#PipelineProtection

Explore tagged Tumblr posts

Text

Corrosion Protection Tapes Market Experiences Steady Growth Due to Technological Advancements and Investments

The global corrosion protection tapes market has experienced steady growth over the past decade, driven by increasing demand across various industries such as oil & gas, water treatment, construction, marine, and infrastructure. These tapes serve as a crucial line of defense against corrosion, prolonging the lifespan of metal structures and equipment. As industries continue to emphasize durability, maintenance cost reduction, and environmental sustainability, corrosion protection solutions have gained prominence, with tapes becoming a preferred method due to their ease of application and effectiveness.

Corrosion protection tapes are used to coat metal surfaces, especially pipelines, tanks, valves, and structural steel, forming a moisture-resistant, UV-stable, and chemical-resistant barrier. Their key advantage lies in their ability to offer long-term corrosion resistance without the need for specialized tools or curing time, unlike paints or sprays. These tapes are generally categorized based on the backing material—polyethylene, PVC, or polypropylene—and the type of adhesive, such as rubber-based or bitumen-based.

The oil & gas industry remains the largest consumer of corrosion protection tapes, particularly for underground and underwater pipeline applications. As exploration and production activities expand in harsher environments, the need for reliable anti-corrosion systems has grown significantly. Likewise, the rising number of pipeline rehabilitation projects in aging infrastructure across North America and Europe has led to increased demand for retrofitting solutions like corrosion protection tapes.

In the water treatment sector, municipal pipelines, storage tanks, and wastewater management systems are increasingly adopting corrosion-resistant solutions. Corrosion protection tapes offer a quick, low-maintenance option for extending the lifespan of these systems. Additionally, governments across the globe are launching initiatives to upgrade aging public infrastructure, providing further impetus to market growth.

Asia-Pacific holds a substantial share in the corrosion protection tapes market and is projected to witness the fastest growth rate during the forecast period. Countries such as China, India, Japan, and South Korea are investing heavily in infrastructure development, including oil pipelines, water distribution systems, and transport networks. These developments, coupled with increased awareness about the long-term cost benefits of corrosion protection, are expected to boost regional market demand.

Technological advancements are also playing a significant role in shaping the market. Modern tapes feature improved adhesion, resistance to extreme temperatures, and environmental compliance. Manufacturers are focusing on producing tapes that meet international standards while reducing the environmental footprint. Eco-friendly formulations, solvent-free adhesives, and recyclable backing materials are being developed to cater to the growing demand for sustainable solutions.

Competitive dynamics in the corrosion protection tapes market remain intense, with several key players competing based on innovation, pricing, product quality, and distribution networks. Notable market participants include 3M Company, Denso Group, Nitto Denko Corporation, Shurtape Technologies, and Berry Global. These companies are increasingly investing in R&D and expanding their global presence to capture a larger share of the growing demand.

Challenges such as fluctuating raw material prices, regulatory compliance, and intense competition from alternative corrosion protection methods (e.g., liquid coatings, epoxy wraps) persist. However, the ease of application, reusability, and reduced labor cost associated with corrosion protection tapes continue to drive their adoption.

Looking forward, the corrosion protection tapes market is expected to maintain a healthy growth trajectory. Market research indicates a compound annual growth rate (CAGR) of around 4% to 6% over the next five years. Key growth drivers include rising infrastructure investments, increasing pipeline installations, emphasis on asset integrity, and environmental awareness.

The market is also witnessing a growing interest in customized solutions tailored to specific industry needs, such as high-temperature resistance, enhanced flexibility, or color coding for safety and maintenance purposes. As end-users seek longer-lasting and cost-effective protection methods, corrosion protection tapes are likely to gain further traction.

In conclusion, the corrosion protection tapes market presents significant opportunities across multiple industries. With evolving product technologies, supportive infrastructure policies, and a growing focus on sustainability, the demand for effective corrosion control methods like protective tapes is poised to rise. Industry players who innovate and align with these trends are well-positioned to lead in this expanding market.

0 notes

Text

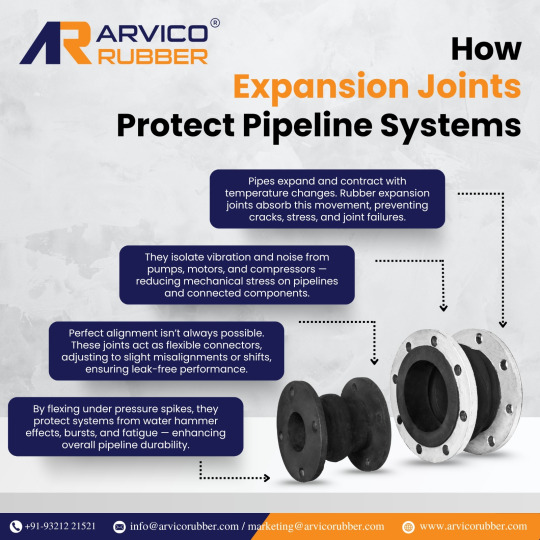

Industrial pipeline systems aren’t static—they move, vibrate, and expand with every degree of temperature change or pressure surge.

