#Chemicals and Materials

Text

Aluminum Market: Products, Applications & Beyond

Aluminum is a versatile element with several beneficial properties, such as a high strength-to-weight ratio, corrosion resistance, recyclability, electrical & thermal conductivity, longer lifecycle, and non-toxic nature. As a result, it witnesses high demand from industries like automotive & transportation, electronics, building & construction, foil & packaging, and others. The high applicability of the metal is expected to drive the global aluminum market at a CAGR of 5.24% in the forecast period from 2023 to 2030.

Aluminum – Mining Into Key Products:

Triton Market Research’s report covers bauxite, alumina, primary aluminum, and other products as part of its segment analysis.

Bauxite is anticipated to grow with a CAGR of 5.67% in the product segment over the forecast years.

Bauxite is the primary ore of aluminum. It is a sedimentary rock composed of aluminum-bearing minerals, and is usually mined by surface mining techniques. It is found in several locations across the world, including India, Brazil, Australia, Russia, and China, among others. Australia is the world’s largest bauxite-producing nation, with a production value of over 100 million metric tons in 2022.

Moreover, leading market players Rio Tinto and Alcoa Corporation operate their bauxite mines in the country. These factors are expected to propel Australia’s growth in the Asia-Pacific aluminum market, with an anticipated CAGR of 4.38% over the projected period.

Alumina is expected to grow with a CAGR of 5.42% in the product segment during 2023-2030.

Alumina or aluminum oxide is obtained by chemically processing the bauxite ore using the Bayer process. It possesses excellent dielectric properties, high stiffness & strength, thermal conductivity, wear resistance, and other such favorable characteristics, making it a preferable material for a range of applications.

Hydrolysis of aluminum oxide results in the production of high-purity alumina, a uniform fine powder characterized by a minimum purity level of 99.99%. Its chemical stability, low-temperature sensitivity, and high electrical insulation make HPA an ideal choice for manufacturing LED lights and electric vehicles. The growth of these industries is expected to contribute to the progress of the global HPA market.

EVs Spike Sustainability Trend

As per the estimates from the International Energy Agency, nearly 2 million electric vehicles were sold globally in the first quarter of 2022, with a whopping 75% increase from the preceding year. Aluminum has emerged as the preferred choice for auto manufacturers in this new era of electromobility. Automotive & transportation leads the industry vertical segment in the studied market, garnering $40792.89 million in 2022.

In May 2021, RusAl collaborated with leading rolled aluminum products manufacturer Gränges AB to develop alloys for automotive applications. Automakers are increasingly substituting stainless steel with aluminum in their products owing to the latter’s low weight, higher impact absorption capacity, and better driving range.

Also, electric vehicles have a considerably lower carbon footprint compared to their traditional counterparts. With the growing need for lowering emissions and raising awareness of energy conservation, governments worldwide are encouraging the use of EVs, which is expected to propel the demand for aluminum over the forecast period.

The Netherlands is one of the leading countries in Europe in terms of EV adoption. The Dutch government has set an ambitious goal that only zero-emission passenger cars (such as battery-operated EVs, hydrogen FCEVs, and plug-in hybrid EVs) will be sold in the nation by 2030. Further, according to the Canadian government, the country’s aluminum producers have some of the lowest CO2 footprints in the world.

Alcoa Corporation and Rio Tinto partnered to form ELYSIS, headquartered in Montréal, Canada. In 2021, it successfully produced carbon-free aluminum at its Industrial Research and Development Center in Saguenay. The company is heralding the beginning of a new era for the global aluminum market with its ELYSIS™ technology, which eliminates all direct GHG emissions from the smelting process, and is the first technology ever to emit oxygen as a byproduct.

Wrapping Up

Aluminum is among the most widely used metals in the world today, and is anticipated to underpin the global transition to a low-carbon economy. Moreover, it is 100% recyclable and can retain its properties & quality post the recycling process.

