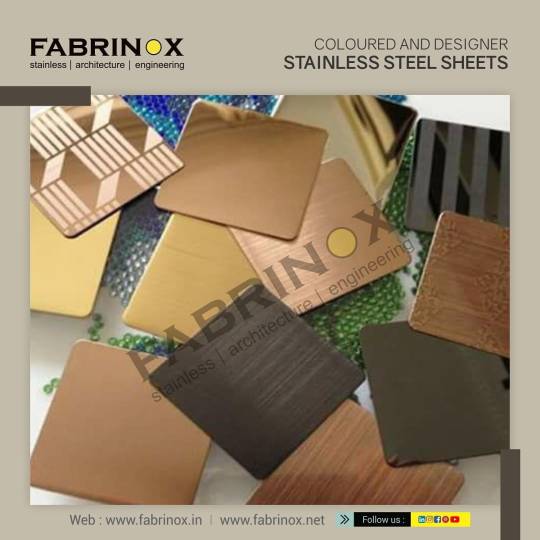

#PVD Colour Stainless steel sheets

Text

Stainless Steel C Patti

Decorative SS “C” Profile Sections are made by CNC Bending. Before Bending, these Sheets are cut to their required sizes by Laser Cutting Machines. Our SS C-Profiles Grooving is done on Metal Sheets before bending them. By following this Process, we can achieve 90 right angle on the bend area.

Our Profile Sections are also available in various colours as per your Requirement. Decorative SS “C” Profile Section are used in many Applications such as exterior cladding, interior decoration, Skirting, Wall Edge Protection, Floor Partitions, Wall Partitions and Many More.

Sterlite Metal and Tubes Brand Stainless Steel Decorative pvd Color Coated trim C profile starts with C - 4 to c - 200 . It is created utilizing Stainless Steel concealing sheet.

0 notes

Text

Exploring The Different Applications of PVD Coatings

In the industry of metals and finishing, PVD coating holds extreme importance which boosts its uses across numerous industries. The main reason behind this is PVD coatings do not corrode very soon and it is free from normal wear and tear. These features make PVD coating a wonderful one. If you are eager to know the products on which these coatings are applied, then we must say that you are on the right page. This is because, in the next segment, we will explore some notable applications of PVD coatings.

Also Read : Different Methods of Sheet Metal Formation in Different Projects

Automotive Industry

In recent years, no one can deny the significance of fuel economy. As a result, automotive brands concentrated a lot on weight reduction and power loss due to friction. These factors become extremely vital in motorsports. PVD coatings are applied to automotive parts as they are more prone to corrosion, rust and other damages. Applying PVD coating to automotive parts can surely increase their shelf life.

Fashion & Decorative Industry

Now you may wonder, how PVD coatings can be used in the fashion industry. To answer this question, we need to keep in mind that the fashion industry doesn't only mean clothes, it also includes accessories and other decoratives. Watches, chains, jewellery, and metal decorative items of our home use PVD coatings to increase their functionality and looks. Most brands use stainless steel fabrication for furniture for better protection.

Sanitary Sector

The next sector that uses PVD coatings on a large scale is the sanitary sector. PVD coating is applied on numerous bathroom fittings faucets, sanitary ware, basins, door hardware, and ceramic products to increase their appearance. In comparison to conventional electroplated coatings, PVD coatings are stronger, more resistant to corrosion, wear and tear, and never fade. The most fascinating aspect of PVD coatings is they never get damaged while staying under UV radiation too.

Machinery Sector

Application on metal cutting tools is one of the most popular uses of PVD coatings. Metal-cutting tools are products that require sharp-edged coatings and PVD coatings fit this criteria very well. PVD-coated tools offer better performance, strength and resistance against any sort of damage and bad weather conditions.

The forming tool is another sort of machinery that needs immense resistance against damage, wear and tear, and heat allegations. PVD coatings possess the capacity to offer a product with all these qualities. This is why, PVD coatings are applied on most forming tools to prevent their possible damage.

Injection moulding tools are tools that are produced by injecting molten material into a mould. This procedure can be performed with numerous materials such as glasses, confections, elastometers, and thermoplastic polymers. PVD coatings are also applied to these tools for better protection.

Also Read : Tips for Cleaning the Custom Steel Fabrication Accurately

Glass Industry

Glass is a material that plays a pivotal role in making numerous products such as TV screens, computer monitors, sunglasses, data displays, windows, interiors, utensils and so on. However, the quality of the glass can be improved by applying further coatings like PVD.

As of now, you may understand that PVD is a superior category of coatings. PVD coatings can be varied in terms of colour and functionality including Rose Gold PVD.

