#PowderHandling

Explore tagged Tumblr posts

Text

The steel industry relies on precise powder handling for processes like recycling, conveying, and dosing. Macawber India’s Pneumatic Conveyor For Steel ensures efficient transfer of materials such as iron ore, lime, and coke dust in pellet, sinter, and blast furnace plants. Boost your steel plant efficiency with advanced pneumatic conveying solutions!

#SteelIndustry#PneumaticConveying#MacawberIndia#IndustrialSolutions#SteelManufacturing#BulkMaterialHandling#MaterialHandling#PowderHandling#EngineeringSolutions#ProcessOptimization#DensePhaseConveying#IndustrialAutomation#ManufacturingExcellence#ConveyingSystems#SteelProduction#EfficiencyMatters#InnovativeEngineering#SteelPlants#SmartManufacturing#BulkPowders#IndustrialInnovation#OperationalExcellence#SteelProcess#PlantEngineering#ManufacturingTech#ProcessEngineering

0 notes

Text

Automate Your Powder Dosing for Perfect Results

Are you still relying on manual scoops and estimations for your powder dispensing needs? Whether it's in a bustling pharmaceutical lab, a high-throughput food processing plant, or even your own meticulous home brewing setup, inconsistent powder dosing can lead to a cascade of problems. From inaccurate formulations and wasted materials to compromised product quality and frustrating inconsistencies, the limitations of manual methods are becoming increasingly apparent. It's time to embrace the future of precision with automatic powder dosing machines.

These intelligent systems are designed to dispense precise and repeatable quantities of powdered substances with unparalleled accuracy and speed. Imagine the benefits: eliminating human error, minimizing material waste, boosting production efficiency, and ensuring consistent product quality every single time.

So, how do these technological marvels work? Automatic powder dosing machines utilize various sophisticated mechanisms tailored to different powder characteristics and application requirements. Volumetric feeders measure powder by volume, while gravimetric feeders, often considered the gold standard for accuracy, weigh the powder as it's dispensed. Advanced control systems, often incorporating microprocessors and sensors, ensure precise and reliable dosing, allowing for programmable dispensing weights and speeds.

The advantages of investing in an automatic powder dosing machine are manifold:

Enhanced Accuracy: Say goodbye to the inconsistencies of manual scooping. Automatic systems deliver precise doses, crucial for applications where exact measurements are paramount, like pharmaceutical formulations or chemical synthesis.

Increased Efficiency: Automating the dispensing process significantly speeds up production cycles. This frees up valuable human resources for other critical tasks, boosting overall throughput and reducing labor costs.

Reduced Material Waste: Over-dosing with manual methods is a common and costly problem. Automatic machines dispense only the required amount, minimizing waste and maximizing the utilization of expensive raw materials.

Improved Product Quality: Consistent dosing directly translates to consistent product quality. Whether it's the exact flavor profile of a food product or the precise potency of a medication, automation ensures uniformity batch after batch.

Enhanced Safety: Handling certain powders can pose health risks. Automatic dosing minimizes operator exposure to potentially hazardous materials, creating a safer working environment.

Data Logging and Traceability: Many modern automatic dosing machines come equipped with data logging capabilities, providing valuable insights into production processes and ensuring traceability for quality control purposes.

Versatility: Automatic powder dosing machines can handle a wide range of powder types, from fine, free-flowing materials to cohesive or granular substances, with appropriate adjustments and configurations.

From small benchtop units for laboratory use to large-scale industrial systems integrated into automated production lines, there's an automatic powder dosing machine to suit virtually every need and budget. Investing in this technology is not just about upgrading equipment; it's about investing in accuracy, efficiency, quality, and the future of your operations.

Ready to ditch the scoop and embrace the precision of automation? Explore the world of automatic powder dosing machines and unlock a new level of control and efficiency in your powder handling processes. It's time to say hello to perfect results, every single time.

#AutomaticDosing#PowderHandling#Automation#PrecisionManufacturing#IndustrialAutomation#Pharmaceutical#FoodProcessing#Efficiency#QualityControl#Innovation

0 notes

Text

Meet the powerhouse of precision! Our diaphragm powder pump ensures consistent and efficient handling of fine powders, making it an essential tool for industries requiring accuracy and reliability. From pharmaceuticals to food processing, this pump delivers seamless performance, minimizing waste and maximizing productivity. Discover how it can enhance your operations today!

#DiaphragmPump#PowderHandling#IndustrialSolutions#PrecisionEngineering#ManufacturingExcellence#PharmaTech#FoodProcessing

0 notes

Text

Best Powder Handling Systems & Material Handling System Manufacturers Suppliers & Exporters Globally | Prochem

Discover top-tier powder handling systems and material handling solutions from Prochem, a global leader in manufacturing, supplying, and exporting. With a commitment to innovation and quality, Prochem delivers reliable systems that optimize production efficiency across diverse industries worldwide.

