#Plastering Sand

Explore tagged Tumblr posts

Text

"Lorry transport drives the backbone of industry, delivering goods, growth, and reliability."

0 notes

Text

Only Friends Episode 9 | Ray being a Troll

I love it when Ray decides to throw himself into situations without giving two shits. He just barges in with a shrug like 'Did you two sex? Whatever, I'm plonking myself riiiiiight between you two, just here.' Poor Nick couldn't wait to leg it out of there.

#only friends#only friends the series#only friends shitpost#ofts#ray x sand#sand x ray#raysan#sanray#khaofirst#firstkhao#first kanaphan#khaotung thanawat#mark pakin#3 grown men + one tiny caravan bed#ray: im here to hug my man and no one is getting in my way#rays little butt wiggle as he tries to plaster himself as close to sand as humanly possible I DIE

694 notes

·

View notes

Text

#I’m so mad#this place is in Belize and we’re here for the shark and ray sanctuary#We picked it cause it’s got a fully equipped dive shop and a course so I can get scuba certified#But it’s trying to be a beach front hidden Mayan jungle paradise complete with tacky fake stone relics in the fake jungle and plaster Olmec#Heads and Hawaiian tiki carvings like give me a break#It’s all plastic foam and manicured sand#I’m in such a foul mood and very this#Anyways I’m going to go take a beginner scuba introduction course and maybe get scuba certified in two hours wish me luck#Can you tell I hate tacky insincere non genuine touristy things lol#And tacky insincere non genuine stuff in general

7 notes

·

View notes

Text

its so crazy how 3L is literally not that serious. but It Can Be. if you use your beautiful mind

#thats where all the fun is at....#i'm haunted by desertduo thoughts sorry. whyd they do all that#3L grian makes me want to chew on plaster the entire thesis of his character ca n be interpreted as him hopelessly trying to atone for a si#that he will ultimately never be forgiven for & that will ultimately become his own downfall!#like the finale of 3L is just this beautiful karmic parallel like this insane manifestation of his guilt coming back to eat him alive#to finish the job! to Make Him to finish the job!#& i think 3L desertduo has this weirdly beautiful capacity to read as a larger metaphor for dealing with the loss of a loved one#internalizing it as your fault; trying to atone for your own guilt; doing whatever you can to keep what little of them is left alive#but in the end no matter how hard you try reality remains reality and the truth remains clear:#one of you is alive and the other is not. and nothing can change this. nothing is going to ever change this#you have to let them go. and it can feel so torturous. it can feel like you're murdering the memory of them all over again#but theres only one way that this can end#something about sand castles not being made to last something about dust and memories slipping in between your fingers#sorry. i feel normal about this i promise

29 notes

·

View notes

Text

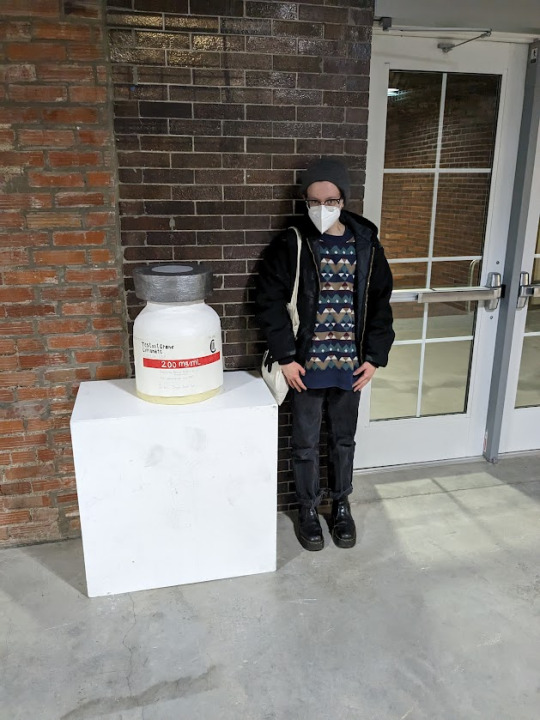

finished my first project for sculpture class :3

#not 100% happy with it but goddamn filing styrofoam and trying to get plaster sanded smooth is HARD#also the label was a struggle#shoutout to my friend for saving my ass during critique tho she was like it helps that the label doesnt look totally realistic cause this#isnt a real thing its youre dream & something you wish existed#but yea it was fun to make#and the color looks less piss-like in person i swear

17 notes

·

View notes

Text

alex doesn't like wuthering heights by kate bush......

