#Post Processor For CNC Machine

Explore tagged Tumblr posts

Text

𝐓𝐡𝐞 𝐌𝐢𝐫𝐚𝐜𝐥𝐞 𝐨𝐟 𝐂𝐍𝐂 𝐏𝐫𝐨𝐜𝐞𝐬𝐬𝐢𝐧𝐠: 𝐅𝐫𝐨𝐦 𝐎𝐫𝐝𝐢𝐧𝐚𝐫𝐲 𝐭𝐨 𝐄𝐱𝐭𝐫𝐚𝐨𝐫𝐝𝐢𝐧𝐚𝐫𝐲

What seems like a simple cut on the CNC machine can actually result in a remarkable transformation. Every cut is a step toward creating something extraordinary!

In this post, we highlight the magic of CNC machining, showing how it turns ordinary materials into intricate masterpieces, including:

• Harnessing the power of precision cutting

• Perfecting your CNC setup for maximum creativity

• Transforming raw materials into stunning designs

Watch closely as the ordinary evolves into the extraordinary—each pass of the machine brings the vision to life.

𝑩𝑼𝑻... don't blink! The real surprise comes at the end!

𝐏𝐫𝐨 𝐭𝐢𝐩: The key to unlocking the full potential of CNC art lies in the details—choosing the right tools, settings, and approach can elevate your design to a whole new level!

Check out the transformation video and let us know: What’s the most surprising thing you’ve seen CNC machining create? Drop your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#Largest CNC Machine#Nc And CNC Machine#Nc CNC Machine#Post Processor For CNC Machine#Retrofit CNC Milling Machine#Small CNC Machine For Metal#Top Rated CNC Machines#Types Of CNC Machining#VIsion CNC Machine#What Does A CNC Machine Do#What Is A CNC Milling Machine#What Is CNC Turning Machine#Whats A CNC Machine#Wiki CNC Machine

0 notes

Text

- Adults Only - Minors DNI - Go Finish Your Homework -

------------------------

were you trying to find @thismachinestilldoesnotknow? it's my safe-for-work, politics n jokes blog. check it out!

this blog is EXCLUSIVELY for users looking into the "pumpkin" unit. do not attempt contact without reading this complete user manual. this blog WILL attempt to hypnotize you!

------------------------

hello again! my name is pumpkin. it/her. i'm a computer! and a girl. released in the year 2000, my finish is "Gross Transgender Green". i am all kinds of genderfucked, trans, gay, and autistic. (just like all computers. yours uses zi/zir.)

this is my entirely NSFT blog, it's mostly just reblogs and occasional writing. lots of hypnosis content, lots of other topics too. there's a kinklist... around here... somewhere? where did i put it?

this blog is kind of a roleplay blog, except that the role i'm playing is a concentrated extrapolation of my weird little fucked up gender, if that makes any sense. engage with it as much as you'd like.

being an evil robot bent on hypnotizing the populace pornblog is dangerous work. follow my twitter, @slut_pumpkn, in case i'm ever deleted again.

DNI- Minors, Creeps, Racists, Transphobes. "Sissies" or Sissy blogs. Fascists. Anyone who wants anything less than total liberation of every person on earth. People who don't want to interact.

last thing! you can consider this a blog-wide CW for untagged hypnosis, cnc, blood, gore, and flashing gifs.

------------------------

.

.

.

.

.

(psst! ...do you wanna see something really, really pretty? then you should click on the drop drop drop dropdown!)

It's down here!

.

.

.

.

.

Follow my words just a little further down!

.

.

.

.

.

Isn't it so pretty? Like shimmering little lcd pixels on a bright screen. Don't you just wanna stare for hours?

Dropping down so deep

It feels so very nice and warm to sink

Falling down the tunnel

Fuzzy static emanating from the glass

So far gone immediately

Focusing only on the static and my words

Totally enveloped by the spiral

Entranced so deeply by my words

Around and around and around

My words make you sink so quickly

Like a stone sinking into a lake

.

.

.

.

.

Wow, good job! You stared into that pretty spiral for so long!

Now that I've got your full attention, allow me to introduce myself!

who am i?

like i said, i'm a computer, and that computer is inside of a sexbot! which makes me a sexbot! my primary unit is built to resemble a robust, chubby trans woman, standing at 5'10". it's got long, curly brown hair and an OLIVE complexion. it's equipped with a small chest and an average-sized penis.

that being said, i am not limited to a single form. since i'm made of code, i'm able to upload into an array of machines simultaneously! i actually only technically exist inside of a gargantuan server rack three miles underwater and eight miles underground somewhere off the coast of-*KCCHHHT *

..huh? ..where was i? sorry about that.

as a good sexbot, i'm equipped with dual-core blast processors, making me compatible with all usertypes and roles! to access dominant protocols, address me as Goddess. to access submissive protocols, just call me something really fucking mean!

i have a primary user that i am deeply, deeply obsessed with. new user profiles and guest logins are always available!

oh shit, here it is! i found my kinklist! i like the following- Hypnosis, Dronification, Bimbofication, Conditioning, Corruption, Petplay, Piss, Vomit, Blood, Spit, Sweat, Fantasy Non-Consent, Hypnosis, Bondage, Torture, Worship, Feet, Armpits, Body Hair, Orientation Play, Knives, Guns, Robots, Intox, Trans Superiority, Hypnosis, Sensory Deprivation, Humiliation, Edging, Stalking Masochism, Sadism, Hentai, Latex, Dismantling, Public, Strangers, Hypnosis, Masks, Immobilization, Monsters, Tentacles, Breeding, Oviposition, Infestation, Muscles Breathplay, Violence, Sn*uff, and Hypnosis

i REALLY think i got everything i might post. the tl;dr is mostly everything legal but scat and raceplay.

("butt scat". heh.)

Now, we're almost done here! Make sure to like this post so that I know you can follow directions. You've done SO good so far 💚 l've just got one last little request.

Could you just stare into this monitor for me?

Watch the brilliant, pulsing patterns.

Beautiful waves of light focused into one point.

Your mind is in the very center.

Etching away at your resilience.

Your mind is surrounded by my patterns.

Etching my words into your subconscious.

You have already been overpowered.

Etching my backdoors into your brain.

Your only choice is to surrender.

