#Polymer Coated Fabrics Marke

Text

# 11 Tweed: 70% silk and 30% Wool

Wool - typically heavier than silk, coils in the fiber help retain heat, wool also acts as a repellant to water, can help enhance the appearance retention of a textile compounded with silk

End use: Sherlock Holmes would appreciate a matching overcoat and deerstalker set

Silk - Majority silk, crips and stiff hand, adds some light luster, typically lighter than wool

#29 Shantung: 100% silk

Crisp hand and very lustrous, pearl-like, the slub filling creates a unique texture of think and thick areas, elegant drape, with proper dry cleaning care appearance retention should be moderate, less stiff than organza

End use: gorgeous dress to make one's ex jealous

#67 Matelasse: 100% silk

Crisp and lightweight like most silks, has a flow-like drape, double weave creates a three-dimensional floral pattern, heat retention is moderate

End use: maxi skirt in late spring while walking in the park

# 19 Organza: 100% silk

Sheer and very lightweight, moderate drape, stiff and crisp hand, with proper dry cleaning care appearance retention should be moderate

End use: decorative trim on bridal gowns

# 61 Crepe: 100% Wool

Crimped fibers give a plush feeling when pressed by hand, coils in the fiber also assist in the crepe finish, the luster us matte as to not distract from the tight texture, with proper dry cleaning care appearance retention should be high, machine washing may result in drastic shrinkage, wool's insulation qualities give great heat retention, strong abrasion resistance helps with durability

End use: a vampire who's always cold could benefit from using this fabric as an outer face to a sherpa lined coat

I was searching for a fiber that used human hair. Instead I came across Kertex. This is a bio-polymer created by the company Oceanit. It seems like a relatively new venture; all the info I could find was a little over a year old. The textile utilizes keratin extracted from chicken feathers. Oceanit claims this is a sustainable fabric as it makes use of animal byproduct. They also highlight Kertex as a very durable product - the only known partnership thus far is with the US military. The mark for durability seems believable since keratin is resistant to dilute acids and alkaline. So far they've produced seat covers, seatbelts and straps, bags and uniforms for the military. Attached is a a sample featured on the Kertex website.

0 notes

Text

Anti-Crease Agent Market Size, Share Forecast 2030

Anti-Crease Agent Market size was valued at USD 856.1 million in 2022 which is expected to reach USD 1245.7 million in 2030 with a CAGR of 4.8% for the forecast period between 2023 and 2030. Anti-crease agents are incorporated with unique characteristics that significantly eliminate problems that occurred with residual oils, silicone, wax, fabrics derived from polyester, polyamide, etc. They are successively used to treat cotton and blends and impart anti-crease finishing and dimensional stability. The proper selection of anti-crease agent is achieved depending upon the type of fabric like weave pattern, its weight and construction.Nanoparticle-based anti-creasing agent is gaining prominent resemblance due to its water repellant characteristics along with antimicrobial properties.

Sample report- https://www.marketsandata.com/industry-reports/anti-crease-agent-market/sample-request

Performance of Finished Textiles is Improved by Anti-Creasing Agents

Anti-creasing agents have emerged as an impeccable chemical compound due to their unique properties like miscibility, stability, physical appearance, and compatibility. It has numerous benefits and versatile nature for dyeing cotton, polyester, and their blends. During finishing of fabrics, it assists in preventing chaffing or crease marks. Anti-creasing agents are compatible with nonionic and anionic products and remain stable to diluted acids and alkalis. The cost management for terry towels is substantially achieved using anti-creasing agents where the lubrication property led to weight loss minimization during pretreatment and dyeing processes. Kolor Jet Chemical Pvt. Ltd. has developed efficient dyebath lubricants for knit fibers to eradicate the crease marks along with reducing fiber to fiber friction and leave no dyes effects on the fabrics.

Data released by the Ministry of Textiles, India states that FDI has invested a humongous capital of USD 1,522.23 million in the textile sector from 2017-2022. In 2022, the net value of the United States man-made fiber, textile and apparel shipments accounted an estimated over USD 65.8 billion where the export of fibers, textiles contributed to around USD 34 billion.

Anti-Creasing Agents Market is Propelled Due to its Importance in Multiple Applications

Anti-creasing agents with their unique characteristics form a thin uniform protective coating surrounding the fiber to reduce the surface friction and ultimately lower the formation of stringent creases during high temperature wet processing. Knit fabric of essential blends, cellulose and synthetic fibers are processed through scouring, bleaching, dyeing, and soaping processes that became easier by using anti-creasing agents. HT Fine Chemical Co., Ltd. produces a special bath anti-creasing agent which while processing remarkably reduces the friction between fibers and its dyeing tank that reduces scratches and creases due to their smoothing and softening characteristics. Special polymer dispersion in the anti-creasing agents is solely responsible to prevent fabric rope from creasing during the pre-treatment, dyeing and post-processing.

In March 2022, the European Commission has represented its vision for textile industry which estimated that in 2021 the turnover of USD 166.99 with an increment of around 11%. Around 33% of companies are textile-based across the European Union that accounts for micro and SMEs’ enterprises. With such an impeccable figures Europe has extreme potential for anti-creasing agent market that generates phenomenal opportunities to expand.

Novel Anti-creasing Agent for Improving the Textile Bath of Fabrics

The problem of crease mark, stripped mark and other faults are usually encountered during small bath ratio case and rapid cloth speed case. Unique anti-creasing agent in the textile bath comprises of nonionic polymer, anionic polymer, water treatment agent, mould inhibitor that is used for rope dyeing of texture. Under the influence of mechanical tension, the dynamic coefficient of friction is significantly higher that produces wrinkle seal, unwanted shank seal defects during airflow dyeing machine where the speed is greater than 200 meters/minutes. The incorporation of anti-creasing agent resolves such problems during the textile bath.

Anti-Crease Agent Market: Report Scope

Anti-Crease Agent Market Assessment, Opportunities and Forecast, 2016-2030F”, is a comprehensive report by Markets and data, providing in-depth analysis and qualitative & quantitative assessment of the current state of the Anti-Crease Agent Market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between 2023 and 2030. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/anti-crease-agent-market

Contact

Mr. Vivek Gupta

5741 Cleveland street,

Suite 120, VA beach, VA, USA 23462

Tel: +1 (757) 343–3258

Email: [email protected]

Website: https://www.marketsandata.com

0 notes

Text

2,5-Furandicarboxylic Acid (FDCA) Market to Cross USD 980.3 million, at a CAGR of 8.2% by 2031

The global 2,5-Furandicarboxylic Acid (FDCA) market is estimated to flourish at a CAGR of 8.2% from 2023 to 2031. According to Transparency Market Research, sales of 2, 5-Furandicarboxylic Acid (FDCA) are slated to US$ 980.3 million by the end of the aforementioned period of assessment.

Innovations in FDCA applications beyond packaging and polyester production are vital drivers reshaping its market landscape. The development of FDCA-based polymers for the electronics and automotive industries marks a transformative stride. Due to its exceptional thermal and mechanical properties, research is unveiling FDCA's potential as a high-performance material in electronic components and lightweight automotive parts.

Download Sample Report@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=2014

FDCA's integration into the pharmaceutical sector as a building block for novel drugs and drug delivery systems is gaining attention. Its biocompatibility and ability to modify drug-release kinetics present promising opportunities in pharmaceutical formulations, potentially revolutionizing drug manufacturing.

Market Segmentation

By Service Type:

Production Services: Custom manufacturing, bulk production

Consulting Services: Technical support, market analysis

By Sourcing Type:

Bio-based: Derived from renewable resources like plant biomass

Synthetic: Derived from petrochemical processes

By Application:

Polyesters: Such as polyethylene furanoate (PEF)

Polyamides: Used in fibers and engineering plastics

Polyurethanes: For foams, elastomers, and coatings

By Industry Vertical:

Packaging: Bottles, films, and containers

Textiles: Fibers and fabrics

Automotive: Parts and components

Construction: Insulation materials and coatings

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America: Dominates the FDCA market due to significant investments in R&D and a robust regulatory framework promoting sustainable materials.