#in the pepper grinder video he makes the molds out of the plaster & sand & water mixture#and he's like “i heard somewhere you're meant to 'agitate' the molds to get the air bubbles out or something”#so he plays the molds wuthering heights from his phone and also he like slaps them around and bothers them.....Im crying desperately#ididathing#alex apollonov#but then that was 5 years ago. maybe his opinion has changed#idat rewatch

7 notes

·

View notes

Text

absolutely drenched in sweat this is awful

2 notes

·

View notes

Text

oh thank fuck my professor extended the assignment due date so i have another week to finish this sculpture which is such a huge relief still have so much to do but at least i dont have to try to do it all in one day

#did not make the kind of progress i wanted to today bc i had to do even more plastering#but god willing on thursday i can sand and pain#paint*#anyways im not letting myself touch the sims until this is finished lmao

5 notes

·

View notes

Text

i made a star shelf for the little stuffs in my room that had no where to go 💫

#its made of cardboard tape glue and plaster. also paint and sealant and i did a little sanding but not enough to get rid of all texture#i like my room but it has gaps of boring wall space that need something so im trying to slowly fill it up with thing i make

2 notes

·

View notes

Text

challenges and opportunities in transport

Challenges in Transport

1. Traffic Congestion

Urban areas face heavy congestion, leading to delays, fuel waste, and increased pollution.

2. Environmental Impact

High carbon emissions from fossil fuel vehicles contribute to climate change and air pollution.

3. Poor Infrastructure

Inadequate or aging roads, bridges, and public transport systems slow down efficiency and increase maintenance costs.

4. Fuel Dependency

Heavy reliance on diesel and petrol, with volatile fuel prices and limited availability of alternatives.

5. Safety Concerns

Road accidents due to poor infrastructure, lack of awareness, and vehicle condition are a major issue.

6. Logistics and Supply Chain Delays

Disruptions in global or local supply chains affect goods movement, especially post-pandemic.

7. Technological Integration

Many transport systems still lack digital systems for tracking, route optimization, and data analysis.

Opportunities in Transport

1. Green Transportation

Electric vehicles (EVs), hydrogen-powered transport, and biofuels are paving the way for sustainable mobility.

2. Smart Transport Systems

Use of AI, IoT, and data analytics to manage traffic, track vehicles, and improve logistics efficiency.

3. Public Transport Modernization

Investment in metro systems, electric buses, and shared mobility to reduce road burden and emissions.

4. Autonomous Vehicles

Self-driving trucks, taxis, and delivery bots offer the potential for safer and more efficient transport.

5. Digital Logistics

Platforms for freight matching, real-time tracking, and digital documentation streamline operations.

6. Urban Mobility Innovations

Rise of e-scooters, bike-sharing, and walkable city planning offer cleaner last-mile solutions.

7. Policy and Global Collaboration

Governments are increasingly supporting sustainable transport policies and international cooperation on infrastructure development.

0 notes

Text

WAIT HAVING FIRST AID KITS IN YOU HOME IS NOT A COMMON THING

#like the basic ones with bandaids sand bandages and sanitizer and a pair of…#✂️ <- idk how to spell these in eng#like we have one at home and in each car and on the tractor#and in the garden shed too and I even have one just for my paintball gear#but the paintball one is just like two rolls of bandages and a whole lot of plasters#noticed this bc I mentioned in a vc that the one in my car is expireing soon#and you are required to have a good one in your car in germany#or else if you get pulled over in a random selection check you can get fined#or if you can‘t give proper first aid in a car accident bc it expires you can get fined#and even sued for failing to provide help

1 note

·

View note

Text

Estimate Cement Calculator for 1000 sq. ft. House

Building a house involves precise planning, especially when estimating the requirements of various building materials, such as cement. Whether it's for foundations, walls or plastering, calculating the right amount of cement is crucial for the structural integrity as well as cost efficiency.