Reprocessing the metal is a more energy-efficient option compared to extracting the element from an ore, causing less environmental damage. As a result, the demand for aluminum in the sustainable energy sector has thus increased. The efforts to combat climate change are thus expected to bolster the aluminum market’s growth over the forecast period.

#Aluminum Market#aluminum#chemicals and materials#specialty chemicals#market research#market research reports#triton market research

4 notes

·

View notes

Text

The Polycaprolactone Market Size accounted for USD 482.6 Million in 2022 and is estimated to achieve a market size of USD 1,327.6 Million by 2032 growing at a CAGR of 10.7% from 2023 to 2032.

0 notes

Text

Unlock the potential of premium raw materials with Viztaar B2B Marketplace for Polymers and for other plastic rw materials. IOCL 010F18S SLIP LLDPE Film Grade is now available for sale.

Engineered by Indian Oil Corporation Limited, this high-quality material sets the benchmark for excellence in LLDPE film manufacturing.

Key Features:

Superior Slip Properties: IOCL 010F18S ensures smooth and efficient processing, enhancing production efficiency.

Consistent Quality: Manufacture LLDPE films of unparalleled quality, meeting and exceeding industry standards.

Versatile Applications: Ideal for a wide range of applications, from packaging to industrial uses, delivering performance across diverse sectors.

Reliable Supply: Count on Viztaar Marketplace for a steady and reliable supply chain to support your manufacturing needs.

Enhance your production capabilities with Plastic Raw Materials — where quality meets innovation. Don’t miss the opportunity; make it yours today!

Join Now

Lldpe Film Grade

Plastic Raw Material

Polymers

#Lldpe Film Grade#Plastic Raw Material#Polymers#Chemical#Chemicals And Materials#Viztaar#ViztaarMarketplace

0 notes

Text

HUGE music blinkie dump.. found some mayhem ones too which i was surprised about!!

#blinkies#music#nu metal#metal#heavy metel#black metel#emo#web graphics#web resources#favicons#dividers#pixel art#cute pixels#banners#decome#pixels#carrd material#bands#mayhem#hole#my chemical romance#evanescence#the cardigans#panchiko#korn#linkin park#system of a down#blink 182#jack off jill#the cure

6K notes

·

View notes

Text

Thermal Interface Materials Market: Top 4 Applications

Thermal interface materials (TIMs) play a pivotal role in electronics and thermal management. They help improve the thermal conductivity between components, ensuring efficient heat dissipation and preventing overheating. By filling microscopic gaps between surfaces, TIMs facilitate heat transfer, and in turn, improve the reliability and performance of electronic devices. According to Inkwood Research, the global thermal interface materials market is set to progress with a CAGR of 9.91% during the forecast years 2023 to 2032, reaching a revenue of $7044.80 million by 2032.

With the rising development and adoption of increasingly compact and powerful electronics, TIMs are becoming indispensable for maintaining optimal operating temperatures, prolonging the lifespan of devices, and ultimately ensuring their seamless functionality. TIMs are available in many forms, including gels, pastes, and greases; they offer excellent thermal conductivity, high-flexibility and better fill larger gaps.

Thermal Interface Materials Market: Enhancing Performance in Electrical Applications

Through the efficient conduction of heat away from critical components such as processors and semiconductors, TIMs prevent overheating and ensure the longevity and reliability of electronic devices. This enhanced thermal management results in improved performance, reduced downtime, and increased energy efficiency, making them an indispensable component of modern electrical applications. Here’s how –

Automotive Electronics:

Thermal conductive materials play a pivotal role in dissipating heat generated by various automotive electronic systems, such as engine control units, infotainment systems, advanced driver-assistance systems (ADAS), and electric vehicle (EV) components. TIMs facilitate heat transfer between electronic components and heat sinks, ensuring that delicate automotive electronics operate at optimal temperatures. For example, the DOWSIL™ 3-6752 by Dow Chemical Company (United States) is a thermally conductive adhesive used for bonding organic as well as ceramic substrates to heat sinks for electronic control modules in automotive applications.

