#Peb warehouse Manufacturers

Explore tagged Tumblr posts

Text

Best PEB Warehouse Manufacturers In India

Thank you for visiting Vedanshi Industries India Pvt. Ltd., PEB Warehouse Manufacturers, your go-to source in Greater Noida for premium pre-engineered building (PEB) warehouse solutions. We specialize in creating inventive and long-lasting warehouse structures that meet your unique requirements as a top manufacturer. Our knowledgeable staff guarantees accurate engineering and prompt delivery, supported by a dedication to quality and sustainability. You get a dependable partner in Vedanshi Industries who is committed to providing PEB warehouse manufacturers with solutions that go above and beyond. You may rely on us to enhance your warehouse projects with superior constructions that become the benchmark for excellence and longevity in Greater Noida and beyond.

Please get in touch with us right now if you would like more details about our PEB Warehouse Manufacturers and how they could support your job. Our staff is always available to assist and identify the ideal options for your unique requirements.

Visit us: https://www.pebmanufacturers.in/

ADDRESS: H-25 Site-C UPSIDC Surajpur Industries Area, Greater Noida, G.B. Nagar, Uttar Pradesh, 201306

0 notes

Text

0 notes

Text

PEB Warehouse Manufacturers in India near Delhi

M/s Vedanshi Industries India Private Limited Building & Decking Solution in Greater Noida based organization specializing in Steel, Aluminum Roofing, Ceiling and Facade Systems, PEB Warehouse Manufacturers & PEB Suppliers. It was founded in late 2020 and has already started penetrating the Interior Decoration market in full swing. We started our career with Vedanshi Metal Building & Decking Solution founded in early 2020, and today we are the major suppliers of architectural products to big houses. Vedanshi Metal Building & Deck Solution today has succeeded in carving a niche for itself in the fast-growing Metal ROOFING, CEILING, AND Pre-Engineered Building Structure, Portable Buildings, and Metal Buildings business. Vedanshi Company operates from its office located at H-25. Site-C UPSIDC Surajpur Ind. Area, Greater Noida, G.B. Nagar (U.P.)-201306

Why Us:

We are a top Manufacturer, Exporter, Supplier, Trader, and Service Provider of an advanced range of Pre Engineered Steel Building (PEB), Modular Site Office, False Ceiling, and Insulated Cladding.

Our Team:

We have an expert team that provides user-friendly services. We have set up a promising warehouse for safe storing of advanced range. Our warehouse personnel maintains an updated record of products.

Quality:

We are Providing Vedanshi Metal Building & Deck Solution today has succeeded in carving a niche for itself in the fast-growing Metal ROOFING, CEILING AND Pre-Engineered Building Structure, Portable Buildings.

Visit Us: PEB Warehouse Manufacturers

Address:

H-25 Site-C UPSIDC Surajpur Industries Area, Greater Noida, G.B. Nagar, Uttar Pradesh, 201306

Email:

Whatsapp:

(+91) 9870340080 - 8384802066

0 notes

Text

Best PEB Warehouse Manufacturers in India

Vipul Infra Projects is leading PEB Warehouse Manufacturer. ISO 9001-2008 certified company having its manufacturing facility based at Delhi & NCR.. We offer turnkey services which includes design, engineering, architectural services and execution. We have the most advanced structure systems manufacturing & PEB Manufacturer in the high quality control on automatic machines to ensure international quality PEB systems.

We have manufactured and executed several large industrial projects in the past 15 years. Vipul infra Projects also PEB Manufacturers and sells metal building components like roof and well cladding, louvers, ridge vents, roof monitors, skylights, integrated rain water collection and disposal systems.

1 note

·

View note

Text

Vipul Infra Systems Pvt. Ltd. is the Best PEB manufacturer In India specializing in pre-engineered buildings and industrial sheds. Known for quality and innovation, they deliver customized, durable, and efficient solutions.

