#Paper Slitting Rewinding

Explore tagged Tumblr posts

Text

Label stock Kraft Paper Lamination Film Jumbo Roll Release Paper slitter

This model jumbo roll slitter rewinder machine mainly use for converting pressure sensitive material, such as self adhesive paper, sublimation paper, BOPP, OPP, PVC film. Differential friction rewinding shaft for better control tension.

sonia wei E-mail: [email protected] whatsapp: 008613306265137

#slitter machine#slitting machine#rewinder machine#slitter rewinder machine#labelstock slitter machine#paper roll slitter machine#roll slitter machine#film rewinder machine#filmslitter rewinder machine#release paper#self adhesive paper#lamination film#jumbo roll#kraft paper

0 notes

Text

KEW ENGG. & MFG. PVT. LTD., we specialize in manufacturing cutting-edge Heavy Duty Drum Slitter Machine designed to meet diverse industrial requirements. Whether it’s for paper, plastic, textile, or packaging applications, our machines deliver unparalleled precision and durability.

#kewengg#machine#machinery#industry#machinemanufacture#industrial#exporter#supplier#manufacturer#manufacturing#Heavydutydrum#heavyduty#slittermachine#paper industry#papermachinery

2 notes

·

View notes

Text

A paper slitter is a slitting device that cuts a wide roll of paper on a paper machine into a narrower width of paper while rewinding it onto a receiving reel.

2 notes

·

View notes

Video

youtube

500mm paper and paper label and plastic film slitting rewinding machine/...

0 notes

Video

youtube

JRT Jumbo Roll Toilet Tissue Paper Converting Slitting Rewinding Making ...

www.opecmachinery.com/

0 notes

Text

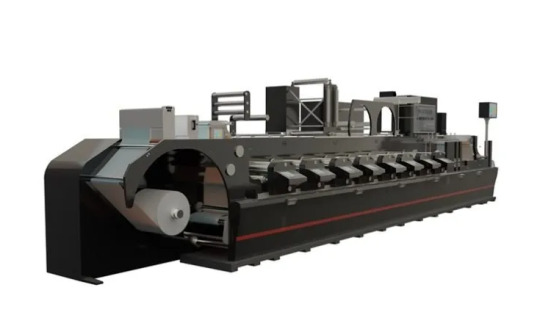

High-Performance Printing & Converting Machines | Advanced Solutions

In the modern world, the printing and packaging industry has started to completely rely on precision, effectiveness, and novelty. Advanced technology such as slitting rewinding machines, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems is among the most significant tools rendering final mba product quality.

Machine manufacturers and converters rely heavily on high-level technological tools to speed up the process of production, increase accuracy, and aid versatility of their machines. The description of the machines' importance in various industrial applications has been outlined in a set of present practice method, showing machines' necessity in printing and packaging industries today.

Slitting Rewinding Machine

A slitting rewinding machine is a vital component in industries dealing with flexible packaging, paper, films, and foil materials. It enables the precise slitting and rewinding of large master rolls into smaller rolls with accurate tension control.

Key Features of a Slitting Rewinding Machine:

High-Speed Performance: Ensures rapid slitting and rewinding without compromising quality.

Precision Cutting: Adjustable slitting blades provide clean and accurate cuts.

Tension Control Mechanism: Maintains optimal tension for smooth rewinding.

User-Friendly Interface: Automated controls for easy operation and reduced downtime.

Versatile Applications: Suitable for plastic films, aluminum foils, paper rolls, and adhesive tapes.

Applications of Slitting Rewinding Machines:

Flexible Packaging Industry: For slitting plastic films and foils.

Label Production: Converts large rolls into label-sized formats.

Printing Industry: For handling coated and laminated materials.

Label Die Cutting Machine

A label die cutting machine is essential for the precise cutting of labels, stickers, and adhesive sheets. It ensures clean edges, intricate shapes, and high-speed production for industries requiring mass labeling.

Key Features of a Label Die Cutting Machine:

Rotary & Flatbed Cutting: Supports various die-cutting methods for different label types.

Automatic Waste Removal: Ensures a cleaner output with no excess material.

High Cutting Accuracy: Ideal for custom shapes and intricate label designs.

Multi-Layer Processing: Allows multiple layers for enhanced durability.

User-Friendly Control Panel: Simplifies operation and reduces labor requirements.

Applications of Label Die Cutting Machines:

Food & Beverage Labeling: Used for bottle and container labeling.

