#Quality Management

Text

Understanding the Difference Between Quality Assurance and Quality Control

In the world of Quality Management, two heroes emerge: Quality Assurance (QA) and Quality Control (QC). They’re not just part of the process; they ARE the process. But how do they differ? Let’s dive in!

QA is your strategic planner; it’s all about prevention. Think of it as a guardian, working tirelessly behind the scenes to ensure everything runs smoothly from the get-go. It’s about setting up…

View On WordPress

2 notes

·

View notes

Text

7 Core Functions of Operations Management

This infographic breaks down the 7 core functions of Operations Management Solutions, demonstrating how this crucial field drives business success. Learn how forecasting, capacity planning, scheduling, inventory management, quality management, supply chain management, and process design & improvement work together to ensure efficient production, optimize resource allocation, and ultimately deliver exceptional customer value.

#Operations Management#core functions#supply chain management#inventory management#quality management

0 notes

Text

A Complete Guide on Using Software for Quality Management in Your Company

To remain competitive in today's fast-paced business environment, it is essential to maintain high quality standards. Quality Administration Programming (QMS) has arisen as a crucial device for associations planning to smooth out their cycles, improve item quality, and conform to industry guidelines. Although it can be a transformative step, carefully planning and carrying it out is necessary. The steps involved in implementing QMS in your business are covered in detail in this guide.

Understanding Quality Management Software An integrated system that aids organizations in managing and streamlining their quality processes is known as quality management software. Document control, non-conformance management, corrective and preventive actions (CAPA), audit management, risk management, and other modules are typically included. The goal of QMS is to guarantee that goods and services adhere to consistent quality standards, which are necessary for customer satisfaction and regulatory compliance.

Advantages of Executing QMS

Executing QMS offers various advantages, including:

Increased Productivity: Employees can concentrate on activities that are more strategic when quality processes are automated because manual tasks require less time and effort.

Improved adherence: By providing a methodical approach to quality management, QMS assists businesses in complying with industry standards and regulations.

Management of risk: Quality management systems (QMS) reduce the likelihood of quality issues by proactively identifying and addressing potential risks.

Using data to make choices: The availability of real-time data and analytics through QMS makes it possible to make well-informed decisions and to continuously improve.

Consumer loyalty: Customer trust and loyalty rise when products and services are consistently of high quality.

Steps to Putting QMS into Practice Examine Your Needs and Set

Goals: Figure out what you intend to accomplish with QMS. Product quality enhancement, regulatory compliance assurance, and operational efficiency enhancement are all common objectives.

Assess the current procedures: Lead an exhaustive evaluation of your current quality cycles to recognize holes and regions for development.

Choose the Right QMS and Define Your Needs: Outline the specific features and functions you require in a QMS based on your objectives and current procedures.

Options for Research: Investigate different QMS arrangements accessible on the lookout. Consider factors like usability, adaptability, joining capacities, and seller support.

Test and Compare: Request demonstrations from the shortlisted vendors and compare the systems to your specifications.

Get Support from Executives and Stakeholders: Make sure that the QMS implementation has the support of upper management. Obtaining the necessary resources and driving organizational change require their support.

Include Important Departments: Engage representatives from various departments, including compliance, IT, quality control, and production, to get their input and address their concerns.

Create a project plan for the implementation: Create a comprehensive project plan outlining the QMS implementation's timeline, milestones, resources, and responsibilities.

Establish a Implementation Group: Form a cross-functional team to carry out the project's plan. Members of this team ought to have experience in IT, project management, and quality management.

Arrange the QMS

Alter the Framework: Adjust the QMS to meet your particular needs and processes. Integration with other systems, workflow configuration, and user roles and permissions are all examples of this.

Migration of Data: Plan and execute the relocation of existing quality information to the new QMS. During the transfer process, guarantee the integrity and accuracy of the data.

Develop training programs for your team: Create extensive training programs to teach workers how to use the QMS effectively. Best practices, workflows, and system functions should all be covered in training.

Offer Continuous Help: Lay out an emotionally supportive network to help workers with any issues or questions they might have during and after the execution.

Conduct a pilot run for pilot testing: Test the QMS's functionality and identify any potential issues by implementing it in a controlled, small environment.