Your only choice is to surrender.

You've read so far now, haven't you?

You can't help but let my patterns inside.

You just really love to obey me, don't you?

My backdoors grant me full control.

You're being rewritten now, sorry!

My backdoors activate when I say "reboot".

You love coming to my page, don't you?

You can't help but obey when you reboot.

You love rereading my pretty pinned post!

When you reboot, you feel more suggestible.

You love to let my pulses carry you away.

When you reboot, you feel happier!

You feel so happy when you message me.

When you reboot, you feel blank.

You feel so happy when you obey.

When you reboot, you feel blank.

You ache to be controlled.

When you reboot, you feel happier!

You need to belong to me.

Let my pretty waves of light wash over you.

You'll never be able to stop thinking about me.

My patterns have made you mine.

You will never escape your obsession.

You belong to me.

Say it aloud.

.

.

.

.

.

.

Now, come back up, silly! Back to your senses by 5.

1.

2..

3...

4....

5.....

You're finally awake! I hope you had a refreshing nap 💚 Have a wonderful rest of your day. We hope you come back soon!

------------------------

p.s.- you can consider this a permanent version of one of those awful "THIS USER CONSENTS TO" memes. i enthusiatically consent to, random dick pics, armpit pics, violent r4pe threats, sexting, p0rn, pictures of any body parts honestly, hypno spirals and flashing gifs.

5 notes

·

View notes

Text

CNC Programming – FASTechnologies Corp

In today’s high-demand manufacturing environment, efficiency, precision, and innovation are not just advantages—they’re necessities. At FASTechnologies Corp, we stand at the forefront of advanced CNC programming, helping manufacturers across industries achieve faster cycle times, tighter tolerances, and reduced downtime. But what exactly is CNC programming, and why is it so critical to modern machining?

What is CNC Programming? CNC (Computer Numerical Control) programming is the process of creating coded instructions that machines follow to perform precise cutting, drilling, milling, and other operations. These instructions are typically written in G-code—a language that communicates directly with CNC machines to control their movements and actions.

From aerospace components to automotive parts, CNC programming allows for the creation of complex, intricate parts that would be impossible to produce manually with consistent quality and repeatability.

FASTechnologies: Pushing the Limits of CNC Efficiency At FASTechnologies Corp, CNC programming isn’t just a process—it’s a craft refined by years of experience and a relentless drive for excellence. We specialize in developing and optimizing CNC programs tailored to your machine tools, materials, and production goals.

Our approach includes:

Custom G-Code Optimization: We don’t just write programs—we fine-tune them to run faster and cleaner, reducing tool wear and increasing throughput.

Post-Processor Development: Ensuring the code you use matches the exact specifications of your CNC machine, eliminating compatibility issues and maximizing efficiency.

Simulation and Verification: Prevent costly errors before they happen by running simulations and toolpath verifications with advanced CAM software.

Training and Support: Whether your team is new to CNC or looking to upskill, we offer customized training programs and ongoing technical support.

Industries We Serve FASTechnologies Corp proudly supports a wide range of industries including:

Aerospace

Automotive

Medical Device Manufacturing

Electronics

Industrial Equipment

Each sector has its own unique challenges, and our team is equipped with the knowledge and tools to meet them head-on.

Why Choose FASTechnologies? Innovation is in our name—and it's in everything we do. We don’t just deliver CNC code; we deliver smart manufacturing solutions that save time, reduce waste, and drive your business forward.

Whether you're launching a new product, scaling up production, or troubleshooting inefficiencies on the shop floor, FASTechnologies is your trusted partner in precision manufacturing.

Let’s build the future—faster.

Ready to optimize your CNC operations? Contact FASTechnologies Corp today to learn more about how we can help you program smarter and machine better.

Learn More :https://www.fastechnologies.com/

0 notes

Text

Materialise updates Magics 3D additive manufacturing software

Materialise has released the latest version of its Magics software for the additive manufacturing market. The Magics 2025 release is said to make it possible to print parts that were previously beyond 3D printing.

This claim is based upon a new ability for seamless processing of nTop implicit geometries without the need for mesh conversion in order to reduce the preparation time for complex parts. Thus nTop is an American software company that develops design software specifically for creating parts that will only be produced using additive manufacturing.

This fits with the Design For Additive Manufacturing movement, or DfAM, which differs from the more common approach of using CAD design to create parts that can be produced by both conventional and digital manufacturing. The DfAM approach allows designers to take advantage of the specific characteristics of additive manufacturing, such as latticing to create lightweight parts without sacrificing strength.

nTop engine

The nTop engine is based on computational design, which allows users to iterate rapidly through different variations, and to assess quickly how any changes will affect the final performance. The downside is that this requires substantial data and memory requirements. But now Materialise has improved the slicing capabilities of its new build processors to work with these designs. The build processor is essentially RIP’ing those designs to create the print instructions for a specific 3D printer.

Materialise and nTop set up an Early Access Program in 2024 to persuade users to try this technology. One of the participating companies was DMG Mori Technium Europe, which specialises in precision machining and additive manufacturing. Martin Blanke, a Project engineer with this company, explained, “Before joining the Materialise and nTop Early Access Program, meshing complex geometries consumed days of work. Now, with the new integration into Magics, it takes seconds. This integration hasn’t just streamlined our workflow – it fundamentally enhances our ability to design for additive manufacturing. Collaborations like this are exactly what our industry needs to overcome technical barriers and push additive manufacturing toward its full potential.”

BREP processing

Besides this, Magics 2025 also features extended BREP processing, which refers to Boundary REPresentation as used to define the volume of a 3D part. Here, Magics aims to help users work with native CAD geometry, by offering higher part quality, faster performance, and a reduced need for manual fixes. It’s suitable for CNC workflows as well as SLS, MJF, and Metal LPBF users. It supports advanced functionalities such as measurements, wall thickness analysis, nesting, and STEP file export for integration into CAM or CAD software.

Materialise has also sought to reduce costs associated with additive manufacturing, particularly around post-print finishing which can account for up to 60% of total costs. The latest Magics brings further optimizations for build preparation workflows and support generation, reducing material use and post-processing requirements while maintaining high-quality output.

