#RFID Handheld Computer

Explore tagged Tumblr posts

Text

Die Bedeutung von mobilen RFID-Handheld-Computern für Lager und Lieferkette

In der schnelllebigen Welt der Logistik sind die Rationalisierung von Abläufen und die Aufrechterhaltung der Transparenz in Echtzeit von größter Bedeutung. Herkömmliche Methoden der Datenerfassung in Lagern und Lieferketten beinhalten oft manuelle Prozesse, die Verzögerungen verursachen und fehleranfällig sind. Glücklicherweise haben sich mobile RFID-Handheld-Computer als Wegbereiter erwiesen, die die Art und Weise, wie wir Bestände verfolgen, verwalten und optimieren, verändern.

Entfesseln Sie die Kraft von Mobile RFID: RFID Handheld Computer sind robuste mobile Geräte, die mit integrierten RFID-Lesegeräten ausgestattet werden. Diese Lesegeräte senden Funkwellen aus, die mit den an den Gegenständen angebrachten RFID-Etiketten interagieren und die Datenerfassung unterwegs ermöglichen. Dies macht stationäre Scanner und papierbasierte Prozesse unnötig und steigert die Effizienz und Genauigkeit.

Erfahren Sie, wie mobile RFID-Systeme Lager und Lieferketten unterstützen:

Verbesserte Bestandsgenauigkeit: Verabschieden Sie sich von zeitaufwändigen manuellen Zählungen. Mobile RFID ermöglicht schnelle, fehlerfreie Bestandsscans, die den Lagerbestand in Echtzeit aktualisieren und Diskrepanzen minimieren.

Rationalisiertes Kommissionieren und Verpacken: Mit gezielten RFID-Scans können Sie Artikel sofort lokalisieren und so die Kommissionierrouten und Verpackungsprozesse optimieren. Dies führt zu einer schnelleren Auftragsabwicklung und einer höheren Kundenzufriedenheit.

Geringerer Schwund und aktive Diebstahlprävention: Nachverfolgungsfunktionen in Echtzeit verhindern aktiv Diebstahl und das Verlegen von Artikeln. Mobile RFID kann bei unbefugter Bewegung des Etiketts einen Alarm auslösen, wodurch die Sicherheit erhöht und Verluste minimiert werden.

Verbesserte Sichtbarkeit der Bestellung: Verfolgen Sie Waren über die gesamte Lieferkette hinweg, vom Wareneingang bis zum Versand. Diese Transparenz eröffnet Möglichkeiten für ein proaktives Auftragsmanagement und schnellere Lieferzeiten.

Mehr als einfache Datenerfassung: Moderne mobile RFID-Computer gehen über das grundlegende Scannen hinaus. Sie verfügen oft über zusätzliche Funktionen wie:

Integrierte Kameras und Barcode-Scanner: Erfassen Sie zusätzliche Datenpunkte wie den Artikelzustand oder Barcodes für eine umfassende Produktidentifikation.

Robuste Konstruktion: Widerstehen Sie rauen Lagerumgebungen und gewährleisten Sie zuverlässige Leistung auch unter staubigen oder nassen Bedingungen.

Konnektivitätsoptionen: Wi-Fi, Bluetooth und Mobilfunkverbindungen ermöglichen den Datenaustausch in Echtzeit und die nahtlose Integration in Lagerverwaltungssysteme.

iDTRONIC: Eine bahnbrechende Kraft bei mobilen RFID-Lösungen Seit über 25 Jahren ist iDTRONIC ein führender Hersteller von hochwertigen RFID-Lösungen, einschließlich einer breiten Palette von mobilen RFID-Handheld-Computern. Die Geräte sind bekannt für ihre Langlebigkeit, Funktionalität und Benutzerfreundlichkeit. Ganz gleich, ob Sie ein kleines Lager oder ein großes Distributionszentrum verwalten, iDTRONIC bietet die perfekte mobile RFID-Lösung für Ihre speziellen Anforderungen.

Aufbruch in die Zukunft der Logistik: Durch den Einsatz mobiler RFID-Technologie können Lagerhäuser und Lieferketten eine neue Ära der Effizienz, Genauigkeit und Transparenz einläuten. Von der Echtzeit-Bestandsverwaltung über verbesserte Sicherheit bis hin zur schnelleren Auftragsabwicklung - die Vorteile sind unbestreitbar. Mit zuverlässigen Partnern wie iDTRONIC können Unternehmen die sich ständig verändernde Logistiklandschaft sicher navigieren und hervorragende Betriebsergebnisse erzielen.

Bei der Investition in mobile RFID-Handheld-Computer geht es nicht nur um die Anschaffung von Technologie, sondern auch um einen intelligenten, flexibleren Ansatz für das Lager- und Lieferkettenmanagement. Die Zukunft der Logistik ist datengesteuert, und mobiles RFID ist der Schlüssel zur Entfaltung des vollen Potenzials.

Weitere Informationen finden Sie auf der Website : https://idtronic-rfid.com/

0 notes

Text

Die Rolle mobiler RFID-Handheld-Computer bei der Optimierung von Lagern und Lieferketten

In der schnelllebigen Welt von heute suchen Unternehmen stets nach Möglichkeiten, ihre Abläufe zu optimieren und die Effizienz zu steigern. Ein Bereich, in dem dies besonders wichtig ist, ist die Lager- und Lieferkettenbranche. Mit dem Aufschwung des E-Commerce und der steigenden Nachfrage nach schnelleren Lieferzeiten müssen Unternehmen Wege finden, ihre Prozesse zu rationalisieren und die Genauigkeit zu verbessern. Eine Technologie, die sich in diesem Bereich als bahnbrechend erwiesen hat, sind mobile RFID-Handheld-Computer. Mit diesen Geräten können Mitarbeiter schnell und einfach Bestände scannen und Artikel in Echtzeit verfolgen, wodurch Fehler reduziert und die Gesamtproduktivität verbessert werden. In diesem Blogbeitrag erfahren Sie, wie mobile RFID-Handheld-Computer zur Optimierung von Lager- und Lieferkettenabläufen beitragen können und warum iDTRONIC Professional RFID der beste Anbieter für diese Technologie ist.

