#VIsion CNC Machine

Explore tagged Tumblr posts

Text

𝐓𝐡𝐞 𝐌𝐢𝐫𝐚𝐜𝐥𝐞 𝐨𝐟 𝐂𝐍𝐂 𝐏𝐫𝐨𝐜𝐞𝐬𝐬𝐢𝐧𝐠: 𝐅𝐫𝐨𝐦 𝐎𝐫𝐝𝐢𝐧𝐚𝐫𝐲 𝐭𝐨 𝐄𝐱𝐭𝐫𝐚𝐨𝐫𝐝𝐢𝐧𝐚𝐫𝐲

What seems like a simple cut on the CNC machine can actually result in a remarkable transformation. Every cut is a step toward creating something extraordinary!

In this post, we highlight the magic of CNC machining, showing how it turns ordinary materials into intricate masterpieces, including:

• Harnessing the power of precision cutting

• Perfecting your CNC setup for maximum creativity

• Transforming raw materials into stunning designs

Watch closely as the ordinary evolves into the extraordinary—each pass of the machine brings the vision to life.

𝑩𝑼𝑻... don't blink! The real surprise comes at the end!

𝐏𝐫𝐨 𝐭𝐢𝐩: The key to unlocking the full potential of CNC art lies in the details—choosing the right tools, settings, and approach can elevate your design to a whole new level!

Check out the transformation video and let us know: What’s the most surprising thing you’ve seen CNC machining create? Drop your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#Largest CNC Machine#Nc And CNC Machine#Nc CNC Machine#Post Processor For CNC Machine#Retrofit CNC Milling Machine#Small CNC Machine For Metal#Top Rated CNC Machines#Types Of CNC Machining#VIsion CNC Machine#What Does A CNC Machine Do#What Is A CNC Milling Machine#What Is CNC Turning Machine#Whats A CNC Machine#Wiki CNC Machine

0 notes

Text

https://hsmleindia.com/product/vision-measuring-machine-vms-series/

Vision Measuring Machine-VMS-Series

HSMLE owns a complete series of vision measurement machine for manual type machine, NC type Automatic measurement machine with practice function to CNC type fully automatic measurement a machine with offline programming, high speed and efficiency function in order to meet different customer’s requirements. All HSMLE Vision Measurement Machines are compatible with RENISHAW high accuracy touch trigger probe to measure parts in Z-axis or simple-3D measurement. SPC statistic analysis software is a standard configuration for all Vision Measurement Machines. It allows customers to carry out scientific analysis for the production flow to find error trend in the flow and problems in the operations. In addition, all measurement results may be outputted in popular Microsoft office software, such as MsExcel, MsWord to make customers save results conveniently for working out a quality inspection report or analysing further.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#measuring machine#measurement machine#vision measuring machine#vision measurement machine#video measuring machine#video measurement machine#cnc vision measuring machine#cnc vision measurement machine#cnc video measurement machine#vision measuring machine supplier#vision measurement machine manufacturer#video measuring machine supplier#video measurement machine manufacturer

1 note

·

View note

Text

Khushal Wood Wood CNC Design Barara Your Trusted Partner for Custom Wood Solutions

Khushal Wood Works started its work in 1990. It does the best work in Barara (Ambala) and is number 1 in Barara. It does all the work related to wood. It also has a CNC cutting machine. Khushal Wood Works also does jali cutting, 2D cutting and 3D carving.

At Maan Khushal Wood Works CNC Design Barara, we specialize in transforming your woodworking visions into reality. With a commitment to precision and creativity, we offer a wide range of services tailored to meet your unique needs. Contact us now at 9996909596 to discuss your project.

Our Services

CNC Wood Cutting and Design: Utilizing advanced CNC technology, we deliver precise and intricate wood cutting and design services.

Custom Wood Cutting & Design: Bring your ideas to life with our custom wood cutting and design solutions, crafted to your specifications.

Wood Engraving & Carving: Add a personal touch to your wood projects with our detailed engraving and carving services.

Laser Cutting Wood: Achieve clean and accurate cuts with our laser cutting technology, perfect for detailed designs.

Wooden Decor & Wall Art: Enhance your space with our custom wooden decor and wall art, designed to impress.

Custom Wooden Signs: Make a statement with our custom wooden signs, ideal for personal or business use.

Custom Wooden Business Signs: Elevate your brand with professionally crafted wooden business signs.

Custom Plywood Cutting: We offer custom plywood cutting services nearby, ensuring convenience and quality.

Affordable CNC Wood Engraving: Experience high-quality wood engraving at competitive prices.

Our Locations

We proudly serve the following areas:

Thamber, Haryana, India

Ugala, Haryana 133205, India

Rajauli, Bihar, India

Adhoya, Haryana 133205, India

Sarakpur, Haryana 133203, India

Tandwali, Haryana 133205, India

Mullana, Haryana, India

Barara, Haryana, India

Tandwal, Haryana, India

Dosadaka, Haryana, India

Holi, Haryana 133201, India

Raju Kheri, Haryana, India

Contact us today to bring your woodworking projects to life with Khushal Wood Works CNC Design Barara.

2 notes

·

View notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

What am I working on right now?

I realise I haven't really listed what I am doing and have been doing in terms of projects on Tumblr so far, so in case you're curious what I'm doing, here you go. With images and all this is gonna be quite lengthy, so have a look under the cut:

First of all, Job and Uni:

At the start of the month, the new uni semester begun, and I also got a job in programming! Uni courses are pretty chill this year, and I'm at the job two days a week. It's really nice so far, and it involves developing algorithms used for CAM and CNC-machines.

As a uni project I did..

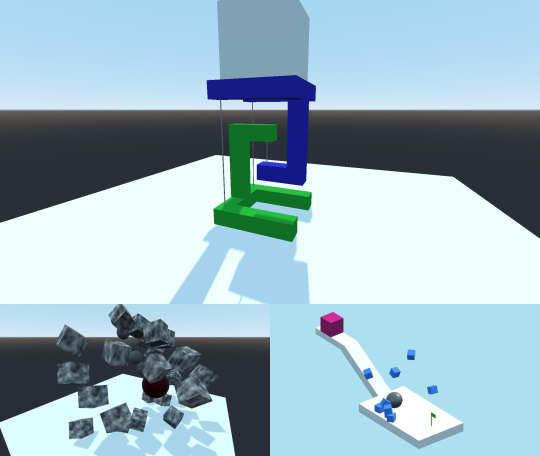

A physics engine for Godot:

Godot is a game engine. As part of an uni course, two fellow students and I wrote the mathsy bulk of a physics engine for it. This includes stuff like collision handling and various joints (like hinge joints you'd use for a physics-based door etc.), but because of time constraints doesn't include collision detection, which is handled by Bullet. Outside of the planned curriculum, I also derived the equations for and implemented rope joints, which simulate, well, ropes.

And currently, outside of uni, I still want to work on the engine by implementing..

Portals:

Yea I want to implement portals using the custom physics engine we built. But not just portals as Valve did them, that would be too easy. I want them to be able to move and interact with other objects while remaining physically accurate (or, as physically accurate as they can be considering they're portals). The current state of things:

The dream is to be able to build gorgeous architecture, like, I'm thinking buildings resting on top of pillars that are always moving. If I can get this to work I really ought to discuss the vision with some artists and creative folk in general, because I feel like there's so much unexplored creativity in art with portals. But yeah, there's still a lot of very intimidating maths/physics until I get there.

