#Polyvinyl Chloride Business

Text

Polyvinyl Chloride Market Size, Trends & Growth | Industry Analysis Upto 2030

The global polyvinyl chloride market is predicted to touch USD 72.0 billion at a 4.5% CAGR over the forecast period (2022-2030), states the latest Market Research Future (MRFR) report. Polyvinyl chloride or PVC is basically a synthetic resin that is created from vinyl chloride polymerization. It is highly preferred over traditional materials, which include wood, copper, or iron in several profile applications owing to multiple benefits, alluring features, and operational efficiencies. PVC can be made soft and flexible with the addition of phthalates and plasticizers. In the soft and flexible form, it is used in inflatable products, plumbing, electrical cable insulation, and some applications that can replace rubber.

PVC has an extensive range of applications including plasticizers, healthcare, clothing, furniture, construction, and others. Today it exists in a plethora of consumer products which includes packaging, cling films, credit cards, bottles, and others. It is also used in several construction materials such as wallpaper, flooring, cables, pipes, window frames, to name a few. Due to its water resistance, durability, and affordability, PVC is ideal for shower curtains, boots, and raincoats.

Various factors are propelling the polyvinyl chloride market growth. Some of these factors, according to the Market Research Future report, include burgeoning demand for polyvinyl chloride in the automotive and construction industries, rapid growth in consumer goods and packaging, and rising applications in the healthcare domain.

On the contrary, the shortage in feedstock supply owing to the rise in the price of different products and closing down of facilities is likely to hamper the polyvinyl chloride market growth over the forecast period.

Polyvinyl Chloride Market Segmentation

The MRFR report offers a wide segmental analysis of the polyvinyl chloride market on the basis of end use, type, and application.

Based on type, the polyvinyl chloride market is segmented into flexible and rigid.

Based on application, the polyvinyl chloride market is segmented into cables, bottles, firms and sheets, tubes and profiles, pipes and fittings, and others.

Based on end use, the polyvinyl chloride market is segmented into automotive, construction, consumer goods, packaging, and others.

Polyvinyl Chloride Market Regional Analysis

By region, the polyvinyl chloride market report covers the latest trends and growth opportunities across the Asia Pacific, North America, Europe, and the Middle East and Africa. Of these, the APAC region will spearhead the market over the forecast period. This is owing to expanding residential properties and numerous electrifying villages, towns, and cities. China is a key contributor in this region as it is the biggest worldwide producer and consumer of polyvinyl chloride.

The polyvinyl chloride market in North America will have the second-largest share in the market over the forecast period. This is owing to the region’s growing construction industry. The US is the key contributor in this region.

Polyvinyl Chloride Market Key Players

Leading players profiled in the polyvinyl chloride market report include I. du Pont de Nemours and Company (US), Xinjiang Zhongtai Chemical Co., Ltd. (China), Vinnolit GmbH & Co. KG (Germany), Kem One SAS (France), Mexichem, S.A.B. de C.V. (Mexico), Axiall Corporation (US), Occidental Petroleum Corporation (US), Ineos Group Limited (UK), Shin-Etsu Chemical Co., Ltd. (Japan), and Formosa Plastics Corporation (Taiwan). Key players are incorporating several strategies to strengthen their position in the market, such as product launches and innovations, expansions, research and development, partnerships, collaborations, and more.

Access Full Report Details and Order this Premium Report @ https://www.marketresearchfuture.com/reports/polyvinyl-chloride-market-1043

Contact:

Market Research Future®

99 Hudson Street,5Th Floor

New York, New York 10013

United States of America

Phone:

+1 628 258 0071(US)

+44 2035 002 764(UK)

email:[email protected]

#Polyvinyl Chloride#Polyvinyl Chloride Market#Global Polyvinyl Chloride Market#Polyvinyl Chloride Industry#Polyvinyl Chloride Business#Polyvinyl Chloride Market Price

0 notes

Text

Best Flex Print Advertising Services in Delhi, India

In the dynamic landscape of advertising, flex printing remains a stalwart method for businesses to reach their target audience effectively.

With its versatility, affordability, and eye-catching appeal, flex printing continues to be a popular choice for outdoor and indoor advertising campaigns in India. However, with numerous flex printing advertising services available, selecting the best one can be daunting.

This comprehensive guide aims to assist businesses in navigating the selection process and identifying the top flex printing advertising services in India.

Understanding Flex Printing Advertising:

Flex printing involves the use of flexible vinyl material known as PVC (polyvinyl chloride) to create visually compelling banners, hoardings, signage, and other promotional materials. The process typically employs large-format printers capable of producing high-resolution prints on the flexible substrate.

Flex printing offers several advantages, including durability, weather resistance, vibrant colors, and cost-effectiveness, making it an ideal choice for both short-term and long-term advertising campaigns.

Factors to Consider When Choosing Flex Printing Advertising Services:

Experience and Expertise: Evaluate the experience and expertise of the flex printing advertising service provider. Look for agencies with a proven track record in delivering successful campaigns across various industries. Experienced providers are adept at understanding client requirements, suggesting innovative ideas, and executing projects efficiently.

Portfolio and Reputation: Review the portfolio of the flex printing advertising service provider to gauge the quality and diversity of their work. Pay attention to the design aesthetics, printing quality, and overall impact of their previous projects. Additionally, consider their reputation in the industry, including client reviews, testimonials, and awards received for excellence in advertising.

Printing Technology and Equipment: Inquire about the printing technology and equipment utilized by the advertising service provider. Opt for agencies equipped with state-of-the-art printing machinery capable of delivering high-resolution prints with precision and clarity. Advanced printing technology ensures superior color reproduction, sharpness, and durability of the final output.

Customization and Design Capabilities: Assess the customization and design capabilities offered by the flex printing advertising service provider. Look for agencies that provide tailored solutions to meet specific client needs and preferences. Evaluate their design team’s creativity, attention to detail, and ability to translate concepts into visually compelling artwork.

Material Quality and Durability: Consider the quality and durability of the materials used for flex printing. Ensure that the advertising service provider utilizes premium-grade PVC flex material that is weather-resistant, UV-stabilized, and tear-resistant. High-quality materials ensure longevity and maintain the visual appeal of printed advertisements over time.

Turnaround Time and Logistics: Evaluate the turnaround time and logistics offered by the flex printing advertising service provider. Choose agencies that can accommodate tight deadlines without compromising on quality. Additionally, inquire about installation services, transportation, and logistical support for the timely deployment of printed materials at designated locations.

Cost-effectiveness and Budget: Compare the pricing structure of different flex printing advertising services to ensure cost-effectiveness. Request detailed quotations that include printing costs, design charges, material expenses, and any additional fees. Balance cost considerations with the quality of services offered to maximize the return on investment (ROI) for your advertising campaign.

Top Flex Printing Advertising Services in India:

Aditya Flex Printing Solutions: Aditya Flex Printing Solutions is a leading provider of flex printing advertising services in India. With over a decade of experience in the industry, they specialize in custom-designed banners, hoardings, signage, and promotional displays. Their state-of-the-art printing facility and skilled team ensure high-quality prints that captivate audiences and drive engagement.

Shri Guru Kripa Printers & Advertisers (SGK Printers) : SGK Printers offers premium flex printing advertising services tailored to businesses’ unique needs. With years of expertise, they deliver high-quality banners, signage, and promotional materials that captivate audiences. Using state-of-the-art printing technology and premium materials, SGK ensures vibrant colors, durability, and weather resistance. Their skilled team combines creativity with precision to produce visually compelling designs that leave a lasting impression. From concept to installation, SGK Printers provides end-to-end solutions, making them a trusted partner for businesses seeking effective and impactful flex printing advertising campaigns in India.

Printland Digital India Pvt. Ltd.: Printland Digital India Pvt. Ltd. offers comprehensive flex printing solutions tailored to the unique requirements of businesses across various sectors. Their cutting-edge printing technology, coupled with a commitment to innovation, enables them to deliver visually stunning and impactful advertising materials. From large-format banners to custom signage, Printland Digital India Pvt. Ltd. is a trusted partner for advertising success.

