#Pneumatic systems work by converting force into potential energy

Text

A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion

A double-acting pneumatic cylinder uses compressed air to move a piston in and out, while a single-acting pneumatic cylinder uses compressed air for one-way movement and a return spring for the other

A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion. A double-acting cylinder uses compressed air to move a piston in and out, while a single-acting cylinder uses compressed air for one-way movement and a return spring for the other

Pneumatic systems work by converting force into potential energy, which then drives an actuator or cylinder with kinetic energy. This is usually in a linear motion by means of a piston rod, or using other forms of actuation commonly called 'rodless

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#pneumaticcylinder#A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion#A double-acting pneumatic cylinder uses compressed air to move a piston in and out#while a single-acting pneumatic cylinder uses compressed air for one-way movement and a return spring for the other#A pneumatic cylinder is a mechanical device that converts compressed air energy into a reciprocating linear motion. A double-acting cylinde#while a single-acting cylinder uses compressed air for one-way movement and a return spring for the other#Pneumatic systems work by converting force into potential energy#which then drives an actuator or cylinder with kinetic energy. This is usually in a linear motion by means of a piston rod#or using other forms of actuation commonly called 'rodless

0 notes

Text

Mastering Precision: A Deep Dive into Metal Stamping Press Machines

Metal stamping press machines, the workhorses of precision manufacturing, play a vital role in shaping the industrial landscape. From automotive giants to electronics manufacturers, these machines are indispensable for crafting intricate metal components. In this article, we'll explore the inner workings of metal stamping press machine, examining their types, applications, and the technological advancements that drive their efficiency.

The Heart of Production: Types of Metal Stamping Press Machines

Metal stamping press machines come in various types, each tailored to specific manufacturing needs. Understanding the distinctions between these types provides insights into their suitability for different applications.

1. Mechanical Stamping Presses

Mechanical presses harness kinetic energy stored in a flywheel, converting it into force to shape metal sheets. These presses are renowned for their high-speed operation, making them ideal for high-volume production where speed is paramount. However, they may be less adaptable to intricate designs compared to other types.

2. Hydraulic Stamping Presses

Hydraulic presses leverage fluid-driven cylinders to generate force, offering precise control over the metal-forming process. These presses excel in tasks requiring intricate details and variable force application. Hydraulic stamping press machines find their niche in applications like deep drawing and forming complex geometries.

3. Pneumatic Stamping Presses

Pneumatic presses utilize compressed air to exert force on metal sheets. While not as powerful as hydraulic or mechanical presses, they are well-suited for lighter materials and simpler operations. Their quick cycle times make them advantageous in scenarios where speed is crucial.

Applications: Where Precision Meets Production

Metal stamping press machines are omnipresent across various industries, contributing to the production of critical components. Here are some key sectors where their influence is most pronounced:

1. Automotive Manufacturing

In the automotive sector, metal stamping is the backbone of component production. From body panels and chassis parts to intricate engine components, stamping press machines ensure uniformity and precision, meeting the stringent quality standards of the automotive industry.

2. Electronics and Consumer Goods

Precision is paramount in the production of electronic components and consumer goods. Metal stamping press machines are integral in shaping components like connectors, brackets, and enclosures for devices ranging from smartphones to household appliances.

3. Medical Equipment Production

The medical industry relies on metal stamping for producing components used in medical devices and equipment. The ability to manufacture intricate and sterile components makes metal stamping crucial in the medical field, where precision is non-negotiable.

Challenges and Innovations: Navigating the Path to Perfection

While metal stamping press machines are invaluable, they aren't without challenges. Manufacturers grapple with issues like tool wear, material waste, and downtime. To address these challenges, continuous innovations are shaping the future of metal stamping.

1. Automation Revolution

Automation is transforming metal stamping processes, enhancing efficiency and minimizing human intervention. Robotic arms and sophisticated control systems are streamlining tasks like material handling and tool changes, resulting in increased throughput and reduced operational costs.

2. Smart Monitoring Systems

Real-time monitoring systems equipped with sensors and data analytics are revolutionizing machine maintenance. Predictive maintenance algorithms help identify potential issues before they escalate, reducing unplanned downtime and ensuring optimal machine performance.

3. Advanced Materials and Tooling Technologies

Innovations in materials and tooling are extending the lifespan of dies and punches. Hardened alloys and advanced coatings are pushing the boundaries of durability, allowing manufacturers to achieve higher precision and quality over extended production runs.

Conclusion: Shaping the Future of Manufacturing

Metal stamping press machines are the unsung heroes of modern manufacturing, silently shaping the products that define our daily lives. As technology continues to evolve, these machines are set to become even more versatile, precise, and efficient. With ongoing innovations, the future promises a manufacturing landscape where metal stamping plays a central role in the pursuit of perfection.

0 notes

Text

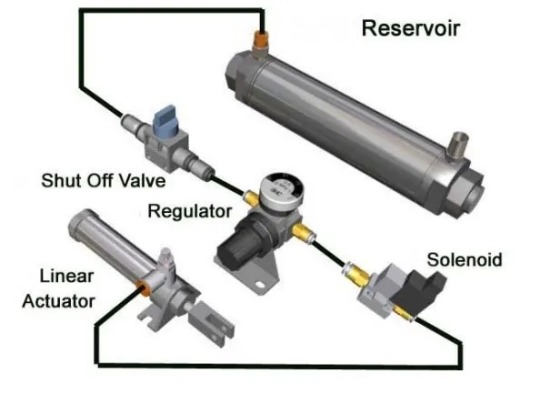

How pneumatic linear actuators work

Pneumatic linear actuators are devices that convert compressed air into linear motion. They are widely used in various industrial applications due to their simplicity, reliability, and affordability. The basic principle behind their operation lies in the conversion of potential energy stored in compressed air into mechanical work.

A pneumatic linear actuator consists of several key components, including a cylinder, a piston, and valves. The cylinder is a hollow tube that houses the piston and provides a sealed environment for the movement of the piston. The piston, which is a solid cylindrical object, is positioned inside the cylinder and is connected to a rod that extends outside the actuator. The valves, located at the inlet and outlet ports of the actuator, control the flow of compressed air into and out of the cylinder Pneumatic Linear Actuator.

