#Paper Scrap Baler Machine

Explore tagged Tumblr posts

Text

Increase Your Recycling Profits with a Paper Scrap Baler Machine in India

Maximize your recycling output and reduce operational waste with a well-built Paper Scrap Baler Machine in India from Power Hydrotech Private Limited. Designed for continuous performance and minimal manual effort, this machine helps businesses compress large volumes of paper scrap into compact bales, making storage and transportation more economical. It supports efficient recycling workflows while saving time and labor costs. Whether you’re running a small recycling unit or a large-scale facility, this machine brings consistent results that support increased profitability. Power Hydrotech Private Limited offers models suitable for various needs, making it easier to handle bulk paper scrap and improve overall productivity. https://www.powerhydrotech.com/paper-scrap-baler

#Paper Scrap Baler Machine#Paper Scrap Baler Machine in Ahmedabad#Paper Scrap Baler Machine in Gujarat#Paper Scrap Baler Machine in India

0 notes

Text

Efficient Baling Machine for Waste Management

Make your waste management process speedy and effective with Baling Machines from EnvCure Technocrat LLP. The high-performance Baler Machines we manufacture are perfect for compressing waste for recycling purposes, thereby helping industries become more operable. Contact us today for effective solutions at a competitive price! Get in touch Email: [email protected] Contact: +91 7990888367 | +91 9724360025 Website: https://www.envcure.com/

0 notes

Text

Scrap Baling Press Machines Manufacturer — Rolcon Technologies Private Limited

Rolcon Technologies Private Limited, based in Sampla, Haryana, is a premier manufacturer of high-quality scrap baling press machines. Known for their robust engineering and innovative designs, Rolcon Technologies specializes in manufacturing machines that streamline the waste management process across industries. With years of expertise and commitment to sustainability, the company provides advanced baling solutions that cater to diverse industries, ensuring efficient recycling and reduced environmental impact.

Rolcon Technologies Private Limited,, is a premier manufacturer of high-quality scrap baling press machines. Known for their robust engineering and innovative designs, Rolcon Technologies specializes in manufacturing machines that streamline the waste management process across industries. With years of expertise and commitment to sustainability, the company provides advanced baling solutions that cater to diverse industries, ensuring efficient recycling and reduced environmental impact.

What Are Scrap Baling Press Machines?

Scrap baling press machines compress recyclable materials like waste paper, metals, and plastics into compact bales. These machines are essential for waste management industries as they simplify transportation, storage, and recycling.

At Rolcon Technologies, the focus is on creating high-performance baling machines that:

Reduce waste volume. Save space and transportation costs. Ensure user-friendly operations. Offer durability and long-term reliability.

Key Products by Rolcon Technologies

Rolcon Technologies offers a diverse range of scrap baling press machines designed to meet the varying needs of industries. Here are their top products:

Auto Tie Horizontal Paper Baler This advanced auto tie horizontal paper baler is ideal for large-scale operations in industries dealing with waste paper and cardboard. Its automated tie system reduces manual effort, increases efficiency, and ensures tightly compacted bales for easy handling and transportation.

Fodder Baler Specially designed for the agricultural sector, this machine efficiently compresses fodder into compact bales. It helps save storage space, reduces transportation costs, and ensures better handling of animal feed and agricultural by-products.

Triple Compression Baling Press Built for heavy-duty operations, this baling press is perfect for industries managing large quantities of ferrous and non-ferrous metal scraps. Its triple compression baling press mechanism ensures maximum density, making it an essential tool for metal recycling plants.

Double Compression Baling Press A versatile and cost-effective solution, this baling press is designed for medium to heavy-duty operations. It is ideal for compressing metal scraps, offering excellent efficiency and durability for recycling operations.

Waste Paper Baler This baler is tailored for recycling waste paper, cardboard, and similar materials. It provides efficient compression and is widely used in paper mills and packaging industries to streamline the recycling process. With their cutting-edge designs and focus on efficiency, Rolcon Technologies’ baling machines are setting new standards in the waste management and recycling industry. Whether you’re dealing with paper, metals, or agricultural waste, their solutions are reliable and eco-friendly.

Why Choose Rolcon Technologies?

State-of-the-Art Manufacturing: Every machine is crafted with precision using cutting-edge technology to ensure high performance and durability.

Customization: Rolcon Technologies understands that every business has unique needs. They offer tailored solutions to match specific requirements.

Eco-Friendly Approach: The company emphasizes sustainable waste management and aims to contribute to a greener future.

Customer Support: A dedicated team provides seamless after-sales service and technical support.

Applications of Rolcon’s Machines

Rolcon Technologies’ baling press machines are versatile and widely used across industries, including:

Paper and Packaging: For recycling waste paper and cardboard. Metal Recycling: Compressing metal scraps into manageable sizes. Plastic Recycling: Managing plastic waste for easier storage and transportation.

About Rolcon Technologies Private Limited

With a mission to innovate and lead the waste management sector, Rolcon Technologies has become a trusted name in the industry. Their focus on quality, innovation, and customer satisfaction has earned them a strong reputation among manufacturers and recyclers.

If you’re looking for efficient and reliable scrap baling press machines, Rolcon Technologies Private Limited is the name you can trust. For more information, feel free to contact their team and explore how they can help you optimize your waste management processes.

#baler#manufacturer#scrap baler machine#scrap baling press#Automatic Scrap Baling Press#Triple Compression Baling Press#Double Compression Baling Press#Auto Door Baling Press

0 notes

Text

Paper Baler Machine: The Ultimate Guide for Efficient Paper Waste Management

Paper Baler Machine has indeed turned into one of the most tools for enterprises aspiring to enhance their recycling processes, miniaturize volume of waste and promote sustainable work environment. Paper Baler is a unique type of machine that is used to compact waste paper, cardboard and any other type of recyclable paper material into bales. These machines apply hydraulic pressure in order to reshape materials into a suitable form for storage, transportation and subsequent recycling of paper waste. Paper Baler Machines can be defined as machines used to compress various types of waste papers into compact bales, for ease of storage, transport, or recycling. Globally, this diverse equipment has integrated into operations affecting different industries, warehouse, and recycling facilities practicing sustainability. It doesn’t matter whether you want a Hydraulic Semi-Automatic Paper Baler, an Automatic Paper Baler Machine, or a Manual Paper Baler Machine; these devices are available in different capacities to facilitate various operations and functionalities in an efficient way to recycle waste paper.

What is a Paper Baler Machine?

Paper Balling Machine is very effective hydraulic equipment used in packing of waste papers, cardboards and similar products into tight compact shaped roll called bale. These machines produce bales that stand to occupy minimal space and which further promote recyclability. Most are categorized according to the amount of automation they have; the manual baler machine, the semi-automated baler machine, and the fully automated baler machine types. With the right paper baler machine on your side, you can elaborate on your waste management techniques; effectively save space as well as transport cost all in an eco-friendly context.