Flex Printing India: Flex Printing India is renowned for its expertise in producing premium-quality flex prints for advertising campaigns of all scales. With a focus on customer satisfaction and attention to detail, they deliver exceptional results that exceed client expectations. Flex Printing India offers a wide range of customization options, ensuring that every project stands out and makes a lasting impression.

Vijay Flex Printing & Advertising: Vijay Flex Printing & Advertising is a prominent player in the flex printing industry, known for its reliability, creativity, and commitment to excellence. Their team of skilled professionals combines artistic flair with technical expertise to deliver visually striking and impactful advertising solutions. Whether it’s outdoor banners, vehicle wraps, or retail signage, Vijay Flex Printing & Advertising ensures maximum visibility and brand exposure.

ColorJet India Ltd.: ColorJet India Ltd. is a leading manufacturer of digital inkjet printers and provider of flex printing solutions in India. Their cutting-edge printing technology and eco-friendly ink formulations enable them to produce vibrant, high-resolution prints on a wide range of substrates. ColorJet India Ltd. offers end-to-end printing solutions, including design, printing, and installation services, making them a preferred choice for businesses seeking quality and reliability.

Conclusion:

Selecting the best flex printing advertising services in India requires careful consideration of various factors, including experience, reputation, printing technology, customization capabilities, material quality, and budget.

By evaluating these factors and exploring the top providers in the industry, businesses can make informed decisions and ensure the success of their advertising campaigns. Whether it’s promoting products, services, events, or brand awareness initiatives, partnering with a trusted flex printing advertising service provider is essential for achieving maximum visibility and impact in today’s competitive market landscape.

#3d printing#3d sign#3d signage#signage#branding#digital art#print on demand#print on demand services#printing company#digital painting#print ads#print on demand agency#print on demand company#print design#unique prints

2 notes

·

View notes

Text

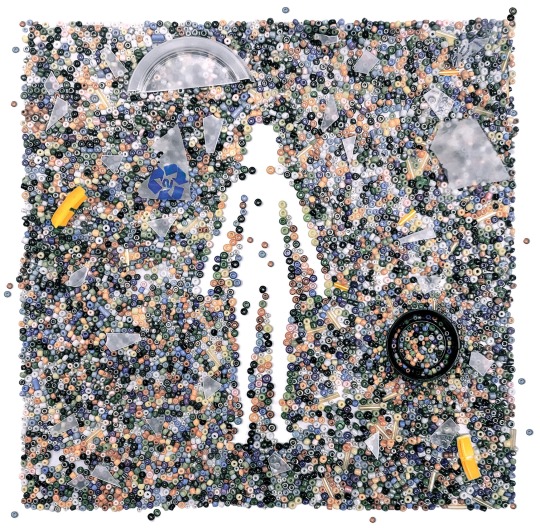

How Plastics Are Poisoning Us

They both release and attract toxic chemicals, and appear everywhere from human placentas to chasms thirty-six thousand feet beneath the sea. Will we ever be rid of them?

— By Elizabeth Kolbert | June 26, 2023

Annual production of plastic exceeds eight hundred billion pounds; much of it ends up as microplastics, spreading across the ocean. Illustration by Daniel Liévano

In 1863, when much of the United States was anguishing over the Civil War, an entrepreneur named Michael Phelan was fretting about billiard balls. At the time, the balls were made of ivory, preferably obtained from elephants from Ceylon—now Sri Lanka—whose tusks were thought to possess just the right density. Phelan, who owned a billiard hall and co-owned a billiard-table-manufacturing business, also wrote books about billiards and was a champion billiards player. Owing in good part to his efforts, the game had grown so popular that tusks from Ceylon—and, indeed, elephants more generally—were becoming scarce. He and a partner offered a ten-thousand-dollar reward to anyone who could come up with an ivory substitute.

A young printer from Albany, John Wesley Hyatt, learned about the offer and set to tinkering. In 1865, he patented a ball with a wooden core encased in ivory dust and shellac. Players were unimpressed. Next, Hyatt experimented with nitrocellulose, a material made by combining cotton or wood pulp with a mixture of nitric and sulfuric acids. He found that a certain type of nitrocellulose, when heated with camphor, yielded a shiny, tough material that could be molded into practically any shape. Hyatt’s brother and business partner dubbed the substance “celluloid.” The resulting balls were more popular with players, although, as Hyatt conceded, they, too, had their drawbacks. Nitrocellulose, also known as guncotton, is highly flammable. Two celluloid balls knocking together with sufficient force could set off a small explosion. A saloon owner in Colorado reported to Hyatt that, when this happened, “instantly every man in the room pulled a gun.”

It’s not clear that the Hyatt brothers ever collected from Phelan, but the invention proved to be its own reward. From celluloid billiard balls, the pair branched out into celluloid dentures, combs, brush handles, piano keys, and knickknacks. They touted the new material as a substitute not just for ivory but also for tortoiseshell and jewelry-grade coral. These, too, were running out, owing to slaughter and plunder. Celluloid, one of the Hyatts’ advertising pamphlets promised, would “give the elephant, the tortoise, and the coral insect a respite in their native haunts.”

Hyatt’s invention, often described as the world’s first commercially produced plastic, was followed a few decades later by Bakelite. Bakelite was followed by polyvinyl chloride, which was, in turn, followed by polyethylene, low-density polyethylene, polyester, polypropylene, Styrofoam, Plexiglas, Mylar, Teflon, polyethylene terephthalate (familiarly known as pet)—the list goes on and on. And on. Annual global production of plastic currently runs to more than eight hundred billion pounds. What was a problem of scarcity is now a problem of superabundance.

In the form of empty water bottles, used shopping bags, and tattered snack packages, plastic waste turns up pretty much everywhere today. It has been found at the bottom of the Mariana Trench, thirty-six thousand feet below sea level. It litters the beaches of Svalbard and the shores of the Cocos (Keeling) Islands, in the Indian Ocean, most of which are uninhabited. The Great Pacific Garbage Patch, a collection of floating debris that stretches across six hundred thousand square miles between California and Hawaii, is thought to contain some 1.8 trillion plastic shards. Among the many creatures being done in by all this junk are corals, tortoises, and elephants—in particular, the elephants of Sri Lanka. In recent years, twenty of them have died after ingesting plastic at a landfill near the village of Pallakkadu.

How worried should we be about what’s become known as “the plastic pollution crisis”? And what can be done about it? These questions lie at the heart of several recent books that take up what one author calls “the plastic trap.”

“Without plastic we’d have no modern medicine or gadgets or wire insulation to keep our homes from burning down,” that author, Matt Simon, writes in “A Poison Like No Other: How Microplastics Corrupted Our Planet and Our Bodies.” “But with plastic we’ve contaminated every corner of Earth.”

Simon, a science journalist at Wired, is especially concerned about plastic’s tendency to devolve into microplastics. (Microplastics are usually defined as bits smaller than five millimetres across.) This process is taking place all the time, in many different ways. Plastic bags drift into the ocean, where, after being tossed around by the waves and bombarded with UV radiation, they fall apart. Tires today contain a wide variety of plastics; as they roll along, they abrade, sending clouds of particles spinning into the air. Clothes made with plastics, which now comprise most items for sale, are constantly shedding fibres, much the way dogs shed hairs. A study published a few years ago in the journal Nature Food found that preparing infant formula in a plastic bottle is a good way to degrade the bottle, so what babies end up drinking is a sort of plastic soup. In fact, it is now clear that children are feeding on microplastics even before they can eat. In 2021, researchers from Italy announced that they had found microplastics in human placentas. A few months later, researchers from Germany and Austria announced that they’d found microplastics in meconium—the technical term for an infant’s first poop.

The hazards of ingesting large pieces of plastic are pretty straightforward; they include choking and perforation of the intestinal tract. Animals that fill their guts with plastics eventually starve to death. The risks posed by microplastics are subtler, but not, Simon argues, any less serious. Plastics are made from by-products of oil and gas refining; many of the chemicals involved, such as benzene and vinyl chloride, are carcinogens. In addition to their main ingredients, plastics may contain any number of additives. Many of these—for example, polyfluoroalkyl substances, or PFASs, which confer water resistance—are also suspected carcinogens. Many of the others have never been adequately tested.

