#ReciprocatingPump

Explore tagged Tumblr posts

Text

Reciprocating Pump Market Growth Driven by Rising Demand Across Oil, Gas, and Energy Industries

The reciprocating pump market has been steadily gaining momentum over the past few years, fueled by demand from industries like oil and gas, water treatment, chemical processing, and power generation. These pumps, known for their ability to handle high-pressure applications with precision, have carved out a crucial role in global industrial operations. As industries increasingly prioritize efficiency, reliability, and performance, reciprocating pumps are finding new avenues for growth.

Understanding Reciprocating Pumps

At their core, reciprocating pumps are positive displacement pumps. They work by using a back-and-forth (reciprocating) motion to move fluids through a system. Typically, these pumps consist of a piston, plunger, or diaphragm that draws fluid into a chamber on the suction stroke and pushes it out on the discharge stroke. This design makes them ideal for applications where precise control over flow rate and pressure is required.

Unlike centrifugal pumps, which are better suited for high-volume, low-pressure applications, reciprocating pumps excel in high-pressure, low-flow environments. This makes them indispensable in tasks like chemical injection, hydraulic systems, and feeding high-pressure boilers.

Market Drivers and Demand

One of the major drivers behind the growth of the reciprocating pump market is the oil and gas sector. As exploration activities expand into deeper offshore fields and more challenging environments, the need for reliable, high-pressure pumping solutions becomes critical. Reciprocating pumps are often used for applications like drilling mud circulation, water injection, and crude oil transfer. The push toward enhanced oil recovery (EOR) techniques further fuels demand, as these methods often rely on precise fluid handling.

Another important factor is the water and wastewater treatment industry. With growing global concerns around water scarcity and pollution, governments and industries are investing heavily in water treatment infrastructure. Reciprocating pumps play a key role in metering chemicals, sludge handling, and reverse osmosis processes. Their ability to handle viscous fluids, abrasive slurries, and corrosive chemicals makes them a preferred choice in these demanding applications.

In the chemical and petrochemical sectors, the demand for exact dosing and fluid transfer under extreme conditions has also supported market growth. Similarly, the power generation industry, particularly thermal and nuclear plants, relies on these pumps for boiler feed, cooling water circulation, and other critical processes.

Technological Advancements and Challenges

While reciprocating pumps have been around for over a century, modern designs are benefiting from technological advancements. Digital monitoring, advanced materials, and smart control systems are improving pump efficiency, reducing maintenance needs, and extending equipment lifespan. Manufacturers are focusing on developing pumps with improved energy efficiency, as end-users increasingly seek ways to lower operational costs and meet environmental regulations.

However, challenges remain. Reciprocating pumps typically have higher initial costs and maintenance requirements compared to centrifugal pumps. Their complex design, with multiple moving parts, makes them prone to wear and tear, especially under harsh operating conditions. Addressing these challenges through better materials, improved sealing technologies, and predictive maintenance solutions is key to sustaining market growth.

Regional Insights

Geographically, the Asia-Pacific region is emerging as a significant market for reciprocating pumps. Rapid industrialization in countries like China, India, and Southeast Asian nations is driving demand across multiple sectors, from power generation to chemical processing. Government investments in infrastructure and water treatment projects further boost the market.

North America and Europe continue to hold strong positions, particularly due to their mature oil and gas industries and stringent environmental regulations that require precise and reliable fluid handling systems. Meanwhile, the Middle East, rich in oil and gas resources, remains a major consumer of high-pressure pumping solutions, with a steady focus on upstream and downstream operations.

Competitive Landscape

The reciprocating pump market is moderately fragmented, with a mix of global players and regional manufacturers. Leading companies like Flowserve Corporation, Grundfos, Sulzer, Gardner Denver, and KSB are focusing on strategic partnerships, mergers, and acquisitions to strengthen their market positions. Innovation remains a key differentiator, with companies investing in research and development to offer more efficient, durable, and customizable pumping solutions.

Future Outlook

Looking ahead, the reciprocating pump market is poised for continued growth, driven by industrial expansion, technological improvements, and evolving regulatory requirements. As industries navigate the balance between operational efficiency and environmental responsibility, the demand for high-performance pumping solutions will remain strong.

Moreover, the integration of digital technologies, such as IoT-enabled monitoring systems and predictive maintenance tools, is expected to reshape the market. These innovations will help operators optimize pump performance, reduce unplanned downtime, and lower total cost of ownership key priorities for industries facing rising operational pressures.

Conclusion

The reciprocating pump market stands at the intersection of tradition and innovation. While the core technology remains fundamentally the same, new materials, smarter controls, and advanced monitoring are unlocking fresh opportunities across industries. As global industrial needs evolve, reciprocating pumps will continue to play a vital role, offering the precision, reliability, and performance that modern operations demand.