Arvico’s rubber expansion joints are purpose-built to adapt to this motion.

Safeguard your infrastructure with engineered solutions that perform smoothly and securely in dynamic pipeline environments.

#PipelineProtection#RubberExpansionJoint#Arvico#SmartSealing#FlowReliability#IndustrialInnovation#RubberSolutions

0 notes

Text

Searching for dependable DI Y Type Strainers suppliers? AsianCorp offers high-performance ductile iron Y type strainers, perfect for filtering debris and protecting pipeline systems in industrial and municipal applications.

#diytypestrainerssuppliers #asiancorp #industrialstrainters #pipelineprotection #ytypestrainer #ductileironstrainters #valvesandstrainters #fluidfiltration #straintersupplier #industrialequipment #qualitystrainters #valvemanufacturer

#diytypestrainerssuppliers#asiancorp#industrialstrainters#pipelineprotection#ytypestrainer#ductileironstrainters#valvesandstrainters#fluidfiltration#straintersupplier#industrialequipment#qualitystrainters#valvemanufacturer#pipelineaccessories#filtrationsolutions#engineeredproducts#pipingcomponents#strainerexperts#infrastructureproducts#processindustry#watermanagement

0 notes

Text

NRV Type Guide: Best Non Return Valves by Udhhyog

🛠️ All About Non Return Valves (NRV): Types, Functions & Supply – From Udhhyog

In industrial piping systems, the non return valve (NRV) is one of the most vital components. Whether it's water, gas, or chemicals, a non return setup ensures that media flows in only one direction—protecting pumps, preventing contamination, and ensuring safety.

At Udhhyog, we are proud to be one of India’s leading suppliers of industrial NRVs. We supply to a wide network across Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and beyond.

In this guide, we’ll explain how non return valves and check valves work, explore NRV types, and help you choose the right solution for your industrial application.

🔍 What is a Non Return Valve?

A non return valve, commonly abbreviated as NRV, is a one-way valve that allows media to flow in a single direction only. Its function is simple yet crucial—it prevents backflow.

Backflow can cause serious problems such as:

Damage to pumps or compressors

Contamination of clean fluid systems

Pressure surges or water hammer effects

This is why every industry from water treatment to oil & gas relies on NRV non return valves.

💡 Non Return Valve and Check Valve – What’s the Difference?

The terms non return valve and check valve are often used interchangeably, and while they serve the same purpose (preventing reverse flow), there are slight differences in design and use.

Non Return Valve (NRV): Typically used in domestic water supply, low-pressure pipelines, or irrigation.

Check Valve: Often used in industrial, chemical, or high-pressure applications.

At Udhhyog, we stock both variants—helping clients across industries choose the right fit based on pressure, media, and installation style.

🧩 NRV Type – Explained

There are multiple NRV types, each suited for different applications. Here are the most common:

1. Swing Type Non Return Valve

This NRV type has a disc that swings open when fluid flows forward and closes with reverse flow pressure.

Applications: Water pipelines, fire protection systems

Benefits: Simple design, low maintenance

2. Lift Type NRV

The internal disc lifts when fluid pressure increases and drops back to seal when flow reverses.

Applications: Steam lines, boilers

Benefits: Tight seal, reliable for vertical flows

3. Ball Type Non Return Valve

This design uses a rubber or metal ball that rolls back to seal off reverse flow.

Applications: Slurry, sewage, chemical industries

Benefits: Self-cleaning, good for dirty liquids

4. Wafer Type Check Valve (Dual Plate)

A compact, flange-mounted design using two spring-loaded plates. One of the best NRV types for space-saving setups.

Applications: HVAC systems, power plants

Benefits: Low pressure drop, compact, corrosion-resistant

🏭 Industries That Use NRV Non Return Valves

Udhhyog supplies valves to a variety of sectors that depend heavily on non return technology:

Water Treatment Plants

Chemical Processing Units

Pharmaceutical Manufacturing

Oil and Gas Refineries

Firefighting Systems

Irrigation and Agriculture

In each of these sectors, a failure in flow control could cause severe safety hazards. This is why the reliability of non return valve and check valve systems is paramount.

🌐 Udhhyog – India’s Trusted Valve Supplier

We at Udhhyog are more than just a supplier—we are a partner in your industry’s growth. Our valves are trusted by engineers, contractors, and project heads across India.

Why Udhhyog?

✔ Pan-India Supply – We are suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh

✔ Huge Inventory – All NRV types available in MS, SS, CI, WCB & more

✔ Fast Dispatch – Orders shipped within 1-2 working days

✔ Credit Facility – Flexible credit for loyal buyers

✔ Technical Expertise – Our experts help you choose the right NRV for your project

Explore our full product catalog: 👉 https://udhhyog.com/valves

🔧 Installation Tips for Non Return Valves

Correct installation ensures long-lasting performance of your NRV non return valve:

✅ Always match the valve size with pipeline diameter

✅ Ensure the flow arrow aligns with your system's direction

✅ Use proper gaskets between flanges

✅ Avoid overtightening to prevent cracking

✅ For vertical installations, use lift-type or ball-type NRVs

A poorly installed non return setup can lead to leakage, water hammer, or pressure failure.