Collect feedback: Gather criticism from clients engaged with the pilot run and make important changes in light of their feedback.

Roll out the system on a massive scale: Proceed with the full-scale implementation of the QMS throughout the organization once the pilot testing proves successful.

Observe and adjust: To ensure that the system meets your quality management goals, keep an eye on its performance and make any necessary adjustments.

Continuous Improvement Evaluation and Review: Examine the QMS's effectiveness on a regular basis and how it affects your quality processes.

Implement Changes: Implement ongoing improvements to improve the QMS and achieve better outcomes based on the findings of the review.

Normal Difficulties and Arrangements

Carrying out QMS can introduce a few difficulties, yet these can be overwhelmed with cautious preparation and execution. Common difficulties and their solutions are as follows:

Solution for Resistance to Change: Establish a culture that values quality and constant improvement. To get employees' support, explain the advantages of QMS to them and involve them in the process of putting it into practice.

Solution: Insufficient Training Ensure that employees are familiar with the new system by investing in comprehensive training programs and providing ongoing support.

Problems with migrating data? Solution: Plan the information relocation process cautiously and lead intensive testing to guarantee information precision and uprightness.

Combination with Existing Frameworks

Arrangement: Select a QMS that integrates seamlessly with your current systems and collaborate closely with your IT team to resolve any technical issues.

Solution for Maintaining Compliance: Remain refreshed with industry guidelines and guarantee that your QMS is arranged to meet these prerequisites. Audits and reviews on a regular basis can help ensure compliance.

Consider the following best practices for a successful QMS implementation to guarantee its success:

Set Clear Targets: Obviously characterize your objectives for carrying out QMS and impart them to all partners.

Pick the Right Situation: Choose a quality management system (QMS) that can grow with your business.

Stakeholders' Engagement: To ensure their support and commitment, involve key stakeholders from the beginning.

Provide Enough Education: Give your employees the skills and knowledge they need to use the QMS well.

Observe Progress: Keep an eye on how the implementation is going and make any necessary adjustments.

Center around Constant Improvement: Utilize the QMS to discover areas in need of improvement and make adjustments to improve your quality procedures.

Real-World Examples of QMS Implementation To illustrate the impact of QMS implementation, the following are some examples from the real world:

Example from the healthcare industry: In order to comply with healthcare regulations and enhance patient safety, a large hospital implemented QMS. The system helped to automate CAPA Management procedures, manage non-conformances, and streamline document control. The hospital saw an increase in compliance with regulatory standards and a significant decrease in medical errors as a result.

Example of the manufacturing industry: In order to lower production costs and improve product quality, a manufacturing company implemented QMS. The business was able to quickly identify and address quality issues thanks to the system's real-time analytics and data. As a result, there were fewer defective products and more satisfied customers.

Example from the food and beverage industry: QMS was implemented by a food processing company to guarantee food safety and conform to industry standards. The system made audits, inspections, and supplier quality management easier to manage. The company maintained high food safety standards and improved control over its quality processes.

Future Patterns in QMS

As innovation keeps on developing, QMS is likewise expected to progress. Future QMS trends include the following:

Trends in Machine Learning and Artificial Intelligence: By providing advanced data analytics, predictive insights, and automated decision-making, AI and ML will play a significant role in QMS.

Integration of the Internet of Things (IoT): In order to provide real-time monitoring and control of quality processes, IoT devices will be integrated with QMS, resulting in more accurate and timely data.

Trend in Cloud-Based Solutions: Due to their accessibility, scalability, and flexibility, cloud-based QMS solutions will continue to gain popularity.

Trend in Mobile Accessibility: Employees will be able to access quality management tools and data while on the go with mobile-enabled QMS, which will improve collaboration and productivity.

Trend for a Better User Experience: Through user-friendly interfaces, individualized dashboards, and streamlined workflows, QMS platforms will concentrate on improving user experience.

In conclusion, implementing Quality Management Software in your business can be a game-changer that increases customer satisfaction, compliance, and efficiency. You can guarantee a successful QMS implementation that drives continuous improvement and business success by adhering to best practices and following the steps outlined in this guide. You'll be able to take advantage of new opportunities and keep your edge in the market by staying up to date on QMS trends as technology changes.