As for other private/free-time projects..

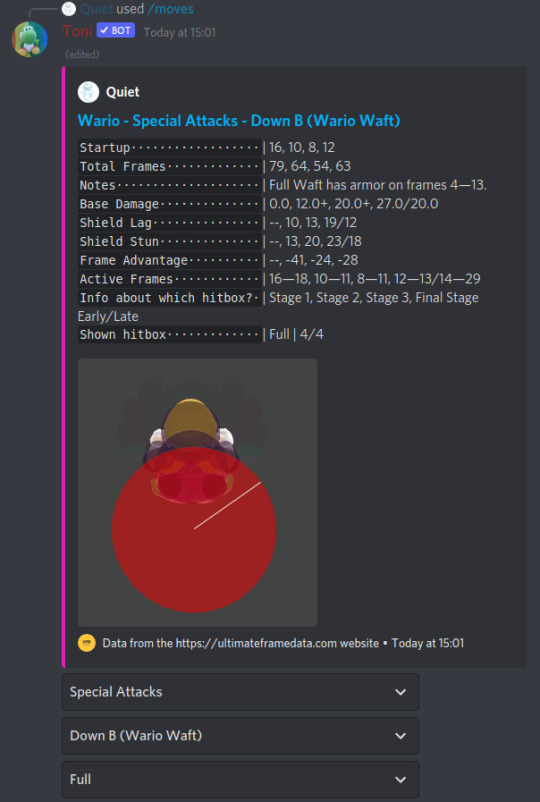

SSBToni:

SSBToni is probably my most ambitious project yet. Toni is a Discord bot for the competitive Super Smash Bros. community (currently in 1.9k servers wowee). Her main selling point is the ability to show frame data and hitbox gifs, but she can also do some other stuff like guide you through a full match of Smash Bros. according to a range of competitive rulesets, from rock-paper-scissors through stage bans all the way to game reporting. She's written in Java with JDA, and her code is hosted here.

I want to do ranked matchmaking and Smash profile images later on, so I have to do some web backend work. The bulk of that is private still, but some of that spun off into separate projects which are..

instant-glicko-2:

The Glicko-2 rating system is great, but it has some issues if you want to use it for real-time ratings/rankings. This Rust library aims to solve these issues to allow for good real-time rankings that are still accurate to the Glicko-2 system. I wrote about how I achieve that here, and the code is hosted here. Note that I do want to change some stuff still which I don't mention in the article I wrote, and in the current form it is probably not production-ready.

cache-compute:

In all honesty, maybe my proudest public thing yet, and it's a single-file ~500 line Rust crate. Based on this blogpost by fasterthanlime, the library makes caching for async stuff much easier, which is gonna be extremely useful in web backend stuff. If a resource isn't available locally (cached), you might have to spend some time making a request to get it from elsewhere to cache it. This library makes sure you only make that request once when you need it, and sorts everything out so that everyone waiting on the resource gets a copy the moment it arrives.

Part of why I'm so proud of this is that, for one, I consider the core finished and very much usable, and secondly, because I wrote so many and such long and exhaustive tests for it, just to hopefully be able to catch any weirdness that comes up. Because writing this kind of concurrent code is hard.

And that's it for projects I would want to show off and write about.

There are of course always ideas in my idea list (currently four or five good ones I'm not working on), maybe I'll post about those too sometime. If you're curious or starved for ideas feel free to ask about them too, I don't think I'll be able to do all of them and the list is only growing larger.

2 notes

·

View notes

Text

'One of the many reasons Christopher Nolan’s filmography is revered in the industry is due to his well-known affinity for IMAX and 70-millimeter film. His most recent feature dominating the box office this summer, Oppenheimer, pushed those limits, maxing out what IMAX film platters can do in the extraordinary biopic. To discuss the magic behind the lens, Collider’s Steve Weintraub had the opportunity to speak with another creative genius and a frequent Nolan collaborator, Director of Photography Hoyte van Hoytema.

In order to capture the gravity of the “father of the atomic bomb,” J. Robert Oppeneheimer’s story, played by Cillian Murphy, Nolan recruited trusted cinematographer Hoytema to work alongside him. While talking with Collider, Hoytema digs into his passion for filming, walking us through the details of all things IMAX, the format that can provide the spectacle a screenplay like this deserves. On top of the technical equipment, Hoytema also tells us everyone, from the visual effects department to lighting to the star-studded cast, including Robert Downey Jr., Florence Pugh and Emily Blunt, worked as a unit to achieve Nolan’s vision.

In this one-on-one, Hoytema also reveals the thing he geeks out over—besides filming—and shares surprising insight into one of today’s greatest filmmakers, having previously worked with Nolan on Interstellar, Dunkirk and Tenet. We find out why, unlike directors like Ridley Scott, Nolan’s productions generally employ the use of one camera, what Hoytema would change about IMAX cameras if he could, the equipment that didn’t exist prior to Oppenheimer, and tons more...

COLLIDER: Because I'm at Comic-Con, I just want to start with, is there anything that you geek out over? Maybe it's cameras, I'm not sure, but is there something that you geek out about

HOYTE VAN HOYTEMA: You mean in general in life?

Yeah, is there anything you collect? What do you geek out over?

HOYTEMA: I geek out over my machine shop. I have a CNC machine, a lot of metalworking things. We build a lot of stuff here in the garage.

I love it. So you have done such incredible work over your career, but there are going to be people who have never seen anything. If someone has never seen anything you've done, what's the first thing you'd like them watching and why?

HOYTEMA: I think, obviously, it's always the last film, you know? The last film you’ve done, it's always sort of an accumulation of things you dropped and things you added, and you're constantly growing, you're constantly evolving. You're constantly becoming wiser/more stupid, more interesting/more stuck up. But I think you always like to show the people who you are at the moment. So, I kind of feel the last film is always the nicest one to watch.

What would surprise Christopher Nolan fans to learn about making a movie with Christopher Nolan?

HOYTEMA: What surprised me, and what was something that I had to learn from working with Chris, is that he is an extremely intuitive person as well. He's, of course, known for his mind-bending intelligence, and his films; they always feel extremely well put together and extremely well planned. But what is very beautiful with Chris is that he is somebody that is not afraid of following his heart, and reacting to intuitive impulses, as well. He's a very sensitive and very much a feeling person. It's in that way, I also feel, that helps him very much in communicating with actors. A lot of actors, they are also people that work extremely much on an intuition level.

Ultimately with a film, you're also sort of translating a feeling to the audience, and in that way, that was something that surprised me back then because it doesn't surprise me today, anymore. But, as people call him sometimes, “Oh, he's very technical,” I would definitely debate it. He is one of the most sensitive and most intuitive directors I work with.

One of the things I'm fascinated by are the various processes that people make movies. For example, Ridley Scott will shoot with six cameras or seven cameras, and Roger Deakins will shoot with just one, and that's it. I'm curious, how often are you just using one camera on set, and how often do you like to do coverage?

HOYTEMA: For most of the time, we work with one camera on set. Effectively shooting with Chris is like a one-camera show. The camera is sort of the magic box that everything that happens around has to be directed and evolving towards, getting sucked into that one little box. So that one camera really becomes an epicenter on our shoes. As soon as you put two cameras on the set, that attention gets somehow divided, and being with Chris on the set is [an] extremely focused group of people that really work towards a very specific goal.