📊 NRV Type Comparison Table

NRV TypeIdeal ApplicationFlow DirectionMaintenanceCostSwing NRVWater, fire systemsHorizontalLowModerateLift NRVSteam, vertical systemsVerticalModerateLowBall NRVSewage, slurryAnySelf-cleaningModerateWafer Type (Dual Plate)HVAC, compact setupsAnyLowAffordable

🔍 What to Consider When Choosing an NRV Non Return Valve?

Media Type: Water, chemicals, slurry, steam

Operating Pressure and Temperature

Pipeline Orientation: Horizontal or vertical

Maintenance Access

Material of Construction: SS304, SS316, CI, MS, etc.

Udhhyog’s team helps industries select the best fit based on detailed specs and flow conditions.

🔄 Benefits of Using Non Return Valve and Check Valve in Your Systems

✅ Prevent backflow damage

✅ Protect pumps and compressors

✅ Prevent contamination in water systems

✅ Reduce water hammer in high-speed flows

✅ Enable automated, maintenance-free operations

With thousands of installations completed across North India, Udhhyog valves are built to last and tested under strict quality control.

🧰 Other Valves Supplied by Udhhyog

In addition to NRVs, we also supply:

Ball Valves

Butterfly Valves

Gate Valves

Foot Valves

Y-Strainers

Explore our complete valve range: 👉 https://udhhyog.com/valves

🔚 Conclusion

Whether you're an engineer designing a water treatment system or a procurement head in the oil & gas sector, investing in the right non return valve and check valve is non-negotiable.

From swing type NRVs to dual plate wafer valves, Udhhyog has every NRV type your system could require—backed by quality, speed, and unmatched service.

🟢 Get in touch with us today to place your order or request a custom valve solution. We’re ready to power your flow with confidence.

#NonReturnValve#NRVType#NRVNonReturnValve#IndustrialValvesIndia#CheckValveIndia#FlowControlSolutions#Udhhyog#DelhiValveSupplier#BackflowPrevention#PipelineProtection

1 note

·

View note

Text

NRV Type Guide: Best Non Return Valves by Udhhyog

🛠️ All About Non Return Valves (NRV): Types, Functions & Supply – From Udhhyog

In industrial piping systems, the non return valve (NRV) is one of the most vital components. Whether it's water, gas, or chemicals, a non return setup ensures that media flows in only one direction—protecting pumps, preventing contamination, and ensuring safety.

At Udhhyog, we are proud to be one of India’s leading suppliers of industrial NRVs. We supply to a wide network across Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and beyond.

In this guide, we’ll explain how non return valves and check valves work, explore NRV types, and help you choose the right solution for your industrial application.

🔍 What is a Non Return Valve?

A non return valve, commonly abbreviated as NRV, is a one-way valve that allows media to flow in a single direction only. Its function is simple yet crucial—it prevents backflow.

Backflow can cause serious problems such as:

Damage to pumps or compressors

Contamination of clean fluid systems

Pressure surges or water hammer effects

This is why every industry from water treatment to oil & gas relies on NRV non return valves.

💡 Non Return Valve and Check Valve – What’s the Difference?

The terms non return valve and check valve are often used interchangeably, and while they serve the same purpose (preventing reverse flow), there are slight differences in design and use.

Non Return Valve (NRV): Typically used in domestic water supply, low-pressure pipelines, or irrigation.

Check Valve: Often used in industrial, chemical, or high-pressure applications.

At Udhhyog, we stock both variants—helping clients across industries choose the right fit based on pressure, media, and installation style.

🧩 NRV Type – Explained

There are multiple NRV types, each suited for different applications. Here are the most common:

1. Swing Type Non Return Valve

This NRV type has a disc that swings open when fluid flows forward and closes with reverse flow pressure.

Applications: Water pipelines, fire protection systems

Benefits: Simple design, low maintenance

2. Lift Type NRV

The internal disc lifts when fluid pressure increases and drops back to seal when flow reverses.

Applications: Steam lines, boilers

Benefits: Tight seal, reliable for vertical flows

3. Ball Type Non Return Valve

This design uses a rubber or metal ball that rolls back to seal off reverse flow.

Applications: Slurry, sewage, chemical industries

Benefits: Self-cleaning, good for dirty liquids

4. Wafer Type Check Valve (Dual Plate)

A compact, flange-mounted design using two spring-loaded plates. One of the best NRV types for space-saving setups.

Applications: HVAC systems, power plants

Benefits: Low pressure drop, compact, corrosion-resistant

🏭 Industries That Use NRV Non Return Valves

Udhhyog supplies valves to a variety of sectors that depend heavily on non return technology:

Water Treatment Plants

Chemical Processing Units

Pharmaceutical Manufacturing

Oil and Gas Refineries

Firefighting Systems

Irrigation and Agriculture

In each of these sectors, a failure in flow control could cause severe safety hazards. This is why the reliability of non return valve and check valve systems is paramount.