#quality management#qms software#capa management#nonconformance#audit management system#quality trends

0 notes

Text

Lean Six Sigma Green Belt Training and Certification

#Lean Six Sigma#Green Belt Certification#Process Improvement#DMAIC#Lean Principles#Operational Excellence#Continuous Improvement#Waste Reduction#Efficiency#Statistical Analysis#Project Leadership#Professional Development#Quality Management#Six Sigma Training.

1 note

·

View note

Text

Understanding Six Sigma: A Path to Process Perfection

Six Sigma is a data-driven methodology focused on improving business processes by reducing defects and variability. Originating from Motorola in the 1980s, it aims for near-perfection, targeting only 3.4 defects per million opportunities. Six Sigma uses DMAIC (Define, Measure, Analyze, Improve, Control) for existing processes and DMADV (Define, Measure, Analyze, Design, Verify) for new ones. It…

View On WordPress

#100 word article#a short article#a short article on six sigma#Business Efficiency#Operational Excellence#Process Improvement#Quality Management#Six Sigma#six sigma methodology#what is six sigma

0 notes

Text

Scope after completing Advanced Diploma in Quality Management

In today's competitive job market, having specialized skills and qualifications is essential for career advancement. One such qualification that can significantly boost your career prospects is completing an Advanced Diploma in Quality Management. This credential not only equips you with the knowledge and skills to excel in quality management but also opens up a plethora of career opportunities across various industries.

Enhanced Career Prospects

Completing an Advanced Diploma in Quality Management can significantly enhance your career prospects. Graduates are equipped with the expertise to ensure that products and services meet the highest standards of quality. This qualification is particularly valuable in industries where quality control and assurance are critical, such as manufacturing, healthcare, and logistics.

Job Roles

Upon completion of the diploma, graduates can explore a wide range of job roles. These include Quality Manager, Quality Assurance Specialist, Compliance Manager, Process Improvement Consultant, and more. These roles are not only financially rewarding but also offer opportunities for professional growth and development.

Industry Demand

The demand for professionals with expertise in quality management is on the rise. As companies strive to deliver products and services that meet or exceed customer expectations, the need for qualified quality management professionals has never been higher. Completing an Advanced Diploma in Quality Management can position you as a valuable asset in the eyes of employers.

Professional Development

In addition to enhancing career prospects, completing an Advanced Diploma in Quality Management also contributes to professional development. The curriculum is designed to provide students with a comprehensive understanding of quality management principles, practices, and tools. This knowledge is not only applicable in the workplace but also invaluable for personal and professional growth.

Conclusion

Completing an Advanced Diploma in Quality Management can have a transformative effect on your career. From enhancing career prospects to opening up new job opportunities, this qualification can significantly boost your professional success. If you're looking to take your career to the next level and make a meaningful impact in the world of quality management, pursuing this diploma could be the key to unlocking your full potential.

0 notes

Text

Six Sigma's Customer Value Delivery

In today's fiercely competitive business landscape, delivering consistent value to customers is paramount for sustained success. Companies across industries are constantly seeking methodologies to streamline processes, reduce defects, and enhance overall efficiency to meet customer demands effectively. One such methodology that has gained widespread recognition for its effectiveness is Six Sigma. Let's delve into how Six Sigma, through its structured approach and rigorous methodologies, delivers tangible value to customers.

Understanding Six Sigma

Before we delve into the value it brings to customers, let's briefly understand what Six Sigma entails. At its core, Six Sigma is a data-driven methodology aimed at improving processes by systematically eliminating defects and minimizing variations. It relies on statistical analysis and precise measurement to identify and eliminate the root causes of problems, ultimately leading to enhanced quality and efficiency. Obtaining a Six Sigma certification signifies proficiency in implementing and managing these methodologies, demonstrating expertise in process improvement.

Enhancing Product and Service Quality

One of the primary ways Six Sigma delivers value to customers is by significantly enhancing the quality of products and services. By meticulously analyzing processes and identifying areas of improvement, organizations can reduce defects and errors, leading to products that meet or exceed customer expectations consistently. Whether it's manufacturing defects, service errors, or process inefficiencies, Six Sigma provides a structured approach to identify and rectify issues, resulting in higher-quality deliverables.