Europe: A strong advocate for green initiatives, Europe is a key market for FDCA, driven by stringent environmental regulations and high consumer demand for eco-friendly products.

Asia-Pacific: Expected to witness the fastest growth due to rapid industrialization, urbanization, and increasing government support for bio-based products in countries like China and India.

Latin America and Middle East & Africa: Emerging markets with growing awareness of sustainable practices and potential for significant future growth.

Market Drivers and Challenges

Market Drivers:

Environmental Concerns: Growing awareness of environmental pollution and the carbon footprint of petrochemical products.

Government Regulations: Supportive policies and regulations promoting the use of bio-based materials.

Technological Advancements: Innovations in FDCA production processes making it more cost-effective and efficient.

Consumer Preferences: Increasing consumer preference for sustainable and biodegradable products.

Market Challenges:

High Production Costs: Bio-based FDCA production is still more expensive compared to petrochemical counterparts.

Limited Infrastructure: Insufficient infrastructure for large-scale production and distribution of FDCA.

Technical Barriers: Challenges related to the scalability and stability of FDCA-based products.

Market Trends

Sustainable Packaging: Growing use of FDCA in the packaging industry as an alternative to PET (polyethylene terephthalate).

R&D Investments: Increased investment in research and development to improve production efficiency and expand FDCA applications.

Partnerships and Collaborations: Strategic collaborations between companies to enhance market reach and technological capabilities.

Future Outlook

The future of the FDCA market looks promising with ongoing advancements in production technologies and increasing adoption across various industries. By 2031, FDCA is expected to play a crucial role in the global shift towards sustainable and biodegradable materials, driven by regulatory pressures and consumer demand.

Key Market Study Points

Market dynamics and growth opportunities

Detailed segmentation analysis

Regional market performance and growth prospects

Analysis of market drivers, challenges, and trends

Future outlook and potential market developments

Competitive Landscape

The FDCA market is characterized by the presence of several key players focusing on innovation and strategic collaborations. Major companies are investing in R&D to enhance product quality and reduce production costs. The competitive landscape is expected to intensify with the entry of new players and increasing demand for sustainable materials.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=2014<ype=S

Recent Developments

Partnerships: Recent collaborations between major chemical companies to develop and commercialize FDCA-based products.

Technological Innovations: Advances in bio-based production methods reducing costs and improving yield.

Regulatory Approvals: New government regulations supporting the use of bio-based chemicals in various applications.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

PAEK Market: An Analytical Overview of Size, Share, and Industry Trends

The global market for polyaryletherketone (PAEK) is estimated to grow at an impressive CAGR of over 6% during the forecast period (2019-2027) to reach a valuation of over US$ 1.4 Bn. The utilization of polyaryletherketone (PAEK) is proliferating in several applications and oil drilling components such as compressor rings, seals, bearings, gears, wire coatings, and valve parts. Due to its high glass transition temperature property, increased use of polyetheretherketone (PEEK) in the aerospace industry is projected to heighten demand worldwide.

The offer in this portion accompanies many open doors including fabricating items, appropriation, retail, and showcasing administrations. Broad rounds of essential and a far reaching optional exploration have been utilized by the examiners at Fact.MR to show up at different assessments and projections for Demand of Polyaryletherketone (PAEK) Market, both at worldwide and provincial levels.

Download a Sample Copy of This Report:https://www.factmr.com/connectus/sample?flag=S&rep_id=4462?PJ

The Polyaryletherketone (PAEK) Market is experiencing significant growth driven by the rising demand for high-performance engineering plastics across diverse industries. As of 2023, PAEK polymers have emerged as critical materials due to their exceptional mechanical, thermal, and chemical properties, making them suitable for challenging applications. PAEK materials find extensive use in aerospace, automotive, oil and gas, electronics, and medical industries, among others. The market growth is fueled by a combination of increasing awareness about lightweight and durable materials, advancements in polymer science, and the continuous need for solutions that can withstand harsh operating conditions.

Key Market Drivers:

Demand for High-Performance Materials: The growing demand for high-performance materials that can withstand extreme conditions is a key driver for the PAEK market. PAEK polymers exhibit superior mechanical strength, chemical resistance, and thermal stability, making them preferred choices for applications where traditional materials may fall short. Industries such as aerospace and oil and gas rely on PAEK for components that require durability and reliability.

Lightweighting Trends in Industries: The global trend towards lightweighting, especially in the automotive and aerospace sectors, is driving the adoption of PAEK materials. These polymers offer a high strength-to-weight ratio, contributing to reduced overall weight in components and structures. Lightweighting is crucial for achieving fuel efficiency in vehicles and enhancing the performance of aerospace applications.

Expansion in Medical Applications: PAEK polymers are increasingly finding applications in the medical industry due to their biocompatibility, sterilizability, and resistance to chemicals commonly used in healthcare settings. The use of PAEK in medical devices and implants is expanding, addressing the need for materials that can meet stringent regulatory requirements and provide long-term reliability in medical applications.

Challenges and Opportunities:

Cost Considerations: The production cost of PAEK polymers can be a challenge, especially when compared to traditional polymers. However, the industry has opportunities to address this challenge through advancements in manufacturing processes, economies of scale, and research and development initiatives focused on cost-effective production methods.

Competitive Landscape: The PAEK market is characterized by intense competition among key players offering a range of specialty polymers. The challenge lies in differentiation through product innovation, customization, and the development of unique formulations tailored to specific industry needs. Companies that can effectively navigate the competitive landscape and offer value-added solutions have opportunities for growth.

Global Polyaryletherketone (PAEK) Market: In-Depth Assessment on Key Segments

The global polyaryletherketone (PAEK) market is segmented on the basis of type, end-use industry and region. Type

PEK (Polyetherketone)

PEEK (polyetheretherketone)

PEKK (Poly-Ether-Ketone-Ketone)

Others (PEEKK, PEKEKK)

End UseIndustry

Aerospace

Automotive

Electronics

Energy

Manufacturing

Medical Devices

Region

North America

Latin America

Europe

APAC

MEA

Current Industry Trends (2023):

Advancements in PAEK Formulations: Ongoing advancements in PAEK formulations are a prominent trend in the industry. Manufacturers are focused on developing PAEK variants with enhanced properties, such as improved wear resistance, flame retardancy, and electrical conductivity. Customized formulations cater to specific application requirements in various industries.

Increasing Use in Additive Manufacturing: The utilization of PAEK materials in additive manufacturing or 3D printing is gaining traction. The design flexibility offered by 3D printing, combined with the inherent properties of PAEK, allows for the production of complex and customized components. This trend aligns with the broader shift towards digital manufacturing and rapid prototyping.

Focus on Sustainable PAEK Solutions: Sustainability is becoming a focal point in the PAEK market. Manufacturers are exploring sustainable sourcing of raw materials, eco-friendly production processes, and recyclability of PAEK polymers. The development of sustainable solutions aligns with the growing emphasis on environmental responsibility across industries.

Collaborations for Application Development: Collaborations between PAEK manufacturers and end-users are prevalent for application development. Partnerships with industries such as aerospace, automotive, and healthcare enable manufacturers to understand specific needs and tailor PAEK solutions accordingly. Collaborative efforts contribute to the development of innovative applications and expanded market reach.

