#Perfluoropolyether (or PFPE)

Explore tagged Tumblr posts

Text

Perfluoropolyether (PFPE)

Perfluoropolyether (PFPE) is a highly specialized lubricant that offers exceptional performance in various industrial applications. PFPE grease, oil, and lubricants are widely used in demanding environments where extreme temperatures, chemical resistance, and low friction are crucial.

PFPE grease is a type of lubricating grease made from perfluoropolyether oil as its base. With its excellent thermal stability, PFPE grease can withstand high temperatures without compromising its lubricating properties. This makes it ideal for use in industries such as aerospace, automotive, and semiconductor manufacturing, where equipment operates under extreme conditions.

PFPE oil, also derived from perfluoropolyether, is known for its superior chemical resistance and non-flammability. It provides long-lasting lubrication and protection for various mechanical components, even in harsh chemical environments. PFPE oil finds applications in chemical processing plants, pharmaceutical manufacturing, and vacuum systems where the integrity of the lubricant is critical.

As a perfluoropolyether-based lubricant, PFPE offers unique advantages over traditional oils and greases. Its low surface tension and high thermal stability contribute to reduced friction and wear, enhancing the overall durability and efficiency of machinery. Moreover, PFPE's inert nature prevents it from reacting with most materials, ensuring compatibility with a wide range of metals, elastomers, and plastics.

When it comes to choosing the right lubricant, PFPE lube stands out as an excellent choice. Its high viscosity index and exceptional load-carrying capacity make it suitable for heavy-duty applications. Whether it's providing lubrication in gears, bearings, or seals, PFPE lube ensures optimal performance and extends the lifespan of critical equipment.

In summary, perfluoropolyether (PFPE) lubricants, including PFPE grease, oil, and lubricants, offer unparalleled performance in extreme conditions. Their thermal stability, chemical resistance, and low friction properties make them indispensable in various industries. With their exceptional reliability and versatility, PFPE-based lubricants play a crucial role in ensuring the efficiency and longevity of industrial machinery.

2 notes

·

View notes

Text

High and low temperature planetary gearboxes will be delivered to Slovenia

A high and low temperature planetary gearbox is a specialized type of planetary gearbox designed to operate reliably under extreme temperature conditions, ranging from very low (e.g., -60°C or below) to very high (e.g., 200°C or above) temperatures. These gearboxes are used in industries where standard gearboxes would fail due to thermal expansion, material degradation, or lubrication issues. High and low temperature planetary gearboxes provide the reliability needed in such challenging environments. Key Features of High and Low Temperature Planetary Gearboxes 1. Specialized Materials Gear Components: Made from high-performance alloys (e.g., stainless steel, titanium, or heat-treated steels) to resist thermal deformation. Housing: Often aluminum alloy or stainless steel with thermal-resistant coatings. These materials are essential for planetary gearboxes operating at high and low temperatures. Bearings: Ceramic or high-temperature steel bearings to prevent failure under thermal stress. 2. High-Temperature Lubrication Synthetic lubricants (e.g., perfluoropolyether (PFPE) or silicone-based greases) that remain stable across a wide temperature range, crucial for high-low temperature planetary operations. Solid lubricants (e.g., graphite or molybdenum disulfide) for vacuum or ultra-high-temperature applications. 3. Thermal Management Heat-resistant seals to prevent lubricant leakage are important in maintaining planetary gearboxes under high and low temperature conditions. Thermal insulation or cooling systems (e.g., heat sinks or forced air cooling) for extreme environments. 4. Precision Engineering Tight tolerances to account for thermal expansion/contraction. Precision is key when engineering planetary gearboxes that withstand high and low temperatures. Optimized gear meshing to prevent binding or excessive wear. Applications Aerospace & Defense: Satellite mechanisms, drone actuators, missile systems. Oil & Gas: Downhole drilling equipment, high-temperature pumps. Industrial Automation: Furnace conveyors, steel mill machinery. Automotive: Electric vehicle (EV) drivetrains in extreme climates. These high and low temperature planetary gear reducers ensure effective operation across varied conditions. Scientific & Research: Cryogenic systems, space exploration rovers. Would you like recommendations for a specific application? You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#Backlash-FreePrecisionPlanetaryGearboxes#IndustrialPlanetaryGearboxes#PlanetaryGearBox#Planetarygeartransmissions#PlanetaryGearboxes#Planetarygearheadsformaximumtorque#PrecisionPlanetaryGearboxes