🌐 Udhhyog – India’s Trusted Valve Supplier

We at Udhhyog are more than just a supplier—we are a partner in your industry’s growth. Our valves are trusted by engineers, contractors, and project heads across India.

Why Udhhyog?

✔ Pan-India Supply – We are suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh

✔ Huge Inventory – All NRV types available in MS, SS, CI, WCB & more

✔ Fast Dispatch – Orders shipped within 1-2 working days

✔ Credit Facility – Flexible credit for loyal buyers

✔ Technical Expertise – Our experts help you choose the right NRV for your project

Explore our full product catalog: 👉 https://udhhyog.com/valves

🔧 Installation Tips for Non Return Valves

Correct installation ensures long-lasting performance of your NRV non return valve:

✅ Always match the valve size with pipeline diameter

✅ Ensure the flow arrow aligns with your system's direction

✅ Use proper gaskets between flanges

✅ Avoid overtightening to prevent cracking

✅ For vertical installations, use lift-type or ball-type NRVs

A poorly installed non return setup can lead to leakage, water hammer, or pressure failure.

📊 NRV Type Comparison Table

NRV TypeIdeal ApplicationFlow DirectionMaintenanceCostSwing NRVWater, fire systemsHorizontalLowModerateLift NRVSteam, vertical systemsVerticalModerateLowBall NRVSewage, slurryAnySelf-cleaningModerateWafer Type (Dual Plate)HVAC, compact setupsAnyLowAffordable

🔍 What to Consider When Choosing an NRV Non Return Valve?

Media Type: Water, chemicals, slurry, steam

Operating Pressure and Temperature

Pipeline Orientation: Horizontal or vertical

Maintenance Access

Material of Construction: SS304, SS316, CI, MS, etc.

Udhhyog’s team helps industries select the best fit based on detailed specs and flow conditions.

🔄 Benefits of Using Non Return Valve and Check Valve in Your Systems

✅ Prevent backflow damage

✅ Protect pumps and compressors

✅ Prevent contamination in water systems

✅ Reduce water hammer in high-speed flows

✅ Enable automated, maintenance-free operations

With thousands of installations completed across North India, Udhhyog valves are built to last and tested under strict quality control.

🧰 Other Valves Supplied by Udhhyog

In addition to NRVs, we also supply:

Ball Valves

Butterfly Valves

Gate Valves

Foot Valves

Y-Strainers

Explore our complete valve range: 👉 https://udhhyog.com/valves

🔚 Conclusion

Whether you're an engineer designing a water treatment system or a procurement head in the oil & gas sector, investing in the right non return valve and check valve is non-negotiable.

From swing type NRVs to dual plate wafer valves, Udhhyog has every NRV type your system could require—backed by quality, speed, and unmatched service.

🟢 Get in touch with us today to place your order or request a custom valve solution. We’re ready to power your flow with confidence.

#NonReturnValve#NRVType#NRVNonReturnValve#IndustrialValvesIndia#CheckValveIndia#FlowControlSolutions#Udhhyog#DelhiValveSupplier#BackflowPrevention#PipelineProtection

1 note

·

View note

Text

NRV Type Guide: Best Non Return Valves by Udhhyog

🛠️ All About Non Return Valves (NRV): Types, Functions & Supply – From Udhhyog

In industrial piping systems, the non return valve (NRV) is one of the most vital components. Whether it's water, gas, or chemicals, a non return setup ensures that media flows in only one direction—protecting pumps, preventing contamination, and ensuring safety.

At Udhhyog, we are proud to be one of India’s leading suppliers of industrial NRVs. We supply to a wide network across Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and beyond.

In this guide, we’ll explain how non return valves and check valves work, explore NRV types, and help you choose the right solution for your industrial application.

🔍 What is a Non Return Valve?

A non return valve, commonly abbreviated as NRV, is a one-way valve that allows media to flow in a single direction only. Its function is simple yet crucial—it prevents backflow.

Backflow can cause serious problems such as:

Damage to pumps or compressors

Contamination of clean fluid systems

Pressure surges or water hammer effects

This is why every industry from water treatment to oil & gas relies on NRV non return valves.

💡 Non Return Valve and Check Valve – What’s the Difference?

The terms non return valve and check valve are often used interchangeably, and while they serve the same purpose (preventing reverse flow), there are slight differences in design and use.

Non Return Valve (NRV): Typically used in domestic water supply, low-pressure pipelines, or irrigation.

Check Valve: Often used in industrial, chemical, or high-pressure applications.

At Udhhyog, we stock both variants—helping clients across industries choose the right fit based on pressure, media, and installation style.

🧩 NRV Type – Explained

There are multiple NRV types, each suited for different applications. Here are the most common:

1. Swing Type Non Return Valve

This NRV type has a disc that swings open when fluid flows forward and closes with reverse flow pressure.