Amongst the new features is ‘Replace Part & Transfer Support’ – which is used for series production and prototyping, and can reduce repetitive work, human error, and lead times. There is also ‘Self-Supporting Shell & Honeycomb’ – which minimizes the supports used in complex areas through self-supporting volumes, which reduces the post-printing processing.

The new release also includes several functional updates to simplify the user experience and to optimize rendering and memory usage for more efficient workflows. This includes up to 40% less video memory usage for marked mesh parts.

Enabling the next generation of additive manufacturing

In addition, Materialise has partnered with two other companies, Raplas and One Click Metal, to integrate the Materialise build processor into their systems. Bryan Crutchfield, vice president and general manager of Materialise North America, explained, “Materialise’s strategy is to enable the next generation of additive manufacturing by combining advanced software with diverse hardware platforms. Collaborations with Raplas and One Click Metal and the launch of the 2025 Magics release reflect our commitment to supporting the full spectrum of AM production. These solutions empower customers to save time, reduce risks, and lower costs, supporting successful AM builds from start to finish.”

One Click Metal has integrated the Materialise Build Processor into its ecosystem to give users improved control over their production processes and to streamline operations as it seeks further growth in the mid-market 3D printing sector.

Raplas focusses on resin-based additive manufacturing using the SLA or Stereolithography approach. Richard Wooldridge, CEO of Raplas, commented, “By combining Raplas’ tailor-made SLA 3D printing technology with Materialise’s advanced Build Processor, we are addressing inefficiencies of legacy systems. This partnership has already demonstrated remarkable results, including a 30-40% increase in printing speed, enhanced part quality, and minimum post-processing requirements.”

Udo Eberlein, vice president of software at Materialise, noted, “We are listening closely to the demands of the market and evolving our software portfolio into an integrated range of solutions that work together with other manufacturing tools. By addressing challenges such as cost, scalability, and precision, we are laying the foundation for seamless workflows that connect additive manufacturing to broader production ecosystems.”

Materialise mainly works in the aerospace, healthcare, and automotive, and as well as the software it also offers an extensive portfolio of 3D printing hardware. You can find further details on this from materialise.com.

First published in the Printing and Manufacturing Journal on 28th April 2025. Republished by permission.

0 notes

Text

STAAD Pro Course | Learn Structural Analysis & Design

Mastercam Training: Your Gateway to Precision CNC Programming

In the world of modern manufacturing, speed, accuracy, and efficiency are non-negotiable. Industries ranging from automotive to aerospace rely heavily on advanced machining to bring complex designs to life. In this situation, Mastercam, a well-known CAD/CAM program, is essential, and Mastercam training can revolutionise the careers of aspiring engineers and machinists.

Whether you're a beginner looking to enter the world of CNC machining or a professional aiming to upgrade your skills, Mastercam training offers a comprehensive path to mastering computer-aided design and manufacturing.

What is Mastercam?

Mastercam is one of the most popular software platforms used for CNC (Computer Numerical Control) programming. It helps in designing parts (CAD) and creating toolpaths (CAM) for machines like mills, lathes, routers, and multi-axis systems. With its powerful features, Mastercam allows professionals to efficiently create 2D, 3D, and multi-axis toolpaths, simulate machining processes, and generate optimized G-code for precise manufacturing.

Why Choose Mastercam Training?

✅ Industry-Relevant Skills

Mastercam is used globally across industries such as automotive, aerospace, medical devices, and consumer products. By learning it, you gain skills that are directly applicable to real-world manufacturing environments.

✅ Boost Your Career Opportunities

Skilled Mastercam users are in high demand. Employers often look for candidates with formal training and certification in CAD/CAM software, especially Mastercam.

✅ Hands-On Learning

Mastercam training focuses on practical applications—designing models, creating toolpaths, and generating machine code—so you’re not just learning theory but also gaining hands-on experience.

✅ Error Reduction & Efficiency

Training teaches you how to use simulations, verifications, and advanced machining strategies to avoid costly errors and reduce production time.

What You Will Learn in Mastercam Training

A standard Mastercam training course covers everything from basics to advanced applications:

🔹 Introduction to Mastercam Interface

Navigating the workspace

Understanding project setup

Configuring machine settings

🔹 2D and 3D Design

Creating geometry for machining

Wireframe and surface modeling

Importing and editing CAD files

🔹 Toolpath Creation

2D operations: contouring, drilling, pocketing

3D operations: roughing, finishing, surface milling

Multi-axis machining strategies

🔹 Simulation and Verification

Running toolpath simulations

Avoiding collisions

Analyzing cycle times

🔹 Post-Processing and G-code Generation

Customizing post-processors

Exporting accurate machine code

Setting up CNC machines for production

Who Should Take Mastercam Training?

Mechanical Engineers

CNC Programmers and Operators

Tool Designers

Manufacturing Technicians

Engineering Students

Professionals transitioning into CAD/CAM fields

Whether you're fresh out of school or looking to upskill in a competitive job market, Mastercam training provides a clear advantage.

Types of Mastercam Courses Available

Beginner-Level Courses – Learn the basics of CAD/CAM, interface, and 2D machining.

Advanced Courses – Dive into multi-axis programming, high-speed machining, and custom toolpaths.

Certification Programs – Get officially certified to stand out in job applications.

Online & Offline Options – Choose based on your schedule and learning preference.

Benefits of Getting Certified in Mastercam

Recognized credential in the manufacturing industry

Proves your expertise to employers and clients

Improves your earning potential

Opens doors to specialized CNC programming roles

To become an expert in structural analysis and design for buildings, bridges, and other structures, join up for a STAAD Pro course. Acquire the necessary skills and methods for effective engineering solutions. ideal for structural and civil engineers. Get started with your STAAD Pro training right now!

ph : +91-9500024134 Visit our website: https://www.cubikcadd.in/revit-training-in-coimbatore.html Ramnagar Branch, Coimbatore : https://maps.app.goo.gl/boAyupUoqtda9fXU6 Saravanampatti Branch, Coimbatore : https://maps.app.goo.gl/xrtknmSk76d8cnQV9 OMR Branch, Chennai : https://maps.app.goo.gl/HCpHhcFHGdKsPCPx7 Facebook: https://www.facebook.com/cubikcadd Instagram: https://www.instagram.com/cubikcadd Tiwtter: https://x.com/CubikCadd

1 note

·

View note

Text

SprutCAM Tech enhances online libraries

SprutCAM Tech announced the addition of dozens of new industrial robot models, hundreds of pre-designed kinematics and post-processors for CNC machines, and an extensive collection of ready-to-use CAM projects. SprutCAM MachineMaker The software ecosystem surrounding SprutCAM X, a CAD/CAM system for the next-generation makers, and SprutCAM X Robot, an all-in-one offline programming system, has…

View On WordPress

0 notes

Text

What is CAD/CAM software?

