bulbs, try looking for ones that are Energy Star certified. These bulbs offer higher lumens per watt than standard bulbs, which means they consume less power and produce less heat.

3. Insulate ductwork

Ductwork carries heated air throughout your house, bringing it back down where needed. But the way it does this is inefficient—it can transfer 80 percent of its heat through the ducts and only 20 percent of it into the room being cooled or warmed. To improve efficiency, you should insulate around the exterior of the ducts to prevent the warm air from escaping into neighboring rooms. Plus, if the ducts are well insulated, they won't radiate quite as much heat into surrounding spaces.

4. Seal cracks & gaps in windows & doors

The best solution for sealing out cold drafts is caulking. Caulk comes in two varieties—polyvinyl chloride (PVC) and silicone. Both types provide good long-term protection, but PVC gets brittle over time. Silicone provides superior performance; however, it may require periodic reapplication. Both options are available in adhesive or caulk gun form, so you can apply them yourself. Be sure to seal any joints between framing members, including those behind switches and outlets.

5. Install a solar thermal water heater

Solar thermal water heaters use the sun's rays to create steam. As the sunlight heats the collector tubes, it turns into water vapor. The hot water then circulates through pipes to your shower, washing machine, tub, or wherever else you want. Because this type of technology provides a continuous hot water supply, you can avoid having to wait until nighttime to shower. And unlike typical electric water heaters, these systems can reduce peak electrical demand. In addition, they are easier and cheaper to install.

With these five tips, you can keep your home cool without running up big utility bills. And if you think about it, it makes sense. After all, how often do we really take advantage of accessible, natural energy sources? When was the last time you left an open window overnight or took a chilly dip in the pool?

In conclusion, there are a number of Easy Ways To Increase Energy Efficiency At Home. Some simple changes can help you cut down on your energy bills and help the environment too. Check out our tips to get started and prepare your home for winter!

0 notes

Text

Reciprocating Saw Uses Guide

Reciprocating saws are versatile for remodeling and demolition. They are excellent for cutting away unneeded materials any hardware you need to redesign or detach.

It works just like a hacksaw but operated by a machine. They are good to use for windows, walls, frames, doors, plumbing system, roof, and many more. Even demolition firms recommend this nifty saw since demolishing doesn't require any precise cutting method.

Thus, this type of saw is perfectly fit for the job due to its inability to cut accurately.

What we mentioned above is just the general purpose of the reciprocating saws. Experienced hobbyists, carpenters, engineers, and seasoned homeowners often use the saw for numerous purposes that you will surely find useful once you check them out below:

Floor Removal

Flooring, such as tiles and wallpaper, is easy to remove due to the saw’s motion that goes back and forth, along with its motor power.

It can be used as an "automatic" scraping blade thanks to its push and pull mechanism. Sturdy floorings such as linoleum and ceramic tiles can be removed cleanly from the floor once you operate the saw at its sides.

The motor’s strength can easily loosen the tiles, even if glued shut for several years. It’s also guaranteed to be less messy than using scraping blades.

Cutting Metal Pipes

You can easily remove PVC pipes using reciprocating saws. However, both electricians and plumbers often use this power tool to cut down metal pipes as well.

Even AC installers treat this as an optional tool when lessening the size of the appliance’s pipes. A double-faced blade for plunge cuts is the best accessory to attach for additional cutting precision.

Otherwise, you can buy the most durable blades instead to make the pipework much better.

Window and Door Installation

Beginners in DIY construction or hardware installation tend a common mistake of miscalculating measurements, particularly when attaching a door or a window.

This is where the reciprocating saws come handy because they can cut down the doors, windows or their respective frames to install the hardware correctly.

All you need to do is to shave some areas of the equipment to fit doors and windows.

Use Different Accessories WIth It

You can resolve the problem of imprecise woodcuts only by attaching a scraping blade to the saw.

The saw's back-and-forth mechanism can adjust adjusting the shapes of materials by tossing out the smallest unwanted parts away.

Sanding paper is also a handy accessory for the saw when working on wood finishes or scrubbing away sturdy rusts after cleansing it with a solution. It can also help you when gardening if you use specialized blades for tasks such as pruning.

Grooming Your Plants

Other homeowners also use the saw as an optional gardening tool. The elderly and those who are suffering from muscle pain can groom plants once again with this "automatic" pruner. You can remove or trim bushes and trees alike without too much effort.

youtube

It also helps you balance, particularly when reaching high branches, which is impossible to do with chainsaws.

Additionally, you only need to use one hand when operating the saw to help you balance much better, especially when you're on top of a ladder.

The following uses can make the reciprocating saws a convenient tool not just for renovation and demolitions.

3 notes

·

View notes

Text

Reciprocating Saw Uses & Buying Guide

Reciprocating saws are versatile for remodeling and demolition. They are excellent for cutting away unneeded materials any hardware you need to redesign or detach.

It works just like a hacksaw but operated by a machine. They are good to use for windows, walls, frames, doors, plumbing system, roof, and many more.