#peb manufacturers#pre engineered building#pre engineered steel buildings#industrial sheds#warehouse construction

2 notes

·

View notes

Text

PEB Plant

#pre engineered buildings manufacturer#pre engineered building structure#Pre engineered building solution#pre engineered building fabricators#pre engineered metal building manufacturers#Pre-engineered metal buildings#PEB construction companies#PEB suppliers#Industrial building manufacturers#Commercial building manufacturers#Warehouse manufacturers#Factory building manufacturers#PEB manufacturers in India#Construction equipment manufacturers#Building material manufacturers

2 notes

·

View notes

Text

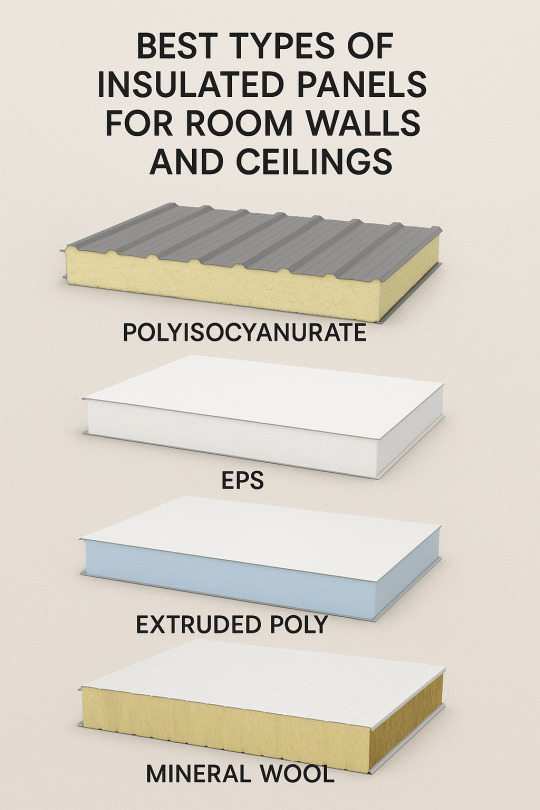

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

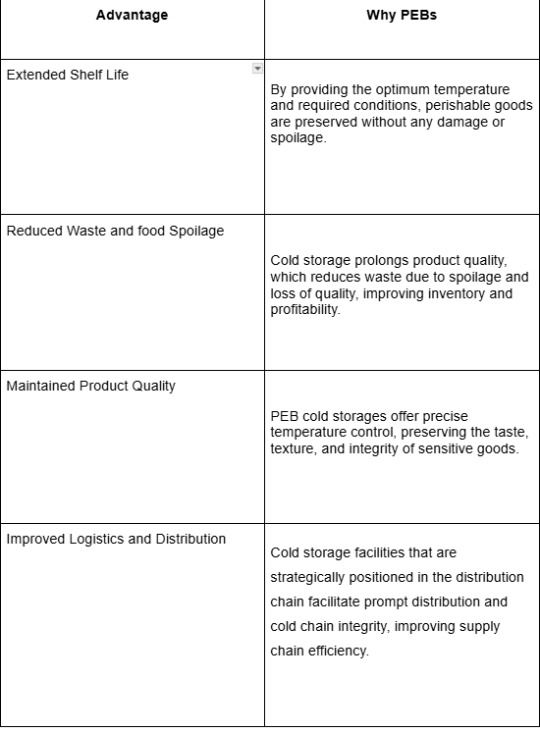

PEB Cold Storage Solutions: Engineered for Excellence in Quality and Preservation

As the demand for cold storage structures is increasing rapidly. Investing in efficient cold storage solutions is more crucial than ever due to increased rules on product safety and consumer demand for high-quality goods with preserved flavor, texture, and integrity.

This blog explores cold storage warehouses' significance, unique features, and how they support a wide range of businesses in ensuring product safety and quality.

Cold storage Warehouses are used for preserving perishable and sensitive Items. As India continues to experience a surge in imports and pharmaceutical production capacity, it becomes essential to have cost-effective and modern cold storage solutions.

PEB structures are manufactured in controlled factory environments, then transported and assembled on-site. These are made with precision and advanced technology, which makes them temperature-sensitive with quick installation, meeting the storage requirements.

Key Considerations When Planning a PEB Cold Storage Facility

Temperature Requirements & Zoning

Specify the temperature zones your product will need, which include frozen, chilled, and/or ambient, and design the PEB structure and ensure that it will allow for multi-zoning flexibility.

Location & Logistics Access

The site should be located in locations close to highways, ports, or production areas. to facilitate efficient logistics.