Customers today have increasingly high standards, and they expect nothing short of excellence from the products and services they invest in. A company that has undergone a Six Sigma course is better equipped to deliver on these expectations, ensuring that each product or service meets rigorous quality standards. This not only enhances customer satisfaction but also fosters loyalty and positive word-of-mouth, further strengthening the company's reputation in the market.

Read this article: Why Six Sigma Certification in India?

Driving Continuous Improvement

Six Sigma is not just a one-time initiative; it's a philosophy centered around continuous improvement. Organizations that embrace Six Sigma are committed to constantly analyzing their processes, identifying areas for optimization, and implementing necessary changes. This relentless pursuit of perfection ensures that customers continually receive enhanced value from the products and services they patronize.

A key aspect of Six Sigma is its focus on data-driven decision-making. By collecting and analyzing data at every stage of the process, organizations gain valuable insights into their operations. This allows them to make informed decisions aimed at improving efficiency, reducing waste, and ultimately delivering greater value to customers. Whether it's shortening lead times, optimizing supply chains, or streamlining customer service processes, Six Sigma empowers organizations to make targeted improvements that directly benefit customers.

What is Quality

youtube

Empowering Employees for Success

Another crucial aspect of Six Sigma's value proposition lies in its emphasis on employee training and development. A well-executed Six Sigma training course equips employees with the tools, techniques, and mindset needed to drive process improvements effectively. By involving employees at all levels of the organization in Six Sigma initiatives, companies foster a culture of accountability, collaboration, and continuous learning.

Empowered employees are better equipped to identify inefficiencies and propose innovative solutions that directly impact customer satisfaction. Whether it's frontline staff identifying bottlenecks in customer service processes or manufacturing personnel optimizing production workflows, every employee plays a vital role in delivering value to customers. Six Sigma training provides employees with the skills and confidence to take ownership of improvement initiatives, ultimately leading to a more responsive and customer-centric organization.

In conclusion, Six Sigma is much more than just a quality improvement methodology; it's a strategic approach to delivering maximum value to customers. By systematically eliminating defects, driving continuous improvement, and empowering employees, organizations that embrace Six Sigma create a culture of excellence that resonates with customers. Whether it's through higher-quality products, streamlined processes, or exceptional service, the principles of Six Sigma enable companies to meet and exceed customer expectations consistently. As competition intensifies and customer demands evolve, investing in Six Sigma institute remains a wise decision for any organization committed to delivering unparalleled value to its customers.

What is Six Sigma

youtube

Six Sigma Green Belt Introduction

youtube

Six Sigma Black Belt Training Introduction

youtube

#six sigma green belt#six sigma course#six sigma training#six sigma certification#six sigma green belt certification#six sigma black belt#quality manager#quality management#Youtube

0 notes

Text

youtube

Quality Control vs Quality Assurance... Explore the nuances!

You can read the full article through this link:

Contrôle Qualité Vs Assurance Qualité - Formi Forma

0 notes

Text

Can software quality be assured by "testers"?

You'd have to live under a rock not to notice the constant flurries of anti-QA rhetoric here on LinkedIn and elsewhere in blogsphere. Have no fear though. In this article, I address some of the misconceptions that are being made that cause folks to have this anti-QA stance that usually revolves around the statement that "testers" cannot assure quality because, in the context of software development, they are not in a position to influence/change the code and therefor have no power to change the quality, directly.

I want to come right off the bat and say this is 100% true! "Testers," as defined by the folks that seem to hold this stance, cannot assure quality. Does this surprise you? It shouldn't, here is why.

Testers only provide information

If testers, per the definition used by Bolton and others, only "evaluate a product to provide information" (this is an overly simple and paraphrased version I use for brevity but you can find their definition readily online), then of course they cannot change the quality of the software! Duh!

And here lies the crux of the matter, testers don't assure quality but Quality Assurance Analysts and Engineers via a Quality Assurance process, do. Now, I don't think that Bolton is confusing Quality Assurance with testing, but I think that he is adding to the confusion by not making this very clear. Which results in practitioners being confused about what they really should do.

When Bolton and others tell folks to "get out of the Quality Assurance business" it could be because they would like them to get into the single purpose testing business instead.