This guide will walk you through the process of determining the cement requirement for a 1,000 sq. ft. house while ensuring an optimal cement and sand ratio for every application.

How Much Cement is Required for Constructing a 1,000 sq. ft. House?

The exact amount of cement depends on several factors, such as construction style, structural elements, and the concrete ratio for PCC (Plain Cement Concrete). Here’s a quick guide to understanding the cement requirements for a 1,000 sq. ft. house.

1 note

·

View note

Text

Do you know the purpose of drywall finishing in Toronto?

Taping and plastering provide a smooth and seamless surface that you can use for painting or wallpapering. Plastering covers any imperfections in the walls and creates a smooth finish. During taping, professionals apply drywall tape over the joints between drywall sheets. Plastering and taping are popular techniques that strengthen the joints between plasterboards. You can hire professionals for taping and plastering in Torontoto prevent cracks and ensure a flawless appearance on walls and ceilings.

#taping and plastering in Toronto#sanding services in Toronto#painting service in Toronto#Drywall finishing in Toronto

0 notes

Text

https://neocoats.in/texture-wall-paint-services-in-ahmedabad.html

What is textured wall paint?

Textured wall paint is a highly popular type of paint used to cover drywall. The paint has a thick consistency and is made up of grains of sand and gypsum bound by a water-diluted base. Using textured paint for interior walls creates a visually appealing effect on your walls. These wall surfaces are typically used to finish interior walls, covering taped drywall seams and other imperfections. At the same time, these surfaces transform flat walls into a finish that reflects light and adds interest to any room.

#Texture Wall Paint Services Ahmedabad#Textured Wall Painting Ahmedabad#Wall Texture Painting Services Ahmedabad#Decorative Wall Painting Ahmedabad#Interior Wall Texture Ahmedabad#Exterior Wall Texture Ahmedabad#Royal Finish Wall Painting Ahmedabad#Venetian Plaster Ahmedabad#Sand Finish Wall Painting Ahmedabad

0 notes

Text

Applications of Plaster Sand: A Comprehensive Overview

Plaster sand is a vital component in the construction industry, especially in the preparation of plaster, mortar, and other building materials. Its unique properties make it indispensable for producing high-quality finishes and strong bonding in various applications. Derived from crushed rock, plaster sand is finer than regular sand and possesses the ideal characteristics for use in construction, particularly in plastering, rendering, and other decorative or functional surfaces.

In this article, we will delve into the various applications of plaster sand, its benefits, and how it is used in different construction processes.

1. Plastering

One of the most common applications of plaster sand is in plastering. Plaster is a versatile material used for coating walls and ceilings to provide a smooth, durable surface. It is typically mixed with water and other ingredients like cement and lime to create a paste-like consistency.

How Plaster Sand is Used in Plastering:

Smooth Finish: Plaster sand is finely graded, allowing it to be mixed into plaster for a smoother finish. The finer particles provide a better consistency, ensuring that the plaster adheres well to the wall or ceiling.

Enhanced Workability: The use of plaster sand improves the workability of the plaster, making it easier to apply and spread over surfaces. The fine texture also reduces the likelihood of cracks or imperfections on the surface once the plaster dries.

Durability: When used in plastering, plaster sand contributes to the durability of the surface. It helps the plaster set correctly, which leads to better resistance to moisture, wear, and tear.

Plastering is essential in creating aesthetic, smooth finishes on both interior and exterior surfaces. The role of plaster sand in this process is crucial for ensuring that the plaster is easy to apply, durable, and long-lasting.

