#Reinforcement Bar supplier

Text

https://apocalypsesteelandpower.com/

#tmt bar supplier#tmt steel suppliers near me#Reinforcement Bar supplier#Ferro Alloys supplier#Ferro Silicon Manganese supplier#Silicon Manganese supplier#Pure Silicon supplier#Scrap Metal supplier#MS Billets supplier#Firebricks#Precast Prefired Blocks For Burners#Steel Grade Pig Iron supplier#ms angle

2 notes

·

View notes

Text

Steel Excellence: Elevating Construction Projects with Gulf Steel Solutions

Introducing Gulf Steel Solutions, your premier partner for top-tier steel products and solutions in the UAE. With a steadfast commitment to excellence and innovation, we stand as a beacon of quality and reliability in the steel industry. Here's why you should choose Gulf Steel Solutions for all your construction needs:

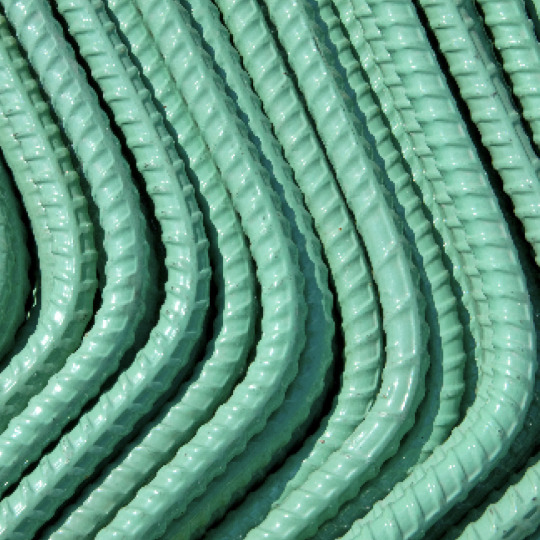

Unrivaled Quality: At Gulf Steel Solutions, quality is our cornerstone. We adhere to the strictest national and international standards, ensuring that our steel products, including rebar, plain bars, and epoxy-coated rebar, surpass expectations in durability and performance.

Comprehensive Product Range: Our extensive selection of steel products caters to diverse project requirements. Whether you need reinforcement steel bars or cut and bend rebar, Gulf Steel Solutions has you covered with precision-engineered solutions tailored to your specifications.

Dependable Supply Chain: With state-of-the-art manufacturing facilities strategically located across the UAE, we boast a seamless and reliable supply chain network. From Abu Dhabi to Dubai and beyond, Gulf Steel Solutions ensures timely deliveries to keep your projects on track.

Expert Guidance: Backed by a team of seasoned professionals, we offer unparalleled technical support and guidance. From project inception to completion, Gulf Steel Solutions is here to assist you in selecting the optimal steel products for your construction endeavors.

Sustainability Commitment: As stewards of the environment, Gulf Steel Solutions prioritizes sustainable practices. We employ eco-friendly manufacturing processes and integrate recycled materials into our production whenever feasible, minimizing our ecological footprint.

Partner with Gulf Steel Solutions: Whether you're embarking on a large-scale infrastructure venture or a residential development project, Gulf Steel Solutions is your trusted ally every step of the way. As your one-stop steel solution provider, we deliver:

Rebar Excellence: Gulf Steel Solutions stands as a premier rebar supplier in the UAE, offering a comprehensive array of rebar products to meet your project needs.

Steel Bar Solutions: With an extensive inventory of steel bars, we provide tailored solutions to fulfill the demands of any construction project, big or small.

Manufacturing Mastery: As a leading steel manufacturer in Abu Dhabi, Gulf Steel Solutions proudly fuels the UAE's construction industry with top-notch steel products.

Contact Gulf Steel Solutions today to explore how we can elevate your projects with our unparalleled steel solutions. Experience the Gulf Steel Solutions difference—a testament to quality, reliability, and excellence in every steel product we deliver.

#best steel manufacturers in uae#best steel factory in abu dhabi#epoxy coated rebar uae#rebar uae#plain bars uae#rebar manufacturers#rebar exporters#rebar suppliers in uae#reinforcement steel bars#reinforcement steel suppliers in uae

0 notes

Text

What Are The Important Stages of Steel Detailing Development in Construction Projects?

The process and work of steel structure detailing are precarious and want detailed understanding. From having a multi-layered phase to getting a holistic look at the structure that's made from steel, Steel Detailing services are required.

For the development projects where anything is made out of steel, the engineers use steel detailing services. It could be the team of structural engineers and architects who place their efforts and strength into the project.

It is the team of contractors and owners who share their drawings and design that is certainly associated with mechanical systems. These systems further require systems that relate to fabrication as well as in context to steel members.