Paper Baler Machines Types and Usages

Selecting the right paper baler machine can significantly improve your waste management processes. Here’s an overview of the primary types available

Automatic Paper Baler Machine

Automatic Paper Baler Machine is the ultimate solution to the problem of waste management especially in companies that produce enormous amount of scrap paper, cardboard as well as any other material that is acceptable for baling. The balers that are described below as fully automated balers; the operations include loading, compression, tying, and ejecting without the need for a human operator. For this reason, they are especially suitable to environment with high operation volume requirements for speed, efficiency, and repetition. This is a detailed article about automatic paper baler machines discussing the product details, its application and its advantages.

Automatic Paper Baler Machine Features & Benefit:

From loading to compressing and bale ejection, the machine operates independently and therefore less human power and effort is required. In most of the automatic balers, there is a use of PLC (Programmable logic controller) this enable the operator to set the machine according to the type of material, density or size of the bale required. Automatic balers are capable of dealing with higher volumes of waste, and have a higher yield in baling density and size which makes transportation and storage easier.

Example Industries:

Recycling centers especially have a lot to gain from automatic paper baler since they deal in large amounts of paper and cardboard on a daily basis. Factories and production plants produce massive amounts of packaging items, most of which are paper based. Medium to large warehouses and distribution centers produce continuous flow of paper-based packaging, commonly cardboard. Large store fronts or grocery stores produce huge amounts of cardboard and paper waste.

Hydraulic Semi-Automatic Paper Baler

Hydraulic Semi-Automatic Paper Baler as an all-purpose baling machine incorporates hydraulic compression mechanism along with semi-automatic control making it suitable for mid to high level applications. This type of baler exerts a lot of pressure to form a smaller volume and more uniform paper wastage into bales that needs occasional tying/ejection by a person. Businesses that require relatively high levels of automation but cannot afford the expenses related to the use of robotics turn to CNC machines.

Hydraulic Semi-Automatic Paper Baler Features & Benefit:

Hydraulic Semi-Automatic Paper Baler more appropriate for facilities that generate average to high amounts of waste since they do not require constant supervision when in operation like fully automatic balers where obtained, semi-automatic machines are usually cheaper and use less power as compared to fully automatic balers. Hydraulic semi-automatic balers are easy to use and there is no need for professional training. Furthermore, hydraulic semi-automatic balers accept not only paper but also cardboard and plastic, thus, such balers are suitable for businesses that deal with the disposal of different types of waste materials.

Example Industries:

Companies such as retail stores, distribution center, mid-sized manufacturing facilities, recycling center, etc. prefer hydraulic semi-automatic balers as this machine system are able to produce high degree of speed, efficiency as well as cost effectiveness.

Horizontal Paper Baler Machine

Horizontal Paper Baler Machine is strong equipment which works to manage heavy amount of waste paper, mostly required in industrial places where lots of paper and cardboard waste are produced. While in vertical balers the waste material is fed into the machine in a vertical position, the horizontal baler is designed to produce the bigger and denser bales because of the way the waste material is fed to the machine. This kind of machine is used mostly in industries, scrap yards and large companies where handling of waste is very important.

Horizontal Paper Baler Machine Features & Benefit:

Using horizontal balers, many of which are automatically fed and can work continuously, amount of material processing is higher. The formation of large bales also has its advantages: handling time is considerably shorter, and storage and transportation costs are less. Horizontal balers offer greater weighting and thus form more compact bales, easier and cheaper to transport. More enhanced horizontal baling systems often incorporate fully automated knotting and bale discharge.

Example Industries:

Paper related industries including print and demand, recycling hubs, horizontal balers are important as they create uniform and compact bales that require fewer trips to the recycling plant and processing companies. For warehouses, supermarkets, and distribution centers that receive loads of packaged materials horizontally bales compacts cardboard and paper wastes reducing storage capacity and ease the flow of transporting them to recycling industries. Though are designed for use with papers, most horizontal balers are made to work

Vertical Paper Baler Machine

Vertical paper baler is a specific type of baler used to compact a relatively large number of waste papers and card boards in manageable bales. Becoming popular in recycling companies, storage firms, supermarkets, and in any organization that deals with large quantities of papers, it aids in simplifying and organizing the flow of papers for recycling while minimizing on storage space required, transportation and environmental effects.

Vertical Paper Baler Features & Benefit:

Compared to their horizontal counterparts, vertical balers rely on gravity to assist in the compression process and take up even less space and are easier to load hydraulic system applies tremendous force straight down to compact the paper into tightly bound bales thus occupying less space. New balers have controls to regulate working conditions such as the compression pressure, and the monitor of the operational conditions of the machines from safety measures, issues like automatic cutting off the machines and safety doors, and emergencies stops are found in balers.

Example Industries:

Standing or vertical baler machines are important in various industries that produce a lot paper and cardboard waste. In retail and grocery stores, warehouses and distribution centers, balers are used for addressing packaging material handling and disposal needs and for creating space. These recycling centers use balers so as to make the waste ready for transportation. To turn a blind eye on the benefits of baler, which can be described as versatile tools for waste management with a wide range of applications in such spheres as Hospitality, Manufacturing, Health Care, Education and etc., meaning in fact Hay making for cleaner tidy and neater environs. This is the case for other production industries which involve uses extensive use of paper such as the print and publishing industries that compress the used papers into compact bales for recycling. These machines offer a low-cost waste management solution, which enhances sustainability and production line in many industries, thanks to reduced volume, and better methods of waste disposal.

Manual Paper Baler Machine

Manual Paper Baler Machine is a simple and affordable technique for baling waste paper and allied recyclable products. Manual paper baler is not an automatic or semi-automatic baler that requires somebody to use their muscle to push levers to work making it optimal for businesses, offices, and centers that produce little waste.

Manual Paper Baler Machine Features & Benefit:

Compression of material is achieved mostly by using a lever or a crank and are very easy to operate. There is no need for technical skill in their operation. Manual balers are most often cheaper than the automatic ones due to the lack of hydraulic or electric systems needed for their work. Manual balers occupy less space and can be used even in facilities with little available space. Many manual balers are light and can be easily transported from one place to another.

Example Industries:

Manual paper baler machines are commonly used in Small offices, Retail stores, Schools, Industries with small warehouses or factories which have little waste production. All in all, a manual paper baler is the best solution for small businesses that do not want to spend money on a special machine to remove accumulated papers while possessing a reliable and effective method at the same time.

Portable Paper Baler Machine

Portable Paper Baler Machine is designed to be lightweight and easy to move so as to accommodate where businesses want to take their waste management. They are compact and can easily be relocated from one section of a facility to another and from one site to another if required. They are common in small-scale establishments, construction firms, and institutions that have incongruous waste disposal requirements.