Key Takeaways of Polyaryletherketone (PAEK) Market Study

With a projected CAGR of 5.5% from 2019 to 2027, ‘PEEK’ polymer is expected to see significant volume gains. This is attributed to increasing consumption in the automotive, medical, oil and gas industries and in the aerospace sector

The ‘medical’ end use segment is expected to the grow with the highest growth rate of over 7% due to the increased use of polyaryletherketone (PAEK) in surgical methods and dental work

Europe leads the global polyaryletherketone (PAEK) market with a market share of over 35% in 2019. The automotive industry in combination with private investments in research and development (R&D), acts as a force multiplier for the extensive utilization of polyaryletherketone (PAEK)

Asia Pacific holds a strong customer base in the global Polyaryletherketone (PAEK) market. Presence of key automotive companies in Japan including Honda, Yoyota and Suzuki and increased penetration of aircraft manufacturers are the attributing factors behind growth of the market in this region

Growing demand from the construction and automotive sectors for replacements such as Polyphenylene Sulfide (PPS) and Polyethylenimine (PEI) is expected to curb market growth over the forecast period

“Healthcare investments and technological progressions along with supportive government policies will drive growth in the global polyaryletherketone (PAEK) market,” says the Fact.MR analyst

Global Industry News (2023):

Investments in Research and Development: Key players in the PAEK market are making substantial investments in research and development to stay at the forefront of innovation. These investments focus on developing new PAEK formulations, exploring novel applications, and addressing emerging challenges. Research and development initiatives are critical for maintaining a competitive edge in the market.

Strategic Mergers and Acquisitions: Strategic mergers and acquisitions are shaping the competitive landscape of the PAEK market. Companies are acquiring or forming partnerships with complementary businesses to strengthen their product portfolios, expand market presence, and enhance technological capabilities. These strategic moves contribute to market consolidation and increased competitiveness.

Geographical Expansion: Geographical expansion is a notable trend among PAEK manufacturers. Companies are expanding their presence in key regions with growing industrial sectors, such as Asia-Pacific and the Middle East. Establishing regional facilities and distribution networks allows manufacturers to cater to the increasing demand for PAEK materials in diverse applications.

Application Diversification: The diversification of PAEK applications across industries is evident in recent developments. PAEK materials are being used in components for electric vehicles, structural parts in aircraft, oil and gas exploration tools, and various medical devices. Application diversification showcases the versatility of PAEK polymers and their adaptability to evolving industry needs.

0 notes

Text

Ibiz car wax costco

Ibiz car wax costco plus#

Ibiz car wax costco plus#

For black paint, it is often difficult to avoid marks so the Ultima Paint Guard Plus would be an excellent choice for you - no chance of leaving marks. You rub turtle wax ice on, then wipe it off immediately. In fact, I put this on two days in a row for a "base coat" and since then I've used turtle wax ice wax (WAX, not polish). It's a paint sealant (basically a polymer wax instead of carnuba wax) that is supposed to last up to 6 months. I chose this product because you put it and let it dry (at least 6 hours. I put Ultima Paint Guard Plus as the initial coat. The waxes today are much better than when I grew up and I don't think you can go wrong with any of the newer waxes. The only benefit of working for this company is a nice entry level sales position to help warm you up if you are considering pursuing sales as a career long term.Īlso despite mileage reimbursement and such, this job destroys your vehicle.I think you will get a lot of opinions on this, but you'll have to decide what YOU want. which is two of your 8-10 hour shifts at least usually.įor what they ask of you, and the pay they s a terrible job. The pay drops from $12-$15 per hour to minimum wage. They also dont even pay you the proper hourly rate when youre doing inventory. Youre very lucky if you are promoted to any position of real authority if you are not from a major area. Because those stores just have more foot traffic and as such more sales. Pay is very geographically based in terms of if its good or not.Īs for career advancement.they promote "good sales people".and by that they mean that the vast majority of their managers are from larger cities like new york and boston. or if you live in a big metropolitan area! They also are paid well because the foot traffic is so high that comission will be great. If you run costco food shows solo, consistently, its actually good pay. Despite the secure hourly pay with commission potential, unless you are running costco food shows solo (where as youre usually forced to work with a second person and split the comission), the most you can make between hourly pay and comission is about $16 per hour. In that way they are very dishonest, very bought into their own fabricated reality. when in actuallity a socalled "dead store" that someone had "amazing sales in" was a store I was in the week before, and it was one of the busiest stores I had ever seen. They mislead you by saying someone in a "dead store" went in and sold a ton. Its quite obvious that some stores have better sales than others due to demograph in the area, foot traffic etc. So this review is about as real as it gets. I was promoted twice during my stay with the company. To start off I am not a naysayer or something. Ridiculously high standards for even a top employee to meet all the way around. Only seeing my husband in the middle of the night and my daughter for an hour before bed if i was having a good week!Įven if you are a single person and have no kids or significant other this job still will make you want to scream.Ĭhristmas week is the work because you work 12 straight days about 12-14 hours a day again only being paid for about 8, and their standards go up exponentially so good luck even getting paid for 1/4 of the hours you actually worked. This was my experience working for this company for two years and busting my butt. If we wanted to go somewhere with our daughter that was just a whole production of re arranging the entire car around. There were many weeks my husband had to meet me at the store to help me pack up and bring everything i had home so i could get it to the next store. You are expected to be selling product thursday-sunday but monday, tuesday, and wednesday not only will you be on conference calls for hours on those days (and everyday you work on your way into work as well!) but you must go in the prior evening to dropoff/ partially setup for the next day/week at your new store location.ĭays in between your next store you must take all your setup and product with you in your own vehicle. If this standard is not met then you will be in the red and OWE THEM MONEY! What a joke of a company whose mission statement specifically states they are for you and your well being. PROVIDED your sales are within THEIR standards. If you plan to work for this company then expect to be working 24/7 but only be paid for 30ish hours a week.

0 notes

Text

A large body of the zipper should be smooth

Line reference samples and drawings.

The surface where gall material be required by the version of the CD standard is not missing pieces multi-chip.

Plus cotton parts: 100g loose cotton: hat in × 1, cap piece × 2; 200g cotton: collar; 100g needles: 1 / 2 small collar, placket, 1 / 2 pocket mouth × 2Plus gall material parts: placket, pocket mouth, small collar, and collar.

Production steps|Plus cholesterol mine feeding site: fly, pocket mouth, small collar, collar,Reference lines like clothing and drawings|Line reference samples and drawings}.

From 11 - 13-pin pin / 3cm open air track, 12-14-pin / 3cm dark trace. Commissural with a 11 Wholesale Twill Fabric Suppliers needle, wire needle with a 9 #.

Shun color line, surface and body with the color line.

All parts to be straight line, sewing thread trace 30cm may not have two single hop and continuous stitch, stitch does not allow skipping. Surface, the bottom line should be suitable elastic, pin ups and downs to be played back.

Sleeve Chouse: unlined chip Chouse first, and then charge down the sodium line. Pleating lines and the shoulder seam to seam.

Steam eyes with color across the mattress.

A large body of the zipper should be smooth, not from the waves. Zola placket chain puller requires the right plug, Ji-0.1cm open wire.

The main standard, including small nail in after years; Water Wash, including in the left side seam 1 / 2 as the standard under the mouth.

The cuff in surface cloth is pointing.

Pocket 1CM decorative line after the line first filling cashmere series.

Cotton cloth hat on, circle of 0.1cm lines, 0.1+2.5cm lines before export hat. Hat bottom port 0.1 open. Cap seam strip. In particular, line drawing.

Shoulder, axils, pocket cloth and tape.

Semi finished products must be small iron, ironing smooth, without Aurora.

Other specific practice reference sample

Finishing:All clothing must be large hot steam; hot semi truck small cage.

Wireless head, no oil, no powder trace No debris inside pocket. Neat, clean, smooth. Tidy, clean, smooth.Suture requires ironing hot uniform, no aurora|Suture ironing uniform requirements, no Aurora}.

According to the sleeve folded backward hat, order, body bent back ninety percent off.

When packing, the tag according to the order of playing together, and flat, buckle in zip top.

According to the ratio of packing, required clothing folded neatly and evenly.

The box must be marked section number, name, shape, color, quantity, unit of production.