Applications: Water pipelines, fire protection systems

Benefits: Simple design, low maintenance

2. Lift Type NRV

The internal disc lifts when fluid pressure increases and drops back to seal when flow reverses.

Applications: Steam lines, boilers

Benefits: Tight seal, reliable for vertical flows

3. Ball Type Non Return Valve

This design uses a rubber or metal ball that rolls back to seal off reverse flow.

Applications: Slurry, sewage, chemical industries

Benefits: Self-cleaning, good for dirty liquids

4. Wafer Type Check Valve (Dual Plate)

A compact, flange-mounted design using two spring-loaded plates. One of the best NRV types for space-saving setups.

Applications: HVAC systems, power plants

Benefits: Low pressure drop, compact, corrosion-resistant

🏭 Industries That Use NRV Non Return Valves

Udhhyog supplies valves to a variety of sectors that depend heavily on non return technology:

Water Treatment Plants

Chemical Processing Units

Pharmaceutical Manufacturing

Oil and Gas Refineries

Firefighting Systems

Irrigation and Agriculture

In each of these sectors, a failure in flow control could cause severe safety hazards. This is why the reliability of non return valve and check valve systems is paramount.

🌐 Udhhyog – India’s Trusted Valve Supplier

We at Udhhyog are more than just a supplier—we are a partner in your industry’s growth. Our valves are trusted by engineers, contractors, and project heads across India.

Why Udhhyog?

✔ Pan-India Supply – We are suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh

✔ Huge Inventory – All NRV types available in MS, SS, CI, WCB & more

✔ Fast Dispatch – Orders shipped within 1-2 working days

✔ Credit Facility – Flexible credit for loyal buyers

✔ Technical Expertise – Our experts help you choose the right NRV for your project

Explore our full product catalog: 👉 https://udhhyog.com/valves

🔧 Installation Tips for Non Return Valves

Correct installation ensures long-lasting performance of your NRV non return valve:

✅ Always match the valve size with pipeline diameter

✅ Ensure the flow arrow aligns with your system's direction

✅ Use proper gaskets between flanges

✅ Avoid overtightening to prevent cracking

✅ For vertical installations, use lift-type or ball-type NRVs

A poorly installed non return setup can lead to leakage, water hammer, or pressure failure.

📊 NRV Type Comparison Table

NRV TypeIdeal ApplicationFlow DirectionMaintenanceCostSwing NRVWater, fire systemsHorizontalLowModerateLift NRVSteam, vertical systemsVerticalModerateLowBall NRVSewage, slurryAnySelf-cleaningModerateWafer Type (Dual Plate)HVAC, compact setupsAnyLowAffordable

🔍 What to Consider When Choosing an NRV Non Return Valve?

Media Type: Water, chemicals, slurry, steam

Operating Pressure and Temperature

Pipeline Orientation: Horizontal or vertical

Maintenance Access

Material of Construction: SS304, SS316, CI, MS, etc.

Udhhyog’s team helps industries select the best fit based on detailed specs and flow conditions.

🔄 Benefits of Using Non Return Valve and Check Valve in Your Systems

✅ Prevent backflow damage

✅ Protect pumps and compressors

✅ Prevent contamination in water systems

✅ Reduce water hammer in high-speed flows

✅ Enable automated, maintenance-free operations

With thousands of installations completed across North India, Udhhyog valves are built to last and tested under strict quality control.

🧰 Other Valves Supplied by Udhhyog

In addition to NRVs, we also supply:

Ball Valves

Butterfly Valves

Gate Valves

Foot Valves

Y-Strainers

Explore our complete valve range: 👉 https://udhhyog.com/valves

🔚 Conclusion

Whether you're an engineer designing a water treatment system or a procurement head in the oil & gas sector, investing in the right non return valve and check valve is non-negotiable.

From swing type NRVs to dual plate wafer valves, Udhhyog has every NRV type your system could require—backed by quality, speed, and unmatched service.

🟢 Get in touch with us today to place your order or request a custom valve solution. We’re ready to power your flow with confidence.

#NonReturnValve#NRVType#NRVNonReturnValve#IndustrialValvesIndia#CheckValveIndia#FlowControlSolutions#Udhhyog#DelhiValveSupplier#BackflowPrevention#PipelineProtection

0 notes

Text

Resistoflex Gimbal Expansion Joints ensure seismic isolation of pipelines, while our SS Braided Hoses provide leak-proof, durable solutions for high-pressure and extreme conditions. Trust us for safe and efficient solutions in every critical application! . . . For more Info Connect with us: 📧 Email: [email protected] 🌐Website: https://www.resistoflex.in/

#Resistoflex#GimbalExpansionJoints#SeismicIsolation#SSBraidedHoses#LeakProof#HighPressureSolutions#ExtremeConditions#PipelineProtection#IndustrialSafety#HVACSolutions#EngineeringExcellence#DurablePerformance#FluidControl#VibrationIsolation#ReliableEngineering

0 notes

Text

Anti-Corrosion Coating Market — Forecast(2025–2031)

🌍 𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐭𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐃𝐮𝐫𝐚𝐛𝐢𝐥𝐢𝐭𝐲: 𝐀𝐧𝐭𝐢-𝐂𝐨𝐫𝐫𝐨𝐬𝐢𝐨𝐧 𝐂𝐨𝐚𝐭𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐓𝐫𝐞𝐧𝐝𝐬 | IndustryARC™

The global anti-corrosion coating market was valued at $32.6 billion in 2023, and is projected to reach $54.4 billion by 2033, growing at a CAGR of 5.4% from 2024 to 2033.