Portable Paper Baler Machine Features & Benefit:

There are basically two types of balers: portable and stationary balers; portable balers specifically are designed to be small and light so that they can easily be moved from one place to another and stored wherever needed. They are easily transportable and are available type’s hydraulic baler and manual baler. Most of these machines are wheeled or have handles so that they can be easily moved from one point to another, and this makes them adaptable to different on site functions. Hydraulic options are usually more compressive due to the density of the bales made hence more appropriate for the purpose while manual ones are usually portable and cheaper to acquire. Some of the portable balers use batteries or have rechargeable power sources available. Balers are designed friendly with controls and ease of operation and are designed for quick use on the go.

Example Industries:

Portable paper baler machines target industries within the Retail and groceries sector, construction sites, events venues, Small to medium sized warehouses .Any business that requires a mobile paper and light waste management solution Portable paper baler machines provide a convenient and cost efficient mobile means of managing paper and other light wastes in varying and multiple informal sector locations and in temporary structures. Also there are more types of paper baler machine as per usages and demand.

Key Benefits of Using a Paper Baler Machine

Cost Savings

Paper baler machines minimize on the accumulation and storage of waste hence cutting on the amount of money that is spent on the vents of storage, handling and transport of the wastes. This is particularly the case in high volume operations where these cost savings can be real and make a baler machine for that matter a beneficial investment.

Improved Recycling Efficiency

Compressed paper bales are easier to be managing and transported to recycling plants. This implies that overall travel will be reduced, fuel consumption minimized and overall time spent on handling wastes will also be reduced. In general, increased efficiency leads to the efficiency of sustainable business approaches.

Reduced Environmental Impact

One reason compacting paper waste is important is because they encourage recycling and take up less space in a landfill than if they were not compacted. Balers machines also conform to sustainable measures since it would assist the companies reduce their impact on the usage of resources thus making the operation environmentally friendly.

Space Optimization

Baling also enhances paper waste volume reduction to an extent of 90% thus saving much needed space for storage. Baler machines prove valuable for business that has little space in their establishments because they can really help in organizing space.

Versatile Material Handling

Though most baler machines are used to compact paper and cardboard, they can also recycle plastic and textile wastes making them effective in treating all kinds of waste.

How to Choosing the Right Paper Baler Machine

When selecting a paper baler, it’s essential to consider several factors:

Waste Volume: Automatic or horizontal baler should be used in the high-output facilities while manual or vertical balers would be suitable in small scale businesses.

Available Space: Assess the fact that you have no space for baling operations. Compact and vertical balers are perfect for use in facilities that are limited in floor space.

Budget: Semi-automatic and manual ones will cost less than fully automated and horizontal ones, nevertheless, the latter will give more profit due to the productivity difference.

Material Type: In case you deal with several kinds of recyclable waste, find a universal one that is designed for not only papers but also plastics and cloths.

Conclusion

Paper balers are most efficient equipment to deal with waste in any organization. By packing waste paper as dense materials that can be transported easily in bales, they afford a business the opportunity to cut on the amount of waste, cost of disposal as well as increase the space utilization of their storage facilities considerably. Moreover, paper balers bear some importance in the movement of recycling efficiency for companies and therefore the conservation of the environment. In retail, warehousing, manufacturing, and healthcare industries, paper balers have the effect of improving hygiene and orderliness of working environment and facilitate proper handling of waste. Any company coming out with a large amount of paper products at the end of the day can greatly benefit from a paper baler in terms of save time and effort and also the environment.

Frequently Asked Questions (FAQs)

Q1: Hydraulic Semi-Automatic Paper Baler Machine – What is it?

A1: Hydraulic Semi-Automatic Paper Baler Machine is a kind of baler that utilizes hydraulic work and semi-automatic operations to make paper waste compact. There is a certain amount of manual operation involved but it is perfect for that business house that requires both power and affordability.

Q2: What’s in it for my business when I invest in an Automatic Paper Baler Machine?

A2: An Automatic Paper Baler Machine is a machine which is designed for baling the papers without a need of any man force to bale it thereby increasing the efficiency. This is most suitable for large organizations that generate large amounts of waste that have to be disposed off regularly and efficiently.

Q3: What’s the difference between Vertical and Horizontal Paper Baler Machines?

A3: Most Vertical Paper Baler machines work vertically, and hence are smaller in size, ideal for organizations with space constraint issues. Horizontal Paper Baler Machines accommodate greater amounts of waste papers and are mainly produced for use in industries with increased paper waste generation.

Q4: How can I buy a Paper Baler Machine that is tailored to my needs?

A4: Indeed many manufacturers produce Customized Paper Baler Machines based on operational needs as per the size of the baler, compaction force, and automation.

Q5: What makes the Portable Paper Baler Machine convenient? A5: A Portable Paper Baler Machine is easily transportable and has flexibility in meeting the requirement of waste handling in different sections of a business facility.

#HydraulicSemiAutomaticPaperBaler#AutomaticPaperBalerMachine#HorizontalPaperBalerMachine#VerticalPaperBalerMachine#ManualPaperBalerMachine#VerticalHydraulicPaperBalerMachine#HorizontalHydraulicPaper BalerMachine#SemiautomaticPaperBalerMachine#FullAutomaticHorizontalPaperBalerMachine#HydraulicPressPaperBalerMachine#CompactPaperBalerMachine#MiniPaperBalerMachine#PortablePaperBalerMachine#IndustrialpaperBalerMachine#PaperRecyclingBalerMachine#CustomizedPaperBalerMachine#PaperPress#PaperBallingMachine#WastePaper#WastepaperBaler

0 notes

Text

How a Scrap Baling Machine Improves Waste Management Efficiency

It will be possible to enhance waste management efficiency with the help of a scrap baling machine. It has the ability to compress large volumes of scrap into more manageable bales. It becomes simpler to store and recycle waste because of this process. The various types of waste can be paper, metal, as well as plastic. The machine helps to save space by minimizing waste. It can be a fantastic solution for businesses handling huge volumes of scrap. Let us find out how this machine improves waste management efficiency.

1. Improves Storage Efficiency

Scrap baling machines can compress waste into tightly packed bales. Thus, you can save plenty of space in the storage area. Loose scrap will consume lots of space without the scrap baling machine. In that case, it can be difficult to manage the scrap. The scrap will become more compact with the help of the baling process.

It implies that more materials can be stored in an identical space. It will prove to be useful in case the storage is limited. It will be feasible to keep the work area more organized by enhancing storage efficiency. It will help to reduce clutter too. Thus, you will be able to store more scrap for extended periods before disposing of it.

2. Enhances Recycling Processes

It is possible to simplify the recycling procedure with the help of a scrap baling machine. You will find it simpler to transport compressed bales to recycling centers. It will expedite the recycling operation when the scrap has been already baled. Compressed scrap is preferred by recycling centers. This is because it helps to save time and effort. Moreover, it will minimize carbon emissions and fuel expenses.