Compliance with Safety & Regulatory Standards

The facility must meet FSSAI, GMP, and specific regulatory requirements applicable to the sector, especially for pharma and food products.

Energy Efficiency & Operational Sustainability

Energy-efficient systems like solar panels, LED lighting, and transparent roofing panels need to be installed in the building to sustain sustainability.

Ventilation & Humidity Control

Ventilation and humidity should be controlled effectively to prevent spoilage and protect the integrity of sensitive goods.

Role of Cold Storage Buildings in India’s Growth

As India's capabilities in production and consumer base continue to grow, there is a greater need for reliable and scalable cold storage capabilities These facilities support various sectors, including agriculture, pharmaceuticals, and exports, contributing significantly to overall economic development.

Reducing Agricultural Waste

Cold storage reduces post-harvest losses, as India is one of the largest producers of fruits, vegetables, and dairy. When products are kept at the right temperature, they reduce waste through extended shelf life and ease of distribution in the country.

Strengthening the Pharmaceutical Industry

Cold storage maintains the effectiveness of vaccines, pharmaceuticals, and other medical products that must remain at specified temperatures for storage and shipping. It is particularly critical in a country that produces a substantial amount of pharmaceuticals in the world.

Promoting International Export and Trade

Cold storage buildings support India's role as a robust global supplier, fulfilling international quality standards and supply chain requirements in the rapidly developing export market, especially for perishables, e.g., fruit, seafood, and processed products.

Improving Supply Chain Effectiveness

cold storage solutions facilitate a steady supply of commodities by reducing transit delays, eliminating spoilage, and improving the overall resilience of supply chains, which is a key part of economic stability and development.

Partner with Us for Future-Ready Cold Storage Solutions

If you're looking for a smart, scalable, and cost-effective cold storage solution, our PEB-based warehouses offer the durability, speed, and flexibility your business needs.

Contact us today, the leading pre-engineered building manufacturer in India, to learn how we can help you build a high-performance cold storage facility tailored to your industry requirements.

#pre engineered structure manufacturer#peb building#peb manufacturer#pre engineered buildings#pre engineered building#peb solution#pre engineered building manufacturer in India#pre engineered building supplier in India#peb building manufacturer in Delhi NCR#PEB#industrial building#peb warehouse manufacturer#pre engineered warehouse construction#ecopeb

0 notes

Text

Mechfab Ghaziabad: Pioneering Pre-Engineered Buildings in India

Pre-Engineered Buildings (PEBs) have revolutionized the construction industry by offering fast, cost-effective, and high-quality structural solutions for a wide variety of applications—from industrial warehouses and logistics parks to commercial complexes and institutional buildings. Among the leading contributors to this transformation is Mechfab Ghaziabad, a name synonymous with innovation, reliability, and engineering excellence in the field of metal building systems.

About Mechfab Ghaziabad

Mechfab Engineers Pvt. Ltd., headquartered in Ghaziabad, Uttar Pradesh, is a dynamic company specializing in the design, fabrication, and erection of Pre-Engineered Buildings across India. Established with the vision of delivering turnkey infrastructure solutions, Mechfab has built a solid reputation through successful projects in sectors such as aviation, logistics, manufacturing, agriculture, and public infrastructure.

The company is known for its integrated approach—offering end-to-end services from concept to commissioning—supported by state-of-the-art manufacturing facilities, advanced design software, and a highly skilled workforce.

What are Pre-Engineered Buildings?

Pre-Engineered Buildings are steel structures fabricated in a factory and assembled on-site. They are customized to meet specific client requirements and are known for their speed of construction, strength, and scalability. Unlike conventional steel buildings, PEBs are designed and engineered in advance, using precise load calculations, minimizing waste and project timelines.

Why Mechfab Stands Out in the PEB Sector

Engineering Excellence

At the heart of Mechfab’s success lies its focus on engineering. Each PEB is designed by a team of experienced structural engineers using advanced software tools like STAAD Pro, Tekla Structures, and MBS. The company adheres to national and international standards such as IS, MBMA, AISC, and IBC to ensure structural integrity, safety, and longevity.

Custom-Tailored Solutions

No two projects are the same. Mechfab excels in providing bespoke building solutions tailored to the client’s industry, location, and purpose. Whether it's a climate-controlled cold storage unit, a multi-span industrial shed, or a high-clearance aircraft hangar, Mechfab adapts its systems to meet the exacting needs of the client.