Market Position: As per Inkwood Research, the automotive electronics segment, under the application category, is set to grow with the highest CAGR of 11.08% between 2023 to 2032.

In addition to performance improvements, these materials also aid in energy efficiency, which is a major concern in the automotive industry. By preventing overheating and ensuring the longevity of vital components, these materials enhance the reliability and performance of modern automotive electronics, thereby contributing to the safety and efficiency of automobiles.

Computers:

Computers, encompassing various devices such as desktops, laptops, servers, and data centers, produce a significant amount of heat during their operation. The use of thermal interface materials, in this regard, is common for enhancing heat dissipation from critical components like CPUs, GPUs, and memory modules to their respective cooling solutions or heat sinks.

The demand for efficient TIMs in computers is projected to increase during the forecast period, driven by the growing popularity of gaming PCs, the expansion of artificial intelligence applications, and the increasing utilization of data-intensive tasks. Additionally, the emergence of technologies like 5G and the Internet of Things (IoT) is fostering the need for robust thermal management solutions in edge computing devices and cloud data centers, as well.

Telecom:

Thermal interface materials (TIMs) are employed in telecom equipment in order to efficiently transfer heat from high-power electronic components, ensuring that devices operate within the required temperature range. Thermal greases, phase-change materials, and thermal pads are commonly used in these applications. As the telecom industry transitions towards 5G, while preparing for the future with 6G technology, the demand for thermal conductive materials is anticipated to increase further.

Aligning with this, telecom is expected to be the dominating application during the forecast period, capturing a revenue share of 24.80% by 2032 (Source: Inkwood Research). Several leading companies are actively engaged in the telecommunications infrastructure space, predominantly with regard to thermal interface materials. These include Henkel AG & Co KGaA (Germany), Parker Hannifin Corporation (United States), and Indium Corporation (United States).

Medical Devices:

Efficient thermal management is critical in medical devices in order to ensure accurate and reliable performance during medical procedures. TIMs assist in heat dissipation from high-powered medical electronics, preventing overheating and maintaining optimal operating temperatures. As pharmaceutical R&D and industrialization continue to grow in major regions, such as Europe, the demand for thermally conductive compounds in medical devices is expected to rise further. For example, Germany’s robust pharmaceutical and medical device sectors highlight the demand for TIMs in medical applications.

With a substantial number of companies in the medical equipment and supplies sector, Italy’s mature market necessitates precise temperature control in medical devices. Likewise, the robust export value of the Polish medical devices and equipment sector, reaching €3.2 billion in 2021, also demonstrates the critical role of TIMs in healthcare technology. These growth factors, in turn, further propel the market demand in the region. Accordingly, as per Inkwood Research, the Europe thermal interface materials market is set to grow with a notable CAGR of 10.15% during the forecast period, 2023 to 2032.

As technology continues to evolve, the need for efficient heat management becomes increasingly crucial. Moreover, with industries and consumers alike demanding smaller, faster, and more powerful devices, the use of TIMs is set to play a pivotal role in maintaining optimal operating temperatures and ensuring the longevity of modern electronics. These factors, in turn, are expected to boost the growth of the global thermal interface materials market during the upcoming years.

FAQ

What is the size of thermal interface materials?

Typically, several interfaces exist between the heat-generating element as well as the eventual heatsink. Their thickness can vary from several hundredths of an inch to a few thousandths of an inch.

Are there eco-friendly TIM options available to reduce environmental impact?

Yes, various TIMs are designed to be environmentally friendly, offering low volatile organic compound (VOC) content and longer lifespans, which reduce waste and environmental impact.

#thermal interface materials market#thermal interface materials#CHEMICALS AND MATERIALS#ADVANCED MATERIALS#inkwood research#market research reports

0 notes

Text

Rising Health Concerns to Drive Global Water Quality MonitoringMarket

Triton Market Research presents the ‘Global Water Quality Monitoring Market’ report sectioned by Component (pH Sensors, DO Sensors, Temperature Sensors, Turbidity Sensors, Other Components), by Application (Utilities, Industrial, Commercial, Residential, Other Applications), and by Regional Outlook (Middle East and Africa, Latin America, Europe, Asia-Pacific, North America).