2. Rendering

Rendering is the application of a layer of cement-based material to the exterior walls of a building. Similar to plastering, rendering creates a protective and decorative finish on walls. Plaster sand plays an essential role in the rendering process by contributing to the smoothness, strength, and texture of the final result.

How Plaster Sand is Used in Rendering:

Bonding Strength: Plaster sand, when mixed with cement, improves the bonding strength of the render. The fine grains help the mixture adhere well to brick, stone, or concrete walls, creating a solid base for additional finishes or coatings.

Weather Resistance: Plaster sand helps the render become more resistant to weathering and environmental conditions. This makes it an ideal material for exterior applications where walls are exposed to rain, sun, and wind.

Aesthetic Finishes: Rendered surfaces often have a textured or patterned appearance. Plaster sand contributes to the creation of smooth, uniform finishes, making it suitable for both decorative and protective purposes.

Rendering can significantly enhance the aesthetic appeal of a building, as well as provide essential protection against the elements. Plaster sand is key to achieving a high-quality, durable render that not only improves the building’s look but also increases its lifespan.

3. Mortar Production

Mortar is a fundamental material used in construction for bonding bricks, stones, and other masonry units. Plaster sand is an essential ingredient in the production of mortar, as its properties allow it to create a smooth, workable mixture that can be easily applied between masonry units.

How Plaster Sand is Used in Mortar:

Strength and Bonding: The fine particles of plaster sand enhance the bonding properties of mortar. When combined with cement and water, plaster sand contributes to the creation of a strong, durable mortar that can withstand the weight and pressure of masonry units.

Workability: Plaster sand improves the workability of mortar, making it easier to spread and apply during construction. Its fine texture allows for a smoother, more consistent mixture, reducing the chances of lumps or air pockets in the mortar.

Consistency: The quality and consistency of mortar are crucial for building solid structures. Plaster sand’s ability to create a smooth and uniform mixture ensures that the mortar is of the highest quality and that masonry work is secure and long-lasting.

Mortar is used in a variety of construction tasks, such as bricklaying, blockwork, and stone construction. The role of plaster sand in creating high-quality mortar ensures that the bonds between building materials are strong and secure, contributing to the overall stability and durability of the structure.

4. Concrete Production

Concrete is a composite material made from cement, aggregates, and water. It is used in everything from foundations and walls to floors and pavements. Plaster sand, when used as a fine aggregate in concrete, improves the overall quality of the concrete mix, especially in the creation of smooth, fine-textured surfaces.

How Plaster Sand is Used in Concrete:

Fine Aggregate for Smooth Finish: Plaster sand acts as a fine aggregate in concrete mixes, ensuring that the final product has a smooth finish. This is particularly important for decorative concrete surfaces or when a fine-textured, polished surface is required.

Reduced Shrinkage: The use of plaster sand can help reduce shrinkage cracks in concrete as it absorbs water more efficiently than coarser aggregates. This leads to better structural integrity and fewer cracks in the hardened concrete.

Strength and Durability: While coarse aggregates contribute to the bulk of the concrete, plaster sand helps improve the overall strength and durability by filling the voids between larger aggregates, creating a more cohesive and resilient material.

Plaster sand is particularly valuable in high-strength concrete applications, decorative concrete, and situations where the surface quality is critical. Its role in enhancing the texture, finish, and durability of concrete makes it an indispensable material in modern construction.

5. Paving and Road Construction

In road construction and the laying of pavements, plaster sand can be used as a component of the base or sub-base layers, providing a stable foundation for the road surface. Its fine texture allows it to create a smooth, level surface that is ideal for laying pavers or constructing solid road foundations.

How Plaster Sand is Used in Paving:

Base Layer for Paving: Plaster sand is often used as part of the base or sub-base material when laying paving stones, bricks, or tiles. Its fine texture ensures that the stones or bricks are laid on a stable, level foundation that minimizes shifting and settling over time.

Improved Drainage: In paving applications, plaster sand is often mixed with other aggregates to improve the drainage properties of the surface. This is particularly important in road construction, where proper water drainage is essential for preventing damage to the surface.

Compaction and Stability: Plaster sand, when compacted, forms a solid, stable layer that can support the weight of traffic or pedestrians. It helps distribute the load evenly across the surface, ensuring that the paving materials remain intact and level.

The use of plaster sand in paving and road construction is critical for creating stable, durable surfaces that can withstand the rigors of everyday use, whether for pedestrian walkways or busy highways.

6. Sandblasting and Surface Cleaning

Sandblasting is a method of cleaning or preparing surfaces by forcing a stream of sand particles at high pressure against the surface. Plaster sand, due to its fine and uniform grain size, is an ideal material for sandblasting applications, where precision and a clean finish are necessary.

How Plaster Sand is Used in Sandblasting:

Surface Preparation: Plaster sand is commonly used in sandblasting to prepare surfaces for painting, coating, or sealing. Its fine texture allows it to clean surfaces effectively, removing rust, old paint, dirt, and other contaminants.

Polishing: In addition to cleaning, plaster sand can be used in certain sandblasting applications for polishing metal or stone surfaces. The fine nature of the sand ensures that surfaces are not damaged or scratched, making it ideal for delicate materials.

Etching and Artistic Designs: Sandblasting with plaster sand is often used to create etchings or intricate designs on glass, stone, or metal surfaces. The precise nature of plaster sand allows for detailed work and high-quality finishes.

The versatility and precision of plaster sand make it a valuable material in industries that require fine surface cleaning, preparation, and decoration.

7. Landscaping and Decorative Uses

Plaster sand is also used in landscaping, where it serves multiple purposes such as providing a base for garden features, leveling the soil, or creating decorative paths and surfaces. Its fine texture and attractive appearance make it a popular choice for aesthetic landscaping projects.

How Plaster Sand is Used in Landscaping:

Leveling Soil and Surfaces: Plaster sand is ideal for leveling uneven ground in gardens or landscapes. It can be spread evenly to create a smooth, flat surface for planting or for laying paving stones.

Decorative Paths and Walkways: Plaster sand can be used to create decorative pathways in gardens or outdoor spaces. Its fine texture provides a clean, attractive finish that complements a variety of landscaping designs.

Improving Drainage in Gardens: Like other fine aggregates, plaster sand can help improve the drainage properties of garden soil. By mixing it into the soil, gardeners can enhance the flow of water and reduce the risk of waterlogging.

In landscaping, plaster sand serves both functional and aesthetic purposes, making it a versatile material for a variety of outdoor projects.

Plaster sand plays an essential role in many aspects of construction and design. From plastering and rendering to concrete production, paving, and even landscaping, its fine, consistent texture ensures that it performs effectively in a wide range of applications. Whether used in creating smooth, durable finishes, providing a solid foundation for structures, or adding decorative touches to gardens and outdoor spaces, plaster sand is indispensable in the construction industry. By understanding its various uses and benefits, builders, architects, and homeowners can ensure that they make the most of this versatile material in their projects.

0 notes

Text

why M sand plants are the future of sustainable building materials

Sustainability is a major concern in today’s rapidly growing construction industry. Traditional building materials such as natural river sand have been in demand for decades. However, the excessive use of river sand leads to environmental degradation, necessitating the use of alternative sources. One such method is M Sand (Manufactured Sand), which is produced by crushing, quarrying, or large aggregates. In this blog, we explore why the M Sand plant is the future of sustainable building materials, and environmental benefits, Readymix Construction Machinery Pvt. Ltd. plays a key role in this transformation.

Understanding M Sand and Its Importance

M Sand is an eco-friendly sustainable alternative to natural sand. It is done in a controlled environment, ensuring quality and regular gradation. M is prepared by transporting gravel through sand fracturing, and the resulting crushed sand is washed and graded to the required standard. Unlike river sand, which is often inconsistent and dirty, M Sand provides excellent strength and stability for construction projects.