Pharmaceutical Industry: For precision-cut medical labels.

Cosmetic & Personal Care Products: Ensures premium quality label cutting.

Paper Core Cutting Machine

A paper core cutting machine is used to cut paper tubes and cores to the desired length, ensuring smooth edges and accurate dimensions for various industrial applications.

Key Features of a Paper Core Cutting Machine:

High Cutting Precision: Produces accurate and smooth cuts for uniform core sizes.

Adjustable Cutting Lengths: Allows customization for different applications.

Heavy-Duty Construction: Ensures durability and longevity.

Automatic & Manual Operation: Supports both automatic and manual cutting modes.

Dust-Free Operation: Minimizes waste and enhances cleanliness.

Applications of Paper Core Cutting Machines:

Packaging Industry: For manufacturing paper cores for packaging rolls.

Printing Sector: Used for paper roll cores and film winding.

Textile Industry: For fabric and yarn core cutting.

Hot Foil Stamping Machine

A hot foil stamping machine enhances the visual appeal of printed products by adding metallic and holographic foil designs. It is widely used in luxury packaging, book covers, greeting cards, and promotional materials.

Key Features of a Hot Foil Stamping Machine:

Advanced Foil Transfer Technology: Ensures sharp and clean imprints.

Temperature & Pressure Control: Allows precise adjustments for different materials.

Multi-Purpose Applications: Works on paper, plastic, leather, and fabric.

Automatic Foil Feeding System: Ensures smooth and continuous foil application.

Energy-Efficient Design: Reduces operational costs and improves efficiency.

Applications of Hot Foil Stamping Machines:

Luxury Packaging: Enhances premium product packaging.

Branding & Promotions: Used for high-end business cards and brochures.

Security Printing: Adds holographic elements for anti-counterfeiting.

UV Curing Systems

A UV curing system is an advanced technology used for instant drying and curing of inks, coatings, and adhesives using ultraviolet light. This method ensures high-quality finishes, durability, and eco-friendly operations.

Key Features of a UV Curing System:

Instant Drying & Curing: Reduces production time significantly.

Energy Efficiency: Consumes less power compared to traditional drying methods.

Eco-Friendly Operation: Eliminates the need for solvents and harmful chemicals.

High Durability: Ensures scratch-resistant and long-lasting prints.

Wide Compatibility: Suitable for offset, flexographic, and screen printing.

Applications of UV Curing Systems:

Printing Industry: For UV-cured inks and coatings.

Electronics & PCB Manufacturing: Ensures durable protective coatings.

Medical Devices: Used for adhesive bonding in healthcare applications.

Why Invest in High-Performance Printing & Converting Machines?

Enhanced Production Efficiency – Reduces downtime and increases output.

Precision & Quality – Ensures accurate cutting, stamping, and curing.

Cost-Effective Solutions – Optimizes material usage and reduces waste.

Versatile Applications – Suitable for various industries, from packaging to textiles.

Advanced Automation – Minimizes manual labor and improves operational accuracy.

By integrating the latest slitting rewinding machine, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems, manufacturers can achieve superior productivity and quality.

Project Name: UV Graphic Technologies Pvt. Ltd

Address: Plot 15, Sector 140A, Noida UP 201305

Contact No: 919810114365

Email ID: [email protected]

Our Website: https://gtigti.com/

Linkedin ID: https://www.linkedin.com/company/uv-graphic-technologies-pvt-ltd/

You tube: https://www.youtube.com/watch?v=EleXfuBanIk&ab_channel=AbhayDatta

0 notes

Text

How to rewind jumbo roll efficiently?

In the toilet paper processing industry, the rewinder, as one of the core equipment, directly determines the production efficiency and quality of the finished product. Today we will focus on a rewinding device that is professionally used to rewind large rolls of base paper (Jumbo Roll) into small rolls of long toilet paper. By analyzing its functions, model parameters and technical highlights, we will provide selection references for industry users.

1. Core functions and applicable scenarios of the equipment

This toilet paper roll rewinding machine is designed for the post-processing of toilet paper. Through the functions of synchronous conveying of the unwinding rack, precise slitting and rewinding, and automatic punching, it can efficiently convert large rolls of base paper with a width of 1800-3500mm into finished small rolls with a diameter of 50-1800mm. Its applicable scenarios include:

Large-scale production of household rolls (medium and low weight);

Processing of customized long toilet paper in the hotel and catering industry;

Secondary slitting service of base paper supplier.