As plastics fall apart, the chemicals that went into their manufacture can leak out. These can then combine to form new compounds, which may prove less dangerous than the originals—or more so. A couple of years ago, a team of American scientists subjected disposable shopping bags to several days of simulated sunlight, in order to mimic the conditions that they’d encounter flying or floating loose. The researchers found that a single bag from CVS leached more than thirteen thousand compounds; a bag from Walmart leached more than fifteen thousand. “It is becoming increasingly clear that plastics are not inert in the environment,” the team wrote. Steve Allen, a researcher at Canada’s Ocean Frontier Institute who specializes in microplastics, tells Simon, “If you’ve got an IQ above room temperature, you have to understand that this is not a good material to have in the environment.”

Microplastics, meanwhile, don’t just leach nasty chemicals; they attract them. “Persistent bioaccumulative and toxic substances,” or PBTs, are a hodgepodge of harmful compounds, including DDT and PCBs. Like microplastics, which are often referred to in the scientific literature as MPs, PBTs are everywhere these days. When PBTs encounter MPs, they preferentially adhere to them. “In effect, plastics are like magnets for PBTs” is how the Environmental Protection Agency has put it. Consuming microplastics is thus a good way to swallow old poisons.

Then, there’s the threat posed by the particles themselves. Microplastics—and in particular, it seems, microfibres—can get pulled deep into the lungs. People who work in the synthetic-textile industry, it has long been known, suffer from high rates of lung disease. Are we breathing in enough microfibres that we are all, in effect, becoming synthetic-textile workers? No one can say for sure, but, as Fay Couceiro, a researcher at England’s University of Portsmouth, observes to Simon, “We desperately need to find out.”

Whatever you had for dinner last night, the meal almost certainly left behind plastic in need of disposal. Before tossing your empty sour-cream tub or mostly empty ketchup bottle, you may have searched it for a number, and if you found one, inside a cheerful little triangle, you washed it out and set it aside to be recycled. You might also have imagined that with this effort you were doing your part to stem the global plastic-pollution tide.

The British journalist Oliver Franklin-Wallis used to be a believer. He religiously rinsed his plastics before depositing them in one of the five color-coded rubbish bins that he and his wife kept at their home in Royston, north of London. Then Franklin-Wallis decided to find out what was actually happening to his garbage. Disenchantment followed.

“If a product is seen as recycled, or recyclable, it makes us feel better about buying it,” he writes in “Wasteland: The Secret World of Waste and the Urgent Search for a Cleaner Future.” But all those little numbers inside the triangles “mostly serve to trick consumers.”

Franklin-Wallis became interested in the fate of his detritus just as the old order of Britain’s rubbish was collapsing. Up until 2017, most of the plastic waste collected in Europe and in the United States was shipped to China, as was most of the mixed paper. Then Beijing imposed a new policy, known as National Sword, that prohibited imports of yang laji, or “foreign garbage.” The move left waste haulers from California to Catalonia with millions of mildewy containers they couldn’t get rid of. “plastics pile up as china refuses to take the west’s recycling,” a January, 2018, headline in the Times read. “It’s tough times,” Simon Ellin, the chief executive of Britain’s Recycling Association, told the paper.

Trash, though, finds a way. Not long after China stopped taking in foreign garbage, waste entrepreneurs in other nations—Malaysia, Indonesia, Vietnam, Sri Lanka—started to accept it. Mom-and-pop plastic-recycling businesses sprang up in places where they were regulated laxly, if at all. Franklin-Wallis visited one such informal recycling plant, in New Delhi; the owner allowed him inside on the condition that he not reveal exactly how the business operates or where it is situated. He found workers in a fiendishly hot room feeding junk into a shredder. Workers in another, equally hot room fed the shreds into an extruder, which pumped out little gray pellets known as nurdles. The ventilation system consisted of an open window. “The thick fug of plastic fumes in the air left me dazed,” Franklin-Wallis writes.

Nurdles, which are key to manufacturing plastic products, are small enough to qualify as microplastics. (It’s been estimated that ten trillion nurdles a year leak into the oceans, most from shipping containers that tip overboard.) Usually, nurdles are composed of “virgin” polymers, but, as the New Delhi plant demonstrates, it is also possible to produce them from used plastic. The problem with the process, and with plastic recycling more generally, is that a polymer degrades each time it’s heated. Thus, even under ideal circumstances, plastic can be reused only a couple of times, and in the waste-management business very little is ideal. Franklin-Wallis toured a high-end recycling plant in northern England that handles pet, the material that most water and soda bottles are made from. He learned that nearly half the bales of pet that arrive at the plant can’t be reprocessed because they’re too contaminated, either by other kinds of plastic or by random crap. “Yield is a problem for us,” the plant’s commercial director concedes.

Franklin-Wallis comes to see plastic recycling as so much (potentially toxic) smoke and mirrors. Over the years, he writes, “a kind of playbook” has emerged. Under public pressure, a company like Coca-Cola or Nestlé pledges to insure that the packaging for its products gets recycled. When the pressure eases, it quietly abandons its pledge. Meanwhile, it lobbies against any kind of legislation that would restrict the sale of single-use plastics. Franklin-Wallis quotes Larry Thomas, the former president of the Society of the Plastics Industry, who once said, “If the public thinks recycling is working, then they are not going to be as concerned about the environment.”

Right around the time that Franklin-Wallis started tracking his trash, Eve O. Schaub decided to spend a year not producing any. Schaub, who has been described as a “stunt memoirist,” had previously spent a year avoiding sugar and forcing her family to do the same, an exercise she chronicled in a book titled “Year of No Sugar.” The year of no sugar was followed by “Year of No Clutter.” When she proposes a trash-free annum to her husband, he says he doubts it is possible. Her younger daughter begs her to wait until she goes away to college. Schaub plunges ahead anyway.

“As the beginning of the new year loomed, I was feeling pretty good about our chances,” she recalls in “Year of No Garbage.” “I mean, really. How hard could it be?”

What Schaub means by “no garbage” is not exactly no garbage. Under her scheme, refuse that can be composted or recycled is allowed, so her family can keep tossing out old cans and empty wine bottles along with food scraps. What turns out to be hard—really, really hard—is dealing with plastic.

At first, Schaub divides plastic waste into two varieties. There’s the kind with the little numbers, which her trash hauler accepts as part of its “single stream” recycling program and so, by her definition, doesn’t count as trash. Then, there’s the kind with no numbers, which isn’t supposed to go in the recycling bin and therefore does count. Schaub finds that even when she purchases something in a numbered container—guacamole, say—there’s usually a thin sheet of plastic under the lid that’s numberless. A lot of her time goes into rinsing off these sheets and other stray plastic bits and trying to figure out what to do with them. She is excited to find a company called TerraCycle, which promises—for a price—to “recycle the unrecyclable.” For a hundred and thirty-four dollars, she purchases a box that can be returned to TerraCycle filled with plastic packaging, and for an additional forty-two dollars she buys another box that can be filled with “oral care waste,” such as used toothpaste tubes. “I sent my TerraCycle Plastic Packaging box as densely packed with plastic as any box could be,” she writes.

Eventually, though, like Franklin-Wallis, Schaub comes to see that she’s been living a lie. Midway through her experiment, she signs up for an online course called Beyond Plastic Pollution, offered by Judith Enck, a former regional administrator for the E.P.A. Only containers labelled No. 1 (pet) and No. 2 (high-density polyethylene) get melted down with any regularity, Schaub learns, and to refashion the resulting nurdles into anything useful usually requires the addition of lots of new material. “No matter what your garbage service provider is telling you, numbers 3, 4, 6 and 7 are not getting recycled,” Schaub writes. (The italics are hers.) “Number 5 is a veeeery dubious maybe.”

TerraCycle, too, proves a disappointment. It gets sued for deceptive labelling and settles out of court. A documentary-film crew finds that dozens of bales of waste sent to the company for recycling have instead been shipped off to be burned at a cement kiln in Bulgaria. (According to the company’s founder, this is the result of an unfortunate mistake.)

