#RTU Transfer Unit

Photo

🔩 A013 - KUKA KR 240 Industrial Robot... 7 axis

RTU Robot Transfer Unit... KL1500 Track 8 mts... Linear Motion Track

PositionTable Position Table

KRC2 Ed05 ... picture via EuroRobots

▸ TAEVision Engineering on Pinterest

Data A013 - Nov 03, 2022

#automation#robot#robotics#KUKA#KR 240#KUKA KR 240#industrial robot#7th axis#RTU#RTU Robot Transfer Unit#RTU Transfer Unit#RTU Assembly Robotics#TransferUnit#transfer unit#PositionTable#position table#linear motion track#EuroRobots

25 notes

·

View notes

Text

🔌💡 Understanding Key Concepts and Protocols in Industrial Automation 💡🔌

In the realm of industrial automation, several key concepts and protocols play crucial roles in ensuring efficient and reliable system operation. Let's explore three important concepts: remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs), along with popular communication protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control):

1️⃣ Remote Terminal Units (RTUs): RTUs are devices deployed in industrial environments to monitor and control remote equipment or processes. They collect data from sensors and other devices, communicate with PLCs or control centers, and execute commands for process control. RTUs are typically installed in remote locations where wired connections may not be feasible.

2️⃣ Programmable Logic Controllers (PLCs): PLCs are specialized computers used to automate industrial processes and machinery. They monitor inputs from various sensors, execute programmed logic based on predefined rules, and control outputs to achieve desired outcomes. PLCs are highly flexible and allow for real-time monitoring and control of complex automation systems.

3️⃣ Human-Machine Interfaces (HMIs): HMIs provide a graphical interface that allows operators to interact with and monitor industrial automation systems. HMIs enable real-time visualization of process data, control system parameters, and facilitate efficient troubleshooting. They enhance the accessibility and usability of complex automation systems.

Now, let's delve into communication protocols commonly used in industrial automation:

- Modbus: Modbus is a widely adopted serial communication protocol used to connect various devices in a network. It provides a simple and robust means of data exchange between devices, such as PLCs, RTUs, and HMIs.

- DNP3: Distributed Network Protocol (DNP3) is designed specifically for utility automation systems. It enables secure and reliable communication between devices, including RTUs, PLCs, and SCADA systems. DNP3 supports efficient data transfer in challenging environments and ensures timely fault detection and response.

- OPC (OLE for Process Control): OPC is a standard interface protocol widely used in industrial automation. It allows different software applications to communicate with each other seamlessly. OPC facilitates data exchange between controllers, HMIs, databases, and other devices, fostering interoperability and enhancing system efficiency.

By understanding concepts like RTUs, PLCs, and HMIs, along with protocols like Modbus, DNP3, and OPC, engineers can design and implement robust industrial automation systems with enhanced operational efficiency and reliability.

#industrialautomation #RTU #PLC #HMI #Modbus #DNP3 #OPC #processcontrol #faultdetection #realtime #engineering #technology

0 notes

Text

Uses for an optical isolator

Opto isolators are also used in computer systems for data transfer by modulating the output voltage of a primary circuit and using light as a medium. Opto isolators are ideal for the recording industry because they reduce all interference that would have been generated by passing a voltage directly from one circuit component to another. Photodiodes and phototransistors are the two most common light receivers. They also have a small light source or LED to send signals and a photosensitive component to receive transmissions. Both types of optoisolators have a casing to prevent outside light from interfering with the device operation. Analog optoisolators reproduce the input signal and provide an analog output that is used when the signal amount is the circuit requirements’ overriding factor. The digital type changes its output to match the signal received and is used when pulse or bit output is required between circuits. There are two types of optoisolators-digital and analog. This allows the input of the secondary component to be equal or slightly less than the output of the primary component. The electricity is then directed to the other components within that circuit. The light beam travels down the closed channel until it reaches the photosensor that then converts the light back into electricity. A voltage from a circuit is used as the isolator’s power source and is used to produce a beam of near-infrared light. Opto isolators consist of a power source, a near-infrared LED, a closed channel, and a photosensor. They now cost less than US$1 and continue to get cheaper. They are good for quality control in the recording industry, and can be used in other industrial applications such as electroencephalography, data transfer, and optoelectronics. The cost of these devices have significantly reduced since they were first invented. Opto isolators regulate voltage levels by converting electricity into a beam of light. This prevents voltage spikes from impacting more than a single circuit and decreases the overall interference and noise that occurs with traditional communications connections. In order to achieve protection, SLAVE device must be powered by other power source than MASTER device (TapHome Core and Modules).An opto isolator is an electronic device that prevents high voltages from components in one side of a circuit from damaging or interfering with components on the other side of the same circuit. The isolator must always be installed on the side of one of the protected devices (MASTER) - as close as possible to it. MASTER side is protected device, typically TapHome Core control unit In this case, also power source must be galvanically isolated - the easiest way is to use separate power source. This is the most common situation when when connecting TapHome modules in the garden house, or meteo station on the roof. TapHome module or other RS485 device device is connected to TapHome BUS, and the wire or device itself is outside of the lightning protection.External device is powered by other (typically its internal) power source and does not have galvanic or optical isolation.Use of optical isolator is obligatory if one of the conditions is met: Optical isolator protects TapHome control unit when connecting Modbus RTU or other RS485 bus device to it. Optical isolator supports bi-directional "half-duplex" transmission for RS485 networks.