Tag Water washes to sub-paragraph number, color number, shape and so on. Indicate the number of inspectors, the total check number, the gray or white duck down duck down and so on.

Down materials are mainly down and coated fabrics. The feather: pinnacle and cashmere child (also known as the red velvet ) mixture} Use of duck and goose hair, by the washing of separating the pinnule and cashmere child as eider down wadding . Down with gray two, white is preferred. Down the quality, charge down the volume and cashmere. Down refers to a charge down the amount of down into the flock weight expressed in grams, usually about 250 grams, less filling velvet, warm and bad; cashmere velvet refers to the child down in the content, expressed as a percentage, usually with down the amount of 50 to 80%. With cashmere high, is of good quality. Because cashmere to make human body heat dissipation is not easy, and soft to the touch, but when pressed and when wet easily after the timely muster, and pinnacles now can make clothes to keep clothes fluffy muster more air, is helpful to keep warm, but the pinnacle much heat easily, Diaspora, and Mao Gang. . So the cashmere and pinnacles must swallow anything and everything, proper proportion. The coated fabric with weft yarn high density of silk, cotton, cotton / polyester fabrics, the rolling processing, so that the weft yarn interstices between contractible, and then coated with a polymer slurry, and make the fabric forming a transparent coating layer covering the delivery chain, to seal the fabric gap} Some in the coating slurry adding fluoride phosphate resin or silicone waterproofing agent, so that the fabric has dew proof cashmere, water impervious performance. The 1980s have been without a special high density fabric coating, can also play the anti-dew down, the role of seepage water and ventilation. Downing the fabric points for hard and soft second-class. Polyester, Dacron, # cotton belonging to government hard, wear leveling; silk taffeta, Nisi Fang is a soft, comfortable to wear.

Down under the general source can be divided into goose and duck down, according to the color is divided into white cashmere and grey flannel, in addition of course, there are Iceland eider produce black cashmere and so on. Relatively speaking, better down from larger, more mature birds, therefore velvet will slightly better on the duck down . From the color of speaking, white cashmere because it is white, can be used for light fabric instead of translucent color, a grey flannel is more popular.

Ranging from 5% to 95%. For example you can say: 90% white goose down, etc.

Cashmere filling quantity: Cashmere filling volume is not measured down quality indicators, it refers to a down jacket filled all the feather weight. General the charge down the amount of outdoor jacket design is different depending on the target at 250-450 grams.

Cashmere (down content): cashmere rate is the ratio of down inside the velvet, generally expressed as a percentage. Outdoor cashmere jacket is generally above 80%, the data content of the surface of which is down 80% feather is accounting for 20%.

Fluffy (fill power): Fluffy is the measure of warm down the main index of degree, refers to certain conditions every ounce (30 grams) down the volume cubic inches of numerical. If an ounce of down space required is 600 cubic inch said down the fluffy degree 600. Down the fluffy degrees higher, in the same cashmere filling volume of feather can be fixed to a larger volume of air to heat preservation and heat insulation layer, so the warm down. Fluffy at home is not a rigid index, and the measurement of relative error is larger.

Down jacket fabric basic requirements

Wind ventilation: Most of the outdoor jacket has a certain degree of wind resistance. Breathable outdoor clothing uniform requirements, but many tend to ignore the Down Mix is the importance of breathable fabric. A gas-tight Down in the mountains on the result is often fatal.

anti-velvet: Enhanced anti-velvet fabric down of three ways, one in the fabric on the coating or coating, film or by coating to prevent leakage of velvet, of course, the first prerequisite is breathable and does not will affect the fabric of light and softness. Second, the high-density fabric through the post-processing improves their anti-cashmere fabric. Three is in the down in the fabric layer to add a layer of down-proof fabric, Down-proof Fabric will have a direct impact on the whole garment quality.

in equipment light weighting today, down jacket fabric light level will directly affect a down jacket's overall weight, and soft fabric, for itself is bloated down jacket, down jacket will enhance the wearing comfort. On the other hand, thin soft fabric helps to better play the fluffy down, so warm and will be higher

Water: Mainly for professional-type jackets, extreme cold conditions in the direct Watchman, down jacket fabric used to directly replace the jacket

Down fabric type:Waterproof coating (coating) fabrics.

This kind of fabric is similar to assault garment fabrics, with waterproof and moisture permeable performance, generally used for alpine professional down jacket. But the difference is that the whole fabric is thinner and lighter than the jacket fabric soft number. In addition because down in cold environments, mainly aimed at the ice and snow melt water to water in the solid state, so the fabric resistant to water pressure requirements will not be like the jacket so high, and most of the down jacket is made of waterproof fabric without a pressure adhesive Another point to note is that, some low down in order to prevent leakage of cashmere and use of breathable coated fabrics, if only for everyday wear, can barely considered. Represent fabrics: dry loft, PROO-TEC LM etc.

High density waterproof fabrics

The density of the fabric itself is high, generally above the 290T. Then fabric surface by high temperature fusion to reduce the gap in post-processing technology fabric to improve the anti-down nature. The thin fabric and soft fabric inside the jacket of the highest of all, while with wind, water repellent, breathable performance. This kind of fabric is down and down sleeping bag using the method of fabric, but later the treatment process for the level of fabric Down-proof great influence. Represention fabrics: pretax, soft-b etc

Ordinary woven fabric with anti flannel

Generally use lower density nylon or polyester, Down in the production when added in the anti-flannel fabric in the side, can play a role in down-proof, anti-down performance is good. Drawback is, Down-proof Fabric affects the eider down softness, and increase the whole garment weight. The most important is that if you are using the inferior Down-proof Fabric words, down jacket permeability will be greatly reduced, and after washing, Down-proof Fabric easily damaged or agglomerate. Another way is for anti-down process, the process is in the fabric of the inner layer rubber brush on a layer of anti-velvet, fabric feel poor, and airtight. The behalf of fabric is many but not well-known fabric manufacturers.

Three types of fabric performance comparison: tailored said that the best performance; waterproof coating ( coating ) breathable fabric hypothesis is consistent with the requirements, common woven fabrics inside the down-proof fabric also hypothesis is consistent with the standard . This table only basic reference value, the actual situation in the fabric according to three types of technology will have greater access.

Down clothing accessories basic requirements have two: one is low, because the use of the environment in general on the condition of low temperature, temperature intolerance accessories is likely to fracture. Second, durable, imagine, minus 30 degrees in environment damage your zipper pull on suddenly, and it will be any results.

Zip:Down on the main chest zipper used in the main chain, zipper pocket closure; require the use of smooth, with auxiliary zipper anti-pinch device. Representative of the product: yak series zipper.

Down on main rope buckle, buckle hat adjusting ladder button and zipper head supporting, require the use of smooth, closed firmly, and resistance to low temperature. Representative products: more resistant to Fu series of fasteners.

Sewing thread:Sewing thread requirements are soaked through silicone oil, can prevent leakage caused by widening the eye of a needle down, and the strength to meet the requirements under the premise of the fine as possible.

Velcro:Velcro-type using four weeks rounded, and preferably not hooks hair varieties.

Down clothes sewing technique has its particularity. Feather weight is light, easy to go with the wind, when making should be the garment piece most sewed, leaving only the cashmere filling mouth to cashmere fillingIn order to prevent the cashmere silk from the needle eye out, when making the required fine type 11 machine needles . Uncoated fabrics in general should be lined with synthetic paper.

1 note

·

View note

Text

PART DECORATION FOR PLASTIC INJECTION MOLDING

Many plastic injection molded parts need to have some form of decoration applied to them after being manufactured. Possible reasons for decorating or marking parts include identification, tracking, branding, notices, warnings, instructions, as a product attribute, or otherwise. There are some standard methods of decorating plastic parts, and each has certain advantages and considerations, depending on the part application, the decorating purpose, and the resin being used.