iDTRONIC Professional RFID ist ein Technologieunternehmen, das RFID-Lösungen für verschiedene Anwendungen anbietet, unter anderem für das Lager- und Lieferkettenmanagement. In der heutigen schnelllebigen Welt ist die Effizienz von Lager- und Lieferkettenabläufen entscheidend für den Erfolg eines jeden Unternehmens. Mobile RFID-Handheld-Computer haben sich zu einem unverzichtbaren Werkzeug für die Optimierung dieser Abläufe entwickelt. Mit der Möglichkeit, Bestände in Echtzeit zu scannen und zu verfolgen, haben mobile RFID-Handheld-Computer den Zeit- und Arbeitsaufwand für die manuelle Bestandsverfolgung erheblich reduziert. Dies hat nicht nur die Effizienz erhöht, sondern auch zu einer besseren Genauigkeit, Transparenz und Kontrolle über die Lieferkette geführt. Mobile RFID-Handheld-Computer sind außerdem in der Lage, Daten wie Standort, Zeit und Bewegungsmuster zu erfassen und geben so Aufschluss über die Produktivität des Lagerbetriebs. Mithilfe mobiler RFID-Handheld-Computer können Unternehmen ihre Lager- und Lieferkettenabläufe optimieren und gleichzeitig Kosten senken und die Kundenzufriedenheit verbessern.

iDTRONIC Professional RFID Handheld Computer ist eine hochmoderne Technologie, die die Art und Weise, wie Lager- und Lieferkettenunternehmen ihre Abläufe optimieren, revolutioniert hat. Durch den Einsatz dieses leistungsstarken Tools haben Unternehmen jetzt Zugang zu Echtzeit-Verfolgungsinformationen, die ihnen helfen, sofort fundierte Entscheidungen zu treffen. Diese RFID-Geräte bieten eine effiziente und genaue Möglichkeit, den Bestand zu verfolgen, die Auftragsabwicklung zu verbessern und das Risiko kostspieliger Fehler zu verringern. Der RFID Handheld Computer kann sogar Hunderte von Artikeln pro Minute scannen und ist damit die ideale Lösung für Betriebe mit hohem Warenumschlag und komplexen Anforderungen. Dank modernster Funktionen wie Scannen mit großer Reichweite und fortschrittlicher Datenverwaltung wird der iDTRONIC Professional RFID Handheld Computer schnell zu einem unverzichtbaren Werkzeug für die Rationalisierung von Lager- und Lieferkettenabläufen.

Zusammenfassend lässt sich sagen, dass der Einsatz der RFID-Technologie die Effizienz und Genauigkeit der Bestandsverfolgung und Auftragsabwicklung in einem Lager oder einer Lieferkette erheblich verbessern kann. Mit dem iDTRONIC Professional RFID Handheld Computer können Unternehmen eine Vielzahl von Artikeln pro Minute scannen und von erweiterten Datenverwaltungsfunktionen profitieren. Darüber hinaus kann diese Technologie dazu beitragen, das Risiko kostspieliger Fehler zu verringern, was sich positiv auf das Geschäftsergebnis auswirkt. Angesichts der rasanten Entwicklung der RFID-Technologie wird es für Unternehmen immer wichtiger, diese Instrumente zu nutzen und auf einem immer stärker umkämpften Markt die Nase vorn zu haben.

Weitere Informationen über mobile RFID-Handheld-Computer finden Sie auf unserer Website https://idtronic-rfid.com/de/handheld-computer/

0 notes

Text

The Role of Mobile RFID Handheld Computers in Warehouse and Supply Chain Optimization

In today's fast-paced world, businesses are always looking for ways to optimize their operations and increase efficiency. One area where this is especially important is in the warehouse and supply chain industry. With the rise of e-commerce and the increasing demand for faster delivery times, companies need to find ways to streamline their processes and improve accuracy. One technology that has emerged as a game-changer in this field is mobile RFID handheld computers. These devices allow workers to quickly and easily scan inventory and track items in real-time, reducing errors and improving overall productivity. In this blog post, we will explore the various ways in which mobile RFID handheld computers can help optimize warehouse and supply chain operations, and why iDTRONIC Professional RFID is the go-to provider for this technology.

iDTRONIC Professional RFID is a technology company that offers RFID solutions for various applications, including warehouse and supply chain management. In today's fast-paced world, the efficiency of warehouse and supply chain operations is crucial for the success of any business. Mobile RFID handheld computers have emerged as an essential tool in optimizing these operations. With the ability to scan and track inventory in real-time, Mobile RFID handheld computers have significantly reduced the time and labor required for manual inventory tracking. This has not only improved efficiency but also led to better accuracy, visibility, and control over the supply chain. Mobile RFID handheld computers are also capable of capturing data such as location, time, and movement patterns, providing insights into the productivity of warehouse operations. With the help of mobile RFID handheld computers, organizations can optimize their warehouse and supply chain operations while reducing costs and improving customer satisfaction.

iDTRONIC Professional RFID Handheld Computer is a state-of-the-art technology that has revolutionized the way warehouse and supply chain companies optimize their operations. By utilizing this powerful tool, businesses now have access to real-time tracking information that helps them make informed decisions instantly. These RFID devices provide an efficient and accurate way to track inventory, improve order processing times, and reduce the risk of costly errors. In fact, the RFID Handheld Computer can scan hundreds of items per minute, making it an ideal solution for high-volume operations with complex demands. With cutting-edge features, such as long-range scanning and advanced data management capabilities, the iDTRONIC Professional RFID Handheld Computer is quickly becoming an essential tool for streamlining warehouse and supply chain operations.