0 notes

Text

Remote Terminal Unit: Its Advantages and Applications

Remote Terminal Unit (RTU) is a type of control unit used in industrial automation and process control. RTUs are used to transfer data between controllers, actuators, and other devices on a plant floor. They are also used in plant monitoring and diagnostics applications.

What is a Remote Terminal Unit?

A Remote Terminal Unit, or RTU, is a device that connects a computer to a remote server or office. RTUs are used in a variety of settings, such as in libraries, schools, and businesses. They allow users to connect to a computer remotely and access files and programs. RTUs are also used in telecommuting situations, such as when a worker needs to work from home but wants to use the same computer they use at the office.

RTUs come in different sizes and shapes, and they can be connected to a computer through a USB port or an Ethernet port. They can also be connected to a telephone line or the Internet.

There are many different applications for RTUs. For example, they are used in libraries to allow users to access the library’s electronic resources from outside the library. They are also used by businesses to allow employees to work from home.

RTUs are relatively inexpensive devices, and they offer several advantages over traditional methods of connecting computers to remote servers or offices. For example, they allow users to connect from anywhere with an Internet connection, eliminating the need for a dedicated network connection or VPN connection. Additionally, RTUs are portable, making them ideal for use

Benefits of a Remote Terminal Unit

Remote terminal units offer many advantages over traditional terminal units. Here are just a few:

- Increased Efficiency: With a remote terminal unit, users can work from anywhere in the world. This increases efficiency and productivity because employees can work on projects without having to travel to the office.

- Reduced Costs: A remote terminal unit can reduce costs by eliminating the need for employees to travel to the office for work. Additionally, remote terminal units can save on expenses such as transportation and lunch costs.

- Increased Communication and Cooperation: Remote terminal units allow employees to communicate with each other more effectively because they are not limited by distance or time. This allows for more cooperation between employees and greater efficiency in the workplace.

Advantages of a Remote Terminal Unit over Other Forms of Communication

A remote terminal unit (RTU) is a communication device that allows operators to control machines and devices remotely. RTUs are advantageous in a number of ways, including the following:

-They are fast and reliable.

-They are easy to use.

-They are secure.

-They can be accessed from anywhere in the world.

Applications for a Remote Terminal Unit

Remote Terminal Units (RTUs) are becoming increasingly popular for a variety of applications, including data acquisition and control, process control and automation, and field services. Here are four reasons why you might want to consider adding an RTU to your operation:

1. Increased Efficiency

With RTUs, you can achieve increased efficiency by taking advantage of electronic data exchange (EDX). This technology allows you to send commands and data between devices over a network in real time, which can save you time and money.

2. Reduced Staffing Costs

Because an RTU can be used to replace dedicated hardware or software devices, it can reduce staffing costs. Additionally, because RTUs offer flexibility and convenience, they can be used in areas where dedicated equipment is not available or is not necessary.

3. Increased Productivity

By using RTUs, you can improve productivity by reducing the amount of time needed to perform tasks. In some cases, this may even allow you to outsource certain tasks to an RTU.

4. Improved Safety Standards Compliance

As technology advances, so do safety standards. By using an RTU, you can ensure that your operations meet all current safety standards without the

Conclusion

The remote terminal unit (RTU) has been around for a while now and its popularity is only increasing. In this article, we will discuss the advantages and applications of RTUs. We hope that this information will help you make an informed decision about whether or not to invest in one, and give you some ideas on how you can use it to improve your business. Read More

#remote terminal unit#terminal block connectors#connector#PCB Connector#port ethernet switches#ethernet switch

0 notes

Text

7kw 3 Phase Solar Inverters the best industrial inverter

7kw 3 Phase Solar Inverter is highly efficient and is perfect for small-size solar. All 7kw 3 Phase Solar Inverters have the highest build quality and a wide range of operating modes.

The many intelligent features make the 7kw 3 Phase Solar Inverter one of the most efficient in its class: for example, the built-in data logging function, the simplicity of connecting to the Internet via WLAN, or replaceable card technology for the integration of additional functions in the future.

The housing of three-phase network inverters has a degree of protection IP66, which allows them to be installed outdoors, including in the open sun.

Features of the 7kw 3 Phase Solar Inverter:

Pure sine wave output;

Maximum efficiency 98.0%;

The adaptation efficiency of MPT is 99.9%;

Installation indoors and outdoors (degree of protection IP 65);

Connecting an external network;

Power limitation during overload;

Protection against incorrect polarity;

Energy management (output with relay decoupling of potentials);

WLAN / Ethernet LAN control interface;

Monitoring and management through the cloud service

Connection and data transfer

Pulse load control in the receiver interface

Has 2x RS422 (RJ45 connector)

Input for overvoltage protection (S0-Meter Interface);

Connector for Modbus RTU SunSpec or counter connection.

THREE-PHASE NETWORK INVERTERS SO FAR SOLAR

7kw 3 Phase Solar Inverter is used in solar stations that operate without batteries. All generated energy immediately goes to the 3-phase network for consumption. When the power consumption decreases, the generation power decreases accordingly. It is monitored by current sensors & the ARPC unit. It is necessary so that the excess generated energy does not go into the network and is not counted by the meter as consumed. Domestic electricity meters are one-way and do not know how to subtract. With the introduction of the "green tariff", when it becomes possible to sell surplus electricity to sales companies, then these restrictions will disappear, and it will be possible to earn additional money.