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Perfluoropolyether (PFPE) Market Size, Share & Trends, Product, Region & Forecasts 2030

Perfluoropolyether (PFPE) Market Size, Share & Trends, Product, Region & Forecasts 2030

Description The impact of a number of factors such as economic, legal, social, political, technological, and modern business developments on market dynamics is briefly examined in the Perfluoropolyether (PFPE) market analysis. The global Perfluoropolyether (PFPE) market analysis focuses on market share and competitiveness index, which helps evaluate the top player’s contributions to the industry.…

View On WordPress

0 notes

Link

0 notes

Text

4 Characteristics of High-Quality Plastic Trays

A high-quality plastic tray is necessary for baking needs because it allows the baker to stack them together and make the best use of their space. It also promotes better airflow and can prevent dehydration of your baked goods. Here are four characteristics of high-quality plastic trays that you should know about.

Non-Stick

Non-stick coatings allow for the easy release of baked goods to keep the food from becoming damaged in the process of cooking.

Most plastic trays use a coating of polytetrafluoroethylene (PTFE) or perfluoropolyether (PFPE). PTFE is often used because it is inexpensive and does not require high processing temperatures. PFPE is often used because it has a higher melting point and provides better protection.

Sturdy

High-quality plastic baking trays are made of durable materials that are not easily broken. The three main types of plastics that are highly durable and dependable for baking are the following:

Polycarbonate: This is the most durable and safest plastic for use in the oven and microwave.

Polypropylene: This is a durable and safe material for use in the oven and freezer. It cannot be used in the microwave.

Polyethylene: This is a durable and safe material for use in the oven, freezer, microwave, dishwasher, and oven as well

Practicality

The most practical plastic baking trays are those that are dishwasher safe, have raised edges for easy removal, and are resistant to breakage. Plastic trays made of polycarbonate and polypropylene are the most dependable and practical trays for any bakeshop or baker.

Price Point

Lastly, highly-dependable plastic trays for baking need not be too expensive. If you can buy them in bulk at a lower price, you’ve found the best option for your bakeshop or baking hobby.

You Won’t Need to Look Far To Find a Dependable Tray Supplier.

You can always count on us at D&V Plastics to provide you with the best trays for all your baking needs. Contact us today to learn more about everything that we can do for you.

0 notes

Text

PFPE Perfluorinated Polyether Market Size Forecast to Reach $1.4 Billion by 2026

PFPE (perfluorinated polyether) Market is forecast to reach $1.4 billion by 2026, after growing at a CAGR of 6.2% during 2021-2026. Owing to its outstanding properties as lubricants, the demand is rising at a considerable pace around the globe. It is also seen in nearly all fields of the industry, from the chemical industry to advanced machinery. Due to its direct usage as lubricants in ball bearings, joints and various pivots used for the manufacture of automotive components, the growing development of vehicles, both commercial and personal, has further improved the market value. Many nations around the globe now dependent on their energy from nuclear power. PFPE is the only lubricant that can tolerate the toxic radiation released during the reaction from this industry, thereby proving valuable in enhancing the lifespan of the machinery. Such aspects have significantly increased the market value.

Impact of Covid-19 Due to the lockdown and various other issues regarding production, the demand of PFPE in automotive and aerospace has reduced drastically, which tends to reduce the consumption of PFPE, and thus constraining the growth of the market in the forecast period.

PFPE Market Segment Analysis - By Type

Oil segment held the largest share in the PFPE Market in 2020 and is anticipated to grow with a CAGR of 5.9% during the forecast period. PFPE oils have low vapor pressure and are chemically inert, non-reactive, and non-flammable, with anti-seizing properties. They are used in various machines as lubricants in bearings, devices with moving parts, oxygen systems, and valves. Moreover, owing to lipo and hydrophobic properties, perfluoropolyether oil is added to dry and oily skin.