Quality Assurance drives the Quality

In a mature organization, QA is responsible for working with management (executive management), understanding the Quality Objectives of an organization, crafting a process that will ensure that these quality objectives are being met and then reporting on said quality; for the purpose of continuous improvement.

Quality Assurance and Testing are not the same thing

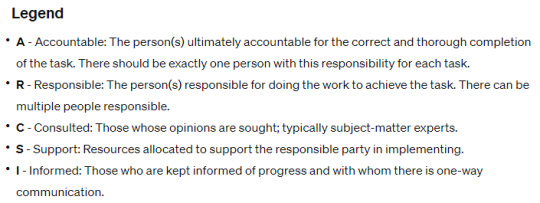

"A picture says a thousand words", one tool that I like to use to illustrate who is responsible for what without using a lot of words is a RACI. To understand this nuanced difference between testing and QA and how they are not the same thing but do work together, let's examine the below example in the context of Software Quality:

As you can see by creating a RACI chart in order for us to outline the responsibilities, in terms of quality, across various roles in the project team (such as Testing (testers), Development, Quality Assurance (QA), Scrum Masters, User) helps to clarify who is responsible for what, this ensures that all aspects of quality are adequately covered thereby assuring quality.

In order to assure quality, though, you first have to define what quality is. What are the Quality Standards for the project? This is the first line in the RACI, if you notice QA is Responsible and Accountable for setting the Quality Standards while "testers" are consulted (this is in line with testers only provide information, no?).

Another difference between QA and testing is that writing the test cases and also actually performing testing are in the realm of "testers" who are both Accountable and Responsible for this. QA plays a Supporting role.

Yet another difference is that testers are Accountable for reporting bugs, risks, etc, but share the Responsibility with QA. This is clearly in line with the "testers" only provide information mantra.

Here is the Legend I used for the RACI for completeness:

Summary

As you can see from the above, it is clear (well at least to me) that "testers" cannot assure quality. It is also clear to me that Quality Assurance is Accountable and Responsible for both owning the Quality Standards for the project as well as setting up the process and following up with the other stakeholders to ensure that the quality standards are being met, therefore resulting in a Quality product (as defined by the project team).

What are your thoughts on this topic? Do you still think that "testers" can assure quality? Are you ready to get out of the "tester" business and join Quality Assurance? A profession that actually has a body of knowledge and common practices that are widely known? Leave your thoughts in the comments!

0 notes

Text

Developers can't test - a bedtime story

Automated tests written after the fact or not by developers are tech debt. BDD as an end-to-end testing framework is a supercharged tech debt creator.

Now that I have your attention allow me to blow your mind a little bit more. The best developers I know are also the best at testing their software. Not only that but they are the best at imagining how their product will be used (and abused) by their customers. They also acknowledge that they can only accomplish this when they build the product by themselves. By the way, I have only met about half a dozen of these unicorns in my career to date. Why do you think that is? I’ll go into it in this article.

The Lone Ranger

The best developers prefer to work alone. I've asked my friend Oscar (a real developer and unicorn) about the reason for this, and the answer is quite simple: "Because developers are taught either by their organizational policies or product test teams, that they shouldn't have to test because we have specialists that take care of it, and they know this is just not true! So it's the path of least resistance to just ignore the status quo and focus on producing high quality, tested software (by themselves) for others to test". At least this is the case for Oscar. I'm picking on him because I've worked with him at a few companies and have gotten first-hand experience at what he can do alone; that is, build products of high quality the first time, in record time, and on time (as promised). One example is a multi-agent system based point-of-sale application that is dynamically configured depending on the context it is deployed in (this was in the early 2000s when AI wasn't a mainstream fad). This was a personal project for him as he is also an entrepreneur (another trait of good developers), that I helped him test.

The first delivery I saw of this product was 99% complete and bug-free. Why was that? Read on.

Batman and Robin

The best developers value QA specialists' involvement and do so from the beginning and they incorporate feedback from ideation. When Oscar came up with the idea for his product, he immediately reached out to me because he knew that, as an entrepreneur myself, I had owned and operated retail stores in the past, so I was the perfect partner for this new endeavor.