👉𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 :

🔹Increase in demand for infrastructure development and rise in focus on #sustainable_coatings are key drivers of growth in the anti-corrosion coating market. Infrastructure projects such as bridges, highways, pipelines, and buildings require robust protective solutions to withstand environmental challenges and extend asset lifespans, leading to higher demand for anti-corrosion coatings.

🔹Anti-corrosion coatings are protective layers applied to metal surfaces to prevent or slow down the process of #corrosion caused by environmental factors such as moisture, chemicals, and temperature fluctuations. These coatings act as a barrier, shielding the underlying material from exposure to corrosive elements, thereby extending the lifespan and maintaining the structural integrity of the object or surface.

🔹According to the opinions of various CXOs of leading companies, the anti-corrosion coating market is expected to witness growth during the forecast period owing to increase in demand for infrastructure development and surge in focus on sustainable coatings.

📊 𝐆𝐞𝐭 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 :

𝐊𝐞𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐫𝐢𝐯𝐞𝐫𝐬:

✨ Rising Infrastructure Projects: Global investments in bridges, pipelines, and offshore platforms are boosting demand.

♻️ Sustainability Focus: Eco-friendly, low-VOC coatings are becoming industry standards.

🚀 Technological Innovations: Nanotechnology and smart coatings are revolutionizing corrosion resistance.

Get this Report on discount of $1000 on purchase of Credit Card

✅ 𝗞𝗲𝘆 𝗖𝗼𝗺𝗽𝗮𝗻𝗶𝗲𝘀 𝗣𝗿𝗼𝗳𝗶𝗹𝗲𝘀 𝗚𝗶𝘃𝗲𝗻 𝗶𝗻 𝘁𝗵𝗶𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗥𝗲𝗽𝗼𝗿𝘁: Evonik Coating Additives | Evonik | Wasco | Graco Protective Coatings Equipment | OIL TECH OIL & GAS SERVICES LLC | HILONG GROUP OF COMPANIES | Man Industries Ltd | Vitracoat, Inc. | Guangzhou Lushan New Materials Co.,Ltd | Lushan Advanced Materials (Malaysia) Sdn. Bhd. | Shandong Kaitai Metal Abrasive Co.,Ltd | Kansai Paint Co.,Ltd | PPG | PPG Asian Paints | Nippon Paint Holdings Co., Ltd. | AkzoNobel | 3M | Sika | Hempel A/S | Axalta | Sherwin-Williams |

#AntiCorrosionCoating#CorrosionProtection#IndustrialCoatings#ProtectiveCoatings#SurfaceTreatment#RustPrevention#MarineCoatings#OilAndGasCoatings#PipelineProtection#CoatingTechnology#AdvancedCoatings#MetalProtection#CorrosionControl#EpoxyCoatings#NanoCoatings#WaterproofCoatings#PolyurethaneCoatings#SurfaceEngineering#CoatingInnovation#SustainableCoatings

0 notes

Text

🔧🌟 Optimize Your Pipeline Performance with Fenhar's G10 Flange Insulation Kits! 🌟🔧

✅ Durable and high-quality insulation ✅ Protects against galvanic corrosion

Get in touch at [email protected] to learn more!

0 notes

Text

Cathodic Protection Industry Update: $13.81B by 2034

Cathodic Protection Market to Surge from $9.8B in 2024 to $13.81B by 2034! 🌍📈 With a CAGR of 3.5%, the cathodic protection market is gaining momentum as industries double down on protecting critical infrastructure from corrosion. This market spans sacrificial anodes, impressed current systems, remote monitoring tech, and maintenance services — all working to extend the life of pipelines, storage tanks, marine structures, and water facilities. In 2024 alone, the market hit 320 million units in volume, led by sacrificial anodes (45%) and impressed current systems (35%), with hybrid systems rising at 20%.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS22552 &utm_source=SnehaPatil&utm_medium=Article

🏗️ The oil & gas sector leads adoption due to its reliance on long-distance pipelines and complex storage networks. Meanwhile, water and wastewater treatment is the second-highest growing segment, reflecting the global focus on infrastructure resilience.

🌎 Regionally, North America tops the charts, fueled by aging infrastructure and regulatory pressures. Asia-Pacific is close behind, driven by rapid industrial expansion in China and India.

💡 Technological innovations, such as real-time corrosion monitoring and IoT-enabled systems, are transforming the market, offering smarter, more efficient protection. As infrastructure investments soar globally, the demand for reliable cathodic protection solutions is set to climb.