“I had wanted so badly to believe that TerraCycle and Santa Claus and the Easter bunny were real, that I had been willing to overlook the fact that Santa’s handwriting looks suspiciously like Mom’s,” Schaub writes. Toward the end of the year, she concludes that pretty much all plastic waste—numbered, unnumbered, or shipped off in boxes—falls under her definition of garbage. She also concludes that, “in this day, age and culture,” such waste is pretty much impossible to avoid.

A few months ago, the E.P.A. issued a “draft national strategy to prevent plastic pollution.” Americans, the report noted, produce more plastic waste each year than the residents of any other country—almost five hundred pounds per person, nearly twice as much as the average European and sixteen times as much as the average Indian. The E.P.A. declared the “business-as-usual approach” to managing this waste to be “unsustainable.” At the top of its list of recommendations was “reduce the production and consumption” of single-use plastics.

Just about everyone who contemplates the “plastic pollution crisis” arrives at the same conclusion. Once a plastic bottle (or bag or takeout container) has been tossed, the odds of its ending up in landfill, on a faraway beach, or as tiny fragments drifting around in the ocean are high. The best way to alter these odds is not to create the bottle (or bag or container) in the first place.

“So long as we’re churning out single-use plastic . . . we’re trying to drain the tub without turning off the tap,” Simon writes. “We’ve got to cut it out.”

“We can’t rely on half-measures,” Schaub says. “We have to go to the source.” Her own local supermarket, in southern Vermont, stopped handing out plastic bags in late 2020, she notes. “Do you know what happened? Nothing. One day we were poisoning the environment with plastic bags in the name of ultra-convenience and the next? We weren’t.”

“We now know that we can’t start to reduce plastic pollution without a reduction of production,” Imari Walker-Franklin and Jenna Jambeck, both environmental engineers, observe in “Plastics,” forthcoming from M.I.T. Press. “Upstream and systemic change is needed.”

Of course, it’s a lot easier to talk about “turning off the tap” and changing the system than it is to actually do so. First, there are the political obstacles. For all intents and purposes, the plastics industry is a subsidiary of the fossil-fuel industry. ExxonMobil, for instance, is the world’s fourth-largest oil company and also its largest producer of virgin polymers. The connection means that any effort to reduce plastic consumption is bound to be resisted, either openly or surreptitiously, not just by companies such as Coca-Cola and Nestlé but also by corporations like Exxon and Shell. In March, 2022, diplomats from a hundred and seventy-five nations agreed to try to fashion a global treaty to “end plastic pollution.” At the first negotiating session, held later that year in Uruguay, the self-described High Ambition Coalition, which includes the members of the European Union as well as Ghana and Switzerland, insisted that the treaty include mandatory measures that apply to all countries. This idea was opposed by major oil-producing nations, including the U.S., which has called for a “country-driven” approach. According to the environmental group Greenpeace, lobbyists for the “major fossil fuel companies were out in force” at the session.

There are also practical hurdles. Precisely because plastic is now ubiquitous, it’s difficult to imagine how to replace all of it, or even much of it. Even in cases where substitutes are available, it’s not always clear that they’re preferable. Franklin-Wallis cites a 2018 study by the Danish Environmental Protection Agency which analyzed how different kinds of shopping bags compare in terms of life-cycle impacts. The study found that, to have a lower environmental impact than a plastic bag, a paper bag would have to be used forty-three times and a cotton tote would have to be used an astonishing seventy-one hundred times. “How many of those bags will last that long?” Franklin-Wallis asks. Walker-Franklin and Jambeck also note that exchanging plastic for other materials may involve “tradeoffs,” including “energy and water use and carbon emissions.” When Schaub’s supermarket stopped handing out plastic shopping bags, it may have reduced one problem only to exacerbate others—deforestation, say, or pesticide use.

“In the grand scheme of human existence, it wasn’t that long ago that we got along just fine without plastic,” Simon points out. This is true. It also wasn’t all that long ago that we got along just fine without Coca-Cola or packaged guacamole or six-ounce bottles of water or takeout everything. To make a significant dent in plastic waste—and certainly to “end plastic pollution”—will probably require not just substitution but elimination. If much of contemporary life is wrapped up in plastic, and the result of this is that we are poisoning our kids, ourselves, and our ecosystems, then contemporary life may need to be rethought. The question is what matters to us, and whether we’re willing to ask ourselves that question. ♦

— Published in the print edition of the July 3, 2023, The New Yorker Issue, with the headline “A Trillion Little Pieces.”

#Plastic Poisoning#Toxic Chemicals#On Earth and Under Seas#Microplastics#Plastic Pollution#PFASs#PBTs#MPs DDT & PCBs#E.P.A.#MIT Press#Coca Cola | Nestlé | Exxon | Shell#Greenpeace

3 notes

·

View notes

Text

Extruded Plastics Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The extruded plastics global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Extruded Plastics Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size -

The extruded plastics market size has grown strongly in recent years. It will grow from $232.87 billion in 2023 to $246.52 billion in 2024 at a compound annual growth rate (CAGR) of 5.9%. The growth in the historic period can be attributed to industrialization and manufacturing growth, lightweighting in automotive, construction and infrastructure development, sustainable practices, consumer goods and packaging.

The extruded plastics market size is expected to see strong growth in the next few years. It will grow to $315.92 billion in 2028 at a compound annual growth rate (CAGR) of 6.4%. The growth in the forecast period can be attributed to eco-friendly extruded plastics, electric and autonomous vehicles, infrastructure modernization, medical device manufacturing, advanced extrusion processes. Major trends in the forecast period include high-performance extruded plastics, 3d printing with extruded plastics, smart extruded products, co-extrusion technology, foam extrusion.

Order your report now for swift delivery @

https://www.thebusinessresearchcompany.com/report/extruded-plastics-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers -

The rise of the packaging industry is significantly contributing to the growth of the extruded plastics market going forward. Packaging refers to enclosing or protecting products for distribution, storage, sale, and use. Extruded plastics are helpful in creating highly durable and effective packaging solutions. As a result, the rise of the packaging industry increases the demand for the extruded plastics market. For instance, in 2021, according to the India Brand Equity Foundation, an Indian government export promotion agency, packaging demand and consumption in India increased by 200%, which increased from 4.3 kgs per person per annum (PPPA) to 8.6 kgs PPPA. Therefore, the rise of the packaging industry is driving the growth of the extruded plastics market.

The extruded plastics market covered in this report is segmented –

1) By Type: Low Density Polyethylene, High Density Polyethylene, Polypropylene, Polystyrene, Polyvinyl Chloride, Other Types

2) By Form: Films, Pipes, Sheets, Tubes, Wires and Cables

3) By End-User: Packaging, Building and Construction, Automotive, Consumer Goods, Electrical and Electronics, Other End Users

Get an inside scoop of the extruded plastics market, Request now for Sample Report @

https://www.thebusinessresearchcompany.com/sample.aspx?id=6589&type=smp

Regional Insights -

Asia-Pacific was the largest region in the extruded plastics market in 2023. Asia-Pacific is expected to be the fastest-growing region in the extruded plastics market during the forecast period. The regions covered in the extruded plastics market report include Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa.

Key Companies -

Major companies operating in the extruded plastics market include Apogee Enterprises Inc., Olsen Doors and Windows Limited, Fletcher Building Limited, YKK AP Inc., Bradnam's Windows & Doors, Fenesta Building Systems, PGT Innovations Inc., Geeta Aluminium Co. Pvt. Ltd., Ply Gem Holdings Inc., Andersen Corporation, Sapa Group, Alupure, Alteza Healthcare Private Limited, Reynaers Aluminium, Schuco International Group, Bemis Company Inc., LyondellBasell Industries N.V., Trex Company Inc., Teijin Limited, Borealis AG, Westlake Corporation, NOVA Chemicals Corporation, Mitsubishi Chemical Group Corporation, Plastipak Holdings Inc., Sigma Plastics Group of FL, Bunzl Extrusions Inc., Avient Corporation, The Ensinger Group, REHAU Polymers Pvt Ltd, Primex Plastics Private Limited

Table of Contents

1. Executive Summary

2. Extruded Plastics Market Report Structure

3. Extruded Plastics Market Trends And Strategies

4. Extruded Plastics Market – Macro Economic Scenario

5. Extruded Plastics Market Size And Growth

…..