The undertaking of steel detailing services is extremely crucial and tedious work. The accuracy a higher level this particular service is 99.9% which adds value towards the time and expense both. Structural steel detailing is a mandatory process undertaken by manufacturing and construction units.

Moreover, this complete process is playing a huge role and is also can be a communication link. It connects key professionals and personnel who're collectively responsible for project deliverables.

Let us now proceed further and check important stages of steel detailing. The process involves two major drawings the first is shop drawings along with the other is erection drawings.

Development Stages of Steel Detailing

Shop Drawings

When implementing a steel detailing project, it will be the steel detailers who help convert and cover the steel drawings and design. The making of steel components, pieces, and fashions that cover the drawings these are known as Shop Drawings. It will be the set of drawings that helps classify important components and specifications of the project. This further, continues with all the fabrication of person pieces and members of a structure.

It will be the steel fabricators who're determined to utilize these drawings also called detailed drawings. The use and wish for having this drawing are to produce steel members. With a comprehensive approach and classification, steel fabrication shop drawings include each amount of individual pieces which are part of the project.

The means of shop drawings emphasizes every bit and part of information that creates a project successful. With this said, the important points are the size of the project, its material specifications, the necessary dimensions, preparation with the surface, plus much more. This further continues with some important features like bolting, welding, painting, conventions, manufacturing process, and some fabricating guidelines.

Erection Drawings

It will be the list of drawings that refers for the steel detailing process. At the construction site, it could be the steel erectors who demand these drawings. These drawings reference knowing when, how, and where you should build fabricated steel pieces.

The work of erection drawings is usually to focus on dimensional plans that help identify details. This identification is to understand the steel members and focus on the project that is required once your there. Also, the project required on the site includes installation, welding, bolting, and masonry anchors.

Being a steel detailer, some additional roles and responsibilities are essential in the steel detailing process.

Detailed observance of structural design , drawings, and detailing with necessary industry standards.

reo mesh Sydney from the drawings and designs by structural engineers and architects before handing them over for the fabricator.

If the structural drawings are insufficient, the engineers offer support and assist with sanction them.

If the detailer is just not sure in regards to the drawings/information they send a request to get the data from your relevant parties. This will be the process taken before continuing the project.

For accuracy and completeness, the drawings are delivered to another detailer who is referred to as the checker.

If you can find any changes within the drawings, they must be monitored with accuracy and precision. These revisions are marked with codes and numeric to be aware of the detail perfectly.

Techniques

The age-old practice that has been used by steel detailing was performed manually. It was within the type of handmade drawings, designs, sketches, and templates. Later, with the use of CAD technology, specific software program is used. It could be the way that is only useful for designing 2D models understanding that too with primitive methods and techniques.

As people say, necessity may be the mother of invention. Same way while using use of advanced technology, the CAD drafting services were replaced. This process helped make the project work easier. faster, and cost-effective. It further, helps deliver an increased amount of work and outcome, as never before.

Though the expense of steel detailing development is at a better level, the program used is Tekla and AutoCAD. It is the process that delivers utmost efficiency which is highly scalable, reliable, and workable.

For a project's success, it is crucial to undertake the right list of services that assists increase the project tracking with proper scheduling.

Final Words

The steel detailing development inside project is an important factor. The blog shared clearly shows quite stages that make a project successful. Since steel detailing services is tedious work and process, they ought to be finalized with utmost precision and care.

#steel rebar suppliers Sydney#reinforcement suppliers Sydney#reinforcing steel suppliers Sydney#steel reinforcement mesh Sydney#reinforcement mesh Sydney#Steel Suppliers near me#galvanized bar#galvanised reo Sydney#galvanised steel Bar#galvanised reinforcing Supply#galvanised rebar supplier Sydney#Galvanised Mesh Sydney#R12#R16#R20#R24#R28 Galvanised Dowel Bar Sydney#S12 Pool steel Sydney#SL72/SL82/SL81/SL102 Galvanised Mesh Sydney#N12#N16#N20#N24#N28#N32 rebar Sydney#SL62/SL72/SL82/SL92 MESH supplier Sydney#SL72 Mesh#Ligature#Bondek Slab Sydney#Dowel Bar

0 notes

Text

Building material supplier in Africa.-When sourcing high-quality building materials in Africa, look no further than Ferro Fabrik Limited. As a leading building material supplier, we take immense pride in providing top-notch products and services that meet the diverse needs of construction projects across the continent.Regarding sourcing high-quality building materials in Africa, look no further than Ferro Fabrik Limited. As a leading building material supplier, we take immense pride in providing top-notch products and services that meet the diverse needs of construction projects across the continent. We care for our customers, and with our excellent team effort, we stand out far better than others. We prioritize exceptional customer service and satisfying experience. We offer the best assistance in selecting the perfect materials for the construction project with guidance at each step. At Ferro Fabrik Limited, we recognize the significance of competitive pricing. Our objective is to provide cost-effective solutions while maintaining the quality of our products. By fostering robust partnerships with trustworthy manufacturers and suppliers, we can secure advantageous prices, which we then extend to our esteemed customers, passing on the benefits. When you select Ferro Fabrik Limited as your building material supplier in Africa, you can trust our company's integrity, quality, and customer satisfaction. We are committed to establishing enduring partnerships with our clients, guaranteeing the triumph of their construction projects.https://www.ferrofabrikltd.com/