Full Audio: Listen Here

For Direction: Click Here

#stainless steel fabrication for luxury furniture near me#stainless fabricators for furniture near me#furniture fabrication#pvd coated furniture#pvd coating service Bangalore#pvd coating glass

0 notes

Text

6 Useful Tips To Identify The Quality Of Stainless Steel Sheet

A versatile fabrication material, stainless steel sheet is lightweight, highly strong, and can be shaped into a variety of shapes. These metal sheets are lightweight and simple to handle, but they are also incredibly strong and corrosion-resistant. There are many different grades of stainless steel sheets, each with unique properties and bronze PVD coating. There are numerous methods for determining the stainless steel sheet’s quality. If you want to buy it for a business venture or your architectural project. A magnet, copper sulphate, and color are used in these tests.

By employing these techniques, you may be certain that the sheet you’re about to buy is constructed of the best possible materials.

Durability

Metals like stainless steel are incredibly resilient. It is more corrosive-effects resistant than other metals. Therefore, determining a stainless steel sheet’s endurance is crucial. Although it has a variety of various metal appearances, stainless steel is much more resilient than aluminium. Once its coating is damaged, aluminium can develop pits or rust, whereas stainless steel does not have this issue.

The alloy composition can be used to gauge the stainless steel’s durability. Alloys must adhere to the requirements set forth by the regulating body. The SAE system’s governing body establishes standards for stainless steel. The most popular stainless steel grades are 304 and 316. Each grade has a slightly unique chemical make-up and physical characteristics.

With Copper Sulphate

Finding copper sulphate is one approach to assess the quality of stainless steel. Both austenitic and ferritic steel can be distinguished using this technique. It works well to spot stainless steel sheets with a lot of manganese in them. The material’s surface needs to be completely cleansed of oil and other pollutants before the test can be conducted. After that, the substance is covered with a drop bottle containing a solution of copper sulphate and PVD company. The results of the test will show if the metal is stainless steel or carbon steel. If it’s made of carbon steel, a layer of copper will form on the surface; if it’s made of stainless steel, neither precipitation nor a copper hue will appear.

Identify The Quality Of Stainless Steel By Color

Stainless steel is a fantastic material that can be used for both interior and exterior decoration. Choosing from a variety of coloured stainless steel sheet options is a terrific way to add color to your design. The best materials are used to create these sheets, which are produced to the highest standards.

Also read about, What Is Chromium Plating? How Is Chrome Plating Done?

Quality With a Magnet

A magnet cannot be relied upon to determine the quality of a stainless steel sheet. A thorough analysis of the stainless steel substance is required. Checking the original papers, including invoices, is the first step. The steel number is typically stamped on these documents. The price of steel should then be compared to that in your area. This approach is more precise. Mastering the procedure will also help you avoid exaggerating the quality of a substance.

Annealing Method

The annealing process is one of the most crucial factors in determining the quality of a stainless steel sheet. A controlled heat procedure called annealing softens and resets the characteristics of the material. Usually, this procedure comes just before a manufacturer begins rolling the sheet. Additionally, it makes the material simpler to handle and utilize when setting up tools. Small changes in aging temperatures can have a big impact on the quality of some steels, which are heat treated to boost their strength and durability.

Conclusion

In addition to steel’s traditional properties, stainless steel has corrosion and heat resistance. It has all of the benefits of steel plus a few of its own. It is less prone to corrosion, can withstand harsh environments better, and has a longer service life.

It is not, however, completely stain-proof. To begin, corrosion resistance is grade dependent. However, abnormal environmental conditions such as low oxygen, poor circulation, and high salinity can permanently stain it.

SurfTech INC is capable of selecting and implementing the best stainless steel product for you, and we provide Assisted PVD coating, thin film coating, and ceramic coating facility in the United States. Contact us today for a quote, to learn more about our process, you can call us on +1-440-275-3356 and email us on [email protected].

REFERENCE URL, https://bit.ly/3Xg9qsv

0 notes

Text

STAINLESS STEEL KITCHEN

Stainless steel, which was historically only used in building as a base material, is slowly gaining prominence in the design of modern kitchens. While they have been used for many years by commercial kitchens, primarily for their strength and ease of maintenance, domestic kitchens are increasingly opening up to the possibilities offered by stainless steel kitchens.

Fabrinox is the industry leader in the manufacture and supply of mobile kitchens made of stainless steel. Their creative team gives your kitchen a streamlined, sleek look to make your cooking experience trouble-free.

The use of honeycombs in the stainless steel kitchens enables them to provide unmatched SS kitchens with the following characteristics:

Stainless steel kitchens denote robustness and quality which is the key reason for their use.

These kitchens are functional and reliable, they wear and tear and stain that most Indian kitchens witness.