Chris is also somebody that loves to sit very close to the camera in order to understand what the camera is seeing, so he's always very close by looking into the set next to the camera. He's not a material collector or a cleaning lady or a vacuum cleaner, you know? It's a very meticulous and very focused process. The actors know exactly towards where they're working, the production designers, the prop people, the set dressers, but also, us, lighting, et cetera. It all has to evolve towards that one direction, and so the one camera should just feel very logical to us. It's sort of a very ultimate way of filmmaking for us. It feels very focused.

You shot with IMAX film, and you also shot with a 65-millimeter. Can you talk about the conversations you guys had as to when it would be an IMAX shot versus not an IMAX shot?

HOYTEMA: As I said before, as a lot of it is very much pulled out, we also work a little bit with our intuition there. That intuition is also very much led by the idea that we just wanna shoot as much as possible on as rich as possible negative. So, we love shooting as much as possible on IMAX. And also, in this film, the more intimate the situation got, the more sort of up close and personal things got, the more we want to get in there with an IMAX camera.

Now, of course, the IMAX camera has a few technical limitations that make it very hard and very challenging. It's a very loud camera, and it’s also bulky, and it's big. You cannot be a fly on the wall, for instance, with it, so in some situations, as much as you want to, they sort of require you to rethink it a little bit. Sometimes we had to record dialogue, so we would shoot on the five per 70-millimeter camera, but we very often would add an extra shot or an extra take on an IMAX camera to see if Chris could probably salvage the sound of it and put it in a film. So ultimately, I would say it's a very intuitive choice, but driven by sort of the will to squeeze as much as possible in there.

Listen, I am so thankful for what you and Chris do with IMAX. It's my favorite format. There's nothing like sitting in a theater with that huge IMAX screen. What do you actually love and hate about IMAX cameras? Like if you could fix something, the big camera, or is it just the sound, how loud it is?

HOYTEMA: If we would be able to fix the sound in an IMAX camera, it would be fantastic. Now, it’s almost to solve that sound problem is like defying physics. It's not just asking, “IMAX, can you make this thing more quiet?” What you have to imagine, and if you just hold on one second—I'll just grab something so I can show you—we got some real fun things here, some film strips. Let's start with this one, right? I'm just gonna show this. This is 35-millimeter, right? This is 35-millimeter anamorphic, that size. So a camera, in order to get these 24 shots per second in, the cam has to drag 24 of those frames per second through a camera, correct? So now we go five per, which is a camera that is 70-millimeter, that does the same as a 35-millimeter camera. And why are these cameras so bulky and heavy? This is five per old fashioned, the 65-millimeter camera. So per second, 24 of these big frames have to be pulled through a little hole. Well, it gets a little louder, it gets a little bulkier. But if you look at IMAX, this is how your negative is exposed, and this is how the film strip looks. So, instead of going like this through the camera, it goes like this through the camera. And here you see every frame is a huge piece of exposed film, so 24 of those frames, you have to pull through the camera per second.

So you can imagine how much power and inertia and how big [of] motors you need in order to do that, and how aggressive your mechanism has to be to every time stop that frame on the dime. That's the reason that that camera is so loud and it's so bulky and it's so heavy. It's just physically, it's very heavy, and it's very difficult. So, there you have the problem. I would love it to be as silent as a nothing, but it's very challenging to get it there. But that's definitely some improvement I would work on. And the more quieter that camera becomes, the more situations we can start applying that camera to. So ultimately, quieter would be my wish. I don't care so much about making it smaller, making it more comfortable. We're all the time sort of adapting the ergonomics of that camera. In the end, it's a little box. It's a mini fridge that you have to put in a special place, with grips that have the sensitivity of ballerinas. And [with] a little bit of smart external engineering, you can get the camera wherever you need it to be. But I think those sounds, that’s something that would be really wonderful to do something with.

This is gonna sound crazy, and I'm obviously just brainstorming in the moment, but is it possible to actually make the camera bigger for certain situations and almost blanket the camera with soundproofing? So instead of going smaller, you're going larger, and you're minimizing all the sound coming out of it, and you're using it in specific shots where you don't have camera movement, or it's on a device that can move separately?

HOYTEMA: That's not crazy at all. I mean, that's exactly what we have built, a certain device — blimps, they're called. So we have blimps for the IMAX cameras—a coffin, as we sometimes say—but it's literally the device that fits like a glove, or like a sort of coffin, that fits like a glove around the camera and is made out of different soundproofing materials. And yes, you get it quieter, but by those kinds of experimentations, we already found out that, exponentially, you have to get so big just because the sound in relation is so loud. Also, what you have to think about, a lot of the sounds that come out of the camera come through the lens, come through the front of the camera, and, at some point, you cannot just keep layering your optics. It's because that will, in the end, start to really affect some of your picture quality.

All I can say is you just demonstrated it with the examples of film, but when you capture an image on an IMAX frame like that, you're capturing so much more information. I don't think people realize when you film on IMAX, and then you bring it down to even 35-millimeter, the image is still so much better. There's so much more information there.

HOYTEMA: Oh yeah, absolutely. That trickle-down effect that people underestimate very often very much. But if you trickle down from an original that is pristine and that is great, you will feel that quality trickle down very, very much in the derived formats. Every time you print down, or you go down on the resolution, you lose a lot of detail, and you also gain a lot of artifacts. The better your original materials, the lesser artifacts you get. So, when I look at that, and at Apple or whatever, and I look at something that's originated in 70-mil or something that originated in 35-mil, I can very easily spot the difference.

I spoke to Chris, and he told me there are no CGI shots in the movie, which I found amazing. What was it like when you and him, and everybody involved, were talking about filming certain sequences, especially the use of light, and he wants to use these big IMAX cameras and do everything in camera? Can you sort of talk about making everything happen, with the visual effects team, obviously?

HOYTEMA: It’s, for me, always a super exciting period in the prep that is everybody sort of throwing those crazy ideas into the hats. And a lot of them, they don't have necessarily technical solutions to it, and then, step by step, people come up with all these kind of weird solutions and weird ideas that we then very often test them, and we start testing them as well as we start building them. Like it was very clear to us that, very early in the start, we wanted to—and I'm talking then about Andrew Jackson and Scott Fisher, our glorious visual and special effects team that were working very close together, also, because visual effects and special effects on a shoot like this is very closely related. Because Andrew Jackson, as much as how he's connected to a visual effects department, wanted to rely as little as possible on CGI. So he really took control over trying to get as much as possible in camera, as well in his world, and with the help of Scott Fisher. So they work very close together.

As much as we wanted this to be IMAX and part of the IMAX sequences, we realized that we want to shoot a lot of microphotography on IMAX format, [which] doesn't really have those kinds of possibilities, right? So straight away, we started engineering those specific lenses for the IMAX camera. Effectively, when you do this sort of microphotography, when you want to have a camera, for instance, in between here, or track in between here to enlarge the world of this to sort of a life-size format, you need special lenses. You need what we call probe lenses. They didn't exist for IMAX, so Dan Sasaki from Panavision built us this pro lens, and we experimented with it, and we improved it, and in the end, it was something that we used a lot for aquarium work and micro work and macro work. So, that was very exciting.