The report further discusses the Market Summary, Industry Outlook (Technology Snapshot, Parent Market Analysis, Porter’s Five Forces Analysis, Market Maturity Analysis, Key Buying Impact Analysis, Regulatory Framework, Key Market Strategies, Drivers, Challenges, Opportunities, Analyst Perspective), Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2023-2030).

Triton’s research report suggests that the global water quality monitoring market would advance with a CAGR of 5.51% in the forecast years from 2023 to 2030.

Two major sources of water-borne diseases include pollutants (such as nitrates, chemicals, and heavy metals that flow into the water due to industrial pollution) and contaminants (such as bacteria, viruses, and parasitic organisms). Health effects caused by consuming polluted or contaminated water range from intoxication to life-threatening diseases or sudden death. With the growing concerns regarding water safety, the demand for water quality monitoring (WQM) systems has grown.

The sales of WQM devices are mainly centered around small-scale specialist retail outlets; whereas, their R&D is focused on large-scale applications like carbon sequestration and soil amendment. This presents a state of uncertainty, which creates challenges in the path of market growth.

North America is the leading regional market globally, which accounted for the highest revenue share in 2022. The contamination of water resources with pathogens (such as fecal coliform bacteria) is a grave concern in many areas across the region. The source of this pathogenic contamination is mainly untreated or poorly treated sewage. Thus, the high adoption of water quality monitoring systems is witnessed across North America.

Leading names engaged in the water quality monitoring market include Xylem Inc, Pentair Plc, Shimadzu Corporation, Agilent Technologies Inc, Thermo Fisher Scientific Inc, Emerson Electric Co, Evoqua Water Technologies Corp, Horiba Instruments Inc, Teledyne Technologies Inc, and Danaher Corporation.

The large capital investment required for R&D, manufacturing, and distribution acts as a hindrance for aspiring market players. The construction of a complete manufacturing unit accounts for the largest share in terms of capital investment. Moreover, the low number of buyers owing to the lack of awareness across several geographical locations hampers the growth prospects for companies. The price wars and ease of substitution are also anticipated to influence the market dynamics in the forthcoming years.

#synthetic leather market share#synthetic leather market#chemicals and materials#polymers and resins industry#triton market research#market research reports

0 notes

Text

3D Printing Materials Market - Global Opportunity Analysis and Industry Forecast (2021-2028)

Meticulous Research®— a leading global market research company, published a research report titled “3D Printing Materials Market by Type (Polymer, Metal, Ceramics & Composites), Form (Filament, Liquid, Powder), Technology (FDM, SLA, Polyjet, Multijet, Binder Jetting, EBM), Application - Global Forecast to 2028”.

The 3D printing materials market is expected to grow at a CAGR of 26.7% by value from 2021 to reach $9.86 billion by 2028. The growth of this market is majorly attributed to factors such as growing demand for polymers in 3D printing, mass customization of various functional parts for industrial equipment, jewelry and consumer goods, and government initiatives to support the adoption of 3D printing. However, the high costs of 3D printing materials obstruct the growth of this market to some extent. Lack of awareness of 3D printing technology among supplies, buyers, users, and lack of skilled laborers to perform 3D printing operations is a major challenge for the growth of the 3D printing materials market.