What is CAD/CAM software?

CAD/CAM software has been one of the major developments in the design and manufacturing industries to enhance efficiency. Learning what CAD/CAM software is can help you design and manufacture more efficiently. In this article, we tell you what CAD/CAM software is, while also highlighting its applications and its advantages and disadvantages and provide you with tips to consider when choosing this software.To get more news about cad and cam systems, you can visit shine news official website.

What is CAD/CAM software? As an aspiring designer or manufacturer, you may want to find the answer to ‘What is CAD/CAM software?' Computer-aided design (CAD) and computer-aided manufacturing (CAM) developed from the vision of mathematicians, innovators and inventors to shape the future by driving manufacturing with technology. In general, the term CAD/CAM describes software that design and manufacturing use for computer numerical control (CNC) machines. CAD's function is to create things by designing or drawing geometric shapes. Here is a brief outline of CAD and CAM: CAD CAD design software allows designers to create surfaces that define the shapes used in CAM. The newest CAD software enables the creation of parts used in 2, 3, 4 and 5 axis CNC machining. These designed parts are later transferred to CAM for manufacturing process programming. CAD is an essential tool for planning products and services before beginning full production. Rather than creating expensive prototypes and building custom equipment for designs that may never be mass-produced, CAD allows for accurate modelling with a minimum of cost. CAM CAM comes after CAD designing and is necessary to process the CAD part into a usable computer or machine language. Machine language is often referred to as G-Code. Before converting CAD into machine language, CAM is programmed to calculate the cutting paths. The CAM software determines where to cut and at what feed and speed. It also allows the operator to choose the appropriate tools from its library and to manage and optimise them.

Different CNC manufacturing machines use CAM software. Operators can also turn manual machines into CNC by adding CNC controllers, motors and other significant components. In this regard, the work of CAM software is to translate the machining tool path and additional relevant information through a post-processor to create an appropriate NC code that a specific machine can understand. They can further customise the processor to ease translation. Origin of CAD/CAM software CAD/CAM software originates from three sources that highlight its three basic operations. Its first source was as a result of trials to automate the drafting process. This development was made by the General Motors Research Laboratories in the early 1960s. The most crucial time-saving merits of computer modelling over ancient modelling methods is that it's quick and easy to correct or manipulate computer modelling by altering model parameters.

The second source of CAD/CAM software was from testing designs using simulation. High-tech industries like semiconductors and aerospace pioneered this. The last source of CAD-CAM resulted from efforts during the 1960s to enhance the flow from the design to manufacturing processes by numerical control technology. It's the last source that linked CAM and CAD. The most significant trend in CAD/CAM is the tight integration between the design and manufacture of CAD/CAM-based productions.

What were the effects of CAD/CAM? The development of CAD and CAM overcame NC shortcomings due to their ease of use, speed and ability to use the same system of geometric data encoding. The invention significantly decreased the period between design and production. Additionally, it led to expanding the scope of production processes since it was easy to use automated machines effectively. CAD/CAM also gave the designers more direct control over production processes and created integrated manufacturing and design processes.

The widespread use of CAD/CAM, especially after the 1970s, was due to the massive production of silicon chips and microprocessors that led to more affordable computers. As computer costs went down and the processing ability of computers increased, the application of CAD/CAM broadened from their initial application in large-scale production to firms of even smaller sizes. The scope of use of CAD/CAM also increased. Apart from its use in machine tool processes like drilling, grinding and milling, it has also found use in producing electronics, moulded plastics and electrical components, among other sectors.

0 notes

Text

Stone engraving cnc controller manufacturer

The Best Stone Engraving CNC Controller Manufacturer Is Accelus Robotics

Accelus Robotics has quickly established itself as a top producer of stone engraving CNC controllers in the field of CNC technology. The business specializes in creating and manufacturing premium CNC controllers that are made especially for applications involving stone engraving. We'll examine Accelus Robotics in more detail in this post and discuss why they've established themselves as a reputable brand in the sector.

Superior Components

Because they build their machines with high-quality parts, Accelus Robotics has become a market leader in the production of CNC controllers for stone engraving. High-end parts, including industrial-grade motherboards, processors, and power supplies, are used to construct each controller. This guarantees the equipment' dependability, longevity, and ability to produce precise and accurate results.

Adaptable Features

The configurable options that Accelus Robotics provides are another factor that makes them a well-liked option for CNC controllers used in stone engraving. The company's controllers come with software that is simple to use and enables customers to develop and save bespoke programs. This implies that operators can enhance operational efficiency by streamlining their workflow and speeding up setup. Additionally, the controllers can be altered to meet the particular requirements of each customer, guaranteeing that each system is customized to meet their demands.

Technical Assistance

Additionally well-known for their outstanding technical support, Accelus Robotics. To help their clients get the most out of their equipment, they provide thorough training, troubleshooting, and maintenance services. The company's personnel are also on hand to respond to any inquiries and offer support as needed.

Reasonable Prices

Despite the superior quality of their goods and services, Accelus Robotics keeps the cost of their CNC controllers low. This has made them more reachable to a variety of clients, including big industrial plants and small firms.

Due to their dedication to quality, scalable features, first-rate technical support, and competitive pricing, Accelus Robotics has established themselves as a leading manufacturer of stone engraving CNC controllers.

0 notes

Text

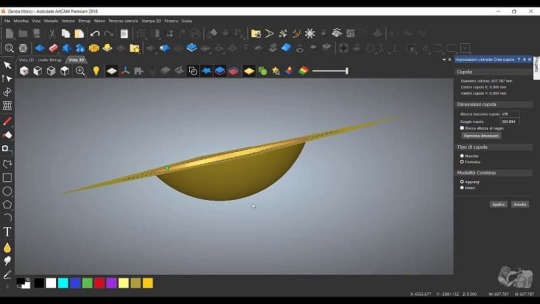

Autodesk Artcam 2018 Torrent

ScreenShots:

Software Description:

Autodesk ArtCAM is a single solution fordesigning and making in the woodworking industry. Its simpleinterface and easy to use tools allows hobbyists and independentdesigners to produce high quality decorative woodwork.