And basically, the visual effects department, you could say, was a tent that was always put up next to our set where we’re doing all these science experiments. We would shoot molded metal, shoot into aquariums with silver particles, or do micro explosions of balloons in reverse, et cetera, et cetera. There's a lot of small, little, very tactile physics experiments going on that we then tried to film in different ways, with different kinds of cameras, as well. And then sort of cobbled together this kind of idea of the quantum physics or particle physics, or atoms crashing into each other, or a gigantic nuclear explosion, et cetera, et cetera.'

#Christopher Nolan#Oppenheimer#Hoyte van Hoytema#IMAX#Cillian Murphy#Interstellar#Dunkirk#Tenet#Andrew Jackson#Scott Fisher#Dan Sasaki#Panavision

3 notes

·

View notes

Text

... I'd like to push back a little bit on the vision of how society would look if we didn't have injection molded plastics. I agree that it would be more rectangular than it is now, and maybe more sharp. But

In the 1910s, we were pushing the limits of what technology at the time would let us do with casting iron. All of my beautifully curved sewing machines? Cast iron.

We really advanced the ability to stamp thin sheets of metal into compound curves in the '30s and '40s. Look at the difference in car design between a car from 1920 and from 1940 (as much as this is the Ford hating website, Ford is a great example of this). Modern cars are also made of stamped metal and those are not rectangle having machines (with one remarkably bad exception).

We invented bakelite and similar moldable plastics in the '40s.

Household appliances of the '50s were defined in all their swoopy curves by stamped metal and bakelite.

We invented CNC machining at the same time as we invented computers and immediately went to work perfecting it. We now have robots at every scale and cost point to create all sorts of things out of all sorts of materials. A four axis CNC milling machine can make parts that can't be stamped or cast.

The thing that separates these processes from injection molding is that they're slow. They're so fucking slow. Stamped metal is pretty fast, but it still can be pretty slow.

So my guess at what society would look like without injection molding is slower and heavier and with less production excess. More objects would have applied details instead of integral decoration - imagine the amount of money that could be made selling swappable trim packs when the trim is held on with little tabs that go through the shell of the appliance.

But humans love curves. We invented special tools to make making spoons easier. We put curves on the decorative trim in our homes, we go crazy over an arched doorway, we bend wood (which hates that shit!) to make hoops from which to make tools and toys from.

I think a lot about manufacturing processes because they’re the most impressive things humanity has ever done and injection moulding wacks me out the most. I was looking at the toy keyboard I bought a while back and it got me thinking about how much of what we consider to be the look of The Modern Era is down to injection moulding.

I hold that injection moulding is one of the pillars of modern society and technology. Can you imagine a world where you couldn’t use injection moulding. It’d look completely foreign. Like looking into an alien world. When you consider it you have to conclude that injection moulding has shaped our culture as much as the development of the camera or the invention of the piano or the creation of glassblowing. If archaeologists had to name our culture in the style of the Corded Ware culture or the Funnel Beaker culture, we’d be the Injection Moulded Plastic culture.

Injection moulding is how we get, oh, almost every plastic thing you’ve ever seen. The keys on your keyboard are injection moulded. Your phone case is injection moulded. Unless you’ve got a fancy milled metal laptop like a macbook then your laptop’s chassis is mostly injection moulded plastic. Your lightswitches are injection moulded. Plastic water bottles are injection moulded. Injection moulding is how we can produce extremely similar objects at breakneck pace for almost no money.

Now it’s important to rememeber that injection moulding isn’t cheap, or, well, injection moulding is only cheap for mass production. Every single unique piece of plastic needs a mould, and each mould will cost somewhere around thousands to tens of thousands of dollars EACH, depending on how tight the tolerances are and how complex the geometry is. Look at how many unique plastic pieces there are on that keyboard. Each one represents an investment of like $7000 into making this toy that gets sold for about $20, so there’s no way this would get made unless the company had plans to sell literally hundreds of thousands of these things.

(This mould can spit out one chair every 30 seconds and it probably cost twenty thousand dollars to make)

Once you learn to see injection moulding you can’t unsee it. It’s like learning about kerning, or musical intervals, or disability compliant designs, or the pantone colours, or about how many insulator disks are needed on different voltage power lines. You start to see it everywhere, you realise that everything in your life relies upon our ability to jam plastic through a heated screw and into a mould reliably, hundreds of times per day, all day, every day.

Unless you’re wandering alone in the wilderness (and even then, maybe: check your clothing), look around and see if there’s something injection moulded near you. I can tell you the answer, there definitely is. It’s inescapable.

What would a world without injection moulded parts look like? It’d be weird. Everything we think of as cheap and easy to make is suddenly expensive. Complex curves and slopes like you’d find on a one dollar potato peeler now require hours of work to form. Every budget consumer item would be like those cheap sheet metal PC cases that have drawn blood from everyone who build a PC in them. Everything now has the aesthetics of a Sun 3/280 system:

Heck, even this sheet steel cube has a dozen injection moulded parts visible.

All the chunky plastic housing of the 90′s and 2000′s, all the sleek curves of the 2010′s, all the cheap plastic knick-knacks, the plastic toy horses, the snugly-fitting appliance chassis, the stacking plastic chairs. All these things now cost ten times as much and have to be formed from heavy steel, or milled out of chunks of cast plastic, or replaced with formed sheet metal.

Our culture, artistic sensibilities, and sense of value has been irrevocably shaped by our ability to squeeze liquid plastic into a metal die.

7K notes

·

View notes

Text

Leading Electric Motor Coil & Machined Components Manufacturer

Introduction

In today’s competitive industrial landscape, businesses seek suppliers who offer not just quality, but consistency, technical expertise, and the ability to scale. Synergy Global Sourcing is a globally trusted name recognized as a leading electric motor coil company and machined components manufacturer. We provide precision-engineered products that help power, move, and elevate industries worldwide.

High-Performance Motor Coils—Designed for Durability

Electric motor coils are the heart of any motor-driven equipment. Whether it’s industrial automation, HVAC, electric vehicles, or heavy-duty machinery, the efficiency of your motor depends on the quality of the coil.

At Synergy Global Sourcing, we design and manufacture:

Stator and Rotor Coils

Field Coils and Armature Coils

AC & DC Motor Coils

Custom Winding Solutions for fractional and integral horsepower motors

✅ Key Features of Our Motor Coils:

Thermal Class Ratings from Class B to Class H

Epoxy-impregnated or VPI-treated for longer life

100% Continuity & Resistance Tested

Corrosion and Vibration Resistant Coils for tough environments

Compliance with IEC, NEMA & UL Standards

Whether you require OEM production, spares for rewinding, or custom-engineered solutions, Synergy is the electric motor coil company you can trust.

Precision Machined Components—Built to Fit, Made to Last

As a full-service machined components manufacturer, we deliver high-tolerance precision parts with clean finishes and exacting specifications. Our state-of-the-art CNC machining centers allow us to produce:

Shafts, Housings, Flanges

Bushes, Couplings, Pins, and Gears

Threaded and Non-threaded Fasteners

Custom Turned and Milled Parts

Die-Cast and Forged Component Machining

🛠️ Capabilities That Set Us Apart:

CNC Turning & Milling up to 5-axis

CAD/CAM Integration for prototyping and DFM

Inspection with CMM & Digital Gauging

Batch Size Flexibility: From 10 to 100,000 parts

Surface Finishing: Anodizing, plating, powder coating & polishing

We cater to diverse industry requirements, ensuring all components meet your technical drawings, tolerances, and performance goals.