Download Sample Report Here : https://www.meticulousresearch.com/download-sample-report/cp_id=5083

Scope of the Report

3D Printing Materials Market, by Type

· Polymer

o Photopolymer

o Polylactic Acid

o Acrylic Styrene

o Polyamide

o Polycarbonates

o Polypropylene

o Thermoplastic Elastomers

o Other Polymers

· Metal

o Steel

o Titanium

o Nickel

o Aluminum

o Copper

o Cobalt Chrome

o Other Metals

· Ceramics & Composites

3D Printing Materials Market, by Form

· Filament

· Liquid

· �� Powder

3D Printing Materials Market, by Technology

· Fused Deposition Modeling (FDM)

· Selective Laser Sintering (SLS)

· Stereolithography (SLA)

· Direct Metal Laser Sintering (DMLS)

· PolyJet

· Multi Jet Fusion

· Digital Light Processing (DLP)

· Binder Jetting

· Electron-beam Melting (EBM)

· Other Technologies

3D Printing Materials Market, by Application

· Consumer Products

o Electronic appliances

o Jewelry, Artistic Items, and Other Products

· Automotive Parts

· Industrial Application

o Equipment & Machines

o Goods & Materials

· Healthcare

· Aerospace & Defense

o Prototype Weapon

o Body & Spare parts

· Other Applications

3D Printing Materials Market, by Geography

· North America

o U.S.

o Canada

· Asia-Pacific (APAC)

o China

o Japan

o India

o South Korea

o Rest of APAC (RoAPAC)

· Europe

o Germany

o U.K.

o Italy

o France

o Russia

o Spain

o Rest of Europe

· Latin America

· Middle East & Africa (MEA)

Access full Report Description, TOC, Table of Figure, Chart, etc: https://www.meticulousresearch.com/product/3d-printing-materials-market-5083

The market is segmented based on type, form, technology, application, and geography. The study also evaluates industry competitors and analyzes the market at the country level.

Based on type, the 3D printing materials market is mainly segmented into polymers, metals, and ceramics & composites. By value, in 2021, the polymers segment is expected to account for the largest share of the 3D printing materials market. The large share of this segment is mainly attributed to its properties such as lightweight, corrosion resistance, toughness, and high strength, increasing demand for 3D-printed retainers made from nylon (PA66) or other polymers to reduce bearing weight, and the use of polymers to manufacture live saving equipment during COVID-19 pandemic. However, the ceramics & composites segment is expected to grow at the highest CAGR during the forecast period.

Based on form, the 3D printing materials market is segmented into powders, filaments, and liquids. In 2021, the powders segment is expected to account for the largest share of the 3D printing materials market. The large share of this segment is mainly attributed to the high demand for designing animal prosthetics, increasing demand for processing various industrial metals by using powder-based additive manufacturing, and manufacturing of three-dimensional lithium-iron batteries. However, the filaments segment is expected to grow at the highest CAGR during the forecast period.

Based on technology, the 3D printing materials market is segmented into fused deposition modeling (FDM), selective laser sintering (SLS), stereolithography (SLA), direct metal laser sintering (DMLS), polyjet, multijet fusion, digital light processing (DLP), binder jetting, and electron-beam melting (EBM). The fused deposition modeling (FDM) segment is expected to account for the largest share of the 3D printing materials market in 2021. The large share of this segment is mainly attributed to the ability to adjust several process parameters, such as both nozzle and build platform temperatures, and growing demand for using high-performance thermoplastics in FDM technology to manufacture customized parts and prototypes. However, the EBM segment is expected to grow at the highest CAGR during the forecast period.

Speak with Our Analyst: https://www.meticulousresearch.com/speak-to-analyst/cp_id=5083

Based on application, the 3D printing materials market is segmented into consumer products, automotive parts, industrial applications, healthcare, and aerospace & defense. The consumer products segment is expected to account for the largest share of the 3D printing materials market in 2021. The large share of this segment is mainly attributed to factors such as growing demand for customized 3D printed consumer goods, high adoption of 3D printing technology by industrial designers, mechanical engineers, packaging designers, and graphic artists to understand the aesthetics and functional appeal of the products.

Geographically, North America is expected to account for the largest share of 3D printing materials in 2021. The large share of this market is mainly attributed to the presence of major 3D printing materials companies, namely 3D Systems Corporation (U.S.), Proto Labs, Ltd., (U.S.), The ExOne Company (US), HP INC. (U.S.), EnvisionTEC, Inc. (U.S.), Markforged, Inc. (U.S.), and Tethon 3D (U.S.) for high adoption of 3D printing technology for making orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics in the healthcare industry.

