#RFISuppression

Explore tagged Tumblr posts

Text

What Causes I/O Noise and Interference in PLC Systems? 8 Common Culprits Revealed!

Exploring Common Causes and Solutions for I/O Noise and Interference in PLC Systems

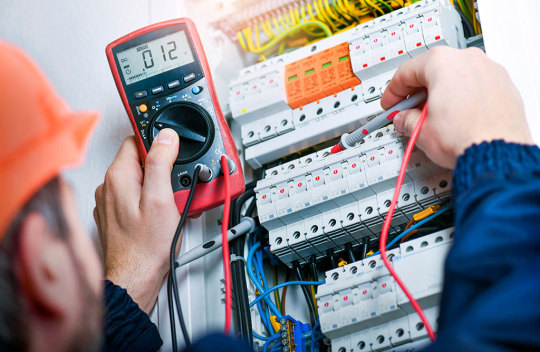

In the realm of industrial automation, PLC (Programmable Logic Controller) systems are indispensable, overseeing the operation of machinery and processes efficiently. However, they face a challenge: I/O (Input/Output) noise and interference. These disruptions can disrupt system stability, leading to malfunctions and downtime. In this comprehensive guide, we delve into the causes and solutions for I/O noise and interference in PLC systems, addressing 8 common culprits that engineers and technicians should understand well.

Understanding I/O Noise and Interference

Before delving into specific causes and solutions, it's crucial to understand the nature of I/O noise and interference. I/O noise refers to unwanted electrical signals or disturbances that corrupt intended signals in PLC systems. Interference includes external factors like electromagnetic radiation, radio frequency interference (RFI), and electromagnetic interference (EMI) disrupting communication between PLC components.

Power Supply Issues: The Silent Saboteur

A stable power supply is crucial for any PLC system. However, fluctuations or disturbances can introduce noise, jeopardizing performance. Issues like voltage spikes, dips, and harmonics can arise, impacting power quality and increasing I/O noise.

Grounding Problems: Unearthing the Root Cause

Proper grounding is vital in mitigating I/O noise and interference. However, inadequate practices can amplify noise within the system. Ground loops and poor connections can create pathways for unwanted currents, resulting in signal distortion and ground noise.

Electromagnetic Interference (EMI): Taming the Invisible Beast

EMI originates from various sources like nearby motors and power lines, inducing unwanted voltages in nearby cables and components. Shielding cables, using twisted pair wiring, and relocating sensitive components can mitigate EMI.

Radio Frequency Interference (RFI): Navigating the Airwaves

RFI, found in industrial environments bustling with wireless devices, poses a threat to PLC systems. Employing frequency filtering techniques and shielding can mitigate RFI.

Crosstalk: When Signals Collide

Crosstalk occurs when adjacent conductors induce voltages in neighboring cables, leading to signal interference. Shielding, spacing, and wiring techniques can mitigate crosstalk.

Environmental Factors: Nature's Influence

External factors like temperature fluctuations and humidity can impact PLC systems. Extreme temperatures and humidity levels accelerate corrosion and compromise signal integrity, while contaminants can lead to short circuits.

Component Aging: The Silent Deterioration

Over time, components within PLC systems deteriorate, impacting performance and reliability. Regular maintenance and component inspection are essential to mitigate aging's impact.

FAQs (Frequently Asked Questions)

1. How do I identify I/O noise in PLC systems? Signal integrity tests using oscilloscopes help pinpoint irregularities in waveforms indicative of noise interference.

2. Can inadequate shielding contribute to I/O noise? Yes, it allows external electromagnetic fields to penetrate cables. Proper shielding minimizes noise ingress.

3. What role does firmware/software play in mitigating I/O noise? Updates may include optimizations or algorithms to filter noise, reducing its impact.

4. Are there industry standards for mitigating I/O noise? Yes, standards like IEC 61000 provide guidelines for EMC.

5. How can ground loops be prevented? Ensuring all ground connections are made at a single point eliminates potential differences and minimizes ground loop currents.

6. What measures mitigate environmental factors' impact? Installing PLCs in controlled environments and using protective enclosures safeguard components from environmental hazards. For more information visit here👉PujaControls

#PLCInterference#EMIandRFI#IndustrialAutomation#ElectricalNoise#PLCTroubleshooting#SignalInterference#ElectricalEngineering#AutomationTechnology#IndustrialControl#NoiseFiltering#ControlSystem#EMIProtection#RFISuppression#FactoryAutomation

0 notes

Text

Filtered Connectors: Powering the Future ⚡ $8.2B Market by 2034 🔌 #TechInfrastructure #Electronics