Prerequisites for work

A feature of the work of network inverters is the need for a regular electrical network.

The line of 3-phase inverters consists of devices of different capacities: from 1 to 66 kW. Almost every inverter has 2 independent MPPT trackers built-in with the possibility of uneven power distribution, except the 55 and 66 kW models, which have 3 MPPT trackers.

The presence of the WI-FI module allows you to connect the inverter to the Internet and monitor the system parameters after registration on the manufacturer's website.

Three-phase solar edge inverter is very common in industrial enterprises, office buildings, business centres, country houses, or other facilities where there is electricity consumption in the daytime & there is an external power grid. The use of network inverters can significantly reduce energy costs, and the payback is only from 1 year to 5 years.

Currently, an increasing number of network operators in various countries are setting limits on the return of energy to the urban network from photovoltaic modules. Thanks to the dynamic reduction in power, Solaredge Inverter offers a solution for optimal management of power generation and output. The inverter first supplies electricity to the household consumers in your home & then reduces the output power of the system to the maximum allowable value allowed by the network operator.

#inverter#solar inverter#hybrid inverter#business#news#solar pv inverter#Solaredge Inverter#7kw 3 Phase Solar Inverter#3 Phase Solar Inverter

0 notes

Text

Hearts of Oak Duo will be signed by RTU in January.

Hearts of Oak Duo will be signed by RTU in January.

When the transfer window opens next month, newly promoted Ghanaian top-flight side Real Tamale United (RTU) is expected to sign Hearts of Oak duo Nuru Sulley and Abdul Manaf Umar.

The Tamale-based club has long admired the two players, but attempts to sign them in the summer were unsuccessful due to a lack of agreement between the two parties.

Nuru Sulley, a defender, has had a falling out with…

View On WordPress

0 notes

Text

Attacker Umar Manaf finally leaving Hearts of Oak to join RTU

Ghanaian attacker, Abdul Umar Manaf is on the brink of finalizing a deal to leave Hearts of Oak to join Real Tamale United (RTU).

The talented attacking midfielder was set to join the Ghana Premier League newcomers prior to the start of the 2021/2022 football season but talks, unfortunately, broke down.

With the second transfer window about to open for player registration, representatives of Abdul Umar Manaf have been working around the clock to seal his anticipated move to RTU.

Today, sources have confirmed to footballghana that a deal has been reached and the player will be registered by RTU for the Ghana Premier League next month.

At his new club, Abdul Umar Manaf will have a key role to play for the team that has David Abagna as its poster boy.

Together and with the quality of other players at the club, RTU will push to avoid relegation at the end of the ongoing Ghana Premier League season.

source: https://footballghana.com/

0 notes

Text

Industrial Controls System Market Research Analysis Including Growth Factors, Types And Application By Regions by 2030

Transparency Market Research has published a new report that studies the global industrial controls systems market. The research report, titled “Industrial Controls System Market – Global Industry Analysis Size Share Growth Trends and Forecast 2015 – 2021”, gives a comprehensive overview of the market dynamics governing this market and its impact on the overall economy. According to the research report, the global industrial controls system market was valued at US$58 billion in 2014 and is expected to be worth US$81 billion by 2021, growing at a robust CAGR of 4.9% from 2015 to 2021.

Industrial control systems are a network of interconnected equipment that are used for supervising and controlling physical equipment in several industrial environments. These systems include numerous control systems such as supervisory control and data acquisition (SCADA) systems, distributed control systems (DCS), and programmable logic controllers (PLC). They are primarily used for remote supervision, process automation, and critical infrastructure automation. SCADA systems are employed for obtaining data from remotely placed devices such as transmitters, pumps, and valves, among others. These systems help in gathering data from faraway devices and transferring it to the master control unit for enhancing control. Distributed control systems or DCS are interlinked networks that ease the controlling activity of several processes that may be spread out over facilities. On the other hand, programmable logic controllers are deployed for making electromechanical processes such as controlling assembly lines in a factory, machinery, or light fixtures automatic.

For More Info | Download PDF Brochure, Click Here: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=4886

The global industrial controls system market has been flourishing due to the growing entry of automation in the industrial sector and the increasing trend of remote supervision in several manufacturing facilities. Analysts predict the increasing software application in industrial control devices is expected to increase the market shares of PLS, DCS, and SCADA systems in the industrial environment. Some of the other factors expected to contribute towards the growth of the global industrial controls systems market are the emerging economies of Indonesia, India, and China, which are making heavy investments in automation and industrial infrastructure. The SCADA segment will witness a stupendous growth rate due to increasing demand for the same in sectors such as food and beverages, oil and gas, and chemicals.

The global industrial controls system market has been segmented on the basis of types, components, applications, and geography. The types of industrial controls systems are programmable logic controller (PLC), distributed control system (DCS), and supervisory control and data acquisition (SCADA). The components in the global industrial controls system market are programmable logic controller (PLC), human machine interface (HMI), remote terminal unit (RTU), SCADA communication systems, and others. The applications of industrial controls system market are seen in industries such as automotive, pharmaceutical, oil and gas, electrical power, and water and waste management. Geographically, this global industrial controls system market is spread over areas such as North America, Europe, Asia Pacific, and Rest of the World. Some of the key players operating in the global industrial controls system market are Emerson Electric Co, Siemens AG, Alstom SA, ABB Ltd, Rockwell Automation, Inc., Omron Corp, Honeywell International, Inc, and Omron Corp.