End-to-End Services

Mechfab offers complete turnkey services including:

Architectural and structural design

Fabrication of primary and secondary framing

Supply of roofing and cladding systems

On-site erection and quality assurance

Project management and post-handover support

This single-window service model reduces the need for multiple vendors and ensures better coordination and project control.

Advanced Manufacturing Facility

Located in Ghaziabad, Mechfab's manufacturing facility is equipped with CNC plasma cutting machines, hydraulic presses, automatic welding stations, and precision rolling machines. The factory has the capacity to deliver thousands of metric tons of fabricated steel structures annually, meeting tight deadlines without compromising on quality.

Commitment to Sustainability

Pre-Engineered Buildings are inherently sustainable due to minimal material wastage, reduced site activity, and recyclability of steel. Mechfab goes further by integrating energy-efficient insulation, solar panel-compatible roofing, and rainwater harvesting systems into its projects, supporting India's green building movement.

Strong Portfolio of Projects

Mechfab has executed several landmark PEB projects across India, including logistics parks, airport terminals, food processing units, and educational campuses. Notably, the company was a key contributor to the Prayagraj Airport Terminal, delivering high-quality steel structures that met stringent aviation standards.

Applications of Mechfab’s PEBs

PEBs are incredibly versatile and are used in a wide range of applications. Mechfab’s portfolio includes:

Industrial Buildings: Warehouses, factories, machine shops, and assembly plants

Infrastructure: Airport hangars, railway shelters, toll plazas

Agriculture: Cold storages, dairy farms, poultry sheds

Commercial: Shopping complexes, car showrooms, office blocks

Institutional: Schools, colleges, auditoriums, sports arenas

Each of these structures is designed for quick installation, long service life, and ease of expansion.

Quality & Safety Standards

Mechfab places the highest emphasis on quality control and safety. The fabrication process is subjected to rigorous inspections including non-destructive testing (NDT), welding inspections, and dimensional checks. At construction sites, the company enforces strict safety protocols including PPE usage, certified lifting equipment, and methodical erection procedures. All project teams are trained in OSHA and IS codes to ensure risk-free implementation.

Speed, Cost Efficiency, and Reliability

A key advantage of choosing Mechfab’s PEB solutions is the significant reduction in construction time—up to 50% compared to traditional methods. The use of bolted connections and pre-cut, pre-drilled components ensures fast assembly. Moreover, Mechfab’s optimized design processes and in-house fabrication contribute to cost savings without sacrificing quality.

Client-Centric Approach

Mechfab operates on a client-first philosophy. Each project begins with a deep understanding of the customer’s objectives, constraints, and vision. With transparent communication, milestone tracking, and adaptable planning, Mechfab ensures on-time, on-budget delivery.

Testimonials from satisfied clients highlight the company’s responsiveness, technical acumen, and ethical business practices—key reasons why many clients return for repeat business.

Future Outlook

As India continues to invest in infrastructure, manufacturing, and logistics, the demand for high-performance PEBs will only grow. Mechfab Ghaziabad is strategically positioned to meet this demand through continual innovation, capacity expansion, and skilled manpower development. The company is also exploring international opportunities in the Middle East and Africa, leveraging its reputation as a dependable PEB provider.

Conclusion

In an era where speed, sustainability, and efficiency drive construction, Mechfab Ghaziabad stands out as a trusted partner for Pre-Engineered Buildings. With its strong technical foundation, customer-focused ethos, and commitment to quality, Mechfab continues to shape the future of industrial and infrastructure development in India and beyond.

Whether you’re planning a greenfield industrial unit or upgrading a logistics hub, Mechfab’s PEB solutions offer the perfect blend of performance, value, and peace of mind.

Visit us:-

#PEB companies in DELHI NCR#PEB companies in Gurgaon#PEB Manufacturers in Faridabad#Warehouse Manufacturers in India#Steel Building Fabricator

0 notes

Text

MAK Building: Leading PEB Warehouse Manufacturers in India

As one of the top PEB Warehouse Manufacturers in India, MAK Building specializes in durable, cost-effective, and customizable pre-engineered warehouses. Our advanced designs ensure quick installation, superior strength, and long-term reliability, making them ideal for various industrial and commercial applications. Choose MAK Building for high-quality PEB warehouses tailored to your needs!