In conclusion, utilizing RFID technology can greatly enhance the efficiency and accuracy of inventory tracking and order processing in a warehouse or supply chain operation. With the iDTRONIC Professional RFID Handheld Computer, businesses can scan numerous items per minute and benefit from advanced data management capabilities. Moreover, this technology can help reduce the risk of costly errors, bringing significant benefits to the bottom line. As RFID technology continues to evolve rapidly, it is increasingly crucial for businesses to leverage these tools and stay ahead of the competition in an increasingly competitive market.

For more information about Mobile RFID Handheld Computers, visit our website https://idtronic-rfid.com/en/handheld-computers/

0 notes

Text

Best Mobile Data Computers for Boosting Workforce Productivity

Boosting workforce productivity, investing in the best mobile data computers is essential. Our powerful devices are designed to withstand tough conditions while delivering reliable performance. Features like long battery life, fast processors, and rugged construction enable employees to access real-time data wherever they are. We interfaces ensure quick adoption, minimizing downtime during training. Whether used in logistics, healthcare, or retail, the right mobile data computer can enhance communication, streamline tasks, and significantly improve efficiency, making it a valuable asset for any team.

#Mobile Data Computer#barcode scanners#handheld mobile computers#RFID scanners#barcode printers#inventory control#warehouse management#asset management#tool tracking

1 note

·

View note

Text

The Significance Of Mobile RFID Handheld Computers For Warehouse And Supply Chain

In the fast-paced world of logistics, streamlining operations and maintaining real-time visibility are paramount. Traditional data-gathering methods in warehouses and supply chains often involve manual processes that are prone to errors and delays. Thankfully, mobile RFID handheld computers have emerged as game-changers, transforming how we track, manage, and optimize inventory.

Unleashing the Power of Mobile RFID: RFID Handheld Computers are ruggedized mobile devices equipped with integrated RFID readers. These readers emit radio waves that interact with RFID tags attached to items, enabling data capture on the go. This eliminates the need for stationary scanners and paper-based processes, boosting efficiency and accuracy.

Here's how mobile RFID empowers warehouses and supply chains: Enhanced Inventory Accuracy: Say goodbye to time-consuming manual counts. Mobile RFID allows for rapid, error-free inventory scans, updating stock levels in real-time and minimizing discrepancies.

Streamlined Picking and Packing: Locate items instantly with targeted RFID scans, optimizing picking routes and packing processes. This translates to faster order fulfillment and improved customer satisfaction.

Reduced Shrinkage and Theft: Real-time tracking capabilities deter theft and misplaced items. Mobile RFID can trigger alerts upon unauthorized tag movement, enhancing security and minimizing losses.

Improved Order Visibility: Track goods throughout the supply chain, from receiving to shipping. This transparency unlocks opportunities for proactive order management and faster delivery times.

Beyond Basic Data Capture: Modern mobile RFID computers go beyond simple scanning. They often boast additional features like:

Integrated Cameras and Barcode Scanners: Capture additional data points such as item condition or barcodes for comprehensive product identification.

Rugged Design: Withstand harsh warehouse environments, ensuring reliable performance even in dusty or wet conditions.

Connectivity Options: Wi-Fi, Bluetooth, and cellular connectivity enable real-time data exchange and seamless integration with warehouse management systems.

iDTRONIC: A Pioneering Force in Mobile RFID Solutions For over 25 years, iDTRONIC has been a leading manufacturer of high-quality RFID solutions, including a diverse range of mobile RFID handheld computers. Their devices are renowned for their durability, functionality, and ease of use. Whether you manage a small warehouse or a vast distribution center, iDTRONIC offers the perfect mobile RFID solution to meet your specific needs.

Embracing the Future of Logistics: By embracing mobile RFID technology, warehouses and supply chains can unlock a new era of efficiency, accuracy, and visibility. From real-time inventory management to enhanced security and faster order fulfillment, the benefits are undeniable. With reliable partners like iDTRONIC, organizations can confidently navigate the ever-evolving logistics landscape and achieve operational excellence.

Investing in mobile RFID handheld computers is not just about acquiring technology; it's about embracing a smarter, more agile approach to warehouse and supply chain management. The future of logistics is data-driven, and mobile RFID is the key to unlocking its full potential.

0 notes

Text

Reliable Hand Held Terminal (HHT) Solutions in Dubai & UAE

At Forte Tech, we specialize in delivering cutting-edge Hand Held Terminal Solutions across Dubai and UAE, tailored to meet the evolving needs of modern enterprises. Whether you're in retail, logistics, warehousing, or field operations, our advanced HHT Solutions streamline your business processes, increase productivity, and reduce operational costs.

What is a Hand Held Terminal (HHT)?

A HHT is a compact, mobile computing device used to collect, access, and manage data on the go. Integrated with barcode scanners, RFID readers, and wireless connectivity, Hand Held Terminals allow seamless data capturing and syncing with backend systems. These devices are crucial in real-time inventory management, order processing, and asset tracking.

Our Comprehensive Solutions

As a trusted provider of Hand Held Terminal Solutions, We offers a full range of services, from hardware supply to customized this Software development. We understand that each business has unique needs, and we tailor our HHT Solutions in Dubai to align perfectly with your workflow and goals.

Key Features of Our HHT Solutions:

Rugged Design: Built for durability in tough environments like warehouses and outdoor operations.

Real-time Sync: Instantly connect with ERP, WMS, or POS systems.

User-Friendly Interface: Simplified UI to ensure ease of use for field workers and warehouse staff.

Long Battery Life: Ensures full-day usage with minimal downtime.

Scalable Software: Our Hand Held Terminal Software is scalable and can be customized to fit various industries.

Why Choose Forte Tech for HHT Solutions in UAE?

Our team brings years of experience in deploying HHT Solutions with a focus on reliability, functionality, and integration. We pride ourselves on understanding your business operations and delivering solutions that improve efficiency at every level.

Industry Applications:

Retail & Point-of-Sale: Stock management, price checks, and digital ordering.

Logistics & Warehousing: Real-time inventory updates, pick and pack operations.

Field Services: Mobile data entry, order tracking, digital signatures.

Healthcare: Patient data access, medication tracking, and record management.