#Reinforced Steel Bar manufacturers#Steel Billets supplier in West Africa#Steel Plant in Ghana#High tensile rebar

0 notes

Text

The best certified armored iron skewers in Saudi Arabia

According to the specifications of the Saudi Authority for Specifications, Measures and Quality ASTM A615:2021 (degree 60)

Proudly made by Saudi Hands

SASO approved Rebars! Top-Ranked in Saudi Arabia

SASO ASTM A615:2021 standards (Grade 60)

Proudly Made in Saudi Arabia

#saso approved rebar#reinforcement steel bar#rebar manufacturer#deformed bars#steel producer in uae#steel supplier in UAE#rebar exporters#steel reinforcing bars

0 notes

Text

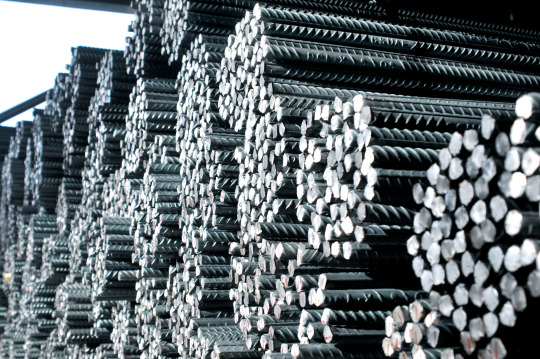

Rebar is one of the most prominent inclusions made in order to strengthen the concrete and bring in the required stability. With the stress-distributing and tension-absorbing quality of the rebars, the concrete is shielded against cracking.

#rebar#rebar manufacturers in the uae#tmt rebar#rebar exporters#reinforcement steel bar#steel supplier#steel manufacturer in uae

0 notes

Text

Stainless Steel Wires Supplier

Saraswati Steel and Engineering Co., established in 2011, is a well-known metal importer, stockholder, and supplier.Saraswati Steel and Engineering Co. specializes in stainless steel angles and channels, pipes and fittings, industrial fittings, flanges and fittings, dairy valves, stainless steel fasteners, UPVC pipes, industrial valves, stainless steel bars and wire rods, as well as stainless steel wires.Manufacturers produce stainless steel wires as high-quality metallic wires made from stainless steel, which is a corrosion-resistant alloy.Features of Stainless Steel Wires:SS wires can withstand high temperatures and resist chemical reactions, making them suitable for applications involving heat or exposure to corrosive substances.Stainless steel wires exhibit good electrical conductivity, making them suitable for applications that require the transmission of electrical signals or currents.Users can easily form stainless steel wires into different shapes and sizes, providing flexibility in various applications such as wire mesh, springs, cables, and more.SS wires exhibit excellent resistance to corrosion, rust, and oxidation, ensuring their durability and longevity even in challenging environments.Applications:Wire mesh and screens for filtration and sieving applications.|

Springs and wire forms for various industries, including automotive and electronics.

Structural components in construction and architecture.

Reinforcement wires in concrete and precast elements.

Fasteners, bolts, and screws for industrial and commercial purposes.

Medical instruments and equipment.

Kitchen utensils and appliances.Saraswati Steel & Engineering Co. is a supplier of stainless steel wires in various locations such as Madurai, Tiruchirappalli, Coimbatore, Chennai, Mysore, Kochi, and more.

For further details, please contact our professional team for a conversation.

Read the full article

#Chennai#IndustrialValves#Kochi#Madurai#Mysore#SaraswatiSteel#SaraswatiSteelandEngineeringCo#SSWires#StainlessSteelWires#UPVCPIPES

2 notes

·

View notes

Text

Unlocking the Strength and Versatility of Round Bars in Construction

Rajkrupa Metal Industries is a top-notch Round Bars Manufacturers in India. We have established ourselves as one of the top brands in the Round Bars sector. With significant commercial and technical personnel skills, Rajkrupa Metal Industries has strategically positioned itself as a top Round Bar manufacturer. Round bars are essential in forming our urban landscapes, from tall skyscrapers to elaborate bridges. Let's examine the benefits they provide, their structural strength, and the various ways they support building projects.

Strength in Form:

Because of its natural strength and cylindrical form, round bars are perfect for supporting large weights and withstanding stress. Their consistent cross-sectional area, which equally distributes stresses along their length, is the source of their strength. Round bars offer long-lasting structural integrity when they are utilised as load-bearing elements in steel frameworks or as reinforcement in concrete buildings.