Request for Sample Report @ https://www.industryarc.com/pdfdownload.php?id=17954

Report Price: $ 4500 (Single User License)

PFPE Market Segment Analysis - By End Use Industry

Aerospace sector held the largest share in the PFPE Market in 2020 and is estimated to grow at a CAGR of 5.8% during the forecast period 2021-2026. Perfluoropolyether products are commonly used in the aerospace industry due to their excellent efficiency and lower environmental impact in challenging circumstances. These products also increase efficiency by reducing the loss of parts, a crucial consideration in the aerospace industry. The oil and grease used in the aircraft boost the service life of the components and have high resistance at high altitudes to vapor losses. There is a steady upsurge in the aerospace industry, which can be due to high passenger demand and increasing military spending. In 2019, in aerospace exports, the United States contributed around USD136 billion. In the next five years, the industry is projected to gain a firm foothold, driven by increased commercial aerospace demand and the need for successful aircraft design to boost overall performance.

PFPE Market Segment Analysis - By Geography

Asia Pacific dominated the synthetic wet silica market in 2020 in terms of revenue with a share of 37% and is projected to dominate the market during the forecast period (2021-2026) followed by Europe and North America. The air passenger base has been increased by the increase in the number of low-cost airlines in the Asia Pacific region. Due to the need for these products in high-temperature applications, the expanding aerospace industry would result in the use of PFPE oil. The continuous growth of the Asia Pacific aerospace industry has created a market for lubricants suitable for low atmospheric radiation, pressure and very low maintenance components. The high performance and long-lasting components were guaranteed by its use at a high temperature application. Asia Pacific's continuous growth of the manufacturing, transportation and construction industries has resulted in strong demand for vehicles, trucks, power tools and industrial machinery. PFPE goods have a large temperature range that supports the lubrication provided by the machines. Such products are specially designed for high temperature ranges and dynamic conditions.

PFPE Market Drivers

Due to its stable 'chemical' bonds in intense conditions improve 'inertness' acts as preferable material, which increases the market demand

Due to the presence of extremely stable C-O and C-F bonds in perfluoropolyether (PFPE) it is basically inert against chemical and oxidizing pressures, making it a perfect match for environments where intense chemical exposure and high temperature instability, particularly in the aerospace bracket. In applications that require superior vacuum, including mass spectrometers, ion implantation, and particle accelerators, the high viscosity of PFPE, around 144, provides flexibility. In addition, perfluoropolyether is used in vacuum pumps for the treatment of gases such as ozone and nitric oxides, owing to its high susceptibility to highly oxidative and reactive compounds, without impacting the parent fluid. Since most fluids are impermeable to the PFPE chain, perfluoropolyether is cross-linked with elastomers during dye diffusion experiments to prevent swelling-induced leakage. In microfluidic experiments, PFPE-based elastomers show substantially lower swelling ratios against legacy polydimethylsiloxane (PDMS), thus replacing PDMS as the material option.

Increasing production of automotive vehicles will boost the demand

Automotive vehicle manufacturing has improved dramatically in recent years. In regions such as Asia Pacific, rapid industrialization is anticipated to increase automotive production. In the foreseeable future, the rise in automobile output is thus anticipated to raise the market for lubricants such as perfluoropolyether. Any factors driving demand for automotive vehicles in emerging regions are rising per capita spending, growing availability, and increasing population growth. This in turn, is expected to generate substantial business growth opportunities in the OEM industry. Perfluoropolyether holds an important role as one of the non-toxic lubricants used in various automotive applications, which is expected to fuel the development of the perfluoropolyether industry in the coming years. The US has one of the best automobile industries in the world, according to the International Trade Administration. U.S. light vehicle sales reached 17.2 million units in 2018, the fourth straight year of sales of 17 million or more. Therefore, as demand for the automotive sector rises, demand for the PFPE industry is projected to rise during the forecast period.

Download Sample Report @ https://www.industryarc.com/pdfdownload.php?id=17954

PFPE Market Challenges

Fluctuating Raw Material Prices

The downstream components of crude oil are the raw materials also used to manufacture PFPE. Therefore, the market fluctuation of crude oil often hinders the price of raw materials from PFPE. In the last year, the market volatility of crude oil, such as the price of crude oil, has risen from $98.95 in 2014 to $52.39 in 2015 and increased from $43.73 in 2016 to $71.31 in 2018, according to the BP Statistical Analysis of World Energy. And because of this confusion regarding the price of crude oil, the PFPE price is also increasing. Thus, the uncertainty in crude oil prices is anticipated to be a major challenge for the manufacturers of the PFPE industry, hampering the development of the PFPE market during the forecast era.