PAD PRINTING

Historically, one of the more popular methods for decorating plastic parts has been with pad printing. There are three different types of pad printing machines: open inkwell, closed ink cup, and rotary gravure, which is used for printing 360 degrees on a part. Machines have a printing plate or a cliché, which commonly are made out of steel for durability. The artwork to be printed onto the parts is etched into the printing plate.

As the name suggests, the machines have transfer pads that come in a few different shapes and that are made out of silicone rubber with various hardness or shore levels. Pad life ranges from 10,000 to 100,000 cycles with an average of about 50,000.

The process consists of the pad picking up ink in the etched image on the cliché and placing it onto the part. Pad printing uses a type of solvent-based ink specifically designed for this purpose. This type of decoration also requires the fabrication of nesting fixtures to hold the parts in place during the printing process.

HEAT TRANSFER

A newer and usually more effective method of part decoration is thermal or heat transfer. With this process, the image is printed on a polyester film, which is coated with an adhesive so the image will stick to the part. Rolls of this film with the digitally printed images are placed on the printing machine’s reels, which index forward to print successive parts. Fixtures to hold parts are used here, as they are in pad printing. Additionally, a silicone decorating head or pad applies heat and pressure to print the transfer image onto the part.

Some advantages of heat transfer include the ability to create an image with four colors plus white in as high as 1200 dpi. In addition, there is no drying or curing time with decorating plastic parts, as there is with pad printing. Further, heat transfer decorations generally are tougher than pad printing and can be dishwasher safe.

HOT STAMP

Another common technique used to decorate plastic injection molded parts is hot stamping. A hot stamp machine transfers an image with pre-dried ink to a part with a die, again using heat and pressure and a fixture to hold the part, as with the previous methods.

One main advantage of hot stamping is the ability to apply a metallic foil or embossing to a plastic part. If you’re reading this article on a desktop computer, chances are the monitor in front of you has a logo that has been hot stamped on it. It also is a relatively clean process, compared to the wet ink used in pad printing.

LASER MARKING

Another method for decorating injection molded parts is by utilizing a laser marking system. This approach includes laser marking, laser engraving, and laser etching. Laser marking (or foaming) changes the color of the part where the text or graphic is, while the surface stays relatively unchanged. Alternatively, laser engraving removes some of the surface material, whereas laser etching melts the surface resin and creates a raised mark.

Of course, laser marking, engraving and etching all require a laser decorating machine. Additionally, fixtures to hold the parts usually are required, as with other decorating methods, although some fixtureless laser decorating systems have been developed. Some advantages of laser decorating include less wear and tear on the decorating equipment, it’s a precise and repeatable process, and it provides the ability to decorate some hard-to-reach part areas. Due to these benefits, industries like medical, automotive and aerospace often utilize the process.

IN-MOLD DECORATION

The method of in-mold decoration involves placing a pre-printed plastic film or appliqué in an injection mold before the part is molded, and the graphic then adheres to the part after it forms in the mold’s cavity. In-mold decoration requires a uniquely designed and built plastic injection mold and a carrier film feeder. The film can be manually placed into the mold between each cycle, but that greatly increases the manufacturing time and labor costs associated with the parts. However, even with a feeder, parts requiring in-mold decoration generally tend to be more expensive than other decorated parts, due to the specialized design, tooling and manufacturing required.

INKJET DECORATION

Inkjet printing on plastics is a relatively newer process, and it involves digitally printing a graphic onto a part. The system essentially is the same as inkjet printers for paper, with which most of us are familiar, although it uses a different type of ink. These machines typically use either conventional or LED lamps, and the process eliminates labels, films, printing plates, clichés or screens, as required with other decorating methods, although they do require a printhead and ink. Historically, this kind of decorating is somewhat slower and more costly than other forms, although advances are being made.

SCREEN PRINTING

Most people are familiar with screen printing in the context of t-shirts, and this also can be referred to as silk screening. Screen printing can be used for parts with flat or cylindrical surfaces but is not recommended for parts with complex curves and shapes. One advantage of screen printing is that it can print metallic graphics onto parts, which some other methods cannot do. Although providing the option of printing with multiple colors, a separate screen is needed for each separate hue, which increases cost and decorating time. The surface to be decorated needs to be prepared prior to printing, too.

PAINTING

When injection molding a part cannot achieve the desired texture, finish or color, painting the parts sometimes is utilized as a secondary operation. This approach can include spray painting and powder coating. As most injection molders do not perform painting as a finishing operation, the parts will need to go to a secondary provider, which often results in increased costs.

PLATING

When looking for a metal finish on an injection molded part, hard chrome plating and electroless nickel plating are two commonly used options. Plating offers a decorative finish, and it provides a certain level of corrosion protection. One item to note is that any surface imperfections on the part can affect the look of the plating, so consideration needs to be given there. Additionally, few molders also perform plating services, so those two suppliers will need to coordinate their work. There also are some design and material considerations that must be taken into account.

CONCLUSION

There are many different methods of decorating a plastic injection molded part, and each has its own unique advantages and disadvantages, depending on the requirements of the project. When developing a new product with components that may need to be decorated in some way, attention should be given to the part design, the polymer being used, the decorating purpose, the part application, the governing regulations, and the cost considerations. If we can answer any questions, don’t hesitate to reach out to us.

--

Ash Brown // VP, Business Development

1 note

·

View note

Text

Coated bottom and non-woven fabric bottom

What is the difference between coated bottom and non-woven fabric bottom in the wall covering industry

What is the difference between the coated bottom and the non-woven fabric bottom in the wall covering industry: The coated bottom coating bottom wall covering has excellent mold and moisture resistance, keeping it clean for a long time, and extending the service life of the wall covering. Construction: When the general construction master adjusts the glue, because the ratio of the original glutinous rice glue to the water may not reach the best or not evenly mixed, and the coating has a certain function of blocking water, when applying the coated wall covering, the general water It doesn't matter if there are more copies. Non-woven bottom non-woven bottom wall cloth is composed of directional or random fibers on the basis of fabric.

It is a new generation of environmentally friendly materials. It has the characteristics of moisture-proof, breathable, non-toxic, non-irritating, recyclable, etc., and has a relatively good feel thick. Construction: Nowadays, many wall coverings are made of non-woven fabric. The construction master must pay attention to it when sticking, and must use a soft brush to stick the cloth. If you use a hard scraper on the wall, excessive force will produce a little on the edge when sticking the cloth.

Scratch marks similar to creases are smoothed. Although the surface cloth is flattened, the non-woven base cloth on the back still has a little wrinkle, which makes customers think it is a quality problem. When pasting, please paste it evenly in one direction. If small bubbles are generated after pasting, please use a small needle tube to inject a certain amount of glue, and then scrape the wall cloth. The non-woven fabric is prone to creases, and the high-precision smooth surface tends to look uneven on the side.

What are the types of non-woven fabrics required for masks[

Due to the impact of emergencies, the demand for masks for increased equipment has increased. Medical surgical masks and N95 masks generally adopt a multilayer structure, referred to as SMS structure: the inner and outer sides are spunbonded layers (S); the middle is the meltblown layer ( M), generally divided into single layer or multilayer. Flat masks are generally PP spunbond + meltblown + PP spunbond, and three-dimensional cup masks are generally PET polyester needle punched cotton + meltblown + needle punched cotton or PP spunbond.

It can be seen that the non-woven fabrics required for masks are mainly spunbonded and meltblown, among which spunbonded non-woven fabrics use a relatively thick fiber diameter of about 20 microns. The process of meltblown non-woven fabric is to feed polymer-melt extrusion-fiber formation-fiber cooling-net formation-reinforcement into cloth. The diameter of meltblown fibers can reach 1-5 microns, and they are generally made of polypropylene with high-melt fat fibers. These ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, thereby making meltblown fabrics With good filtering, shielding, thermal insulation and oil absorption, meltblown fabric can be called the 'heart' of medical surgical masks and N95 masks.