Customized Hand Held Terminal Software Development

We don’t just provide devices — we build intelligent Hand Held Terminal Software tailored to your workflows. Our developers design intuitive, responsive apps for Android and Windows-based terminals that integrate with your existing ERP or WMS platforms, including Dynamics 365, SAP, Oracle, and more.

From barcode scanning to location tracking and cloud data sync, our software ensures your team can perform critical tasks quickly and accurately.

Forte Tech – Your Partner for HHT Solutions in Dubai

As a leading name in HHT Solution providers, We ensures your handheld terminals are configured, secured, and ready to perform. From initial consultation and device selection to software deployment and ongoing support, we offer end-to-end Hand Held Terminal Solutions in UAE.

We are also partners with global hardware manufacturers like Zebra, Honeywell, and Datalogic, bringing you the most reliable and rugged devices available in the market today.

Benefits of Choosing us:

Local support team

Fast deployment and training

Custom integrations with existing business systems

Reliable post-sale support and AMC options

Competitive pricing on both hardware and software

Get Started with us Today

Looking for a reliable provider of HHT Solutions in UAE? Contact Forte Tech today for a free consultation and discover how our Hand Held Terminal Solutions in Dubai can revolutionize the way your business operates. Whether you need just the hardware, customized software, or a full-service deployment, we’ve got you covered.

Let us help you improve your operations, reduce manual errors, and boost efficiency with our reliable Hand Held Terminal Software and HHT Solutions.

0 notes

Text

On-shelf availability solution market experiencing robust demand due to rising interest in real-time intelligence

In today’s competitive retail landscape, ensuring that products are available on shelves when customers are ready to buy is more than a logistics challenge it is a strategic imperative. The On-Shelf Availability (OSA) solution market has emerged as a critical enabler for retailers and suppliers aiming to enhance customer satisfaction, drive sales, and reduce operational inefficiencies. As consumer expectations evolve and technological capabilities expand, the on-shelf availability solution market is undergoing rapid transformation, fueled by innovations in automation, data analytics, and artificial intelligence.

Understanding On-Shelf Availability

On-shelf availability refers to the presence of products in the right place, at the right time, and in the right quantities on store shelves. When products are out of stock, not only do sales suffer, but customer loyalty can be eroded. Research indicates that out-of-stock events result in lost sales of up to 8% for retailers, a significant figure in a low-margin industry.

OSA solutions are designed to combat this problem through real-time monitoring, predictive analytics, and responsive replenishment systems. These tools provide end-to-end visibility into the supply chain and store operations, enabling proactive identification and resolution of availability issues.

Market Drivers

Several factors are propelling the growth of the OSA solution market:

Rising Consumer Expectations: Today’s consumers expect seamless shopping experiences, both in physical stores and online. The inability to find desired products in-store often drives them to competitors or online alternatives. OSA solutions help retailers meet these expectations consistently.

Technological Advancements: The integration of IoT, AI, computer vision, and machine learning is revolutionizing how retailers monitor inventory. Smart shelves, RFID tagging, and shelf-scanning robots are increasingly being deployed to automate data collection and improve accuracy.

Shift to Omnichannel Retail: With retailers operating across multiple channels, maintaining accurate inventory across platforms is essential. OSA solutions ensure that inventory data is synchronized, enabling better fulfillment strategies such as buy-online-pick-up-in-store (BOPIS).

Supply Chain Disruptions: Global events such as the COVID-19 pandemic have highlighted the fragility of supply chains. In response, retailers are investing in OSA tools that provide early warnings for potential stockouts and optimize replenishment processes.

Focus on Operational Efficiency: Retailers are under pressure to control costs while improving service levels. OSA solutions support these objectives by reducing manual labor, minimizing inventory holding costs, and streamlining in-store operations.

Competitive Landscape and Key Players

The OSA solution market is characterized by a mix of established technology firms and innovative startups. Key players include Zebra Technologies, SAP, Oracle, Avery Dennison, and Trax. These companies offer diverse solutions ranging from handheld inventory scanners to sophisticated AI-powered image recognition systems that assess shelf conditions.

Retailers are also partnering with supply chain technology vendors and consultants to implement tailored OSA strategies. Customization, scalability, and integration with existing retail systems are critical factors influencing vendor selection.

Challenges to Market Growth

Despite its potential, the OSA solution market faces several challenges:

High Implementation Costs: Advanced OSA technologies can be capital-intensive, particularly for small and mid-sized retailers. The cost of sensors, infrastructure, and training can be prohibitive without clear short-term ROI.

Data Integration Issues: OSA tools must integrate seamlessly with point-of-sale (POS), ERP, and warehouse management systems to be effective. Data silos and legacy systems can hinder real-time visibility.

Privacy Concerns: Some OSA technologies, especially those involving video and image capture, raise concerns about customer privacy and data security.

Change Management: Organizational resistance to adopting new technologies can delay or limit the impact of OSA implementations. Training and leadership support are essential to ensure successful adoption.

Outlook and Opportunities

The future of the OSA solution market appears robust, with steady growth anticipated across global regions. North America and Europe are currently leading in adoption, but Asia-Pacific is expected to experience the highest growth rate due to the expansion of modern retail and e-commerce.

Emerging trends include the use of generative AI to forecast demand with higher precision, edge computing for real-time analytics at the store level, and integration with sustainability initiatives to reduce waste through smarter inventory practices.

Retailers that embrace OSA solutions not only stand to improve availability and reduce lost sales but also gain a competitive edge through enhanced operational agility and customer loyalty. As technology matures and becomes more affordable, broader adoption across all retail tiers is expected.

0 notes

Link

0 notes

Text

Understanding RFID Scanners: Key Technology for Tracking and Identification

Radio Frequency Identification (RFID) technology has become a game-changer in industries that require efficient tracking and management of assets, inventory, and personnel. RFID scanners, which are essential components of this technology, provide a way to automate identification and data collection through radio waves. Whether it's managing warehouse inventories, enhancing supply chain operations, or improving access control systems, RFID scanners offer significant advantages in terms of speed, accuracy, and reliability. In this blog, we’ll delve into how RFID scanners work, their types, applications, and benefits.