Stainless steel kitchens are heat-resistant and can withstand temperature vagaries in cooking that many other materials are unable to handle.

They are easy to clean and maintain, do not rust easily and can be cleaned with any sort of cleaning agents on them.

Metallic highlights match well with every color scheme, from light and colorful spaces to solid, dark palettes.

They also tend to establish an elegant modern look with paint or wood accents.

They have a light structure and are also recyclable.

Safe due to fire-resistant properties.

Work easily due to excellent flatness.

Avoids any energy jerk due to good thermal & electrical conductors.

There are a few other factors as well that makes the stainless steel kitchen stand out in comparison to other types of kitchen:

Low support:

The high stainless steel solidity makes holding up substantially easier. The most real harm to it is scratching and can be removed with copper or metal cleaners. Whatever the amount of time it is usually washed, flushed, and dried, you can see it will go on for quite some time.

High toughness:

Steel is now an extremely severe metal unlike anyone else, and its refusal to bend or crack makes it genuinely fair for professional use. The stainless angle originates from its chromium mix, which interacted with the air to form a chromium oxide coating on its surface. It protects the steel from dust and heat, which prevents the item from rusting. Stainless steel is also able to withstand high temperatures, and its impermeability to fire makes it suitable for use in the kitchen close to the range of cooking appliances.

The stainless steel items by Fabrinox are rigid and hard, ideal specifically as the stuff holder for the entire kitchen. They use honeycombs of high quality to create the kitchen cabinets for the crockery and other items. All the products their production unit manufactures are durable and recyclable even after use. They ensure to deliver style & comfort and you can also select from a wide collection of designs and accessories.

youtube

#Stainless steel kitchen#PVD stainless steel Partitions#3d pattern stainless steel sheet#Modular stainless steel kitchens#designer tables#PVD Stainless steel designer doors#PVD Colour Stainless steel sheets#Bead blast#Cross hairline#Vibration finish#antique finish pvd#antique finish sheets#PVD wall art#Fabrinox

1 note

·

View note

Text

WHAT IS STAINLESS STEEL USED FOR? | Fabrinox

Stainless Steel sheet is one of the most versatile metals available. It is durable, has high tensile strength, is affordable, and is comparatively easy to work with. It is a steel alloy containing at least 10.6% chromium, which gives the stainless steel its anti-corrosion and anti-staining properties.

The stainless-steel sheet is only ¼ inch thick. If it gets thicker than that, it's called a "plate." Stainless steel sheet comes in many variations, each with different advantages and disadvantages.

Ferritic, duplex, 200 Series Austenitic, and 300 Series Austenitic are a few types of stainless steel sheets. Stainless steel can be used in products, from electronic to high-range industrial applications. Working with this metal is relatively easy, but it depends on why you use it. It can be cut, bent, or welded, but each requires different precautions and heating temperatures, and the sheet is thin.

USES OF STAINLESS STEEL SHEET: -

PVD Colour Stainless steel sheets can get molded into various shapes and sizes for making cookers, sinks, pots, and many other cookware items.

It is used in making license plates for vehicles.

It is used to make food storage containers as it is corrosion resistant, so it is unaffected by acidic food, and steel does not affect the flavor of the food.

Stainless steel sheet is used in the construction, aerospace, and architecture industries.

It is used in making surgical tools and medical equipment.

It is also used in making the body panel of cars, bikes, and other vehicles.

It is used to make electronic gadgets like phones, laptops, and TVs.

It is also used in science laboratories and nuclear power plants.

It is used in the construction of bridges, light bulbs, etc.

Stainless steel is chosen for various reasons: it is machinable, customizable, and comparatively more affordable than sheets of other metals. Especially in India, stainless steel production is rapidly increasing cause of its numerous uses.

Also, read:

Designer Metal Sheet | Fabrinox

#Stainless steel Partition design#PVD Colour Stainless steel sheets#antique finish sheets#Stainless Steel Partitions in Delhi#Stainless Steel Furniture in Delhi#Stainless Steel Furniture

0 notes

Audio

With over 24 years of brilliant achievement, Wanjiahong has been recognized as a famous brand in Chinese stainless steel decoration business. The companies are equipped with advanced machines, such as 5 fully automatic flatten & slitting machines, 8 PVD colour coating machines, 6 mirror 8K polishing lines, 2 embossed lines, over 150 welding equipment and 10 automatic packing machines.

Core products are stainless steel 201/304 decorative sheets, 201/304 stainless steel pipes, No.4&Hairline/Mirror 8K stainless steel coils. 47 of our embossed products are with appearance patents, and our continuous innovation still going further to meet all of your special pattern designs.