Request For Covid19 Impact Analysis Across Industries And Markets – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=4886

The industrial controls market is segmented as below:

Global industrial controls market, by Types

Global SCADA market, by Components:

Global industrial controls market, by Applications:

Supervisory Control And Data Acquisition (SCADA)

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

Human Machine Interface (HMI)

Programmable Logic Controller (PLC)

Remote Terminal Unit (RTU)

SCADA Communication Systems

Others

Electrical Power

Chemicals

Oil & Gas

Food and Beverages

Manufacturing

Automotive

Pharmaceutical

Water and Waste Water Management

Others (Aerospace, Defense, Mining, and Materials)

Global industrial controls market, by Geography:

North America

Europe

Asia Pacific

Rest of the World (ROW)

U.S.

Canada

Mexico

United Kingdom

Germany

France

Italy

Rest of Europe

China

India

Japan

Taiwan

South Korea

Rest of Asia Pacific

Middle East

Africa

South America

Customization of the Report: This report can be customized as per your needs for additional data or countries. – https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=4886

Contact

Mr.Sudip S

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: https://www.transparencymarketresearch.com

0 notes

Text

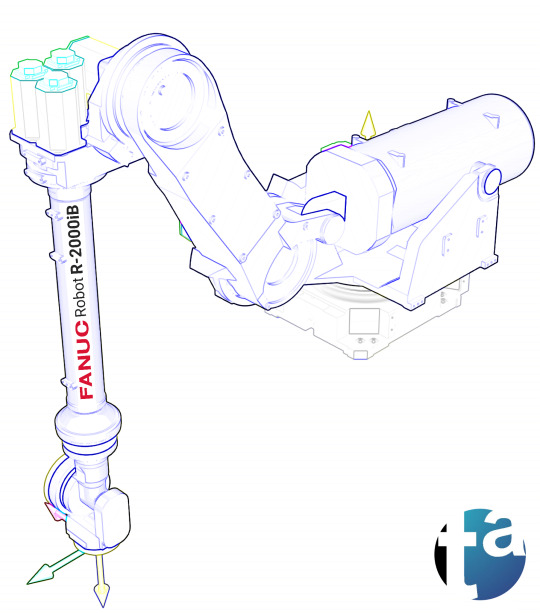

🦾 A010 - Robot FANUC R-2000iB Camshaft Machining Center automotive appl

engineparts machining TranTek's Courtesy Robotics

RTU Transfer Unit - linear motion track

▸ TAEVision Engineering on Pinterest

Data A010 - Jul 23, 2023

#automation#robot#robotics#FANUC#R-2000iB#FANUC R-2000iB#camshaft machining center#automotive applications#machining center#engineparts machining#TranTek courtesy#RTU#RTU Transfer Unit#transfer unit#TransferUnit#linear motion track#automation linear motion

4 notes

·

View notes

Link

Cam followers are power-transmission devices with a rotary bearing core that bears load while serving as the interface between independently moving machine sections. Applications include those on rotary indexing tables and turntable conveyors, long-stroke robot transfer units (RTUs), and an array of highly customized machinery

To know more visit Cam Follower Dealer India

0 notes

Text

Juniper Publishers - Open Access Journal of Engineering Technology

Brief Industrial Networks Data Transfer Protocols Characteristics Analysis

Authored by : Vladlen Shapo

Keywords: Industrial networks; Protocols; Tunnelling; Internet; Control Networks

Abbreviations: IoT: Internet of Things; IIoT: Industrial Internet of Things; ACN: Architecture for Control Networks; AYIYA: Anything In Anything; CIP: Common Industrial Protocol; ODVA: Open Device Net Vendors Association; DNP3: Distributed Network Protocol Version 3

Opinion

During last 5-7 years in industry, at the different kinds of transport, in energetic field, etc. are very actively implementing data exchange technologies between separate devices, device groups and networks. These technologies based on Industry 4.0 (4th industrial revolution), IoT (Internet of Things), IIoT (Industrial Internet of Things) concepts. In accordance with these concepts a lot of different devices became smart, possessing of own CPUs, memory and different wired and wireless interfaces for external data exchange. Some of them (like complex PLCs) allow to unite different industrial network segments, having sufficient productivity and much lower cost compared to computers [1].

From the beginning of 90th years of 20th century in industry are very popular some protocols and data transfer technologies, most known are ASi, ProfiBus, Field Bus, HART, Mod Bus, CAN, BAC and so on. But in connection with Internet development and forth coming of absolutely new challenges were created some protocols, based on TCP/IP. These protocols allow to perform remote control of complex technical systems for enhancement of control quality, decreasing response time for force majeure situations and cost for control and exploitation of such systems. Protocols ProfiNet, Mod Bus/TCP, Ethernet/IP, Ether CAT became well known; they are compatible with previous generations, but allow to solve fundamentally new tasks. But in some situations by cost/productivity ratio win protocols and technologies, which don't have wide spread, but firmly hold theirs niche. Some of them are described below.