2. Model parameter analysis: How to select from 1575 to 3500?

According to the base paper width and production capacity requirements, this series of rewinders provides 5 mainstream models (1575/1760/1880/2800/3500)

Selection suggestions:

1575/1760: Suitable for small processing plants with a daily output of less than 5 tons, taking into account cost-effectiveness and flexibility.

1880/2800: Recommended for medium-sized enterprises, which can meet diversified order requirements (such as finished products with different diameters and weights).

3500: For ultra-wide base paper (such as 3500mm), suitable for large-scale paper mills or OEM companies.

3. Technical highlights: How to achieve efficient and stable production?

Three-layer synchronous paper unwinding rack design

Adopting three-layer base paper synchronous transmission technology, it supports continuous loading of large rolls with a diameter of less than 1100mm, reduces the frequency of paper replacement, and improves production capacity utilization.

Stepless frequency conversion speed regulation system

The 5.5-15kW power configuration is combined with the frequency conversion speed regulation function, which can flexibly adjust the speed according to the base paper weight (14-40gsm), while ensuring the slitting accuracy and avoiding paper breaks.

Intelligent punching and tension control

Equipped with 2-blade/3-blade punching knife group, the spacing covers 80-300mm, which can meet the needs of different products such as paper drawing and paper rolling;

PLC system monitors tension in real time to ensure uniform tightness of finished rolls (diameter error ≤±1mm).

Pneumatic system optimization

It needs to be equipped with a 3-horsepower air compressor (air pressure ≥5kg/cm²), and the pneumatic pressure roller can be used to achieve fast roll change and reduce the intensity of manual intervention.

4. User pain point solution

In actual production, the rewinding link often faces the following problems, and the equipment has designed a targeted solution:

Poor compatibility of base paper → Support 76mm standard paper core (other specifications can be customized), suitable for more than 90% of base paper suppliers on the market.

Low slitting efficiency → Maximum processing speed of 280 meters/minute, single-shift output can reach 15-20 tons (depending on the base paper weight).

Low qualified rate of finished products → The human-machine interface presets parameter templates, and one-click switching of different specifications reduces human errors.

1 note

·

View note

Text

Krishna Engineering Works has a solution that best fits your manufacturing unit or enterprise. Know more about its latest machines from Krishna Engineering Works. Upgrade your paper-making productivity and establish your company as an industry leader in the long term.

heavy duty type slitter drum rewinder machine can process all kinds of paper of any GSM thickness. In our heavy duty series paper slitting rewinding machine, the rewinding diameter can be achieved up to 1200mm.

#krishnaengineeringworks#machine#manufacturer#machinery#industry#export#supplier#industrial#machinemanufacturer#slitterrewindermachine#heavydutyslitterrewindermachine#slittingrewindingmachine#paperindustry#papermachinery

1 note

·

View note

Text

Webtech Group’s live demonstrations at Printpack 2025

Webtech Group, a leading manufacturer of printing and paper-converting machinery, will showcase its range of machines at Printpack 2025, to be held from 1 to 5 February 2024, at India Expo Centre and Mart in Greater Noida. It show demonstrate the fully servo flexographic printing machine in 450 mm working width, thermal roll slitting rewinding machine with single color online flexo printing, honeycomb paper die cutting machine, and servo-controlled label slitter rewinder machine

Along with the showcased machines, the Webtech team will highlight its entire range of products, including fully servo flexographic printing machines, web offset printing machines, slitting rewinding machines, and die cutting machines at its stand. The team will discuss technological advancements, share insights into the industry’s trajectory, and offer tailored solutions.

Singh emphasized the strategic importance of participating in Printpack 2025. “Printpack provides a vital platform to showcase technological advancements to a global audience and expand our clientele. The exhibition offers invaluable insights into emerging trends and challenges, enabling us to enhance our product offerings and stay ahead of market demands,” he said.

By participating in such exhibitions, Webtech aims to solidify its industry presence while forging new relationships with global clients. “For Printpack 2025, we aim to build on our previous successes by introducing our latest fully servo flexographic printing machine and other innovations. We look forward to engaging with industry leaders and further strengthening our position in the market,” Singh added.

Singh highlighted the evolution of the printing and packaging industry, driven by increasing demand for sustainable and flexible packaging solutions. Key advancements, such as fully servo-driven machines, automation, and eco-friendly substrates, are shaping the future of the industry.