Versatility Unleashed:

The adaptability of circular bars is among its most alluring features. Available in a variety of materials, including titanium, steel, stainless steel, and aluminum, they provide versatility to meet particular project requirements. In order to meet a variety of structural requirements and climatic circumstances, different grades and alloys further customize their qualities.

Round bars can also be easily used into a variety of construction methods. They improve the tensile strength and longevity of structures by acting as crucial elements in concrete reinforcing. Furthermore, because of their malleability, they may be easily shaped and customised to fit a variety of unusual building shapes and complex architectural ideas.

Beyond Structural Support:

Round bars are well known for their ability to support structures structurally, but they are useful for more than just that. Architectural embellishments such as beautiful facades, artistic installations, and ornamental railings are used to add aesthetic value to structures. Round bars' rounded, smooth form encourages artistic expression and provides architects and designers with a flexible tool to bring their ideas to life.

Additionally, round bars support environmentally friendly building methods. They are environmentally friendly options that fit in with the increased emphasis on green building projects because of their durability and recyclability. Construction projects can lessen resource depletion and their carbon footprint by using recycled materials or sustainable alloys.

Innovation and Advancements:

The evolution of round bar technology continues to drive innovation in the construction industry. Advanced manufacturing processes, such as hot rolling, cold drawing, and extrusion, enable the production of round bars with enhanced properties and precise dimensions. High-strength alloys and composite materials push the boundaries of performance, opening new possibilities for lightweight structures and seismic-resistant designs.

Furthermore, digital tools and computational modelling empower engineers to optimise the use of round bars in construction projects. Finite element analysis (FEA) and computer-aided design (CAD) software facilitate structural simulations and predictive modelling, ensuring optimal placement and sizing of round bars for maximum efficiency and safety.

We are also top quality Aluminium Bronze Round Bar Manufacturer In India. We have established ourselves as one of the market's top names in Aluminium Bronze Round Bar. Rajkrupa Metal Industries has deliberately positioned itself as a top-tier manufacturer and retailer worldwide. Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, resistance to corrosion, and thermal and electrical conductivity.

#Round Bars Manufacturers in India#Round Bars Manufacturers#Round Bars#Aluminium Bronze Round Bar Manufacturer In India#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Suppliers

0 notes

Text

Unveiling the Trusted Partners for Quality Steel: Raunaq Steel Pvt. Ltd

In the bustling city of Chennai, where construction projects thrive and infrastructure development never ceases, finding reliable suppliers for construction materials is paramount. Among the essential components for any construction project, steel reigns supreme. For builders and contractors in Chennai, the search for quality steel suppliers often leads to Raunaq Steel Pvt. Ltd., a name synonymous with trust and excellence in the industry. Specializing in MS rounds and serving as a premier SAIL TMT Bar distributor Chennai, Raunaq Steel Pvt. Ltd. has earned a reputation for its unwavering commitment to quality and customer satisfaction.

Unmatched Quality in MS Rounds

MS rounds are a vital component in various construction applications, ranging from reinforcement to structural framing. Raunaq Steel Pvt. Ltd. stands out as one of the leading dealers of MS rounds Chennai, offering a diverse range of sizes and specifications to meet the unique needs of every project. What sets Raunaq Steel apart is its unwavering dedication to quality assurance. Each MS round undergoes stringent quality checks to ensure compliance with industry standards, providing customers with the assurance of durability and reliability in their construction endeavors.

Trusted SAIL TMT Bar Distributor

When it comes to structural integrity and reinforcement, SAIL TMT bars are the preferred choice among builders and contractors. As a trusted distributor of SAIL TMT bars in Chennai, Raunaq Steel Pvt. Ltd. upholds the highest standards of product quality and integrity. These bars are manufactured using advanced technology and undergo rigorous testing processes to guarantee superior strength and resilience, making them ideal for construction projects of any scale. Whether it's for residential complexes, commercial buildings, or infrastructure developments, Raunaq Steel delivers SAIL TMT bars that exceed expectations in performance and reliability.

Customer-Centric Approach

At the heart of Raunaq Steel Pvt. Ltd.'s success lies its customer-centric approach. Understanding the unique requirements and challenges faced by its clients, the company goes the extra mile to provide personalized solutions and unparalleled support. From timely delivery to technical assistance, Raunaq Steel ensures a seamless experience for its customers throughout the procurement process. Building lasting relationships based on trust and mutual respect, Raunaq Steel has emerged as the preferred choice for discerning builders and contractors seeking quality steel products in Chennai.