The aforementioned machine helps to make sure that the materials are not wasted. You will contribute to a sustainable waste management system by making recycling efficient.

3. Increases Operational Productivity

It is possible to enhance productivity in waste management operations while using a scrap baling press machine. Workers might spend plenty of time managing loose scrap without this aforementioned device. It can make your process more sluggish eventually. Baling the scrap will make it simpler for you to move it around. Thus, your workers will be capable of emphasizing other essential jobs.

The machine likewise functions quicker compared to handling scrap manually. Therefore, you can process more material within a short time. Enhanced productivity will allow you to handle large volumes of scrap easily. No additional time or manpower will be required whatsoever.

4. Streamlines Material Handling

Handling loose scrap might be time-consuming and difficult. It is possible for a scrap baling machine to simplify the process. This can be done by making the scrap more compact. The machine can lift and transport the bales easily using equipment like forklifts. This will minimize the volume of manual labor needed to move around the scrap. The machine will streamline the process of handling various types of waste. This can be plastic, paper, or metal. Simplifying material handling will allow you to enhance the overall waste management system flow. It will become more efficient eventually.

5. Ensures Better Scrap Organization

One significant advantage of using a scrap baling machine is that it offers enhanced organization. It can be difficult to manage loose scrap once it piles up quickly. Using a baler will compress the scrap into tidy and organized bales. It is feasible to label and categorize the bales according to the type of material. Therefore, it will become simpler to monitor and manage your inventory.

You can maintain the cleanliness of your facility by having better organization. It will also help you to prevent any clutter in the facility. Therefore, you can easily locate some particular materials when they are in demand. This kind of organization will enhance your waste management efficiency significantly.

6. Improves Workplace Safety

The aforementioned machine will result in a safer work ambiance. It is possible for loose scrap to form hazards that might be injurious. However, one can handle and move around scrap safely once it is baled. The machine will minimize the requirement for manual labor. It will reduce the risk of injury in the workplace. It will create a safer and cleaner work area for everybody involved in the process of waste management.

Wrapping up

A scrap baling machine will be essential for enhancing the efficiency of waste management. Investing in this device will help you to achieve a more sustainable and efficient process to manage the scrap materials.

Visit us: https://handyclassified.com/how-a-scrap-baling-machine-improves-waste-management-efficiency

0 notes

Text

Essential Tips for Operating a Scrap Baling Machine

A scrap baling machine is a powerful piece of equipment used to compact and bale large amounts of scrap and waste materials. These machines are commonly used by manufacturing companies to deal with paper, cotton, and metal scraps, while the retail and service industries utilize them for cardboard and paper waste. Operating a Scrap Baling Machine requires adherence to strict safety protocols and efficient maintenance practices to ensure optimal performance and avoid injuries. Here are some essential tips to keep in mind when working with these machines:

Safety First

Operating a Scrap Baling Machine demands strict adherence to safety protocols to prevent injuries and ensure smooth operations. Understanding the machine's design, especially safety features like emergency stops and interlocks, is crucial. Regular checks for any signs of wear or malfunction are necessary to maintain these systems effectively. Safety barriers should be employed to restrict access during operation, preventing unauthorized or unsafe use

Before Operation: Conduct thorough daily inspections to check for potential hazards like loEnsure the scrap baling machine is idle for about three minutes before operation, and test the oil tank for any leaks. Pay attention to the usual sounds of the engine, hydraulic unit, valves, fittings, and piston, as any unusual noises may indicate a problem.

Emergency Protocols: Ensure that emergency stop buttons are functional and accessible, and train all operators on how to use them effectively.

Interlocks and Guards: Maintain mechanical guards and safety interlocks to prevent accidental starts during maintenance or when the chamber is open.

Operator Training

Training is a vital component of operating a Scrap Baling Press Machine. It should cover all aspects of operation, maintenance, and emergency handling. Only trained personnel should operate the machine to ensure they understand the operational procedures and can identify potential hazards.

Training Programs: Include hands-on sessions that cover the machine's operations, maintenance, and troubleshooting.

Certification: Operators should be certified after completing training programs that include safety protocols and operational procedures.

Ongoing Training: Regular refresher courses to update the operators on new safety protocols and operational techniques.

Maintenance and Housekeeping

Regular maintenance is key to the longevity and optimal performance of your baling press machine. Implement a comprehensive maintenance program that includes general housekeeping practices.

Scheduled Maintenance: Keep the machine and its surroundings clean, paying special attention to areas like behind the ram(s), sensors, and the oil cooler. Regular cleaning prevents fires, reduces the risk of overheating, and minimizes oil contamination.

Oil Maintenance: Establish an oil maintenance program. Oil is the lifeblood of your baling press machine, so it is crucial to sample and test it regularly—approximately every 1,200 operating hours. Send the samples to a reputable oil analysis company to identify any contamination and address issues promptly.

Clean Work Environment: Keep the area around the baler clean and free of debris to avoid accidents. Regularly clear out waste materials that can build up and cause jams.

Record Keeping: Maintain logs of maintenance activities and any issues encountered during operation to help diagnose problems and plan preventive maintenance.

Understanding Materials

Proper material handling and understanding are critical to maximizing the efficiency of a Scrap Baling Machine. The materials suitable for baling vary and include recyclables like cardboard, paper, plastic, and metals, which should be sorted and prepared before baling to enhance processing efficiency and bale quality. This preparation involves removing contaminants and non-recyclable items, which helps prevent machine damage and ensures high-quality bales.

Sort and Prepare: Implement rigorous sorting to separate materials based on type and quality. This reduces contamination and ensures only suitable materials are processed.

Understand Material Characteristics: Different materials require specific handling and baling pressures. Knowledge of material characteristics can optimize the baling process and prevent machinery wear.

Continuous Feed: Utilize systems that allow for the continuous feeding of materials, such as conveyor belts, to maintain a steady and efficient baling operation.

Routine Inspections:

Routine inspections maintain the operational integrity and safety of a Scrap Baling Machine. Regular checks help identify potential mechanical issues or safety hazards before they lead to operational downtime or accidents. Effective inspection routines can significantly extend the life of baling equipment and enhance safety on the production floor.

Daily Checks: Perform daily visual and functional checks to assess the hydraulic systems, electrical components, and structural integrity of the baler.

Maintenance Schedule: Follow a strict maintenance schedule to check for wear and tear, lubricate moving parts, and replace worn-out components.

Documentation and Records: Keep detailed records of inspections, maintenance activities, and any repairs done to track the machine’s condition and predict future maintenance needs.