When compressed air is supplied to the actuator, it enters the cylinder through the inlet valve, pushing the piston and the attached rod forward. This movement is facilitated by the difference in pressure between the compressed air and the atmosphere. As the piston moves forward, the air behind it is vented through the outlet valve, allowing for continuous motion. To reverse the direction of the actuator, the flow of compressed air is redirected through the valves, causing the piston to move in the opposite direction.

Pneumatic linear actuators offer precise and controlled linear motion, making them suitable for applications that require repetitive and accurate movements. Their design allows for high-speed operation and high-force output, making them ideal for tasks such as clamping, lifting, pushing, and pulling. Furthermore, their modular nature enables easy integration into existing systems, making them a versatile choice for various industries.

In summary, pneumatic linear actuators work by converting compressed air into linear motion through the interaction of a piston, cylinder, and valves. Their simple yet effective design allows for reliable and efficient operation, making them a popular choice in industrial automation.

0 notes

Text

Advantages of Motorized Butterfly Valves with Actuators in Industrial Settings

In modern industrial settings, the demand for efficient and reliable flow control systems is on the rise. Motorized butterfly valves with actuators have emerged as a popular choice due to their numerous advantages over traditional valve designs. These valves offer precise control over fluid flow, making them indispensable in various industries. This article explores the benefits of using motorized butterfly valves with actuators in industrial applications.

Understanding Butterfly Valves and Actuators

What are Motorized Butterfly Valves?

A motorized butterfly valve with actuator is a type of quarter-turn valve that uses a circular disc to control the flow of fluids through pipelines. The disc is positioned at a right angle to the flow, allowing it to rotate freely within the valve body. When the disc is parallel to the flow, the valve is fully open, and when it is perpendicular, the valve is closed. Motorized butterfly valves are equipped with electric or pneumatic actuators, enabling automated and remote operation.

How do Actuators work with Butterfly Valves?

Actuators are devices responsible for converting energy into motion. In the case of motorized butterfly valves, electric or pneumatic actuators provide the necessary force to rotate the disc, allowing precise control over flow rates. The actuator's torque output determines the valve's closing and opening speed, ensuring a smooth and gradual operation.

Advantages of Motorized Butterfly Valves in Industrial Settings

Increased Control and Precision

Motorized butterfly valves offer superior control over fluid flow compared to traditional valves. The ability to modulate the valve's position allows for precise regulation of flow rates, pressure, and temperature, ensuring optimal performance in diverse processes.

Energy Efficiency

With their quarter-turn design, motorized butterfly valves require less energy to operate fully open or closed, resulting in reduced energy consumption. The efficient sealing of the disc also minimizes pressure losses across the valve, further enhancing energy efficiency.

Cost-Effectiveness

Motorized butterfly valves are cost-effective solutions due to their simple construction and automated operation. They have lower installation and maintenance costs compared to other valve types, making them an attractive option for budget-conscious industries.

Space-saving Design

The compact design of motorized butterfly valves makes them ideal for applications with limited space. Their small footprint allows for easy integration into existing piping systems without major modifications.

Quick and Easy Operation

Automation provided by the actuators enables motorized butterfly valves to respond rapidly to control signals, facilitating swift adjustments to fluid flow. This agility is especially beneficial in processes that require frequent changes in flow rates.

Low Maintenance Requirements

Motorized butterfly valves have fewer moving parts compared to some other valve types, resulting in reduced wear and tear. Consequently, they have lower maintenance requirements and longer service life, contributing to cost savings.

Suitable for a Wide Range of Applications

Motorized butterfly valves find application in various industries, including water treatment, chemical processing, HVAC systems, food and beverage, pharmaceuticals, and power generation. Their versatility makes them suitable for both industrial and commercial applications.

Reducing the Risk of Leakage

Properly installed and operated motorized butterfly valves with high-quality seals significantly reduce the risk of leakage. This ensures enhanced safety and minimizes the potential for environmental contamination.

Automation and Integration Capabilities

Motorized butterfly valves can be easily integrated into process automation systems, allowing for remote control and monitoring. This automation enhances operational efficiency and reduces the need for manual intervention.

Enhanced Safety Features

In critical applications, motorized butterfly valves come equipped with safety features like fail-safe operation, which ensures that the valve returns to a predetermined position in case of power failure or emergency situations.

Applications of Motorized Butterfly Valves in Industries

Motorized butterfly valves find extensive use in a wide range of industrial applications:

Water Treatment and Distribution

Motorized butterfly valves play a crucial role in regulating water flow in treatment plants and distribution networks, enabling efficient water management and conservation.

Chemical Processing

In chemical processing plants, motorized butterfly valves control the flow of various chemicals, ensuring precise dosing and preventing leaks that could lead to hazardous situations.

HVAC Systems

Motorized butterfly valves are essential components in heating, ventilation, and air conditioning systems, allowing for the precise control of airflow and temperature.

Food and Beverage Industry

In food processing, motorized butterfly valves are used to control the flow of ingredients and finished products, meeting strict hygiene standards.

Pharmaceutical Manufacturing

Motorized butterfly valves are employed in pharmaceutical manufacturing to maintain accurate dosing of ingredients and ensure product quality and purity.

Power Generation

In power plants, motorized butterfly valves regulate the flow of steam and other fluids, contributing to the efficient generation of electricity.

Factors to Consider When Choosing Motorized Butterfly Valves

Several factors should be considered when selecting motorized butterfly valves for specific applications:

Valve Size and Pressure Rating

Choosing the right valve size and pressure rating is crucial to ensure optimal performance and prevent potential issues related to flow restriction or pressure limitations.

Material of Construction

The choice of materials affects the valve's compatibility with the fluid being handled, as well as its resistance to corrosion and wear.

Actuator Type and Torque Output

Selecting the appropriate actuator type and torque output depends on the valve's intended use, operating conditions, and the level of control required.

Control Options

Consider the available control options, such as manual override, modulating control, or remote automation, based on the application's needs.

Temperature and Environmental Conditions

Evaluate the valve's performance under different temperature ranges and environmental conditions to ensure reliable operation.

Conclusion

Motorized butterfly valves with actuators offer numerous advantages that make them a top choice in industrial settings. Their ability to provide precise control, energy efficiency, and cost-effectiveness make them invaluable in various applications. From water treatment to power generation, these valves play a crucial role in ensuring smooth and efficient processes.

#motorized butterfly valve with actuator#motorized butterfly valve with actuator manufacturer#motorized butterfly valve with actuator supplier

0 notes

Text

describe an air compressor?

Image result for air compressor kit description

An air compressor is a pneumatic device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure.

4 basic components of air conditioning system?

Air Conditioner Components. An air conditioner is made up of many components, but the major parts doing the heavy lifting of moving the air indoors and outdoors are the evaporator, condenser, expansion valve, and compressor. Keep in mind they're each either located outside (the hot side) or inside (the cool side)

air compressor kit do?

The main function of a tire air compressor is to inflate a tire when the pressure is too low. It can also help, if used with a sealant, to repair a damaged tire. Importantly, the car tire compressor just needs to be connected to a regular cigarette lighter socket in the car for it to work effectively

main components of an air compressor?

Components of a compressed air system

compressor.

air cooler.

air receiver tank.

filter.

dryer.

condensate trap.

distribution system.

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#aircompressor

0 notes

Text

What Is a Pneumatic Compressor?

A pneumatic compressor is a device that takes in the air as input at a certain pressure, processes that, and provides the compressed air at a higher pressure.

An air compressor is a pneumatic device which converts power into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure.

There are various types of pneumatic compressors such as reciprocating piston compressors, rotary piston compressors, and flow compressors.

Reciprocating piston compressors are further divided into piston and diaphragm compressors.

Owing to piston compressors being extensively used in automotive and general industrial sectors, it would be useful to know the fundamentals of the reciprocating or piston compressor operation, kinds, applications, and advantages.

The piston compressor or reciprocating compressor is the most common among the air compressors available in the market. It comes in single-acting or double-acting, oil-lubricated or oil-free versions, and various arrangements with variable numbers of barrels.

Industries and workshops which need more compressed air use piston compressors. Furthermore, if the pressure falls below the set point, the piston compressor will automatically stop until it attains the maximum set point pressure. Other advantages of a piston compressor include the following.

Inexpensive maintenance

Feasibility to use high pressure and high power.

Piston Compressors can be placed near the point of usage. It avoids long pipelines and pressure dips.

Affordably priced, long-lasting, and effective

The main advantage of pneumatic compressors is that, unlike conventional compressors, pneumatic systems do not require lubrication or consistent maintenance. Running continuously for a long period, they are to be simply cleaned with water and soap. Thus, reducing the operator's cost of following up on a maintenance schedule.

Then there are oil-free compressors which help in lowering the energy costs and consequently the carbon footprint.

Oil free air compressors have various advantages as follows:

1. Elimination of product contamination

An oil-free compressor can be an absolute necessity for many applications and industries, where contamination from compressed air produced by oil injected screw compressors is a major source of concern.

2. Reduction in maintenance requirements

Oil-free air compressors need lesser maintenance as compared to oil-injected air compressors. One needs to just drain the compressor tank to remove vapor, which is a much smaller commitment.

3. Reduction in cost of ownership

Since oil-free air compressors require less preventative maintenance, they can offer a much lower cost of ownership.

4. Increase in speed

Oil-injected air compressors require more power to heat up and start working because oil is viscous and difficult to get moving, especially in cold conditions.

5. Reduction in noise

Another advantage of oil-free compressors is their ability to operate quietly. Some have sound levels as low as 48 dBA.

6. Reduction in carbon footprint

Oil-free air compressors are more environmentally friendly than their oil-injected counterparts simply because they don’t release oil contaminants into the air.

7. Class Zero – best air quality

With the stringent quality requirements, Class Zero oil-free air compressors represent and guarantee the best air quality possible, and hence are reliable.

0 notes

Text

The President elect told The New York Times

The President elect told The New York Times in an interview after the election, "I think there is some connectivity," when asked about the role that carbon dioxide produced by humans plays in climate change.. Right on, Mr. I will confess the idea did occur to me, then, that you rather than anyone might secure his happiness. Clarke: (Sniffs) Schoenborn: (inaudible) I, it, it's, it's passed that. Based on its tests, Consumer Reports says a good choice is the $29 Filrete y Living Ultra Allergen Filter 4 MPR 1550, available online.. “The council of masters has been unable to agree. Air Malta shared a little love in the skies in April 2015. And if that pale soft stupid creature could incite the animals when fully clothed, how much more lust would bottines cloutees femme a queen inspire?. I was able to get Dad's Bible out of the bedroom, so that was one good thing.". Vets don come in with anything, every little bit helps.. Even the Little Pigeon and his Herons paled beside the folly of the brothers the sellswords called the Clanker Lords. Whether you're just starting out or have been in business for years, these proven marketing strategies will help your business find new customers without spending a fortune.Plan your attack. The favoured format for 2011 is in effect a reversion to the one used in sandalias doradas gioseppo South Africa in 2003 where in the first round there were two ghete galbene piele groups of seven teams, with the top three in each group progressing to the Super Sixes. He and his family live two blocks from the clinic and this is the only place he has gone for his care since his family saved him from a puppy mill in Homer.. Her eyes were red and puffy, but the boy was in her arms, bundled tight. I'm disappointed in the direction they've gone. If he get off his throne and get Kovalchuk in here, then maybe Avs fans would have a reason to hope. The cream cakes appeared then, and the conversation took a lighter turn. No one paid them any mind. Leadership in Energy and Environmental Design (LEED) certified buildings follow design and construction practices that significantly reduce or eliminate the negative impact of buildings on the environment.For renderings of phase two amenities and construction photos, visit our photo gallery.Why are you building it?Gore Meadows Community Centre and Library provides much needed services to the growing communities in northeast Brampton. As for the crown and other baubles, Clapton said, "We used these to [convey] mood or to send messages. The "Stuff the Mini to the Max" supply drive was held at the staples in Glastonbury to collect donated school supplies. Jon Snow was unsurprised. The ability to use atmospheric nitrogen to support more widespread life was thought to have appeared roughly 2 billion years ago. And I really kind of bored to have to shoot it. Robett, wine for the Hand, if you will be so good. The event is hosted by the Evangelism Committee and includes special music. Then, after a long time he opened it again, saw me, and shut it again. That was not supposed to happen. It's hard to monetize free. A female passenger was detained at the car by an officer, while another officer, Erick Supplee, and his K 9 partner, "Zlatan," chased after McCurdy. If I should learn that you or yours are hiding them, protecting them, or assisting them in any way, I will not hesitate to send you your son’s head. The two famous franchises with the top two picks have one major current difference: While the Celtics were the Eastern Conference's top playoff seed last season, the Lakers are coming out of the worst four year stretch in franchise history. This cooler was redesigned with peace and quiet in mind all while achieving a high level of performance and a simplistic installation.. The hairs on the back of Tyrion’s neck began to prickle. Dad was going to Minneapolis later this week, маратонки puma mercedes amg so I wanted to get the Tires Plus job started before he left. Of course, the aerodynamic properties are also essential at the extremely high speeds the BRABUS ROCKET 900 "DESERT GOLD" so effortlessly attains. She had the water. They need a coach who is paying attention to what is happening now, not what happened two minutes ago. Persons bringing Negroes by railroad or steamboat will find it very convenient to secure their Negroes, as my Jail is adjoining the Railroad Depot and near the Steamboat Landings.. Behind the city’s thick white walls, the New Castle rose proud and pale upon its hill. With both back rows folded, puma red bull racing evo cat ii the sandisk mp3 mode d emploi Grand C Max offers 60 cubic feet of cargo room, and in five passenger mode, there's still a reasonable 25 cubes on hand.. 6. In September, our comp store sales are up about 7% through Wednesday, September 23rd. They are washable and provide superior ventilation which keeps fungal infections at bay. Working. A battle was being fought in the yard; Ryswells pelting Barrowton boys izraeli kézműves ékszerek with snowballs. This scene shattered him completely. I must . Payne began broadcasting live on June 28, 1962, at age 22 from air jordan aj4 a one car garage in Edmond. Yesterday when I walked into the gym to get ready for lunch Tay asked me what size shoe I wear and I said why and he said tomorrow I want you to show up at this exact spot, ok and I said man Today when I duci alkalmi ruha went into the gym there was a small crowd of students around Tay who had a footlocker bag, when he saw me come in he pulled out a Jordan shoe box and he opened it and it had retro 1 jordans, and then he handed them to me saying you go man these are yours at first I didn know what he was talking about, but then he told his friends to put my book bag somewhere, while he laced my shoes, when they were on I asked him don understand why are you giving me these when he said heard people have been bullying you, so I wanted to get you these to make you feel better and when he said that I hugged him and I almost cried, and I cannot thank him enough, and then he said if anybody bullying you, you let me know alright and I said you so much thereareawesomepeopleintheworld. Taylor and Darryl Hamilton leave gaps in the secondary, but Reggie Barnette is also back, along with Kerry Wynn on the line and Aaron Roane at linebacker. Heated, insulting words were overheard, uttered on both sides. When she read the dry brown words, her black mood grew blacker still. To get home and call his banners, Stark had to cross the mountains to the Fingers and find a fisherman to carry him across the Bite. “You should go sleep now, child. He didn’t sleep, and he had no tea; he took up his hat and went out. He is eligible to return next Tuesday.. The law is now in force. This is one more good reason to stay well away from the edge. Geoff Molson, who along with his brothers Andrew, Justin, and some other partners had returned the Habs to the family fold in 2009, paying American businessman George Gillett more than $500 million for the team and the rink, posted a message on the club website. nike jean jacket Converting gravitational potential energy into air pressure to launch a projectile?Hello my name is Aaron! I am a high school senior from northeastern Kentucky designing a pneumatic system of sorts for a science competition and need some help.

0 notes

Text

Comprehensive tips on different types of air compressors

Air compressors convert power into energy stored in compressed air. In this article, we want to introduce you to the types of air compressors and their efficiency. So if you have questions about the types of air compressors, read this article to the end. Double acting In the double acting design, there are two sets of suction and discharge valves on both sides of the piston. The movement of the system in one direction is the expansion/suction stroke for one side of the piston, while being the compression stroke for the other. In other words, both sides of the piston are used for continuously compressing the air. Click here

Air Compressors Types discussed here are also seen when you need a compressor for another gas type, so if you see here, you’ll see it all about gas compressors!

An air compressor is a pneumatic device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When the tank's pressure reaches its engineered upper limit, the air compressor shuts off. The compressed air, then, is held in the tank until called into use.The energy contained in the compressed air can be used for a variety of applications, utilizing the kinetic energy of the air as it is released and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. An air compressor must be differentiated from a pump because it works for any gas air, while pumps work on a liquid. Read more

References:

https://www.wartsila.com/marine/build/engines-and-generating-sets/wartsila-engines-auxiliary-systems

https://en.wikipedia.org/wiki/Air_compressor

https://www.linquip.com/blog/types-of-air-compressors/

0 notes

Text

What Are The Differences Of Various Engine Starters

To learn the differences among the engine starters, firstly we need to learn how we can start an engine from a state of rest.

You need to start crankshaft of the engine at first, then the piston reciprocates. After that, the combustible mixture work in the cylinders pushes the piston downward to turn the crankshaft. At last, the diesel engine is able to run the working cycles automatically.

Several necessary conditions for starting a diesel engine

1. Diesel

2. Air

3. Sufficient energy to drive cylinder compressed.

Diesel and air are both fuels. The only way to ignite them is to turn the crankshaft to a certain speed.

The device used to turn the crankshaft is starter, which turns the flywheel first, and then flywheel turns the crankshaft.

Several types of starters

Hand Starter

Hand starter is the oldest way to start an engine, and it only needs manpower to crank the shaft to the rated speed. If the operation for the starter is inappropriate, people always get injured. Some small agricultural machines are still using hand starter.

Electric Starter

The electric starter is also called electric motor which can convert electricity into mechanical power, driving flywheels. It is the most popular and cheapest method to start an engine, and it is even available for remote control. The complete electric starter system includes starter motor, battery, cable, charger, and etc. You can find an electric starter almost everywhere, such as an electric starter for the car.

Air Starter

An air starter is also called a pneumatic motor, it can convert the pressure energy which compressed by air into mechanical energy. To start a diesel engine, it needs to use external force to turn the crankshaft first. Then the motor reciprocating, pneumatic power drives piston motor and gear motor. The complete air starter system includes air starter, pipe, gasholder, air compressor etc. The complete system of air starter is relatively expensive.

Hydraulic Starter

The hydraulic starter is also called a hydraulic start motor, which can convert hydraulic energy into mechanical energy. A complete hydraulic starter includes a fuel tank, hydraulic starter, manual charging device, filter, manometer, accumulator and control valve. The complete system is also expensive, and it often applies to special working conditions.

Compressed Air Starter

According to the ignition sequence of the diesel engine, a compressed air starter pushed the compressed air into the cylinder during the expansion stroke. And the piston will work with the driving force by compressed air, so that the diesel engine reaches the starting speed and start to work automatically. The complete system has more power than other systems, and it is reliable. You can also use the compressed air for braking, but it is more complicated and heavier than any other starting system. So it is not applicable for small engines.

Spring Starter

Spring starter is a new product for an indirect hand starter, which has been improved. It is also called a mechanical spring starter. It uses a friendly design comparing to the old hand crank starter. You only need to fit and rotate the handle to compress the disc-springs, and the springs will store the energy. After you pull the trip, the system will release the spring’s potential energy to turn the flywheel of the engine. Mechanical spring starter can make sure that the engine can start well even there is out of electricity or other power resources.

As you can see, the spring starter is the best way to start an engine if it is an emergency. I know you are searching for it now, actually you can click Cqstart spring starter to get more info.

You can also contact these people directly:

Sales: Julie He(Ms.),

Tel/Whatsapp/Wechat: +86-13637706003,

Email: [email protected]

Marketing: Harland Wang (Mr.),

Email: [email protected]

For more information, please visit on cqstart.com

0 notes

Text

Acquiring the Right Industrial Air Compressor

cyklónové odlučovače

Air compressors have many purposes in business and are applied in numerous fields, such as automation and assembly, chemical production, agriculture and construction. All compressors get the job done by converting power from an exterior source, these as an electric powered motor or diesel engines, into stored energy which can be unveiled in the sort of pressurised air. The pressurised air is then used to electric power instruments and machinery.

Picking the Correct Air Compressor

On the other hand compressors fluctuate in their system of procedure, air potential and degree of tension that they can deliver. The appropriate compressor will capable to maintain ample air and provide a high adequate level of pressure for the activity, but overall performance should be well balanced against considerations these as price and durability. Compressed air is calculated in cubic toes per minute (CFM), with a higher necessity for CFM needing a bigger air capability and better horsepower (HP).

Varieties of Industrial Air Compressor

There are a few significant forms of industrial air compressor dependent on the approach of operation. These are reciprocating compressors, rotary screw compressors and centrifugal compressors.

Reciprocating

Reciprocating compressors are positive displacement compressors, the place air is lowered in volume to increase its tension. Reciprocating incorporate pumps pushed by pistons with a cylinder compressing and displacing the air. There are two sorts, direct travel compressors and belt push compressors. Belt generate compressors are much more tough and in a position to supply greater pressures. Reciprocating compressors are accessible in one phase and multi stage. Multi stage compressors deliver larger pressures and are a lot more effective, which means lower electrical power use and reduced charges. Reciprocating compressors are generally transportable and appropriate for trades folks involved in design and similar fields.

Rotary Screw

Rotary screw air compressors also perform by a constructive displacement procedure. They use two helical screws meshed alongside one another to power air by way of and compress it. The technique of procedure is a smoother course of action than that of pistons, with a lot less surges and vibration than that from time to time located in reciprocating compressors. They are durable and straightforward to retain. Rotary screw air compressors commonly have better capacities than reciprocating compressors and can supply better air pressures. Some sorts have variable velocity drives meaning that airflow and force can be carefully controlled, and in which airflow needs are variable this can end result in substantial energy financial savings. Rotary screw air compressors have a variety of programs, acquiring use in regions such as building web-sites, factories and hospitals.

Centrifugal

Centrifugal air compressors work by a different system. They use the momentum gained from a rotating disk to transfer and pressurise air. This process is recognized as dynamic displacement and is a continual method, resulting in a continual offer of pressurised air. They can deliver very higher pressures. However the system also needs increased speeds and better air capacities than other compressors. The capability and airflow can be managed by way of inlet tutorial vanes. Centrifugal compressors have quite a few purposes, and are utilised for equipment this kind of as pneumatic drills and automotive superchargers and turbochargers, as properly as for air conditioning and refrigeration. They are also found in gasoline turbines, gas pipelines, oil refineries, petrochemical plants and chemical crops.

0 notes

Text

The Specifics About Air Compressors

regulátory tlaku

An air compressor is a unit constructed to compress or consolidate air inside of a tank. Air compressors work relatively in the same way to the way our lungs function when we hold our breath and, perhaps, blow up a balloon. The air is pulled and compressed in the tank (like air in our lungs) growing the air's pressure and lowering its quantity. When working with the instrument, the compressed air releases by a hose in a constant, highly effective stream - like from our lungs and out of our pursed lips in a bursting stream of air. In compressors, the air force inside the tank will continue on to increase till it reaches a preset stress restrict. The tool's strain limit varies from high to reduced with the form and sizing of your compressor. Air compressors also feature a regulator that is established to compliment the precise tool's and application's needed stress.

Compresses are utilized for a wide variety of needs from powering pneumatic or electrical power tools (like nailers, and staplers) blowing dust and particles off/out of these electricity tools, or as an inflation system for tires, flotation equipment, and and many others. Readily available in a variety of measurements and capacities, air compressors are versatile and amazingly long-long lasting a very good product could absolutely final a life time if appropriately cared for. Making use of compressor driven pneumatic instruments provides a range of advantages pneumatically run tools are likely to be far more brawny than all those powered with strictly energy, they offer you better torque and greater RPM for rapid operate and speedy firing. Pneumatic resources also supply an environmentally pleasant option to toxic battery waste.

There are two types of air compressor, fuel or electric, but every single of these sorts is available with a number of versions. Some compressors are little and transportable, other people are quite huge and stationary - the sum of electric power your compressor has normally coincides with its measurement. These big, stationary compressors are finest suited for industrial purposes and can be utilised by much more that just one human being at the same time. Compressors also differ from solitary phase to two stages a two stage motor has the potential to change speeds for the duration of additional continuous and arduous steps - fundamentally a two stage motor functions more difficult when you want it to. Lastly, some compressors need oil lubrication whilst other folks operate entirely with no oil. Oil lubricated compressors are likely to operate much more quietly they do, even so, have to have oil alterations, procedure on a flat, degree surface, and could launch an oil mist into the air which is hugely sick-suited for apps like painting. Despite the fact that a lot of craftsmen desire to use oil-lubed compressors mainly because they tend to past more time and operate quieter (as with any other sort) they may possibly not be functional for some apps.

Gas run compressors are optimal on jobsites or development zones that have not still been outfitted with electrical electricity. These compressors present the electric power and pace of pneumatic instruments devoid of the need for power cords or electric power. Gasoline compressors ought to, even so, be used in open and effectively ventilated areas. Electrical compressors are typically the greatest decision for property and shop use. They are inclined to run a lot more quietly and really don't stink up the joint, if you will, with a gasoline motor.

Maintaining your air compressor well taken care of will really establish how very long your compressor will retain on kicking. There are a few uncomplicated actions to making sure your compressor stays in ideal situation, and you definitely is not going to regret the time you commit caring for your tool. The compression that takes place in the air tanks of your compressor will cause humidity to accumulate inside of these tanks. That dampness, in convert, runs the possibility of rusting out the tanks, and possibly destroying a paint combination (if utilized with a paint sprayer). On the base of the compressor there is a humidity release valve it is essential to launch this valve with every single use, this need to avert rust or other h2o injury. An in-line filter can also be be bought for any compressor to get rid of h2o mist in your air strains.

Its important to inspect your compressors periodically test and tighten any fasteners, make positive your air filters are jogging cleanse and change them when essential, check your hoses generally for breaks, cracks, or leaks and be ready to substitute them when necessary as well. Its also essential to be selected that the compressors basic safety valve is useful. The security valve (both automatically or manually) releases air ought to the compressor become more than-pressurized a vital element, so be positive its operational or have it repaired. If you have an oil-lubed compressor, verify the oil degrees just before every single use to make sure the device is adequately lubricated. Adjust the oil as the maker suggests. As far as cleanliness is anxious, its generally helpful to keep all your instruments clear as a whistle and specifically essential to maintain the compressor's intake vents thoroughly clean and clear. If you have a gasoline compressor you may also think about periodically cleaning the gasoline tank for good evaluate.

A excellent compressor is a excellent resource, and can genuinely consider the edge off a jobsite or residence-repair task. With unmatched speed and energy a compressor and their partnering pneumatic tools will change the way you build. Really like your compressor, invest in the model that ideal suits you, preserve it nicely-managed, and your compressor will operate as challenging as you do.

0 notes

Text

Acquiring the Correct Industrial Air Compressor

kompresory

Air compressors have several apps in business and are utilised in several fields, such as automation and assembly, chemical producing, agriculture and construction. All compressors perform by converting energy from an external source, this sort of as an electric powered motor or diesel engines, into stored power which can be released in the form of pressurised air. The pressurised air is then used to power tools and equipment.

Choosing the Appropriate Air Compressor

Nevertheless compressors fluctuate in their approach of procedure, air capability and amount of force that they can deliver. The suitable compressor will able to keep ample air and deliver a large sufficient level of stress for the task, but performance should be balanced versus considerations this sort of as cost and toughness. Compressed air is measured in cubic toes for each moment (CFM), with a significant need for CFM needing a bigger air capability and higher horsepower (HP).

Kinds of Industrial Air Compressor

There are three key forms of industrial air compressor based on the system of procedure. These are reciprocating compressors, rotary screw compressors and centrifugal compressors.

Reciprocating

Reciprocating compressors are positive displacement compressors, where air is reduced in quantity to enhance its tension. Reciprocating contain pumps pushed by pistons with a cylinder compressing and displacing the air. There are two kinds, immediate generate compressors and belt generate compressors. Belt push compressors are far more long lasting and able to supply increased pressures. Reciprocating compressors are obtainable in single stage and multi phase. Multi stage compressors supply higher pressures and are more productive, which means lower electric power usage and reduce fees. Reciprocating compressors are frequently moveable and suitable for trades men and women associated in building and related fields.

Rotary Screw

Rotary screw air compressors also work by a positive displacement method. They use two helical screws meshed with each other to force air by and compress it. The approach of operation is a smoother process than that of pistons, with considerably less surges and vibration than that from time to time discovered in reciprocating compressors. They are sturdy and simple to maintain. Rotary screw air compressors commonly have greater capacities than reciprocating compressors and can produce higher air pressures. Some forms have variable pace drives which means that airflow and force can be closely managed, and where airflow specifications are variable this can result in significant power financial savings. Rotary screw air compressors have various applications, finding use in locations these kinds of as development internet sites, factories and hospitals.

Centrifugal

Centrifugal air compressors work by a diverse mechanism. They use the momentum attained from a rotating disk to transfer and pressurise air. This process is regarded as dynamic displacement and is a constant approach, resulting in a steady provide of pressurised air. They can provide incredibly substantial pressures. Nevertheless the strategy also needs higher speeds and greater air capacities than other compressors. The potential and airflow can be controlled by way of inlet manual vanes. Centrifugal compressors have several programs, and are applied for machinery these kinds of as pneumatic drills and automotive superchargers and turbochargers, as effectively as for air conditioning and refrigeration. They are also found in fuel turbines, gasoline pipelines, oil refineries, petrochemical plants and chemical plants.

0 notes

Text

Obtaining the Correct Industrial Air Compressor

cyklónové odlučovače

Air compressors have several purposes in sector and are utilised in different fields, like automation and assembly, chemical producing, agriculture and design. All compressors work by converting electrical power from an external supply, this kind of as an electric powered motor or diesel engines, into stored energy which can be produced in the form of pressurised air. The pressurised air is then employed to power equipment and machinery.

Choosing the Appropriate Air Compressor

On the other hand compressors differ in their strategy of procedure, air capacity and degree of force that they can deliver. The appropriate compressor will equipped to keep ample air and provide a large adequate degree of tension for the process, but effectiveness need to be well balanced in opposition to issues such as value and toughness. Compressed air is calculated in cubic feet for each minute (CFM), with a higher need for CFM needing a much larger air potential and larger horsepower (HP).

Types of Industrial Air Compressor

There are three significant types of industrial air compressor based mostly on the technique of operation. These are reciprocating compressors, rotary screw compressors and centrifugal compressors.

Reciprocating

Reciprocating compressors are positive displacement compressors, the place air is minimized in volume to enhance its tension. Reciprocating have pumps pushed by pistons with a cylinder compressing and displacing the air. There are two forms, direct travel compressors and belt drive compressors. Belt travel compressors are a lot more long lasting and in a position to produce increased pressures. Reciprocating compressors are obtainable in one phase and multi stage. Multi phase compressors provide increased pressures and are much more economical, that means decreased electric power consumption and reduce expenditures. Reciprocating compressors are often transportable and suited for trades people included in building and equivalent fields.

Rotary Screw

Rotary screw air compressors also perform by a optimistic displacement process. They use two helical screws meshed alongside one another to power air through and compress it. The method of procedure is a smoother approach than that of pistons, with considerably less surges and vibration than that often observed in reciprocating compressors. They are resilient and effortless to keep. Rotary screw air compressors normally have increased capacities than reciprocating compressors and can provide larger air pressures. Some varieties have variable velocity drives that means that airflow and strain can be closely controlled, and wherever airflow demands are variable this can end result in substantial energy financial savings. Rotary screw air compressors have several purposes, locating use in areas such as development web sites, factories and hospitals.

Centrifugal

Centrifugal air compressors work by a diverse mechanism. They use the momentum received from a rotating disk to transfer and pressurise air. This method is identified as dynamic displacement and is a continual process, resulting in a steady offer of pressurised air. They can deliver incredibly substantial pressures. Nonetheless the system also involves larger speeds and better air capacities than other compressors. The capacity and airflow can be controlled by way of inlet information vanes. Centrifugal compressors have quite a few programs, and are utilised for machinery this sort of as pneumatic drills and automotive superchargers and turbochargers, as properly as for air conditioning and refrigeration. They are also discovered in gasoline turbines, gas pipelines, oil refineries, petrochemical vegetation and chemical vegetation.

0 notes

Text

Buying the Correct Industrial Air Compressor

manometry

Air compressors have many applications in business and are used in numerous fields, including automation and assembly, chemical manufacturing, agriculture and design. All compressors work by converting power from an external resource, this kind of as an electric motor or diesel engines, into saved power which can be released in the variety of pressurised air. The pressurised air is then used to power resources and machinery.

Choosing the Suitable Air Compressor

Nevertheless compressors vary in their system of procedure, air potential and level of strain that they can deliver. The correct compressor will ready to keep ample air and supply a high ample degree of tension for the job, but effectiveness ought to be well balanced in opposition to concerns this kind of as expense and longevity. Compressed air is measured in cubic feet per moment (CFM), with a substantial prerequisite for CFM needing a bigger air capacity and better horsepower (HP).

Varieties of Industrial Air Compressor

There are a few significant types of industrial air compressor dependent on the method of operation. These are reciprocating compressors, rotary screw compressors and centrifugal compressors.

Reciprocating

Reciprocating compressors are beneficial displacement compressors, exactly where air is decreased in volume to increase its force. Reciprocating consist of pumps driven by pistons with a cylinder compressing and displacing the air. There are two types, direct travel compressors and belt drive compressors. Belt drive compressors are additional long lasting and in a position to produce better pressures. Reciprocating compressors are available in solitary stage and multi phase. Multi phase compressors supply better pressures and are far more productive, meaning reduced energy use and reduced costs. Reciprocating compressors are generally moveable and suited for trades persons associated in development and very similar fields.

Rotary Screw

Rotary screw air compressors also work by a constructive displacement method. They use two helical screws meshed together to pressure air by and compress it. The approach of operation is a smoother process than that of pistons, with much less surges and vibration than that occasionally discovered in reciprocating compressors. They are long lasting and straightforward to keep. Rotary screw air compressors usually have greater capacities than reciprocating compressors and can provide better air pressures. Some types have variable velocity drives that means that airflow and tension can be closely controlled, and wherever airflow needs are variable this can final result in significant energy savings. Rotary screw air compressors have several apps, locating use in places this sort of as building internet sites, factories and hospitals.

Centrifugal

Centrifugal air compressors function by a diverse mechanism. They use the momentum received from a rotating disk to transfer and pressurise air. This method is acknowledged as dynamic displacement and is a continuous process, ensuing in a continuous source of pressurised air. They can supply particularly higher pressures. Nonetheless the approach also involves larger speeds and better air capacities than other compressors. The potential and airflow can be managed by way of inlet guide vanes. Centrifugal compressors have many apps, and are utilised for machinery this kind of as pneumatic drills and automotive superchargers and turbochargers, as nicely as for air conditioning and refrigeration. They are also discovered in gas turbines, fuel pipelines, oil refineries, petrochemical vegetation and chemical vegetation.

0 notes

Text

Acquiring the Correct Industrial Air Compressor

kompresory

Air compressors have numerous purposes in business and are applied in numerous fields, including automation and assembly, chemical manufacturing, agriculture and construction. All compressors work by converting power from an external resource, this kind of as an electrical motor or diesel engines, into stored energy which can be released in the sort of pressurised air. The pressurised air is then used to energy equipment and machinery.

Choosing the Correct Air Compressor

Nonetheless compressors fluctuate in their method of procedure, air capability and amount of tension that they can produce. The right compressor will in a position to keep plenty of air and produce a substantial enough amount of tension for the activity, but efficiency really should be well balanced towards concerns such as price and longevity. Compressed air is calculated in cubic feet per minute (CFM), with a substantial necessity for CFM needing a greater air potential and larger horsepower (HP).

Types of Industrial Air Compressor

There are three main forms of industrial air compressor based on the system of procedure. These are reciprocating compressors, rotary screw compressors and centrifugal compressors.

Reciprocating

Reciprocating compressors are beneficial displacement compressors, in which air is decreased in volume to improve its force. Reciprocating include pumps driven by pistons with a cylinder compressing and displacing the air. There are two sorts, immediate drive compressors and belt generate compressors. Belt drive compressors are more long lasting and in a position to supply increased pressures. Reciprocating compressors are offered in one phase and multi stage. Multi phase compressors produce greater pressures and are far more economical, this means decrease electrical energy consumption and lower expenditures. Reciprocating compressors are often portable and suitable for trades individuals concerned in building and related fields.

Rotary Screw

Rotary screw air compressors also function by a constructive displacement approach. They use two helical screws meshed jointly to force air through and compress it. The system of procedure is a smoother approach than that of pistons, with a lot less surges and vibration than that at times identified in reciprocating compressors. They are sturdy and effortless to keep. Rotary screw air compressors normally have larger capacities than reciprocating compressors and can produce better air pressures. Some kinds have variable speed drives indicating that airflow and strain can be closely managed, and the place airflow demands are variable this can consequence in major vitality cost savings. Rotary screw air compressors have numerous programs, locating use in parts such as design web sites, factories and hospitals.

Centrifugal

Centrifugal air compressors function by a distinct system. They use the momentum attained from a rotating disk to transfer and pressurise air. This method is identified as dynamic displacement and is a constant course of action, resulting in a regular source of pressurised air. They can supply extremely significant pressures. However the technique also needs better speeds and larger air capacities than other compressors. The capability and airflow can be controlled by way of inlet tutorial vanes. Centrifugal compressors have numerous apps, and are employed for equipment this kind of as pneumatic drills and automotive superchargers and turbochargers, as very well as for air conditioning and refrigeration. They are also identified in gasoline turbines, fuel pipelines, oil refineries, petrochemical plants and chemical vegetation.

0 notes

Text

The Best New Green Energy Tech Could Be Right Underfoot

As Fitbit users like to pointout, walking burnsa lot of calories. But theenergyyou expend doing it ceases to be useful after your sneakers hit pavement. That’s where Pavegen CEO and Founder Laurence Kemball-Cook find room to create a new kind of sustainable energy technology. His company’sPavegen floor tiles generate electricity by harnessing the power of footsteps.

The tiles are a kind of kinetic energy recovery system .We’veseen these beforein race carsandbuses–but where recovery systemsin automobiles convert the kinetic energy commonly lost in braking to electrical energy, Pavegen tiles areall about capturing the spring in your step. Treadon a tile and the surface depress up to one centimeter( Kemball-Cook compares the sensationto walking in a children’s play-area ). The downward force drives an energy-storingflywheel inside the tile, which spins to convert kinetic energy into electrical energy through electromagnetic induction. It’s like a generator–only instead of spinning a turbine with breeze, water, or coal, it’s spinninga flywheel with footsteps.

The beauty ofthese tiles is that they can conceivably go anywhere there’s floorspace and foot trafficthinkairport terminals, sidewalks, andplayingfields. That notion has attracted support from companies as big asShell and celebrities as diverse as Al Gore and Akon( yes, that Akon) but backers were hard to come by when Kemball-Cook started out.He began developing the technology while studying designat Loughborough University, and developed the first prototype in all of 15 hours.” I only hacked it together. There was timber in it, and it was held together by duct tape. I went to 150 venture capitalists, and they all said no. The government said,’ It would never work, we cant help you.'”

That was seven years ago. Pavegen tiles have since been used to help light football pitches in Brazil and Nigeria, a hallway in Heathrow Airport, and offices and shopping centers in London. And that was all with less-efficient technology. Earlier versions of tiles were rectangular, and only made power when someone’s foot has declined in the center of a tile. The latest generation of Pavegen tile, V3, is triangular, which allows them to include a generator in each corner. That entails the whole tile fulcrums toward a generator no matter where you step. The V3generates 5 continuous watts of power as you walk across it–that’s more than 200 times more efficient than Kemball-Cook’s first prototype.

Granted, five watts isnt a ton, and not everyone is convinced that the world will ever run on Pavegen. For the 2013 Paris Marathon, Pavegen laid down a 25 -meter strip of the last generation of tiles, and they objective up making 4.7 kilowatt hours of energy–enough tokeep an LED bulb burning for over a month, but nowhere near enough to power your home .” The very basic physics of it is pressure times the deformation of the material ,” says David Horsley, a mechanical and aerospace technologist at UC Davis.” You’re not going to get very much for a step, considering you can get 100 watts from a square meter of solar paneling. But for small wearable electronics like watches, or maybe even your phone, this kind of energy harvesting attains sense .”

So it’s not going to put big petroleum out of business, and you may need to take a lot of steps to stimulate them worth it. Good thing they’re durable as hell.” The floor is one of the harshest surroundings known to human ,” Kemball-Cook says.” You have to be able to withstand environment challenges, water, vandalism. You need good test equipment. We have a footfall rig with four pneumatic drivers that’s being running nonstop for four years, running analytics and just trying to destroy the product .”

With the V3, Kemball-Cook thinks he’s finally reached the phase where lower costs and higher efficiency will allow him to scale. Other people think so, too, with installings slated for locatings like Oxford Street, London’s bustling shopping thoroughfare, and walkways outside the White House. Tribal Planet, a mobile analytics and activism company, thinks the V3′ s new data-tracking abilities could help people forge more personal conceptual models of energy production and intake. Energy hasnt genuinely been a consumer product. Even utilities are a very abstract notion ,” says Tribal Planet CEO Jeff Martin, a former Apple executive.” Is my utility getting this energy from nuclear power plant or a wind farm or a coal mine? I have no idea. Its probably a combination of all that .”

If Pavegen tiles have been continuously underfoot–and connected to your phone–you could track how much energy you produced personally. Kemball-Cook likes to think you could even be rewarded for it.” Imagine if you go to get sneakers and you get money off, because youve been making energy for the store ,” he says. There’s altruistic potential as well; Kemball-Cook foresees users donating the energy produced by their footsteps to any Pavegen-powered community in the world.

This notion of person-to-person energy accountability arouses Pavegen and Tribal’s leadership. They want users to think of their steps almost like” a referendum” in favor of a place, an organization, or a policy.” Not wasting your footsteps, or anyone else’s, genuinely starts a dialogue around energy that I think is more constructive than abstract theories, like carbon-offset, that consumers are typically engaged in, Martin says. My vision is that this becomes a civic responsibility, because sustainability and wellness are inextricably connected.

That’s not going to happen over night, and its highly unlikely that Pavegens technology will outshine the promise of solar or wind power. But its own unique they are able to stimulate the road toward greener energy tangible is what attains it exciting. With Pavegen, whether you are able to wrap your head around the subtleties of breeze turbines or carbon accounting or not, doing your proportion for sustainable energy can literally be your next step.

Read more:

The post The Best New Green Energy Tech Could Be Right Underfoot appeared first on Top Rated Solar Panels.

from Top Rated Solar Panels http://ift.tt/2rJqZFT

via IFTTT

0 notes