27. Extruded Plastics Market Competitor Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

A Guide to Choosing the Best Super Heavy Duty Tarps in Columbus

Super heavy-duty tarps are an essential tool for many homeowners, contractors, farmers, and business owners in Columbus, Ohio. Choosing the right tarp can make a significant difference if you're looking to protect your property from the elements, secure outdoor equipment, or shield your construction site. With so many options available, finding the best super heavy-duty tarp can feel overwhelming.

In this guide, we'll walk you through everything you need to know about choosing the best super heavy-duty tarps in Columbus. We'll cover their applications, materials, features, and how to make an informed decision based on your specific needs.

What Are Super Heavy Duty Tarps?

What Makes a Tarp "Super Heavy Duty"?

Super heavy-duty tarps are thicker, more durable, and stronger than regular tarps. While standard tarps may be suitable for light protection, such as covering a picnic table during a rainstorm, super heavy-duty tarps are designed for demanding tasks. They are often used in construction, agriculture, outdoor events, and even emergencies where protection from harsh weather or debris is critical.

These tarps are characterized by:

High thickness (mil): Typically 12-20 mil (1 mil = 0.001 inches).

Heavy-duty grommets: Usually made from brass or rust-resistant metal.

Reinforced corners: These are for added strength when securing.

UV protection: Designed to resist degradation from sun exposure.

Waterproof or water-resistant coating: Provides complete protection from moisture.

High-density material: Often made from polyethylene or vinyl, ensuring durability and resistance to tears, punctures, and abrasions.

Common Uses for Super Heavy Duty Tarps in Columbus

Given the diverse weather in Columbus, from hot summers to cold winters, super heavy-duty tarps are used year-round for a variety of purposes, including:

Construction site cover: Protecting building materials, machinery, and work areas.

Roofing projects: Temporary cover during repairs.

Emergency shelter: Provides rapid protection from storms, snow, or wind.

Agricultural uses: Protecting crops, hay bales, or equipment on farms.

Truck bed cover: Securing and covering goods during transportation.

Temporary outdoor flooring: For events, fairs, or gatherings.

Pool cover: Preventing debris from entering a pool during the off-season.

Key Factors to Consider When Choosing Super Heavy Duty Tarps

1. Material Type

The material of your tarp is one of the most important factors to consider, as it will dictate its durability, weight, and performance in various conditions. There are several materials to choose from:

a. Polyethylene (PE) Tarps

Polyethylene tarps are some of the most common types of super heavy-duty tarps. They are made from woven and laminated layers of polyethylene, which makes them both lightweight and extremely durable. Key features of PE tarps include:

Waterproof: These tarps are fully waterproof and are excellent for outdoor use.

UV-resistant: They protect against sun exposure and can prevent fading or degradation.

Tear-resistant: Their construction makes them resistant to rips and tears, even in high winds or heavy use.

b. Vinyl (PVC) Tarps

Vinyl tarps, also known as PVC tarps, are thicker and heavier than polyethylene tarps. They are made from polyvinyl chloride and are ideal for more demanding applications. Features include:

High durability: Vinyl tarps are resistant to punctures, abrasion, and chemicals.

Fire-retardant options: Some vinyl tarps come with fire-retardant coatings, making them suitable for industrial or high-heat applications.

Heavyweight: Vinyl tarps tend to be heavier, which can make them more stable in windy conditions but harder to maneuver.

c. Canvas Tarps

Canvas tarps are made from heavy-duty cotton fabric and are often used for more rugged applications. While they are less common than polyethylene or vinyl tarps, they have some distinct advantages:

Breathability: Canvas tarps allow moisture to evaporate, making them ideal for covering items that need airflow, such as firewood.

Eco-friendly: Made from natural fibers, canvas tarps are biodegradable and environmentally friendly.

Not fully waterproof: While canvas tarps are water-resistant, they are not entirely waterproof like polyethylene or vinyl.

2. Tarp Thickness (Mil)

The thickness of a tarp is measured in mils, where 1 mil equals 0.001 inches. Super heavy-duty tarps typically range from 12 to 20 mil in thickness, with thicker tarps offering greater strength and durability.

a. 12-15 Mil Tarps

Suitable for moderate to heavy use.

Ideal for covering vehicles, and equipment, or using as a tent or canopy.

Easier to handle and install due to their relatively lightweight nature.

b. 16-20 Mil Tarps

Designed for the most demanding applications, such as construction site coverage, roofing, or long-term outdoor use.

Extremely resistant to punctures, tears, and abrasions.

Can handle harsh weather conditions, including heavy rain, snow, or wind.

3. Waterproof vs. Water-Resistant

When selecting a tarp, it's essential to determine whether you need it to be fully waterproof or simply water-resistant.

a. Waterproof Tarps

Waterproof tarps are completely impervious to moisture and are ideal for applications where total protection from rain or snow is necessary. This includes roofing, construction sites, and transportation of goods.

b. Water-Resistant Tarps

Water-resistant tarps can repel water to some extent, but they are not entirely waterproof. These are better suited for temporary coverings or situations where some airflow is beneficial, like covering firewood.

4. Size of the Tarp

The size of the tarp you choose will depend on the specific job you need it for. Tarps come in a wide range of sizes, from small 5’ x 7’ tarps to massive 100’ x 100’ covers. Consider the following:

Measure your space: Before purchasing, measure the area you need to cover, and choose a tarp that provides adequate overlap for securing.

Consider storage and portability: Larger tarps can be heavy and difficult to store. If you need a portable tarp, opt for a size that balances coverage with ease of handling.

5. Grommet Placement and Quality

Grommets are metal rings that are placed around the edges of a tarp, allowing you to tie it down securely. For super heavy-duty tarps, the grommets should be made of rust-resistant metal, like brass or aluminum, and placed every 18-36 inches along the edges. This spacing ensures that the tarp can be evenly secured, preventing it from tearing in high winds or harsh weather.

6. UV Protection

If you’re using the tarp outdoors, UV protection is essential, especially during the summer months when Columbus experiences intense sun. UV-resistant tarps are coated to block harmful rays, which not only protects the tarp from degradation but also shields whatever you're covering from sun damage.

7. Fire Retardant Coatings

For industrial or construction use, especially in environments where heat or open flames may be present, choosing a tarp with a fire-retardant coating is critical. Fire-retardant tarps can prevent the spread of flames and are required by safety regulations in many work environments.

8. Color Considerations

The color of your tarp may seem like a minor detail, but it can have practical implications depending on the application:

Silver or white tarps: These reflect sunlight and are ideal for keeping areas cooler during the summer months.

Blue or green tarps: These colors are common for general-purpose use and tend to blend into outdoor environments.

Brown or camouflage tarps: Great for covering items in nature without standing out.

Black tarps: Absorb heat and are useful for applications where you want to dry out items or keep heat contained.

Specific Applications for Super Heavy Duty Tarps in Columbus

1. Construction Sites

In Columbus, construction projects are often exposed to unpredictable weather conditions, making super heavy duty tarps a necessity. These tarps can protect tools, machinery, and building materials from rain, snow, or wind, ensuring that the project stays on schedule.

2. Agriculture

Farms in Ohio use super heavy-duty tarps to cover hay bales, protect crops, and shield livestock from the elements. Because these tarps are durable and can withstand exposure to rain, sun, and wind, they are ideal for long-term use in agriculture.

3. Roofing and Home Renovations

When performing roof repairs or renovations, super heavy-duty tarps can provide temporary protection, preventing water from entering your home while work is being completed. The waterproof and UV-resistant properties of these tarps ensure that the interior remains dry, even during heavy storms.

4. Emergency and Disaster Relief

In emergencies, such as after a tornado or severe storm, super heavy-duty tarps create temporary shelters or cover damaged structures. Their ability to withstand harsh weather makes them an essential tool for disaster recovery.