Conclusion: EnvCure's Commitment to Sustainability

At EnvCure, our commitment extends beyond providing top-tier equipment. We believe in empowering our clients to make substantial environmental contributions through the proper use of technology. Operating a scrap baling machine not only streamlines waste management but also supports recycling initiatives, reducing the ecological footprint of industrial activities. We understand the challenges posed by recyclable and non-recyclable waste, and through innovation, we aim to offer solutions that benefit both our clients and the planet.

For more detailed guidance and to ensure you're using your scrap baling machine to its fullest potential while adhering to safety standards, always consult the manufacturer's instructions and stay updated with the latest safety protocols.

0 notes

Text

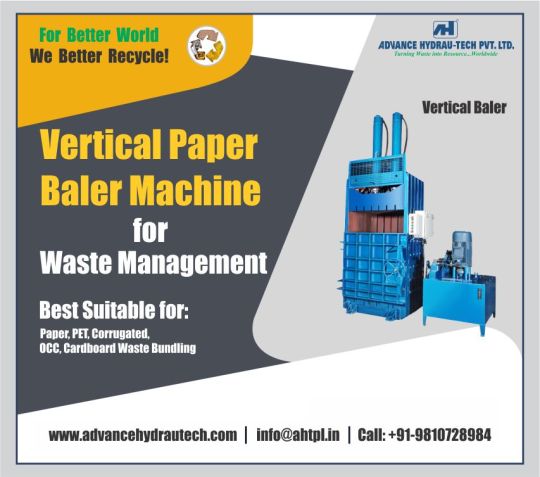

Waste Paper Compacting with Vertical Baler

Compact your low to medium of waste with vertical baler machine. Advance Hydrau-Tech’s manufacturing vertical baler machine is suitable for compressing paper, plastic, cardboard, occ, kraft paper etc. Compact design and small size make vertical balers ideal for customers with space issues. It easily fits into confined spaces. You can expect high productivity, operational efficiency and low maintenance with our double-cylinder vertical baling press. These vertical balers can compress waste into bundles measuring 30” x 48” and manually operated machines, which are available in both single compression and double compression models. For all types of scrap processing solutions, contact Advance Hydrautech.

0 notes

Text

Scrap Baling Machines: How They Contribute to Sustainable Waste Management & Handling Solutions

In an age where environmental concerns are paramount, businesses worldwide are seeking innovative solutions to address waste management challenges. One such solution gaining prominence is the use of scrap baling machines. These machines play a pivotal role in transforming how we handle waste, making it more sustainable and eco-friendly. In this blog, we will discuss about the world of scrap baling machines and their contribution to sustainable waste management, with a special spotlight on Balertech Industries Private Limited.

Understanding Scrap Baling Machines

Scrap baling machines, also known as balers, are industrial equipment designed to compress various materials into compact, manageable bales. These materials can range from paper, cardboard, plastics, metals, and more. The primary purpose of a scrap baling machine is to reduce the volume of waste materials, making them easier to store, transport, and recycle.

Environmental Benefits

The environmental benefits of scrap baling machines are substantial. By compacting materials into bales, they reduce the space required for storage and transportation. This not only lowers transportation costs but also minimizes carbon emissions associated with hauling bulkier, loose materials. Additionally, baled materials are more accessible for recycling facilities, enhancing the recycling rates and decreasing the burden on landfills.

Balertech Industries Private Limited: Leading the Way

When it comes to reliable and efficient scrap baling machines, Balertech Industries Private Limited stands out as an industry leader. Our commitment to sustainability and innovation has earned them a stellar reputation in waste management solutions. Let's explore some of the key reasons why Balertech is a go-to choice for businesses seeking sustainable waste management solutions.

Cutting-Edge Technology: Balertech invests in cutting-edge technology to design and manufacture state-of-the-art scrap baling machines. These machines are equipped with advanced features that enhance efficiency while minimizing energy consumption.

Customization: Balertech understands that each business has unique waste management needs. We offer a range of customizable baling machines, ensuring that clients get solutions tailored to their specific requirements.

Durability: The longevity of the machines is a testament to the quality. Balertech's scrap baling machines are built to last, reducing the need for frequent replacements and minimizing waste in the long run.

Customer Support: Balertech prides itself on excellent customer support. Our team is readily available to assist clients with installation, maintenance, and troubleshooting, ensuring a seamless experience.

Scrap baling machines have emerged as game-changers in the realm of sustainable waste management and handling solutions. The ability to compress materials, reduce waste volume, and facilitate recycling makes them indispensable in the fight against environmental degradation. Balertech Industries Private Limited, with its dedication to innovation and sustainability, exemplifies the positive impact that businesses can have on the environment.

Investing in scrap baling machines not only benefits the environment but also makes economic sense by reducing waste disposal costs and increasing recycling revenues. As we move forward in our collective effort to build a more sustainable future, scrap baling machines will undoubtedly play a pivotal role in reshaping waste management practices. So, if you're looking to make a meaningful contribution to sustainable waste management, consider integrating Hydraulic Scrap Baling Machines into your operations. And when you do, keep Balertech Industries Private Limited in mind as your trusted partner in this eco-conscious journey. Together, we can create a greener and cleaner world for generations to come.

1 note

·

View note

Text

Rosauers Supermarkets to Pay $350K in Back Wages

Department of Labor Recovers $350,000 in Back Wages and Damages After Finding Spokane-Based Super Market Chain, Rosauers Supermarkets Denied 602 Workers Overtime Pay. Rosauers Supermarkets assessed $72K in penalties for willful, repeated child labor violations. SPOKANE, WA (STL.News) An extensive U.S. Department of Labor investigation into the pay and employment practices at 23 stores operated by a Spokane-based supermarket chain, Rosauers Supermarkets, has recovered more than $350,000 in back wages and damages for 602 employees and assessed penalties of $72,862 for the employer’s willful violations. The department’s Wage and Hour Division discovered Spokane’s Rosauers Supermarkets Inc. did not pay employees for meal breaks less than 20 minutes long, as required, and failed to include evening premium pay, hazard pay, and non-discretionary bonuses in regular pay rates when calculating overtime wages. Investigators found these violations at 16 stores in Washington, four in Montana, two in Idaho, and one in Oregon. The division also learned the employer violated federal child labor regulations by employing five minors, ages 16- and 17 years old, to operate a powered scrap paper baler and paper box compactor at its Ridgefield, Washington store. “Too often, our investigators find grocery industry employers taking advantage of these essential workers by failing to pay them correctly,” said Wage and Hour Division District Director Carrie Aguilar in Portland, Oregon. “In addition to denying hundreds of employees pay for short meal breaks, Rosauers Supermarkets jeopardized the safety of children by employing them to illegally operate dangerous machines.” The company operates stores such as Rosauers Supermarkets, Super1Foods, and Huckleberry’s Natural Market. Specifically, the division identified violations of the Fair Labor Standards Act’s overtime and recordkeeping requirements at stores in Hood River, Oregon; in Lewiston and Moscow, Idaho; in Bozeman, Kalispell, Libby, and Missoula, Montana; and in Colfax, Colville, Ellensburg, Pullman, Ridgefield, Spokane, Walla Walla and Yakima, Washington. Investigators found child labor violations at the Ridgefield location. “The U.S. Department of Labor is determined to enforce laws that protect workers’ rights to be paid fully and to prevent young employees from being employed in dangerous jobs. The Fair Labor Standards Act allows for developmental experiences but restricts the employment of young workers in certain jobs and provides for penalties when employers do not follow the law,” Aguilar added. In addition to recovering $175,363 in unpaid overtime wages and an equal amount in liquidated damages, the penalties assessed by the department included $17,820 for repeated child labor violations. The division cited the employer for similar child labor infractions at 10 stores in 1993. SOURCE: U.S. Department of Labor (DOL) Read the full article

0 notes

Text

Scrap baling machines: How It Helps In Investing in Sustainable Waste Management & Handling Solutions?