Covid-19 outbreak

For oil, gas, and chemical industries, the effects of COVID-19 and the oil price war is proving to be a two-pronged problem. Oil prices are declining due to the collapse of production reduction negotiations and the demand for chemicals and refined goods is slowing in the midst of this global pandemic due to manufacturing slowdowns and travel restrictions. Global chemical production decreased by 3.1 percent in March 2020 because of the impact of the COVID-19 coronavirus. While chemical production in some categories increased in January 2020 compared to December 2019, production in each category declined in February compared to January and in March compared to February. Given the recession, leading producers are reducing capital and operating spending. Owing to labor shortages and delays in the procurement of raw materials, manufacturing activities for these industries have been scaled down to 40 percent-60 percent availability. The COVID-19 pandemic crisis could affect development until the end of the year 2020, considering the rise in investment. In addition, the COVID-19 pandemic has further weakened the sector impacted by the PFPE market.

PFPE Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the PFPE Market. Major players in the PFPE Market are Solvay, Daikin Industries, Inc., Klüber Lubrication, The Chemours Company, Nye Lubricants, M&I Materials Limited, LUBRILOG SAS, Miller-Stephenson, Inc., Metalubgroup, TECCEM GmbH, IKV Tribology, HUSK-ITT Corporation, Fluorotech USA, Setral Chemie GmbH, Jet lube, among others.

Acquisition/Product Launches:

In 2018, M&I Materials Ltd has begun producing PFPE Material for fire resistant and biodegradable ester dielectric fluids for electricity transformers.

Key Takeaways

The growth of the perfluoropolyether industry is assisted by its coverage of a wide variety of spectrums distinguished by the phase of fuel used, generators, operation and combustion. The PFPE oil used in the aerospace and automotive industries is characterized by performance and viscosity additives. In addition to the need for sealing, cooling, washing and rust protection, the need to minimize wear and friction has contributed to the trend of using various classes of lubricants.

Less commonly used vehicles and aircraft have the ability to acquire rust & corrosion and need to be repaired and lubricated in a timely manner. Perfluoropolyether products aim to maintain the materials and solve the challenges of aircraft and truck downtime of rust and corrosion.

Related Reports :

A. Polyurethanes Market

https://www.industryarc.com/Report/11682/polyurethanes-market-analysis.html

B. Polydimethylsiloxane Market

https://www.industryarc.com/Report/16099/polydimethylsiloxane-market.html

For more Chemicals and Materials Market reports, please click here

#PFPEPerfluorinatedPolyetherMarket#PFPEPerfluorinatedPolyetherMarketShare#PFPEPerfluorinatedPolyetherMarketSize

0 notes

Text

Perfluoropolyether Market Size, Share With Top Companies, Region Forecast 2021-2027

Perfluoropolyether Market 2021-2027

A New Market Study, Titled “Perfluoropolyether Market Upcoming Trends, Growth Drivers and Challenges” has been featured on fusionmarketresearch.

Description

This global study of the Perfluoropolyether market offers an overview of the existing market trends, drivers, restrictions, and metrics and also offers a viewpoint for important segments. The report also tracks product and services demand growth forecasts for the market. There is also to the study approach a detailed segmental review. A regional study of the global Perfluoropolyether industry is also carried out in North America, Latin America, Asia-Pacific, Europe, and the Near East & Africa. The report mentions growth parameters in the regional markets along with major players dominating the regional growth.

Request a Sample Report @ https://www.fusionmarketresearch.com/sample_request/(COVID-19-Version)-Global-Perfluoropolyether-Market/12699

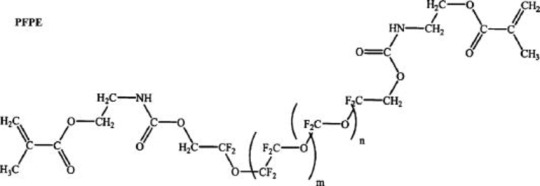

Perfluoropolyether (or PFPE) is a long chain polymer which consists of carbon, oxygen and fluorine atoms. The molecular structure can be branched, linear, or a combination thereof depending on the desired physical properties. Perfluoropolyether has lubricating effect on mechanical structure.

The report offers detailed coverage of Perfluoropolyether industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Perfluoropolyether by geography. The report splits the market size, by volume and value, on the basis of application type and geography.

First, this report covers the present status and the future prospects of the global Perfluoropolyether market for 2015-2024. And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru].