The key players operating in the 3D printing materials market are 3D Systems Corporation (U.S.), Proto Labs, Ltd., (U.S.), The ExOne Company (U.S.), HP INC. (U.S.), EnvisionTEC, Inc. (U.S.), Markforged, Inc. (U.S.), Tethon 3D (U.S.), Evonik Industries AG (Germany), Materialise NV (Belgium), EOS GmbH (Germany), Stratasys Ltd. (Israel), Zortrax (Poland), Sculpteo (France), Lithoz GmbH (Austria), and IC3D, LLC. (U.S.).

Download Free Research Sample @ https://www.meticulousresearch.com/download-sample-report/cp_id=5083

Key Questions Answered in the Report-

· Which are the high-growth market segments in terms of type, form, technology, application, and geography?

· What is the historical market size for 3D printing materials across the globe?

· What are the market forecasts and estimates for the period 2021-2028?

· What are the major drivers, restraints, opportunities, and challenges in the 3D printing materials market?

· Who are the major players in the market, and what are their market shares?

· Who are the major players in various countries?

· How is the competitive landscape for the 3D printing materials market?

· What are the recent developments in the 3D printing materials market?

· What are the different strategies adopted by the major players in the market?

· What are the key geographic trends, and which are the high-growth countries?

· Who are the local emerging players in the 3D printing materials market, and how do they compete with other players?

Contact Us:

Meticulous Research®

Email-

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn-

https://www.linkedin.com/company/meticulous-research

#3D Printing Materials Market#3D Printing Materials#3D Printing#Printing Materials Market#Chemicals and Materials#Chemicals#printing industry#printing#chemical industry#printing and packaging#automotive#electronics#consumer electronics#aerospace

0 notes

Text

Synthetic Diamonds Market: Global Prospects & Challenges

The staggering ramifications of the COVID-19 pandemic affected the global distribution system of major countries producing synthetic diamonds. However, post-pandemic, the diamond industry was stimulated through digital platforms. With reduced operations, companies relied heavily on digital activities while focusing on their B2C online business. Sale of synthetic diamonds was expected to increase as manufacturers gave more importance to environment friendliness and sustainability in the production of lab-grown diamonds. Thus, due to the rising branding and marketing, along with increasing industrial uses, the global synthetic diamonds market is anticipated to advance with a CAGR of 8.26% during the forecasting period 2022-2028.

Additionally, major countries such as India and China have become a hub for the production and processing of lab-grown diamonds as a result of technological breakthroughs, cost-efficient production of gem-quality stones and growing consumer awareness. The rising production is because synthetic diamonds make an ideal window material for many industrial, R&D, defense and laser applications.

Rising Industrial Demand - Key Driver

Modern technology resembles the conditions under which diamonds naturally develop by using either of the two manufacturing methods high pressure-high temperature (HPHT) or chemical vapor deposition (CVD). Our study estimates that the high pressure-high temperature will dominate the manufacturing method segment, capturing a share of 59.59% during the forecast period 2022-2028. These processes produce synthetic diamonds with the same chemical properties as earth-mined diamonds, allowing them to be used in a variety of industry applications:

Construction

Mining

Healthcare

Defense

Future Prospects

Even though lab-grown diamonds are an inexpensive alternative to earth-mined ones, the high cost of production can result in a setback for the synthetic diamonds market. For instance, a perfect CVD diamond can take 400 hours of hatching time and specialized reactors to culture the diamonds. These reactors consume approximately 10000 units of power monthly, thereby increasing operational costs. However, the ongoing research around quantum computing, simulation, communication and sensing, with potential impacts in healthcare and the automotive industry, is expected to increase synthetic diamonds’ applications and reduce the overall production cost.