Stainless steel tube

1 note

·

View note

Text

How To Blacken Stainless Steel HD Quality

It’s not as simple as you might think to blacken stainless. I remember using stainless steel as the anode (i think it is anode.

202,304 Stainless Steel Black Coloured Sheet, Rs 3800

The thickness of the layer of blackening (consisting of oxides) has a value about 0.1 mcron.

How to blacken stainless steel. For small parts you could easily set up to use stainless salts at home, but it's probably not very economical. Recommended for color coding parts and blackening engravings on stainless steels. Produces a pleasing dark gray/black finish.

I have used brownells stainless bluing salts (oxynate 84) quite a bit and have had mixed success. These measures are used to remove more difficult residue from steel. That sound interesting, but mostly in the states….

Try other metals, maybe nickel or. Stainless steel blackener 370 is an acidic liquid concentrate used full strength or diluted with up to 3 parts water to blacken stainless steel at room temperature. Hang the stainless steel off a metal wire and suspend it into the fluid until it turns your desired shade of black.

If it beads off the steel, it requires more cleaning. A quick google search on “blackening stainless steel” found a few. The steel must be free of any dirt, oil or other contamination before proceeding.

Check for cleanliness by wetting the cleaned steel with water. How to blacken steel furniture. As mentioned above the blackening of stainless steel is achieved by immersion in oxidizing solutions at a temperature of 120/130°c.

So yeah just buy a black one. Depending on the chemical mix used, you may require a second step to affix the oxide to the steel so it doesn't rub off as easily. We use their black oxide for our steel products in my business we manufacure all kinds of steel parts, works pretty slick i have not used it on stainless yet but if a customer wants it done thats what i will use.

They range from fairly benign room temperature baths. Clean the metal thoroughly with a degreaser and remove any rust. How to blacken steel tools.

Recommended for color coding parts and blackening engravings on stainless steels. Repeat as needed until the steel is uniformly blackened. Put the metal on to a metal baking sheet.

Do not touch the concentrate with your skin. The metal finishing guidebook lists 3 formulations of blackening baths for stainless steel. Produces a pleasing dark gray/black finish.

Steel in general is blackened by oxidizing the surface with a chemical reaction producing a stable layer of black rust fe3o4 (flakey, unstable red rust is fe2o3). Honestly you best bet would be to send it out and have it pvd coated. How to blacken stainless steel at home.

Getting acid involved can work but i depends on the steel used and the acid. Wipe the damp cotton ball down the steel from end to end repeatedly until the steel turns black. There are a number of chemical solutions available to darken.

If rotary engraved the paint (rustoleum flat black) will work nicely. We are blackening stainless steel (302 & 304) parts in barrels. Some surfaces that have more severe rusting may need blast cleaning, acid pickling (muriatic acid), use of a wire brush, or chemical stripping to be totally prepped.

Stainless steel blackener 370 is an acidic liquid concentrate used full strength or diluted with up to 3 parts water to blacken stainless steel at room temperature. This would be an experimental situation on the stainless. To nasty industrial hot salts.

You shouldn’t have any problems with a non mount brake and it’ll typically be easier to clean, should you choose to do so. How to blacken steel with beeswax at home. You might also use steel wool or a scotch brite if you need a little more abrasion.

Let us know how this works out. How to blacken steel knife. How to blacken steel engraving.

You can tumble the parts after coating in large ceramic media for a very cool worn finish or just rough it up with some scotch bright after some flash curing and then finish it up. Using acetone and a clean rag, wipe off excess oil, rust, etc off of your metal parts. If the cold blue oxidizes the metal, then diamond drag would work well.

Keep dipping the cotton into hot vinegar and wipe until the steel color cannot darken any further. But yes, it probably wont shave as good as before and you may need to resharpen/at least strop a little bit. If done by diamond drag, i'd try cold blue found in most gun stores.

You can see the bubbles) and a piece of iron for sacrifice. How to blacken steel with motor oil. Check out caswell metal finishing online they have something to offer to blacken stainless.

Do not soak the stainless steel for more than three minutes or you can damage the structural integrity of the stainless steel. Remove the metal from the oven and take it to a ventilated area. Preheat an oven to 425 degrees fahrenheit.

Oxy 84 will only blacken certain stainlesses, such as 416r, but will not work on most 300 series materials like 304. It also will eat away the surface of the steel and destroy tolerances. Otherwise, proceed to step 2.

The one that sounds simplest to me, although i can't comment on its efficacy, reads: Should give it a darker color the more you use it. Let the metal get hot in the oven.

0 notes

Text

PERRELET TURBINE PILOT

The Perrelet Turbine Pilot does not subscribe to the traditional pilot’s watch style. On the contrary, the Swiss firm has conceived a very original aviation-themed timepiece that sidesteps convention with its bold use of colour and animated dialscape. Angus Davies gets ‘hands-on’ with this aviation-themed watch.