Imagine a world where waste management is a seamless process instead of a difficult one. Today, he introduces one of his great solutions to make that dream a reality: the scrap baler. But before we get to the point, let's first touch on a broader problem facing many businesses and public institutions: inefficient waste management.

The Challenge of Space in Waste Management

Waste management is a complex subject with many challenges. One of the most pressing concerns in this situation is the efficient use and management of space. In many businesses and organizations, waste disposal is often an afterthought, resulting in inefficient use of space and increased operating costs.

If not handled properly, waste can quickly fill designated disposal areas and form vast landfills. These landfills aren't just unsightly. It also leads to wasteful use of precious land resources. A World Bank study estimates that the total amount of waste produced by humans will increase by 70% by 2050 if current habits are left unchecked.

Landfills: Non-biodegradable waste such as scrap metal and scrap takes up a lot of space, leading to inefficient and bloated landfills.

Environmental Hazards: Improper storage of these materials can contaminate soil and freshwater sources.

Transportation: This waste takes up a lot of space, making it more difficult and expensive to transport.

Safety Risks: There is a risk of injury when handling the material itself.

These difficult problems require innovative solutions. That’s where baling machines come into the picture.

Introducing the Scrap Baling Machine

At the intersection of technology and environmental sustainability is EnvCure, a company dedicated to tackling environmental challenges by providing practical, efficient and economical solutions. One of the wonders of the company's product line is the vertical scrap baling machine.

Designed to compact waste, this machine compresses waste to a manageable size and offers many benefits.

Better Space Management: Balers improve space utilization and enable industry and public institutions to manage waste more efficiently.

Ease of Transportation: Compressed waste occupies less space, allowing businesses to transport larger volumes and save costs.

Ease of Handling: Compressed waste is easier and safer for workers, reducing the risk of injury.

Power Efficiency: Baler machine optimizes power consumption by designing to efficiency and high-performance standards.

A Versatile Solution

One of the main advantages of scrap balers is their versatility. It is not limited to scrap metal compaction only. Whether plastic, paper, cardboard, textiles or even agricultural waste, this machine can handle a wide variety of garbage.

Its versatility offers companies in various industries the opportunity to manage waste efficiently. Manufacturing industries, recycling centres, farms, hospitals, and educational institutions can all benefit from this dynamic solution. Not only does this machine help with waste management, but it also facilitates recycling, which is an integral part of sustainability.

Versatility Highlights:

Waste Material Diversity: The machine can compact a wide range of waste materials.

Industry-Wide Application: Usage is not limited to a specific type of business or industry.

Promotes Recycling: The machine compacts and manages waste to facilitate recycling and is a step towards environmental sustainability.

Economic Implications of a Baling Machine

It is important to recognize that incorporating balers into your waste management strategy not only contributes to environmental sustainability but also provides significant economic benefits.

Compressing and organizing waste materials makes transportation easier and saves transportation costs. In addition, compacted waste is easier to store, improving space utilization and potentially saving storage costs.

In industries where waste can be sold or recycled, balers can turn waste into a profitable resource. Compact bales of scrap are easy to sell to recyclers and other businesses, providing additional revenue for businesses.

Economic Highlights:

Transportation and Storage Savings: Compact waste reduces transportation and garage costs.

Revenue Generation: Compressed waste can be sold or recycled, providing an additional revenue stream.

Long-term Investment: Machines require an up-front investment, but the long-term savings and potential revenue generation are worth considering.

Embracing Sustainable Waste Management

Waste baling machines enable businesses to transform their waste management processes. Isn't that a daunting challenge? Rather, it becomes a manageable task that contributes to sustainability goals while reducing costs.

A scrap baler is more than just a tool. it's an investment. This contributes to the organization's long-term sustainability plans and strengthens its commitment to protecting the environment. It's not just big companies and waste treatment plants. Hospitals, universities, canteens, etc. can use this technology to better manage their waste.

Conclusion: Investing in a Sustainable Future with EnvCure

Now is the time to develop efficient waste management strategies for a more sustainable future. Using a scrap baling machine not only contributes to a healthier environment, it also makes your waste disposal process more efficient and cost-effective.

At EnvCure, we strive to create a healthier environment for everyone. Through a combination of technology, awareness and a commitment to environmental solutions, we can build a better world for future generations. Experience a sustainable future with EnvCure. Invest in a scrap baler today.

Source URL: https://www.envcure.com/scrap-baling-machines-how-it-helps-in-investing-in-sustainable-waste-management-handling-solutions/

0 notes

Text

How to Choose the Best Paper Scrap Baler Machine in India

A paper scrap baler machine in India is essential for compressing paper waste into compact bales, saving space and simplifying transport.

Used across recycling plants, warehouses, and industries, these machines help manage bulk paper waste efficiently and support better waste disposal practices across Indian operations.

#Paper Scrap Baler Machine#Paper Scrap Baler Machine in Ahmedabad#Paper Scrap Baler Machine in Gujarat#Paper Scrap Baler Machine in India

0 notes

Text

Baling Machine: The Perfect Solution for Efficient Waste Management

Effective waste management is paramount now, especially given the fast-paced nature of industrial development. Baling Machine is important in the waste management process to bind and compress waste materials into manageable bales. These machines are widely used in several industries, including manufacturing, recycling, agriculture, and logistics, for reducing waste volume, improving handling, and encouraging environmentally friendly processes.

What is a Baling Machine?

A Baling Machine is a machine that works by compacting different kinds of garbage and waste, these types include; Cardboard, Plastic, Textile, Paper, Metal Cans etc. With the use of pressure, this equipment compresses the solid waste into bales of standardized size that are then stored and transported easily.

The Top Advantages of Using a Baling Machine

1. Reduction in Waste Volume:

The biggest benefit of having a baling machine is that it minimizes the waste volume by almost 90%. That is a big help in saving storage space and disposal costs.