0 notes

Text

"Engineering Efficiency: Trends and Projections for the Mechanical Pump Market (2024-2033)"

Mechanical pumps are the backbone of countless industrial and commercial applications, driving efficiency and reliability in systems ranging from water supply and wastewater treatment to chemical processing and oil refining. These pumps operate by converting mechanical energy into fluid movement, utilizing designs such as centrifugal, reciprocating, and rotary pumps to suit various needs. Innovations in materials and engineering have significantly enhanced the durability and performance of mechanical pumps, allowing them to handle more demanding tasks with greater precision. Modern mechanical pumps often incorporate smart technology, such as IoT-enabled sensors and automated controls, enabling real-time monitoring, predictive maintenance, and energy optimization. This not only reduces operational costs but also minimizes downtime and extends the lifespan of equipment. As industries strive for sustainability and efficiency, mechanical pumps play a crucial role in ensuring smooth, reliable operations. Embrace the advancements in mechanical pump technology to stay ahead in the competitive landscape and drive forward industrial innovation.

#MechanicalPumps #IndustrialEfficiency #PumpTechnology #FluidManagement #CentrifugalPumps #ReciprocatingPumps #RotaryPumps #WaterSupply #WastewaterTreatment #ChemicalProcessing #OilRefining #SmartPumps #IoTIntegration #PredictiveMaintenance #EnergyOptimization #DurableDesign #IndustrialInnovation #OperationalEfficiency #TechInIndustry #SustainableSolutions

0 notes

Text

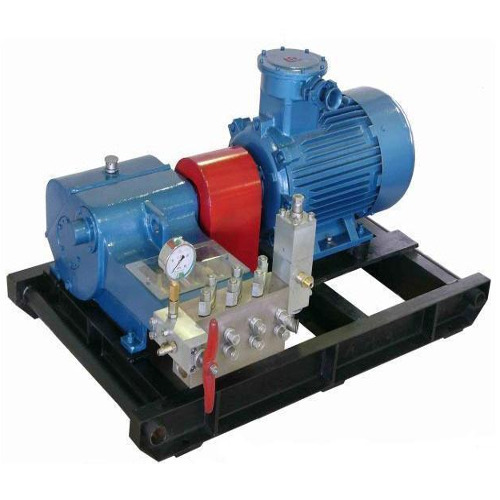

Triplex Plunger Pump

Triplex Plunger Pump :- A modern innovation derived Goma’s triplex plunger pump is a hefty equipment towards achieving smooth flow without any pulsation dampeners.

0 notes

Text

Maintenance video of High Pressure Plunger Pumps.

PressureJet is an industry leader in the field of triplex plunger pumps. The company focuses on different pumps like Firefighting Pumps, Hydroblasting, Hydrotest. pressure jet cleaner and hydro Jetting. More than 25 years of experience in the field makes us more reliable and trustworthy. To know more about us, visiti - https://www.uhpfirefightingpump.com/

#PressureJet#Triplexplungerpumps#pressurejetsystems#highpressurecleaning#hydrojettingmachine#firesuppressionsystem#firefightingequipment#hydrotesting#pumpsystem#reciprocatingpumps#High pressure Plunger Pump#Reciprocating plunger pump#Maintenance of plunger pumps#Firefighting Pump#Firefighting equipment#UHP Firefighting Pump#Best high pressure plunger pump#Price of firefighting pump#Fire suppression system

0 notes

Text

Reciprocating Pump Market Growth Driven by Expanding Industrial Applications and Rising Energy Efficiency Demands

Introduction

The reciprocating pump market has witnessed significant growth over the past decade, driven by increasing demand from industries such as oil and gas, water treatment, chemical processing, and manufacturing. These pumps, known for their ability to handle high-pressure applications with precision, are widely used for fluid transfer and metering purposes. As industries continue to seek efficient and reliable pumping solutions, the reciprocating pump market is poised for steady expansion in the coming years.

What is a Reciprocating Pump?

A reciprocating pump is a type of positive displacement pump that uses a piston, plunger, or diaphragm to create a back-and-forth (reciprocating) motion, resulting in fluid displacement. The pump's working mechanism allows it to deliver a consistent flow rate, making it highly effective for applications requiring precision and control. Reciprocating pumps are commonly used in situations where the fluid viscosity, pressure, or flow rate needs to be maintained with accuracy.

Market Size and Growth Trends

The global reciprocating pump market was valued at approximately $7.5 billion in 2024 and is expected to grow at a compound annual growth rate (CAGR) of around 5-7% over the next five years. This growth is primarily fueled by rising industrialization, increasing energy demand, and the expansion of water treatment and desalination plants worldwide.

The oil and gas sector continues to be a dominant end-user of reciprocating pumps, particularly for applications such as crude oil transportation, enhanced oil recovery (EOR), and hydraulic fracturing. Meanwhile, the pharmaceutical and chemical industries are also contributing to market growth due to the need for precise fluid handling and metering in production processes.

Key Market Drivers

Increasing Demand from Oil and Gas Industry

The oil and gas sector remains a primary driver of the reciprocating pump market. With the resurgence of exploration activities, the need for high-pressure pumps capable of handling crude oil, natural gas, and other hydrocarbons is growing.

The use of reciprocating pumps in hydraulic fracturing (fracking) and well stimulation has surged, particularly in regions such as North America and the Middle East.

Growing Water Treatment and Desalination Projects

The expanding global population and water scarcity issues have led to increased investments in water treatment and desalination plants.

Reciprocating pumps play a critical role in these facilities by ensuring high-pressure fluid transfer, particularly in reverse osmosis systems.

Rising Industrial Automation

The trend toward industrial automation is driving demand for precision pumps with advanced monitoring and control features.

Modern reciprocating pumps equipped with IoT-enabled sensors offer real-time performance data, enabling predictive maintenance and improving operational efficiency.

Technological Advancements

Advancements in pump materials and designs, including the use of corrosion-resistant alloys and enhanced sealing technologies, are boosting the durability and performance of reciprocating pumps.

Smart pump systems with remote monitoring capabilities are becoming increasingly popular, particularly in large-scale industrial applications.

Challenges in the Market

Despite the promising growth, the reciprocating pump market faces several challenges:

High Maintenance Costs: Reciprocating pumps are prone to wear and tear due to their moving parts, resulting in higher maintenance costs. This can deter small and medium-sized enterprises (SMEs) from investing in these pumps.

Energy Consumption: Although efficient, reciprocating pumps consume considerable energy, particularly in high-pressure applications. Energy efficiency regulations could pose challenges for manufacturers.

Competition from Alternative Pump Technologies: Centrifugal pumps and other advanced pumping technologies are becoming more efficient and cost-effective, posing a potential threat to reciprocating pump market share.

Regional Analysis

North America

North America is one of the leading markets for reciprocating pumps, largely driven by the extensive oil and gas operations in the United States and Canada.

The increasing number of shale gas projects and hydraulic fracturing activities is driving the demand for high-pressure pumps.

Europe

The European market is characterized by its focus on industrial automation and sustainability initiatives.

Countries like Germany, the UK, and France are investing heavily in wastewater treatment plants, boosting demand for reciprocating pumps in the region.

Asia-Pacific

The Asia-Pacific region is experiencing rapid industrialization and urbanization, resulting in increased demand for reciprocating pumps in water treatment, chemical processing, and power generation sectors.

China and India are leading markets due to their expanding manufacturing and infrastructure sectors.

Middle East and Africa

The Middle East, with its strong oil and gas sector, continues to be a major market for reciprocating pumps.

Investments in desalination projects, particularly in Saudi Arabia and the UAE, are further driving market growth.

Market Segmentation

The reciprocating pump market can be segmented based on the following criteria:

Type:

Piston pumps

Plunger pumps

Diaphragm pumps

End-User Industry:

Oil and Gas

Water Treatment

Chemical Processing

Pharmaceuticals

Power Generation

Application:

High-pressure cleaning

Fluid metering

Chemical injection

Desalination

Future Outlook

The reciprocating pump market is expected to continue its growth trajectory, driven by ongoing industrialization, infrastructure development, and the increasing need for reliable pumping solutions. Manufacturers are likely to focus on energy-efficient designs and smart pump systems to meet evolving industry demands.

The integration of predictive maintenance features and the use of eco-friendly materials will also become key differentiators. Furthermore, the demand for custom-engineered pumps tailored to specific applications is expected to rise, particularly in specialized sectors such as pharmaceuticals and food processing.

Conclusion

The reciprocating pump market is set for steady growth, fueled by its extensive application across various industries. While challenges such as high maintenance costs and competition from alternative technologies persist, ongoing technological advancements and the rising demand for efficient fluid transfer solutions will continue to drive market expansion. As industries increasingly embrace automation and energy efficiency, the reciprocating pump sector is expected to witness continuous innovation and evolution.

0 notes

Text

PressureJet is an industry leader in the field of triplex plunger pumps. The company focuses on different pumps like Firefighting Pumps, Hydroblasting, Hydrotest. pressure jet cleaner and hydro Jetting. More than 25 years of experience in the field makes us more reliable and trustworthy. To know more about us, visit - https://www.uhpfirefightingpump.com/

#PressureJet#Triplexplungerpumps#pressurejetsystems#highpressurecleaning#hydrojettingmachine#firesuppressionsystem#firefightingequipment#hydrotesting#pumpsystem#reciprocatingpumps

0 notes