I later found out, though that the product wasn't really a point-of-sale system but a way to prove that the Multi-agent system engine he had built the year before to incorporate into a hobby product that teaches a player how to win in Black Jack (which I also helped him with) would in fact be able to be used in multiple products and for multiple purposes.

Just like superheroes team up and combine their superpowers in fantasy series, developers and quality specialists (the good ones) team up in product development. Hence, a product was delivered with only 2 bugs that were edge cases we both missed during design.

Superman

It so happens that the best developers and quality specialists are outcasts from development communities, forcing them into a life of solitude. Not in the sense that they are alone, but just like Superman was forced to live his life as a common person for fear of persecution, they must hide their true talents from a team that may feel threatened by this unknown power that they possess. Little do they know that they, too, can have this power if they only open up to different perspectives.

Transformers - More than meets the eye!

So how do we fix this? I would take a multi-faceted approach.

The first thing we have to do is acknowledge there is a problem. The problem is this false perception that developers shouldn't test because they can't. This is just not true. Developers don't test because we don't teach those who don't know they have to do this AND don't trust those who want to do it.

Second, assess your teams and figure out who on the team is of the Batman and Robin type and who isn't. Pair those that are with those that aren't.

Third create a safe space where the newly formed superteams can come and share their challenges, solutions, and triumphs. Focus your efforts on those who are trying to get there by praising them to elevate their strengths.

This doesn't have to be a huge transformation. What we are trying to accomplish here is a two-pronged shift in mindset. The developers think they shouldn't test, and the test specialists think that developers can't test. These two completely false mindsets need to be reversed.

Conclusion

Once you are able to overcome this developers can't test and test specialists are the only ones that can problem (which I will go on the line here and assume is present in a lot of organizations), you'll be able to not only deliver high-quality software the first time but you'll be able to do it faster as well. If you find yourself struggling with continuous testing and continuous delivery to production and cannot pinpoint why that is, do a quick sniff test around your organization and see if it is not rooted or minimally related to what I just described here.

What are your thoughts on this topic?

0 notes

Text

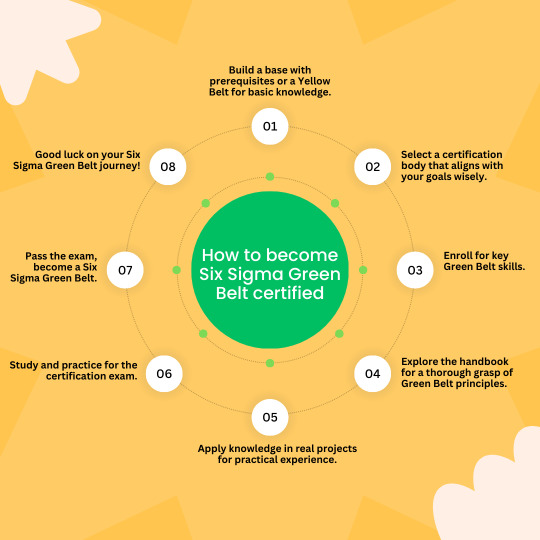

Join the journey to become a Six Sigma Green Belt certified professional! Our guide includes step-by-step instructions, training tips, and resources to help you pass the certification. Advance your career in quality management and recognize the value of continuous improvement.

#Six Sigma Green Belt#Certification#Quality Management#Professional Development#Career Advancement#Process Improvement#Training Program#Exam Preparation

0 notes

Text

Mastering Excellence: Your Comprehensive Guide to Total Quality Management

When we talked about total quality management (TAQ) long-term success through customer satisfaction is a core definition of total quality management where all members of an organisation participate all together to improve the work procedure of an organization to achieve their desired goals.

Visit more :- https://www.indiaassignmenthelp.com/blog/mastering-excellence-your-comprehensive-guide-to-total-quality-management

1 note

·

View note

Text

From Reactive to Proactive: Leveraging AI for Predictive Nonconformance Management

Many reports have suggested customers switch their loyalties with just three bad experiences. Today, when people have many options to choose from, quality management is non-negotiable. Meeting and exceeding customer expectations is indispensable to your organization's success.

Quality management assumes more significance in critical industries such as pharmaceuticals, which are intolerant of quality shortcomings. Nonconformance management software is a modern approach to identifying nonconformances and taking the required steps to pre-empt them.