2. Cost-Effective and Efficient:

With reduced volume, waste can be collected less frequently as well as pay for all costs involved in waste transportation. Compact bales are more convenient to handle as well as moved around, increasing overall productivity.

3. Eco-Friendly Waste Management:

It encourages a recycling process through the recycling baling machine technology. Baled materials' easy transfer to recycling plants enables eco-based waste disposal.

4. Saving Space:

These machines are considered to be space saving because they have a small footprint and thus suit businesses with floor space limitation, but they still have powerful baling performances in spite of their small footprint.

Applications of Bailing Machines

Retail and Warehousing: Managing all packaging wastes effectively.

Manufacturing Mills: For compact industrial scrap and reducing the volume of waste.

Recycling Centers: Preparing recyclables (like cardboard, plastics, textile wastes) into forms suitable for transport in bales.

Hospitality and Health Care: A bulk waste management solution such as paper, plastic, and food packaging.

Also read, Scrap baling machines: How It Helps In Investing in Sustainable Waste Management & Handling Solutions?

What Is the Need for a Baling Machine?

Effective Waste Handling: Businesses can easily manage bulk waste with quick and consistent compaction.

User-Friendly Operation: Baling machines are designed to allow easy operations and so on for various industries.

Better Working Environment Safety: Through the restriction of loose waste within the factory boundaries, balers help to maintain a relatively clean and safe working environment.

Conclusion

Purchasing a Baling Machine is a wise investment for businesses striving to improve their waste management. Cost efficiency, improved performance, and environmentally friendly make balers indispensable in industries with huge waste handling.

EnvCure Technocrat LLP also provides baling machines of high efficiency to meet the different needs of the companies, ensuring their waste management is always reliable and efficient.

0 notes

Text

Revolutionizing Recycling: The Versatility of Baling Press Machine

Are all of you tired of dealing with mountains of waste? Do you want to do your part to save the environment in the future? Look no further than the revolutionary baling press! This powerful and versatile equipment is changing the game when it comes to recycling. With its ability to compress and bundle various materials, from cardboard and plastic to paper and metal, the Baling Press Machine is a true game-changer. In this blog post, we will explore what exactly a baler machine is, how it works, its different types, as well as the countless benefits it offers. So buckle up and get ready to dive into the world of recycling innovation like never before!

What Is A Baling Press Machine?

A Hydraulic Baling Press Machine is a specialized device utilized in the recycling industry to compact and bind different types of materials into dense bales. These machines efficiently consolidate waste such as paper, cardboard, plastics, textiles, and metals, reducing their volume for easier storage and transportation. Baling presses streamline recycling operations by automating the process and integrating with other equipment. They enhance the value of recyclable materials by increasing their weight per unit volume, reducing storage and transportation costs. With their versatility and ability to handle various materials, Baling Machine significantly contributes to sustainable recycling practices and the conservation of resources.

How Does A Baling Press Machine Work?

A Plastic Baling Machine operates through a series of steps that involve compressing and binding recyclable materials into dense bales. Here's a simplified overview of how a typical baling press works:

Material Loading: The operator or an automated system feeds the recyclable materials, such as paper, cardboard, plastics, or metals, into the baling chamber of the machine.

Compression: The baler machine applies pressure to the materials using hydraulic cylinders or a mechanical mechanism. This compresses the materials, reducing their volume.

Binding: Once the materials are compressed, the baling press machine uses wires, straps, or twine to tightly bind the compressed materials together. This ensures the bale remains intact during handling and transportation.

Bale Ejection: After binding, the bale is ejected from the baling chamber. Depending on the machine, the bale can be manually removed or automatically conveyed to a storage area.

Bale Tying: In some cases, the bale may require additional securing. This can involve manually or automatically tying off the wires, straps, or twine to prevent the bale from coming apart.

Bale Removal and Storage: The completed bales are removed from the baler press machine and stored for further processing, transportation, or sale.

The Various Types of Baling Press Machines

There are several types of baling press used in the recycling industry:

Vertical Baling Press: Suitable for compressing materials like cardboard, paper, plastic film, and textiles. They have a vertical orientation and are compact, ideal for smaller operations.

Horizontal Baling Press: Designed for larger volumes of materials such as plastics, foam, and metal scrap. They have a horizontal orientation and offer high throughput for industrial-scale recycling.

Two-Ram Baler: Versatile machines capable of handling various materials, including paper, cardboard, plastics, and metals. They use two hydraulic rams to compress materials, offering flexibility in bale size and density.

Drum Crusher: Specialized machines for crushing and compacting steel or plastic drums, optimizing storage and transportation.

Scrap Metal Baler: Used specifically for compressing and baling scrap metal, such as aluminum cans or steel components, facilitating efficient recycling and transportation.

The Benefits of Using a Baling Machine

Efficient waste management: Baler machines compact recyclable materials into dense bales, reducing their volume and optimizing storage and transportation. This saves space, reduces handling costs, and improves waste management efficiency.

Time and labor savings: These machines automate the baling process, reducing the need for manual labor. They streamline operations, increase productivity, and allow for the processing of larger quantities of materials in less time.

Cost-effectiveness: Baler machines help reduce transportation costs by compressing materials into dense bales. The denser bales require fewer trips, resulting in lower fuel consumption and transportation expenses.

Increased revenue: Baled materials have higher market value due to their improved density and reduced storage requirements. This leads to increased revenue for recycling facilities.

Environmental sustainability: These press machines contribute to environmental sustainability by reducing the need for landfill space. They promote resource conservation by enabling the reuse and recycling of materials, reducing waste, and minimizing carbon emissions.

Conclusion

Baling press machines are instrumental in revolutionizing the recycling industry. They provide efficient waste management, time and labor savings, cost-effectiveness, increased revenue, and contribute to environmental sustainability. By compacting and binding recyclable materials into dense bales, these machines optimize storage and transportation, streamline operations, and enhance the value of recyclables. With their versatility and ability to handle various materials, baling press machines play a vital role in promoting recycling and preserving our environment for a greener future.

0 notes

Text

Choose the Right Hydraulic Baling Press Machine For Your Metal Recycling Business

One of the most vital pieces of equipment in the scrap processing sector is the hydraulic baling press. The global economy, which is lurching towards becoming more circular, is being shaped by the scrap metal recycling sector. Businesses are learning how to recycle outdated equipment by utilizing modern technology. However, most firms still aren't aware of how to recycle their metal waste in an economical way.

In steel mills, the metal processing industry, and even the smelting industry, a hydraulic baling press has several uses. Balers assist in compacting huge amounts of recyclable material for simpler storage and transportation. In the case of industries that recycle metal, a baler can be used to extrude different metal scraps into bales, minimizing the amount of storage space and transportation expenses needed to dispose of waste metal. By maximizing the value of each bale, they also enable higher commodity values. Balers are typically used to crush recyclables such as cardboard, paper, plastic, and metal.