How to Properly Care for Your Super Heavy Duty Tarp

To ensure the longevity of your tarp, it's important to follow these maintenance tips:

1. Cleaning

Clean your tarp regularly, especially after exposure to dirt, chemicals, or heavy rain. Use a mild soap and water solution to wipe away debris. Avoid using harsh chemicals, as they can degrade the material.

2. Storage

When not in use, store your tarp in a cool, dry place. Fold it neatly to avoid creases or tears. Keep it away from direct sunlight to prevent UV damage during storage.

3. Repairing Tears

Small tears or holes can be patched using tarp repair tape or a patch kit. It's important to address any damage immediately to prevent it from worsening.

Final Thoughts

Choosing the best super heavy duty tarp in Columbus depends on understanding your specific needs, from material type and thickness to size and special features. By considering factors like weather resistance, UV protection, and intended use, you can ensure that your tarp will provide reliable protection and long-lasting performance.

Whether you're a homeowner looking to protect outdoor furniture or a contractor securing a job site, investing in the right super heavy-duty tarp will save you time, money, and effort in the long run. Make sure to explore different materials and designs to find the tarp that meets your needs and stands up to the varied weather conditions of Columbus.

#Heavy Duty Tarps Columbus#Super Heavy Duty Tarps Columbus#Super Heavy Duty Tarps Columbus OH#super durable tarps columbus#Heavy Duty Thick Tarp#non-recycled polyethylene super durable tarps#Core Tarps Heavy Duty columbus#Core Tarps Extreme Heavy Duty Store in Columbus#Heavy Duty Tarps#Super Heavy Duty Tarps#Super Heavy Duty Tarps shop in Columbus super durable tarps#Core Tarps Heavy Duty#Core Tarps Extreme Heavy Duty#Fire retardant tarps#Polyethylene tarps#Vinyl Tarps#Canvas Tarps#heavy duty waterproof tarps#heavy duty commercial tarps#Mesh Tarps

1 note

·

View note

Text

Starmaxpipes: Leading UPVC Fittings Manufacturers in India for Quality and Reliability

In the sector of plumbing and piping solutions, Starmaxpipes has hooked up itself as a key player, specially as one of the main UPVC fittings producers in India. Renowned for his or her commitment to turning in top-notch best products, Starmaxpipes offers a complete range of UPVC pipe fittings that meet the diverse desires of families, industries, and big-scale infrastructure tasks. Along with UPVC products, Starmaxpipes additionally excels in producing remarkable PVC pipe fittings, offering a whole option to all of your plumbing and piping necessities.

In this text, we will explore what makes Starmaxpipes a desired name among UPVC fittings producers in India, how their PVC and UPVC solutions are tailored for a extensive range of programs, and why the brand stands proud for first-class, sturdiness, and affordability.

Understanding the Importance of UPVC and PVC Pipe Fittings

Before diving into the specifics of why Starmaxpipes is a marketplace chief in the Indian plumbing and piping industry, it’s essential to recognize the value of UPVC and PVC pipe fittings.

UPVC (Unplasticized Polyvinyl Chloride) is a kind of plastic this is pretty durable, value-effective, and proof against corrosion. This fabric is especially famous in plumbing applications due to its capacity to face up to high pressure, publicity to harsh environments, and aggressive water situations. The fabric’s non-poisonous nature makes it perfect for drinking water supply structures. UPVC pipe fittings are usually utilized in residential, business, and business projects, offering long-lasting performance with out the want for common protection.

PVC (Polyvinyl Chloride), on the other hand, is a flexible thermoplastic used in a wide form of piping programs. PVC pipe fittings are preferred for his or her flexibility, durability, and resistance to corrosion, making them an first rate desire for drainage, sewage, and irrigation systems.

Why Choose Starmaxpipes for UPVC Pipe Fittings?

When it involves UPVC fittings manufacturers s in India, Starmaxpipes has carved out a recognition for itself as one of the most relied on manufacturers. Here’s why Starmaxpipes is the pinnacle preference for customers searching for first-class UPVC pipe fittings:

1. High-Quality Products

At Starmaxpipes, high-quality is a pinnacle precedence. Every product, together with UPVC pipe fittings, is manufactured to satisfy both countrywide and global standards. This ensures that customers get hold of merchandise that are long lasting, leak-proof, and proof against chemical substances and UV rays.

2. Extensive Product Range

Starmaxpipes gives an intensive array of UPVC pipe fittings, designed to cater to numerous plumbing needs. From elbows, couplings, and tees to reducers and unions, the emblem has a comprehensive catalog of fittings that assist various kinds of pipe installations. Their extensive choice makes it less difficult for customers to locate the right product for their specific necessities, whether or not for family plumbing or big-scale business programs.

Three. Innovative Manufacturing Technology

As a ahead-wondering business enterprise, Starmaxpipes employs modern-day production generation to provide UPVC fittings that aren't best dependable however additionally environmentally pleasant. Their modern day manufacturing tactics make sure that each fitting is crafted with precision, resulting in perfect merchandise that ultimate longer and perform better.

Four. Cost-Effective Solutions

While Starmaxpipes is understood for generating top rate-first-rate UPVC fittings, additionally they provide price-powerful answers that don’t compromise on performance. Their competitive pricing makes them the appropriate choice for finances-conscious clients, whether it’s for a small plumbing assignment or a huge infrastructure development.

5. Commitment to Sustainability

One of the standout functions of Starmaxpipes is their willpower to environmental sustainability. Their UPVC and PVC pipe fittings are synthetic the usage of eco-friendly techniques, reducing the environmental impact whilst nonetheless turning in pinnacle-tier merchandise. This dedication to sustainability aligns with the growing demand for environmentally responsible building substances in India.

6. Durability and Longevity

When you pick out UPVC pipe fittings from Starmaxpipes, you’re investing in merchandise which are built to ultimate. The fittings are proof against rust, corrosion, and chemical damage, making sure that they offer a protracted-lasting, maintenance-unfastened solution for all styles of piping systems. Whether you need fittings for drinking water supply, irrigation, or drainage structures, Starmaxpipes merchandise are designed to resist harsh conditions whilst preserving brilliant performance.

Starmaxpipes: A Leader Among UPVC Pipe Manufacturers in India

Beyond being recognized for his or her fittings, Starmaxpipes is also called one of the pinnacle UPVC pipe manufacturers in India. The corporation’s UPVC pipes are engineered to meet the needs of modern construction, plumbing, and water management structures. Here’s why their UPVC pipes are a smart desire for experts and house owners alike:

1. Corrosion-Free and Non-Reactive

One of the biggest benefits of UPVC pipes from Starmaxpipes is their resistance to corrosion. Unlike metallic pipes, UPVC pipes do not react with the substances they convey, making them ideal for transporting drinking water and chemicals with out worry of infection or corrosion.

2. Lightweight and Easy to Install

Starmaxpipes ensures that their UPVC pipes are lightweight, which makes them easier to transport and deploy. This effects in reduced labor fees and faster assignment completion instances, supplying clients with a value-effective piping answer.

Three. High-Pressure Tolerance

Whether it’s for residential or commercial use, the UPVC pipes from Starmaxpipes are designed to withstand high pressure, making them suitable for water deliver systems that require sturdiness and reliability. These pipes are best for use in each excessive-upward thrust homes and tremendous irrigation networks.

4. Safe for Potable Water

Starmaxpipes manufactures UPVC pipes which are secure for wearing ingesting water. These pipes are non-poisonous and meet the important safety requirements to make certain that the water being transported stays uncontaminated. This makes them the move-to preference for water supply structures in houses, colleges, hospitals, and different institutions.

5. Ideal for a Range of Applications

From irrigation and plumbing to chemical transportation, UPVC pipes from Starmaxpipes are flexible enough to fulfill the wishes of a huge range of industries. Whether you want pipes for agricultural, commercial, or commercial functions, Starmaxpipes gives answers that supply exceptional outcomes.