ACN (Architecture for Control Networks) is network control protocol, initially destined for entertainment industry [2]. It has open source code and maintains some subordinate protocols (Table 1).

AYIYA (Anything In Anything) is network protocol for tunnelling between IP-networks and controlling there [3]. Very often it's used for IPv6 packets transit through the networks based on IPv4 protocol. Network security is provided with absence of addresses and content of tunnelled packets falsification possibility. At least one of two tunnel endpoints allows mobile devices connecting.

CIP (Common Industrial Protocol) is the set of standards [4], which are maintained by Open Device Net Vendors Association (ODVA). CIP extensions are CIP safety, CIP Sync and CIP Motion protocols. CIP contains full set of requirements and possibilities for complex automation systems and their subsystems development from following sides: control, information security, motion organizing, informing. Some most important protocols and industrial data transfer technologies are based on CIP as well and briefly described below.

EtherNet/IP is open industry protocol, which uses standard Ethernet chips and cable systems, based also on IEEE 802.3 standard, and serve for input/output real time data exchange and information messages in Device Net and Control Net industrial networks. CIP provides common application level between networks, which doesn't depend on media (cable system). It allows to perform direct routing CIP messages in Ether Net/IP, Control Net and Device Net networks.

Depending on application requirements EtherNet/IP network may be stand alone or combined with Device Net or Control Net networks for additional flexible information and control services realization. EtherNet/IP transfers big user, configuration and input/output data volumes in the same high speed network; tightly associates technological and corporate operations; facilitates technical maintenance expenses decreasing thanks to existing network resources and technical facilities using; allows to commercial and industrial technological levels to coexist in the same network; works with TCP/IP and HTTP protocols.

DNP3 (Distributed Network Protocol, version 3) is a set of communication protocols [5], which are used for data transfer between components in automation systems. It's developed for communications between different types of equipment for data acquisition and control and described in IEEE 1815 standard. In SCADA systems DNP3 is used by SCADA master stations (control centers), Remote Terminal Units (RTU) and different Intelligent Electronic Device (IED). It uses 3 levels of OSI model (data link, transport and application) and contains Secure Authentication v5 mechanism, which allows to master or remote DNP3- system uniquely determine, that connection is established with legitimate user or host, but not with malicious user.

HART-IP (Highway Addressable Remote Transducer) protocol [6] based on standard Ethernet IEEE 802.3 hardware and cable systems (twisted pair and fiber optics) and with Wi-Fi IEEE 802.11 equipment, that's why it's possible to use it with standard network switches, routers, access points, cables and connectors. It may be used in redundant mesh or ring topologies and with PoE (Power over Ethernet) power supply standard by twisted pair Possible data transfer rates are 10Mbps, 100Mbps and 1Gbps. HART network, including devices working with Wireless HART protocol, is compatible with office and industrial LAN-switches, fiber optics media converters, Wi-Fi access points and equipment. Compatibility with classic HART protocol allows to put corresponding gateways into action and to work with classic analogue 4-20mA technologies. Using IP as base interaction protocol allows HART-IP to work in the same network together with multiplicity of protocols, based on IP and Ethernet (Figure 1).

More than 60 millions devices with HART protocol supporting are installed in the world. HART over Ethernet or HART-IP widen HART accessibility in local internal industrial networks with interconnection with corporate networks and ERP (Enterprise Resource Planning) software.

Variables and diagnostic data in HART are encapsulated in HART-IP packets. It allows to realize real time processes in existing corporate networks and to use corporate VPN (Virtual Private Networks).

For more articles in Open Access Journal of Engineering Technology please click on:

https://juniperpublishers.com/etoaj/index.php

To read more...Fulltext please click on:

https://juniperpublishers.com/etoaj/ETOAJ.MS.ID.555561.php

#Engineering Technology open access journals#Juniper Journals Reviews#Juniper publisher journals#Juniper publishers#Open Access Journals#Peer Review Journals

0 notes

Text

Umar Manaf, has finally left Hearts of Oak to join RTU.

Umar Manaf, has finally left Hearts of Oak to join RTU.

Abdul Umar Manaf, a Ghanaian attacker, is close to signing a deal to leave Hearts of Oak and join Real Tamale United (RTU).

The gifted offensive midfielder was expected to join the Ghana Premier League’s newcomers before the start of the 2021/2022 season, but negotiations fell through.

With the second transfer window for player registration ready to begin, Abdul Umar Manaf’s representatives have…

View On WordPress

0 notes

Text

On-loan Chelsea defender Baba Rahman donates to Premier League newcomers RTU

On-loan Chelsea defender, Abdul Baba Rahman has donated to Ghana Premier League newcomers Real Tamale United (RTU).

Rahman fulfilled his promise to the club after securing qualification to the top-flight.

The former Asante and Dreams FC left-back donated 50 footballs, 50 Bibs, 50 cones, and other football items worth over GHS 12,000.

The donation was done on behalf of his elder brother, Alhaji Suleman Adam Baba, and Northern Regional FA Chairman, Alhaji Abu Hassan Rhyzo.

Baba Rahman also donated an undisclosed amount to RTU to help in their preparations for the upcoming season.

Last year, 27-year-old he presented football jerseys, over 500 footballs, 600 pips, and other football equipment worth thousands of Ghana cedis to support Juvenile football and Women’s football in the region.