0 notes

Text

The Economic Impact of Warehouse Manufacturers & PEB Manufacturers on Supply Chains

Introduction: The Critical Role of Warehouses in Global Supply Chains

In today’s fast-paced global economy, warehouses have become the backbone of modern supply chains. They are essential hubs where products are stored, sorted, and distributed across various regions. The demand for efficient and high-capacity warehouses has surged, primarily driven by the rise of e-commerce, global trade, and the need for faster delivery times. As a result, warehouse manufacturers play a pivotal role in shaping supply chains that are not only effective but also cost-efficient.

Warehouse manufacturers, especially those focusing on Pre-Engineered Buildings (PEBs), are revolutionizing the way warehouses are designed, constructed, and utilized. The growth of these specialized manufacturers has had a profound economic impact, affecting not only the logistics sector but also the broader economy.

Understanding Warehouse Manufacturers and PEB Manufacturers

Warehouse manufacturers specialize in the design and construction of storage facilities tailored to specific business needs. These manufacturers handle everything from constructing large distribution centers to creating highly specialized storage solutions for niche industries.

On the other hand, PEB manufacturers focus on pre-engineered building systems that are designed and fabricated in factories and then assembled on-site. These structures offer several advantages, such as faster construction timelines, lower costs, and more flexible designs. PEBs have become a popular choice for warehouse construction due to their efficiency and scalability.

While traditional warehouse designs might involve complex construction processes with higher material costs, PEB manufacturers use modular systems that can be customized and quickly deployed. This transition to PEBs has made a significant economic difference by reducing construction costs and timelines.

How Warehouse Manufacturers Drive Efficiency in Supply Chains

Warehouse manufacturers have a direct influence on the overall efficiency of supply chains. The design and construction of a warehouse can impact how well a company manages its inventory, processes orders, and delivers goods to customers. An optimized warehouse layout minimizes the time required for moving products, reduces waste, and enhances the speed at which goods can be shipped.

The role of automation is also essential. Many modern warehouses, especially those built by specialized warehouse manufacturers, incorporate automated systems that improve accuracy and reduce human error. These innovations allow for quicker order fulfillment, ensuring products are shipped faster and more reliably.

The Economic Benefits of Efficient Warehouse Design

Efficient warehouse design directly translates into economic benefits for companies, especially in a time when supply chain costs are under intense scrutiny. Warehouse manufacturers are increasingly tasked with optimizing storage space to ensure that every square foot is utilized effectively. Proper space management allows companies to store more goods without expanding their physical footprint, saving on rental or land costs.

Moreover, well-designed warehouses reduce labor costs by minimizing the number of workers required for tasks such as picking, packing, and shipping. With the integration of technology, including robotics and automation, warehouse manufacturers are able to create facilities that reduce reliance on manual labor, allowing companies to streamline operations and increase profitability.

The Role of PEB Manufacturers in Shaping Modern Warehouse Infrastructure

PEB manufacturers have transformed the warehouse construction landscape by offering solutions that are not only cost-effective but also highly adaptable. Pre-engineered buildings can be tailored to a company’s specific requirements, whether they need to expand quickly or adapt to changes in product lines. Unlike traditional construction, which can be slow and inflexible, PEB warehouses offer scalability and speed.

The advantages of PEB warehouses are clear: they are quicker to build, more energy-efficient, and offer lower maintenance costs. Many large corporations are turning to PEB manufacturers to build distribution centers that can support their growing business needs. For instance, major e-commerce players have utilized PEBs to construct vast fulfillment centers that can accommodate rapid growth in demand.

Warehouse Manufacturers and the Supply Chain Resilience Factor

The resilience of a supply chain depends heavily on the flexibility and adaptability of its infrastructure. Warehouse manufacturers contribute to supply chain resilience by designing and constructing facilities that can quickly adapt to changing conditions. For example, during the COVID-19 pandemic, many businesses found their existing warehouse systems insufficient to handle the sudden shift to e-commerce and direct-to-consumer shipping.

Warehouse manufacturers have responded by creating designs that allow for easy reconfiguration, faster implementation of new technologies, and better risk management strategies. These innovations not only help businesses recover from disruptions but also allow them to operate with more agility and foresight.