Before selecting a hydraulic baling press for their business operations, every business owner should take into account the following factors:

The Amount of Raw Material to be Baled

The amount of material that needs to be processed should be the primary consideration for the business owner when choosing the type of baling machine to buy. Every company is unique, and each produces stuff in varying quantities that must be processed. Before making a choice to purchase equipment, it is crucial to analyze the needs of the company. Based on their size and capacity, hydraulic baling presses are available in a variety of sizes and are priced differently. A corporation should be certain of the volume of material it plans to regularly process and recycle before investing in the machine. Overpaying for capacity that the company doesn't produce is not a good idea.

The lifespan of the Equipment

Durability is crucial since a hydraulic baling press can be used continuously for many hours to maximize production. The business owner must evaluate the needs and compare them to the machine's lifespan before making a purchase. When making a purchase, it's crucial to take into account elements like the equipment's durability, a warranty on part replacement, and a maintenance routine for the machine. Knowing about these issues might help firms plan their work and budgets to account for the equipment downtime.

Raw Material to be Processed

One of the primary determinants of the type of hydraulic baling press to be purchased is the type of material that will be compressed. The type of business and the type of trash that is recycled or disposed of have an impact on the equipment that is best for the organization. The company can recycle in an environmentally responsible and economically viable way by selecting the appropriate recycling equipment.

Safe Operation of Equipment by Staff

Heavy machineries like balers, which have numerous moving parts and crushing rams, must be handled with extreme caution. Two key factors that a business intending to buy balers should look at before making the purchase are the safety features of the equipment and the availability of employee training. The company ought to place a high premium on the working conditions of the personnel using this equipment. Companies must invest in training to help protect employees since safe equipment handling is essential to reducing workplace accidents.

Benefits of Hydraulic Baling Press Machine:

Reduces the cost of garbage disposal.

Offers a simpler recycling procedure that can contribute to creating a hassle-free and hygienic working environment. helps to generate extra revenue from processed garbage.

Facilitates the transit or storage of items

A firm can make the best purchase by first studying and comprehending its equipment requirements and by considering the opinions and recommendations of other business owners. They can use these techniques to locate the ideal hydraulic baling press for the task.

Triple Action Baling Machine | Plastic Baler | Baling Pres Machine | Hydraulic Baler | Automatic Baler | Baling Machine MFR

#baling press machine#baling machine#plastic baler#plastic baling machine#hydraulic baler#hydraulic baling press machine#automatic baler#automatic baler machine#automatic baling press machine#triple action baling machine#Baling machine mfr#baler machine mfr

15 notes

·

View notes

Text

Scrap Baling Machine for Compacting Iron, Aluminium, Steel And CRC

Compress your scrap to get high density bundles. Our scrap baling machine can compact wide range of scrap material such as Iron, Aluminum, Steel And CRC Scrap easily and effectively. Advance Hydrau-Tech is one of the leading manufacturer in India always offers high quality recycling machines for metal recycling and automobile recycling industry. Our waste processing machines also support paper and plastic recycling industry.

Features of Metal Balers as Follows:

1. Can Compress Iron, MS, Steel, MS, CRC from 2 - 50 ton per shift

2. Available Baling machines for metal, paper, automobile and agriculture waste processing

3. Get compacted and high density bales

4. Models available - Single, Double and Triple Compression

5. Suitable machines for small traders, scrap collector and big manufacturers

6. Machines available - Mini and Jumbo Models as per scrap need

Why to Prefer Advance Hydrau-Tech

1. We are India's Largest manufacturer and over 8000 machines exported worldwide

2. High professional Sale Service Team

2 notes

·

View notes

Text

Straight Balers For Your Business Recycling Program

Straight balers are wonderful devices for customers of Full Recycling that have a greater quantity of recyclables than an upright baler can successfully refine. Because horizontal balers have the capability for huge batches of material, they often tend to have more features that automate the procedure, relying on the version. As well as they can use up considerably even more space. There are three sorts of frequently used straight balers: closed-door manual-tie straight balers, open-end automated tie straight balers and also two-ram straight balers.

Closed-Door Manual-Tie Horizontal Baler

When contrasted to various other types of balers, the closed-door manual-tie baler is the most easy of its kind. This tools has a hopper (vicinity where materials are fed) that absorbs recyclables that are either provided by hand or be available in from a reusing conveyor.

When sufficient products have been filled right into the equipment and also begins the compression cycle, this type of industrial baler finds.

More material can after that be added until the equipment detects that an enough bundle has been formed, density wise. The thickness is identified by a setting set into the device per the user's requirements. Once the full bale is developed, it's all set to be manually linked by a worker.

Depending upon the kind of material processed, some business will include an accessory tool such as an industrial shredder to their reusing tools services. Shredders can be used to process product better prior to baling. Complete Recycling can enlighten your business one of the perfect kind of equipment for your center.

Open-End Automatic-Tie Horizontal Baler

The open-end auto-tie straight baler is excellent for Full Recycling customers that have a heftier lots of recyclable material. This sort of baler machine (just click Hlbaler) enables for a continual feed of products to be refined for reusing. The recyclables can be fed through the receptacle by a conveyor belt or by hand. However as the name suggests, it's an open-ended machine, which permits materials to be baled and instantly connected by the equipment in one dropped swoop.

Since this is an extra refined piece of tools than the fundamental closed-door manual-tie straight baler, its rate point is greater. But, it's crucial to weigh the possible prices with the benefits. The auto-tie function can connect the bundle in seconds. This can conserve your internal resources as well as enable your staff to concentrate on other points. And some of these designs have an auto-clean feature that assists with the upkeep of the equipment.

Full Recycling works with our clients to guarantee they are educated on one of the most efficient item of baling devices for their price factor. As well as with our equipment financing choices, you can be equipped with the balers you need, right currently.

Two-Ram Horizontal Balers

These sorts of balers are perfect for customers of Total Reusing that have all various sorts of by-product recyclable materials. And those who have recyclables on a larger range than what the various other equipment can fairly handle.

Two-ram straight balers are equipped for handling:

Paper recyclables Plastic recyclables Scrap metal recyclables

When with no demand for a guidebook driver, the two-ram horizontal baler can handle a large load of material at. Frequently, clients that utilize this kind of equipment enhance it with a conveyer belt for optimum efficacy. This is since the two-ram straight baler has a cutting element that shreds materials throughout the baling process.

As the name suggests, this tools has two rams. One ram works to bale the material and also the other expels the bundle. The two-ram horizontal baler has an automatic tying system also, so throughout, this machine releases your employees to focus on other points.

Because this is a more challenging baler than the other kinds, upkeep and operating prices can be higher.

Full Recycling can analyze your recycling needs, possible workload as well as costs/benefits of any sort of baler. This guarantees you're finest furnished with the right equipment for the task.

1 note

·

View note