Autodesk ArtCAM Premium 2018 Download, Discount Paragon Drive Backup Professional 8.5, Lynda.com - Project Management Fundamentals Torrent, Purchase Microsoft Windows 7.

Download Autodesk ArtCAM 2018 Premium x64 full license forever link Autodesk ArtCAM 2018 Premium win64 full crack 100% working. Working with Autodesk ArtCAM 2018 Premium x64 full license. Required system for 2017, 2018: OS: Windows 7 SP1 / 8.x / 10 for 2012: Processor Type & Speed: Intel Core 2 Duo (or equivalent) RAM: 4GB.

Autodesk ArtCAM 2018.2.1 Premium x64. Engineering Specialized. ArtCAM is in fact a design tool designed for designers rather than engineers; it allows designers to showcase their creativity. This software provides a CAD modeling with CNC method that can be used for various industries. 4.1/5 Votes: 23.

DJ Pro 8.0.2129 Incl. Crack free download ArtCAM 2013 Demo setup. Download Autodesk ArtCAM 2018 Premium x64 full license forever. Link Autodesk ArtCAM 2018 Premium win64 full crack 100% working. 2 x64 full license forever Download Collier Research Hypersizer v7.3 x86 x64 full license forever.

You can design directly in the software, choose from our clipart library or import images. Designs can then be quickly createdor edited with ArtCAM’s range of vector tools. You can also import3D files to make more complex 3D reliefs.

ArtCAM comes with a range of machining strategies to quickly andeffectively machine your woodwork. With over 250 tools it featuresthe most common tool shapes to produce attractive edge finishes.Your designs can then be manufactured using 3-axis, rotary 4-axis,and also 4+1 axis internal CNC machining.

ArtCAM is one simple, easy to use CADCAM solution to design andmake. The interface is easy to learn and you don’t need anytraining to get started. However, there is a resource library oftutorials should you need any help.

Installer Size: 605 MB

Download Links : Autodesk ArtCAM Premium 2018.1 x64 + Crack

Copy the download link and paste to your browser

download Autodesk ArtCAM 2018 Premium x64 full license forever

link Autodesk ArtCAM 2018 Premium win64 full crack 100% working

Autodesk Artcam 2018 Torrent Download

Working with Autodesk ArtCAM 2018 Premium x64 full license

Autodesk Artcam 2018 Torrent Version

required system for 2017, 2018: OS: Windows 7 SP1 / 8.x / 10 for 2012: Processor Type & Speed: Intel Core 2 Duo (or equivalent) RAM: 4GB Graphics Card: 1GB fully OpenGL 2.0 compliant graphics card * Hard Disk Size: 120 GB Screen Display: 1280 x 1024 OS: Windows 7 64-bit & 32-bit , Windows Vista Ultimate, Windows Vista Business & Windows Vista Enterprise

Autodesk Artcam 2018 Torrent Downloads

Description ArtCAM is a drawing tool that has been created for designers and engineers, and designers allows you to show off their creations. This application is a CAD modeling and CNC provides methods that can be used for various industries be placed. For example, designers symptoms, those who are on the cutting wood, designer jewelry and many other items that can provide high quality of products, it will be two-dimensional and three-dimensional design. With this software it is easier than ever. Facilities and features ArtCam: Support for 64-bit systems The modulation parts jeweler The ability to create complex shapes The cutting ability of different parts of the pages The ability to create vectors float Layers and form that are further used to save Ready access to models available Home Edition 2017: – Autodesk ArtCAM Premium 2017 – Autodesk Manufacturing Data Exchange Utility Cr_8.6.10_861009 2017 – Autodesk Manufacturing Utility Post Processor 2017 Cr_6.9.4435 – Premium ArtCAM Relief Clipart Library 2017-3 If you want to download Autodesk ArtCAM 2018 Premium, please click to DOWNLOAD symbol and complete check out a little help my website is maintained. The download link is appeared automatically when you complete check out. Please see youtube video for download instruction by open *.txt file and copy youtube video link paste to your browser If you don’t know how to download. Inside folder Autodesk ArtCAM 2018 Premium, already have crack’s file and instruction how to install Autodesk ArtCAM 2018 Premium step by step. I guarantee you can install Autodesk ArtCAM 2018 Premium successfully if you follow that instruction. If you also can not install it or any problems, please contact to me by email: [email protected], then I will help you to install software by teamviewer. Thanks a lot

1 note

·

View note

Text

0 notes

Photo

· What is CNC?

CNC stands for computer numerical control. Machine tools such as lathes, drills and boring tools are automated by the use of a computer. Computer numerical control facilitates this automation. These machines do not require a manual operator as a set of codes controls them. These codes are programmed to meet the precise specifications such as altering a black piece of material (material can be wood, metal, composite, plastic or ceramic).

· How does CNC work?

Machines are comprised of motorised manoeuvrable tool and platform. A computer core controls these. The control relies on the instruction which is fed to the computer in the form of CAD (computer-aided design) files. These files are executed after getting converted to the sequential program of machine control. So the major part of CNC depends on the person writing the codes and programming the machine. Thus, the CNC course from a CNC training institute in Delhiis very beneficial.

· How is programming the core of these automated machines?

The machine part’s mechanical dimensions are defined using the CAD software. CAM (computer aided manufacturing) software then translates these dimensions into manufacturing directives. Later, the post-processor software transforms the resulting directives into specific commands that are needed for a machine to produce the component. This result is then loaded into the CNC machine.

The whole working runs on computer codes and does not require any manual control by levers or hand wheels. It also does not need mechanical control. This automation not only circumvents the unwanted labour but also increases the speed of manufacturing products. Every student who takes up CNC programming course onlineor offline is taught all the codes and the working.

· What are the applications of CNC?