#cathodicprotection #corrosioncontrol #infrastructureprotection #oilandgasindustry #pipelineprotection #marineengineering #waterinfrastructure #sacrificialanode #impressedcurrent #hybridsystems #remotemonitoring #assetprotection #corrosionprevention #metalprotection #industrialsolutions #offshoreengineering #subseatechnology #zincanodes #magnesiumanodes #aluminumanodes #corrosionresistance #constructiontech #smartinfrastructure #maintenanceinnovation #infrastructuredevelopment #energyefficiency #industrialmaintenance #sustainabilitysolutions #digitalmonitoring #structuralintegrity #energysector #iotinfrastructure #onshoreprojects #subseaprotection #civilengineeringtech #powercables #resiliencetech #watertreatmenttech #globalinfrastructure #futureproofing #techdrivenengineering

Research Scope:

· Estimates and forecast the overall market size for the total market, across type, application, and region

· Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

· Identify factors influencing market growth and challenges, opportunities, drivers, and restraints

· Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

· Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Corrosion Protection Tapes Market Innovation Increasing with New Materials and Sustainable Adhesive Technologies

The corrosion protection tapes market has witnessed steady growth in recent years, driven by the increasing need to preserve metal surfaces in harsh environments. Corrosion can degrade pipelines, structural components, and industrial equipment, leading to significant maintenance costs, operational disruptions, and safety risks. As industries look for cost-effective and efficient methods to extend the lifespan of their assets, corrosion protection tapes have emerged as a critical solution.

Market Drivers

One of the primary drivers of the corrosion protection tapes market is the rising investment in oil and gas infrastructure, particularly in pipeline construction and maintenance. Pipelines are highly susceptible to environmental damage, especially when laid underground or underwater. Protective tapes offer a convenient and reliable method for shielding these pipes from moisture, chemicals, and extreme temperatures. They are often preferred over paints and coatings because they are easier to apply, reapply, and maintain over time.

Moreover, urbanization and industrialization in emerging economies have significantly boosted demand for corrosion-resistant infrastructure. Developing countries are investing heavily in transportation networks, power plants, and water treatment systems, all of which require durable and corrosion-resistant components. Corrosion protection tapes help ensure long-term reliability and reduce repair costs, making them a favored solution across multiple sectors.

Product Types and Materials

Corrosion protection tapes are typically made from polyethylene, PVC, and butyl rubber, each offering distinct benefits. Polyethylene tapes are lightweight and moisture-resistant, commonly used for general-purpose protection. PVC tapes provide excellent electrical insulation in addition to corrosion resistance, making them suitable for wiring and electrical applications. Butyl rubber tapes, known for their high adhesion and resistance to aggressive chemicals, are ideal for high-demand industrial settings.

The tapes are also classified based on their adhesive systems—pressure-sensitive, self-fusing, and heat-activated. Pressure-sensitive tapes are the most widely used due to their ease of application. Self-fusing and heat-activated tapes, on the other hand, are used in environments where a higher level of bonding strength and sealing capability is required.

Application Areas

Corrosion protection tapes are used across a wide range of industries, including oil & gas, marine, water treatment, construction, automotive, and electrical. The oil and gas industry remains the largest consumer due to the need to protect pipelines, valves, and joints from corrosion in both onshore and offshore operations.

In the marine industry, the challenge of saltwater corrosion makes these tapes essential for ship maintenance, dock equipment, and underwater pipelines. Similarly, in construction and water infrastructure, corrosion protection ensures the durability of steel reinforcements and pipelines used in public utility networks.

Regional Insights

Geographically, North America and Europe dominate the corrosion protection tapes market, driven by mature infrastructure, strict regulations, and high maintenance standards. These regions also show a strong inclination toward sustainable solutions, encouraging the use of eco-friendly and low-VOC (volatile organic compounds) tapes.

Asia-Pacific is expected to witness the fastest growth, led by countries like China, India, and Southeast Asian nations. Rapid industrialization, increased construction activities, and significant investments in energy and water infrastructure are key factors fueling the market in this region.

Market Challenges and Trends

While the market outlook remains positive, it is not without challenges. The availability of alternative corrosion protection methods, such as liquid coatings and cathodic protection, may limit the adoption of tapes in certain sectors. Additionally, fluctuations in raw material prices—particularly petrochemical-based adhesives and films—can impact manufacturing costs and profit margins.

On the other hand, the market is seeing trends such as the integration of advanced materials that offer better thermal resistance, UV stability, and chemical durability. Manufacturers are also focusing on biodegradable and recyclable tapes to meet the growing demand for sustainable solutions. Digital advancements in inspection and monitoring systems are expected to complement the use of corrosion protection tapes by enabling more targeted and timely application.

Future Outlook

The corrosion protection tapes market is poised for continued expansion over the next decade. With infrastructure development, aging pipelines, and increased emphasis on asset preservation, the demand for reliable corrosion protection solutions is only set to rise. Manufacturers that invest in innovation, sustainability, and customization are likely to gain a competitive edge in this evolving market landscape.