What is RFID Technology?

RFID stands for Radio Frequency Identification, and it’s a technology that uses radio waves to automatically identify and track tags attached to objects. RFID tags can store data, such as an ID number or information about the item, and this data is transmitted to an RFID scanner when the tag is in range of the scanner’s radio signal.

An RFID system consists of three key components:

RFID Tag: A small device that stores information and is attached to an object. It contains a chip and an antenna to communicate with the RFID scanner.

RFID Reader/Scanner: The device that emits radio waves and receives the signals from the RFID tags. It reads the information stored on the tag and sends it to a computer or database for processing.

Database/Software: The system that processes the data from the RFID scanner and uses it for analysis, decision-making, or tracking purposes.

How Do RFID Scanners Work?

RFID scanners work by emitting radio waves that activate the RFID tag when it's in range. The scanner sends out a signal at a specific frequency, and the RFID tag responds with the data stored on it. The scanner captures this response and decodes the information, which can then be transmitted to a backend system for further processing.

There are two primary types of RFID tags:

Active RFID Tags: These tags have their own power source (usually a battery) and can transmit signals over longer distances (up to 100 meters). They are often used for tracking larger objects or assets in large-scale environments.

Passive RFID Tags: These tags do not have their own power source. Instead, they rely on the energy emitted by the RFID scanner’s radio waves to power the tag's response. Passive tags are usually cheaper and are commonly used for inventory management, asset tracking, and access control.

Types of RFID Scanners

RFID scanners come in different forms, depending on the application and the environment in which they are used. Some common types include:

Handheld RFID Scanners: These are portable devices that allow operators to scan RFID tags manually. They are typically used for inventory checks, asset tracking, and logistics in smaller to medium-sized environments.

Fixed RFID Scanners: These scanners are mounted in a fixed location, often at strategic points such as entrances, exits, or conveyor belts. They automatically scan RFID tags as items pass by, making them ideal for large-scale inventory management or warehouse applications.

Integrated RFID Scanners: These are embedded within other systems, such as kiosks, point-of-sale (POS) terminals, or industrial machines, providing seamless tracking without the need for handheld or fixed scanners.

Applications of RFID Scanners

RFID scanners have found applications across various industries due to their ability to enhance tracking, improve efficiency, and reduce human error. Some of the most common uses include:

Inventory Management: RFID scanners are widely used in retail and logistics to track stock levels, manage warehouse inventories, and streamline order fulfillment. By scanning RFID tags on products, businesses can easily monitor inventory without manual counting or barcode scanning.

Supply Chain Management: RFID technology plays a crucial role in optimizing supply chain operations. Scanners help track the movement of goods from one location to another, improving transparency, reducing delays, and preventing lost or stolen items.

Asset Tracking: RFID scanners are frequently used to track high-value assets, such as machinery, tools, and vehicles, in industries like manufacturing, construction, and healthcare. By attaching RFID tags to assets, businesses can easily monitor their location and condition.

Access Control: RFID scanners are often used in security systems for employee identification, building access, and time tracking. RFID-enabled badges or key fobs are used to grant access to secure areas or register employees' attendance automatically.

Healthcare: RFID scanners are used in hospitals and healthcare facilities to track medications, medical equipment, and patient identification. This enhances patient safety by preventing errors in medication administration and ensuring proper handling of medical devices.

Libraries and Document Management: RFID technology is increasingly used in libraries for tracking books and other media. RFID scanners provide an efficient way to check in and check out items, as well as keep track of inventory.

Benefits of RFID Scanners

Improved Efficiency: RFID scanners allow for fast, automated data collection, reducing the need for manual input and minimizing human error. This leads to quicker transactions, faster processing times, and more efficient workflows.

Accurate Tracking: RFID technology provides real-time tracking of assets, inventory, or personnel, ensuring that data is always up-to-date and accurate. It reduces the likelihood of misplaced or lost items, especially in large environments.

Cost Savings: By automating processes and improving inventory accuracy, RFID scanners can help businesses reduce operational costs. The reduction in labor for manual scanning and the prevention of stock discrepancies contribute to long-term savings.

Enhanced Security: RFID scanners improve security by ensuring that only authorized individuals or items can access restricted areas. They can also track and record every movement, making it easier to detect and prevent theft.

Contactless Operation: RFID technology allows for contactless scanning, meaning that tags don’t need to be manually aligned or touched, which is especially beneficial for industries like healthcare, where hygiene is a priority.

Challenges of RFID Scanners

While RFID scanners offer many advantages, they are not without challenges. Some of the key challenges include:

Cost: The initial investment in RFID technology, including scanners and tags, can be high, especially for large-scale deployments.

Interference: RFID scanners can sometimes face interference from metal objects or liquids, which may disrupt the radio waves and reduce scanning effectiveness.

Privacy Concerns: The ability to track items or individuals using RFID raises potential privacy concerns, especially if personal data is stored on the tags.

Conclusion

RFID scanners are revolutionizing industries by providing efficient, accurate, and automated tracking and identification solutions. With applications ranging from inventory management to healthcare and access control, RFID scanners are proving to be essential in streamlining operations and improving security. As the technology continues to evolve, we can expect even greater advancements in the way we track and manage assets, making RFID scanners an indispensable tool in modern business operations.

0 notes

Text

Automatic Identification And Data Capture Market Key Players, Revenue And Growth Rate

The global automatic identification and data capture market size is expected to reach USD 136.86 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to grow at a CAGR of 11.7% from 2025 to 2030. With an increase in the use of smartphones for image recognition and QR code scanning along with an increase in the development of e-commerce platforms internationally, the market is anticipated to experience a noticeable growth during the forecast period.

Furthermore, increased automatic identification and data capture (AIDC) solution acceptance due to their capacity to reduce discrepancies is likely to drive the growth of the AIDC industry during the forecast period. For instance, in April 2022, Arcion Labs, Inc., a truly real-time database replication platform, announced the release of Arcion Cloud, a fully managed change data capture data replication as a service that empowers businesses to leverage more significant, big data pipelines in minutes.