The once-in-a-lifetime pandemic disrupted the quality management landscape. Regulations globally have become stringent, demanding strict adherence to set quality standards. Noncompliance with requirements set by regulatory bodies invites penalties and, in extreme cases, leads to shuttering of businesses. The old approach to quality management is passe.

Today, cutting-edge enterprise quality management software modernizes quality management, streamlines business processes, and ensures compliance. However, compliance is not enough in an ever-evolving quality management ecosystem.

Conformance, which means meeting and exceeding customer expectations, is indispensable in the quality management processes. Nonconformances lead to dissatisfied customers. Mismanaging nonconformances can earn businesses a bad reputation, driving down their profits.

Modernizing nonconformance management with the help of state-of-the-art technology, such as nonconformance management software, plays a crucial role in overhauling the approach to quality management, bringing better results and streamlined business operations.

This blog spotlights the significance of managing nonconformances proactively to ensure uninterrupted business growth.

Reactive vs Proactive Approach

Earlier, the approach to nonconformances was reactive. When an issue came to light, the organization took measures to manage it. In the present day, this approach is neither desirable nor practical.

The disruption wrought by technology means that the world has shrunk into a hyper-interconnected village. An incident in one remote part of the world can have repercussions globally. Social media has changed communication strategies on its head. A dissatisfied customer can post negative reviews and feedback about a brand or product on different social media platforms and ruin your brand's value in a jiffy way.

Waiting for a quality issue to come to your notice before you take measures to mitigate damage can backfire on your organization and prove to be very costly. On the other hand, a proactive approach to nonconformance management anticipates and pre-empts nonconformances, giving you an edge over your competitors and ensuring a hassle-free experience for your customers.

Today's customers value experience as much as the products and services they buy. Research on customer sentiment has highlighted the importance of offering a smooth experience to customers to win their respect and loyalty. Proactive nonconformance management enables customer delight, creating a conducive environment for your organization to grow uninterruptedly and achieve its full potential. Additionally, transitioning from reactive to proactive nonconformance management through the transformative power of

Artificial Intelligence (AI) enables eliminating nonconformances cost-effectively and efficiently. AI's ability to sift through vast amounts of data and identify patterns not obvious to human eyes empowers you to predict and pre-empt nonconformances. The proactive approach allows you to take preventive measures, saving time and resources and eventually enhancing product quality.

The High Cost of Reactive Nonconformance Management

Reactive nonconformance management has significant and unavoidable drawbacks:

Delayed Detection: Issues often go unnoticed until they are apparent in the final product, leading to rework, scrappage, and delays. The rework and recall of products escalate costs, reducing profits and earning a bad reputation.

Cost Escalation: These issues translate into higher production costs, warranty claims, and potential customer dissatisfaction.

Limited Prevention: Reactive approaches focus on fixing existing problems, offering minimal insight into preventing future occurrences.

The Power of AI in Predictive Nonconformance Management

AI offers a modern solution to the nonconformance challenge. By leveraging machine learning algorithms, AI analyzes a vast trove of data encompassing historical production data, quality control records, sensor readings, and process parameters. Using AI in analysis uncovers hidden patterns and trends that can predict potential nonconformances before they arise.

Here's a deeper peek into how AI enables predictive nonconformance management:

Real-Time Anomaly Detection: AI algorithms monitor production lines in real time, identifying deviations from normal operating parameters that might indicate an impending nonconformance.

Predictive Analytics: By analyzing historical data, AI can predict the likelihood of specific nonconformances occurring based on factors like material variations, machine wear, and environmental conditions.

Putting AI into Action: A Practical Approach

Implementing AI for predictive nonconformance management requires a foolproof approach:

Data Gathering and Preparation: The foundation lies in collecting high-quality, relevant data from various sources across the production process. Data cleaning and standardization are crucial for accurate analysis.

Model Selection and Training: Choosing the appropriate AI model, such as decision trees, random forests, etc., and training it on the prepared data enables it to recognize patterns and predict nonconformances.

Integration with Existing Systems: Seamless integration of the AI model with existing quality management systems ensures real-time alerts and facilitates the implementation of preventive actions.

Continuous Monitoring and Improvement: The AI model's performance needs constant monitoring and refinement as new data becomes available and production processes evolve.