Even demolition firms recommend this nifty saw since demolishing doesn’t require any precise cutting method. Thus, this type of saw is perfectly fit for the job due to its inability to cut accurately.

Reciprocating Saw Uses

What we mentioned above is just the general purpose of the reciprocating saws. Experienced hobbyists, carpenters, engineers, and seasoned homeowners often use the saw for numerous purposes that you will surely find useful once you check them out below:

Floor Removal

Flooring, such as tiles and wallpaper, is easy to remove due to the saw’s motion that goes back and forth, along with its motor power.

It can be used as an "automatic" scraping blade thanks to its push and pull mechanism. Sturdy floorings such as linoleum and ceramic tiles can be removed cleanly from the floor once you operate the saw at its sides.

The motor’s strength can easily loosen the tiles, even if glued shut for several years. It’s also guaranteed to be less messy than using scraping blades.

Cutting Metal Pipes

You can easily remove PVC pipes using reciprocating saws. However, both electricians and plumbers often use this power tool to cut down metal pipes as well. Even AC installers treat this as an optional tool when lessening the size of the appliance’s pipes.

A double-faced blade for plunge cuts is the best accessory to attach for additional cutting precision. Otherwise, you can buy the most durable blades instead to make the pipework much better.

Window and Door Installation

Beginners in DIY construction or hardware installation tend a common mistake of miscalculating measurements, particularly when attaching a door or a window.

This is where the reciprocating saws come handy because they can cut down the doors, windows or their respective frames to install the hardware correctly. All you need to do is to shave some areas of the equipment to fit doors and windows.

Use Different Accessories WIth It

You can resolve the problem of imprecise woodcuts only by attaching a scraping blade to the saw.

youtube

The saw's back-and-forth mechanism can adjust adjusting the shapes of materials by tossing out the smallest unwanted parts away.

Sanding paper is also a handy accessory for the saw when working on wood finishes or scrubbing away sturdy rusts after cleansing it with a solution.

It can also help you when gardening if you use specialized blades for tasks such as pruning.

Grooming Your Plants

Other homeowners also use the saw as an optional gardening tool. The elderly and those who are suffering from muscle pain can groom plants once again with this "automatic" pruner.

You can remove or trim bushes and trees alike without too much effort. It also helps you balance, particularly when reaching high branches, which is impossible to do with chainsaws.

Additionally, you only need to use one hand when operating the saw to help you balance much better, especially when you're on top of a ladder.

How to Choose Reciprocating Saw

Choosing a reciprocating saw shot must require certain factors to consider. All you need are the following specifications in order to acquire the best type of saw that will be perfect for your wood cutting hobbies:

Performance

The performance of your reciprocating saw is very important. The factors that affect this are the stroke length and its cutting speed.

The stroke length should be set at 1 1/8 to 1 1/4 inches. You also need to find a cutting power of 3000 strokes per minute. The saw should be efficient as well, which is why you need to use a blade changing mechanism for an easier means of switching the blades.

A reciprocating saw with an orbital action is also efficient as it makes cutting faster as well.

You can compare different reciprocating saw shots based on performance alone. But if you need to focus on its usage, especially when working on long projects, then the two other factors are also important to observe.

Motor Power

Battery-powered tools have strong performance that’s fit for heavy duties.

That’s why you8 need to check reciprocating saws with an amp motor ranging from 7 to 15. Picking a reciprocating saw shot needs to provide a powerful motor that can cut materials with ease.

Battery

You will need voltages for your amperes. That’s why you need to pick a strong type of battery ranging from 12 to 36V.

To easily figure out the performance of your battery when being used on a reciprocal saw under a certain motor power, simply look for the watt hours by multiplying the batter’s voltage with the amp hours of your saw’s motor power.

The reciprocating saw is a convenient tool that’s not just for renovation and demolitions. Keep in mind that you can improvise anything using a power tool only by exploiting its mechanisms and specs.

In the case of reciprocating saws, its back-and-forth motion is excellent for performing different tasks, such as the ones we mentioned, with better precision and speed.

1 note

·

View note

Text

PVC window frame making machine

PVC door/window frame profile making machine is one of our advantage products , xinda precision machinery company has focused on plastic machinery over 21 years with rich experience and strong technology , our machinery exported to 25 countries , such as Iran , Turkey , Vietnam , UAE , Africa , Germany , America , etc.

we continue to perfect the design and quality , ensure the top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner ! please contact Mr John Yu to get more details .Mr John Yu +86 13301561523 ; Email : [email protected]

The PVC UPVC profile making machine consist of twin screw extruder , vacuum calibration device , hauling off machine , automatic cutter , tipping table . the main spare parts adopt the top quality famous brand , such as ABB converter , SIEMENS motors , SCHNEIDER electric parts , OMRON temperature meters , etc . special design the screw and barrel , it’s high efficiency extrusion and easy to disassemble for maintenance . it can process the PVC powder or PVC + wood powder .

#PVC window frame making machine#PVC window profile making machine#PVC window frame production line#PVC window machine

1 note

·

View note