In the dynamic landscape of Chennai's construction industry, finding a reliable partner for quality steel is indispensable. With its steadfast commitment to excellence, Raunaq Steel Pvt. Ltd. has established itself as a beacon of reliability and trustworthiness. As a leading dealer of MS rounds and a trusted distributor of SAIL TMT bars in Chennai, Raunaq Steel continues to set new benchmarks for quality and customer satisfaction. For builders and contractors seeking premium steel products backed by unparalleled service, Raunaq Steel Pvt. Ltd. remains the undisputed choice, driving the growth and success of construction projects across the city.

0 notes

Text

Navigating Construction Excellence: Choosing the Right TMT Supplier in Uttar Pradesh

Introduction:

In the realm of construction, selecting the right TMT (Thermo-Mechanically Treated) supplier is paramount to ensuring the structural integrity and longevity of your projects. As a trusted leader in the construction industry, Primegold International Limited emerges as a reliable partner, offering top-quality TMT bars in Uttar Pradesh. This blog aims to provide valuable insights into the process of selecting the best TMT supplier in the region to meet your construction needs.

Understanding the Significance of TMT Bars:

TMT bars play a pivotal role in reinforcing concrete structures, providing them with the necessary strength, durability, and resilience against external forces such as corrosion, seismic activities, and adverse weather conditions. The thermo-mechanical treatment process employed in their manufacturing imparts superior mechanical properties, making them indispensable in modern construction projects.

Key Factors to Consider When Choosing a TMT Supplier:

Quality Standards: The foremost consideration when selecting a TMT supplier is ensuring the quality of their products. Look for suppliers who adhere to stringent quality control measures and possess relevant certifications such as the Bureau of Indian Standards (BIS) certification, signifying compliance with industry standards.

Product Range: Evaluate the range of TMT bars offered by the supplier, considering factors such as grade, size, and specifications. A diverse product portfolio allows you to choose TMT bars tailored to your specific project requirements, ensuring optimal performance and structural integrity.

Manufacturing Process: Gain insights into the manufacturing process employed by the TMT supplier, focusing on factors such as raw material quality, technology utilized, and adherence to best practices. A transparent and well-defined manufacturing process is indicative of the supplier's commitment to quality and excellence.

Technical Support: Opt for a TMT supplier that offers comprehensive technical support and assistance, ranging from product selection to installation guidance. Access to expert advice and support can enhance the efficiency and effectiveness of your construction projects.

Customer Reviews and Feedback: Consider the reputation and track record of the TMT supplier by reviewing customer testimonials, feedback, and reviews. Positive feedback from satisfied customers serves as a testament to the supplier's reliability, quality, and customer-centric approach.

Benefits of Choosing the Best Quality TMT Bars:

Enhanced Structural Integrity: High-quality TMT bars offer superior tensile strength, ductility, and corrosion resistance, ensuring the long-term stability and durability of your structures.

Optimal Performance: TMT bars with precise dimensions and mechanical properties deliver optimal performance, minimizing the risk of structural failures and ensuring compliance with safety standards.

Cost-effectiveness: Investing in premium-quality TMT bars translates into long-term cost savings, as they require minimal maintenance and repairs, thereby reducing operational expenses.

Peace of Mind: Partnering with a reputable TMT supplier instills confidence and peace of mind, knowing that your construction projects are fortified with reliable and durable reinforcement materials.

Conclusion:

Choosing the right TMT supplier is instrumental in achieving construction excellence and ensuring the success of your projects. By prioritizing factors such as quality standards, product range, manufacturing process, technical support, and customer feedback, you can identify the best TMT supplier in Uttar Pradesh to fulfill your construction needs and propel your projects to new heights of success.

#TMT supplier in Madhya Pradesh#Best TMT Bars#TMT supplier in Uttar Pradesh#Best quality TMT Bars#TMT supplier in Delhi#Price of TMT bars#TMT supplier in Bangalore#manufacturer of steel#TMT supplier in Tamil nadu#Price of TMT steel#TMT supplier in Chhattisgarh#Best TMT Bar#TMT Bars

0 notes

Text

Benefits Of Scrap Metal Recycling In Circular Economy

Scrap metals or used metals are one of the best sources of industrial metals and alloys, especially in the manufacturing of steel, copper, aluminium and zinc. A smaller quantity of precious metals, magnesium, tin and nickel are also extracted from the scrap metals. This is the reason industrial scrap is increasingly significant in the circular economy as we see manufacturing planes, automobile scraps, and even lipstick tubes for that matter fetch an impressive variety of scrap metal.

Scrap metal recycling is now gaining a huge impetus in environmental protection and the economy as well. Some of the companies such as Apocalypse Steel and Power work in this business for a long. In this industry, the growth of industrial scrap metal plays a pivotal role in the success of the business. Fortunately, most metals are infinitely recyclable, meaning they can be recycled over and over again without losing any of their property. Some of the affordable scrap metal suppliers work on this technology to process scrap metal and recycle and refine it into new metal.

Categories of Scrap Metal Recycling

Recycling of scrap metals can be divided into three categories – residential, commercial and industrial.