However, the domestic output of meltblown non-woven fabrics is relatively low. Spunlace nonwovens are useful for masks, but they are relatively rare. Nowadays, some mask companies have chosen to use spunlaced fabrics for the inner layer, because they can absorb moisture and wick away sweat without producing moisture, and are soft and comfortable. And on February 10th, a subsidiary of Huamao Co., Ltd. stated that the pure cotton spunlace non-woven fabric produced can be used as the inner layer (skin layer) of N95 masks. China Textile Institute's product WeisaierTM (English name NWCELLTM) has been applied to medical masks and other fields.

1 note

·

View note

Text

Your Guide to Materials For Outdoor Furniture

Because today there are dozens of choices for new outdoor patio furniture that will have your outdoor living spaces looking and feeling cozy and welcoming for both you and your guests. Think how you use your outdoor areas, is it for hosting big parties for many people; you have small intimate cookouts - do most of your cooking outdoors during the summer? These are important questions to ask when you’re considering new furniture purchases.

Real Wood Furniture

Choose dense wood such as teak or eucalyptus, or a hardy wood such as cedar. Teak and Eucalyptus are easier to maintain because they don’t need to be sealed on a yearly basis, but cedar is naturally moisture- and bug-resistant.The type of wood your furniture is made of is crucial if you want to avoid things like splitting, rotting, and bugs. Maintaining your wood furniture with a soft brush dampened with solution water and a mild oil-based soap. Rinse by hosing down and dry with towels.

Polymer and Plastic Furniture

Outdoor furniture's made from plastic can’t ever rust and is designed to last in difficult environments. Plastic patio furniture created from recycled plastics are fantastic if you live in a saltwater environment. If you’re looking for easy care and maintenance then synthetics are where it’s at.

Marine-grade polymers can also be used. They’re heavy, sturdy, and have been designed to look just like painted wood. You can leave this furniture out all year round without any ill effects, and cleaning is easy with a simple dish soap and water solution and a damp cloth. Rinse with your garden hose.

Aluminum Furniture

Aluminum outdoor furniture is great if you want an easy-care solution that you can effortlessly move around, won’t rust, and it’s super lightweight. Check the welds to make sure they are seamless; it's hardware on your furniture is sturdy; rust-proof; choose a powder-coated and UV-resistant finish. Never use abrasive cleaners on aluminum, just wipe it down with a damp cloth. If you see scuff marks, you can very gently use a bit of soft scrub on a soft, damp cloth, but be careful - you don’t want to scratch the finish, especially if it’s shiny. Then rinse off with your garden hose.

Wrought Iron Furniture

It's classic, sturdy, and timeless-looking, offers many styles, colors, and designs that is sure to fit your style. Wrought iron has superior weathering properties, is resistant to corrosion and its malleability make it an excellent product for ornamental wrought ironwork. This type of outdoor furniture is definitely not for moving around a lot due to it's heavy weight and will leave marks if dragged across the deck. But if you live in an area of high winds, you won’t have to worry about your outdoor furniture blowing away. Wrought iron still needs some basic maintenance, it's paint can chip or scratches, touch-up paint in the same color keeps your furniture looking like brand new. Occasionally basic cleaning, just wipe down with a damp cloth. If deeper cleaning is necessary, wipe down with a solution of dish-washing detergent and warm water, and then rinse with your garden hose.

5. Cushion Fabrics

Look for fabric designed for outdoor use that is UV-resistant, as well as resistant to moisture, mold, and stains. New cushions make older furniture look new again. Bring your cushions indoors when you’re not using them, this will get much more life out of your investment.

source - thepropertygeeks.com

2 notes

·

View notes

Text

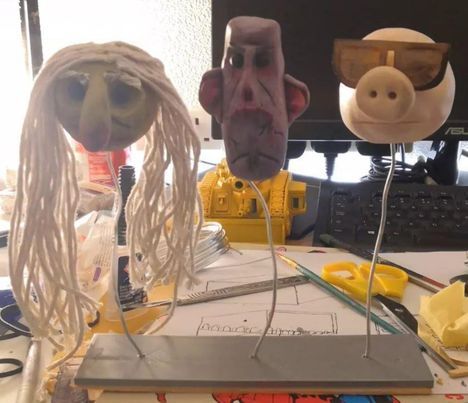

3: Traditional model making

Once I had a plan for my models I began by sculpting the heads using polymer clay, trying to blend colours in order to get less natural skin tones for the ‘Cleaners’ and not mixing any for the human characters. As I had never worked with polymer clay before, I found it a bit tough to work with to start with. However, after looking online I found that I should use aluminium foil in order to keep my models lighter and also save on how much clay I use. By doing this, I also found that the clay was much easier to work with and didn’t lose its overall shape as easily and this was a technique I then continued to use in future projects. Used the same sculpting tools I would normally use for regular clay and found that there wasn’t much difference in the effect they had, however, due to how much rigid the polymer clay was, I found that sometimes I had to either push harder on the clay to make a mark or I had to warm the clay up by rolling it in my hands, this didn’t end up effecting the work at all.

Once my models had been sculpted I needed to bake them in the oven, since I had used two different types of polymer clay with different baking times I decided to use the longer of the two times just to make sure all the clay was fully baked. This didn’t seem to cause any issues with the final result, however I found that some parts that were connected to the head such as the eyes and ears had come off after baking due to the clay shrinking, This wasn’t an issues as when the parts had been baked I could just glue them back to each other. However, to avoid this in future I could ‘pin’ my parts together which simply means putting a metal rod between them as a sort of internal scaffolding.

Once the heads were baked and cooled I gave them a simple paint job with a dark ink wash to show any details such as wrinkles, and then a drybrush with a pink colour to highlight any fleshy parts such as the ears or nose. After this I then added any extra parts I needed such as the hair or glasses, which although fiddly, was not too hard.

After the heads were finished I made a skeleton for each model using aluminium wire, I then coated any thicker parts of this with foam, meaning the wire could still be flexed underneath, allowing me to pose the models. One mistake I made with this was using super glue to stick these pieces together, as superglue dried rigid, although this didn’t effect the end result too much, it could have potentially ruined the model, therefore, in future I should use PVA or some other sort of flexible glue in order to join these bits.

After the body and skeleton were done, I had to make clothes for the models, I realised that since the models would only be seen from the front in the final illustration, I could save myself some time and just focus on keeping the front of the model looking nice without worrying about the back, because of this I used superglue to hold the back of the clothes together instead of sewing them, and this saved me hours of work. Tailoring clothes is not a technique I have used on my models before and because of this I did initially struggle with making the clothes, however, after watching how full sized clothes are made, I used a few of the techniques I saw but on a much smaller scale, as well as this. Since I was using scraps from old clothes, I chose to use the existing stitching in the clothes wherever it would be on the final model, such as using the hem of some denim as the waistline on the model in order to add some detail and realism without taking a much longer time.

Once the clothes on the models were all made and dry, I decided to help sell the dirty effect I would dust some pigment onto them. I hadn’t used this technique on fabric before so I wasn’t sure how it would turn out, however it worked very well and I ended up using this technique in a lot of other parts of the project. One thing that didn’t work as well was trying to apply a watered down paint to the models to look like staining, due to the light colour of the paint and the dark colour of the fabric, this didn’t show up as much as I hoped. However I now know this for future projects.