Back in the 1930s, the German Ministry of Aviation, or Reichsluftfahrtministerium (RLM), created a specification for pilots’ watches. These were intended for use by the Luftwaffe, serving as a supplement to the plane’s cockpit instruments. The watches had to be 55mm in diameter and needed to have a large winding crown, facilitating manipulation even when wearing gloves.

The RLM also made additional stipulations that suppliers were obliged to meet. For example, all pilots’ watches had to be equipped with a hacking seconds, allowing the wearer to halt the second hand by pulling out the crown. This was an essential feature when synchronising watches ahead of a bombing mission.

The watch also needed to have a Breguet hairspring, chronometer certification and a long leather strap allowing it to be worn over a flying suit. Furthermore, the RLM specification stated the watch had to be housed in an anti-magnetic case. Even the triangular-shaped index at noon, with two dots on either side, was a requirement of the RLM. Several companies were entrusted with supplying the Luftwaffe with these watches, sometimes termed ‘Grosse Fliegeruhr’ or ‘B-Uhr’ timepieces. These firms included Lange & Söhne, Laco (Lacher & Co), Stowa (Walter Storz), Wempe and IWC.

Many pilots’ watches after WWII continued to incorporate elements that were originally specified by the RLM. Although the Grosse Fliegeruhr may have been robust, precise and highly legible, it was never intended to be attractive. Today, some pilots’ watches have received a touch of cosmetic surgery with a nip and tuck here and there, improving wearability and augmenting eye-appeal. However, in many cases, the genre’s utilitarian origins still remain apparent.

Recently, I had the opportunity to get hands-on with the Perrelet Turbine Pilot and appraise its composition at close quarters. The Maison from Biel/Bienne has not followed the same path as others, preferring to look at the pilots’ watch with a fresh set of eyes. Vibrant colours enliven the model’s dial which also incorporates an enchanting dose of animation. Consistent with traditional pilot’s watches, the Perrelet Turbine Pilot is a practical proposition, but it also possesses a fresh-faced, handsome visage.

The dial

The Perrelet Turbine Pilot is available in seven different variants, encompassing a variety of hues and even a camouflage variant, ideally suited to covert military action. My press sample was rather more flamboyant, sporting various ebullient red dial details.

White luminescent hour and minute hands convey meaning with notable efficiency. The boss in the centre of the dial, connected to the canon pinion, is oversized, introducing a stylish departure from the norm.

The hours are denoted with plump Arabic numerals at the cardinal points and rectangular batons in between. Interestingly, the indexes are affixed to the underside of the sapphire crystal. The dialogue between the hands and indexes is notably clear and intelligible.

As the model’s name implies, the watch is endowed with the Maison’s ‘turbine’ system. To understand the rationale for this system, it is necessary to look at the company’s past.

Abraham-Louis Perrelet invented the automatic pocket watch (1777) and it remains very much at the heart of everything today’s eponymous brand does. In 1995, the firm released its first ‘double rotor’ watch. Both of these rotors were functional. However, the dial-side rotor proved particularly interesting to clients who were no doubt captivated by its revolving motion. Perrelet unveiled the inaugural ‘Turbine’ model in 2009. The dial-side rotor didn’t tension the mainspring but was designed to deliver a unique animated display. The turbine blades, similar to those found on an aeroplane engine, readily spin, intermittently revealing detail on the lower dial level.

Beneath each index, located on the said lower dial level, are red chevron markings emulating those often found on cockpit instruments.

The indications include a black central sweep seconds hand with a prominent orange tip. Perrelet has incorporated other flight-themed references such as the fletching style counterweight affixed to the central sweep seconds. Quite simply, the Maison has expended much effort on this watch, lavishing various surfaces with a plethora of details.

Various scales in eye-popping red hues encircle the main dial area. An additional scale adorns the bezel. The aviation style slide rule doffs its hat to a pre-electronic era when pilots made calculations manually.

The case

Measuring 48mm in diameter, the scale of the Perrelet Turbine Pilot may prove off-putting to some potential buyers. However, when affixed to the wrist, the watch feels smaller than the stated dimensions suggest. When the watch is placed on its side atop a table, the strap readily curves, eager to encircle the wrist. Another reason for the watch appearing smaller is that the lugs are comparatively short and they arc sharply downwards. Personally, I found the watch granted an ergonomic union with my wrist and it conferred impressive wearer comfort.

The stainless steel case is dressed in black PVD, imbuing it with a stealthy nature and providing a wonderful juxtaposition with the model’s vibrant red tones. Four sections emanating from the caseband rise upwards and hug the bezel. Two similar sections of metal, positioned centrally between each set of lugs, provide a further link between the strap and the watch head.

Perrelet has equipped the Turbine Pilot with a ‘bi-material’ leather strap enriched with an alligator pattern. Interestingly, it was only after I read the specification sheet that I determined the strap wasn’t made from reptile skin. As more people express concern about using alligator skin, Perrelet’s approach seems very sensible.

Tactility is an important factor when appraising the composition of any watch. With an outstretched index finger and a keen eye, the Perrelet Turbine Pilot rewards the senses with a palpable sense of quality. The crown features cross knurling, inviting the wearer to caress it and derive cathartic benefit from its texture.

To the rear of the watch, an exhibition caseback affords views of the self-winding movement.

The movement

The Perrelet Turbine Pilot is fitted with an in-house automatic movement, the calibre P-331-MH. Recently, I reviewed this movement in detail, however, for those readers who are time-poor, I have detailed some points below that are worth mentioning:

The bridges that are positioned centre stage are adorned with perlage, while the visible edges of the mainplate feature colimaçon.

The oscillating weight is an openworked design, affording superior views of the components below.

COSC certification provides independent validation of the model’s accuracy.

Various types of tests have also been performed to ensure robustness, water resistance and tolerance to various temperatures. This test regime forms part of the Chronofiable certification standard (independent assessment).

The rate is adjusted with an index-adjuster

Assuming the watch is fully wound, the Perrelet Turbine Pilot will run autonomously for 42 hours.

Closing remarks

The dial of the Perrelet Turbine Pilot proves very legible. By fitting the indexes to the underside of the crystal, adding the turbine and the lower dial level, Perrelet has introduced layers of detail that confer depth and masterfully play with light.

Moreover, by equipping the dial with various graduated scales, the Swiss marque has endowed the display with many numbers and markings. Those prospective purchasers who prefer less detail can select one of the company’s Turbine Evo models which eschew the aforementioned red elements, thereby bestowing a calmer temperament. Personally, when wearing the Turbine Pilot, I adored its liberal application of red hues. This is a watch that exudes optimism and will readily elicit a smile on any face.

One thing is clear, Perrelet has never looked over anyone’s shoulder and copied their work. Indeed, its design is very much its own. Some traditional pilots’ watches were produced with practical considerations in mind and little thought to the aesthetic charms they might proffer. Over the years, some military pilots’ watches have received a make-over with perhaps a green dial or by using more avant-garde case materials, etc. However, the approach taken by Perrelet has not been to adapt an existing style of watch, but to conceive something fresh and new. Indeed, Perrelet has looked to the heavens and conceived a timepiece that delivers both practicality, ingenious animation and an extraordinary amount of style.

0 notes

Text

Colour coated steel and its Uses

Coloured steel is made in two different varieties PPGL and PPGI. PPGL stands for Pre-painted galvalume steel and PPGI stands for Pre Painted galvanised Iron steel. Here is how the steel is painted and what its uses are.

Stainless steel is painted in many different ways, vacuum chamber paint, powder paint and PVD coating. Coloured steel has multiple uses and the uses are all for the exterior use. The coating of the steel has to strong enough to handle all the environmental changes.

Architecture: The coloured steel is used for exterior of the building, this requires the steel to be presentable and weather resistant.

Hardware: Interior and plumbing nowadays require the steel to be water resistant and rust free.

Design: The colour and finish of coloured steel makes it a great steel for art installation and floor or wall installation.

Elevators: Coloured steel are a great choice for lifts/elevators because they add to the beauty and they last long.

Daily use: Electrical appliances, gym equipment, refrigerators and even in the food industry coloured steel is used for the exteriors.

Coloured steel has many different advantages, the colour adds to the beauty of any place it is installed. The pre painted steel does not peel, crack or fade. Coloured steel is light in weight but lasts long as compared to the steel that is coloured later. Pre painted steel also super resistant to corrosion. Pre painted Steel is also very durable. Coloured steel can also be recycled and hence proves to be a better choice in every scenario.

Coloured steel helps you achieve what you want in less steps. Making a product in simple steel and then painting it can be a bit of a hassle, it can also cost extra money. Pre painted steel saves both time and money.

We at JSWMI we provide Colour coated steel. It is available in wide range of colour combination and emboss patterns, cut into slit or sheet as required by home appliance industry customers. We are steel processing center and we also give other services and product.

#cold rolled close annealed steel#galvanized steel#stainless steel#electrical steel#color coated steel

0 notes

Text

Stainless Steel C Patti Exporters

The above Decorative SS “C” Profile Sections are made by CNC Bending. Before Bending, these Sheets are cut to their required sizes by Laser Cutting Machines. Our SS C-Profiles Grooving is done on Metal Sheets before bending them. By following this Process, we can achieve 90 right angle on the bend area.

Our Profile Sections are also available in various colours as per your Requirement. Decorative SS “C” Profile Section are used in many Applications such as exterior cladding, interior decoration, Skirting, Wall Edge Protection, Floor Partitions, Wall Partitions and Many More.

Sterlite Metal and Tubes Brand Stainless Steel Decorative pvd Color Coated trim C profile starts with C - 4 to c - 200 . It is created utilizing Stainless Steel concealing sheet.

For More Information :

Email : [email protected]

Call Us :+91-9920888220

Website : www.decorativecoatedprofiles.com

0 notes

Text

Designer Colored Metal Sheets

FeCuNi is one of the leading organisation providing Coloured Stainless Steel Decorative Sheets or PVD Stainless Steel Sheets.

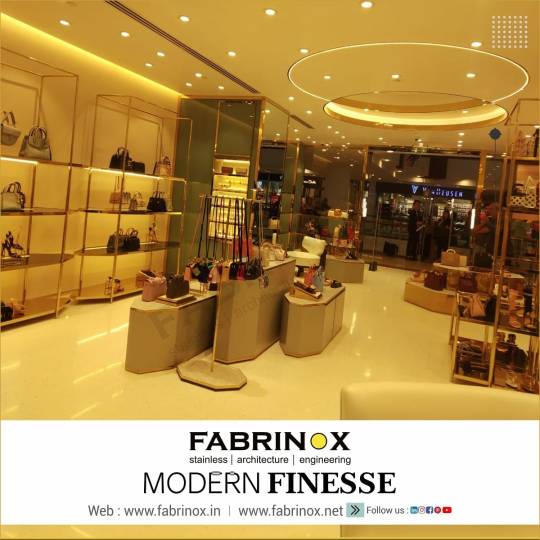

Coloured Stainless Steel Decorative Sheets are used in various Applications such Shopping Malls, Banks, Airports & Restaurants, Ice Cream Parlours, Railway Stations, Museums, Architraves, Escalators, Retail Shops, and various Decorative purposes.

#designer colored metal sheets#decorative ss colored sheets#stainless steel colored sheets suppliers#ss designer sheets

1 note

·

View note

Text

Is it easy to imitate decorative PVD coated colored stainless steel sheets for indoor applications?

If it is a new product, it is not easy to imitate within six months, and the new product has certain technical difficulties. However, with the replacement of colored stainless steel sheets, its shelf life is also shortening.

CBSA International has dozens of new colored stainless steel decorative sheets products, and is also constantly innovating and developing, mainly innovating and applying on the surface of stainless steel. It not only innovates in production technology, but also improves the surface color and process texture to make new products It has become more beautiful, the production is more difficult, and the freshness period of new products is prolonged at the level of seeking seeds.

With the wide demand for interior decoration applications, designers have higher requirements for colored stainless steel decorative sheets for interior applications. CBSA international has not stopped innovation, has been in the forefront of the world, product output covers more than 30 countries and regions around the world, has a professional R & D team and installation engineering team to help customers around the world to solve installation technical problems. Foshan, China is a cluster of colored stainless steel decorative sheets and has a mature stainless steel industry chain. A large number of overseas merchants come to inspect and purchase every day.

The indoor application of colored stainless steel decorative sheet is mainly used for interior wall decoration, hotel lobby image wall, pillar decoration, screen partition of space function partition, elevator cabinet and aisle decoration, etc. The wide application range mainly depends on the designer's knowledge and application scheme of the colored stainless steel sheet.

If you want to know more about the coloured stainless steel decorative sheets with PVD coating for indoor application, please consult or click to view other products

0 notes

Text

Stainless Steel C Patti Suppliers

The above Decorative SS “C” Profile Sections are made by CNC Bending. Before Bending, these Sheets are cut to their required sizes by Laser Cutting Machines. Our SS C-Profiles Grooving is done on Metal Sheets before bending them. By following this Process, we can achieve 90 right angle on the bend area.

Our Profile Sections are also available in various colours as per your Requirement. Decorative SS “C” Profile Section are used in many Applications such as exterior cladding, interior decoration, Skirting, Wall Edge Protection, Floor Partitions, Wall Partitions and Many More.

Sterlite Metal and Tubes Brand Stainless Steel Decorative pvd Color Coated trim C profile starts with C - 4 to c - 200 . It is created utilizing Stainless Steel concealing sheet.

0 notes

Text

PVD STAINLESS STEEL | FABRINOX

PVD stands for Physical Vapor Deposition. PVD coatings are a cost-effective technique to significantly upsurge the performance of the surface with negligible environmental effect. No harmful fumes or other materials are out and there is no surplus.

There are various other advantages to the PVD finishing method. Here we have mentioned 3 to keep in mind when requiring door hardware for your building project.

1. Provides Greater Corrosion-Resistance

Many designers make the statement that by using stainless steel on your exterior door hardware, you don't have to fear corrosion.

2. Expands Durability, Outspreading the Lifecycle of Door Hardware

Old-style electroplating methods need polish upper coats that damage over the period, from time to time devastatingly, while the microns-thin PVD coating makes attractively.

3. Environmentally Sustainable Coating Process

The moneymaking PVD coating procedure goes out there its efficient durability. As intricate as the PVD procedure may appear, it is a method more approachable to our environment when compared to other hardware finishes.

Why choose stainless steel kitchen?

A rising sum of individuals nowadays is opting for Stainless steel kitchens for their homes too. There are so many reasons as to why to go for stainless steel kitchen.

Some persons favor old-style kitchens just because of their hard-wearing resistance and durability. Others prefer stainless steel since they want a kitchen that’s relaxed to clean and they won’t be finding the middle ground on hygiene. There are individuals who can’t battle their exclusive, strong, warm design that’s definitely filled with punch. Some reflect them to be an outlay to hand down, for example, a vintage car, or a watch. There are also people who relish having guests over in the garden and consequently want a kitchen that’s designed for outdoor use, hard-wearing, built to endure all climates. Lastly, there are also those who select a stainless-steel kitchen because they only want the best in their home!

For the best stainless steel kitchen switch to Fabrinox.

Also, read:

PVD stainless steel Partitions

PVD wall art

PVD Colour Stainless steel sheets

Stainless Steel Furniture in Delhi

Follow us:

Instagram

Facebook

Pinterest

LinkedIn

#pvd stainless steel#Stainless steel kitchen#PVD Colour Stainless steel sheets#PVD wall art#PVD stainless steel Partitions#PVD#wall art#Stainless steel#kitchen#Home

0 notes

Link

Stainless steel materials are utilized in just about anything with some industry capacity. Regardless of the strength or the nature, the most widely known and favorable characteristics of stainless steel are its elegant looks, resistance from corrosion, and trustworthy insurance.

Ancient Steel:

Whenever individuals think of Steel, they typically think that it is a contemporary innovation. But in reality, this durable material has been around for more than 400 years. It indicates that individuals have been using this spectacular material for a much longer time. The popularity of stainless steel has expanded over the last hundred years. But it is for older material than anyone realizes.

#PVD stainless steel Partitions#PVD Colour Stainless steel sheets#3d pattern stainless steel sheet#stainless steel

0 notes

Text

Why would you choose the Fabrinox Brand for your home?

Steel shits are molded by an industrial process into thin and fast sheets that are later used for various purposes in various sectors starting from living spaces to industrial spaces. After forming into thin and flat sheets they are later Fabricated into numerous amounts of everyday objects. The thickness of these steel sheets may vary prominently. The thinnest sheets are Dalles foil while the thickest sheets are called structural sheets.

While most households are looking for stainless sheets for various purposes since they are extremely durable, resistant to corrosion, and are strong and sturdy. The structure and texture of stainless steel are long-lasting However, a coating of PVD, makes it everlasting.

Strength, ductility, and toughness are some of the essential factors while choosing a stainless steel grade. Listed below are some of the important factors:

Consider the operating movement

Formability

Weldability

Level of corrosion resistance

Toughness and strength

Magnetic Response

Material cost and Availability

Your preference

Get a one-stop solution to all the listed factors under one roof at Fabrinox.

Fabrinox presents a range of stainless steel sheets with PVD coatings, Pipes, and furniture. Here, Stainless steel of wooden textures, leather, and marble finish is manufactured to source the exact shade of color, variety, and quantity required for every picky architectures and Designer who dream to craft an interior with exquisitely and perfection.

Our featured collection includes Designer sheets, sheets with a special finish, LCM sheets, Steel etching sheets, partition screens, steel furniture, and many more on the bucket list.

Fabrinox aims to provide quality furniture with its remarkable service. Designed with the innovation and technology of renowned engineers, Fabrinox has everything the Contemporary world needs. Explore a wide range of products on our website that suits the décor of your spaces.

Also, read:

Stainless Steel Furniture in Delhi

Vibration finish sheet

PVD Colour Stainless steel sheets

PVD wall art

Follow us:

Instagram

Facebook

Pinterest

LinkedIn

#stainless sheets#Stainless Steel Furniture in Delhi#PVD wall art#PVD Colour Stainless steel sheets#Cross Hairline Finish Sheets#Stainless Steel#pvd

0 notes