#Prochem#PowderHandling#MaterialHandling#IndustrialEquipment#EfficientProcessing#ManufacturingSolutions#IndustrialAutomation#BulkHandling#EngineeringExcellence#InnovativeSolutions#SafeHandling#IndustrialMachinery

0 notes

Text

Powder Screw Feeding Conveyor – VGA Automation

VGA Automation powder screw feeding conveyor, also known as a screw conveyor or auger conveyor, is a mechanical device used to transport fine materials, such as powders from one point to another point in a controlled and Consistent manner. It uses a rotating helical screw blade within a tube or trough to move the material along the conveyor's length.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationscrewfeeder#ScrewConveyor#PowderFeeder#PowderFeeding#AugerConveyor#vgapackingmachine#vgaprocessingmachine#packingmachine#processingmachine#batchingsystem#PowderHandling#BulkMaterialHandling#IndustrialConveyors#ProcessingEquipment#IndustrialAutomation#ConveyorSystems

1 note

·

View note

Text

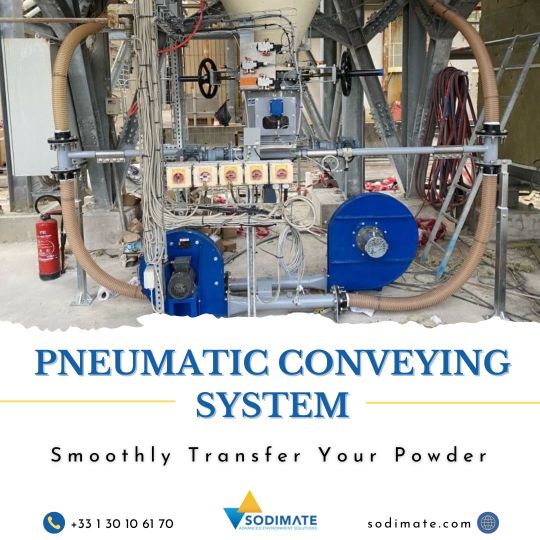

Efficient Pneumatic Conveying System

Sodimate's pneumatic conveying systems use compressed air to transport powders, which allows them to be used in applications with complex paths. They can transport powders over long distances, from 0.2 kg / h up to 1000 kg / h, using fans or blowers depending on the product flow and the length of the piping. Contact us for top-notch powder conveying solutions.

#PneumaticConveying#MaterialHandling#BulkMaterialTransport#PneumaticTransportation#ConveyorSystems#IndustrialAutomation#PowderHandling#PneumaticConveyorTechnology#EfficientConveying#MaterialTransfer#ConveyorSolutions#MaterialHandlingEquipment#PneumaticConveyorSystem#ProcessAutomation#MaterialHandlingSolutions#PneumaticConveyorDesign#IndustrialConveying#PneumaticTransfer#MaterialTransportation#BulkHandling

1 note

·

View note

Link

Specifications:Brush Material: Goat HairBrush Material: Wool FiberQuantity: 1 pcsModel Number: Makeup BrushesSize: -Used With: ConcealerUsed With: Eye ShadowUsed With: LipUsed With: PowderHandle Material: WoodColor: Gold / White / Black/ Pink

0 notes

Text

Looking to enhance your industrial batching process? This article explains precision batching systems in depth, highlighting their major components like load cells, control systems, and feeding mechanisms. Learn how they work together to deliver reliable, accurate, and efficient material handling, helping industries meet production goals with minimum waste.

#PrecisionBatching#BatchingSystems#IndustrialAutomation#MaterialHandling#ProcessEngineering#ManufacturingSolutions#EngineeringInnovation#AutomationTechnology#IndustrialEquipment#SmartManufacturing#PowderHandling#WeighingSystems#LoadCells#ProcessControl#BulkMaterialHandling#IndustrialBatching#EngineeringSolutions#MacawberIndia#AutomationSystems#ManufacturingTechnology

0 notes

Text

Ash handling is crucial in industries like power generation and cement production, requiring efficient systems to manage large volumes while minimizing wear and energy consumption. Two primary pneumatic conveying methods—dense phase and lean phase—offer distinct advantages. Dense phase systems operate at low velocity and high pressure, moving ash in compact slugs, reducing wear, and enhancing energy efficiency. In contrast, lean phase systems use high velocity and low pressure, keeping ash suspended in the air stream but causing more equipment wear. While dense phase is ideal for abrasive or fragile materials, lean phase suits lighter, non-abrasive ones. Selecting the right system depends on material properties, energy efficiency, and infrastructure constraints.

#AshHandling#PneumaticConveying#DensePhase#LeanPhase#IndustrialAutomation#MaterialHandling#EnergyEfficiency#BulkMaterialHandling#PowerPlantOperations#CementIndustry#ConveyingSystems#AshConveying#IndustrialProcessing#BulkHandling#EngineeringSolutions#EfficientTransport#IndustrialEquipment#ManufacturingProcess#SustainableEngineering#PlantMaintenance#IndustrialEfficiency#PowderHandling#AirConveying#SystemOptimization#HeavyIndustry#OperationalExcellence

0 notes

Text

#PneumaticConveying#BulkMaterialHandling#PowderHandling#IndustrialAutomation#ManufacturingTech#ProcessEquipment#ConveyingSolutions#MaterialTransport#IndustrialMachinery#PowderProcessing#EngineeringSolutions#SmartManufacturing#IndustrialInnovation#ProcessEngineering#MaterialHandling#AutomationTechnology#FactoryAutomation#MechanicalEngineering#EfficiencyInManufacturing#macawber engineering

0 notes

Photo

A screw feeder is ideal for discharging smaller quantities of product delivered in 50 lb bags. It allows accuracy in powder dosing. Sodimate offers customized, flexible, and rigid screw feeders for every operation. Upgrade your feeding system today. Contact Us!

1 note

·

View note

Link

Specifications: Brand Name: ELECOOLBrush Material: Wool FiberQuantity: 1pcModel Number: Beauty Facial Mask Brush(random hair color)Size: -Used With: PowderHandle Material: Plasticdropship: supportNote: keep clean and dry before next time you want to useLength: 140mm

0 notes

Link

Specifications:Brush Material: Goat HairBrush Material: Wool FiberQuantity: 1 pcsModel Number: Makeup BrushesSize: -Used With: ConcealerUsed With: Eye ShadowUsed With: LipUsed With: POWDERHandle Material: WoodColor: Gold / White / Black/ Pink

0 notes