“The printing and packaging sector is experiencing robust growth, with sustainability and precision at its core. We are poised to capitalize on these trends by offering innovative and efficient machinery that addresses challenges such as waste reduction and enhance productivity,” Singh explained.

Webtech International Machineries will be present in hall no 5, stands C19 and C28.

0 notes

Text

Bopp / Paper Tape Coating Machine

Mohindra is recognized as one of the top manufacturers of Doctoring Slitting Machines in India. Although we are located in Delhi, we supply our wide range of products across the country. We use premium quality raw materials in the production of all our machines. As you may know, the demand for Doctoring Slitting Machines is increasing daily, driven by the rising consumption of paper bags in India. Mohindra Machine stands out as a leading manufacturer of Doctoring Slitting Machines. We are dedicated to producing and supplying these machines to potential customers in the market. The Doctoring Slitting Machine is designed to cut and convert large sheets of paper, foil, and film materials into narrower rolls. These machines consist of three main components: the slitter, unwind, and rewind.

#Bopp paper tape coating machine price#Bopp paper tape coating machine price in india#Bopp paper tape coating machine in india#Bopp paper tape coating machine for sale

1 note

·

View note

Text

Jandu PPM - Printing and Packaging Machines Manufacturer

Jandu Printing and Packaging Machines Company is a professional Slitting and Rewinding Machine manufacturer and supplier in Delhi, India. We are manufacturing an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper.

Jandu PPM offers highly versatile Roll To Sheet Cutting Machine and centre drum slitting and rewinding machines suitable for slitting plastic films, paper, and metal foils. This machine comes with slitting.

Contact Jandu Printing and Packaging Machines

Company: Jandu PPM

Call: +91-9811100842, 9811510842

Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi-110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#ReelToSheetCuttingMachine#RollToSheetCuttingMachine#JanduPPM

1 note

·

View note

Text

Jandu PPM - Slitting and Rewinding Machine Manufacturer

Jandu Printing and Packaging Machines Company is a leading Slitting and Rewinding Machine manufacturer and offers an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper. Key Features of Slitting and Rewinding Machines Latest in Design Good Performance Simple in Operating Easy Maintenance High Speed Contact for Slitter and Rewinder…

0 notes

Video

youtube

500mm paper and paper label and plastic film slitting rewinding machine/...

500mm paper and paper label and plastic film slitting rewinding machine/آلة شق/Machine de refendage

0 notes

Video

youtube

JRT Jumbo Roll Toilet Tissue Paper Converting Slitting Rewinding Making ...

www.opecmachinery.com/

0 notes

Text

"Optimizing Workflow: Slitting Rewinding Machines at Their Best"

Cutting and handling materials are critical among industries that routinely engage the services of slitting rewinding machines. These machines have one specialty: slicing a larger roll into narrower widths, rewinding them into a neat roll at the same time. Materials such as paper, film, and foil can be cut to specific size requirements and be ready for downstream processing or immediate use.

These overseer machines run on high technology automating every process while ensuring that materials get wasted as little as possible and encouraging quicker turnaround times. Features include eye broaches, customizable slit widths, and tension control systems; providing mass production across a wide range of industries, the above-mentioned creates a new level in quality and productivity.

To avail the world-class slitting rewinding machines, the organization needs to visit UV Graphic, which is known for making the right innovative machines that are reliable and efficient. True believers in precision engineering and superior performance, UV Graphic sponsors an unprecedented level of operational excellence for all businesses.

#uv curing systems#curing machine manufacturer#label punching machines manufacturer#uv coating machines manufacturer#Slitting Rewinding Machine

0 notes

Text

How to Eliminate Static Electricity in Packaging Printing

It is well known that materials used in the packaging and printing industry, such as paper, plastic, ink, adhesives, and guide rollers (some of which are anodized to form alumina), are insulators. The processes of printing, laminating, rewinding, and slitting are high-speed operations that involve friction, contact, and separation—essentially "surface" engineering. The generation of static electricity in packaging and printing plants is mainly related to the chemical composition, molecular structure, mechanical properties, smoothness, and electrical properties of the insulating materials, as well as environmental factors like temperature, humidity, and external mechanical actions such as contact pressure and the speed of frictional separation. The type of film, contact method, contact time, contact area, and separation speed all influence the time of static discharge and the voltage produced.