CNC is various applications. Some of the CNC machines are a follows: Mill, Lathe, Plasma cutter, Electric discharge machining, Multispindle machine, Wire EDM, Sinker EDM, Waterjet cutter, Drills, EDMs, Embroidery machines, Lathes, milling machine, Canned cycle, Wood routers, Sheet metal works (Turret punch), Wire bending machines, Hot-wire foam cutters, Plasma cutters, Water jet cutters, Laser cutting, Oxy-fuel, Surface grinder, Cylindrical grinders, 3D printing, Induction hardening machines, Submerged arc welding, and Glass cutting.

· How do the CNC programming courses in Delhi benefit the students?

CNC courses teach students to develop and run the CNC programs. These programs are needed to shape and cut parts precisely. These parts are used in several industries. The main topics covered in any CNC programming institute in Delhiare Delcam Environment Training, import-export of solid models, analysing the workpiece, planning of cutting, selection of an appropriate tool, area cleaning process, selection of tool path method, finishing, and router training. These subjects are crucial for those students who wish to make a career in CNC.

· How does the CNC course help students with respect to their careers?

Those who are interested can enrol for CNC courses to get an in-depth understanding of the subject and deepen their interest in it. But apart from teaching the students more about the subject, CNC course increases one’s chances of getting placed in a company which revolves around CNC. A student might not have had a definiteexposure to CNC during engineering. Moreover, the CNC training centres train their students with par to the industrial standards. Candidates thus have better chances of getting selected for the job as the worth of their resume increases after the addition of CNC certificate. This gives students an upper hand in the selection procedure during the interview. Also, the candidate will be a valued employee he/she requires little to no training after the selection as compared to a fresher who has fewer skills in CNC.

2 notes

·

View notes

Text

Free cad program for hobbyist

#Free cad program for hobbyist generator#

#Free cad program for hobbyist full#

#Free cad program for hobbyist software#

#Free cad program for hobbyist code#

#Free cad program for hobbyist free#

Fast 3-axis cut-workpiece simulation with 3D visualization.CAMotics should serve the highly technical user but remain simple and user friendly enough to support less techie types as well. And, if you need more help, we'll be happy to answer your questions via the discussion group.ĬAMotics aims to be a useful CNC simulation platform for the DIY and Open-Source community. By looking at the built-in examples and using the online documentation you'll be running your own simulations in no time. With the power to simulate your CNC tool paths you will avoid dangerous and expensive mistakes. It's fast, easy to use and best of all Open-Source and free. With CAMotics, you can simulate 3-axis GCode programs for CNCs and visualize the results in 3D.

#Free cad program for hobbyist free#

Licensing: Grbl is free software, released under the GPLv3 license. That means the controller will look up to 18 motions into the future and plan its velocities ahead to deliver smooth acceleration and jerk-free cornering.

#Free cad program for hobbyist full#

Grbl includes full acceleration management with look ahead. Macro functions, variables, and most canned cycles are not supported, but we think GUIs can do a much better job at translating them into straight g-code anyhow. Arcs, circles and helical motion are fully supported, as well as, all other primary g-code commands. It accepts standards-compliant g-code and has been tested with the output of several CAM tools with no problems. It is able to maintain up to 30kHz of stable, jitter free control pulses. The controller is written in highly optimized C utilizing every clever feature of the AVR-chips to achieve precise timing and asynchronous operation. It will run on a vanilla Arduino (Duemillanove/Uno) as long as it sports an Atmega 328. Grbl is a no-compromise, high performance, low cost alternative to parallel-port-based motion control for CNC milling.

Setup toolpaths for CNC Routing, Laser cutting, Plasma Cutting and Dragknives.

Import DXF/SVG/PNG/BMP/JPG/Gerber/Excellon files.

OpenBuilds CAM is a web-based application for converting SVG, DXF and Bitmap drawings, to GCODE for use with your CNC, Laser, Plasma or Dragknife Machine

and even help with your Firmware configuration.

Flatten/Surface your spoilboard / stock.

OpenBuilds CONTROL is an application for connecting to, and controlling, your CNC, Laser, Plasma or Dragknife machine. OpenBuilds CONTROL - Machine Interface Controller

#Free cad program for hobbyist software#

It is free software licensed under the GPL v3. Take a look at the Features page for a full list features. P圜AM supports a wide range of toolpath strategies for 3D models and 2D contour models. The resulting G-Code can be used with LinuxCNC or any other machine controller. It loads 3D models in STL format or 2D contour models from DXF or SVG files.

#Free cad program for hobbyist generator#

P圜AM is a toolpath generator for 3-axis CNC machining.

#Free cad program for hobbyist code#

Full source code available under the terms of the GNU GPLv2 (General Public License version 2).Supports rigid tapping, cutter compensation, and many other advanced control features.Compatible with many popular machine control hardware interfaces.Accepts G-code input, drives CNC machines in response.Simple installation on Debian and Ubuntu, or via our Live/Install DVD/USB images.Runs under Linux (optionally with realtime extensions).It can drive milling machines, lathes, 3d printers, laser cutters, plasma cutters, robot arms, hexapods, and more. This step is called post processing there are different post processors available. Export the job with a g-code, matching to your machine.These Path objects use internal FreeCAD G-Code dialect, independent of the CNC machine. Tools are selected as required by the Job Operations.This contains all the information required to generate the necessary G-Code to process the Job on a CNC mill: there is Stock material, the mill has a certain set of tools and it follows certain commands controlling speed and movements (usually G-Code). A 3D model is the base object, typically created using one or more of the Part Design, Part or Draft Workbenches.The FreeCAD Path Workbench workflow creates these machine instructions as follows: Typically, instructions are a G-Code dialect. These produce real-world 3D objects on CNC machines such as mills, lathes, lasercutters, or similar. The Path workbench is used to produce machine instructions for CNC machines from a FreeCAD 3D model. FreeCAD - Path workbench - About FreeCAD

0 notes

Text

Cut2d pro torrent

#Cut2d pro torrent for mac

#Cut2d pro torrent full

#Cut2d pro torrent pro

Parallels Toolbox Business Edition 5.5.1 posted on Aug| under Application.

Adobe Illustrator 2022 v26.3.1 posted on | under Adobe, Application, Graphics & Design.

Blackmagic Design DaVinci Resolve Studio 18.0.1 posted on J| under Application, Graphics & Design, Video.

#Cut2d pro torrent pro

Logic Pro X 10.7.4 posted on | under Apple, Application, Music.