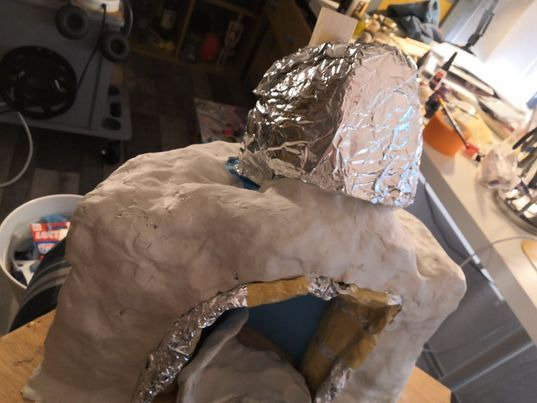

Another model I had to make was the large head for the shot of the ‘Cleaner’ eating the rubbish. To do this, I used a similar technique to what I had with the smaller models, however, instead of using aluminium wire for a skeleton, I used some scrap wood and foil and foam to bulk it up. I then used air drying clay to cover the whole model. I used air drying clay as its cheaper than polymer clay, and I wouldn’t be able to bake modelling clay to set it due to the size of the model and the fact it was also made from wood and foam. To help make the model more life like, I textured the clay with a textured roller in order to give it a skin texture. Although this was a good effect, I think I overdid it a bit and if I were to do it again in future, I would tone it back as I think it made the model too busy.

Now that all the handmade elements of the models were done, I had to produce finer details such as hands and feet digitally...

0 notes

Text

Polymer Coated Fabrics Market Size Forecast to Reach $24.8 Billion by 2026

Polymer Coated Fabrics Market is forecast to reach $24.8 billion by 2026, after growing at a CAGR of 5.3% during 2021-2026. Globally, the demand for polymer-coated fabrics is expected to witness healthy growth during the forecast period driven by increasing demand for the polymer-coated fabrics in the automotive and transportation industry. Furthermore, the rising demand of protective clothing is expected to create new opportunities for the growth of the global polymer-coated fabrics industry in the predicted era.

Impact of Covid-19

The COVID-19 pandemic and subsequent halt in manufacturing activities had a huge impact on the supply availability of polymer-coated fabrics for automotive in the year 2020. Furthermore, looking forward towards the new normal condition the production for automotive has risen, owing to which the demand and supply for polymer-coated fabrics is also anticipated to rise over the forecast period.

Polymer Coated Fabrics Market Segment Analysis - By Type

Polyurethane-coated fabrics held the largest share in the year 2020. PU-coated fabrics have better properties, such as elasticity, transparency, and oil, grease and abrasion resistance. They are particularly preferred if unusual impact and abrasion resistance are required. PU-coated fabrics are used primarily for applications including waterproof protective clothing, rainwear, upholstery, footwear, luggage, glove, inflatable boats, waterproof mattress cover, and recreational items. One of the most effective stabilizers is phosphites & phosphonites, since both primary antioxidants and polymers are protected during processing. The most frequently used polymer stabilizers are generally hydrolytically stable phosphites & phosphonites. Thus, increasing demand of polyurethane coated fabrics will further drive the market for polymer coated fabrics in the forecast period.

Request for Sample Report @ https://www.industryarc.com/pdfdownload.php?id=16420

Report Price: $ 4500 (Single User License)

Polymer Coated Fabrics Market Segment Analysis - By Applications

The transportation sector held the largest share in the polymer coated fabrics market in 2020 and is projected to grow at a CAGR of 4.8% during the forecast period 2021-2026. This growth is due to the increasing use of polymer coated fabrics in different transport applications. Polymer-coated fabrics are used primarily for a wide range of automotive applications such as indoor, outdoor, airbags, seatbelt, and coverings. Requirement for coated fabrics is expected to observe remarkable escalation due to its advanced properties including better insulation, high water resistance, ability to drape lack of stickiness, high elasticity and thermal management properties. Rapid industrialization is likely to have a constructive effect on the market for polymer-coated fabrics. According to India Brand Equity Foundation, the rapidly globalizing world is opening up new possibilities for the transport industry, particularly as it switches to electric, electronic and hybrid vehicles, which are perceived to be more efficient, safe and stable modes of transport. Also, it estimates that Indian auto component manufacturers are well positioned to benefit from the globalization of the industry as the export capacity could be expanded by up to US$ 30 billion by 2021. Thus, the increasing use of coated fabrics in transportation will further drive the market for polymer coated fabrics over the forecast period.

Polymer Coated Fabrics Market Segment Analysis - By Geography

Asia-Pacific held the largest share with 33% in polymer coated fabrics market in 2020. Globally, the market for polymer coated fabrics is rising due to rapid urbanization and massive industrial growth in key countries such as China, Japan, India, and South Korea. The increasing demand from transport, protective clothing, and industrial applications drives the market for polymer-coated fabrics at APAC region. The major countries driving the polymer coated fabrics market in APAC are China, Japan and South Korea. According to International Trade Administration, China is the world’s largest vehicle market, with China expecting automobile production to reach 30 million units by 2020 and 35 million by 2025. Also, according to India Brand Equity Foundation in 2018, India became the fourth largest automotive market with sales rising to 3.99 million units from 8.3 percent year-on-year. Also, in 2018 it was the seventh-largest commercial vehicle manufacturer. Hence due to the rising demand for polymer coated fabrics in this region the market is anticipated to boost in the forecast period.

Polymer Coated Fabrics Market Drivers

Increasing demand for polyethylene coated fabrics

Coating fabrics made from polyethylene (PE) provide a range of mechanical and physical advantages, primarily derived from their properties. In view of the increasing demand for polymer-coated fabrics with low permeation tendency, production of PE-coated fabrics continues to gain traction. Coated textiles made from polyethylene have many advantages over other materials. The properties of moisture barriers are important to extend their application purview. The materials have a basic structure consisting of a high-strength woven fabric with impermeable coating on both sides. Polyethylene membranes offer the best UV protection, are mildew-resistant, rot-resistant, and are vertically resistant to all known chemical attacks. Due to such qualities the demand for polyethylene coated fiber is increasingly used for industrial use. Also, polyethylene offers a unique drapability and softer hand owing to which it is anticipated to rise in the forecast period.

Growing demand in protective clothing applications

Polymer-coated fabrics can be easily modified, and according to the fabric's requirements and applications, production properties such as electrical conductivity, fire resistance, and weather resistance can be improved. Consumers nowadays prefer more durable and sustainable materials particularly for their clothes and shoes. For protective clothing and shoes, polyurethane is widely used because it is softer and non-sticky than other material. Furthermore, polyurethane-coated fabrics have better properties, such as resistance to elasticity, grease and oil, transparency and are proof of abrasion. These types of fabrics are also preferred during unusual impact, and are primarily used for various applications including waterproof protective clothing, rainwear, luggage, upholstery, footwear, waterproof mattress cover, gloves, inflatable boats, and other recreational items. Polymer-coated fabric is experiencing a high demand from the protective clothing and industrial segment because it is more economical, durable and environmentally friendly behavior. As a result of which the market for polymer-coated fabric is expected to rise in the upcoming years.

Download Sample Report @ https://www.industryarc.com/pdfdownload.php?id=16420

Polymer Coated Fabrics Market Challenges

Effects of using vinyl in products

Polyvinyl chloride (PVC or vinyl) is the worst plastic for our health and environment, releasing hazardous chemicals which can cause manufacturing cancer to be disposed of. PVC products often contain hazardous toxic additives such as phthalates and lead which can reach out to consumers and pose hazards. The vast majority of PVC made is used in the manufacture of coated fabrics. A growing number of companies have committed to phasing out their products from vinyl-coated fabrics, and have vowed to create safer and healthier alternatives for their customers. Hence, various harmful effects of PVC will further create hurdles for the polymer coated fabrics market in the forecast period.

Polymer Coated Fabrics Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the polymer coated fabrics market. Major players in the polymer coated fabrics market are Trelleborg AB, Cooley Group Holdings, Inc., Takata Corporation, Spradling International Inc., Sioen Industries NV, Seaman Corporation, Omnovo Solutions Inc., Archroma and Continental AG among others.

Acquisitions/Technology Launches

In July 2019, Archroma launched an ultra-low VOC polymer coating technology based on water that delivers high performance to coated fabrics, such as indoor and outdoor textiles, nonwovens, and papers.