PVC Pipe Fittings: Another Strength of Starmaxpipes

In addition to their know-how in UPVC fittings, Starmaxpipes is likewise a main producer of PVC pipe fittings. PVC is a distinctly flexible cloth that can be used in lots of programs, from drainage structures to water distribution. Here are a few motives why Starmaxpipes’ PVC pipe fittings stand out:

1. Versatility

Starmaxpipes produces PVC pipe fittings in a whole lot of shapes and sizes to suit one of a kind plumbing systems. These fittings are typically used in drainage, waste disposal, and water control systems, presenting a flexible and flexible solution for modern-day infrastructure.

2. Resistance to Weather and Chemicals

The PVC pipe fittings from Starmaxpipes are designed to face up to publicity to chemical compounds and cruel climate conditions, making them ideal for out of doors use. Their exceptional resistance to environmental factors ensures lengthy-time period sturdiness, even in extreme conditions.

3. Leak-Proof Connections

Leak prevention is one of the maximum critical elements of any piping machine. Starmaxpipes guarantees that its PVC pipe fittings are designed to provide tight, leak-evidence connections, preventing water wastage and retaining the integrity of the piping gadget.

Four. Ease of Installation

Starmaxpipes’ PVC pipe fittings are lightweight and smooth to install, lowering labor time and associated fees. This ease of set up makes those fittings perfect for contractors operating on time-touchy initiatives.

Applications of UPVC and PVC Pipe Fittings from Starmaxpipes

The UPVC and PVC pipe fittings from Starmaxpipes can be used in a extensive variety of packages, making them a versatile desire for distinctive industries:

1. Water Supply Systems

Both UPVC and PVC pipe fittings are exceptional for water deliver structures in residential, business, and commercial setups. These fittings are designed to offer leak-proof connections and ensure smooth water float.

2. Drainage Systems

For efficient waste control, PVC pipe fittings from Starmaxpipes offer superior performance in drainage structures. Their corrosion resistance guarantees that the pipes stay purposeful for extended durations, even when exposed to waste and chemical compounds.

Three. Agriculture and Irrigation

UPVC pipes and fittings are broadly used in agricultural irrigation systems due to their high resistance to chemical compounds and sturdiness beneath pressure. They are ideal for transporting water and fertilizers over large distances with out degradation.

Why Starmaxpipes is the Right Choice

As one of the pinnacle UPVC fittings manufacturers in India, Starmaxpipes offers a combination of satisfactory, sturdiness, and price-effectiveness that sets them aside from the opposition. Their determination to innovation, patron pleasure, and sustainability guarantees that each product they manufacture meets the best standards of overall performance.

Whether you’re searching out UPVC pipe producers in India or remarkable PVC pipe fittings, Starmaxpipes gives you products that meet the various desires of clients throughout the usa. Choose Starmaxpipes for your next plumbing or piping assignment and experience the distinction that pinnacle-tier products could make!

0 notes

Text

Durable PVC ID Cards: IVYPrints' Promise of Quality and Longevity

In today’s fast-paced world, businesses and institutions require solutions that are not only efficient but also durable. One such solution that plays a pivotal role in ensuring smooth operations and secure environments is the ID card. Whether it’s for schools, offices, or large events, having a robust and reliable identification system is crucial. And at the forefront of this essential service in India is IVYPrints – a leading ID card printing company based in Jaipur. IVYPrints stands out for its high-quality PVC ID cards, known for their durability, longevity, and superior design.

Trusted by top corporations and businesses across India, IVYPrints has set the benchmark for ID card printing services, offering fast delivery, customer satisfaction, and a wide range of customizable templates. Let’s dive into what makes IVYPrints' PVC ID cards a premium choice and why businesses rely on their promise of quality and longevity.

1. The Importance of Durable ID Cards in Today’s Environment

In many sectors, from corporate offices to educational institutions, ID cards are a daily necessity. These cards not only serve the purpose of identification but also act as tools for access control, security management, and in some cases, even attendance tracking. Given the frequency of their use, it is essential that ID cards are built to last.

Cheaply made ID cards can fade, break, or wear out quickly, causing frustration for employees, students, and management alike. This is where durable PVC ID cards come in, offering a long-lasting solution that withstands the rigors of everyday use. PVC (polyvinyl chloride) is a strong, flexible plastic material that can resist damage from frequent handling, ensuring that your ID cards remain functional and looking good for years to come.

At IVYPrints, the commitment to producing high-quality PVC ID cards guarantees that businesses and institutions receive a product that is not only visually appealing but also built to last.

2. Why Choose PVC ID Cards?

PVC ID cards are widely recognized for their durability and flexibility. Unlike paper or laminated cards, PVC cards are resistant to water, dirt, and physical wear and tear. This makes them an ideal choice for environments where ID cards are frequently handled, such as schools, offices, and events.

Here’s why PVC ID cards stand out:

Durability: PVC cards can handle rough conditions without getting easily damaged. Whether it’s being stored in a wallet, worn around the neck on a lanyard, or scanned multiple times a day, PVC cards are built to endure.

Customization: IVYPrints offers over 250 unique design templates, allowing businesses and institutions to customize their ID cards with logos, brand colors, and other essential details. PVC cards also support advanced features such as barcodes, RFID chips, and magnetic strips for added functionality.

Professional Finish: The high-quality printing used in PVC cards gives them a professional and sleek appearance. IVYPrints utilizes advanced printing technology to ensure that the colors are vibrant and the text is crisp, resulting in a card that reflects your brand’s professionalism.

Environmental Resistance: PVC cards are resistant to environmental factors such as moisture and temperature changes, making them suitable for both indoor and outdoor use.

3. IVYPrints: Setting the Standard for PVC ID Card Quality

IVYPrints has built a reputation as one of India’s leading ID card printing companies by consistently delivering products that meet the highest standards of quality and longevity. Here’s how IVYPrints ensures that their PVC ID cards stand out in the market:

Advanced Printing Technology: IVYPrints uses state-of-the-art printing technology to produce high-resolution, durable ID cards. Each card is printed with precision, ensuring that every detail, from text to design, is rendered perfectly.

Customized Solutions: No two businesses are alike, and neither should their ID cards be. IVYPrints offers fully customizable ID card solutions, allowing businesses to design cards that reflect their unique identity. From company logos to employee photos, IVYPrints ensures that every aspect of the card is tailored to your specifications.

Fast and Reliable Service: Time is a valuable resource for any business. With IVYPrints, you don’t have to worry about delays. They offer dispatch within 24 hours, ensuring that your ID cards are ready when you need them. This commitment to fast delivery is one of the reasons why IVYPrints has over 100,000 happy customers.

Trusted by Top Corporations: IVYPrints has earned the trust of top corporations and institutions across India. Their ability to consistently deliver high-quality products on time has made them the go-to partner for businesses looking for reliable ID card solutions.

4. Versatility for Multiple Sectors

IVYPrints’ PVC ID cards cater to a wide range of industries, each with unique needs. Here are a few examples of how their PVC ID cards are used across different sectors:

Corporate Offices: For businesses, PVC ID cards play an important role in access control and employee identification. IVYPrints’ cards can be customized with RFID chips or magnetic strips to integrate with access control systems, making them not just an ID but a security tool.

Schools and Universities: In educational institutions, ID cards are essential for both identification and security. IVYPrints provides durable cards that withstand daily use by students, teachers, and staff, ensuring a seamless experience for everyone.

Events and Conferences: For event management companies, IVYPrints offers ID cards that can be used as passes or badges for attendees. These cards can be customized to include event logos, sponsor branding, and even QR codes for easy scanning.

Healthcare: In hospitals and healthcare institutions, ID cards are critical for managing access and ensuring security. IVYPrints’ PVC cards are designed to endure the demands of the healthcare environment, offering a reliable solution for patient identification and staff access control.

5. Sustainability and Environmental Responsibility

IVYPrints is committed to not only delivering durable products but also doing so in an environmentally responsible way. PVC cards, while incredibly durable, can be recycled, and IVYPrints ensures that their production processes are as sustainable as possible. They continuously strive to reduce waste and optimize their production methods to minimize environmental impact.