Why M sand plants are a sustainable solution

1. Reduce environmental footprint

One of the main benefits of M Sand plants is helping to reduce environmental damage due to the over-mining of river sand. River mining for natural sand results in water erosion, degradation of aquatic ecosystems and negative impacts on groundwater. This ecosystem damage is avoided in M Sand plants, making M Sand an environmentally friendly alternative.

2. Resource Management

Unlike natural sand, which deteriorates due to overuse, M Sand can be manufactured using a variety of materials including waste from other industries to make these sustainable materials that it not only help preserve natural sand but keep waste out of landfills, contributing to a circular economy

The role of plaster sand in sustainable construction

Plaster sand is another important ingredient in construction, used primarily for plastering and finishing walls. Like M Sand, plaster sand can also be made with Plaster Sand Making Units. These units ensure a polished sandblast which is ideal for achieving a smooth finish to the walls. The construction project can further reduce the environmental impact by using plaster sand rather than natural river sand.

Benefits of Plaster Sand:

– Better Workability: Plaster sand increases workability, reducing the need for additional cement or water.

– Low Cost: Because plaster sand is produced, its consistent quality reduces waste and keeps costs down.

– Long Lasting Finish: The uniform size of the plaster sand pieces ensures smoothness and durability, reducing the need for frequent maintenance.

M Advanced Technology in Sand Production

In Readymix Construction Machinery Pvt. Ltd., we use state-of-the-art technology to produce high-quality M Sand and plaster sand. Our Plaster Sand Classifiers and Dry Sand Washing System ensure that the sand is properly graded and free of silt, clay, dust and other contaminants.

1. Plaster Sand

Grade Our Plaster Sand Classifier ensures that the sand is classified according to particle size. This classification system is necessary to ensure that the sand meets the specific requirements of various types of construction, whether for plastering or concrete work.

2. Dry Sand Washing System

With the help of our Dry Sand Washing Systems, we can remove sand, clay and dust particles without using water. Not only is this dry cleaning method environmentally friendly, but it also ensures that the sand is ready to use without further cleaning, saving water in the process

The main advantages of m sand and plaster sand plants

1. Consistency: M The sand and plaster sand produced by the Plaster Sand Plant is consistent in size and shape, increasing the overall strength and durability of the construction.

2. Availability: Unlike river sand, which is often scarce and expensive, M sand is readily available and can be produced in large quantities to meet the demand of the growing construction industry.

3. Cost Savings: Manufacturing sand and plaster sand reduces transportation costs locally, resulting in overall cost savings in construction projects.

4. Better Performance: M sand is known to provide better tensile strength and bond than natural sand, making it more durable.

5. Reduced water consumption: Using advanced technology such as dry sand washers eliminates the need for water in the sand cleaning process, and it improves water conservation.

How M Sand Plants Support Green Manufacturing

Green manufacturing is the future, and M Sand plants play a key role in this transformation. Sustainability has become a priority in the construction industry, so the use of materials such as M Sand and Plaster Sand is a step towards reducing the carbon footprint and encouraging environmentally friendly building practices environment.

At Readymix Construction Machinery Pvt. Ltd., we are committed to providing quality M Sand Plants, Plaster Sand Making Units, Plaster Sand Classifiers, and Dry Sand Washing Systems. it will remain for the construction project Requirements. Our innovative solutions help architects, contractors and contractors make environmentally friendly choices without compromising on quality.

conclusion

Switching to M Sand plants is an important step in the journey to sustainable construction. As the demand for environmentally friendly and cost-effective products increases, M Sand offers practical solutions that help preserve natural resources through high-quality construction management Readymix through investment in advanced technologies like Plaster Sand Classifier and Dry Sand Washer inside the Readymix Construction Machinery Pvt. Ltd. is at the forefront of promoting a green, sustainable future for the construction industry.

Whether it is concrete, plaster, or any other construction project, there is no doubt that M Sand and Plaster Sand are the future of sustainable building materials.

#M Sand Plant#Plaster Sand Making Unit#Dry Sand Washing System#Plaster Sand Classifier#Dry Sand Washer#Plaster Sand Plant#Sand Manufacturing#Sand Processing Equipment

0 notes