At the same time, we classify Perfluoropolyether according to the type, application by geography. More importantly, the report includes major countries market based on the type and application. Finally, the report provides detailed profile and data information analysis of leading Perfluoropolyether company.

Key Companies Corning BD Thermo Fisher Crystalgen Greiner Bio-One Pall Corporation Gosselin Phoenix Biomedical Merck Millipore Reinnervate Schott TPP Techno Plastic Products Narang Medical Limited Biosigma Aicor Medical NEST Biotechnology Surwin Plastic Citotest Labware Huaou Industry Membrane Solutions Kang Jian Medical Hangzhou Shengyou

Market Segment as follows: By Region Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia] Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland] North America[United States, Canada, Mexico] Middle East & Africa[GCC, North Africa, South Africa] South America[Brazil, Argentina, Columbia, Chile, Peru]

Market by Type Glass Petri Dishes Polystyrene Petri Dishes Others

Market by Application Laboratory Hospital Pharmaceutical industry Others

Ask Queries @ https://www.fusionmarketresearch.com/enquiry.php/(COVID-19-Version)-Global-Perfluoropolyether-Market/12699

Table of Contents

Part 1 Market Overview 1.1 Market Definition 1.2 Market Development 1.2.1 Current Situation 1.2.2 Aspects of COVID-19 Impact 1.3 By Type Table Type of Perfluoropolyether Figure Global Perfluoropolyether Market Share by Type in 2019 1.4 By Application Table Application of Perfluoropolyether Figure Global Perfluoropolyether Market Share by Application in 2019 1.5 By Region Figure Global Perfluoropolyether Market Share by Region in 2019 Figure Asia Perfluoropolyether Market Share by Region in 2019

Part 3 Global Market Status and Future Forecast 3.1 Global Market by Region Table Global Perfluoropolyether Market by Region, 2015-2019 (Million USD) Figure Global Perfluoropolyether Market Share by Region in 2019 (Million USD) Table Global Perfluoropolyether Market by Region, 2015-2019 (Volume) Figure Global Perfluoropolyether Market Share by Region in 2019 (Volume) Table Price List by Region, 2015-2019 3.2 Global Market by Company Table Global Perfluoropolyether Market by Company, 2015-2019 (Million USD) Figure Global Perfluoropolyether Market Share by Company in 2019 (Million USD) Table Global Perfluoropolyether Market by Company, 2015-2019 (Volume) Figure Global Perfluoropolyether Market Share by Company in 2019 (Volume) Table Price List by Company, 2015-2019 3.3 Global Market by Type Table Global Perfluoropolyether Market by Type, 2015-2019 (Million USD) Figure Global Perfluoropolyether Market Share by Type in 2019 (Million USD) Table Global Perfluoropolyether Market by Type, 2015-2019 (Volume) Figure Global Perfluoropolyether Market Share by Type in 2019 (Volume) Table Price List by Type, 2015-2019 3.4 Global Market by Application Table Global Perfluoropolyether Market by Application, 2015-2019 (Million USD) Figure Global Perfluoropolyether Market Share by Application in 2019 (Million USD) Table Global Perfluoropolyether Market by Application, 2015-2019 (Volume) Figure Global Perfluoropolyether Market Share by Application in 2019 (Volume) Table Price List by Application, 2015-2019 3.5 Global Market by Forecast Figure Global Perfluoropolyether Market Forecast, 2020-2025 (Million USD) Figure Global Perfluoropolyether Market Forecast, 2020-2025 (Volume)

…

Part 9 Market Features 9.1 Product Features 9.2 Price Features 9.3 Channel Features 9.4 Purchasing Features Part 10 Investment Opportunity 10.1 Regional Investment Opportunity 10.2 Industry Investment Opportunity

PART 11 Coronavirus Impact 11.1 Impact on Industry Upstream 11.2 Impact on Industry Downstream 11.3 Impact on Industry Channels 11.4 Impact on Industry Competition 11.5 Impact on Industry Obtain Employment Part 12 Conclusion

Continue…

ABOUT US :

Fusion Market Research is one of the largest collections of market research reports from numerous publishers. We have a team of industry specialists providing unbiased insights on reports to best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from a number of global leaders across industry segments.