6. Customer Satisfaction: 100K+ Happy Customers

IVYPrints’ dedication to quality and service is reflected in their customer satisfaction. With over 100,000 happy customers and a large portfolio of top corporations trusting their services, IVYPrints has established itself as a leader in the ID card printing industry. Their ability to deliver durable, high-quality products that meet the needs of diverse sectors has cemented their reputation as a trusted partner for businesses across India.

Conclusion

When it comes to ID cards, durability and quality are non-negotiable. IVYPrints has set the gold standard with its premium PVC ID cards, offering businesses and institutions a solution that is both long-lasting and visually appealing. From their commitment to fast delivery and customer satisfaction to their wide range of customizable templates, IVYPrints ensures that your ID cards are designed to meet your exact needs.

Choose IVYPrints for your PVC ID card requirements and experience the perfect blend of quality, durability, and exceptional service. Elevate your brand, enhance security, and ensure longevity with IVYPrints’ superior PVC ID cards.

0 notes

Text

Prestige Plastics: The Best Provider of Prestige FlowGuard® CPVC in Lahore, Pakistan

When it comes to reliable plumbing solutions, particularly in residential, commercial, and industrial settings, choosing the right material is crucial. For customers in Lahore, Pakistan, Prestige Plastics is the go-to supplier of the innovative and trusted Prestige FlowGuard® CPVC (Chlorinated Polyvinyl Chloride) systems.

With a reputation for high-quality products and exceptional customer service, Prestige Plastics has cemented its position as the leading distributor of FlowGuard® CPVC in the region. Here’s why Prestige Plastics is the best for Prestige FlowGuard® CPVC.

1. Industry-Leading Prestige FlowGuard® CPVC

FlowGuard® CPVC is widely recognized as one of the most reliable piping systems available, offering superior performance and safety over traditional materials. Prestige Plastics specializes in the distribution of Prestige FlowGuard® CPVC, which provides the following key advantages:

High Temperature Resistance: FlowGuard® CPVC can withstand temperatures up to 200°F (93°C), making it ideal for hot and cold water distribution.

Chemical Resistance: It is highly resistant to chemicals, ensuring it doesn’t corrode or degrade, even when exposed to harsh chemicals found in water supplies.

Longevity: With a lifespan exceeding 50 years, FlowGuard® CPVC is a durable solution that offers a long-term investment for both residential and commercial projects.

These features make Prestige FlowGuard® CPVC the material of choice for homeowners, builders, and engineers in Lahore who are looking for a reliable and safe piping solution.

2. Trusted Supplier with Extensive Experience

Prestige Plastics has built a solid reputation in Lahore and throughout Pakistan for its expertise in the distribution of top-tier piping systems. With years of experience in the industry, the company has become a trusted name in plumbing and construction solutions. Prestige Plastics works closely with its customers, providing expert advice on the best piping materials for their specific needs, and consistently delivers reliable solutions for:

Residential Plumbing Systems

Commercial Infrastructure Projects

Industrial Piping Solutions

Their extensive knowledge of the local market and plumbing requirements means customers can rely on Prestige Plastics for top-quality products and personalized service.

3. Commitment to Quality and Certification

One of the core values of Prestige Plastics is their commitment to providing only the highest-quality products to their clients. Prestige FlowGuard® CPVC meets or exceeds international standards and has been tested for performance and safety. Some of the certifications include:

NSF International Certification: Ensures the product meets strict health and safety standards.

ISO Certification: Guarantees the piping systems are manufactured to the highest international standards for quality.

Fire Safety Approval: FlowGuard® CPVC has been approved for use in fire sprinkler systems due to its flame-resistant properties.

Prestige Plastics takes pride in offering products that not only meet but surpass the regulatory requirements, giving customers peace of mind when choosing FlowGuard® CPVC for their projects.

4. Cost-Effective and Environmentally Friendly Solutions

In addition to being a high-performing material, Prestige FlowGuard® CPVC offers an environmentally friendly and cost-effective alternative to traditional piping materials like metal and PVC. The following features make it a superior choice:

Energy-Efficient Production: The manufacturing process of CPVC requires less energy compared to other materials, making it a sustainable option.

Lower Maintenance Costs: FlowGuard® CPVC is corrosion-resistant, reducing the need for repairs and maintenance, which translates to lower long-term costs for homeowners and businesses.

Reduced Environmental Impact: FlowGuard® CPVC is lead-free and non-toxic, making it a safer option for both indoor plumbing and the environment.

By offering FlowGuard® CPVC, Prestige Plastics is helping customers in Lahore reduce their environmental footprint while providing a cost-effective solution.

5. Excellent Customer Service and Support

Prestige Plastics is renowned not just for the quality of its products but also for the excellent customer service it offers. The team is highly knowledgeable about the products they distribute and works closely with clients to ensure they receive the best solution for their needs. The company provides:

Expert Consultation: Prestige Plastics assists customers in selecting the appropriate CPVC systems for their specific applications, ensuring efficiency and reliability.

Timely Delivery: With a robust distribution network in Lahore and beyond, Prestige Plastics ensures that customers receive their products promptly and efficiently.

Technical Support: For any issues related to installation or maintenance, Prestige Plastics offers dedicated technical support to guide customers every step of the way.

This commitment to service has earned Prestige Plastics a loyal customer base and a reputation as the most reliable supplier of Prestige FlowGuard® CPVC in Lahore.

6. Tailored Solutions for Various Industries

One of the key reasons why Prestige Plastics has become a leader in the CPVC market is its ability to provide tailored solutions across various industries. Whether it's residential plumbing, commercial building infrastructure, or industrial piping needs, Prestige Plastics ensures the right product for every application. Their solutions are widely used in:

Real Estate Developments

Manufacturing Plants

Hospital and School Facilities

Fire Safety Systems

Each project is unique, and Prestige Plastics takes pride in offering customized piping systems that meet the demands of diverse industries.

Conclusion: Why Prestige Plastics is the Best Choice for FlowGuard® CPVC in Lahore

When it comes to choosing the best CPVC piping system in Lahore, Prestige Plastics is the clear leader. Their expertise in distributing high-quality Prestige FlowGuard® CPVC, combined with their commitment to customer satisfaction, positions them as the top supplier in the region. For any plumbing or piping project in Lahore, Prestige Plastics delivers solutions that are reliable, safe, cost-effective, and built to last.

If you’re looking for the best provider of FlowGuard® CPVC in Lahore, look no further than Prestige Plastics.

0 notes

Text

Chlorinated Polyvinyl Chloride (CPVC) Prices | Pricing | Trend | News | Database

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic material widely used in various industries, including plumbing, industrial processing, and fire suppression systems. One of the critical aspects when considering CPVC for any project is its price, as it can significantly impact the overall budget. CPVC prices fluctuate based on multiple factors, making it essential for businesses and consumers to stay informed. In recent years, CPVC prices have been influenced by a combination of raw material costs, demand and supply imbalances, energy prices, transportation costs, and global economic conditions.

The cost of CPVC is primarily dependent on the price of raw materials, particularly chlorine and vinyl chloride monomer (VCM). These two essential components are crucial in producing CPVC, and any fluctuations in their availability or cost directly affect CPVC prices. When there is a shortage of chlorine or VCM, the supply of CPVC tends to tighten, driving prices higher. Conversely, when these raw materials are abundant and prices fall, CPVC manufacturers can offer the product at lower prices. However, since these raw materials are also used in other chemical processes, competing demand can result in increased prices, even when CPVC-specific demand is not significantly rising.

Get Real Time Prices for CPVC : https://www.chemanalyst.com/Pricing-data/chlorinated-polyvinyl-chloride-1411Energy prices are another key factor in determining CPVC prices. The production of CPVC is an energy-intensive process, and any changes in the cost of electricity, natural gas, or oil can impact the overall price. When energy prices rise, manufacturers often pass the additional cost on to consumers in the form of higher CPVC prices. The global energy market is highly volatile, influenced by geopolitical events, natural disasters, and government regulations. Therefore, any significant changes in energy costs can have an immediate and long-lasting effect on CPVC prices.