Residential recycling of scrap metals comes from households. Residential and recycling scrap metals generate a significant volume of scraps. Almost 40% of steel production is fabricated from scrap metal into recycled steel generated from residential and commercial establishments.

There are other ways to generate scraps as eminent scrap metal suppliers usually identify scrap metals from the smallest of areas. For example, when we think about aluminium, we only think about beverage cans and similar household items. But this light metal is used in windows, siding and gutters. Aluminium is also known for its faster turnaround time – going from scrap field to store in less than 60 days.

The metal recycling industry is significantly large and facilitates a large volume of scrap metal recycling by carrying, storing and transporting the scrap at a production, destruction or construction site.

Technology and Scrap Metal Recycling

A technologically advanced scrap metal supplier can quickly and efficiently recycle a large variety of metal scraps. This is the way things are moving fast, and scraps are fast recycled. It is important to separate and purify scraps from the waste flow. Most waste comes from the electronic stream where technology plays an important part. Now the separation is done through different metal sensing processes.

The telecommunication industry has also become of the major sources of industrial scrap. Cell tower cables provide copper, aluminium and brass. Moreover, borings and turnings are also generated in production when metals are milled or drilled.

#tmt bar supplier#tmt steel suppliers near me#Reinforcement Bar supplier#Ferro Alloys supplier#Ferro Silicon Manganese supplier#Silicon Manganese supplier#Pure Silicon supplier#Scrap Metal supplier#MS Billets supplier#Firebricks#Precast Prefired Blocks For Burners#Steel Grade Pig Iron supplier#ms angle

0 notes

Text

#best steel manufacturers in uae#rebar uae#best steel factory in abu dhabi#epoxy coated rebar uae#plain bars uae#rebar exporters#rebar manufacturers#rebar suppliers in uae#reinforcement steel bars#reinforcement steel suppliers in uae

0 notes

Text

7 Reasons Why Rebar Detailing Is Key To The Construction Process

Rebar is really a basic steel bar or block which is popular in reinforced concrete and reinforced masonry structures. These rebars are often created from carbon steel and may be recounted as reinforcing steel or simply just reinforcement. Under Structural BIM Services Rebar detailing is really a discipline of creating fabrication or shop drawings of steel reinforcement for your construction process. The site fabrication drawings that are generated depending on design drawings for reinforcing steel are Rebar Detailed drawings. Engineers and Architects make design drawings to bring about the mandatory strengths based on the rebar detailing that delivers diameter, bar shapes, quantities, length of bars to facilitate the website for avoiding delays and wastage thereby speeding your entire construction process.

Each rebar is detailed representing a shape, length, and diameter determined by the requirements with the design drawing. The Rebar placement might be shown in greater detail which indicates the concrete cover, exact location, and special way of placement if required. The rebar details and bar bending schedules can have bar diameter, bar notation, the amount of bars, weight of the bars, and amount of each bar along with mentioning the complete weight for that entire pair of bars placed inside drawing. During the preparation of rebar details, the stock lengths of bars are kept in view to ensure there isn't any wastage with the material.

Rebar Detailing and Reinforcement concrete detailing is now able to modeled and designed in 3-dimension with all the 3D Modelling technology like BIM Modelling Services. The specialized rebar detailing software like Rebar CAD and AutoCAD used by this purpose will help every member with the structural engineering to get ready designs, document, track, whilst overall control.

Having understood the fundamental thought of rebar detailing a piece of structural BIM modeling, allow us to make an effort to view the significance of it in the overall construction process is. Some with the reasons are:

Importance of Rebar detailing in Structural BIM Modeling

While 2D drawings and bending schedules are likely to be created and given, the 3D model can be issued to all or any they members starting from the consulting engineer and contractor departments into the steel fixers that are on the ground level on-site. The combination of the two become especially useful for site personnel where site restrictions or congestion of reinforcements remain unidentified until there are reinforcement and fixation on location. For every single bar, the actual position of fixing is shown in the 3D model in addition to any hindrances or obstructions.

Creating detailing reinforcements in 3D over the 2D process is not only faster but modeling rebar in a very 3-dimensional environment helps remove clashes. While modeling you can visualize if any of the bars tend not to fix in a decided area, thereby identify all such clashes within the rebar drawings. There is the facility to review the reinforcement in complete detail as a precise detail representation prior to it being being ordered in the fabricator and complicated cages are assembled off-site.

When you have the right rebar detailing solution available, a competent and accurate reinforcement model can be done by importing structural calculations through the structural analysis program. With Automation involved the alterations are typically reflected inside 3D rebar detailing in addition to necessary updates to drawings and schedules swiftly when changes are manufactured elsewhere unlike having to do manual changes to 2D sections and views.