Rahman is currently with the Black Stars preparing for the 2022 FIFA World Cup qualifier against Ethiopia at the Cape Coast Stadium on Friday.

He joined English Championship side Reading FC on a year loan deal from Chelsea in the just-ended summer transfer window.

source: https://footballghana.com/

0 notes

Text

EU Stage II Emission 100KW Perkins Generator

Introduction to Perkins 1100 Series 1104C-44TAG2 Power Generation Engine

Building upon Perkins proven reputation within the power generation industry, the newly introduced 1100 Series range of ElectropaK engines now fit even closer to the needs of their customers.

In the world of power generation success is greeted for those providing more for even less. Therefore with this new 1104C-44TAG2 unit, Perkins has engineered for its customers even higher levels of reliability, yet lowered the cost of ownership. And with six cylinder capability from a four cylinder package performance increases, but crucially, bare engine noise is lower than ever before.

Rapid starting and pick-up are naturally builtin especially for cold operation, but where legislation or local markets demand an emissions capability, then the 1104C-44TAG2 satisfies EU 2007 Stage II mobile off-highway legislation; and also complies to TA Luft (1986) regulations.

1100 Series see the marriage of technology to customer need. A 4.4 litre unit very quietly setting a new standard in prime power supply and standby for the power generation industry.

Engine General Data

Model: 1104C-44TAG2

Standard: ISO 8528/1, ISO 3046/1: 1986, BS 5514/1

Prime/standby power: 93.5KW/103

Overload capacity (prime power): Overload of 10% permitted for 1 hour in every 12 hours operation (For standby power, no overload is permitted)

Number of cylinder: 4 vertical in-line

Bore and stroke: 105 x 127 mm

Displacement: 4.41 litres

Aspiration: Turbocharged, air to air

Cycle: 4 stroke

Combustion system: Direct injection

Compression ratio: 18.2:1

Rotation: Anti-clockwise viewed on flywheel

Cooling system: Water-cooled

Total lubrication system capacity: 8.0 litres

Lubricating oil: API CH4/ACEA E5.

Fuel consumption

Prime power (100%): 22.6 L/h

At 75% of prime power: 17.1 L/h

At 50% of prime power: 11.2 L/h

Fuel specification: BS 2869 Class 2 or ASTM D975 D2.

Total coolant capacity: 12.6 litres

Dimension: 1259 x 721 x 966 mm

Dry weight: 550kg

Engine Specifications

Air inlet

Mounted air filter

Fuel system

Rotary type pump

Ecoplus fuel filter

Lubrication system

Wet cast iron sump with filler and dipstick

Spin-on oil filter

Cooling system

Thermostatically-controlled system with gear-driven circulation pump and belt-driven pusher fan

Mounted radiator and piping incorporating air-to-air charge cooler

Electrical equipment

12 volt starter motor and 12 volt 65 amp alternator with

DC output

12 volt shutdown solenoid energised to run

Glow plug cold start aid

Flywheel and housing

Flywheel to SAE J620 size 10/111/2

SAE 3 flywheel housing

Literature

User’s Handbook

Optional equipment

24 volt alternator

24 volt starter motor

Workshop manual

Parts book

Features of Perkins 1104C-44TAG2 Engines

Compact and Efficient Power

The Perkins 1100 Series family was developed following an intensive period of customer research. The 3.3 and 4.4 litre engines feature new cylinder blocks which ensure bore roundness is maintained under the pressures of operation, as well as significantly reducing mechanical and combustion noise. A new cross-flow cylinder head design optimises combustion control, and combines with turbocharger and charge cooler technology to achieve the best combination of power delivery and low exhaust emissions.

Cleaner and Quieter Power

The refined structure of the 1100C range leads to an exceptionally low noise signature. To meet environmental needs swirl conditioned air is delivered through the new cross-flow cylinder head, and burns cleanly with the high pressure fuel from an advanced technology rotary pump.

Quality by Design

Class A manufacturing improvements ensure that product reliability meets the high standards demanded by customers. Product design is focused on maintaining Perkins’ legendary reputation for durability.

Cost Effective Power

The compact packaging and low noise performance of the 1100C range bring clear benefits to the Genset packager. Low cost of operation is assured by lower fuel and oil consumption, 500 hour service intervals, and the two year warranty.

Product Support

Total worldwide service is provided through a network of 4,000 distributors and dealers. TIPSS - The Integrated Parts and Support System enables customers to specify and order parts electronically as well as service engines with on-line guides and service tools.

Alternator General Data

Brand: Leroy-Somer

Model: LSA 44.3 S6

Insulation class: H

Winding pitch: 2/3 (wdg 6)

Number of wires: 12

Protection: IP 23

Excitation system: AREP

AVR type: R438

Voltage regulation (*): ±1%

Attitude: ≤ 1000 m

Overspeed: 2250 min-1

Air flow: 0.25 m3/s

Specially adapted to applications General characteristics

Leroy-Somer LSA 44.3 alternator is designed to be suitable for typical generator applications, such as: backup, marine applications, rental, telecommunications, etc.

Compliant with international standards

The LSA 44.3 alternator conforms to the main international standards and regulations:

- IEC 60034, NEMA MG 1.32-33, ISO 8528-3, CSA / UL 1146 (UL 1004 on request), marine regulations, etc.

It can be integrated into a CE marked generator.