Filtered Connectors is experiencing significant growth, fueled by rising demand for electromagnetic interference (EMI) and radio frequency interference (RFI) suppression across multiple industries. These connectors play a crucial role in ensuring signal integrity and reliability in sectors such as aerospace, defense, telecommunications, and industrial applications. As industries increasingly focus on high-performance electronic systems and compliance with stringent EMI/RFI standards, the market presents numerous opportunities for innovation and technological advancements.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS26880 &utm_source=SnehaPatil&utm_medium=Article

The aerospace and defense sector dominates the market, accounting for the largest share due to the critical need for secure and interference-free communication systems. The automotive industry follows closely, driven by the integration of advanced electronic components in modern vehicles, including electric and autonomous cars. Regionally, North America leads the market, supported by strong defense investments and technological advancements, while Europe remains a key player due to its stringent regulatory frameworks and strong automotive industry. The United States and Germany stand out as top-performing countries, leveraging robust technological infrastructures and manufacturing capabilities.

Market segmentation includes low-pass, high-pass, band-pass, and band-stop filtered connectors, with products such as EMI filters, RFI filters, power line filters, and signal line filters. Key technologies encompass surface mount, through-hole, hybrid, and micro-miniature designs, utilizing components like capacitors, inductors, resistors, and diodes. Applications span telecommunications, data processing, industrial automation, consumer electronics, automotive, and medical devices.

By 2028, the market is projected to reach a volume of 500 million units, up from 300 million in 2024. The aerospace and defense segment holds a 45% market share, followed by telecommunications at 30% and automotive at 25%. Leading players, including TE Connectivity, Amphenol Corporation, and Molex, continue to drive innovation through cutting-edge technologies and strategic market expansions.

#filteredconnectors #emiprotection #rfisuppression #electronicsafety #aerospaceengineering #defensetechnology #telecomsolutions #automotiveelectronics #signalintegrity #datacommunication #highperformanceconnectors #militarytechnology #industrialautomation #smartmanufacturing #electroniccomponents #nextgentech #securecommunication #electromagneticcompatibility #advancedengineering #techinnovation #circuitprotection #powerfilters #signalfilters #iotinfrastructure #cloudcomputing #automotiveconnectivity #wirelessnetworks #shieldingtechnology #highreliability #electromagneticshielding #microelectronics #futuretech #connectivitysolutions #innovationintech #datasecurity

0 notes

Text

Filtered Connectors Market to Expand to $8.2 Billion by 2034 – The Future of Connectivity

Filtered Connectors Market is experiencing rapid growth, fueled by the increasing need for EMI and RFI suppression in high-performance electronic systems. These connectors integrate advanced filtering technologies to ensure signal integrity and reliability, making them indispensable in aerospace, defense, telecommunications, and industrial applications.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS26880 &utm_source=SnehaPatil&utm_medium=Article

Among the leading market segments, military and aerospace dominate, driven by their demand for secure and interference-free communication systems. The automotive sector follows as the second-largest segment, reflecting the rising integration of electronic components in vehicles for enhanced connectivity and safety.

Key Market Insights

✅ North America leads the market, benefiting from technological advancements and defense investments ✅ Europe follows, with Germany emerging as a key player, supported by a strong automotive industry ✅ The U.S. remains the top-performing country, leveraging defense and aerospace innovation

Market Segmentation

🔹 By Type: EMI Filters, RFI Filters, Signal Line Filters, Power Line Filters 🔹 By Product: Circular Connectors, Rectangular Connectors, D-Sub Connectors, Filtered USB Connectors 🔹 By Application: Aerospace, Military, Automotive, Industrial, Medical, Telecommunications 🔹 By Technology: Capacitive Filtering, Inductive Filtering, Hybrid Filtering 🔹 By End User: Defense Contractors, Telecom Operators, Automotive Manufacturers, Medical Device Companies

In 2024, the market reached 120 million units, with projections to hit 200 million units by 2028. The military and aerospace sector holds the largest market share at 50%, followed by automotive (30%) and telecommunications (20%).

Leading players such as TE Connectivity, Amphenol, and ITT Cannon dominate the market, driving advancements in EMI shielding and high-performance connectivity solutions.

#filteredconnectors #emiprotection #rfisuppression #electroniccomponents #aerospaceengineering #militarydefense #automotiveelectronics #telecommunications #dataintegrity #electromagneticshielding #emi #rfishielding #signalintegrity #highreliabilityconnectors #aviationtechnology #industrialautomation #medicalelectronics #defenseelectronics #teconnectivity #amphenol #ittcannon #powerlinefilters #communicationsystems #secureconnections #innovationintechnology #militaryapplications #connectivitysolutions #automotiveinnovation #wirelesscommunications #radarshielding #smartvehicles #advancedmanufacturing #regulatorycompliance #criticalinfrastructure #shieldedcables #highperformanceelectronics #inductancefiltering #capacitivefiltering #hybridfiltering

0 notes