Industries We Serve

Thanks to our dual expertise, we support a wide range of sectors:

Automotive & EV—Motor coils, shafts, rotors, precision parts

Energy & Power—Generator coils, transformer coils, turbine components

Aerospace—High-tolerance machined parts with light-weight materials

Industrial Automation—Coils and assemblies for robotic arms, drives

Marine & Railways—Heavy-duty, corrosion-resistant components

Home Appliances & HVAC—Compact motor coils and fast-moving parts

Why Choose Synergy Global Sourcing?

🌍 Global Standards. Local Efficiency.

Our manufacturing and sourcing operations follow international quality benchmarks while maintaining cost-effective production cycles. Whether you're in India, Europe, or North America, we provide on-time delivery and technical support.

🏭 End-to-End Manufacturing

From raw material sourcing and CAD design to manufacturing, testing, and packaging—everything is managed under one roof for seamless operations.

🔒 Uncompromised Quality

Each product batch is tested under stringent quality protocols. We’re committed to zero-defect delivery and complete customer satisfaction.

🤝 Strategic Partnership Approach

We don't just supply components; we become an extension of your engineering and procurement team—offering insights, redesign suggestions, and scalable solutions.

Our Vision

At Synergy Global Sourcing, our vision is to be a globally respected electric motor coil company and machined components manufacturer known for innovation, reliability, and value. We’re not just suppliers—we’re partners in your growth.

0 notes

Text

New! Arisaka MMH Magnifier Mount in 2.26": Unmatched Performance

Arisaka Defense releases new Magnifier mount High 2.26″ Arisaka Defense has launched the MMH (Magnifier Mount High), featuring a 2.26″ optic centerline height and a unique pivot system for easy rotation. It allows increased peripheral vision with unobstructed views for the non-dominant eye. Compatible with Aimpoint and Eotech magnifiers, it includes a quick disconnect lever and is CNC machined…

0 notes

Text

Professional Modelmaking for Creative Thinkers and Technical Doers

Modelmaking is the art of creating physical representations of objects, spaces, or products on a smaller scale. It’s widely used in industries like architecture, product design, education, and even entertainment. At Fixie 3D, we bring creativity and precision together to turn concepts into tangible models. These models help in visualizing complex ideas, testing new designs, or simply showcasing creativity. Whether you're a student working on a school project, an architect planning a new building, or a filmmaker constructing a miniature set, modelmaking gives you a hands-on way to bring your vision to life. The process involves detailed planning, use of various materials, and often combines traditional skills with digital tools like 3D printing and laser cutting. By using quality tools and techniques, modelmakers can create accurate and realistic versions of just about anything.

Helps visualize ideas clearly and effectively

Used in architecture, education, entertainment, and product design

Make Architectural Designs Stand Out with Realistic Models

Modelmaking in architecture helps translate design concepts into visual, tangible forms. It allows architects and clients to see how a building will look and function before it’s built. At Fixie 3D, we specialize in making scale architectural models that reflect every detail — from layout and shape to textures and surroundings. These models are not only helpful during presentations but also improve the overall design process. Using materials like foam board, cardboard, acrylic, and wood, we create accurate models that reflect lighting, spacing, and structure. Laser cutting and 3D printing make the process even more efficient and precise. Architects use modelmaking to explore design alternatives, study spatial relationships, and detect errors before construction begins. It’s a bridge between creative thinking and technical application, especially when presenting to clients or reviewing site plans.

Used for design validation, presentations, and planning approval

Materials include foam board, acrylic, cardboard, and balsa wood

Test Your Product Ideas with Functional Prototypes

In product design, modelmaking allows designers to test how a product will look and work before manufacturing it. It’s a crucial step in the development process, especially for items that require precise functionality and user interaction. Fixie 3D helps create functional prototypes and mock-ups that closely resemble the final product. These can be used for testing ergonomics, material fit, and design appeal. Our team uses advanced tools such as 3D printers, laser cutters, and CNC machines, along with traditional methods like hand-cutting and assembling. This gives clients a clear view of how the product performs and what improvements are needed. Prototypes not only reduce risk and cost but also provide valuable feedback from real users before mass production begins.

Supports early-stage concept validation and performance testing

Prototypes help detect design flaws before final manufacturing

Bring Film Sets and Fantasy Worlds to Life

Modelmaking is also a big part of the film, gaming, and entertainment industry. Miniatures and practical models are often used in movies, TV shows, and commercials to create scenes, landscapes, or props without the cost of full-size sets. Fixie 3D works with directors, designers, and content creators to build custom models that bring imaginary worlds to life. From tiny buildings to alien spacecraft, we make everything with realistic detail and scale accuracy. Our artists combine painting, sculpting, and fabrication techniques to create film-ready pieces. Modelmaking is also used in stop-motion animation and VFX, where even the smallest set plays a big role in storytelling. These physical models add realism, depth, and texture that can be hard to achieve with CGI alone.

Used in film sets, props, gaming environments, and stop-motion animation

Helps create believable and visually rich scenes at low cost

Turn Class Projects into Creative Learning Experiences

Modelmaking makes learning fun, interactive, and hands-on for students. It helps simplify complex ideas in subjects like science, history, and geography. Students build models of volcanoes, human anatomy, or historical monuments as part of school projects, science fairs, or competitions. At Fixie 3D, we provide custom educational model kits that are safe, engaging, and easy to assemble. These kits improve problem-solving skills, teamwork, and creativity. Teachers also use models to explain theories or demonstrate experiments. With tools like foam board, clay, plastic, and simple cutting tools, students develop basic skills in measurement, crafting, and spatial thinking. Modelmaking boosts confidence and encourages curiosity — making it an ideal supplement to classroom learning.

Encourages hands-on learning, creativity, and concept retention

Great for science fairs, project displays, and subject demonstrations

Use the Right Tools to Build the Perfect Model

Whether you're building a miniature city or a product prototype, having the right tools and materials is essential for quality modelmaking. At Fixie 3D, we select materials based on the type, scale, and purpose of your model. Basic tools include cutting mats, precision knives, glues, and rulers. For more advanced needs, we use laser cutters, 3D printers, and specialty plastics or acrylics. Materials like foam board and cardboard are best for lightweight models, while balsa wood or acrylic sheets offer more durability and structure. Paints, textures, and detailing supplies help in finishing touches. By combining modern technology with classic craftsmanship, our team ensures every model is functional, presentable, and built to impress.

Foam board, acrylic, and balsa wood are commonly used materials

3D printers, laser cutters, and paints enhance detail and accuracy

Conclusion

Modelmaking is more than just building miniatures — it’s a vital tool for communication, education, design, and creativity. Whether you are sketching out a building, testing a product, creating a school project, or shooting a film, modelmaking brings your ideas to life in a way that’s clear, useful, and impactful. At Fixie 3D, we combine craftsmanship with technology to deliver models that serve real-world needs. Our models are accurate, reliable, and tailored to suit each project’s goals. No matter the industry or purpose, modelmaking continues to play a crucial role in shaping how we imagine, design, and explain our ideas.

0 notes

Text

Designing Dreams with Durability: Why Woodminium is a Top Aluminium Windows and Doors Manufacturer in Bangalore

In today’s urban Bangalore, the aesthetics and functionality of a home’s design go far beyond just interiors and furniture. The soul of every home lies in how it connects with the outside world—through well-designed, secure, and efficient windows and doors. That’s where Woodminium makes all the difference. As one of the most trusted aluminium windows and doors manufacturers in Bangalore, Woodminium is not just a supplier, but a design partner for modern homeowners.