The most prevalent devices used to identify and capture the data are RFID scanners and RFID tags, barcode scanners, fixed-position, and handheld laser scanners and imagers, wearables devices, voice recognition solutions, and rugged tablets. Automatic identification and data capture systems, such as wearables, barcoding solutions, and RFID scanners, are critical in e-commerce and warehouse management.

AIDC technology not only assists the e-commerce business in automatically identifying objects, collecting data about them with high accuracy and precision, and electronically entering this data into the computer system. By keeping track of inventories, accounting, human resources, and overall procedures, technology also helps increase productivity and operational efficiency.

Gather more insights about the market drivers, restrains and growth of the Automatic Identification And Data Capture Market

Automatic Identification And Data Capture Market Report Highlights

• North America dominated the market and accounted for the largest revenue share of 38.5% in 2024. This high share can be attributed to the increasing awareness and high adoption of AIDC devices and increased government legislative and investment, particularly in retail, healthcare, and manufacturing industries.

• AIDC systems are routinely used to manage assets, inventory, delivery, document scanning, and security in various industries, including transport and logistics, chemical, pharmaceutical, food and beverage, automotive, consumer products, retail and warehousing, and distribution

• Radio Frequency Identification (RFID) tags, barcodes, biometrics, labels, smart cards, and speech and voice recognition have gained acceptance across various industries due to their increased accuracy, precision, and smooth functioning

• Banks and financial institutions' increasing implementation of AIDC solutions to ensure customer security, safety, and data privacy is projected to fuel market expansion

Automatic Identification And Data Capture Market Segmentation

Grand View Research has segmented the global automatic identification and data capture market on the basis of component, end-use, and region:

Automatic Identification And Data Capture Component Outlook (Revenue, USD Billion, 2017 - 2030)

• Hardware

o RFID Reader

o Barcode Scanner

o Smart Cards

o Optical Character Recognition Devices

o Biometric Systems

o Others

• Software

• Services

o Integration & Installation Services

o Support & Maintenance Services

Automatic Identification And Data Capture End-user Outlook (Revenue, USD Billion, 2017 - 2030)

• Manufacturing

• Retail

• Transportation & Logistics

• Hospitality

• BFSI

• Healthcare

• Government

• Energy & power

• Others

Automatic Identification And Data Capture Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

o U.S.

o Canada

• Europe

o UK

o Germany

o France

• Asia Pacific

o China

o Japan

o India

o Australia

o South Korea

• Latin America

o Brazil

o Mexico

• Middle East and Africa

o Saudi Arabia

o South Africa

o UAE

Order a free sample PDF of the Automatic Identification And Data Capture Market Intelligence Study, published by Grand View Research.

#Automatic Identification And Data Capture Market#Automatic Identification And Data Capture Market Size#Automatic Identification And Data Capture Market Share#Automatic Identification And Data Capture Market Analysis#Automatic Identification And Data Capture Market Growth

0 notes

Link

0 notes

Text

Industrial PDA, Global Top 16 Players, Market Share and Ranking (2023)

Industrial PDA Market Summary

PDA is a portable device with data processing, communication, positioning and other functions. Industrial PDA is specially used in the industrial field or designed and developed for work application scenarios.

This article mainly counts handheld PDA (mobile data terminal). Industrial mobile data terminal is a collection terminal that can integrate multiple functions and mainly uses barcode, vision and other recognition technologies. It can realize data collection, transmission and processing functions according to customer needs.

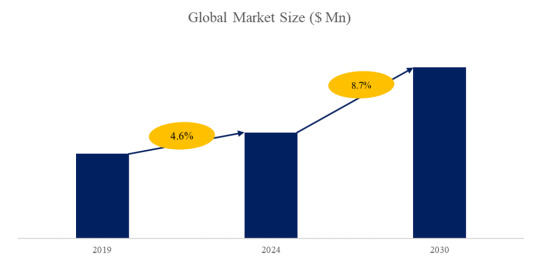

According to the new market research report “Global Industrial PDA Market Report 2024-2030”, published by QYResearch, the global Industrial PDA market size is projected to reach USD 2.51 billion by 2030, at a CAGR of 8.7% during the forecast period.

Figure. Global Industrial PDA Market Size (US$ Million), 2019-2030

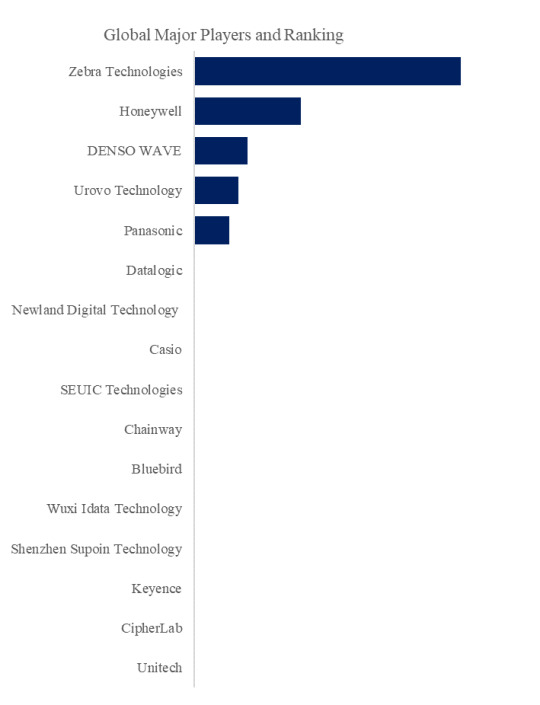

Figure. Global Industrial PDA Top 16 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

This report profiles key players of Industrial PDA such as Zebra Technologies, Honeywell, DENSO WAVE, Urovo Technology

In 2023, the global top five Industrial PDA players account for 55.16% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Industrial PDA.