CONTACT US

PH : +(210) 775-2636

0 notes

Text

Perfluoropolyether (PFPE) Market to Hold a High Potential for Growth by 2029

Perfluoropolyether Market: Introduction

Perfluoropolyether is among the family of fluorinated synthetic fluid. PFPE is a long chain organofluorine polymer consisting of carbon, oxygen and fluorine atoms. In terms of physical appearance it is colorless and odorless in nature and is completely inert to most chemical agents including oxygen. Perfluoropolyether is compatible with other liquids and materials over a high range of temperature from -40oC to 200oC. Perfluoropolyether have specific end use applications according to which different molecular structures of PFPE such as linear or pendant are applied. Perfluoropolyether find prominent application as a lubricant where they are used to formulate the most thermooxidatively stable lubricants. They are long chain fluoropolyether that wets the surface well and are slippery in nature which makes them as an ideal lubricant. Moreover, oxidative stability of the compound extends the component life and are well suited for demanding environmental conditions. Other properties such as chemical inertness imparts excellent stability in harsh environmental conditions and very low reactivity with other chemicals or surfaces. They can be available in various viscosities from very light for low-temperature applications to very viscous for application in heavy loaded applications. PFPE can be used directly as a lubricating oil or it can be combined with various thickeners to form variety of perfluoropolyether greases. Therefore, perfluoropolyether finds increasing applications in automotive industry, aerospace, electronics and coating applications. Thus, Perfluoropolyether market is slated to grow at healthy pace owing to its increasing usage in the application segments.

Perfluoropolyether Market: Dynamics

Perfluoropolyether is widely used as a lubricant in automobile industry where is used in lubrication of automobile components such as bearings, pivots and joints. Thus the demand from automobile oil segments is expected to drive the perfluoropolyethers market. Furthermore, perfluoropolyether finds extensive applications in aerospace applications as they can withstand the harsh environmental conditions. Significant investments in R&D by several countries is also one of the key driving factors along with growing demand for perfluoropolyethers in the semiconductor processing industry. Therefore, increasing usage of perfluoropolyethers in the end use industry is anticipated to boost the demand over the forecast period.

Visit For Sample>>https://www.futuremarketinsights.com/reports/sample/rep-gb-5647

Perfluoropolyether is used as coating lubricant in CD drives in electronic industry. However, declining market of CD drives may result decline in growth of perfluoropolyether market. Furthermore, PFPE is known for emission of fumes which are environmentally harmful at higher temperature. Hence, aforementioned are some of the factors which might hamper the growth of perfluoropolyether market over the forecast period.

Increasing usage of perfluoropolyether in aeronautical applications along with growing investment in R&D for testing its applicability in other applications are some of the ongoing key trends in the perfluoropolyether market.

Perfluoropolyether Market: Segmentation

The global perfluoropolyether market can be segmented on the basis of type, form and application. On the basis of type, the perfluoropolyether market can be segmented as PFPE-K, PFPE-Y, PFPE-D, PFPE-M and PFPE-Z. On the basis of form, the perfluoropolyether market can be segmented as PFPE- grease and PFPE- oil. On the basis of application, the perfluoropolyether market can be segmented as automotive, aerospace, electronics, chemicals and others.

Perfluoropolyether Market: Regional Outlook

Usage of perfluoropolyether in aerospace applications is one of the key factor which is anticipated to drive the growth over the forecast period. Growing investment in aerospace and defense applications is estimated to create high growth avenues. North America is expected to dominate the perfluoropolyethers market owing to high investment in aerospace applications along with booming semiconductors industry. Europe is also slated to grow at steady pace owing to increasing spending on R&D for defense and aerospace applications. Asia Pacific is expected show robust growth owing to high demand in automotive, aerospace industry. Furthermore, growing semiconductors market is expected to further boost the demand. Latin America and Middle East & Africa is anticipated to show steady growth over the forecast period owing to increasing demand in automobile industry.

For any queries linked with the report, ask an analyst >>https://www.futuremarketinsights.com/ask-question/rep-gb-5647

Perfluoropolyether Market: Market Participants

Examples of some of the market participants in the global Perfluoropolyether market are-

DAIKIN INDUSTRIES, Ltd.

Klüber Lubrication

The Chemours Company

Dow Corning Corporation

Solvay Solexis

Halocarbon Products Corporation

ICAN

Hunan Nonferrous Chenzhou Fluoride Chemical Co., Ltd.

M&I Materials Ltd

IKV Tribology Ltd

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

Buy Report >>https://www.futuremarketinsights.com/checkout/5647

The report covers exhaust analysis on:

Market Segments

Market Dynamics

Market Size

Supply & Demand

Current Trends/Issues/Challenges

Competition & Companies involved

Technology

Value Chain

Regional analysis includes:

North America (U.S., Canada)

Latin America (Mexico. Brazil)

Western Europe (Germany, Italy, France, U.K, Spain)

Eastern Europe (Poland, Russia)

Asia Pacific (China, India, ASEAN, Australia & New Zealand)

Japan

Middle East and Africa (GCC Countries, S. Africa, Northern Africa)

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Report Highlights:

Detailed overview of parent market

Changing market dynamics in the industry

In-depth market segmentation

Historical, current, and projected market size in terms of volume and value

Recent industry trends and developments

Competitive landscape

Strategies of key players and products offered

Potential and niche segments, geographical regions exhibiting promising growth

A neutral perspective on market performance

Must-have information for market players to sustain and enhance their market footprint

About FMI

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in Dubai, the global financial capital, and has delivery centers in the U.S. and India. FMI's latest market research reports and industry analysis help businesses navigate challenges and make critical decisions with confidence and clarity amidst breakneck competition. Our customized and syndicated market research reports deliver actionable insights that drive sustainable growth. A team of expert-led analysts at FMI continuously tracks emerging trends and events in a broad range of industries to ensure that our clients prepare for the evolving needs of their consumers.

Contact

Mr. Abhishek Budholiya

Unit No: AU-01-H Gold Tower (AU), Plot No: JLT-PH1-I3A,

Jumeirah Lakes Towers, Dubai,

United Arab Emirates

MARKET ACCESS DMCC Initiative

For Sales Enquiries: [email protected]

For Media Enquiries: [email protected]

0 notes

Text

Engineered Fluids Market Research: Key Player profile, Size, Share, Trends, Demand and Regional Outlook by 2027

Engineered fluids (fluorinated oils) are also known as perfluoropolyether (PFPE). They are a type of lubricant used to provide high-performance applications in extreme heat. They offer excellent features such as electrical, thermal, and chemical resistance; non-flammable; non-reactive to metal, plastic, rubber, and elastomers; non-toxic and environment-friendly. Electronic coolants are extensively used as engineered fluids for high-temperature applications in semiconductors, which is expected to fuel the demand for the product during the forecast period.

Browse Report@ https://www.marketresearchfuture.com/reports/engineered-fluids-fluorinated-oils-market-7803

Market Segmentation

The global engineered fluids (fluorinated oils) market has been segmented on the basis of application and region.

On the basis of application, the global engineered fluids (fluorinated oils) market has been categorized into automotive, aerospace and military, oil & gas, chemical processing, electricals & electronics, food processing machinery, and others. The electrical & electronics is the largest application segment of the global market due to the advantage of thermal and chemical stability for longer period. The adoption of high-tech manufacturing technologies for semiconductors is expected to fuel the demand for fluorinated oils during the forecast period. In the automotive industry, fluorinated oil or lubricants are used in connectors, switches, sensors, bearing, and actuators to keep away from dust, water, acid gases, and fuel. In the aerospace and military industry, fluorinated oil is used to provide radiation resistance and is safe for chemical and oxygen services. In the oil and gas industry, it upholds lubrication during the drilling operations.

Regional Analysis

Asia-Pacific, North America, Europe, Latin America, and the Middle East & Africa are the five key regions studied for the global engineered fluids (fluorinated oils) market. Asia-Pacific accounted for the largest market share of the global engineered fluids (fluorinated oils) market, since 2017.

North America and Europe are the other significant regional markets for engineered fluids). High investments in developing high-performance lubricants to bear extreme temperature is expected to increase the product demand during the assessment period.

Get a Free Sample@ https://www.marketresearchfuture.com/sample_request/7803

Competitive Analysis

Some of the prominent players in the global engineered fluids market are Solvay (Belgium), The Chemours Company (US), Daikin Industries, Ltd. (Japan), 3M (US), AGC Chemicals (Japan), Honeywell International Inc. (US), Halocarbon Products Corporation (US), Halopolymer Kirovo-Chepetsk (Russia), Engineered Custom Lubricants (US), F2 Chemicals Ltd (Showa Denko K.K.) (UK), Interflon (Netherlands), Finish Line (US), Frontier Performance Lubricants, Inc. (US), Condat Lubricants (France), and Klüber Lubrication (Germany).

0 notes