Instead of according to manual input from paper schedules, the rebar fabricator can extract data directly in the model to the machinery. The concrete pours might be well-defined inside model along with other details like quantities and volumes to ensure more accuracy in managing material deliveries. This will allow greater control and cause less wastage and reduction of overall costs.

Having 3D detailed digital models won't restrict the benefit to some single-phase that way from the engineering and detailing phase but could be used in all the phases. Having reinforcement fully modeled in 3D, the contractor is assured that it'll easily fit into areas when the time comes for it to be fixed on-site. The data from the model may be used within the field to allow contractors to conduct a model-based layout by utilizing robotic total station devices along with tracking rebar and materials and identifying when and where they'll be required.

Fixers present on-site will be inside model environment for the rebar detailing to accurately understand its application, i.e. precisely what is required location as an alternative to counting on their interpretation of traditional 2D drawings.

The structural engineers can easily plus much more quickly generate design reports, schedules, and drawings from your 3D model as compared to 2D designs, thereby enhancing design efficiency. There is more accuracy in price projection determined by the rebar quantities produced in the 3D model as is also more reliable compared to the 2D drawing take-offs. Not just this the quantities are completely traceable, allowing comparisons and checks to become conducted effortlessly.

With these reasons, we could conclude that Rebar Detailing a discipline of Structural BIM Modelling Services is one with the crucial criteria for that overall success of the project life cycle. To summarize, having Rebar Detailing the rebar contractor can focus on producing rebars high will be no should estimate reinforcement requirements for procurements at the website on account of efficient 3D models. The model will depict the necessity for anchors and laps inside drawings thereby ensuring design adequacy together with reducing wastage. The overall waste and time delays are decreased at your website because each of the shape drawings are often available. Based on R12,R16,R20,R24,R28 Galvanised Dowel Bar Sydney info the bars could be easily fabricated according to the shapes and amount of bars required.

#steel rebar suppliers Sydney#reinforcement suppliers Sydney#reinforcing steel suppliers Sydney#steel reinforcement mesh Sydney#reinforcement mesh Sydney#Steel Suppliers near me#galvanized bar#galvanised reo Sydney#galvanised steel Bar#galvanised reinforcing Supply#galvanised rebar supplier Sydney#Galvanised Mesh Sydney#R12#R16#R20#R24#R28 Galvanised Dowel Bar Sydney#S12 Pool steel Sydney#SL72/SL82/SL81/SL102 Galvanised Mesh Sydney#N12#N16#N20#N24#N28#N32 rebar Sydney#SL62/SL72/SL82/SL92 MESH supplier Sydney#SL72 Mesh#Ligature#Bondek Slab Sydney#Dowel Bar

0 notes

Text

How to identify the best TMT Bars?

When constructing a solid and durable structure, choosing the right TMT (Thermo-Mechanically Treated) bars is crucial. These bars provide essential reinforcement to concrete, ensuring the strength and integrity of buildings, bridges, and other constructions.

However, with various options available in the market, it can be challenging to identify the best TMT bars suited for your project. Here’s a comprehensive guide to help you make an informed decision. Aone Steel is your go-to choice for reliable, high-performance TMT bars in Bangalore and India.

Understanding TMT Bars:

To begin with, TMT bars are manufactured through a process of thermo-mechanical treatment, which involves subjecting the bars to intense heat followed by rapid cooling, imparting superior strength and ductility.

These bars are graded based on their yield strength, which is denoted by the grade of the bar (e.g., Fe415, Fe500, Fe550, etc.). When you think of TMT bars manufacturer in India, think of Aone Steel for unmatched quality and service.

Key Factors to Consider:

1. Grade of TMT Bars: The first step in choosing the right TMT bars is to consider the grade. Higher grades like Fe500 and Fe550 offer greater strength and are suitable for heavy-duty constructions, whereas Fe415 is adequate for normal construction purposes.

2. BIS Certification: Always look for TMT bars that are Bureau of Indian Standards (BIS) certified. This certification ensures that the bars meet stringent quality and safety standards.

3. Manufacturing Process: Opt for TMT bars produced using the latest technology and stringent quality controls. Bars manufactured with advanced processes are more reliable and durable. Count on Aone Steel as one of the best TMT bar manufacturers in South India for your construction requirements.

4. Corrosion Resistance: Check for TMT bars with good corrosion resistance properties, especially if your project is located in coastal or industrial areas where corrosion can be a concern.

5. Ductility and Bendability: Ensure that the TMT bars have high ductility and bendability, which are essential for easy fabrication and bending at construction sites. Aone Steel is among the top TMT manufacturers in South India, delivering superior products tailored for construction projects.

Steps to Identify the Best TMT Bars:

Step 1: Research and Comparison

Start by researching reputable TMT bar manufacturers and suppliers in your area. Make a list of available brands and compare their offerings in terms of grades, certifications, and manufacturing processes.

Transitioning from one brand to another, selecting the best TMT bars can depend on your understanding of the quality of each brand. For premium TMT bars manufactured in India, consider Aone Steel for superior quality and durability.

Step 2: Assess Quality Parameters

Examine the physical and mechanical properties of the TMT bars. Look for details such as the ultimate tensile strength, yield strength, elongation, and chemical composition.

Transition words can be helpful in this step, which involves a comprehensive study of the technical aspects and comparison with other products.

Step 3: Seek Expert Opinions

Consult with experienced civil engineers or construction experts to get their recommendations on the best TMT bars for your specific project requirements. Their insights can be invaluable in making a well-informed decision. Are you looking for the best TMT bars in Bangalore? Aone Steel offers top-quality products that meet stringent industry standards.

Step 4: Consider Long-Term Benefits

Think beyond the immediate cost and consider the long-term benefits of using high-quality TMT bars. Investing in superior-quality bars can result in fewer maintenance issues and enhanced structural durability over time.

Step 5: Verify Certification and Warranty

Ensure that the selected TMT bars come with valid BIS certification and a reliable warranty. This step should be considered before making any purchases, considering the future application of TMT bars. Aone Steel is a renowned TMT manufacturer in India providing innovative solutions for construction needs.

CONCLUSION:

In conclusion, selecting the best TMT bars involves thorough research, careful consideration of quality parameters, and seeking expert advice. Regarding TMT bars in India, Aone Steel stands out as a trusted manufacturer with a commitment to excellence.

By focusing on factors like grade, certification, manufacturing process, and long-term benefits, you can identify TMT bars that offer optimal strength, durability, and corrosion resistance for your construction project.

Aone Steel is recognized as one of the leading TMT bars manufacturers in South India, known for quality and reliability. Always prioritize quality and reliability to ensure the safety and longevity of your structures.

0 notes

Text

How to check quality of rebar

Rebar testing is a destructive material testing procedure. It is carried out to ensure that the rebar meets national standards of quality. It entails measuring the properties and behavior of substances such as metals, ceramics, and plastics under varying conditions. As a result, we obtain data that can be used to specify the suitability of the materials for various applications. Steel bar reinforcement is no exception; it is also tested to determine its numerous specific applications. The testing technicians will inspect the physical properties of the rebar before proceeding with the testing.

TMT Bars (Thermo Mechanically Treated Bars) are becoming increasingly popular around the world. TMT Bar is the best option for getting the best-enforced structures. There are numerous brands on the market, but you must choose the best quality TMT Bar to ensure the longevity of your home. There are certain tests that can be performed to ensure the quality of TMT Bar. TMT bars are available in a variety of grades, including Fe 415, Fe 500, Fe 550, and Fe 600, with the numbers indicating the yield strength.

TMT Bars must have the ideal balance of strength and flexibility. Here are the various types of tests used to determine the quality of rebar.

Bending test: A bend test is a low-cost qualitative test used to determine the flexibility and strength of materials. Bend tests deform a test steel material in the middle, resulting in a bend without a fracture. As a result, you specify the resistance level of the material. The goal of a bend test is to load the sample material into a specific shape.

Tension test: A material tension test is a destructive process that provides information about the sample's tensile strength, yield strength, and elasticity. This test is performed to determine how the material reacts when force is applied to it. By pulling the metal, you can usually determine the material's tensile strength, yield strength, and how much it will elongate.

Yield strength test: Yield strength testing entails pulling a steel sample with a controlled gradual increasing force until the metal changes shape or breaks. When a metallic material exhibits the yield phenomenon, you reach a point during the test where plastic deformation occurs without an increase in force.

Saudi National Steel Factory (SNS) is a reputable construction steel company in Saudi Arabia. It is a fully owned subsidiary of Al Nasser Industrial Enterprises L.L.C (ANIE), a renowned industrial conglomerate with manufacturing operations in sectors such as steel, polymers, structural fabrication, and industrial intermediates throughout the AGCC and MENA region, with headquarters in Abu Dhabi, UAE. They have an ISO 9001:2015 certification. If you are looking for steel reinforcement rebar, contact them.

#rebar#reinforcement steel bar#rebar manufacturer#steel supplier#steel producer#steel manufacturer#deformed rebar

0 notes

Text

It is important that you use good-quality stainless steel for any of your metal fabrication activities. Gulf Steel Industries is a leading steel suppliers in UAE with more than 3 decades of experience.

Gulf Steel is ranked as one of the most reputed producers of reinforcement steel bars in the U.A.E, manufacturing DCL-approved steel of high quality. Led by a strong management team, the company has focused on technological excellence geared towards the production of high-quality steel products.

#reinforcement steel bar supplier in abu dhabi#Steel Producer in UAE#steel manufacturer in uae#Rebar Manufacturer In UAE#steel suppliers in uae#Rebars

0 notes