How Warehouse Manufacturers Support E-Commerce Growth

As e-commerce continues to grow, so does the need for efficient, high-performing warehouses. Warehouse manufacturers are at the forefront of supporting this growth by designing and constructing distribution centers and fulfillment hubs that cater specifically to the needs of online retailers. Fast shipping, real-time inventory tracking, and order fulfillment are key elements of the e-commerce logistics chain.

By building larger, more automated warehouses, manufacturers have made it possible for e-commerce giants like Amazon, Alibaba, and Walmart to offer rapid delivery services at scale. These warehouses allow companies to keep costs down while increasing the speed of service, which directly influences customer satisfaction and retention.

The Global Economic Impact of Warehouse Manufacturers

The global demand for efficient warehouses is growing rapidly, and warehouse manufacturers are a key part of this economic boom. The construction of new warehouses creates job opportunities across a range of sectors, from labor-intensive roles in construction to high-tech jobs in robotics and automation. The increased efficiency in supply chains also helps drive down the cost of goods, benefiting consumers and businesses alike.

Moreover, warehouse manufacturers are expanding their operations internationally, tapping into new markets and contributing to local economies. As global trade and e-commerce continue to rise, the role of warehouse manufacturers in shaping economic growth becomes even more critical.

Future Trends in Warehouse Manufacturing and Supply Chain Integration

The future of warehouse manufacturing is poised to be shaped by several trends, including automation, robotics, and sustainable building practices. Warehouse manufacturers are increasingly focusing on building smart warehouses that incorporate cutting-edge technology to improve efficiency and reduce environmental impact.

Additionally, as supply chains become more interconnected and reliant on real-time data, warehouses will need to adapt to support seamless integration with other parts of the supply chain. The future of warehouse construction will likely involve further advancements in automation, artificial intelligence, and Internet of Things (IoT) technology.

Conclusion: The Vital Role of Warehouse Manufacturers in Economic Growth

Warehouse manufacturers play a pivotal role in modern supply chains by providing efficient, cost-effective, and scalable storage solutions. Their impact extends beyond the logistics sector, influencing global trade, e-commerce, and local economies. As the world continues to evolve, the innovations brought about by warehouse manufacturers, particularly PEB manufacturers, will remain central to the success of supply chains worldwide.

0 notes

Text

EPACK Prefab offers customized solutions for Industrial Factory Buildings, delivering durable, cost-effective, and efficient structures. Designed with precision using advanced pre-engineered techniques, our factory buildings ensure optimal functionality and space utilization.

✅ Key Features:

Quick construction with PEB technology

High-quality steel ensuring strength and durability

Energy-efficient designs with insulated panels

Custom layouts to suit specific industrial needs

👉 Contact EPACK Prefab today for innovative factory building solutions tailored to your requirements!

#Industrial Factory Building#Factory Building Construction#Pre-Engineered Buildings#PEB Structures#Industrial Construction Solutions#Steel Factory Buildings#Warehouse Construction#Prefabricated Industrial Buildings#Durable Factory Buildings#Custom Industrial Structures#EPACK Prefab#Modern Industrial Construction#Factory Building Design#Turnkey Construction Solutions#Industrial Building Manufacturers#Energy-Efficient Buildings#Steel Structures for Factories#Fast Construction Solutions#Prefab Industrial Structures#Reliable Factory Buildings

0 notes

Text

0 notes

Text

PEB Warehouse Manufacturers in India

M/s Vedanshi Industries India Private Limited Building & Decking Solution in Greater Noida based organization specializing in Steel, Aluminum Roofing, Ceiling and Facade Systems, PEB Warehouse Manufacturers & PEB Suppliers. It was founded in late 2020 and has already started penetrating the Interior Decoration market in full swing. We started our career with Vedanshi Metal Building & Decking Solution founded in early 2020, and today we are the major suppliers of architectural products to big houses. Vedanshi Metal Building & Deck Solution today has succeeded in carving a niche for itself in the fast-growing Metal ROOFING, CEILING, AND Pre-Engineered Building Structure, Portable Buildings, and Metal Buildings business. Vedanshi Company operates from its office located at H-25. Site-C UPSIDC Surajpur Ind. Area, Greater Noida, G.B. Nagar (U.P.)-201306

Why Us:

We are a top Manufacturer, Exporter, Supplier, Trader, and Service Provider of an advanced range of Pre Engineered Steel Building (PEB), Modular Site Office, False Ceiling, and Insulated Cladding.