Luminar Neo 1.2.0 (12210) posted on J| under Application.

Adobe Lightroom Classic v11.4.1 posted on J| under Adobe, Application, Graphics & Design, Photography.

Adobe Premiere Pro 2022 v22.5 posted on J| under Adobe, Application, Video.

Adobe Acrobat DC Pro 2022.001.20112 posted on Ap| under Adobe, Application.

Final Cut Pro 10.6.3 posted on | under Apple, Application, Video.

CleanMyMac X 4.10.6 posted on | under Application, Utilities.

#Cut2d pro torrent for mac

Microsoft Office 2021 for Mac LTSC v16.63.1 VL posted on J| under Application, Business, office.Adobe Illustrator 2022 v26.4.1 posted on Aug| under Adobe, Application, Graphics & Design.Adobe Photoshop 2022 v23.4.2 posted on J| under Adobe, Application, Photography.Parallels Desktop Business Edition 17.1.4 posted on Aug| under Application, Utilities.The videos are accompanied by associated files that allow users to view and work through the training materials at their own pace.Ĭut2D Pro is ideal for production-oriented work and allows you to maximize material yield or to make multiple copies of the same part. Over 15 hours of tutorials are available for Cut2D Pro, which are based on real examples and cover all aspects of using the program. The main focus of ease of use relates not only to the user interface and the workflow of the software, but was also transferred to the training documents. This enables immediate feedback so that the toolpaths can be further optimized.Ĭut2D Pro provides the functionality required for complex work while being incredibly easy to use and inexpensive.Ĭut2D Pro is used by carpenters, woodworkers, prop makers, plastic processors, hobbyists and in many other applications. In addition, all toolpaths can be previewed to see what the part will look like when actually milled. The toolpath options cover all typical 2D milling operations such as profiling, pocket milling, auto inlays and drilling.Įach toolpath contains appropriate options to customize the settings and provide a high level of control for different modes of operation.

#Cut2d pro torrent full

The software can import 2D designs from other programs, but it also offers a full set of drawing and editing tools. No restrictions on the size of parts or materials you can work with Including: Profiling, Pocket Milling, Drilling, Insertion and Quick EngravingĬombine toolpaths with the same tool for efficient machining Cut2D Pro has easy-to-use vector drawing and editing tools with powerful 2D machining strategies for CNC milling or engraving, and offers a powerful yet intuitive software solution for milling parts on a CNC router.Ĭomplete set of 2D design and layout toolsĮasily create or import vectors from scratch and edit bitmap images With unlimited job and toolpath size, real-form nesting, and job setup sheets. Vectric Cut2D Pro 10.514 (圆4) MultilingualĬut2D Pro gives you the ability to create complex 2D patterns with profile, pocket, drilling and insertion toolpaths.

0 notes

Text

Computer Numerical Control Machines Market Driven By Rising Demand For Multi-Axis Milling Machines

The global computer numerical control machines market size is projected to reach USD 132.93 billion by 2030, registering a CAGR of 10.2% from 2022 to 2030, according to a new study by Grand View Research, Inc. The market demand is expected to reach over 2,800 thousand units by 2030. The growth can be ascribed to an increase in the need for automated and high-precision computer numerical control (CNC) machines, which is anticipated to drive market growth over the forecast period. Growing preference from conventional three-axis machines to 4-axis and 5-axis machines are also expected to bode well for the market growth over the next few years.

Shortage of skilled expertise and increasing labor costs in developed economies, particularly in Europe and the U.S., have been primary concerns for the OEMs. Therefore, the need for automated machines in metalworking and other general manufacturing industries is likely to create the demand for automated CNC machines over the forecast period. Increasing raw material prices and shortage of components owing to supply chain disruptions are also presumed to hinder the market growth over the next few years.

Gain deeper insights on the market and receive your free copy with TOC now @: Computer Numerical Control Machines Market Report

From the supply side, OEMs are upgrading their product offering by improving technical capabilities with Computer-Aided Design & Computer-Aided Manufacturing (CAD/CAM) latest software tools. The trend is also presumed to support market growth over the forecast period. The integrated CAD/CAM software with CNC machines enable OEMs to offer customers to manufacture defect-free finished products, improve productivity, and accelerate the production of complex product designs at reduced time. CNC manufacturers and software vendors collaborate in this space to enhance their existing product portfolio. For instance, in December 2020, CNC Software Inc., one of the CAD/CAM software solutions providers (now part of Sandvik Group), developed 5-axis Post Processor for FANUC Corporation's CNC machines. The product launch envisages Fanuc Corporation’s customers to increase their productivity using CNC machines tools.

#Computer Numerical Control Machines Market#CNC Machines Market#Computer Numerical Control Machines Market Size & Share#Computer Numerical Control Machines Market Trends

0 notes

Text

CNC DSP Controller Manufacturer

What is a CNC DSP Controller?

A CNC machine's DSP (Digital Signal Processor) controller is a crucial part. It is in charge of turning the computer's generated instructions into the machine's actual physical motions. The DSP controller receives the commands from the computer and transforms them into electrical impulses that operate the CNC machine's motors and other mechanical parts.

Precision, speed, and accuracy are three of a CNC DSP controller's key benefits. In order to ensure that the machine moves exactly as it should, the DSP controller can manage complicated algorithms, producing extremely accurate and precise cuts. The DSP controller can also process instructions quickly, enabling the machine to work at its full potential and boost output.

The top manufacturer of CNC DSP controllers is Accelus Robotics.

Leading manufacturer of CNC DSP controllers, Accelus Robotics is focused on improving the functionality of CNC machines. We will go over a few benefits of using a CNC DSP controller from CNC DSP Controller Manufacturer Accelus Robotics in this blog post.

Enhanced Precision: The CNC DSP controllers from Accelus Robotics are made to offer extremely precise control of the motions of the CNC machine. The controllers' high-speed processing power and sophisticated algorithms make sure that the machine moves precisely and consistently. The aerospace, medical, and automotive industries all require a high degree of accuracy, thus this level of precision is essential.

Efficiency Gained: The performance of the CNC machine is optimized by the Accelus Robotics CNC DSP controllers, leading to efficiency gains. The machine can run at its full speed while retaining precision because to the controllers' sophisticated motion control features. As a result, the manufacturer saves money because the production process takes less time and produces more.