1. The Hazards of Static Electricity

When paper becomes static-charged, it brings numerous challenges to printing. First, static causes sheets of paper to stick tightly together, making it difficult to neatly separate them. During the printing process, static attraction causes individual sheets to adhere together firmly, sometimes in twos, threes, or even stacks, making it hard for the paper feeder to pick up the sheets, which severely impacts printing efficiency. In color printing on plastic materials, static discharge can lead to issues such as jagged ink overflow around the edges of prints, increased misalignment of overprinting, and other printing defects. Static on ink can also result in light-screen or missing-print issues. Plastic films and inks attract dust, hairs, and other contaminants from the environment, leading to problems like blade streaks. During processes like rewinding, slitting, and bag-making, static discharge can damage equipment such as the optical correction system and electromagnetic control systems.

2. Methods for Eliminating Static Electricity

Different anti-static techniques should be applied based on production conditions, the packaging materials' intended use (what product is being packaged), and customer usage requirements. Common anti-static techniques include: 2.1 Physical Elimination Method The physical method eliminates static without altering the material's properties by utilizing static's inherent characteristics. One such method is the "grounding" elimination method, which involves installing a static elimination brush. The brush body is placed at the roll or unrolling area of paper or plastic materials, and the grounding end of the static brush must be reliably grounded—not connected to equipment or rollers, which may not be properly grounded. Some rollers are anodized, producing alumina, which is non-conductive. 2.2 Chemical Elimination Method Chemical static elimination, also known as antistatic agent treatment, involves adding or coating antistatic agents (surfactants) to modify the electrical properties of resins or substrates. This method is more thorough and effective but can change the chemical composition of materials. Therefore, this technique is unsuitable for treating paper but is commonly used to modify plastic resins. Special care must be taken when using this technique for packaging food, pharmaceuticals, cosmetics, and chemical products, considering factors like safety, hygiene, and compatibility with the base resin. Packaging materials with antistatic properties not only prevent various quality issues caused by static but also improve packaging efficiency and ensure sealing strength, earning customer approval. 2.2.1 Additive Treatment Technique This method, also known as the masterbatch technique, involves mixing antistatic agents at specific concentrations (ranging from a few percent to several tens of percent) with thermoplastic resins along with various additives. The mixture is then melted, compounded, and granulated to produce antistatic masterbatches. The selection of antistatic agents should consider their compatibility with the base resin. Poor compatibility results in poor performance of the antistatic particles, while excessive compatibility slows the migration of the antistatic agent to the surface, making it difficult to form an antistatic water film. Selecting a resin identical to the product's base resin is important during the melting, compounding, and granulation process. Care should be taken to maintain low processing temperatures to prevent decomposition or deterioration of the antistatic agent due to poor thermal stability. The production of antistatic plastic films often employs a three-layer (ABC) co-extrusion blown film process. The proportion of antistatic masterbatch should be adjusted according to the concentration of the effective ingredient and based on test results, ensuring that the surface resistivity (ps) is around 10^11 Ω. Excessive addition not only increases production costs but may negatively impact subsequent processing. 2.2.2 Coating Treatment Technique The coating antistatic agent technique involves applying ionic surfactants as antistatic coatings on the surface of plastic films to prevent charge accumulation. The selection of coating antistatic agents depends on the work function of the substrate being coated. If the work function of the plastic material is large, it tends to carry a negative charge; if it is small, it tends to carry a positive charge. Among common plastics, the order of work function from large to small has been discussed earlier, with PP and PE tending to carry negative charges, making cationic surfactants more suitable for coating. PET and PA tend to carry positive charges, making anionic surfactants more appropriate. The plastic film surface should have a wetting tension greater than 38 dyn/cm. The antistatic coating should have good film-forming properties, be resistant to friction and chemical corrosion, and offer long-lasting effects.

Explore our book printing services on the Printing in China page.

3. Static Electricity Measurement and Testing

In packaging printing plants, static measurement mainly involves determining the voltage of the accumulated charge on packaging materials using an electrostatic voltmeter. It is recommended to select the maximum range first and then gradually reduce it. For surface resistivity testing of packaging materials, follow the GB/1410-89 standard "Test Methods for Volume and Surface Resistivity of Solid Insulating Materials." Testing should be conducted under specified environmental conditions of temperature and relative humidity. If the surface resistivity of packaging materials falls within the range of 10^9 Ω to 10^12 Ω, the material has antistatic properties.

0 notes