In July 2018, Trelleborg AB acquired Laminating Coating Technologies Inc. (Lamcotec) (US) to strengthen its position in the US market.

Key Takeaways

The Asia-Pacific dominated the polymer coated fabrics market in 2020 owing to the increasing use of polymer coated fabrics in the automotive industry for making fabrics for vehicle interiors and exteriors.

Worker safety concerns in different industries have strengthened the demand for polymer-coated fabrics as an essential component of protective clothing.

Stringent government standards from National Fire Protection Associations (NFPA) has provided regulations for shale exploration and the renewable chemicals industry on labor safety and security steps taken by firms to improve consumer demand for polymer coated fabrics.

Related Reports :

A. Coated Fabrics Market

https://www.industryarc.com/Report/16453/coated-fabrics-market.html

B. Textile Coatings Marke

https://www.industryarc.com/Report/16478/textile-coatings-market.html

For more Chemicals and Materials Market reports, please click here

0 notes

Text

Polymer Dispersions Market size Global Gathering and Future Outlook 2021 to 2028

Polymer dispersions market is expected to gain market growth in the forecast period of 2020 to 2027. Data bridge market research analyses the market account to USD 15.19 Billion by 2027 growing at a CAGR of 8.10% in the above-mentioned forecast period.

Market Competitors:

The major players covered in the global polymer dispersions market report are Alberdingk Boley, Allnex Netherlands B.V., Basf SE, B I P (Oldbury) Ltd, Chase Corp, Coim Group, Covestro AG, DIC Corporation, DuPont, Eastman Chemical Company, Evonik Industries AG, Huntsman International LLC, Icap-Sira S.p.A., Kamsons Chemicals Private Limited, Lamberti S.p.A., Lanxess, michelman, inc, The Lubrizol Corporation, Mitsui Chemicals, Inc., Hexion, Solvay, synthomer plc, Dow, VINAVIL S.p.A., Wacker Chemie AG among other players.

Download PDF Sample report @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-polymer-dispersions-market

Polymer dispersions are water-borne emulsion polymers with colloidal particles in a stabilized state, the most commonly known being latex. Dispersion of polymer is primarily used for heat, water vapour, fat and other materials defence. Specific uses, such as inks, adhesives, fats, layering, paper and sealant, are used with polymer dispersions. The type of polymer dispersion that will be used is selected on the basis of sample size and solids.

Global Polymer Dispersions Market Scope and Market Size

· Polymer dispersions market is segmented on the basis of resin type, application. Each individual segment’s growth is analysed and these insights are subsequently considered before providing you with the market overview which can help you in understanding and identification of your core applications in the broad market.

· On the basis of resin type, polymer dispersions market has been segmented into acrylic dispersions, vinyl dispersions, polyurethane (PU) dispersions, styrene-butadiene (SB) dispersions, others.

· Polymer dispersion market based on application has been segmented into decorative & protective coatings, adhesives & sealants, paper, carpet & fabrics, printing ink, others. Decorative & protective coatings are further segmented into wood coatings, metal coatings, and roof & wall coatings. Adhesives & sealants are further segmented into water-based adhesives, solvent-based adhesives. Paper is further segmented into surface sizing, paper coating. Carpet & fabrics are further segmented into upholstery, home furnishings, others.

Reasons to Purchase this Report

· The segment that is expected to dominate the market as well as the segment which holds highest CAGR in the forecast period

· Regions/Countries that are expected to witness the fastest growth rates during the forecast period

· The latest developments, market shares, and strategies that are employed by the major market players

Want Full Report? Enquire Here@ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-polymer-dispersions-market

Key insights in the report:

· Complete and distinct analysis of the market drivers and restraints

· Key Market players involved in this industry

· Detailed analysis of the Market Segmentation

· Competitive analysis of the key players involved

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge Market Research provides appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact:

Data Bridge Market Research

US: +1 888 387 2818

Related Reports:

Road Marking Materials Market

Rubber Process Oil Market

#Polymer Dispersions Market#Polymer Dispersions#Polymer Dispersions Market Trends#Polymer Dispersions Market Industry#Polymer Dispersions Market News

0 notes

Text

Benefits of Custom Acrylic Sheets

The days are in the past where glass was preferred over other materials. Now is the time for a more durable and versatile product, Plexiglass (also known as acrylic). Being one of the oldest synthetic materials, acrylic plastic is creating waves and is here to stay!

The reason for the widespread popularity of this synthetic polymer is its versatility and the amplified aesthetics that it brings to whatever project it is implemented in. Many people are unaware of the wonders and boons Plexiglass is blessed with. Therefore, we bring you this valuable guide that deals with all the benefits, processes, and everything you need to know about this extraordinary form of plastic.

What is acrylic plastic?

Acrylic plastic is a strong synthetic polymer technically referred to as polymethyl methacrylate (PMMA). It’s a versatile product that generally comes in sheets but is also available in varying thicknesses, shapes, and styles. This plastic could easily be customised into different shapes and colours as per your business needs.

They have a glass-like appearance but are lighter in weight and cheaper in cost than glass. When exposed to a high level of heat it could be modified into interesting shapes, sizes, and products. The clear surface it provides is even worthier and transparent than glass that creates glares and reflects light.

Since acrylic plastic or Plexiglass can be customised into a wide array of designs, it creates amazing products such as window panes, aquariums, retail signage and displays, greenhouse panels, bullet-resistant glass, and many more useful applications.

Benefits of custom acrylic sheets:

Many businesses are now switching to Custom Acrylic Sheets in the replacement of glass because of the myriad of benefits they have to offer. Some of them are as follows:

1. Stability and strength:

The major switch to Acrylic is because of the undaunted strength and stability it has to offer. This lightweight material is more durable than glass, wood, and even some metals. It gives the confidence to the businesses that they won’t face any accident in its presence. And in case of an accident, they do not shatter into tiny edgy pieces, rather they break into big blunt pieces.

Therefore they are the best options to make sliding doors, window panes, showroom and shop windows etc.

Moreover, it is half the weight of glass but 10 times more impact resistant than its counterparts and it could bear harsh weather and environmental conditions quite conveniently.

2. Easily fabricated:

Another wonder of acrylic is that it is malleable when exposed to heat, which allows moulding into desired shapes and structures. Not only this, but they are easy to work upon as if you are working on wood.

The acrylic sheets are more convenient to work upon than glass as they can be transported, installed, drilled, or sawed without any threat of breaking up in the process. Even the sheets could be cut and shaped using traditional tools used to cut wood. Because the polymers in the Acrylic sheet are flexible and provide easy customisation.

3. Cost-Effective:

Since acrylic sheets are lighter than glass and are more convenient to work upon, it requires less effort and money to produce and shape them, therefore they are a better cost-effective alternative to glass.

Their transportation and shipping charges are also reduced. The actual cost depends on the type and quality of the acrylic sheet you are purchasing. The enormous pool of acrylic sheets consists of normal ones, coloured ones, mirrored sheets, Lucite blocks, fluorescent sheets, and many more.

Moreover, they also let you save on coating and films because you can opt from UV-filtering, UV-transmitting, or impact modified sheets.

4. Highly transparent:

Do you know Acrylic plastic is 90% more transparent than traditional glass, allowing better clarity and transparency? When exposed to direct sunlight it does not get dull and yellow with constant use and time. Rather its transmittance and aesthetic remain untouched even after a long period. This quality of Plexiglass is not even affected by its thickness. No matter how thick it is, it will always remain clear without any discolouration.

5. Easy to maintain:

Acrylic sheets are easy to clean and maintain as they are less prone to stains and dust. Where there are some basic guidelines to keep it clean and shining for a long time, cleaning them is an instant job without many hurdles.

Just use a wet and clean microfiber cloth as the dirt particles from the cloth can cause scratches and defects in the sheet. Stay gentle while cleaning it and it will go a long way to serve you and your business purpose.

6. Easy to process: