#Polyolefin Catalyst Market

Explore tagged Tumblr posts

Text

The Global Polyolefins Market: Trends, Challenges, and Opportunities

The polyolefins market is a cornerstone of the plastics and polymers industry, encompassing a range of versatile materials such as polyethylene (PE) and polypropylene (PP). These materials are widely used in various applications, from packaging and automotive parts to consumer goods and construction. As sustainability concerns and environmental regulations shape the industry, the polyolefins market is undergoing significant transformation. This article explores the latest trends, challenges, and opportunities in this dynamic sector.

Market Overview

Polyolefins, primarily polyethylene and polypropylene, account for a significant portion of the global plastics market. According to recent industry reports, the global polyolefins market is expected to continue growing steadily over the next decade, driven by increased demand from emerging economies, technological advancements, and the rise of e-commerce.

Polyethylene (PE): This is the most widely used polyolefin, with high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE) being the primary types. PE is commonly used in packaging, agriculture, and consumer goods.

Polypropylene (PP): Known for its versatility, PP is used in automotive components, textiles, and packaging. It offers high durability and resistance to heat and chemicals.

Trends in the Polyolefins Market

Sustainability and Circular Economy: As global awareness of environmental issues grows, there's increasing pressure on the plastics industry to adopt sustainable practices. Companies are exploring bio-based polyolefins, recyclable materials, and closed-loop recycling systems. The shift towards a circular economy is driving innovation in recycling technologies and the development of biodegradable polyolefins.

Advanced Manufacturing Technologies: Technological advancements, such as advanced catalysts and polymerization processes, are improving Polyolefins Market the efficiency and quality of polyolefins production. These innovations are helping to reduce energy consumption and emissions, contributing to the industry's sustainability goals.

Rising Demand from Emerging Markets: Emerging economies, particularly in Asia and Latin America, are experiencing significant industrial growth. This is driving demand for polyolefins in construction, packaging, and consumer goods. The expanding middle class in these regions also contributes to increased consumption of plastic products.

Lightweighting in Automotive and Transportation: The automotive industry is increasingly adopting lightweight materials to improve fuel efficiency and reduce emissions. Polyolefins, with their high strength-to-weight ratio, are becoming popular choices for automotive components, leading to further growth in this market segment.

Challenges Facing the Polyolefins Market

Environmental Regulations: Governments and environmental organizations are imposing stricter regulations on plastic production and disposal. The polyolefins industry must navigate these regulations while meeting market demand.

Plastic Waste and Recycling: The global challenge of plastic waste continues to pose a significant threat. The industry is under pressure to develop effective recycling solutions and reduce the environmental impact of polyolefins.

Volatility in Raw Material Prices: The price of raw materials, such as crude oil and natural gas, can impact the cost of polyolefins production. Fluctuations in these markets can affect profitability and pricing strategies.

Opportunities for Growth

Bio-based Polyolefins: The development of bio-based polyolefins presents a promising opportunity for the industry. These materials are derived from renewable sources and have a lower environmental impact, attracting environmentally conscious consumers.

Innovative Applications: As technology advances, new applications for polyolefins are emerging. From 3D printing to advanced textiles, the versatility of polyolefins offers ample room for innovation and market expansion.

Global Collaboration: The polyolefins industry can benefit from collaboration among stakeholders, including manufacturers, regulators, and environmental organizations. By working together, the industry can address sustainability challenges and drive positive change.

Buy the Full Report for Regional Insights into Polyolefins Market Download a Free Report Sample

0 notes

Text

Polyolefin Catalyst Market Size, Share, Trends, Forecast 2030

0 notes

Text

0 notes

Text

Global Alpha Olefin Market: Key Drivers, Challenges, and Strategic Opportunities

Increasing Demand for Polyolefins, Detergents, and Lubricants Drives Growth in the Alpha Olefin Market.

The Alpha Olefin Market Size was valued at USD 10.5 Billion in 2023 and is expected to reach USD 16.6 Billion by 2032 and grow at a CAGR of 5.3% over the forecast period 2024-2032.

The Alpha Olefin Market is fueled by increasing demand from the plastics, automotive, and industrial sectors. Alpha olefins are key intermediates used in the production of polyethylene (PE), synthetic lubricants, surfactants, plasticizers, and oil field chemicals. With their chemical versatility and wide-ranging applications, alpha olefins—such as 1-butene, 1-hexene, and 1-octene—are vital in producing high-performance materials. The market is also benefiting from advancements in metallocene catalyst-based polymerization technologies and the rising adoption of linear low-density polyethylene (LLDPE) in packaging and consumer goods.

Key Players:

Chevron Phillips Chemical Company LLC

Royal Dutch Shell plc

INEOS Oligomers

SABIC

ExxonMobil Chemical Company

Sasol Limited

Qatar Chemical Company Ltd.

Evonik Industries AG

Mitsubishi Chemical Corporation

Idemitsu Kosan Co., Ltd.

Future Scope & Emerging Trends:

The future of the Alpha Olefin Market is shaped by the growing demand for sustainable and high-performance polyolefins, especially in packaging, automotive parts, and industrial applications. As consumers and regulators push for eco-friendly plastics and lubricants, producers are focusing on cleaner, more energy-efficient production processes. Innovations in bio-based alpha olefins and circular economy initiatives are emerging, with companies exploring renewable feedstocks and advanced recycling techniques. Moreover, the rising demand for high-purity alpha olefins in synthetic lubricants, particularly in electric vehicles (EVs), is opening new growth avenues. Rapid industrialization and infrastructure development in Asia-Pacific and the Middle East are also driving alpha olefin consumption upward.

Key Points:

Alpha olefins are essential in plastics, lubricants, and chemical manufacturing.

Major applications include polyethylene production, surfactants, and oil field chemicals.

LLDPE demand and metallocene catalysts drive product innovation.

Shift toward sustainable and bio-based alpha olefins.

Asia-Pacific expected to lead global demand growth.

Growing use in EV lubricants and specialty chemicals.

Conclusion:

The Alpha Olefin Market is on a dynamic growth path, supported by innovations in polymer technologies, sustainable practices, and increasing demand across several key industries. As manufacturers invest in cleaner production methods and strategic expansions, the market will continue to evolve with a strong emphasis on efficiency, quality, and environmental responsibility.

Read Full Report: https://www.snsinsider.com/reports/alpha-olefin-market-4139

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Alpha Olefin Market#Alpha Olefin Market Size#Alpha Olefin Market Share#Alpha Olefin Market Report#Alpha Olefin Market Forecast

0 notes

Text

Global Amorphous Polyolefin Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2030

Amorphous poly-alpha-olefins (APAO/APO) are produced by (co-) polymerisation of α-olefins, e.g. propylene or 1-butene with Ziegler-Natta catalysts. The (co-)polymers have an amorphous structure which makes them useful for the production of hot melt adhesives. According to our (Global Info Research) latest study, the global Amorphous Polyolefin market size was valued at USD 476.4 million in 2022 and is forecast to a readjusted size of USD 600 million by 2025 with a CAGR of 3.3% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. Currently, there are five major suppliers, such as Evonik, Eastman, REXtac, Liaoyang Liaohua Qida Chemicals and Hangzhou Hangao. Evonik is world largest player with about 41% market shares. This report is a detailed and comprehensive analysis for global Amorphous Polyolefin market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided.

Sample Plan: https://www.reportsintellect.com/sample-request/2911767 Key Features: Global Amorphous Polyolefin market size and forecasts, in consumption value ($ Million), sales quantity (K MT), and average selling prices (USD/MT), 2018-2030 Global Amorphous Polyolefin market size and forecasts by region and country, in consumption value ($ Million), sales quantity (K MT), and average selling prices (USD/MT), 2018-2030 Global Amorphous Polyolefin market size and forecasts, by Type and by Application, in consumption value ($ Million), sales quantity (K MT), and average selling prices (USD/MT), 2018-2030 Global Amorphous Polyolefin market shares of main players, shipments in revenue ($ Million), sales quantity (K MT), and ASP (USD/MT), 2018-2025

Inquire Request: https://www.reportsintellect.com/discount-request/2911767 The Primary Objectives in This Report Are: To determine the size of the total market opportunity of global and key countries To assess the growth potential for Amorphous Polyolefin To forecast future growth in each product and end-use market To assess competitive factors affecting the marketplace This report profiles key players in the global Amorphous Polyolefin market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments. Key companies covered as a part of this study include Evonik, Eastman, REXtac, Liaoyang Liaohua Qida Chemicals and Hangzhou Hangao. etc. This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence. Market Segmentation Amorphous Polyolefin market is split by Type and by Application. For the period 2018-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets. Market segment by Type Propylene Homopolymer Copolymer of Propylene and Ethylene Propylene Homopolymer and Ethylene Copolymer Others Market segment by Application Hot Melt Adhesive and Pressure Sensitive Adhesive Bitumen Modification Polymer Modification Others Major players covered Evonik Eastman REXtac Liaoyang Liaohua Qida Chemicals Hangzhou Hangao Market segment by region, regional analysis covers North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

0 notes

Text

0 notes

Text

0 notes

Text

Polypropylene Compounds Market Primed for Growth Driven by Rising Use in Automotive Industries

The polypropylene compounds market involves manufacturing of polyolefin and polyolefin compounds. Polypropylene compounds are used in automotive, packaging, medical and construction industries owing to their heat resistance and durability properties. The automotive industry widely uses polypropylene compounds in interior and exterior automotive parts like battery casings, seat covers, bumpers and instrument panels.

The global polypropylene compounds market is estimated to be valued at US$ 26.74 Mn in 2024 and is expected to exhibit a CAGR of 3.6% over the forecast period 2024 to 2031. Key Takeaways Key players operating in the polypropylene compounds market are Albemarle Corporation (US), W R Grace (US), BASF (Germany), Haldor Topsoe (Denmark), Honeywell UOP (US), Clariant (Switzerland), Axens (France), Johnson Matthey (UK), China Petroleum and Chemical Corporation (Sinopec) (China), and Shell Catalyst & Technologies (Netherlands), Arkema (France), Anten Chemicals (China), Chempack (China), Dorf-Ketal Chemicals Pvt. Ltd. (India), Exxon Mobil Corporation (US), Gazprom (Russia), JGC Catalyst and Chemicals (Japan),KNT Group (Russia), Kuwait Catalyst (Kuwait), N.E.Chemcat (Japan), Porocel (US), Qingdao Huicheng Environmental Technology (China), Taiyo Koko Co. Ltd. (Japan), Unicat Catalyst Technologies (US), and Yueyang Sciensun Chemicals (China). Growing demand for polymer compounds from automotive and packaging industries is presenting huge growth opportunities in the polypropylene compounds market. Additionally, rising demand from emerging economies of Asia Pacific and Latin America is fueling the global expansion of the polypropylene compounds market. Market Drivers The automotive industry is expected to remain the key end user of Polypropylene Compounds Market Growth, driven by rising vehicle production across the globe. As per forecasts, global vehicle production is projected to reach 117 million units by 2024 from around 93 million units in 2020. This rising automotive production will drive the demand for polymer compounds used in various interior and exterior automotive parts.

Get more insights on Polypropylene Compounds Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

Thermoplastic Polyolefin Market: Current Trends and Future Prospects

Thermoplastic polyolefin (TPO) is a significant segment within the polymer market, primarily known for its versatility, resilience, and economic viability. TPOs are a blend of polypropylene (PP), polyethylene (PE), and an elastic component, often making them a preferred material in various applications. This article delves into the current trends, drivers, and future prospects of the thermoplastic polyolefin market.

Market Overview

The thermoplastic polyolefin market has witnessed substantial growth over the past decade, driven by increasing demand from the automotive, construction, and packaging industries. The unique properties of TPOs, such as their high impact resistance, flexibility, and ease of processing, make them ideal for a wide range of applications.

Key Drivers

1. Automotive Industry:

The automotive industry is one of the largest consumers of TPOs. The material's lightweight nature and superior durability make it an ideal choice for automotive parts such as bumpers, interior trims, and dashboard skins. The growing trend towards lightweight vehicles to improve fuel efficiency and reduce emissions has further boosted the demand for TPOs in this sector.

2. Construction Sector:

TPOs are extensively used in the construction industry, particularly in roofing membranes. The material's resistance to UV radiation, weathering, and chemical exposure ensures long-lasting performance in roofing applications. The ongoing growth in the construction sector, particularly in emerging economies, is a significant driver for the TPO market.

3. Sustainability:

Environmental concerns and the push towards sustainable materials have positively impacted the TPO market. TPOs are fully recyclable and can be reprocessed without losing their inherent properties, making them a preferred choice for eco-friendly applications.

4. Advancements in Manufacturing:

Technological advancements in polymer processing have enhanced the quality and performance of TPOs. Innovations such as improved catalysts and polymerization techniques have led to the development of TPOs with superior properties, further driving market growth.

Regional Analysis

North America: The North American market for TPOs is well-established, with significant demand from the automotive and construction sectors. The presence of major automotive manufacturers and a robust construction industry are key factors driving the market in this region.

Europe: Europe is another prominent market for TPOs, driven by stringent environmental regulations and a strong emphasis on sustainable materials. The region's well-developed automotive industry also contributes to the demand for TPOs.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth in the TPO market, fueled by rapid industrialization, urbanization, and economic development in countries like China and India. The expanding automotive and construction industries in these countries are major growth drivers.

Latin America and Middle East & Africa: These regions are gradually emerging as significant markets for TPOs, with increasing construction activities and growing automotive industries. However, market penetration is still relatively low compared to North America, Europe, and Asia-Pacific.

Request for a sample of the report browse through – https://univdatos.com/get-a-free-sample-form-php/?product_id=26877

Future Prospects

The future of the thermoplastic polyolefin market looks promising, with several trends expected to shape its growth trajectory:

1. Increased Focus on Sustainability:

The global emphasis on sustainability and the circular economy is likely to drive the demand for recyclable materials like TPOs. Innovations aimed at improving the recyclability and environmental performance of TPOs will play a crucial role in market growth.

2. Technological Advancements:

Continuous advancements in polymer processing technologies will lead to the development of TPOs with enhanced properties, expanding their application scope and driving market growth.

3. Expansion in Emerging Markets:

Emerging economies, particularly in Asia-Pacific, Latin America, and the Middle East, offer significant growth opportunities for the TPO market. The rapid industrialization and urbanization in these regions are expected to drive demand for TPOs in various applications.

4. Automotive Industry Evolution:

The evolution of the automotive industry, with a focus on electric and hybrid vehicles, will create new opportunities for TPOs. Lightweight materials like TPOs will be crucial in developing energy-efficient vehicles.

Conclusion

The thermoplastic polyolefin market is poised for significant growth, driven by increasing demand from various end-user industries, technological advancements, and a strong emphasis on sustainability. As industries continue to seek durable, lightweight, and eco-friendly materials, TPOs are set to play a crucial role in meeting these demands, ensuring a bright future for the market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Polyolefins Market Trends, Revenue, Size-Share, Growth Drivers, Challenges, Demand, Business Opportunities, Challenges and Competitive Analysis 2032: SPER Market Research

Polyolefin belongs to the thermoplastic family. It is mainly made from natural gas and oil through the polymerization of ethylene and propylene, respectively. It is made from olefins, hydrocarbons, and monomers and has excellent processability, chemical stability, and long-term durability. It is the most frequently used thermoplastic polymer, utilized in a variety of industries including packaging, consumer goods, and fiber and textiles. Polyolefin is a polymer formed by the polymerization of monomer olefin in the presence of a suitable catalyst. Common polyolefins include polyethylene and polypropylene. These chemicals are widely employed in a variety of applications across sectors. Some of the most significant polyolefin-consuming industries include automotive, construction, electrical and electronics, and packaging.

According to SPER Market Research, ‘Polyolefins Market Size- By Type, By Application- Regional Outlook, Competitive Strategies and Segment Forecasts to 2032’ states that the Global Polyolefins Market is estimated to reach USD 487.46 billion by 2032 with a CAGR of 5.23%.

Numerous factors contribute to the growth of the global polyolefins market, including the development of the solar power industry and an increase in demand from the packaging industry in industrialized nations. On the contrary, the growth of the packaging industry in developing nations such as India and China is likely to provide profitable prospects for market participants over the projection period. Polyolefin is easily transformed into fibrous structures such as nonwovens, knitted textiles, and yarns. Thus, it is widely employed in the textile sector. The rise of the global textile sector is driving up demand for polyolefin. Furthermore, increasing research and development activities by market participants may result in the possible application of polyolefin with nanotechnologies that can be applied across a variety of sectors. Advancements and advancements in polyolefin fibers are projected to expand their medicinal applications. Furthermore, the increasing demand for sheets and films from the construction and buildings is expected to drive the market expansion.

The high cost of polyolefin, rising environmental concerns, and challenges with plastic disposal may limit industry growth. Furthermore, shifting crude oil prices will put the market's growth pace at risk. However, variable raw material prices impede market expansion. Volatility in the cost of primary substances is a barrier to polyolefin production because as the price of raw materials rises, so do the costs of polyolefins. The government's efforts to limit the use of plastic pose a significant hurdle. The need for sustainable solutions has reached high. Consumers' increased use of non-plastic materials may hinder market growth in the future.

Request For Free Sample Report @ https://www.sperresearch.com/report-store/polyolefins-market.aspx?sample=1

The COVID-19 epidemic has resulted in the partial or entire suspension of non-essential industrial facilities in major countries such as the United States, China, Japan, India, and Germany. It has suspended the production activity in the majority of industrial units around the world. The COVID-19 outbreak has impacted both demand and production of polyolefins. The proliferation of COVID-19 in many countries throughout the world interrupted manufacturing activity in industries including automotive and construction, resulting in a fall in demand for polyolefins. The worldwide health crisis has a significant influence on raw materials in the chemical industry supply chain.

Asia-Pacific dominates this market. Some of the key players are Exxon Mobil Corp Braskem, Chevron Corp., Borealis AG, Dow, Exxon Mobil Corp.

Our in-depth analysis of the Polyolefins Market includes the following segments:

By Type:

Ethylene-Vinyl Acetate

Polyethylene

Polypropylene

Polystyrene

By Application:

Blow Molding

Film & Sheet

Injection Molding

Profile Extrusion

By Region:

Asia-Pacific

Europe

Middle East & Africa

North America

Latin America

For More Information, refer to below link:-

Polyolefins Market Outlook

Related Reports:

Metallic Powder Coatings Market Size- By Process Type, By Pigment Type, By Resin Type- Regional Outlook, Competitive Strategies and Segment Forecast to 2033

Asia-Pacific Wood Charcoal Market Size- By Type, By Application- Regional Outlook, Competitive Strategies and Segment Forecast to 2033

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant – U.S.A.

SPER Market Research

+1-347-460-2899

#Polyolefins Market#Polyolefins Market Analysis#Polyolefins Market Challenges#Polyolefins Market Competition#Polyolefins Market Demand#Polyolefins Market Forecast#Polyolefins Market Future outlook#Polyolefins Market Growth#Polyolefins Market Opportunity#Polyolefins Market Overview#Polyolefins Market Research Report#Polyolefins Market Revenue#Polyolefins Market segmentation#Polyolefins Market Share#Polyolefins Market Size#Polyolefins Market Top Industry Players#Polyolefins Market Trends#USA Polyolefins Market#Canada Polyolefins Market#Europe Polyolefins Market#Global Polyolefins Market

0 notes

Text

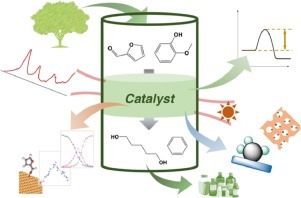

Catalyst Market: Charting New Pathways for Growth in an Evolving Market

The global catalyst market size is expected to reach USD 42.63 billion by 2030, as per the new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 4.6% from 2024 to 2030. Catalyst refers to the class of compounds or chemicals that enables a chemical reaction to proceed at a pace faster than otherwise possible. Depending on the similarity or dissimilarities of the catalyst with the reactants, a catalyst can be either homogeneous or heterogeneous. Therefore, based on product type, the market is segmented as homogeneous and heterogeneous catalysts.

Catalyst Market Report Highlights

Chemical compounds dominated the market with a volume share of 39.8% in 2023, it is used as catalyst raw materials for numerous applications in chemical, petrochemical, and polymer industries

Homogenous is predicted to witness the fastest growth, in terms of revenue, with a CAGR of 4.9% from 2023 to 2030. The growing popularity of organometallic compounds to produce polyethylene and polypropylene is further expected to fuel their demand in the near future

Asia Pacific dominated the catalyst market with a volume share of 34.8% in 2023. This can be attributed to the rapid development of the chemical industry, predominantly in the emerging economies of the region such as China and India

In June 2020, Albemarle Corporation entered into a definitive agreement with W. R. Grace & Co. for selling its polyolefin catalyst and components business for a value of around USD 416 million

With the escalating demand from applications including chemical synthesis, petroleum refining, polymers and petrochemicals, and environmental there has been an upsurge in demand for catalysts for process optimization, yield improvement, cost-saving, and energy saving amongst the manufacturers globally

For More Details or Sample Copy please visit link @: Catalyst Market Report

The raw materials used for catalyst manufacturing include acids, peroxides, and amines, which are generally classified as chemical compounds. Metals including precious metals and base metals besides zeolites are the prominent raw material market segments. A catalyst finds numerous applications in end-use industries such as chemicals (adsorbents, polyolefins); petroleum refining (alkylation, hydrotreating, hydrocracking, catalytic reforming); polymers and petrochemicals; and automotive (motorbikes, light-duty, and heavy-duty vehicles) owing to the benefits obtained by the application of a catalyst in any particular chemical reaction.

The global market has witnessed a significant growth rate over the past few years owing to the benefits it has gained from high-value product segments. For instance, the application of catalysts in an automobile reduces carbon emissions that are harmful to the environment and, thus, their application is highly promoted by governments globally. Favorable government regulations, in turn, have increased the demand for catalysts in the automotive industry across regions.

Catalysts are increasingly being used to reduce the processing time of crude oil refining along with improving refining equipment efficiency. These factors are likely to fuel the demand for catalysts over the projected forecast period. However, volatile prices of raw materials, including gold and platinum, are expected to hamper the manufacturing output of catalysts, thereby restraining the market growth. Nonetheless, the introduction of biocatalysts is expected to open new avenues for the market over the forecast period.

Key market players include BASF, Johnson Matthey, W.R. Grace, Albemarle Corporation, Evonik Industries AG, and DuPont. In July 2014, Johnson Matthey Process Technologies established a new production site in Brazil which manufactures catalyst for captive hydrogen production in the refining sector. This initiative was taken to ensure product supply to refining companies located in Latin America over the next eight years.

#Catalysts#ChemicalIndustry#CatalystMarket#CatalystTechnology#CatalystApplications#CatalystInnovation#CatalystManufacturing#CatalystSupplyChain#CatalystResearch#CatalystTrends#CatalystDemand#CatalystFuture#SustainableCatalysts#GlobalCatalystMarket#CatalystIndustry#CatalystAnalysis#CatalystDynamics#CatalystPerformance#CatalystSolutions

0 notes

Text

Battery Separators Market Growth, Global Survey, Analysis, Share, Company Profiles and Forecast by 2027

The battery separator market is anticipated to witness tremendous growth owing to rising investments in automotive sectors, wide-scale usage of polypropylene, and surging adoption of lead acid batteries. Increasing demand for efficient batteries in numerous end-use industries such as automotive, consumer electronics, and industrial among many others will also influence the business landscape.

A battery separator is essentially a polymeric membrane positioned between the negatively charged cathode and positively charged anode in order to prevent an electrical short circuit.

The separator is basically a microporous layer which is dampened by the electrolyte acting as a catalyst to surge the ions movement from one electrode to another. When the battery gets discharged the ions tend to move in the reverse direction. Whereas when the battery is being charged the ions move from cathode to anode. Here, the separator controls the various ions moving between the negative and positive terminal, thus it is mainly responsible for the leakage of ions when the battery is supreme.

Get sample copy of this research report @https://www.gminsights.com/request-sample/detail/3547

The battery separator market is segmented in terms of product, battery, end-user, and regional landscape.

Based on product, the market for battery separator is classified into nylon, ceramic, PE, PP, and others. In 2020, polypropylene generated a revenue of over $1.8 billion and will exhibit strong growth over the coming years. Polypropylene is widely used in the consumer electronics sector largely because of its low price.

With respect to battery, the battery separator market is categorized into lead-acid, lithium ion, and others. Among these, lead acid battery segment will witness a respectable CAGR of around 16.2% over the projected time period. Earlier, lead acid battery separators included polyolefins, organic rubber, cellulose, and polyvinyl chloride. At present, most of the flooded lead acid batteries use polyethylene separators, a misnomer since these microporous separators need huge quantities of precipitated silica to be acid-wettable.

In terms of end-user, the overall battery separator market is bifurcated into power storage, industrial, consumer electronics, automotive, and others. In 2020, consumer electronics segment held a market share of around 25% and is anticipated to witness strong growth over the coming years.

The industrial segment is considered to be one of the most prominent end users of the battery separator market. The power storage segment accounted for a market share of over 5.6% in 2020 and is likely to foresee robust growth over the coming years.

From a regional frame of reference, North America battery separator is projected to witness a 15.2% CAGR over the forecast time period. This anticipated growth is ascribed to the rising investments in automotive sectors.

Read Full Report Description @ https://www.gminsights.com/industry-analysis/battery-separator-market

Meanwhile, in 2020, Middle East held a market share of 5% and is expected to showcase a healthy growth rate over the study time period.

About Global Market Insights

Global Market Insights Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy, and biotechnology.

Contact Us

Aashit Tiwari Corporate Sales, USA Global Market Insights, Inc. Phone: 1-302-846-7766 Toll Free: 1-888-689-0688 Email: [email protected]

0 notes

Text

Polyolefin Catalyst Market – Forecast (2021-2026)

Polyolefin catalyst market size is forecast to reach $3.6 billion by 2026, after growing at a CAGR of 4.9% during 2021-2026. The polyolefin polymerization using the Ziegler-Natta catalysts, polyolefin has become one of the most important polymers produced industrially. In particular, polyethylene, polypropylene and ethylene propylene diene monomer (EPDM) rubber have been widely used for catalysis. The rapid growth of the packaging industry has increased the demand for polyolefin catalysts; thereby, fueling the overall market growth. In addition, increased R&D investment on new manufacturing technologies, along with capacity expansion for polyolefin plants, would also boost product demand in the coming years. Furthermore, the flourishing automotive and packaging industry is also expected to drive the polyolefin catalyst industry substantially during the forecast period.

Polyolefin Catalyst Market COVID-19 Impact

Companies were moving steadily towards their sustainability targets before COVID-19. However, a multitude of industries around the world, especially the packaging industry, have been adversely affected by the coronavirus pandemic. Innovative developments have been developed by packaging companies that are environmentally friendly, reusable, and biodegradable. Concerns over the hygiene and safety of recycled packaging, however, have temporarily stalled the progress of the packaging industry towards a healthy, evolving and circular supply chain. The use of polyolefin catalysts such as single-site catalyst and ziegler-natta catalyst for injection molding also suddenly halted, contributing to a major loss in the polyolefin catalysts market. Thus, there was a disruption in the supply and demand of packaging materials owing to the pandemic, which largely impacted the polyolefin catalyst market.

Report Coverage

The report: “Polyolefin Catalyst Market – Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the polyolefin catalyst Industry.

By Resin: Polyethylene (High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), and Others), Polypropylene (PP), and Ethylene Propylene Diene Monomer (EPDM) Rubber.

By Catalyst Type: Ziegler-Natta catalyst, Single Site catalyst (Metallocene, and post-Metallocene), Chromium catalyst, and Others.

By Application: Injection Molding, Extrusion Molding, Blow Molding, Films, Fibers, Foam, and Others.

By End-Use Industry: Automotive (Passenger Cars, Light Commercial Vehicles (LCV), Heavy Commercial Vehicles (HCV), and Others), Packaging (Food & Beverages, Cosmetics, and Others), Medical & Healthcare (Medical Packaging, Bone Substitute, Drug Delivery, Tissue Adhesive, and Others), and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Request Sample

Key Takeaways

Asia-Pacific dominates the polyolefin catalyst market, owing to the increasing demand for the packaging materials in the region. The increasing per capita income coupled with the population growth is a key factor in the region's rising personal care and cosmetic products industry.

The demand for packaging has pushed steadily towards lightweight and translucent materials. This has resulted in a rising market for films with polyolefin.

The increasing commercial performance of polyolefin materials in various end-user segments, including automotive, food and beverage and packaging, among others, is expected to contribute significantly during the forecast period to the overall demand for catalysts.

Polyolefin Catalyst Market Segment Analysis - By Resin

The polypropylene and polyethylene segment held a significant share in the polyolefin catalyst market in 2020 and is growing at a CAGR of 5.6% during 2021-2026. Polypropylene is being utilized in everything from drinking straws and food containers and reusable water bottles, to thermal underwear, roofing materials, marine ropes and carpet. Polypropylene, the polymerized embodiment of propylene, is both solid and versatile (hence its use in drinking straws), highly resistant to heat (making it useful in laboratory research applications) and lightweight. By polymerizing ethylene, polyethylene (PE) is formed. It is the most common type of plastic that occurs everywhere, from plastic bags and bottles to electrical cable insulation and water pipes. Such wide application of polypropylene and polyethylene is the major factor driving the segment growth.

Polyolefin Catalyst Market Segment Analysis - By Catalyst Type

The Ziegler-Natta catalyst segment held the largest share in the polyolefin catalyst market in 2020. Because of their wide use in the production of polypropylene, high density polyethylene, and linear low-density polyethylene, Ziegler-Natta catalysts are the most common. Ziegler-Natta catalyst is used by over 90% of global polypropylene production, while ziegler-Natta catalyst is used by more than 50 percent in all cases in polyethylene production. Another big catalyst used mostly to manufacture high density polyethylene is the Phillips or chromium catalyst (HDPE). The catalyst used for the development of polypropylene is mainly a titanium-based ZN catalyst enabled by aluminium alkydes and external donors, whereas the catalyst used for HDPE comprises titanium, Phillips and metallocene systems. Linear low density polyethylene use over 80% of Ziegler Natta catalyst and metallocene catalyst at a lesser extent.

Polyolefin Catalyst Market Segment Analysis - By Application

The film segment held the largest share in the polyolefin catalyst market in 2020 and is growing at a CAGR of 5.4% during 2021-2026. Among the different polymers that are used in film extrusion, polyethylene (HDPE, LDPE and LLDPE) is the main polymer. PVC films are increasingly being replaced by polyolefin films because they are safer for food packaging and more stable in a wide range of temperatures. In 2018, approximately 2.53 million tonnes of plastic films and sheets were manufactured in Japan, according to the Ministry of Economy, Trade, and Industry, Japan, reflecting a small increase from about 2.46 million tonnes in 2016. This increase can be attributed to the increasing packaging industry in various regions. Thus, the continuous growth of these industries has made films the largest and fastest-growing segment under the application segmentation of the market during the forecast period.

Polyolefin Catalyst Market Segment Analysis - By End-Use Industry

The packaging segment held the largest share in the polyolefin catalyst market in 2020 and is growing at a CAGR of 5.9% during 2021-2026, owing to the increasing usage of polyolefins in the packaging industry. Polyolefins are chemically inert and do not react with the contents of the material. This makes them perfect food packaging materials. No hazardous chemicals, additives or goods are present that can be ingested by the contents of the packaging and thus consumed by the consumer. Polyolefins, when in contact with food, are extremely healthy. It can then be used to manufacture anything from lightweight food packaging wrap to much heavier film for agricultural use, depending on the thickness of the film. According to the Sea-Circular Organization, the packaging industry in China is projected to record a Compound Annual Growth Rate (CAGR) of 13.5 percent during the forecast period (2021-2026). It is anticipated that the flourishing packaging industry will accelerate the growth of polyolefin catalyst market for manufacturing packaging materials.

Polyolefin Catalyst Market Segment Analysis - By Geography

Asia-Pacific region held the largest share in the polyolefin catalyst market in 2020 up to 38%, owing to the flourishing food & beverage industry, which is boosting the demand for packaging materials in the region. According to the United States Department of Agriculture (USDA), in 2018, the total value of all retail food and beverage sales in Japan was $479.29 billion (¥53,339 billion), an overall increase of 2.3 percent. According to the United States Department of Agriculture (USDA), China’s food processing industry continued to grow in 2017. Revenue climbed to $1.47 trillion, an increase of 6.3 percent compared with the previous year. The rising disposable income has resulted in the increasing demand for the food and beverage industry in various regions, which is further driving the growth of the packaging material in the region. And with the increasing demand for packaging materials in the region, the demand for polyolefin to manufacture packaging materials will substantially increase, which will then drive the polyolefin market growth in Asia Pacific during the forecast period.

Inquiry Before Buying

Polyolefin Catalyst Market Drivers

Increasing Automotive Production

Polyolefins in automobiles have experienced a great deal of interest in the recent years, and their applications have been increasing with a tendency of further growth compared with other materials used in automobiles. The major advantages of polyolefin catalysts are their functionality, cost-effective manufacturing methods, and comparatively lower fuel consumption. In automobiles, the polyolefin catalysts are largely used in the internal and external areas, in the engine section, and in the bodywork. The automotive production is increasing. For instance, the Automotive Mission Plan 2016-26 (AMP 2026) initiatives is launched by the Indian government to boost the automotive industry in the country. According to Organisation Internationale des Constructeurs d'Automobiles (OICA), the production of passenger cars in Africa was 776,967 in 2018, which then rose to 787,287 in 2019, an increase of 1.3%. Thus, increasing automation production will require more polyolefin catalyst, which will act as a driver for the polyolefin catalyst market.

Increasing Demand for Polyolefins from the Healthcare Industry

In the medical and healthcare sectors, polyolefin catalysts has recently gained traction as they are easy to fabricate into useful products and have increasing design capability. They also have the potential for use in many applications because of their excellent cost/performance values such as low density, easy recyclability, and diverse processability. Biomedical applications of these POs are in medical implants, medical devices, and in the production of pharmaceutical consumables in the form of packaging materials; vials, bottles, and syringes. And the growing investment in healthcare services is strengthening the healthcare industry. For instance, in 2018, the Australian Government announced to drive a new era of better health care in Australia and will invest $1.3 billion in the Health and Medical Industry Growth Plan. According to the European Commission, public expenditure on healthcare and long-term care is expected to increase by one-third by 2060 in Europe. Thus, the polyolefin catalysts market growth will be spurred by the rapid expansion of the healthcare industry across the regions

Polyolefin Catalyst Market Challenges

Volatility in Crude Oil Prices

Polyolefin catalyst is a derivative of crude oil and its domestic price is highly susceptible to the prices of its crude oil-derived feedstock. Both polyethylene and polypropylene are produced from crude oils; thus, increases in feedstock prices in turn hamper the overall production, adversely affecting the market for catalysts. In the last few years, there has been volatility in the price of crude oil. For instance, the price of crude oil has decreased from $98.95/bbl in 2014 to $52.39/bbl in 2015 and increased from $43.73/bbl in 2016 to $71.31/bbl in 2018 and then decreased to $64.21/bbl in 2019, according to the BP Statistical Review of World Energy. And because of this uncertainty in crude oil prices, the price of polyolefin catalysts also increases, which is expected to be a significant challenge for the polyolefin catalyst market manufacturers during the forecast period.

Buy Now

Polyolefin Catalyst Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the polyolefin catalyst market. Major players in the polyolefin catalyst market are W.R. Grace, Univation Technologies, LLC, LyondellBasell Industries N.V., Johnson Matthey Inc., TOHO Titanium Company Limited, Idemitsu Kosan Co., Ltd., INEOS Group, Mitsui Chemicals, Inc, Clariant AG, Evonik Industries, DuPont, Inc., DORF-KETAL Chemicals India Private Limited, AGC Chemicals Inc., and NOVA Chemicals Corporation.

Acquisitions/Technology Launches

In March 2020, LyondellBasell signed definitive agreements to expand in China with the Liaoning Bora Enterprise Group through a 50-50 joint venture. Under the agreement, the partners formed a Sino-foreign joint venture, the Bora LyondellBasell Petrochemical Co. Ltd, which operated a 1.1 million metric tons per annum ethylene cracker and associated polyolefin derivatives complex in Panjin, China.

In November 2019, PQ Group Holdings Inc. signed an agreement with INEOS Polyolefin Catalysts to commercialize certain polyethylene catalysts to customers of selected processes. This collaboration expanded PQ’s current catalyst product offering to its customers. In addition, enabled PQ to access new customers through an enhanced product offering and associated technical support.

Relevant Reports

Polyolefin Foam Market – Forecast (2021 - 2026)

Report Code: CMR 1179

Polyethylene Catalyst Market – Forecast (2021 - 2026)

Report Code: CMR 1325

For more Chemicals and Materials Market reports, Please click here

0 notes

Link

polyolefin catalyst market size was USD 2.2 billion in 2022 and shall exhibit a 4.5% CAGR throughout the forecast period

0 notes

Text

Asia-Pacific Region will Aribute Towards the Polyolefins Market Growth through Forecast Period| MarketsandMarkets™

Asia-Pacific Region will Aribute Towards the Polyolefins Market Growth through Forecast Period| MarketsandMarkets™

The report “global Polyolefins Market by Type (Polethylene, Polypropylene, and Functional Polyolefins, Application (Film & Sheet, Injection Molding, Blow Molding, Fibers & Raffia), and Region – Global Forecasts to 2021”, The market size of PO is estimated to grow from USD 206.81 Billion in 2015 to USD 297.09 Billion by 2021, at a CAGR of 7.82% between 2016 and 2021. The Polyolefins market size is…

View On WordPress

#additives for polyolefins#COVID 19 impact on Polyolefins Market#crosslinked polyolefin#demand for polyolefins#expanded polyolefin#Functional Polyolefins#market size of polyolefins#metallocene polyolefin#plastomers market#Polethylene#polyolefin catalyst market#polyolefin elastomers market#polyolefin fibers#polyolefin shrink film market#Polyolefins Industry#Polyolefins Market#Polyolefins Market Forecast#Polyolefins Market Growth#Polyolefins Market Key Players#Polyolefins Market share#polypropylene#Sales of Polyolefins#thermoplastic polyolefin

0 notes

Text

Polyolefin Catalyst Market Research On Chemical Advancements 2021 to 2026: BASF

The global research report titled “Polyolefin Catalyst Market” has recently been published by The Research Insights which helps to provide guidelines for the businesses. It has been aggregated based on different key pillars of businesses such as drivers, restraints, and global opportunities. This Polyolefin Catalyst Market research report has been compiled by using primary and secondary research techniques. Finally, researchers direct their focus on some significant points to give a gist about investment, profit margin, and revenue.

(Get Impressive Discount)

Download a Sample Copy of This Report(including full TOC, Tables and Figures):

https://www.theresearchinsights.com/request_sample.php?id=369378&mode=Arundhati

The report presents the market competitive landscape and a corresponding detailed analysis of the major vendor/key players in the market. Top Companies in the Global Polyolefin Catalyst Market: BASF, Chevron Phillips Chemical, Clariant International, DuPont, Eastman Chemical, Evonik Industries, Exxon Mobil, Ineos Technologies, Johnson Matthey, Nova Chemicals

This report segments the global Polyolefin Catalyst Market based on Types are:

Lynx Polypropylene Catalysts

Lynx Polyethylene Catalysts

Others

Based on Application, the Global Polyolefin Catalyst Market is segmented into:

Laboratory

Chemical Production

Others

Buy Exclusive Report @:

https://www.theresearchinsights.com/checkout?id=369378&mode=Arundhati

Regional analysis of Global Polyolefin Catalyst Market:

Geographically, the global Polyolefin Catalyst Market has been fragmented into several regions such as North America, Latin America, Asia-Pacific, Africa, and Europe based on the productivity of several companies. Every segment along with its sub-segments is analyzed in the research report. The competitive landscape of the market has been elaborated by studying numerous factors such as top manufacturers, prices, and revenue.

The information on the global Polyolefin Catalyst Market is accessible to readers in a logical chapter-wise format. Driving and restraining factors have been listed in this research report, which helps to understand positive and negative aspects in front of the businesses.

Access Full Report information with TOC, here:

https://www.theresearchinsights.com/reports/COVID19-Global--China-Polyolefin-Catalyst-Market-Research-by-Company-Type--Application-20152026-369378?mode=Arundhati

What are the market factors that are explained in the report?

-Key Strategic Developments: The Polyolefin Catalyst Market study also includes the key strategic developments of the market, comprising R&D, new product launch, M&A, agreements, collaborations, partnerships, joint ventures, and regional growth of the leading competitors operating in the market on a global and regional scale.

-Key Market Features: The Polyolefin Catalyst Market report evaluated key market features, including revenue, price, capacity, capacity utilization rate, gross, production, production rate, consumption, import/export, supply/demand, cost, market share, CAGR, and gross margin. In addition, the study offers a comprehensive study of the key market dynamics and their latest trends, along with pertinent market segments and sub-segments.

-Analytical Tools: The Global Polyolefin Catalyst Market report includes the accurately studied and assessed data of the key industry players and their scope in the market using several analytical tools. The analytical tools such as Porter’s five forces analysis, SWOT analysis, feasibility study, and investment return analysis have been used to analyze the key players' growth in the market.

Customization of the Report: This report can be customized as per your needs for additional data up to 3 companies or countries or 40 analyst hours.

About us:

The Research Insights – A global leader in analytics, research, and advisory that can assist you to renovate your business and modify your approach. With us, you will learn to take decisions intrepidly. We make sense of drawbacks, opportunities, circumstances, estimations, and information using our experienced skills and verified methodologies. Our research reports will give you an exceptional experience of innovative solutions and outcomes. We have effectively steered businesses all over the world with our market research reports and are outstandingly positioned to lead digital transformations. Thus, we craft greater value for clients by presenting advanced opportunities in the global market.

Contact us:

Robin

Sales manager

Contact number: +91-996-067-0000

https://www.theresearchinsights.com

0 notes