#CorrosionProtection#AntiCorrosion#PipelineProtection#InfrastructureMaintenance#OilAndGasIndustry#IndustrialSafety

0 notes

Text

Corrosion Protection Tapes Market Poised for Steady Growth Amid Rising Global Infrastructure Investment

Corrosion is a major challenge in industries where metal structures are exposed to harsh environments. From pipelines and tanks to marine equipment and industrial machinery, corrosion can lead to severe degradation, system failure, and costly repairs. Corrosion protection tapes have emerged as a reliable, efficient, and easy-to-apply solution to safeguard metal surfaces. As demand for infrastructure durability and asset longevity increases, the corrosion protection tapes market is witnessing steady growth.

Market Overview

Corrosion protection tapes are adhesive tapes designed to prevent or slow down the corrosion process on metal surfaces. Typically made from materials such as polyethylene, PVC, and fabric-based composites, these tapes are coated with anti-corrosive adhesives and are used across a range of industries including oil & gas, water treatment, construction, and marine.

The global corrosion protection tapes market has been growing consistently, driven by rising infrastructure development, aging pipelines, and the growing need for long-term protective solutions. In 2024, the market was valued at approximately USD 1.6 billion, with projections suggesting a compound annual growth rate (CAGR) of 4-5% through 2030.

Key Market Drivers

1. Expanding Oil & Gas Sector: One of the primary drivers of the corrosion protection tapes market is the oil and gas industry. Pipelines transporting crude oil, natural gas, and petroleum products are particularly vulnerable to corrosion. Corrosion protection tapes offer a non-invasive and cost-effective solution for pipeline maintenance and extension of operational life.

2. Rising Infrastructure Investment: Governments and private investors worldwide are pouring resources into building and maintaining roads, bridges, water systems, and power plants. As these structures involve steel and metal frameworks, the use of corrosion protection solutions is essential. Tapes offer a quick and practical method to protect both underground and above-ground infrastructure.

3. Maintenance of Aging Assets: In mature economies, industrial assets and public infrastructure built decades ago are still in use. Maintenance and rehabilitation of these aging systems require effective anti-corrosion strategies, where tapes play a crucial role due to their ease of use and minimal downtime during application.

Market Segmentation

By Material Type:

Polyethylene Tapes: Widely used due to their excellent resistance to moisture and chemicals.

PVC Tapes: Preferred in environments requiring higher flexibility and temperature resistance.

Fabric-based Tapes: Used in heavy-duty applications where extra mechanical strength is needed.

By Application:

Pipelines

Storage Tanks

Marine Equipment

Underground Utilities

Steel Structures and Bridges

By End-user Industry:

Oil & Gas

Water & Wastewater

Construction

Chemical Processing

Marine & Shipping

Regional Insights

North America: The U.S. leads in terms of market share due to its extensive oil & gas pipeline network and active infrastructure maintenance programs. Environmental regulations also necessitate the use of non-toxic, environmentally friendly corrosion protection solutions.

Europe: Stringent EU standards for environmental protection and workplace safety are pushing the adoption of high-quality, low-VOC corrosion protection tapes, particularly in the marine and water sectors.

Asia-Pacific: This region is the fastest-growing market, driven by massive infrastructure investments in countries like China and India, along with rapid industrialization. The oil & gas and construction sectors are key contributors to demand.

Middle East & Africa: With the region's dependence on oil exports, maintaining pipeline integrity is critical. Corrosion protection tapes are a go-to solution for extending pipeline lifespans in harsh desert environments.

Competitive Landscape

The corrosion protection tapes market is moderately fragmented, with several global and regional players competing for market share. Major companies include:

3M Company

Denso Ltd.

Nitto Denko Corporation

Shurtape Technologies

Berry Global Inc.

These companies focus on product innovation, expanding distribution networks, and developing environment-friendly tapes to meet regulatory requirements and sustainability goals.

Innovations and Trends

Eco-Friendly Tapes: The push for sustainable construction and industrial practices has led to the development of solvent-free and recyclable corrosion protection tapes.

Smart Tapes: Research is ongoing into tapes that change color or texture when corrosion begins beneath them, helping with early detection and reducing maintenance costs.

High-Temperature Resistance: New tapes are being designed to withstand extreme temperatures, making them suitable for aerospace and thermal processing industries.

Hybrid Protection Systems: Some industries are combining tapes with coatings and cathodic protection for multilayered defense systems, especially in highly corrosive environments.

Challenges

Despite their advantages, corrosion protection tapes have limitations. They may not offer the same long-term performance in extremely aggressive environments as specialized coatings. Improper surface preparation or poor application can also reduce effectiveness. Additionally, fluctuating raw material prices and environmental regulations regarding VOC content can impact manufacturing costs.

Future Outlook

The outlook for the corrosion protection tapes market remains positive. With a growing focus on preventive maintenance, sustainability, and cost-efficiency, these tapes are expected to become an integral part of asset management strategies across sectors. As innovation continues, enhanced performance characteristics and user-friendly features will further drive market adoption.

0 notes