Benefits of Predictive Nonconformance Management

There are many advantages of adopting a proactive approach to nonconformance management:

Cost-Effective: By pre-empting quality issues, businesses can minimize rework, recall, and scrappage, leading to significant cost savings.

Improved Quality: Predictive capabilities allow for proactive adjustments to processes or materials, resulting in a consistent and high-quality final product.

Increased Efficiency: Early detection of potential problems minimizes production delays and ensures smooth operation.

Enhanced Customer Satisfaction: Consistent quality and reduced defect risk lead to happier customers and a stronger brand reputation.

Challenges and Considerations:

While AI offers immense potential, there are many challenges, too:

Data Quality and Availability: The effectiveness of AI models depends on the quality and relevance of data. Poor-quality data can lead to inaccurate predictions.

Model Explainability: Understanding how AI models reach their conclusions is crucial for building trust and ensuring transparency in decision-making.

AI Expertise: Implementing AI solutions might require collaboration with qualified data scientists and AI specialists.

Parting Shot:

The integration of AI into quality management is a significant leap forward. By proactively addressing potential nonconformances, businesses can achieve a new level of efficiency, cost-effectiveness, and robust quality. As AI technology evolves, we can expect even more sophisticated and powerful tools to emerge, ushering in a future of truly preventative quality management.

0 notes

Text

Trends in Quality Management: Navigating the Path to Excellence

Introduction

Quality Management, a cornerstone of organizational success, revolves around ensuring products and services meet or exceed customer expectations. Let's delve into the trends shaping this dynamic field.

Importance of Quality Management

In today's hypercompetitive market, Quality Management is indispensable. It not only guarantees customer satisfaction but also enhances operational efficiency, fostering a robust brand reputation.

Current Trends

Embracing Technology

Innovations like automation and AI are revolutionizing Quality Management, streamlining processes and minimizing errors.

Data-Driven Decision Making

Smart organizations leverage data analytics to make informed decisions, optimizing their quality strategies for maximum impact.

Focus on Sustainability

Modern consumers prioritize environmentally conscious brands. Quality Management now integrates sustainable practices, aligning businesses with global environmental goals.

Quality Management Systems

ISO 9001:2015 Implementation

Adopting the ISO 9001:2015 standard ensures a systematic approach to quality, promoting consistency and customer satisfaction.

Six Sigma Methodology

Rooted in process improvement, Six Sigma methodology enhances efficiency, reduces defects, and elevates overall product and service quality.

Lean Management Principles

Lean principles eliminate waste, enabling organizations to do more with fewer resources while maintaining high-quality standards.

Role of Leadership

Effective leadership sets the tone for a quality-focused culture, engaging employees in continuous improvement initiatives.

Challenges in Quality Management

Navigating the delicate balance between cost and quality, adapting to rapid technological changes, and ensuring regulatory compliance pose ongoing challenges.

Future Outlook

As technology evolves, artificial intelligence integration and a commitment to continuous improvement will define the future of Quality Management. Global collaboration in setting quality standards will be paramount.

Case Studies

Exploring successful Quality Management implementations and learning from failures provides valuable insights for organizations aiming for excellence.

Training and Skill Development

Investing in training and skill development is crucial. Online platforms offer accessible resources, empowering quality professionals with the latest knowledge.

Measurement Metrics

Key Performance Indicators (KPIs) and benchmarking are essential tools for gauging and improving the effectiveness of quality management initiatives.

Best Practices

Documented processes, regular audits, and feedback loops are among the best practices ensuring sustained quality excellence.

Trends in Quality Management: A Closer Look

Dive deeper into emerging subtopics within Quality Management and explore industry-specific quality standards shaping the future.

Conclusion

Quality Management is a dynamic field that continually evolves to meet the demands of a changing world. Stay vigilant, embrace trends, and commit to continuous improvement to excel in your quality journey.

0 notes

Text

When searching for healthcare staffing agencies, you must assess certain qualities that will help you align with an agency that fulfills your needs and delivers top-notch healthcare professionals. If you’re seeking valuable information on this topic, Quality Elite Healthcare Solutions, your dependable healthcare staffing agency in Auburn, California, is here to assist you!

0 notes