Our Team:

We have an expert team that provides user-friendly services. We have set up a promising warehouse for safe storing of advanced range. Our warehouse personnel maintains an updated record of products.

Quality:

We are Providing Vedanshi Metal Building & Deck Solution today has succeeded in carving a niche for itself in the fast-growing Metal ROOFING, CEILING AND Pre-Engineered Building Structure, Portable Buildings.

Visit Us: PEB Warehouse Manufacturers

Address:

H-25 Site-C UPSIDC Surajpur Industries Area, Greater Noida, G.B. Nagar, Uttar Pradesh, 201306

Email:

Whatsapp:

(+91) 9870340080 - 8384802066

0 notes

Text

How to Minimize Factory Construction Cost in India? Trust OSG Build Infra!

Looking to reduce factory construction cost in India? OSG Build Infra focuses on efficient designs, bulk material procurement, and sustainable practices to save costs without compromising on quality. Contact us for tailored solutions that align with your budget.

#construction#renovation#factory construction#civil engineering#warehouse#peb manufacturers#peb building

0 notes

Text

Understanding Pre-Engineered Buildings (PEBs)

Pre-engineered buildings (PEBs) represent a significant advancement in modern construction, offering numerous advantages over traditional building methods. These structures are fabricated in a factory setting and assembled on-site, which allows for rapid construction and reduced labor costs. This blog explores PEB structures, their benefits, and highlights some of the top PEB companies in India.

What are PEB Structures?

PEB structures are made up of components that are manufactured at a factory and then transported to the construction site for assembly. This method not only ensures high precision but also significantly reduces construction time. The use of steel in PEBs contributes to their strength and durability, making them suitable for various applications, including industrial buildings, warehouses, and commercial spaces.

Benefits of PEB Building Construction

Speed of Construction: One of the primary advantages of PEB building construction is the speed at which these structures can be erected. Since components are pre-engineered, the on-site assembly is quick, often reducing construction time by 30% or more compared to traditional methods.

Cost-Effectiveness: PEBs are generally more cost-effective than conventional buildings. They minimize waste and reduce labor costs due to faster assembly times. Additionally, the materials used in PEBs are often more affordable than traditional building materials.

Customization: Contrary to common misconceptions, PEB buildings can be customized to meet specific design requirements. This flexibility allows architects and builders to create unique structures that align with client needs while maintaining structural integrity.

Durability and Maintenance: PEBs are constructed using high-quality steel, which provides excellent resistance to environmental factors such as corrosion and extreme weather conditions. This durability translates to lower maintenance costs over the lifespan of the building.

Sustainability: Many PEB manufacturers focus on environmentally friendly practices by using recyclable materials and energy-efficient designs, contributing to sustainable construction practices.

Top PEB Companies in India

India has witnessed a surge in companies specializing in PEB manufacturing. Here are some of the top PEB companies in India:

Epack Prefab: Known for its innovative solutions in prefabricated structures, Epack offers a range of customizable PEB options tailored to client specifications.

Utkarsh India: With extensive experience in manufacturing PEBs, Utkarsh is recognized for its high-quality steel fabrication and efficient project execution1.

Screw Expert: This company provides various PEB solutions with a focus on durability and customization, catering to diverse industrial needs3.

Perfect Metal Structure: They specialize in creating efficient and flexible PEB designs that meet modern construction demands6.

Conclusion

In summary, PEB building manufacturers play a crucial role in transforming the construction landscape in India. The advantages of speed, cost-effectiveness, customization, durability, and sustainability make PEBs an attractive option for various applications. As the demand for efficient building solutions continues to grow, so does the prominence of leading PEB manufacturers in India, ensuring that clients receive high-quality structures tailored to their needs.By understanding the benefits and capabilities of PEB structures, stakeholders can make informed decisions that enhance project outcomes while contributing to sustainable development practices.

#peb structures#peb building construction#prefabricated industrial shed#peb building#top peb companies in india#temporary shed construction#warehouse manufacturers#industrial shed design#peb building manufacturer#peb manufacturers in india

0 notes