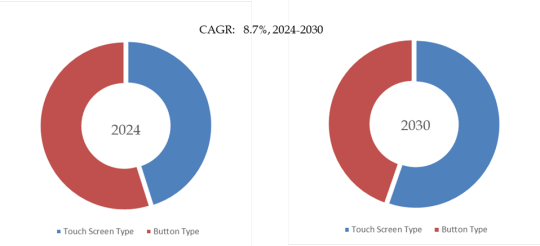

Figure. Industrial PDA, Global Market Size, Split by Product Segment

In terms of product type, Button Type is the largest segment, hold a share of 56.97%. Compared with the common touch-screen mobile devices today, key-type mobile terminals are an earlier form of mobile communication technology. These devices use physical buttons rather than touch screens as the main input method for user-device interaction. It is expected that by 2030, the touch-screen market share will exceed that of key-type PDAs.

Figure. Industrial PDA, Global Market Size, Split by Application Segment

In terms of product application, Warehouse Logistics is the largest application, hold a share of 48.66%%. Industrial handheld terminals are widely used in warehousing and logistics. For example, in the warehousing management process, handheld terminals can be used to scan product barcodes or RFID tags to quickly and accurately complete warehousing registration, including product information entry, quantity confirmation, and storage location allocation, to ensure real-time update and accuracy of inventory data.

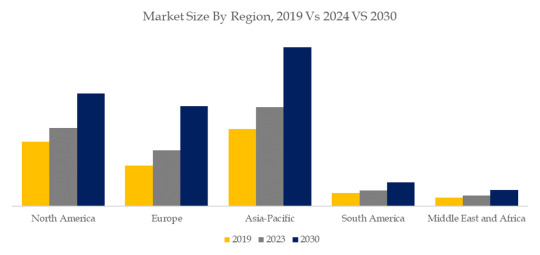

Figure. Industrial PDA, Global Market Size, Split by Region

Market Drivers:

1. Downstream market demand: mainly reflected in the retail, medical, logistics and other industries. For example, the growing demand for medical equipment and drug tracking, patient management and mobile care in the medical industry has promoted the application of industrial PDAs with barcode scanning and RFID functions to improve the quality of medical services and management efficiency.

2. Government policies: The strengthening of government regulations such as food safety, drug traceability, and anti-counterfeiting and shoddy products requires a stricter product tracking and tracing system. Industrial PDAs, as data collection terminals, are essential to meet regulatory requirements.

3. Technology integration: The development of IoT, cloud computing and AI technologies has promoted the seamless integration of industrial PDAs with other systems (such as ERP, WMS), enabling instant data upload and remote management, and improving decision-making efficiency and business flexibility.

4. Intelligence and integrated AI: With the development of artificial intelligence technology, future industrial handheld terminals will place more emphasis on intelligence, achieve more efficient recognition, prediction, and analysis functions through integrated AI algorithms, enhance the autonomous decision-making ability of equipment, and optimize workflows.

Restraint:

1. Fierce competition: With the development of the industry, more and more handheld terminal manufacturers have emerged at home and abroad, resulting in increasingly fierce market competition.

2. Accelerated technological iteration: The rapid advancement of technology requires companies to continue to invest in research and development to maintain the competitiveness of their products. This includes processors, sensors, communication technologies (such as 5G), operating system upgrades, etc. Any lag may cause products to become obsolete.

3. Shortage of industry talent: The design, research and development, and production of automatic identification and data acquisition equipment involve the comprehensive application of multidisciplinary professional knowledge such as mechanical engineering, structural engineering, materials, automation, and informatization. Professional and technical personnel must not only master professional knowledge, but also have a deep understanding of upstream raw materials and downstream logistics, express delivery, retail e-commerce and other industries, and they also need to have rich production and management practical experience.

4. Import dependence: Some high-end components, such as chips and modules, have not yet been localized. Factors such as international trade wars may affect the supply of raw materials.

Trend:

1. Higher performance: With the increase in application requirements, industrial handheld terminals will adopt more powerful processors, larger storage capacity, clearer display technology, and more accurate scanning and recognition capabilities to ensure that tasks can be completed efficiently and accurately in harsh environments.

2. AI intelligence: With the development of AI technology, future industrial handheld terminals will be more intelligent, integrating advanced analysis, predictive maintenance, voice recognition, image recognition and other functions to enhance the equipment's autonomous decision-making ability and interactive experience.

3. Multi-function (5G+IoT) integration: The application of 5G technology will greatly improve the communication speed and data transmission capacity of industrial handheld terminals, and achieve more efficient remote monitoring, large-scale data processing and real-time decision support. At the same time, the deep integration with IoT technology will make the device an important node in the IoT ecosystem, realizing seamless connection and information sharing between devices and systems.

4. Customization needs are more significant: With the expansion of the application field of industrial handheld terminals, the specific needs of different industries have become more obvious. Suppliers need to provide customized solutions based on the needs of specific industries to meet the workflow of different industries.

About The Authors

Jiashi Dong

Lead Author

Email: [email protected]

QYResearch Nanning Branch Analyst, as a member of the QYResearch Semiconductor Equipment and Materials Department, his main research areas include automotive electronics, semiconductor equipment, materials and thermally conductive powders. Some subdivided research topics include automotive diodes, automotive inductors, automotive lidar, radio frequency power supplies, plastic sealing machines, high-purity non-ferrous metals, battery materials, precursors, electroplating equipment, thermal conductive ball aluminum, semiconductor chemical plating solutions, semiconductor coating devices, etc. At the same time, he is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

RT40 Handheld Computer: Redefining Mobile Data Collection

Experience the power of versatility in the palm of your hand with the RT40 Handheld Computer. This remarkable device is designed to adapt to your ever-changing needs, making it the ultimate tool for diverse applications. Whether it's inventory management, asset tracking, or field inspections, the RT40 delivers exceptional performance every time. With its compact yet rugged design, it can withstand the toughest environments, ensuring uninterrupted operations. Equipped with advanced data capture technologies like barcode scanning, RFID, and GPS, it enables accurate and efficient data collection. The RT40 Handheld Computer also offers seamless integration with existing systems, providing real-time visibility and enhancing overall operational efficiency. With this versatile device, you can tackle any task with ease, revolutionizing the way you work in the field.