For instance, in 2021, a German-Australian start-up Quantum Brilliance announced the installation of a diamond-based quantum accelerator leveraging synthetic diamond technology. The start-up stated promising applications, leading to major benefits for drug design, chemical synthesis, energy storage and nanotechnology.

#synthetic diamonds market#synthetic diamonds#cvd diamonds market#specialty chemicals#chemicals and materials#market research reports#triton market research

0 notes

Video

The automotive industry has seen an increased demand for aluminum castings over the past few years. Increasing fuel economy is a big concern for car makers, and using lightweight aluminum components can improve fuel economy.

0 notes

Text

Demand for Bio-based Products Drive Synthetic Leather Market

Triton Market Research presents the Global Synthetic Leather Market report segmented by Type (Polyurethane [PU], Polyvinyl Chloride [PVC], Bio-based), End-use (Footwear, Automotive, Clothing, Furnishing, Bags & Wallets, Other End-uses), and Regional Outlook (Middle East and Africa, North America, Asia-Pacific, Europe, Latin America).

The report further includes the Market Summary, Industry Outlook, Parent Market Overview, Manufacturing Process Overview, Impact Analysis, Key Insights, Porter’s Five Forces Analysis, Market Maturity Analysis, Industry Components, Key Buying Impact Analysis, Regulatory Framework, Key Market Strategies, Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2023-2030).

Request Free Sample Report:

https://www.tritonmarketresearch.com/reports/synthetic-leather-market#request-free-sample

Based on Triton’s research report, the global synthetic leather market is deemed to witness revenue and volume growth at a CAGR of 7.48% and 7.26%, respectively, during the forecast period 2023-2030.

Synthetic leather is also known as faux or vegan leather resembling an animal’s skin. This material is formed by encasing natural or synthetic fibers in a plastic polymer or similar substance.

Several bio-based materials are employed for the production of synthetic leather, including flax, cotton, soybean, corn, etc. In recent years, pineapple leaves have been used to develop ‘Pinatex’ – a new synthetic leather product. They are primarily employed since they have flexible fiber, making them beneficial in manufacturing. Additionally, this process aids in reducing environmental harm. Hence, the growing use and demand for bio-based products create opportunities for the synthetic leather market.

However, different characteristics of synthetic to real leather and processing concerns pertaining to PU and PVC impedes the overall growth of the synthetic leather market.

The North America is estimated to witness the fastest growth over the forecast period. The growing innovations related to bio-based leather and rising concerns about animal rights support the market’s growth to a large extent. Further, there is a rising demand for formal footwear, along with vegan fashion, which has also elevated the adoption of synthetic leather to meet the demand. These trends have influenced players to increase R&D of artificial leather, thereby propelling the studied market on a growth path.

The major companies listed in the synthetic leather market include Mayur Uniquoters Limited, San Fang Chemical Industry Co Ltd, Achilles USA Inc, BASF SE, Nan Ya Plastics Corporation Inc, Teijin Limited, Alfatex Italia SRL, Kuraray Co Ltd, HR Polycoats Pvt Ltd, and Toray Industries Inc.

Large players have a wide geographic presence with strong pricing strategies. Moreover, the initial fixed costs are higher in the market. These factors have thus intensified the competition among existing players. Also, the established players own imported technologies and advanced R&D facilities, which significantly lowers the entry of players with less capital. Thus, the entry of new players is expected to be low or moderate, while the competition among players is likely to be high over the forecast period.

Contact Us:

Phone: +44 7441 911839

#Synthetic Leather Market#synthetic leather#polymer industry#chemicals and materials#polymers and resins#market research report#market research reports#triton market research

0 notes

Text

look alive, sunshine

#carrd material#transparent png#aesthetic#transparent#random moodboard#messy moodboard#pngs#random png#fashion png#mcr#my chemical romance#danger days

503 notes

·

View notes

Text

The Thermal Ceramic Market Size accounted for USD 4.2 Billion in 2022 and is estimated to achieve a market size of USD 7.4 Billion by 2032 growing at a CAGR of 5.9% from 2023 to 2032.