Whether you're building a luxury villa in Whitefield, renovating a penthouse in Jayanagar, or upgrading your office façade in Koramangala, our solutions are built for style, strength, and sustainability.

Built in Bangalore, Designed for the World

Woodminium was born with a vision: to bring world-class quality and innovation to Indian homes through superior aluminium windows and aluminium doors. With complete manufacturing facilities under one roof, our process eliminates quality compromises and reduces lead times.

A Homegrown Brand with a Global Outlook

We use globally sourced aluminium profiles, premium-grade hardware, and imported finishing materials. But all the crafting, powder-coating, glazing, and assembly happen right here in Bangalore. This gives us better control over product integrity and allows us to offer highly customizable options for our clients.

As Bangalore's skyline continues to evolve, so do the needs of its homeowners. That’s why we’re constantly innovating to provide the best aluminium windows and doors for a new generation of smart, stylish homes.

What Makes Woodminium a Leader Among Aluminium Windows and Doors Manufacturers in Bangalore?

1. All-in-One Manufacturing Ecosystem

From material sourcing to final installation, our in-house operations give us an edge. Unlike manufacturers who depend on third-party contractors, we do everything in one place. This helps reduce material handling issues and minimizes defects like scratches or misalignments.

2. Custom Design Expertise

No two homes are alike, and neither are their windows and doors. Our in-house design experts help you create custom aluminium windows and doors that align with your architectural goals. Whether it's a French door for your patio or a panoramic slider for your living room, we shape your vision with precision.

3. Certified Safety Features

We don't just build stylish windows—we build safe aluminium windows that protect your home from intruders, weather, and noise. Our products come with multi-point locking systems, laminated safety glass, and robust internal frames that comply with international safety standards.

4. Eco-Conscious Innovation

At Woodminium, sustainability isn’t an afterthought. Aluminium is recyclable, and our processes are designed to minimize waste. Our aluminium windows and doors are also engineered for energy efficiency—reducing heating and cooling costs in your home.

What You Get When You Choose Woodminium

Being one of the leading aluminium windows and doors manufacturers in Bangalore, we deliver a complete solution. Here’s what makes us stand out:

Precision fabrication using CNC machines

UV- and moisture-resistant powder coatings

Premium-grade locks, handles, and gaskets

Soundproof and thermally insulated glass options

End-to-end project handling—from measurement to installation

And most importantly, we provide peace of mind. Your windows and doors are not just building components—they're part of your lifestyle.

Our Flagship Products: Beauty Meets Performance

At Woodminium, we have an extensive product line tailored for every kind of Bangalore home.

Sliding Aluminium Doors

Perfect for balconies and terraces, they save space and invite natural light.

Casement Aluminium Windows

Timeless in style, these open wide for ventilation and are available with insect mesh options.

Bi-Fold Aluminium Doors

Elegant and functional, they create a seamless transition between indoors and outdoors.

Tilt-and-Turn Windows

Great for modern apartments, these offer dual opening positions for flexibility and security.

Fixed Frame Glazing

Designed to offer uninterrupted views—ideal for living rooms or commercial façades.

Each product is designed with form and function in mind. And every system is compatible with safe aluminium windows practices, prioritizing your security and comfort.

The Best Aluminium Windows for Bangalore Homes

What makes a window the "best"? It’s not just looks—it’s how well it handles Bangalore’s monsoons, summer heat, and urban noise. That’s why Woodminium’s best aluminium windows come with features like:

Double or triple glazing for sound and temperature control

High-tensile aluminium frames for structural strength

Insect screens and airtight seals

Color-customizable powder-coated finishes

Our goal is to deliver windows that last for years, look stunning, and require minimal maintenance.

Homeowners Trust Us. Builders Recommend Us.

We’ve partnered with architects, builders, and interior designers across Bangalore to supply high-quality aluminium windows and aluminium doors for villas, apartments, and commercial spaces. Over the past few years, we’ve completed successful installations in:

Yelahanka

HSR Layout

Indiranagar

Rajajinagar

Electronic City

“We wanted modern aluminium doors for our duplex, but also needed them to be child-safe. Woodminium delivered both—with elegance!” — Sneha D., Marathahalli

“As a builder, I need vendors I can rely on. Woodminium’s team is prompt, professional, and their product quality is unmatched.” — Harsha R., Hebbal

Frequently Asked Questions (FAQs)

Do aluminium windows rust?

No. Aluminium is a non-corrosive material. With Woodminium’s powder-coated finishes, our aluminium windows resist rust, even in Bangalore’s humid conditions.

Are aluminium windows better than wooden windows?

Yes. Aluminium is stronger, lasts longer, and requires far less maintenance than wood. It also offers slimmer frames and modern aesthetics.

Can I install Woodminium products in an old home?

Absolutely. Our team specializes in retrofitting aluminium windows and doors in both new and old buildings.

Are these windows energy-efficient?

Yes. Our windows are designed with thermal breaks and can be double-glazed to improve insulation and reduce electricity bills.

How long does installation take?

Most residential installations are completed within 5–7 working days after final measurement. Timelines may vary based on project complexity.

A Word on Pricing

Woodminium offers premium solutions—but that doesn’t mean we’re expensive. Our pricing is completely transparent and based on:

Size and style of window/door

Type of glass (clear, tinted, laminated, etc.)

Number of panels and custom elements

Hardware and locking mechanisms

Finish and color options

Whether you're looking for luxury or functional elegance, we work within your budget without compromising on quality.

Conclusion: Choose Woodminium for End-to-End Excellence

In the growing urban landscape of Bangalore, choosing the right windows and doors is a decision that affects your home’s style, security, and sustainability. As one of the most reliable aluminium windows and doors manufacturers in Bangalore, Woodminium delivers a complete solution—from design consultation to professional installation.

We don’t believe in one-size-fits-all. We believe in one-size-fits-YOU. That’s why Bangalore trusts Woodminium for safe aluminium windows, sleek aluminium doors, and the most durable, elegant window systems available today.

Ready to Upgrade Your Space?

Explore our full product range at www.woodminium.com For consultations, site visits, and quotes, reach out via our Contact Us page.

Your dream home deserves nothing less than the best. Let’s build it together—with Woodminium.

0 notes

Text

From Concept to Creation: How the Best ACP Signage in Chennai Comes to Life

When it comes to making a bold statement for your business, signage plays an indispensable role. In Chennai's vibrant commercial hubs, Aluminium Composite Panel (ACP) signage has emerged as the top choice for many businesses looking to combine aesthetics, durability, and impact. But how exactly does the process unfold from the initial idea to the installation of the best ACP signages in Chennai?

In this blog, we take you on a journey through the creative and technical process that transforms concepts into stunning ACP signage — signage that Chennai businesses trust to elevate their brand presence.

Understanding the Importance of the Best ACP Signages in Chennai

Before we dive into the process, it's essential to understand why ACP signage is the preferred solution for many businesses in Chennai. ACP combines lightweight construction with exceptional durability and a smooth, modern finish that lends itself beautifully to vibrant digital prints and creative designs. The best ACP signages in Chennai are crafted not only to capture attention but to withstand Chennai’s tropical weather, making them an investment that lasts.

Step 1: Conceptualization and Design

The journey of the best ACP signage begins long before the physical creation — it starts with the concept. Businesses collaborate with expert designers to articulate their vision, branding goals, and practical needs.

Tailored Design Consultation

The best ACP signages in Chennai companies offer in-depth consultations to understand your brand identity, target audience, and the environment where the signage will be placed. This helps in creating a design that is visually compelling and perfectly aligned with your business message.

Visual Mockups and Approval

Once the design team sketches initial concepts, they create digital mockups showcasing colors, fonts, layouts, and graphics on ACP panels. These previews allow you to visualize how the final product will look, and adjustments are made based on your feedback to ensure every detail meets your expectations.

Step 2: Material Selection and Preparation

With the design finalized, attention shifts to the materials — a critical factor in ensuring quality and longevity.

Choosing the Right ACP Panels

The best ACP signages in Chennai are made using premium-grade ACP sheets known for their smooth surface, resistance to corrosion, and ability to retain color vibrancy even under intense sunlight and rain.

Additional Components

Apart from the ACP panels themselves, other materials like LED modules (for illuminated signs), mounting brackets, and protective coatings are selected. These choices contribute to the sign’s durability and aesthetic appeal.

Step 3: Precision Fabrication

Fabrication is where the concept starts to take physical form.

Cutting and Shaping

Using advanced CNC machines and laser cutters, ACP sheets are cut precisely according to the design specifications. The best ACP signages in Chennai manufacturers ensure sharp edges, accurate dimensions, and smooth finishes, which are essential for a polished look.

Printing and Finishing

High-definition digital printers apply vibrant colors and graphics directly onto the ACP surface. UV-resistant inks are often used to prevent fading over time. For illuminated signs, LED backlighting is integrated during this stage to create a glowing effect that captures attention day and night.

Step 4: Quality Checks and Testing

Before delivery, stringent quality control procedures ensure the signage meets all standards.

Color Accuracy: Verification that the colors match brand guidelines.

Structural Integrity: Checking panel strength, mounting fixtures, and electrical components for safety and durability.

Weather Resistance: Testing resistance to water, heat, and UV rays to guarantee long-term performance in Chennai’s climate.

The best ACP signages in Chennai never leave the workshop without passing these rigorous tests.

Step 5: Professional Installation

The final stage in bringing your ACP signage to life is installation.

Expert Installation Teams

Skilled technicians from trusted companies handle the mounting and electrical setup with precision and care. Proper installation is vital to ensure the sign is secure, aligned, and fully operational.

Minimizing Business Disruption

The best service providers plan installations at times that cause minimal disruption to your business operations, completing the job swiftly without compromising quality.

Why Choose TN Signs for the Best ACP Signages in Chennai?

At TN Signs, we pride ourselves on delivering not just signs but complete branding solutions. Our process mirrors the best industry standards, ensuring your ACP signage journey is smooth from start to finish.

Customized Design: We tailor every design to fit your brand’s unique identity.

Premium Materials: Only top-quality ACP sheets and components are used to guarantee durability.

Cutting-Edge Technology: Our fabrication facilities are equipped with the latest machinery for flawless production.

Skilled Installation: Experienced teams ensure your sign is mounted perfectly and safely.

After-Sales Support: We provide maintenance advice and services to keep your signage looking brand new.

Discover why we are trusted for the best ACP signages in Chennai by visiting https://tnsigns.in/ and starting your signage project with us today.

Final Thoughts: The Journey Matters as Much as the Result

Creating the best ACP signages in Chennai is a meticulous process that demands creativity, precision, and experience. From the initial concept through design, fabrication, and installation, every step plays a crucial role in producing signage that not only looks stunning but performs exceptionally well in Chennai’s dynamic business environment.

By choosing expert partners like TN Signs, you ensure your business’s signage is crafted to perfection, helping you attract more customers, enhance your brand visibility, and ultimately grow your business.

Take the first step to bring your signage vision to life with the best — visit https://tnsigns.in/ today!

0 notes

Text

Winding the Future with Precision in Every Coil

Imagine a world where electronic devices are more efficient, reliable, and powerful. This vision is made possible by the tiny yet mighty capacitor, a component that relies heavily on precision manufacturing. At the foundation of this precision is the capacitor winding machine, a technology that automates the process of winding capacitor elements. By uniformity and consistency in every coil, these machines have revolutionized capacitor production, enabling the creation of high-quality capacitors that power everything from smartphones to industrial machinery. Be it in consumer electronics, automotive systems, or renewable energy solutions, the capacitor winding machine plays a crucial role in meeting the demand for efficient and reliable electronic components. These machines are also used for manufacturing various types of capacitors, including film, electrolytic, and ceramic capacitors, which are essential components in electronic devices and electrical systems.

Perks of Capacitor Winding Machine

A capacitor winding machine offers a range of benefits, from enhanced precision to increased productivity. By automating the winding process, manufacturers can provide consistent quality and reduce production time. Modern capacitor winding machines often comes with advanced automation technologies such as CNC systems and PLCs, allowing for precise control over winding patterns and tension. This not only improves product reliability but also supports the mass production of capacitors needed for applications in consumer electronics, automotive systems, and renewable energy solutions.

The versatility of capacitor winding machines extends to handling different capacitor designs, including high-voltage capacitors and hybrid film capacitors. As the demand for electronic devices continues to rise, investing in a capacitor winding machine is a strategic move for manufacturers seeking to improve efficiency and meet the industry needs. Using these machines, companies can ensure consistent performance, reduce costs, and stay competitive in the global market.

0 notes

Text

Winding the Future with Precision in Every Coil

Imagine a world where electronic devices are more efficient, reliable, and powerful. This vision is made possible by the tiny yet mighty capacitor, a component that relies heavily on precision manufacturing. At the foundation of this precision is the capacitor winding machine, a technology that automates the process of winding capacitor elements. By uniformity and consistency in every coil, these machines have revolutionized capacitor production, enabling the creation of high-quality capacitors that power everything from smartphones to industrial machinery. Be it in consumer electronics, automotive systems, or renewable energy solutions, the capacitor winding machine plays a crucial role in meeting the demand for efficient and reliable electronic components. These machines are also used for manufacturing various types of capacitors, including film, electrolytic, and ceramic capacitors, which are essential components in electronic devices and electrical systems.

Perks of Capacitor Winding Machine

A capacitor winding machine offers a range of benefits, from enhanced precision to increased productivity. By automating the winding process, manufacturers can provide consistent quality and reduce production time. Modern capacitor winding machines often comes with advanced automation technologies such as CNC systems and PLCs, allowing for precise control over winding patterns and tension. This not only improves product reliability but also supports the mass production of capacitors needed for applications in consumer electronics, automotive systems, and renewable energy solutions.

The versatility of capacitor winding machines extends to handling different capacitor designs, including high-voltage capacitors and hybrid film capacitors. As the demand for electronic devices continues to rise, investing in a capacitor winding machine is a strategic move for manufacturers seeking to improve efficiency and meet the industry needs. Using these machines, companies can ensure consistent performance, reduce costs, and stay competitive in the global market.

0 notes

Text

How Architectural Joinery Shapes Sydney’s Built Environment

Architectural joinery in Sydney plays a crucial role in defining the quality and character of both residential and commercial interiors. From custom-built cabinetry to intricate wall panelling and integrated storage solutions, architectural joinery bridges the gap between function and aesthetics. In a city known for its diverse architectural styles — from heritage buildings to contemporary high-rises — skilled craftsmanship and thoughtful design are essential to creating spaces that are both beautiful and highly functional.

What Defines High-Quality Architectural Joinery?

The standard of joinery work significantly impacts the overall finish and usability of an interior space.

Precision Craftsmanship : Accurate measurements, clean lines, and seamless joints contribute to a polished, professional result.

Material Selection : The choice of timber, finishes, and hardware affects both durability and visual appeal, with native and imported timbers being popular choices.

Attention to Detail : Small elements such as shadow gaps, concealed hinges, and bespoke handles elevate the design beyond basic cabinetry.

Integration with Design Intent : Good joinery complements the broader architectural vision, enhancing spatial flow and functionality.

These qualities distinguish high-end joinery from mass-produced alternatives.

How Is Joinery Integrated into Residential Projects?

In homes across Sydney, architectural joinery is used to maximise space while maintaining a cohesive design language.

Custom Storage Solutions: Bespoke wardrobes, built-in shelving, and hidden storage compartments help maintain clutter-free living areas.

Kitchen and Bathroom Joinery: Tailored cabinetry enhances both utility and style, often incorporating premium materials and innovative layouts.

Feature Walls and Panelling: Timber wall linings, coffered ceilings, and decorative screens add texture and depth to interiors.

Sliding and Pocket Doors: These space-saving solutions blend seamlessly into modern open-plan designs while offering privacy when needed.

Residential joinery is tailored to suit individual lifestyles and spatial constraints.

What Role Does Joinery Play in Commercial Spaces?

Commercial environments rely on architectural joinery to support branding, functionality, and user experience.

Office Fit-Outs: Custom desks, meeting room partitions, and reception counters reinforce brand identity while supporting workflow efficiency.

Retail Fixtures: Display units, fitting rooms, and service counters are designed to guide customer interaction and enhance product presentation.

Hospitality Interiors: From bar counters to booth seating and acoustic panels, joinery contributes to both atmosphere and practical operation.

Public Buildings: Libraries, schools, and healthcare facilities benefit from durable, ergonomic joinery that meets accessibility and safety standards.

Each application requires a balance between aesthetics and performance.

How Are Sustainability and Material Innovation Influencing Joinery?

Environmental concerns are shaping how joinery is sourced and manufactured.

Use of FSC-Certified Timber: Sustainably harvested wood ensures responsible forestry practices and traceability.

Recycled and Reclaimed Materials: Old beams, flooring, and offcuts are repurposed to create unique, eco-conscious designs.

Low-VOC Finishes: Water-based stains, oils, and adhesives reduce indoor air pollution and promote healthier environments.

Digital Fabrication Techniques: CNC machining and 3D modelling allow for precision manufacturing with minimal waste.

These trends reflect a growing emphasis on ethical sourcing and long-term environmental impact.

What Should Clients Consider When Commissioning Joinery?

Working effectively with joiners ensures that the final outcome aligns with both design goals and practical needs.

Design Intent vs. Practicality: A visually striking piece must also be functional, durable, and easy to maintain.

Budget Planning: Custom joinery can vary widely in cost depending on complexity, materials, and scale.

Collaboration with Design Professionals: Architects, interior designers, and joiners should work together from the early stages for optimal integration.

Lead Times and Installation Logistics: Bespoke pieces often require longer production times and careful handling during installation.

Clear communication and realistic expectations lead to successful outcomes.

Final Thoughts

Architectural joinery in Sydney remains a key element in shaping refined, functional interiors across a range of building types. Whether in a private residence or a bustling commercial environment, well-crafted joinery enhances both the usability and aesthetic value of a space. As design expectations evolve and sustainability becomes more central, the role of skilled joiners in delivering high-quality, enduring interiors continues to grow in importance.

0 notes

Text

Can Metal Interiors Add Luxury to Dubai Spaces?

Dubai is a global trendsetter when it comes to architectural brilliance and luxurious interiors. From high-end apartments in Downtown to sprawling villas in Emirates Hills, every space reflects taste, status, and a forward-thinking design approach. One material that’s increasingly being used to elevate this luxury feel is metal. But can metal interiors truly add luxury to Dubai spaces? The answer is a definite yes—and here’s why.

The Blend of Elegance and Strength

Metal has long been seen as a utilitarian material, often used for industrial or structural purposes. However, modern interior designers in Dubai have redefined this notion. With the right finish, form, and placement, metal becomes a symbol of contemporary elegance. It pairs exceptionally well with glass, marble, and wood—creating balanced interiors that are both bold and refined.

Gold-toned brass, matte black steel, brushed aluminum, and rose gold accents are some of the metallic elements making a strong impact in luxury spaces across Dubai. Whether it’s for high-end retail, modern villas, or executive office interiors, metal installations bring an element of richness that goes beyond mere aesthetics.

Popular Luxury Applications of Interior Metal in Dubai

Luxury doesn’t only mean expensive—it also means thoughtful, timeless design. Metal fits right into this definition with its versatility and long-lasting nature. Some of the most luxurious uses of metal in Dubai interiors include:

Designer Room Dividers: Laser-cut metal screens with intricate patterns not only separate spaces but serve as art pieces.

Statement Staircases: Floating steps with custom metal railings give a futuristic yet upscale vibe.

Wall Features & Paneling: Brushed bronze or gold wall panels create a visual statement in lounges, hotels, or private residences.

Decorative Light Fixtures: Hanging lights and chandeliers crafted from high-quality metal become the focal point of any room.

Furniture Details: Metal-framed consoles, dining tables with metallic legs, and shelves with golden brackets all hint at quiet luxury.

These elements are not just stylish—they also speak to the character of Dubai’s modern design scene: polished, minimal, and built to last.

Why Metal Is Ideal for Dubai’s Environment

Dubai’s climate—hot, dusty, and occasionally humid—poses challenges for traditional materials like wood. Metal, on the other hand, can be treated with weather-resistant coatings and finishes that prevent corrosion, fading, or wear. That makes it perfect for both indoor and semi-outdoor installations like balconies, staircases, and rooftop lounges.

Another advantage is that interior metal installation in Dubai can be customized to an extraordinary level. CNC machines and laser-cutting technology ensure accuracy in design, while powder coatings and electroplating allow for a variety of finishes that mimic premium materials like gold, copper, or nickel.

The Role of Professional Craftsmanship

Luxury comes from details—and achieving that level of finesse requires skilled hands and experienced professionals. The quality of welding, finishing, polishing, and fitting plays a major role in how “luxurious” your metal interiors actually look. This is why many architects and interior designers in Dubai turn to reliable metal experts to execute their vision.

Whether you're building from scratch or upgrading a current property, choosing the right partner ensures that your metal features match the overall tone and value of the space. Companies like Almaha Metal specialize in delivering this level of craftsmanship with precision and flair.

Check Out:- What Makes Custom Metal Fabrication So Useful?

Conclusion:

Metal is no longer just a functional choice, it's a luxury statement in modern Dubai interiors. When used creatively and professionally, it transforms everyday elements into design highlights that exude richness, durability, and style. If you’re looking to add that extra layer of elegance to your space, trust Al maha Metal to deliver bespoke metal solutions tailored to your unique vision.

0 notes