0 notes

Text

Zebra MC93, the ultimate data capture device designed for enterprise-level efficiency. Powered by Android mobile technology, this versatile device revolutionizes inventory management and warehouse scanning with its robust features and intuitive interface.

Equipped with advanced data capture capabilities, the Zebra MC93 streamlines inventory operations, ensuring accurate tracking and real-time visibility of assets throughout the supply chain. Its high-performance scanning functionality effortlessly captures barcodes, RFID tags, and other crucial data, empowering businesses to optimize inventory control and minimize errors.

Designed for rugged environments, the Zebra MC93 is built to withstand the demands of warehouse settings, ensuring reliability and durability in challenging conditions. Its ergonomic design and intuitive user interface enhance productivity, allowing workers to focus on tasks without dis

0 notes

Text

How an RFID Asset Tracking System Works?

An RFID asset tracking system uses radio waves to automatically identify and track assets. Here’s a breakdown of the process:

Tags: Tiny RFID tags are attached to each asset. These tags contain a microchip that stores data about the asset, like a unique ID, location, or condition. There are two main types of tags:

Passive tags: These have no battery and are activated by the RFID reader’s radio waves. They have a shorter read range but are less expensive.

3. Active tags: These have their own battery and can transmit data over longer distances. They can also be used to sense environmental conditions.

RFID Reader: An RFID reader emits radio waves that interact with the tags. It can read the data stored on the tag and transmit it to a computer system. Readers can be stationary or handheld.

Software: The data from the RFID reader is sent to software that tracks and manages the assets. This software can be used to:

See the location of assets in real-time.

Set up alerts for missing or misplaced assets.

Track the history of an asset’s movements.

Generate reports on asset usage.

4. Benefits of RFID Asset Tracking:

Improved accuracy and efficiency in asset tracking.

Reduced time spent searching for lost or misplaced assets.

Better asset utilization and management.

Real-time visibility into asset location and status.

We at iMedic, located at Annamalai Chittiyar Street, Water Tank Road, Karaikudi (Contact: 81226 50904, Website: www.imediconline.com) don’t currently offer RFID asset tracking systems, but we can help you connect with a company that does.

0 notes

Text

What Companies Produce Touch Screen Monitors?

In today's digital age, touch screen monitors have become an integral part of various industries, from retail and healthcare to education and manufacturing. As the demand for touch screen monitors continues to rise, numerous companies around the globe have stepped up to meet this demand. This article delves into the landscape of touch screen monitor manufacturers, focusing particularly on rugged tablet PC manufacturers and their presence in China.

1. Major Players in Touch Screen Monitor Manufacturing

The touch screen monitor market boasts a plethora of manufacturers, each offering unique features and specifications to cater to diverse consumer needs. Some of the prominent players in this industry include established brands like Dell, HP, and Lenovo, known for their reliability and wide range of products. These companies have been at the forefront of touch screen technology, consistently innovating to deliver cutting-edge solutions to their customers.

2. Specialized Rugged Tablet PC Manufacturers

Rugged Tablet China

In recent years, there has been a growing demand for rugged tablet PCs, especially in industries that require durable and resilient devices for challenging environments. Several specialized manufacturers have emerged to address this niche market segment. Companies such as Panasonic, Getac, and Zebra Technologies have established themselves as leaders in rugged tablet PC manufacturing. Their devices are designed to withstand harsh conditions, including extreme temperatures, moisture, and physical impact, making them ideal for use in fields such as construction, logistics, and military operations.

3. Emerging Trends in Rugged Tablet Manufacturing

The rugged tablet market is witnessing rapid growth, driven by advancements in technology and increasing demand from various industries. One notable trend is the integration of additional features and functionalities into rugged tablets to enhance their utility and versatility. Manufacturers are incorporating features such as barcode scanners, RFID readers, and thermal imaging cameras to cater to specific industry requirements. Moreover, there is a growing emphasis on connectivity and compatibility, with manufacturers offering rugged tablets that support various wireless communication standards such as Wi-Fi, Bluetooth, and 4G/LTE.

4. The Role of China in Rugged Tablet Manufacturing

China has emerged as a key player in the global manufacturing landscape, including the production of rugged tablets. The country boasts a robust ecosystem of electronics manufacturers, supported by a skilled workforce and advanced manufacturing infrastructure. Several Chinese companies have gained prominence in the rugged tablet market, leveraging their expertise in hardware manufacturing and cost-effective production capabilities.

5. Leading Rugged Tablet Manufacturers in China

Among the numerous rugged tablet manufacturers based in China, several companies stand out for their quality products and competitive pricing. One such company is RugGear, known for its rugged smartphones and tablets designed for outdoor use. RugGear's devices are built to meet military-grade standards for durability and reliability, making them popular choices for professionals working in rugged environments.

Another notable player in the Chinese rugged tablet market is RuggON Corporation, which specializes in designing and manufacturing rugged computing solutions for various industries. RuggON's rugged tablets feature robust construction, sealed design, and advanced performance capabilities, making them suitable for demanding applications such as field service, transportation, and public safety.

Additionally, Handheld Group, a Swedish company with manufacturing facilities in China, offers a wide range of rugged tablets tailored to different industry requirements. The company's rugged tablets are designed to withstand extreme conditions while delivering superior performance and functionality. Handheld Group's products are used across various sectors, including utilities, construction, and agriculture.

In conclusion, the touch screen monitor market is characterized by a diverse array of manufacturers catering to different segments and industries. From established brands offering general-purpose touch screen monitors to specialized manufacturers focusing on rugged tablet PCs, consumers have a wide range of options to choose from. With China's growing influence in the manufacturing sector, the country's role in producing rugged tablets is becoming increasingly significant, with several companies gaining prominence for their quality products and competitive pricing. As technology continues to evolve, the rugged tablet market is expected to witness further innovation and growth, driven by the demand for durable and resilient computing solutions across various industries.

0 notes