The LSA 44.3 is designed, manufactured and marketed in an ISO 9001 environment and ISO 14001.

Characteristics of Leroy-Somer LSA 44.3 S6 Alternator

Reinforced mechanical structure using finite element modelling

1. Compact rigid assembly to better withstand generator vibrations.

2. Steel frame and terminal box.

3. Aluminium flanges and shields.

4. Two-bearing and single-bearing versions designed to be suitable for commercially-available heat engines.

5. Half-key balancing two bearing.

6. Permanently greased bearings (20 000h).

7. Direction of rotation: clockwise and anti-clockwise (without derating).

Controller General Data

Brand: Deep Sea

Model: DSE 7320 MKII (AUTO START & AUTO MAINS FAILURE CONTROL MODULES)

Introduction to DSE7320 Control Model

DSE7320 MKII module has been designed to allow the operator to start and stop the generator, and if required, transfer the load to the generator either manually or automatically.

Additionally, the DSE7320 MKII automatically starts and stops the generator set depending upon the status of the mains (utility) supply

DSE7320 MKII module monitors the engine, indicating the operational status and fault conditions, automatically shutting down the engine and giving a true first up fault condition of an engine failure by the text LCD display.

KEY BENEFITS

1. Automatically transfers between mains (utility) and generator (DSE7320 MKll only) for convenience.

2. Hours counter provides accurate information for monitoring and maintenance periods

3. User-friendly set-up and button layout for ease of use

4. Multiple parameters are monitored & displayed simultaneously for full visibility

5. The module can be configured to suit a wide range of applications for user flexibility

6. PLC editor allows user configurable functions to meet user specific application requirements.

Deep Sea Controller RS232 Interface

The dual mutual system utilises the RS232 or RS485 hardware interface to allow multiple modules to communicate to one another. The R232 port can be configured for connection to a modem or remote monitoring equipment (i.e. Building Management System, PLC or PC RS232 port).

Using the RS232 port for dual mutual communication frees up the RS485 interface for connection to a MODBUS engine or remote monitoring equipment (i.e. Building Management System, PLC or PC RS485 port).

While this is a very useful feature in some applications, the obvious drawback is that the RS232 port is no longer available connection to a modem or remote monitoring equipment (i.e. Building Management System, PLC or PC RS232 port).

RS485 Interfaces

The RS485 port on the controller supports the MODBUS RTU protocol and is for connection to a single MODBUS master device only.

The DSE MODBUS register table for the controller is available upon request from the DSE Technical Support Department.

RS485 is used for point-to-point cable connection of more than one device (maximum 32 devices) and allows for connection to PCs, PLCs and Building Management Systems (to name just a few devices).

One advantage of the RS485 interface is the large distance specification (1.2 km when using Belden 9841 (or equivalent) cable. This allows for a large distance between the module and a PC running the DSE Configuration Suite software. The operator is then able to control the module, starting or stopping the engine, selecting operating modes, etc.

The various operating parameters (such as coolant temperature, oil pressure, etc.) of the remote engine are viewed or changed.

If you are interested in 100KVA silent diesel generator set with the specifications of Perkins 1104C-44TAG2 engine, Leroy-Somer LSA 44.3 S6 alternator and Deep Sea 7320 MKII control module, welcome to contact us for the latest quotation.

0 notes

Text

Industrial Controls System Market Prominent Manufacturers Steering Growth during 2019-2027

Transparency Market Research has published a new report that studies the global industrial controls systems market. The research report, titled “Industrial Controls System Market – Global Industry Analysis Size Share Growth Trends and Forecast 2015 – 2021”, gives a comprehensive overview of the market dynamics governing this market and its impact on the overall economy. According to the research report, the global industrial controls system market was valued at US$58 billion in 2014 and is expected to be worth US$81 billion by 2021, growing at a robust CAGR of 4.9% from 2015 to 2021.

Browse the full Industrial Controls System Market – Global Industry Analysis Size Share Growth Trends and Forecast 2015 – 2021 report at https://www.transparencymarketresearch.com/industrial-controls-market.html

Industrial control systems are a network of interconnected equipment that are used for supervising and controlling physical equipment in several industrial environments. These systems include numerous control systems such as supervisory control and data acquisition (SCADA) systems, distributed control systems (DCS), and programmable logic controllers (PLC). They are primarily used for remote supervision, process automation, and critical infrastructure automation. SCADA systems are employed for obtaining data from remotely placed devices such as transmitters, pumps, and valves, among others. These systems help in gathering data from faraway devices and transferring it to the master control unit for enhancing control. Distributed control systems or DCS are interlinked networks that ease the controlling activity of several processes that may be spread out over facilities. On the other hand, programmable logic controllers are deployed for making electromechanical processes such as controlling assembly lines in a factory, machinery, or light fixtures automatic.

For More Info | Download PDF Brochure, Click Here: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=4886

The global industrial controls system market has been flourishing due to the growing entry of automation in the industrial sector and the increasing trend of remote supervision in several manufacturing facilities. Analysts predict the increasing software application in industrial control devices is expected to increase the market shares of PLS, DCS, and SCADA systems in the industrial environment. Some of the other factors expected to contribute towards the growth of the global industrial controls systems market are the emerging economies of Indonesia, India, and China, which are making heavy investments in automation and industrial infrastructure. The SCADA segment will witness a stupendous growth rate due to increasing demand for the same in sectors such as food and beverages, oil and gas, and chemicals.

The global industrial controls system market has been segmented on the basis of types, components, applications, and geography. The types of industrial controls systems are programmable logic controller (PLC), distributed control system (DCS), and supervisory control and data acquisition (SCADA). The components in the global industrial controls system market are programmable logic controller (PLC), human machine interface (HMI), remote terminal unit (RTU), SCADA communication systems, and others. The applications of industrial controls system market are seen in industries such as automotive, pharmaceutical, oil and gas, electrical power, and water and waste management. Geographically, this global industrial controls system market is spread over areas such as North America, Europe, Asia Pacific, and Rest of the World. Some of the key players operating in the global industrial controls system market are Emerson Electric Co, Siemens AG, Alstom SA, ABB Ltd, Rockwell Automation, Inc., Omron Corp, Honeywell International, Inc, and Omron Corp.

Request For Covid19 Impact Analysis Across Industries And Markets – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=4886

The industrial controls market is segmented as below:

Global industrial controls market, by Types

Global SCADA market, by Components:

Global industrial controls market, by Applications:

Supervisory Control And Data Acquisition (SCADA)

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

Human Machine Interface (HMI)

Programmable Logic Controller (PLC)

Remote Terminal Unit (RTU)

SCADA Communication Systems

Others

Electrical Power

Chemicals

Oil & Gas

Food and Beverages

Manufacturing

Automotive

Pharmaceutical

Water and Waste Water Management

Others (Aerospace, Defense, Mining, and Materials)

Global industrial controls market, by Geography:

North America

Europe

Asia Pacific

Rest of the World (ROW)

U.S.

Canada

Mexico

United Kingdom

Germany

France

Italy

Rest of Europe

China

India

Japan

Taiwan

South Korea

Rest of Asia Pacific

Middle East

Africa

South America

Customization of the Report: This report can be customized as per your needs for additional data or countries. – https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=4886

Related Reports Press-Release –

https://www.prnewswire.com/news-releases/3d-animation-market-to-exhibit-robust-14-5-cagr-due-to-growing-teenagers-interest-for-gaming–increasing-demand-from-media-and-entertainment-sector-says-tmr-300792995.html

https://www.prnewswire.com/news-releases/connected-living-room-market-to-reach-us984-51-bn-by-2024–owing-to-technological-advancements—tmr-300816943.html

About Us

Transparency Market Research (TMR) is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact

Mr.Sudip S

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: https://www.transparencymarketresearch.com

0 notes

Text

Industrial Controls System Market: Quantitative Market Analysis, Current and Future Trends

Transparency Market Research has published a new report that studies the global industrial controls systems market. The research report, titled “Industrial Controls System Market – Global Industry Analysis Size Share Growth Trends and Forecast 2015 – 2021”, gives a comprehensive overview of the market dynamics governing this market and its impact on the overall economy. According to the research report, the global industrial controls system market was valued at US$58 billion in 2014 and is expected to be worth US$81 billion by 2021, growing at a robust CAGR of 4.9% from 2015 to 2021.

Industrial control systems are a network of interconnected equipment that are used for supervising and controlling physical equipment in several industrial environments. These systems include numerous control systems such as supervisory control and data acquisition (SCADA) systems, distributed control systems (DCS), and programmable logic controllers (PLC).

Request For Report Sample https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=4886

They are primarily used for remote supervision, process automation, and critical infrastructure automation. SCADA systems are employed for obtaining data from remotely placed devices such as transmitters, pumps, and valves, among others. These systems help in gathering data from faraway devices and transferring it to the master control unit for enhancing control. Distributed control systems or DCS are interlinked networks that ease the controlling activity of several processes that may be spread out over facilities. On the other hand, programmable logic controllers are deployed for making electromechanical processes such as controlling assembly lines in a factory, machinery, or light fixtures automatic.

The global industrial controls system market has been flourishing due to the growing entry of automation in the industrial sector and the increasing trend of remote supervision in several manufacturing facilities. Analysts predict the increasing software application in industrial control devices is expected to increase the market shares of PLS, DCS, and SCADA systems in the industrial environment. Some of the other factors expected to contribute towards the growth of the global industrial controls systems market are the emerging economies of Indonesia, India, and China, which are making heavy investments in automation and industrial infrastructure. The SCADA segment will witness a stupendous growth rate due to increasing demand for the same in sectors such as food and beverages, oil and gas, and chemicals.

Request For Report Brochure https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=4886

The global industrial controls system market has been segmented on the basis of types, components, applications, and geography. The types of industrial controls systems are programmable logic controller (PLC), distributed control system (DCS), and supervisory control and data acquisition (SCADA). The components in the global industrial controls system market are programmable logic controller (PLC), human machine interface (HMI), remote terminal unit (RTU), SCADA communication systems, and others.

The applications of industrial controls system market are seen in industries such as automotive, pharmaceutical, oil and gas, electrical power, and water and waste management. Geographically, this global industrial controls system market is spread over areas such as North America, Europe, Asia Pacific, and Rest of the World. Some of the key players operating in the global industrial controls system market are Emerson Electric Co, Siemens AG, Alstom SA, ABB Ltd, Rockwell Automation, Inc., Omron Corp, Honeywell International, Inc, and Omron Corp.

0 notes