0 notes

Text

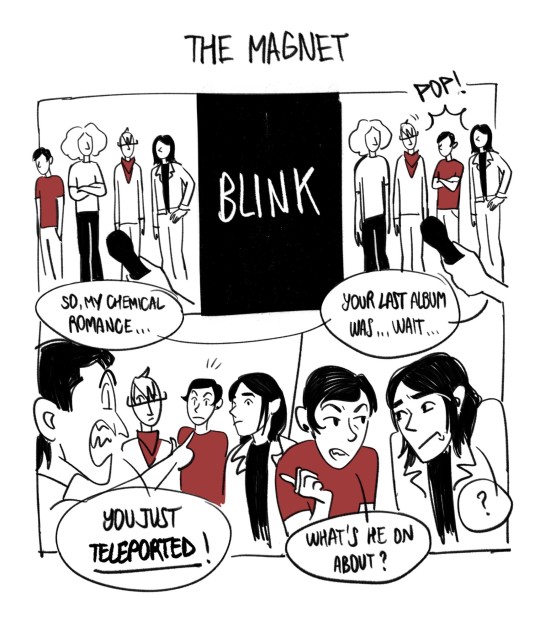

just something i find funny watching my chem interviews lol

#take a shot every time you see frank materialize next to g#my chemical romance#frank iero#gerard way#ray toro#mikey way#mcr#art#digital art#comics

950 notes

·

View notes

Text

PMK Oil CAS 28578-16-7

As an excellent chemical raw material supplier, Amarvelbio provides high-quality products and the best service.

0 notes

Photo

heard you guys like wet gerard way

#mcr#my chemical romance#gerard way#safe and sound#btw gotta say#kyosuke himuro????#quality dilf material in this video#no wonder gerard collabed

1K notes

·

View notes

Note

your posts today are how i found out if i ever went to japan i wouldn't be able to take my medication even with a letter (adderall)

the controlled substances list for japan is hysterical and bizarre and only gets funnier the longer you look at it

-there are only FOUR substances on planet earth that are straight up prohibited like cannot bring them in legally even with the correct paperwork

-they are heroin, methamphetamine, amphetamine (adderall).... and cannabis

-there are 3 laws that collectively deal with substances. the narcotics & psychotropics law, the stimulants & stimulants raw materials law.... and the cannabis law

-the latter 2 were clearly drafted later because the only things defined as "stimulants" are methamphetamine, amphetamine, and lisdexamphetamine. that's not a stimulants law that's an amphetamine law

-this means cocaine and MDMA are classed as narcotics not stimulants

-this means that technically, hypothetically, you could import cocaine easier than adderall

-THC is not defined as a cannabis product

-You can bring in THC as long as it is not derived from cannabis. Unsure how you prove that

-cannabidiol (CBD) is not on there at all

-so you can bring in CBD and THC but not cannabis

-flatpack cannabis. some assembly required.

-the result of this list is that cannabis is more illegal than cocaine, morphine, barbituates, MDMA, LSD, GHB, and fentanyl

-adderall is also more illegal than any of those

-dexamfetamine, which is the same drug as lisdexamfetamine but shorter acting (the body converts lisdexamfetamine into dexamfetamine that's why it's slower release) is not on the list at all

-on a legal technicality i will not be arguing at the border i could bring in dexamfetamine without any paperwork at all because they forgot it existed

-levoamphetamine also is not on the list

-lisdexamfetamine is the only thing labelled as a "stimulants raw material" the two actual stimulants raw materials (ie, component parts of amphetamine) are not on the list. lisdexamfetamine is not a component part of adderall, it's an altered version of a component part.

-technically you can make DIY adderall on the other side of the gate

-it would still be easier to get in with cocaine

#SORRY correction lisdexamfetamine is the only like. complete drug assigned SRM#the others are literal chemicals like. phenylacetone#but the point is neither of the actual complete drugs that are raw materials are on the list at all#and the one that is... isn't technically a raw material

353 notes

·

View notes