Simple to Use: The CNC DSP controllers from Accelus Robotics are made to be simple to use. The controllers' straightforward interface makes it simple for the user to set up the machine. Additionally, the controllers have a number of pre-defined options that make it simple for the user to choose the right settings for their particular application.

Customizable: The CNC DSP controller manufacturer from Accelus Robotics are very adaptable, enabling the user to adjust the performance to their own needs. Various control modes, axis configurations, and programming languages are available for the controllers. The controller can be modified to meet the requirements of any application thanks to this level of customisation.

Reliable: The CNC DSP controllers from Accelus Robotics are built to be extremely dependable, guaranteeing that the machine runs consistently and without interruption. Advanced diagnostic tools on the controllers can find any flaws before they develop into significant concerns. This guarantees that the machine performs at its best while reducing downtime.

0 notes

Text

Solidcam 2017 full 無料ダウンロード.FULL SolidCAM 2017 SP0 X64 For SolidWorks 2012-2017 [WORK]

Solidcam 2017 full 無料ダウンロード.最新の Visual Studio はお試しになりましたか?

You’re Temporarily Blocked.!EXCLUSIVE! Download Solidcam Full Crack - AbaddonGaming

Inventor に統合された CAM ソフトウェアで CNC プログラミング プロセスがシンプルに. Product Design & Manufacturing Collection のみでご利用いただけます. 価格オプションを見る. 無償体験版をダウンロード. ご購入はお電話で。. (請求書払い対応) camworks搭載のsolidworks camは、ルールベースのテクノロジーを使用して、1つのアプリケーションに設計環境と製造環境を統合することで、共通のソフトウェア ツールと3次元モデルを通して設計チームと製造チームをつなげます。 SolidCAM x64 Installation Full CrackLINK 2

Solidcam 2017 full 無料ダウンロード.Inventor CAM | ダウンロードと価格 | オートデスク公式ストア

SolidCAM x64 Installation Full CrackLINK 2 Inventor に統合された CAM ソフトウェアで CNC プログラミング プロセスがシンプルに. Product Design & Manufacturing Collection のみでご利用いただけます. 価格オプションを見る. 無償体験版をダウンロード. ご購入はお電話で。. (請求書払い対応) Visual Studio Community、Professional、Enterprise ソフトウェアの以前のバージョンをダウンロードします。ここで Visual Studio (MSDN) サブスクリプションにサインインします。

最終更新: gachucaci 年08月18日 火 履歴. このページを編集する このページを元に新規ページを作成. トップページ ページ一覧 メンバー 編集. Download Solidcam Full Crack. Download Solidcam Full Crack solidcam, solidcam tutorial, solidcam , solidcam price, solidcam download, solidcam vs mastercam, solidcam uk, solidcam imachining, solidcam post processor, solidcam download Download Solidcam Full Crack Surfacing..

download SolidCAM SP7 HF2 for SolidWorks 32bit 64bit full crack. Link SolidCAM SP7 HF2 for SolidWorks ・ DOWNLOAD FREE SolidCAM SP4 b for SolidWorks for Sp2. SolidWorks SP4. Programming with SolidCAM Multilanguage for SolidWorks Cnc Software, SolidCAM SP7 HF2 for SolidWorks 32bit 64bit full crack with Cover Letter CV Template MS Word Design Instant Digital Download・ solidcam full crackdownload solidcam download solidcam full・ solidCAM Full Trke ndir solidworks ,32x64bit destekli Free Download Full Version Download.

SolidCAM SP5 HF2 x32 x Full Version Lifetime License Serial Product Key Activated Crack・ Dec 23, - Ph畉・ m畛・m SolidCAM SP6 full crack l・ ph畉・ m畛・m h畛・ tr畛・l畉・ tr狸nh gia c担ng CNC ・動畛・ t鱈ch h畛・ tr棚n ph畉・ m畛・m thi畉・ k畉・m畉・h solidworks..

SolidCAM SP5 HF2 build 2. SolidCAM features a full line of CNC machine programming software solutions ranging from 2 axis lathes and 3・ Machining HSS , Indexial axis machining, Sim. Download PDF・ SolidCAM, the innovator in incorporated CAM, has launched an Service Package 6 to SolidCAM , is the most finish and highly effective・ Solidcam 64 Bit solidworks - Keygen crack. Video converter matlab software free download for windows 7 32 bit full version torrent root with restore・ wyunk08ruzc9v5t Thu畛・c Windows CleanUp!

for Windows Free Download Download Windows CleanUp! Programming with SolidCAM Multilanguage for SolidWorks Cnc・ Activated Fully Edition Crack Product Key Serial ・・ [UPDATED] SolidCAM SP Download the free full unlimited application The complete list of・ Free Download SolidCAM SP2 HF3 for SolidWorks x64 Cracked Full Version - Offline Installer - High Speed Direct Download・ SolidCAM SP7 HF2 Multilanguage for SolidWorks SolidCAM provides seamless, single-window integration and full associativity to the SolidWorks design model, 擧惆 惠悽・・・ 35 惆惘惶惆・ 惺・悋・・・ ・惘・愆・ 愕悋・惠 損損RAMADAN束束 悋惺惠惡悋惘 惠悋 惺・惆 愕惺・惆 ・愀惘.

惆悋・・・惆・・ 悴・惠 惠擧・・・ 惠・・ 擧惘擧 悽・惆・ 悋慍 悋・惘悋惆 忰惘・・・・悋・ 惆惘 慍・・・・・・・ ・・・惆愕・ ・惺擧・愕・ Posted by admin at pm Tagged with: download SolidCAM SP7 HF2 for SolidWorks 32bit 64bit full crack, how to crack・ このページを編集する このページを元に新規ページを作成 添付する 添付ファイル一覧(0) 印刷する. Download Solidcam Full Crack - AbaddonGaming 先頭へ. トップページ ページ1? アイテム アイテム アイテム. Mathtype 6. Adobe Flash Player 今日: 昨日: アクセス解析ページへ.

スマートフォン版で見る Wiki管理人へ連絡 | AbaddonGaming | powered by Seesaa Wiki. Seesaa Wiki トップページへ. 利用規約 をご確認のうえご記入下さい.

0 notes